Soaping enzyme, soaping method thereof and application of soaping enzyme in washed and dyed fabric

A soaping enzyme and soaping technology, applied in dyeing methods, chemical instruments and methods, detergent compounding agents, etc., can solve the problem of insignificant wet rubbing fastness of dark dyed fabrics, large sewage treatment load, water, electricity and steam consumption It can solve the problems such as the increase of quantity, and achieve the effect of excellent de-floating ability, improving production efficiency and increasing enterprise benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

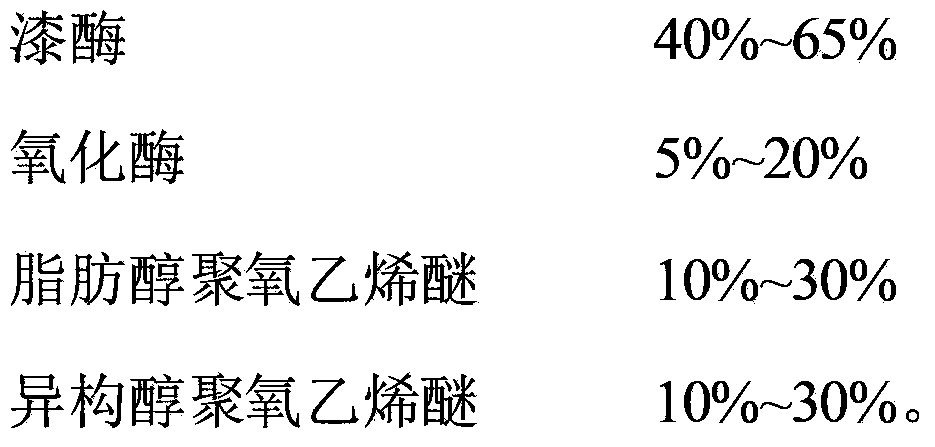

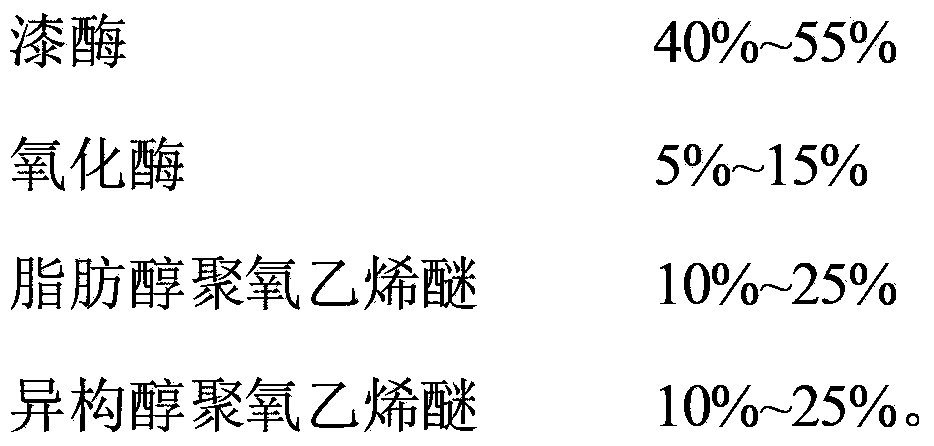

[0027] A kind of preparation method of soaping enzyme, comprises the steps:

[0028] a) Under sterile conditions, weigh laccase, oxidase, fatty alcohol polyoxyethylene ether and isomeric alcohol polyoxyethylene ether according to the formula ratio, and then pour them into a premixer for uniform mixing;

[0029] b) Quantitative packaging of the mixed materials;

[0030] c) Store the packaged product in a cool and dry place.

[0031] The instrument industry equipment used in the present invention is the general instrument equipment of this industry, is the instrument equipment that can obtain by those skilled in the art, and used raw material can be selected from commercially available any one. Fatty alcohol polyoxyethylene ether and isomeric alcohol polyoxyethylene ether can choose commercially available AEO-20 or AT80, etc.

[0032] The laccase in step a is a copper-containing evolved reductase, which widely exists in nature, in plants, and even in almost all fungi. This cl...

Embodiment 2

[0037] Same as Example 1, the difference is:

[0038] The mass percentages of laccase, oxidase, fatty alcohol polyoxyethylene ether, and isomeric alcohol polyoxyethylene ether are: 50%, 10%, 10%, and 30%, respectively.

Embodiment 3

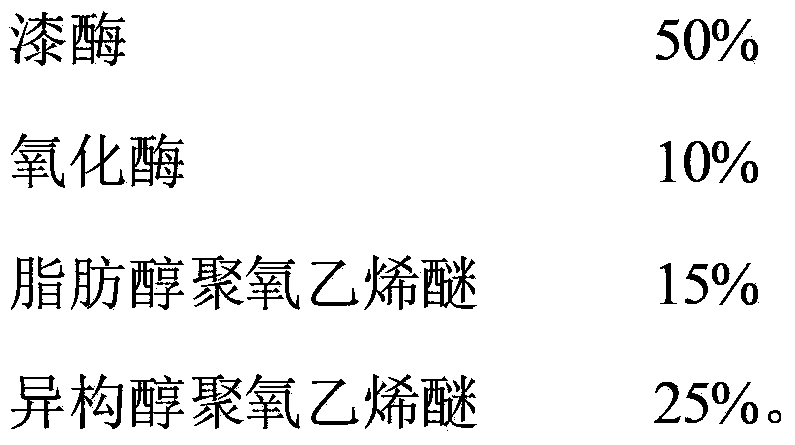

[0040] Same as Example 1, the difference is:

[0041] The mass percentages of laccase, oxidase, fatty alcohol polyoxyethylene ether, and isomeric alcohol polyoxyethylene ether are: 50%, 10%, 15%, and 25%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com