Patents

Literature

36results about How to "Improve color fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pigment printing binding agent and synthesizing method thereof

ActiveCN102182080AGood flexibilityImprove breathabilityDyeing processHazardous substanceALLYL SUCROSE

The invention provides a pigment printing binding agent and a synthesizing method thereof. The binding agent is prepared from silicone-acrylate copolymer, aqueous polyurethane, liquid rubber, an emulsifying agent and the like. By taking advantage of the high film-forming property of polyacrylic acid, the high flexibility of organic silicone, the high air permeability of polyurethane and the high elasticity of the liquid rubber, the high-fastness and super-soft pigment printing binding agent is prepared by a complex synergistic technology. The binding agent has high film-forming property, air permeability, flexibility and elasticity, good handfeel and high color fastness. After the binding agent is applied to a printing fabric, the release amount of a harmful substance, namely formaldehyde, is small.

Owner:成都德美精英化工有限公司

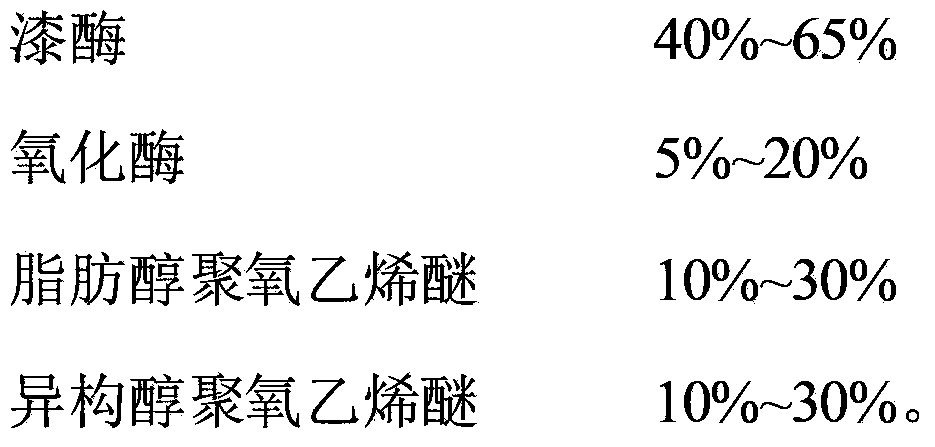

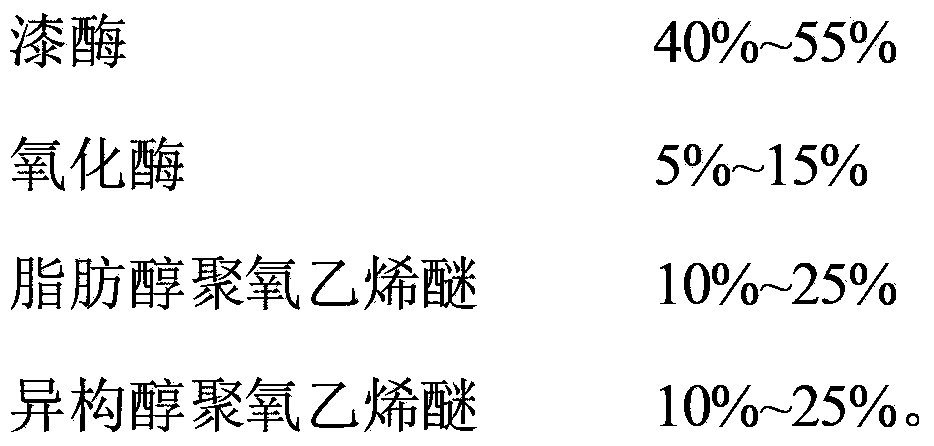

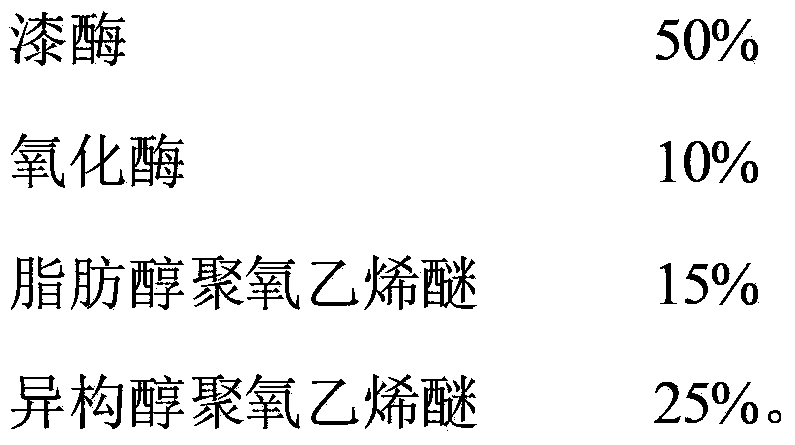

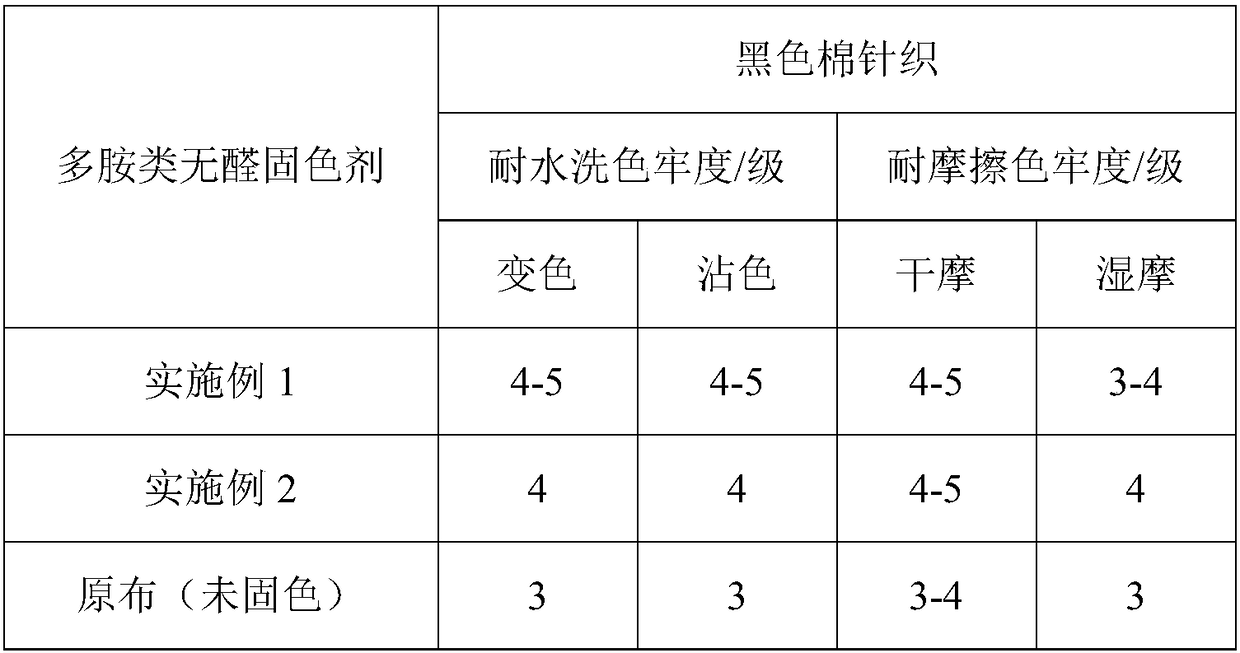

Soaping enzyme, soaping method thereof and application of soaping enzyme in washed and dyed fabric

InactiveCN103409244AExcellent de-floating abilityImprove color fastnessSurface-active detergent compositionsDetergent compounding agentsChemistryDecomposition

The invention provides a soaping enzyme, a soaping method thereof and application of the soaping enzyme in washed and dyed fabric. The soaping enzyme comprises the following components in mass percentage: 40-65% of laccase, 5-20% of oxidase, 10-30% of fatty alcohol-polyoxyethylene ether, and 10-30% of isomeric alcohol polyoxyethylene ether. The soaping enzyme has decomposition and decoloration effects on hydrolyzed coloring matters in the solution and coloring matters adhered to fibers, and has no any influence to coloring matters combined with fibers via covalent bonds; meanwhile, washing and soaping procedures after dyeing can be shortened, water, energy and time are saved, production cost is lowered, and dyed fabric is enabled to acquire better washing fastness, perspiration fastness and rubbing fastness; moreover, the soaping enzyme is a biological agent, simple in use technology, easy to operation, more environmentally friendly, and safer in use.

Owner:HUIZHOU TAIHE CHEM

Successively-impregnating after-finishing method of suede-like superfine fiber synthetic leather

ActiveCN104179031AEasy to operateImprove color fastnessFabric breaking/softeningSolvent-treatmentEmulsionChemistry

The invention relates to a successively-impregnating after-finishing method of suede-like superfine fiber synthetic leather. The method comprises the steps of impregnating unfigured islands-in-sea superfine fiber synthetic leather base cloth with neutral dye liquid, drying for dyeing the unfigured islands-in-sea superfine fiber synthetic leather base cloth to obtain the dyed base cloth; impregnating the dyed base cloth with organic silicone emulsion, and drying the dyed base cloth for softening treatment to obtain softened base cloth; impregnating the softened base cloth with fluororesin emulsion, and drying for three-proofing treatment to the softened base cloth, thereby achieving successively-impregnating after-finishing to the suede-like superfine fiber synthetic leather. The method totally adopts the environment-friendly materials and the clean production process to obtain the water-proofing suede-like superfine fiber synthetic leather, therefore, the level of the suede-like superfine fiber synthetic leather is greatly improved and good application prospect is achieved.

Owner:JIANGSU KEMEI NEW MATERIALS

Polyamine formaldehyde-free fixing agent as well as preparation and application method thereof

InactiveCN108660810APrevent falling offImprove color fastnessDyeing processQuaternary ammonium surfactantIon

The invention provides a polyamine formaldehyde-free fixing agent as well as preparation and application method thereof. The polyamine aldehyde-free fixing agent is prepared from the following components in parts by weight: 8 to 15 parts of organic amine monomer, 5 to 15 parts of N-aminoethyl piperazine, 10 to 20 parts of quaternary ammonium cationizing agent, 15 to 25 parts of dicyandiamide, 2 to5 parts of organic acid, 8 to 15 parts of organic solvent, 5 to 15 parts of epichlorohydrin, 10 to 20 parts of cationic etherifying agent, 5 to 10 parts of polyvinyl alcohol (PVA) and 40 to 60 partsof deionized water. The polyamine formaldehyde-free fixing agent provided by the invention is green and environmentally friendly, and can eliminate reddish color produced during dyeing while fixing, thus avoiding repairing dyeing, and effectively improving various color fastnesses of fabrics, such as washing fastness, friction fastness and boiling water fastness.

Owner:苏州联胜化学有限公司

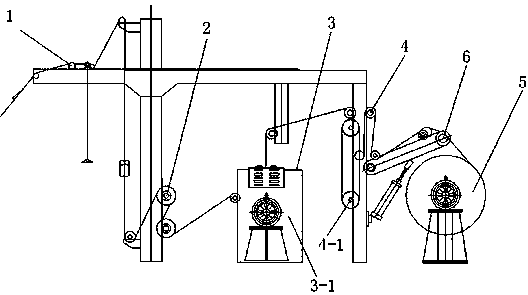

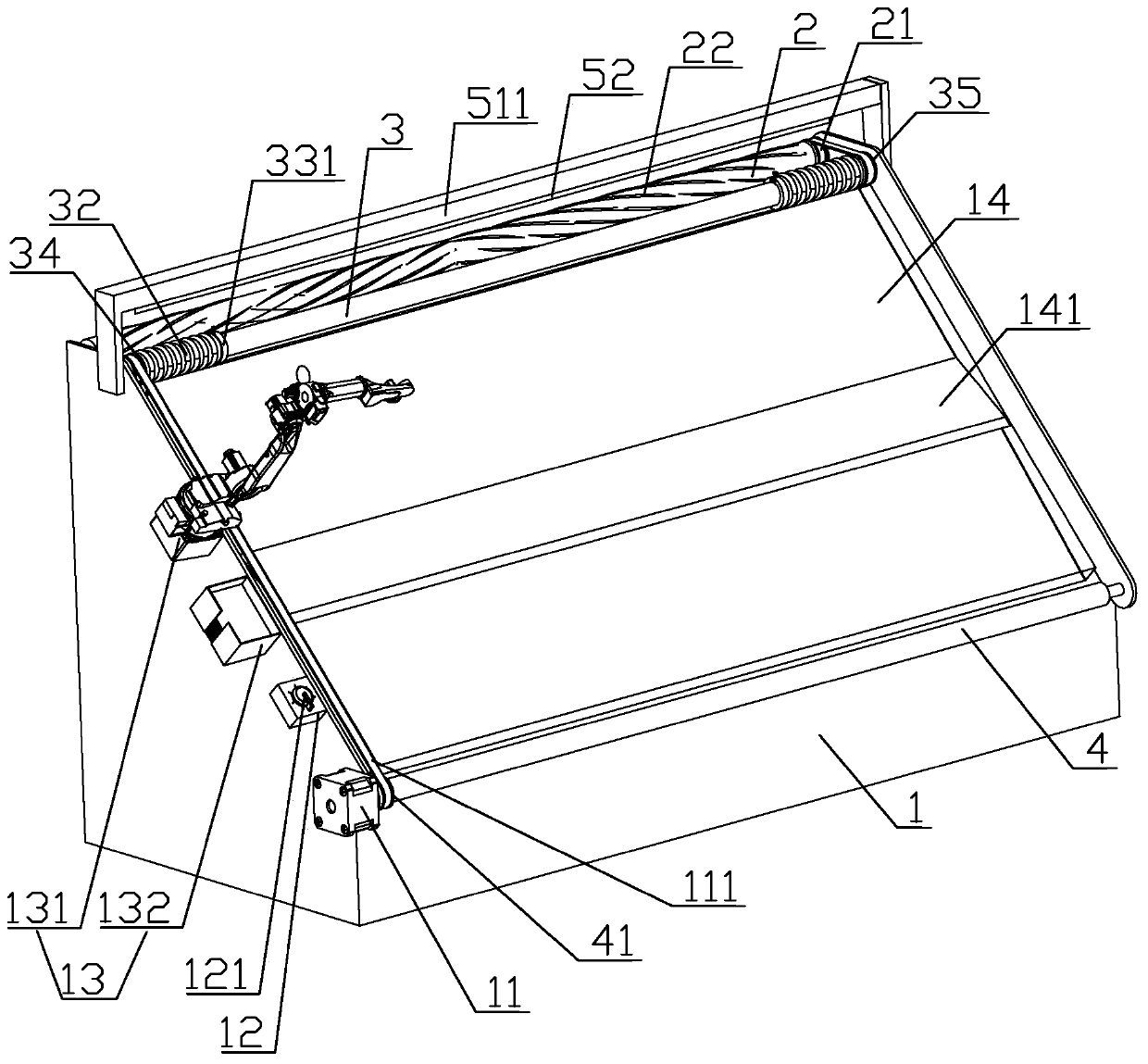

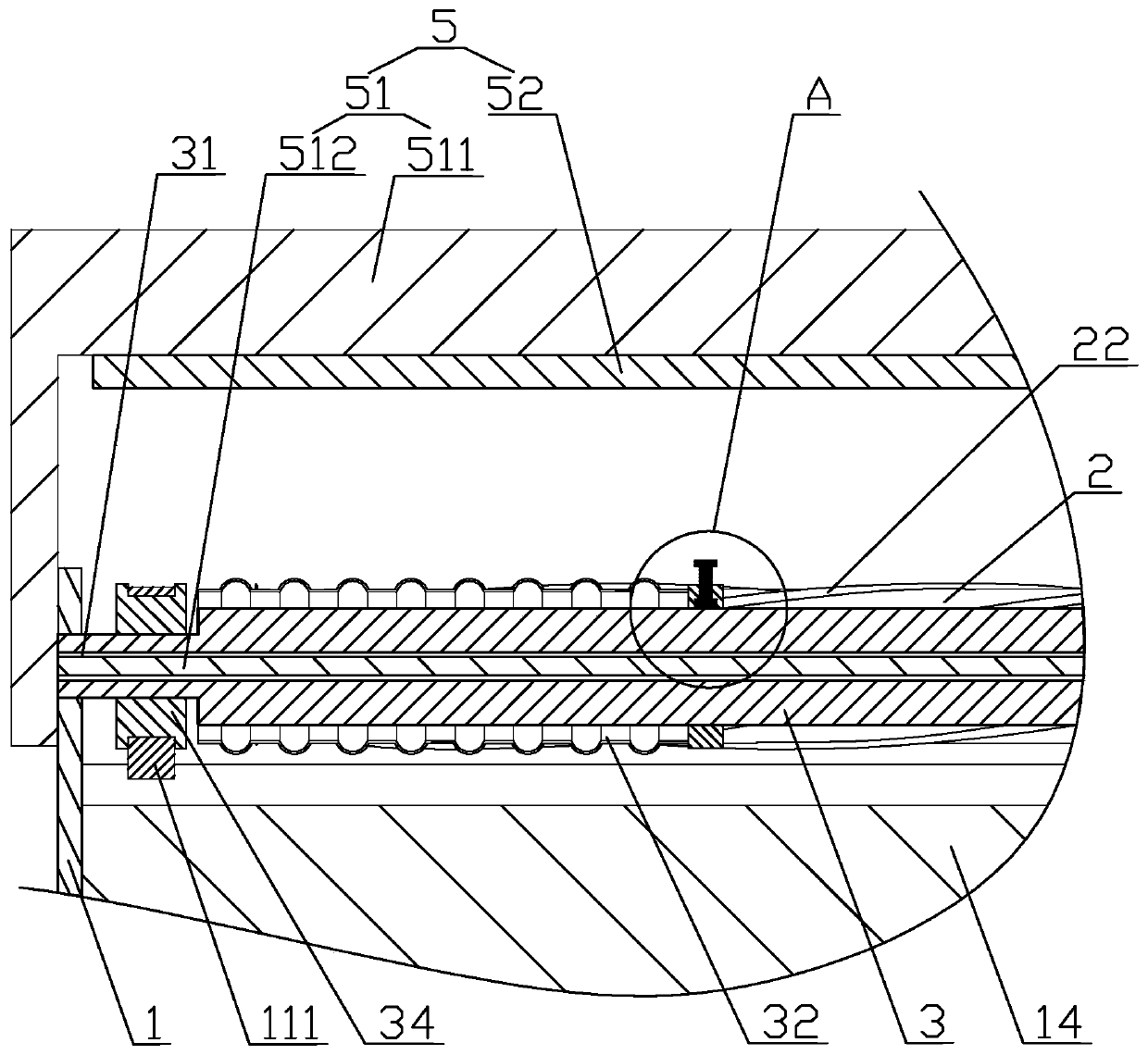

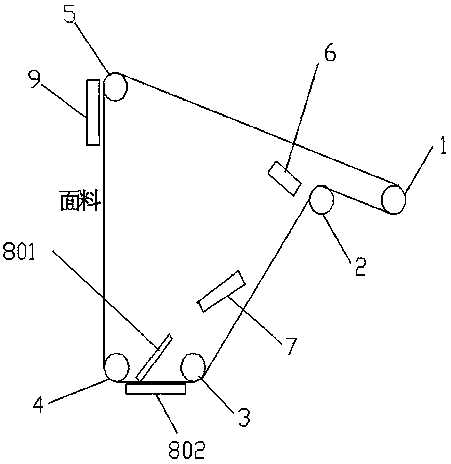

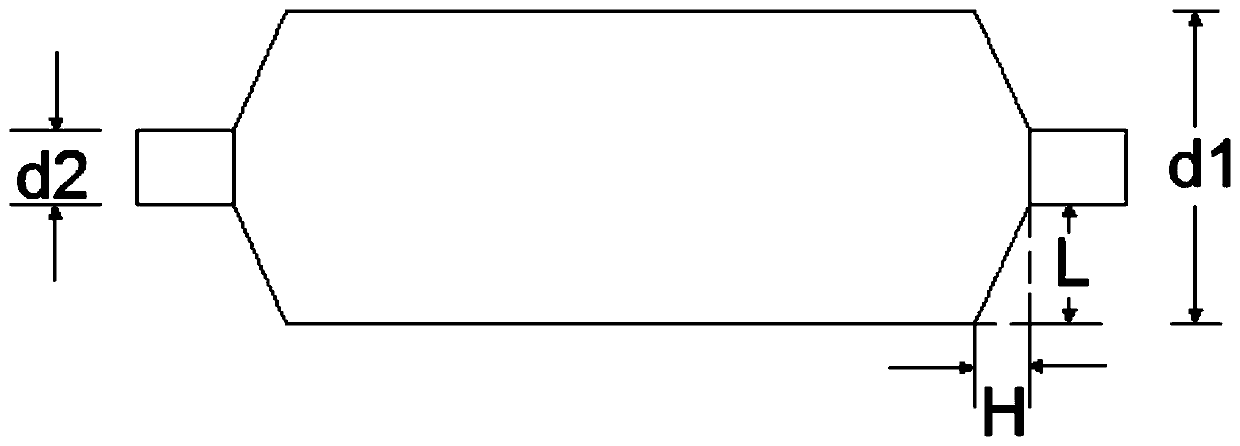

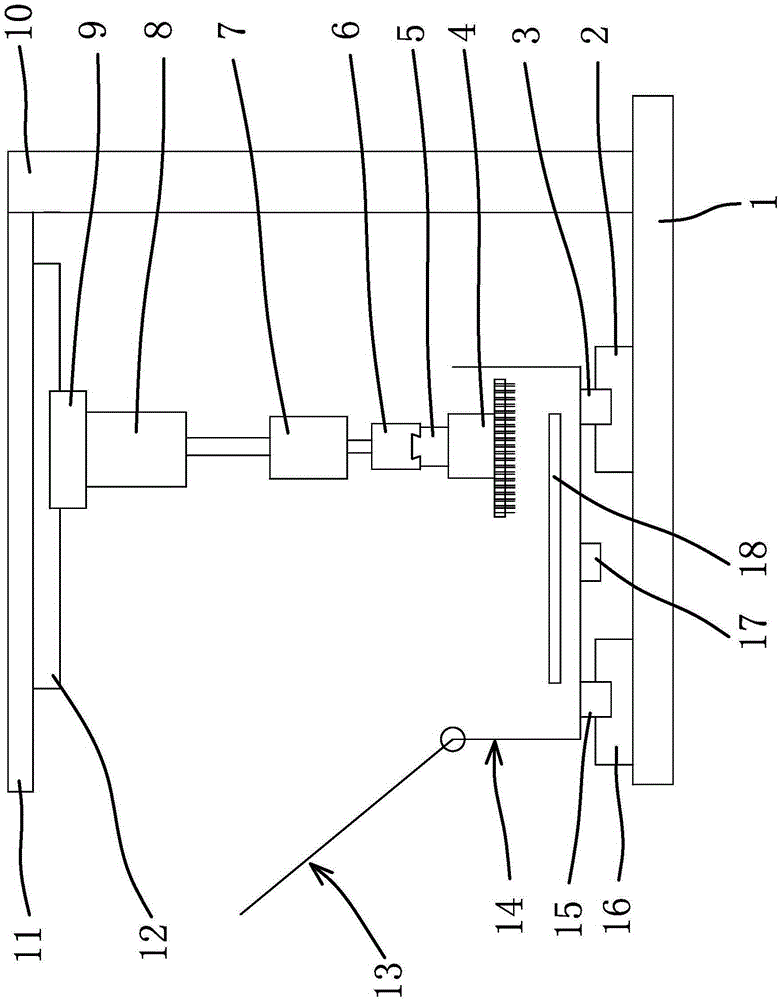

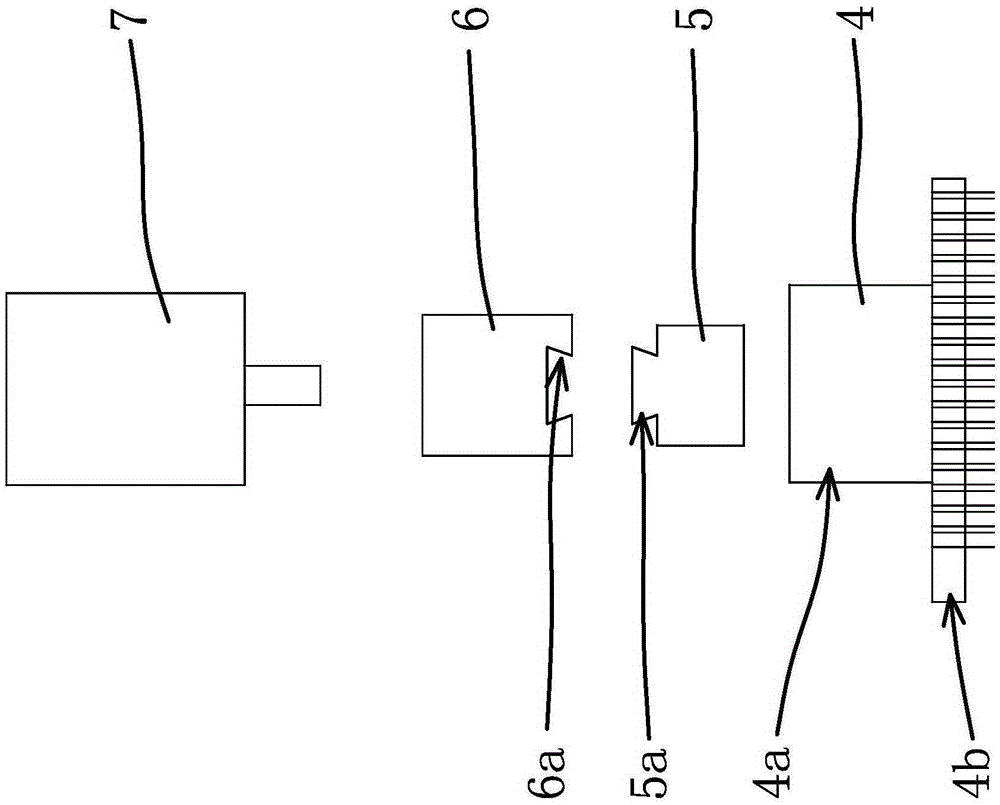

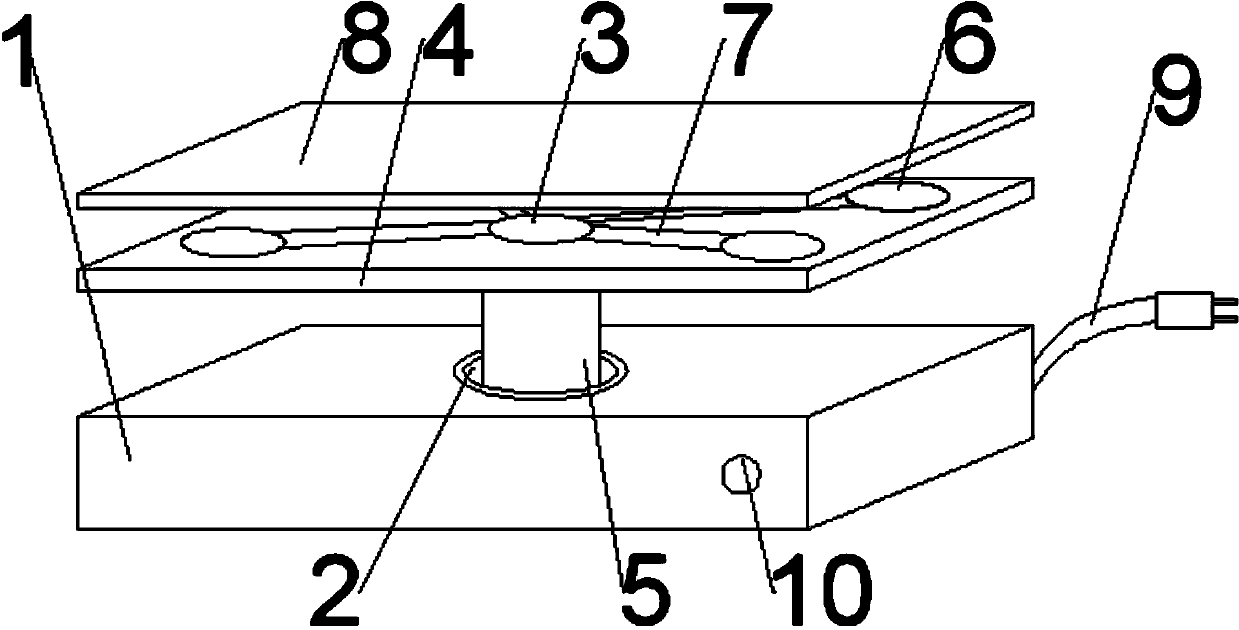

Ultrasonic-assisted cold pad-batch dyeing machine

InactiveCN103938389AReduce consumptionReduce water consumptionLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsUltrasonic assistedEngineering

The invention relates to an ultrasonic-assisted cold pad-batch dyeing machine which comprises a machine frame. The machine frame is provided with a cloth feeding device, a cooling device, a tension control device and an active winding device. An evenness padder is arranged between the cooling device and the tension control device, the tension control device is connected with the active winding device through a bearing arm, a roller is arranged between the evenness padder and the tension control device, the evenness padder comprises an ultrasonic penetration groove, and the active winding device is a constant low tension active winding system. Compared with an existing dyeing process, dyeing is achieved through ultrasonic waves, far infrared drying is not needed, steam does not need to be consumed, water consumption is small, pollution is little, consumption of dye and auxiliaries is little, the process is simple and reliable, preparation cycles are short, labor cost is reduced, equipment investment is little, the occupied area is small, and maintenance cost is low.

Owner:扬州市江都区东盛印染机械厂

Preparation method for colored silicon oxide aerogel

InactiveCN105084374ADyeing component ratio is easy to controlSmall chemical segregationSilicaSilicon oxideAerogel

The invention relates to a preparation method for a colored silicon oxide aerogel. The preparation method is characterized by comprising the following steps: adding a developing carrier into a silicon oxide sol precursor solution; uniformly stirring the solution and adding a gelation catalyst; and after the gel is aged, drying the gel to obtain the colored silicon oxide aerogel. The preparation method provided by the invention is small in environmental pollution, high in coloring firmness, difficult to elute, easy to control component and small in chemical segregation.

Owner:SICHUAN KENINGTAI TECH CO LTD

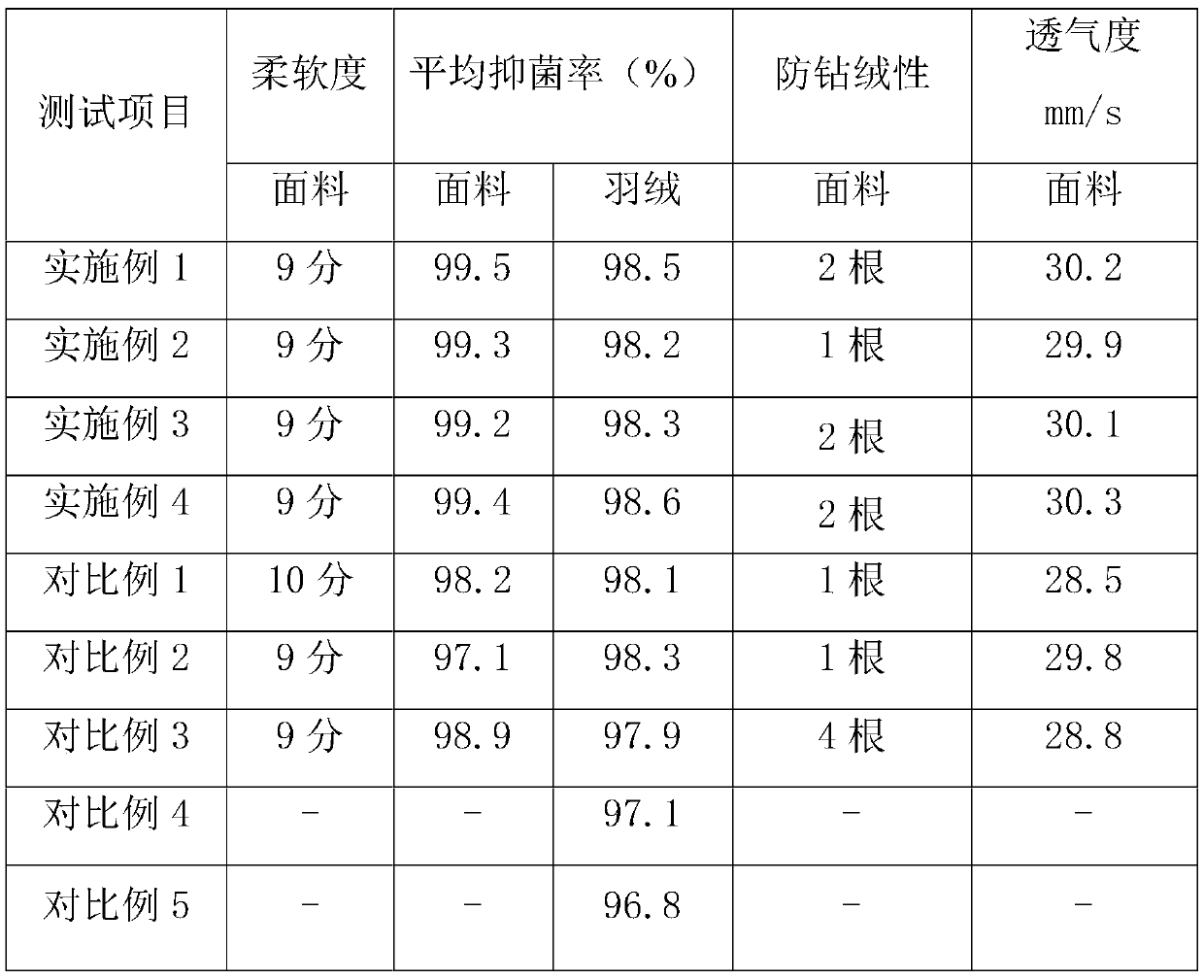

Production process for antibacterial breathable down feather silk quilt

InactiveCN110215095AImprove color fastnessGood coloring effectBlanketBiochemical fibre treatmentHemp fiberCotton fibre

The invention discloses a production process for an antibacterial breathable down feather silk quilt. The production process includes preparation of antibacterial fabric, preprocessing of down featherfillers, antibacterial finishing of the down feather fillers and a mixed down feather filling process, and specifically includes the steps that S101, yarn selection: warp yarns include long-staple cotton fibers and bamboo charcoal fibers; S102, warp blended processing; S103, yarn dyeing and antibacterial finishing; S104, fabric weaving; S105, preprocessing of the fabric before calendering; S106,fabric calendering; S201, selection of the down feather fillers: white goose down, silk and hemp fibers; S202, preprocessing of the white goose down; S301, antibacterial finishing of the down featherfillers; S302, drying and sterilizing; and S401, mixed down feather filling. The production process is stable, and the produced down feather silk quilt has the advantages of being comfortable and soft, capable of adsorbing moisture, breathable, and high efficient and lasting in antibacterial performance.

Owner:KAISHENG TEXTILE

Method for manufacturing dyed leather based on aqueous resin and dyed leather

ActiveCN103696273AImprove color fastnessSave organic solvent resourcesSynthetic resin layered productsDyeing processChemistryOrganosilicon

The invention discloses a method for manufacturing dyed leather based on aqueous resin, which comprises the following steps: S1) preparing an aqueous polyurethane surface layer slurry (100 parts of aqueous polyurethane, 0.2-0.5 parts of aqueous organosilicon levelling agents and 0.1-0.3 parts of aqueous organosilicon antifoaming agents); S2) preparing three editions of surface treatment slurry (100 parts of aqueous delustring polyurethane, 0.2-0.5 parts of aqueous polyurethane thickening agents and 0.2-0.5 parts of aqueous organosilicon levelling agents); S3) preparing the dyed leather using a veneering technology: coating the surface layer slurry on a piece of release paper, and veneering the paper and bass from wet method, and separating paper and leather, and embossing according to conventional method; S4) carrying out three-edition surface treatment; S5) dyeing. The leather manufactured by the method has the advantages of soft handle, high color fastness, wear resistance and scratch resistance, and the invention also has good antibiosis and mildew resistance properties, and the performance is better than the industrial standard.

Owner:浙江德美博士达高分子材料有限公司

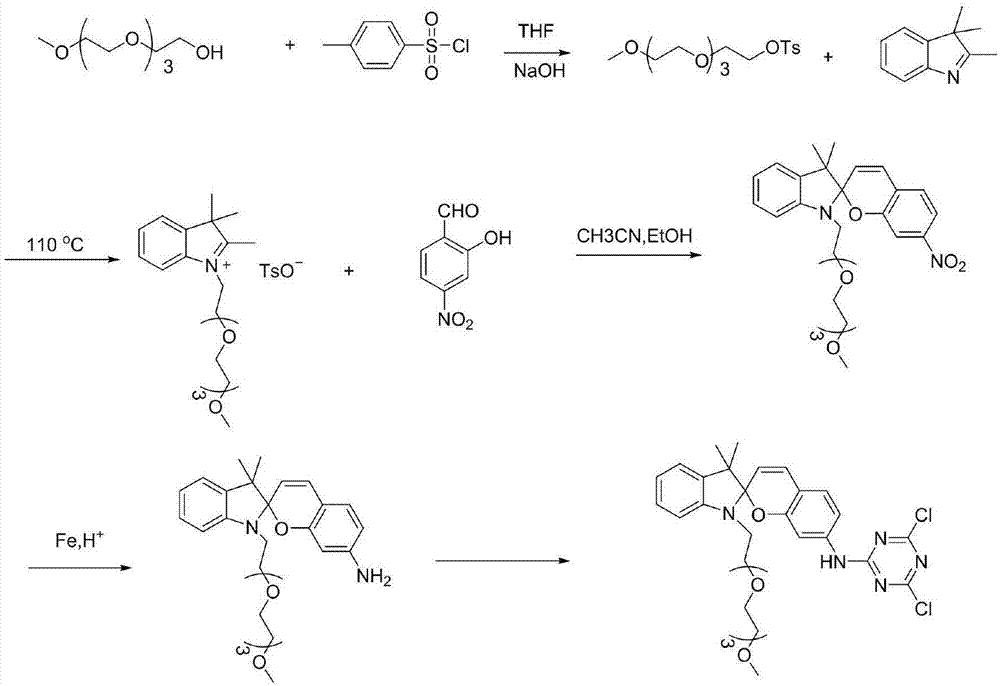

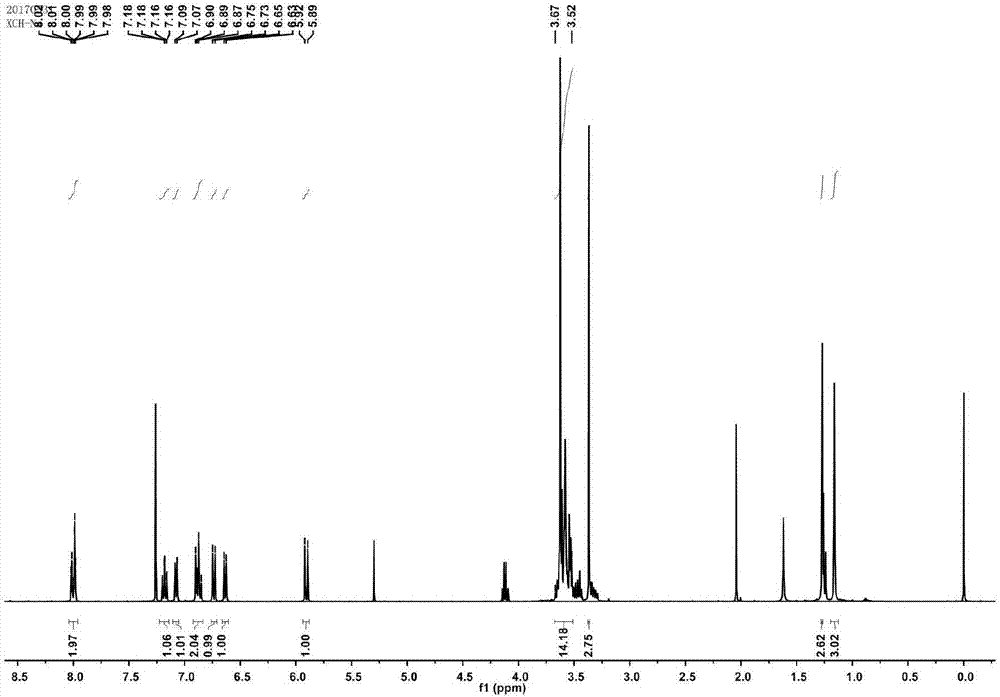

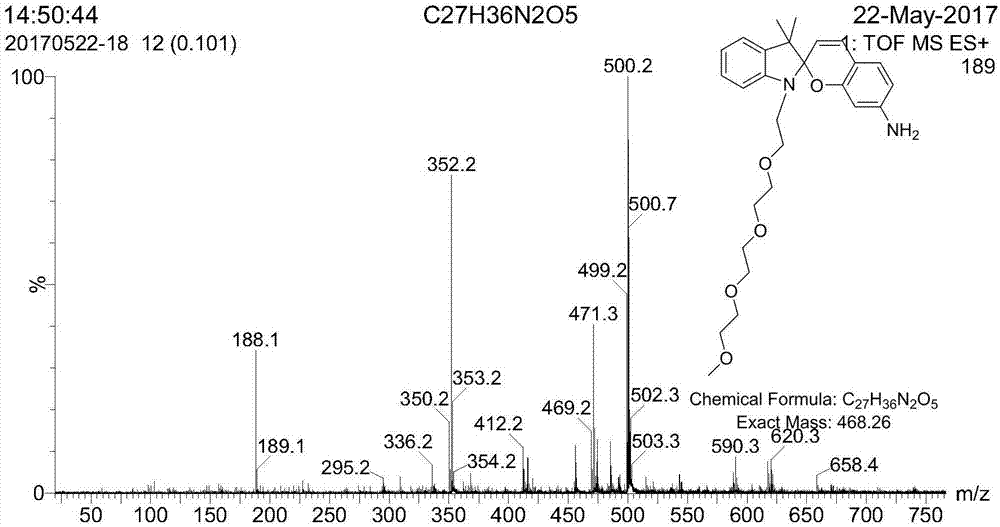

Synthesis method of spiro reverse photochromic reactive dye

ActiveCN107446379AImprove water solubilityImprove color fastnessOrganic chemistryReactive dyesChemical industryReactive dye

The invention discloses a synthesis method of a spiro reverse photochromic reactive dye and belongs to the field of light chemical industry. The method comprises the following steps: firstly activating polyethylene glycol monomethyl ether, then modifying polyethylene glycol monomethyl ether onto N atom of 2,3,3-trimethylindole, forming a photochromic dye intermediate with a spiropyrane structure with 4-nitrosalicylaldehyde and finally reducing, then introducing s-triazine reactive functional groups to prepare the photochromic reactive dye. The color of the photochromic reactive dye solution is gradually faded under illumination of sunshine, is even faded to be colorless, can also gradually restore the color indoors, and has reversibility; the dye is capable of dyeing and processing according to the conventional process of dyeing cotton via the reactive dye, is capable of effectively dyeing cotton fabrics, and is high in color fastness; meanwhile, the fabrics dyed by the photochromic reactive dye have certain photochromic effects.

Owner:JIANGNAN UNIV

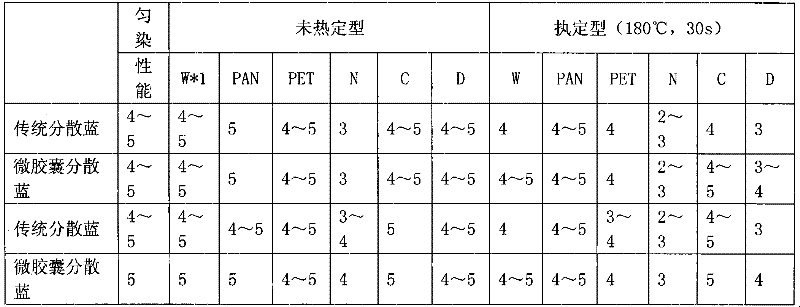

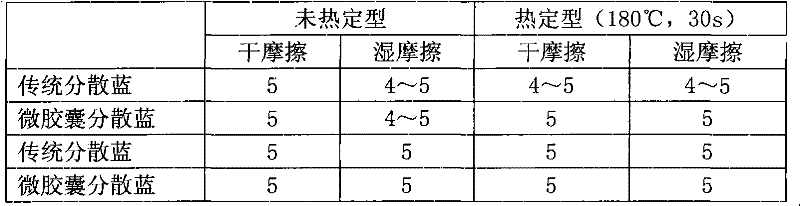

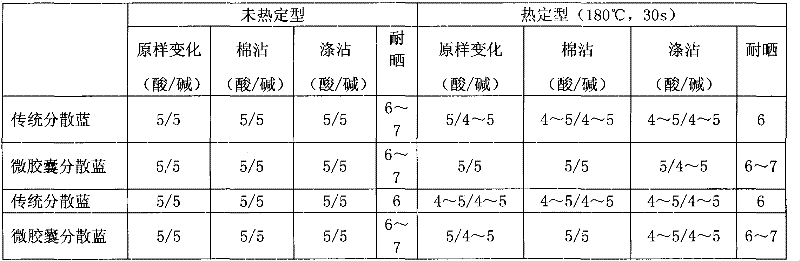

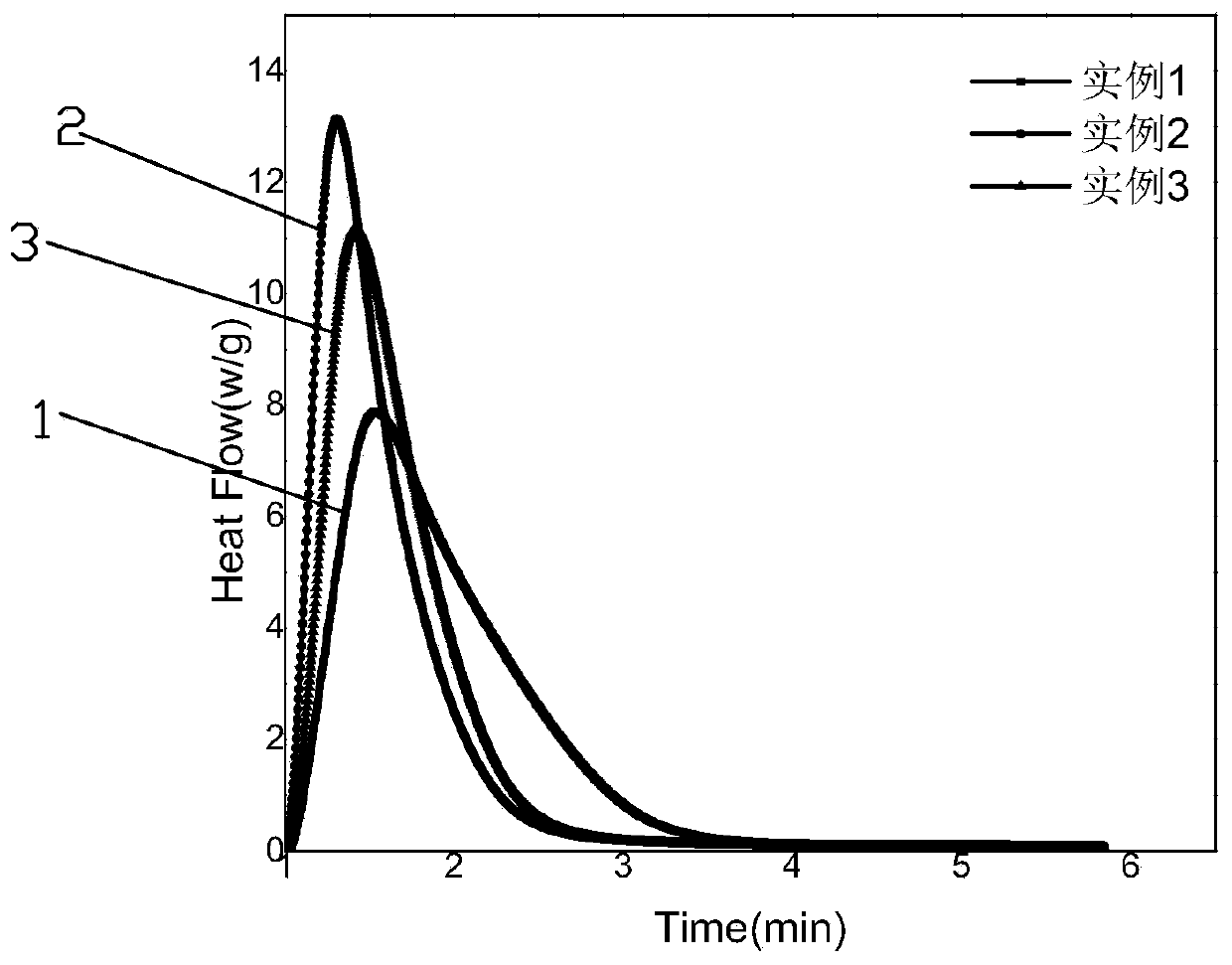

Method for dyeing with non-washing dispersing dye

InactiveCN102454117AImprove color fastnessReduced staining proceduresDyeing processChemical potentialCirculating pump

The invention discloses a method for dyeing with a non-washing dispersing dye and is characterized by comprising the following steps of: fully mixing a microcapsule disperse dye with water, followed by cycling through a circulating pump and a dye vat, continuously extracting a single molecular dye, allowing the single molecular dye to contact with a fabric for dyeing, cutting out the cycling after dyeing, stopping supplying the dye into the dye vat, allowing the dye floating on the fiber to permeate into the fiber until the dye is completely permeated into the fiber, and directly drying. The invention has the following advantages: by the adoption of the above technology, residual dye molecules in the dye vat and single molecular dye molecules adsorbed on the fiber surface during the final phase of dyeing are all dispersed into the fiber by the chemical potential effect; trace adsorption dye (surface dyeing) remains on the surface of the fiber and the color fastness can be effectively improved by direct drying of the surface dyeing; in addition, with the application of the technology provided by the invention, dyeing procedures can be effectively minimized to realize clean dyeing.

Owner:JIANGSU SHUNYUAN NEW MATERIAL TECH CO LTD

Preparation method of photo-curing integrated white coating ink

PendingCN111574883AImprove photopolymerization performanceImprove color fastnessInksPrepolymerDi-isocyanate

The invention discloses a preparation method of photo-curing integrated white coating ink, which comprises the following steps: (1) modifying a white pigment for later use; (2) carrying out a reactionon an oligomer polyol and a diisocyanate compound in a nitrogen atmosphere to prepare a polyurethane prepolymer, then, ultrasonically dispersing the modified white pigment prepared in the step 1 in asolvent and then adding the solution into the polyurethane prepolymer for reaction, finally, adding an end-capping reagent for end capping to obtain an integrated white coating; and (3) adding a photo-initiation system and an acrylate monomer into the integrated white coating according to a certain ratio, and fully and uniformly stirring to obtain the integrated photo-curing coating ink. The surface of the white pigment is modified, so that a pigment-cured film cross-linked structure is formed in the curing process of the ink. Not only is the photopolymerization performance of the ink improved, but also the color fastness of the coating ink is improved.

Owner:ZHEJIANG SCI-TECH UNIV

Efficient-leveling leather dye fixation aid

The invention discloses an efficient-leveling leather dye fixation aid, relating to the technical field of leather working. The efficient-leveling leather dye fixation aid is prepared from the following raw materials in parts by weight: 15-20 parts of ceramic micropowder, 10-15 parts of polyoxyethylene, 5-10 parts of polyvinyl butyral, 5-10 parts of modified hydrogenated rosin glyceryl ester, 3-6 parts of trimethylolpropane triacrylate, 3-6 parts of anionic polyacrylamide, 2-4 parts of hexamethylolmelamine hexamethyl ether, 2-4 parts of polyvinyl acetate, 1-2 parts of hydrogenated palm oil, 1-2 parts of nano rubber powder, 1-2 parts of triallyl cyanurate, 0.5-1 part of lanonol, 0.5-1 part of epoxy soybean oil, 0.5-1 part of bis pentaerythritol and 150-200 parts of water. The fixation aid is firmly combined with the leather fibers under the dual actions of adsorption and flocculation to form the insoluble dye salt precipitate, thereby preventing the dye from shedding from the leather fibers and from hydrolysis due to ionizing, and further enhancing the color fastness of the dye.

Owner:肇庆高新区飞越信息科技有限公司

Antistatic multicomponent-fiber blended woven fabric and manufacturing method thereof

InactiveCN105155090AGood air permeabilityImprove color fastnessConjugated cellulose/protein artificial filamentsWoven fabricsMethylimidazoleacetic acidPolypropylene

The invention discloses an antistatic multicomponent-fiber blended woven fabric. The antistatic multicomponent-fiber blended woven fabric is composed of warp yarns and weft yarns which are woven by an air-jet loom. The raw materials of the warp yarns and the weft yarns are made from the following components, by weight, 25 to 30 parts of syndiotactic polypropylene, 18 to 25 parts of thermoplastic polyurethane resin, 16 to 19 parts of polyimide fiber, 15 to 18 parts of spandex fiber, 14 to 17 parts of wool fiber, 24 to 34 parts of cuprammonuium fiber, 22 to 32 parts of phloem fiber, 0.4 to 0.9 part of 3-aminopropyltriethoxysilane, 1 to 3 parts of calcium carbonate, 2 to 4 parts of sodium alginate, 5 to 8 parts of tributyl citrate, 12 to 15 parts of 2-carboxyl propyl methacrylate, 3 to 5 parts of red sage root, 4 to 6 parts of honeysuckle flower, 2 to 5 parts of curcuma tuber, 100 to 105 parts of 1-butyl-3-methylimidazolium acetate, 95 to 115 parts of 1- allyl-3-methylimidazolium bromide, 5 to 9 parts of auxiliary agent and a proper amount of water. The antistatic multicomponent-fiber blended woven fabric is antistatic, anti-microbial, mildew-resistant, good in permeability, and can absorb sound and keep warm.

Owner:安徽省中日农业环保科技有限公司

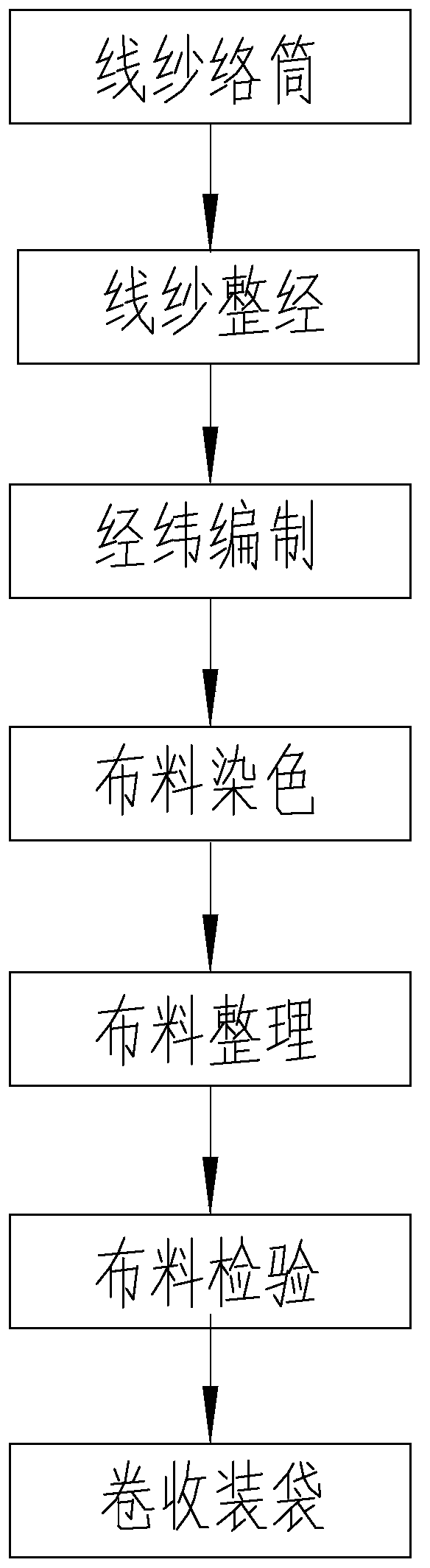

Processing technology and inspection device for textile fabric

ActiveCN111575868ASpeed up dryingImprove color fastnessMarking textilesInspecting textilesYarnDyeing

The invention relates to processing of textile fabric. The processing comprises the following steps: a, yarn spooling: re-winding finished white cop through a spooling machine to prepare cheese; b, yarn warping: winding the cheese on a warp beam in parallel through a warping machine, and penetrating every two warps into a heald eye and a reed; c, warp and weft weaving: interweaving wefts and the warps through a shuttleless loom in a criss-cross manner, and weaving according to the fact that two warps and one weft are interwoven up and down alternately to obtain white gray fabric; d, fabric dyeing: dyeing the gray fabric; e, fabric finishing: pre-shrinking, shaping and deburring the dyed fabric to obtain finished fabric; f, fabric inspection: inspecting the finished fabric by an inspectiondevice, and removing defective fabric sections; and g, rolling and bagging: rolling qualified fabric, bagging and storing. According to the processing technology, every two warps and one weft are interwoven up and down alternately, so that the number of interweaving points is reduced by half, the weaving density of the wefts is reduced, the wefts are prevented from rebounding, and the quality of the fabric is effectively improved.

Owner:上海广顺机械有限公司

Double-layer double-sided hemp fabric

InactiveCN108532088AImprove color fastnessEasy to cleanSynthetic resin layered productsClothingsCardingEngineering

The invention provides a double-layer double-sided hemp fabric. The fabric comprises an inner layer fabric and an outer layer fabric, and the inner layer fabric and the outer layer fabric are connected by sewing. A processing method includes the steps of step 1, hemp fiber processing: 1 ) hemp pretreatment; 2) opening and picking; 3) cotton carding; 4) combing; 5) drawing; step 2, polylactic acidfiber processing: 1) polylactic acid production; 2) solution spinning; 3) spinning; step 3, spinning of the inner layer fabric: 1) roving; 2) spinning; 3) weaving; step 4, spinning of the outer laterfabric: 1) roving; 2) spinning; 3) weaving; step 5, sewing: overlapping the inner layer fabric and the outer layer fabric, and feeding into a textile machine for stitching. Compared with the prior art, the fabric has the advantages that the purposes of dyeing firmness improvement, easy cleaning, light resistance, good skin-friendly property and ultraviolet resistance are achieved.

Owner:SHICHUN TEXTILE WEAVING & DYEING IND CO LTD

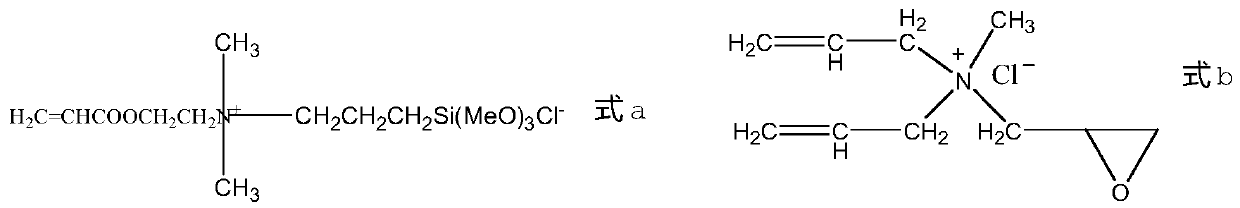

Environment-friendly hydrophilic color fixing agent for cotton and preparation method thereof

ActiveCN111945446ALow water solubilityImprove color fastnessGrip property fibresDyeing processFunctional monomerReactive dye

The invention relates to a hydrophilic color fixing agent for cotton and a preparation method thereof. The color fixing agent is prepared from a quaternary ammonium cationic polyurethane color fixingagent, a polyacrylic acid color fixing agent, a pH regulator, a cosolvent, ethyl alcohol and water, and the quaternary ammonium cationic polyurethane color fixing agent and the polyacrylic acid colorfixing agent are prepared through polymerization of several functional monomers; and a quaternary ammonium cationic group and a reactive epoxy group are introduced into a polyurethane macromolecular chain, so that the final product color fixing agent has an excellent film-forming property, and the color fastness of reactive dyes is remarkably improved. Meanwhile, harmful substances such as formaldehyde are not contained, and environment-friendly requirements are met.

Owner:多恩生物科技有限公司

Mercerized cloth dyeing method

InactiveCN106245339AImprove color fastnessNot easy to color flowersBiochemical treatment with enzymes/microorganismsDyeing processSodium carbonateEnzyme

The invention relates to the technical field of dyeing, especially a method for dyeing mercerized cloth. Pretreatment: add mercerized cloth and water into a dye vat, add degreasing agent, chelating agent, refining enzyme and hydrogen peroxide at the same time, then raise the temperature to 98°C and keep it warm for 60 minutes , cool down to 80°C at a rate of 1°C / min, and then carry out peracid deoxidation treatment; dyeing: raise the temperature to 40°C, add additives, keep warm for 15 minutes, then add dyes and keep warm for 30 minutes, add 1 / 6 of Yuanming Keep the powder warm for 20 minutes, then add 1 / 3 of the sodium sulfate and keep it for 20 minutes, add 1 / 2 of the sodium sulfate and keep it for 20 minutes, then raise the temperature to 60°C at a rate of 1°C / min, keep it for 20 minutes, and then lower the temperature to 50°C. Add 1 / 6 of soda ash and keep it for 20 minutes, then add 1 / 3 of soda ash and keep it for 20 minutes, add 1 / 2 of soda ash and keep it for 15 minutes, then raise the temperature to 60°C, keep it for 60 minutes, and finally leave the tank. The dyeing method of the mercerized cloth obtained by the invention can effectively improve the color fastness of the mercerized cloth, and is not easy to produce colored flowers.

Owner:博森纺织科技股份有限公司

Pressure type wet circulation spray dyeing device used for spinning

InactiveCN108118474AReduce moistureIncrease temperatureLiquid/gas/vapor removalLiquid/gas/vapor treatment of indefinite length materialsAgricultural engineeringIdler-wheel

The invention discloses a pressure type wet circulation spray dyeing device used for spinning. The pressure type wet circulation spray dyeing device comprises a feeding idler wheel, a first deliveringidler wheel, a second delivering idler wheel, a reversing idler wheel, a circulating idler wheel, a steam nozzle, a dyestuff nozzle, a pressure plate and a drying nozzle, the first delivering idler wheel and the feeding idler wheel are parallel, the second delivering idler wheel is arranged below the first delivering idler wheel, the reversing idler wheel and the second delivering idler wheel areparallel, and the circulating idler wheel is arranged over the reversing idler wheel. Through the mode, several idler wheels are adopted by the pressure type wet circulation spray dyeing device to circularly deliver fabric according to a preset path to run, then through circulation of soaking, spray dyeing, draining and drying in sequence, the uniformity and coloring firmness of spray dyeing aregreatly improved, the structure is novel, the efficiency is improved, and the device is convenient to use and practical and has a good market prospect on popularizing the pressure type wet circulationspray dyeing device for spinning.

Owner:宿迁市恒信纺织有限公司

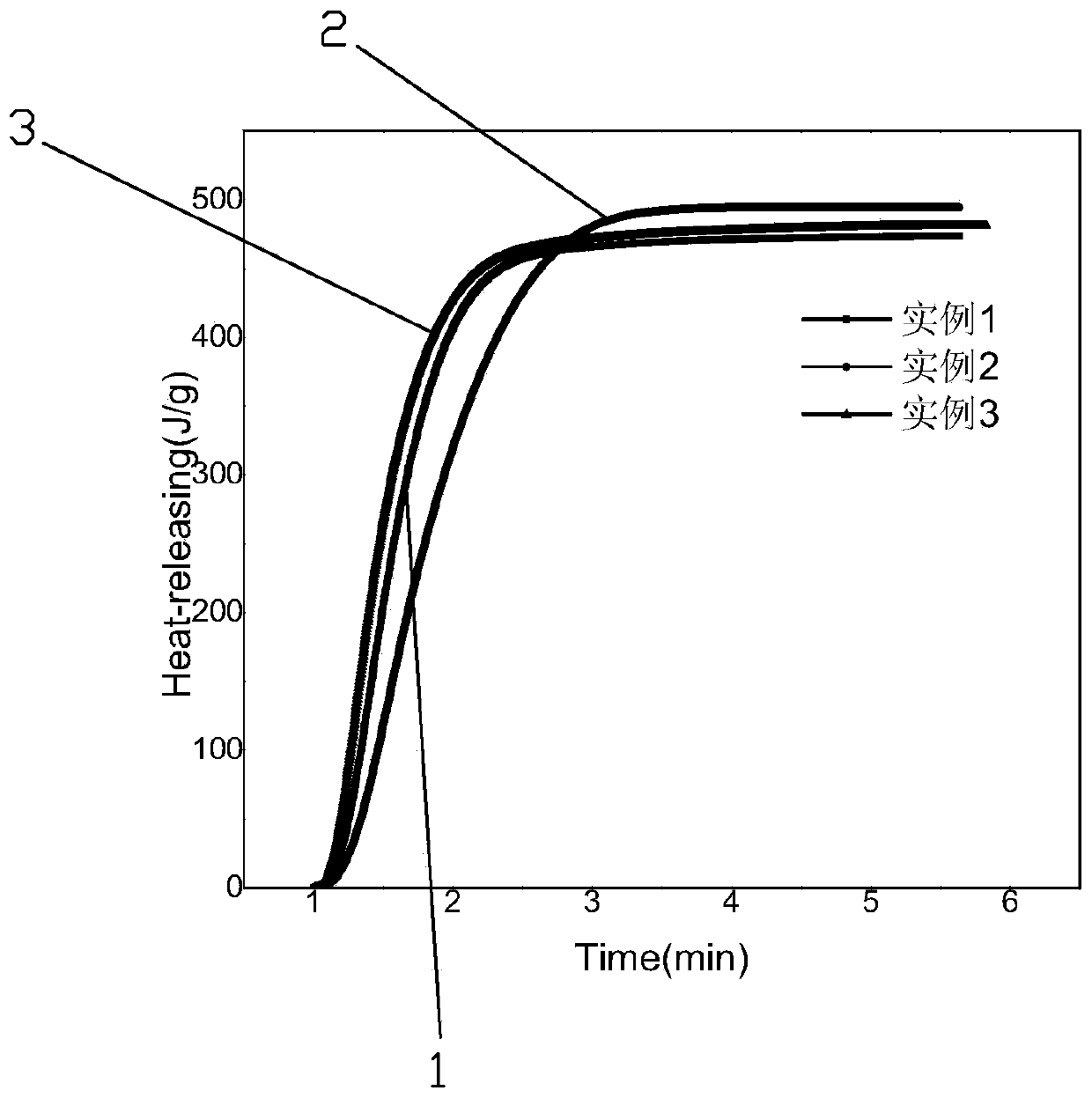

Dyeing process for FDY bright fiber yarn

ActiveCN111501380AUniform and firm dyeingImprove color fastnessLiquid/gas/vapor removalDyeing processPolymer chemistryYarn

The invention provides a dyeing process for FDY bright fiber yarn. The dyeing process includes the following steps of double twisting; shaping; bobbin loosening; unoiling; dyeing; washing; and softening. The twist of double-twisting yarn is 100; the yarn obtained after double twisting is shaped at the temperature of 80 DEG C; and after the yarn is bobbin-loosened to proper tightness, an unoiling agent is added for unoiling, dye and a leveling agent are added to the unoiled yarn for dyeing, then the yarn is washed, and then the yarn is softened. According to the dyeing process for the FDY bright fiber yarn, the treated FDY bright fiber yarn does not easily shrink, can be dyed without being woven, and still has high glossiness after being dyed.

Owner:中山市源兴恒纺织品有限公司

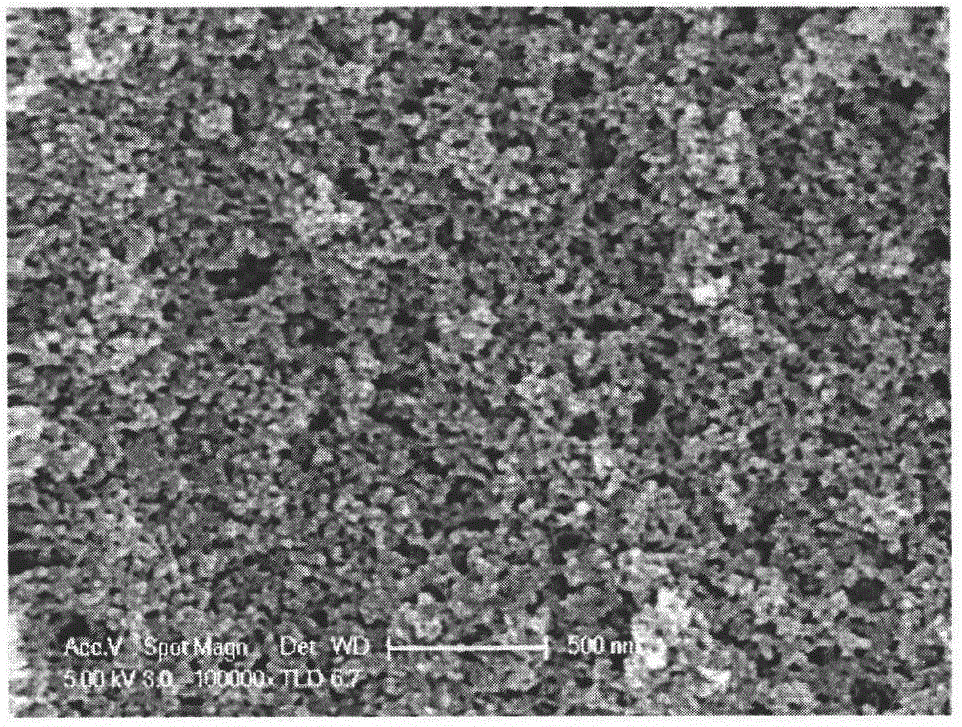

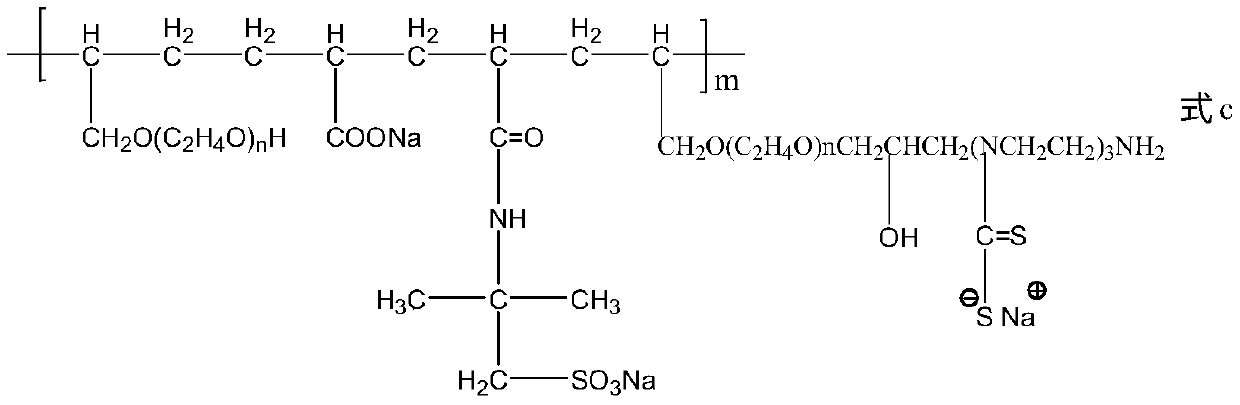

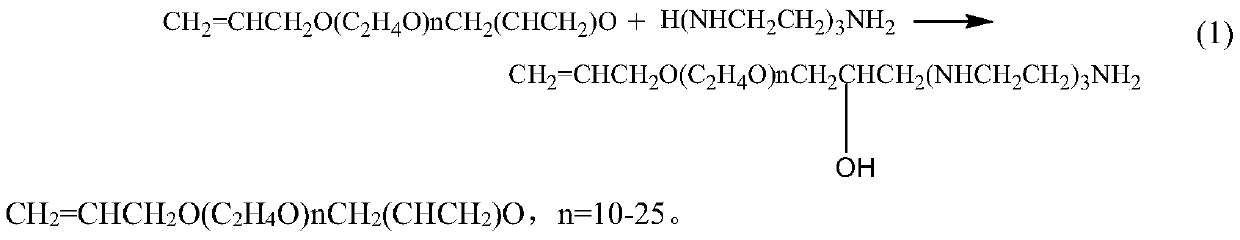

In-situ mineralization auxiliary agents and after backwashing method used in dyed slubbing after backwashing

ActiveCN106638055AImprove color fastnessExtend the lifespanDyeing processChemistrySodium carboxymethylcellulose

The invention relates to in-situ mineralization auxiliary agents SZK and SZH and after backwashing method used in dyed slubbing after backwashing. The auxiliary agent SZK is composed of 0.001 to 10% of sulfamic acid, 0.001 to 5% of polyacrylic acid, 0.001 to 3% of potassium chloride, 0.001 to 3% of copper sulphate, and the balance water; and the auxiliary agent SZH is composed of 5 to 15% of potassium permanganate, 1 to 5% of carboxymethyl cellulose, 1 to 10% of anhydrous sodium sulfate, and the balance water. According to the after backwashing method, dyed slubbing is delivered though after backwashing bath containing the auxiliary agent SZK and after backwashing bath containing the auxiliary agent SZH successively for washing, wherein water bath temperature and concentration, and slubbing moving speed are controlled. In-situ mineralization is adopted in after backwashing process, so that advanced water-saving and emission reduction are realized; operation requirements are low; operation is simple; and popularization is convenient to realize.

Owner:JIANGSU SHENZHOU WOOLEN CO LTD +1

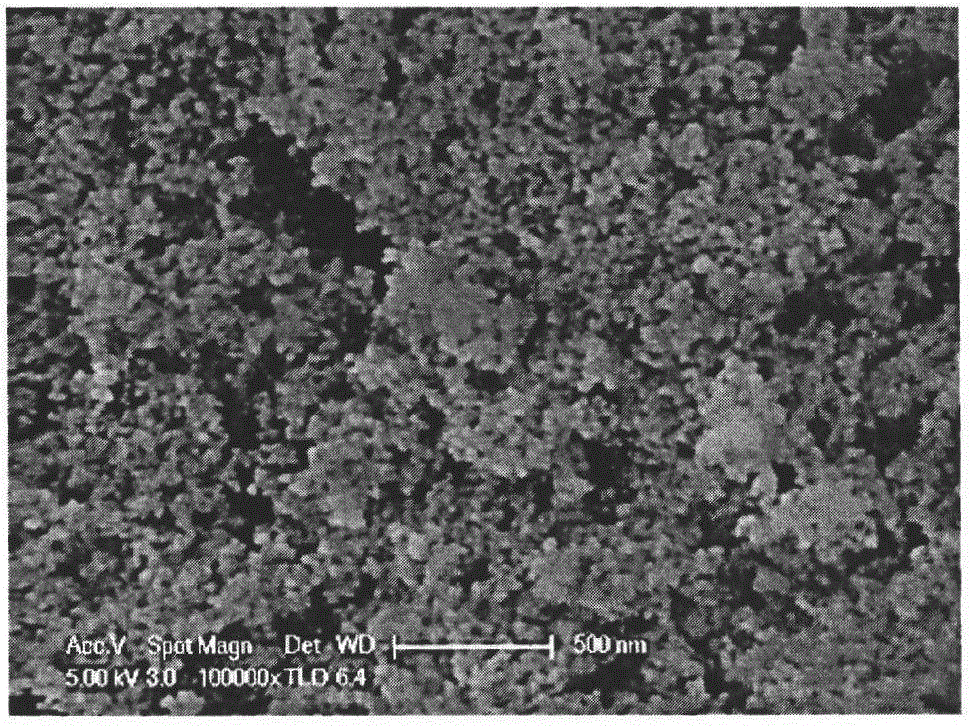

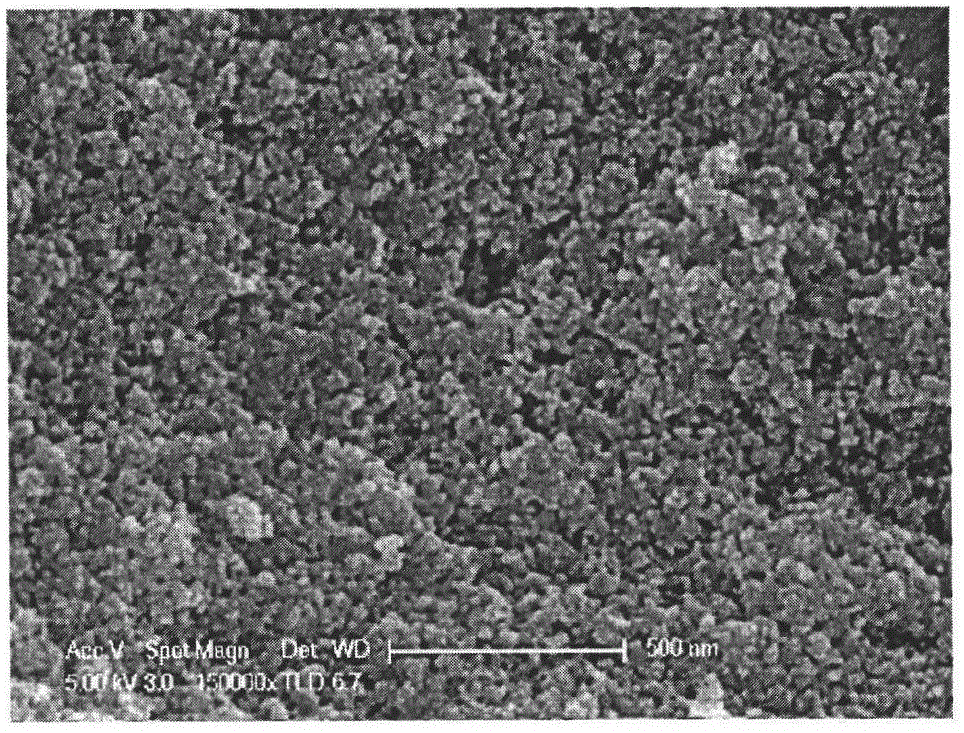

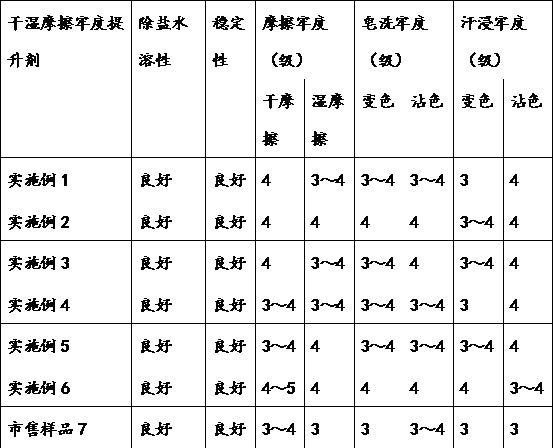

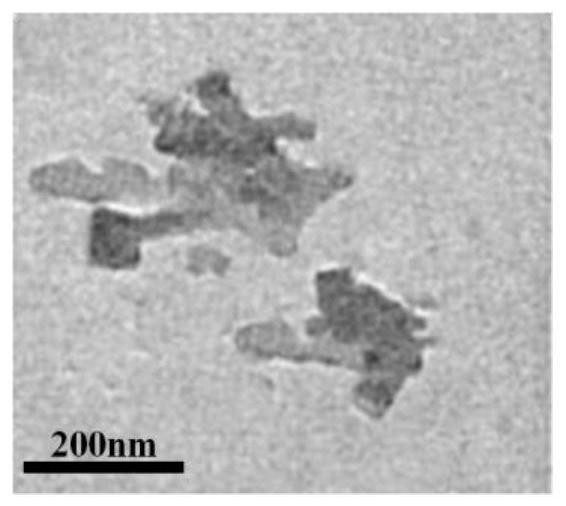

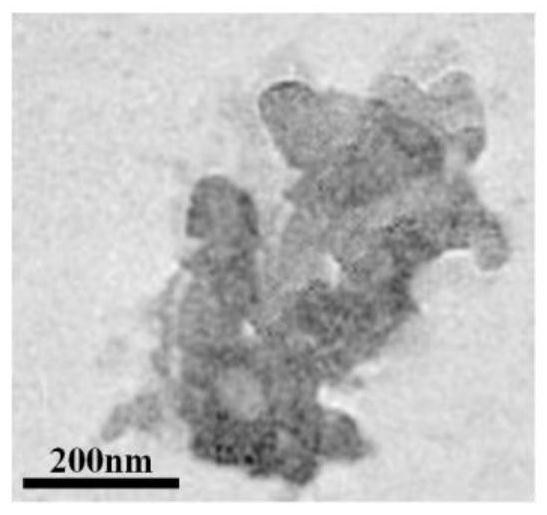

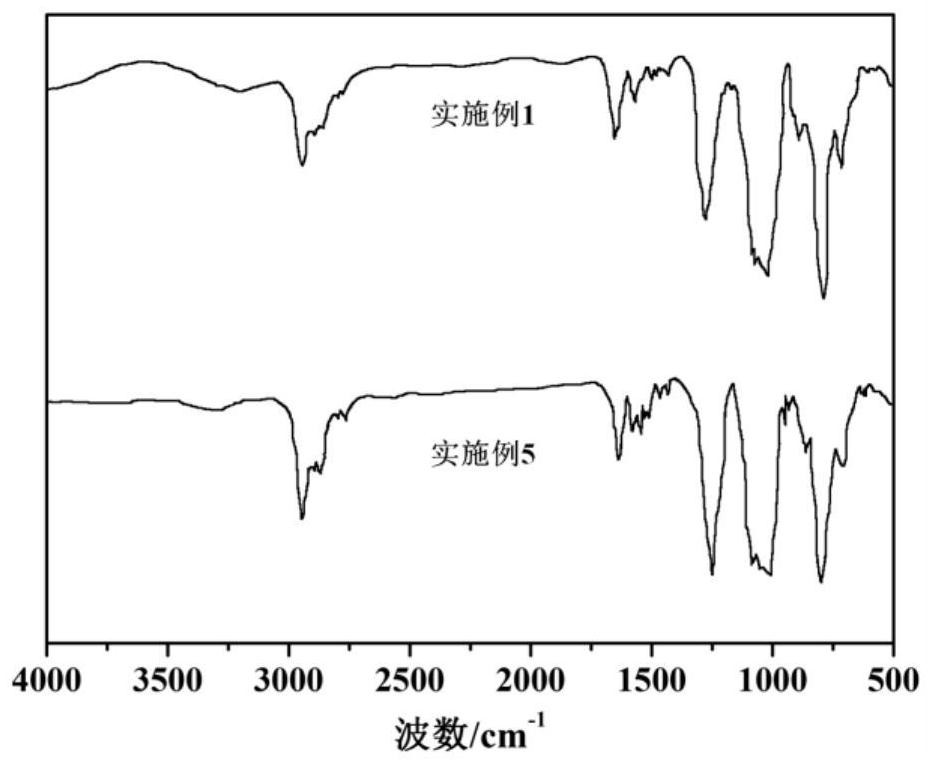

A kind of modified carboxymethyl starch polymer and its preparation method and application

ActiveCN110016103BImprove dry rubbing fastnessImprove color fastnessDyeing processVegetal fibresIsocyanatePolymer

The invention discloses a modified carboxymethyl starch polymer and its preparation method and application. The modified carboxymethyl starch polymer is prepared from the following raw material components in parts by mass: carboxymethyl starch 33~ 42 parts, 1 to 5 parts of modifier, 1 to 5 parts of vinyl isocyanate, 2 to 6 parts of epichlorohydrin, 0.2 to 0.8 parts of initiator, 48 to 62 parts of desalinated water, which are used as dry and wet rubbing fastness improvement When the agent is used, it has the advantages of high color fastness, can improve the dry and wet fastness, and the color fastness to washing with desalinated water, has little effect on the shade of sensitive colors, and has the advantages of less dosage.

Owner:FUJIAN QINGYUAN TECH

Production technology of fiber cloth

InactiveCN104862902AImprove color fastnessReduce defective rateLiquid/gas/vapor removalTextile treatment by spraying/projectingFiberPulp and paper industry

The invention discloses a production technology of fiber cloth. The technology comprises four steps, namely, pretreatment, dyeing, water washing and aftertreatment; a dyeing technology comprises steps as follows: cloth is placed on a flat plate machine, colors are sprayed onto the cloth through movement of dyes; after the cloth is heated to a certain temperature, the temperature is kept, the cloth is washed with water, and the dyeing technology is finished. With the adoption of the production technology of the verdant viscose fiber cloth, components of an alkaline agent and the addition manner of the alkaline agent are adjusted, so that the probability of dyeing defects of grey cloth is decreased, and the production quality is improved.

Owner:RUGAO DONGZHAO CLOTHING CO LTD

Alkaline color fixing agent for reactive dyes and preparation method of alkaline color fixing agent

InactiveCN110656520AImprove color fastnessImprove wet and dry fastnessDyeing processIsocyanateReactive dye

The invention discloses an alkaline color fixing agent for reactive dyes. The alkaline color fixing agent comprises, in weight percent, 20wt%-40wt% of dimethylamine, 10wt%-20wt% of sucrose, 5wt%-15wt%of unsaturated isobutyrate compounds, 0.05wt%-2wt% of initiating agents, 5wt%-10wt% of alkaline regulators and the balance deionized water, and the sum of the weight percent of raw materials is 100%.The invention further discloses a preparation method of the alkaline color fixing agent for the reactive dyes. The alkaline color fixing agent has the advantages that the prepared color fixing agentcontains groups such as hydroxyl, carboxyl, isocyanate and acylamino, a 'bridge' action between a fiber and a dye is achieved, the color fixing agent can be linked with reactive groups of dye molecules and hydroxyls on cellulose molecules, the prepared color fixing agent is free from formaldehyde pollution, and the formaldehyde content of a fabric is effectively reduced.

Owner:艾绳瑞

Coloring agent for garment plus material and preparation method thereof

InactiveCN108385414AGood colorImprove the safety of useDyeing processCarboxymethyl cellulosePolymer science

The invention provides a coloring agent for a garment plus material and a preparation method thereof. The coloring agent is prepared from the following components: polyvinyl alcohol resin, ethyl acetate, dibutyl phthalate, terpene resin, polytetrafluoroethylene, sodium pyrophosphate, carboxymethyl cellulose, initiator, powder, surfactant and deionized water. The coloring agent prepared by the preparation method is easy in coloring and high in soaping fastness, fastness to light and fastness to sublimation, cannot generate a fading phenomenon in a use process, and moreover, has excellent waterproofness and permeability.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Method for preparing fancy cashmere yarns by using colored spun fibers

PendingCN113755025AImprove mechanical propertiesImprove shipping efficiencyOrganic dyesGrip property fibresYarnFiber

The invention discloses a method for preparing fancy cashmere yarns by using colored spun fibers, and relates to the technical field of spinning. The method specifically comprises the following steps: S1, dyeing cashmere wool to prepare uniform wool tops, putting the wool tops into production, and making the wool tops into rough yarns through worsted spinning or semi-worsted spinning; S2, conducting fancy twisting PAFA production, namely carrying out fancy yarn production on the rough cashmere yarns by adopting a fancy twisting machine to obtain fancy cashmere yarns; S3, conducting napping on the made fancy cashmere yarns; S4, performing yarn steaming on the napped yarns; and S5, rewinding the steamed yarns into cone yarns to obtain a product. According to the method provided by the invention, a technological process is greatly shortened, cost is reduced, yarn delivery efficiency is improved, the problem of chromatic aberration is avoided, and the method has the advantages of energy conservation and emission reduction; and the prepared fancy cashmere yarns are excellent in mechanical property and good in softness, the color fastness of pigment on a fabric is high, and dye uptake is better.

Owner:康宝莱(宁波)织造有限公司

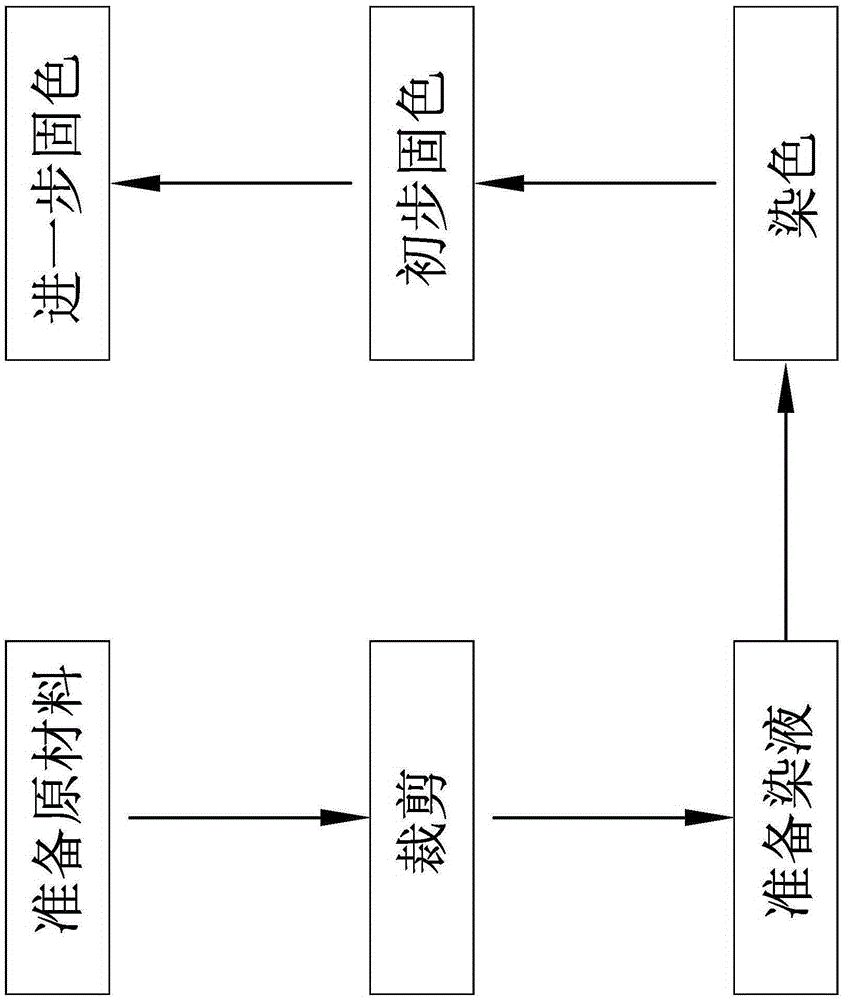

Color fixation process of thin suede leather

The invention provides a color fixation process of thin suede leather, aiming at solving the technical problems of an existing process that steps are too simple and relatively good friction and washing fastness and the like of fabrics cannot be guaranteed. The color fixation process of the thin suede leather, provided by the invention, comprises the following steps: S1, preparing raw materials; S2, cutting; S3, preparing dyeing liquid; S4, dyeing; S5, carrying out primary color fixation; and S6, further fixing the color. The color fixation process of the thin suede leather has the advantages that the friction and washing fastness of the dyed suede leather can be greatly improved.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Preparation method of dyeing-assisted composition

The invention discloses a preparation method of dyeing-assisted composition. The preparation method comprises the steps of adding acetophenone, an emulsifying agent and dimethylol dihydroxy ethylene urea into water, and stirring to be uniform, wherein the mass ratio of the acetophenone to the dimethylol dihydroxy ethylene urea is 1:(0.2-0.5). Compared with the dyeing-assisted composition prepared by the existing swelling method or the carrier dyeing method, the dyeing-assisted composition prepared by the method can remarkably improve the dye-uptake of the aramid fiber in dyeing and can improve the color fastness.

Owner:泰州万诺纺织科技有限公司

Ultra-black cotton-like silk and processing method thereof

PendingCN114164515AImprove color and blacknessImprove color fastnessMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterMelt spinning

The invention discloses a processing method of ultra-black imitation cotton silk, which comprises the following steps: carrying out esterification reaction on phthalic acid, ethylene glycol and isophthalic acid to obtain a mixture A; adding an antioxidant, a delustering agent, color master batches and an antibacterial agent into the mixture A to obtain modified polyester chips; wherein the color master batch is prepared from the following raw materials in percentage by weight: 0.4 to 5.8 percent of carbon black and 94.2 to 99.6 percent of polyester chips; the modified polyester slices are dried through a rotary drum and then extruded through double screws for melt spinning, and the super-black cotton-like silk is obtained.

Owner:福建百宏聚纤科技实业有限公司

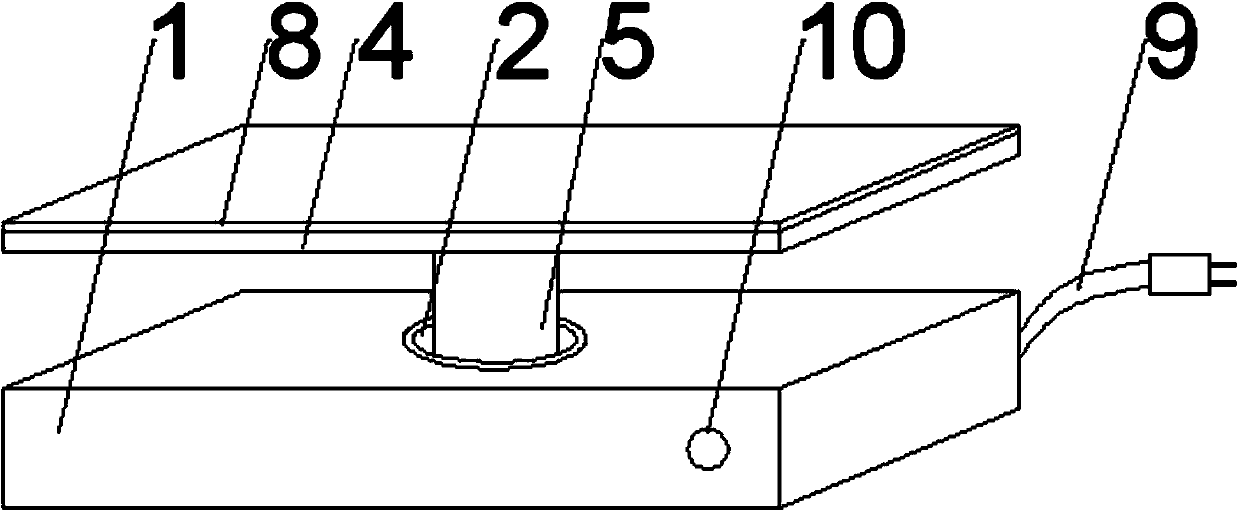

Heating base for mobile phone shell painting machines

InactiveCN104175710ASpeed up dryingImprove paint ratePrinting press partsElectricityInsulation layer

The invention relates to a heating base for mobile phone shell painting machines. The heating base comprises a base body, an inner cavity is arranged inside the base body, a circular through hole communicated with the inner cavity is formed in the upper surface of the base body, an electric heating unit is fixedly connected to the interior of the base body, a heat conducting pipe is fixedly connected on the electric heating unit, a support plate is fixedly connected above the base body, the upper end of the heat conducting pipe penetrates the through hole to be fixedly connected with the bottom of the support plate, a ceramic heat insulation layer is fixedly connected to the outer wall of the heat conducting pipe, a plurality of circular heat conducting pieces are fixedly connected to the upper surface of the support plate and are connected to the top end of the heat conducting pipe through heat conducting blocks, and a heat conducting plate used for conducting heat to heating the surface of a mobile phone shell is fixedly connected to the upper surface of the support plate. By the arrangement, the bottom of the mobile phone shell is heated while the mobile phone shell is painted, quick drying speed of painting on the surface of the mobile phone shell is greatly increased, and painting material rate is increased while color fastness is improved.

Owner:JIANGSU JUNYUN MACHINERY TECH CO LTD

Cotton knitted fabric short-process dyeing and finishing process

PendingCN111441180AImprove adhesion strengthImprove color fastnessGrip property fibresDyeing processChemistryReactive dye

The invention discloses a cotton knitted fabric short-process dyeing and finishing process which comprises the steps of pre-processing, dyeing, and softening after-finishing. The step of pre-processing comprises the process of placing a cotton knitted fabric into pre-processing finishing liquor with the bath ratio being 1:8 at room temperature, raising the temperature to 100 DEG C at a rate being2 DEG C / min, and preserving heat for 30 to 45min; the step of dyeing comprises the process of feeding the fabric at room temperature, adding a leveling agent after 5min, adding a reactive dye after 10min, raising the temperature to 60 DEG C at a rate being 1 DEG C / min, adding 1 / 2 the total use amount of anhydrous sodium sulphate, preserving heat for 15min, then adding 1 / 2 the total use amount of anhydrous sodium sulphate again, continuing to preserve heat for 15min, adding sodium carbonate, continuing to perform dying for 30 to 60min, and performing cooling and water washing; the step of soaping is carried out under the conditions that the bath ratio is 1:8, the concentration of a soaping agent is 2g / L, the temperature is 95 DEG C, and the time is 10min; and the step of softening and setting comprises the process of padding the soaped cotton knitted fabric in 15 to 30g / L silicone oil softening agent finishing liquor, and performing stentering and drying through a setting machine at thetemperature ranging from 180 to 190 DEG C and at the speed ranging from 20 to 35m / min.

Owner:ZHEJIANG YINGFENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com