Cotton knitted fabric short-process dyeing and finishing process

A short process, cotton needle technology, used in dyeing, textiles and papermaking, plant fibers, etc., can solve the problems of poor impurity removal, long process flow, waste water pollution, etc., to improve film fastness and shorten process flow. , the effect of enhancing the adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

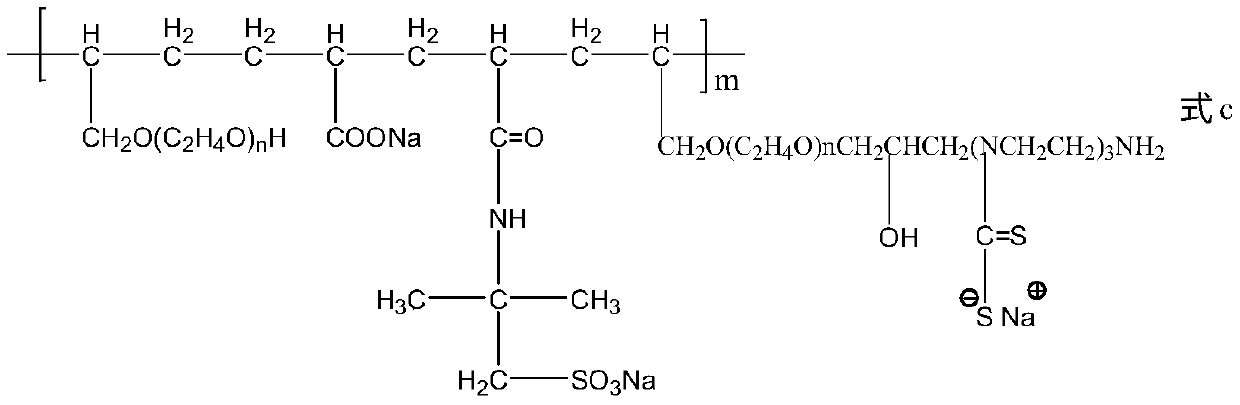

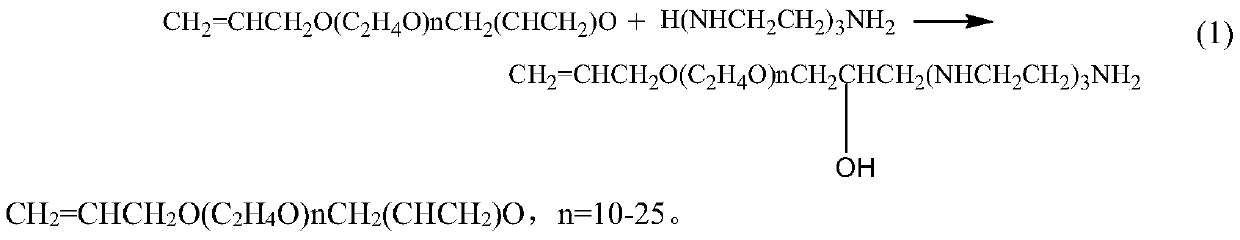

[0033] A chelating agent consisting of 24 parts of hydroxypropyl polyamino allyl polyoxyethylene ether, 8 parts of allyl polyoxyethylene ether, 11 parts of acrylic acid, 12 parts of 2-acrylamido-2-methylpropanesulfonate Acid, initiator, sodium hydroxide, carbon disulfide, water, etc. are polymerized; when polymerizing, hydroxypropyl polyamino allyl polyoxyethylene ether, allyl polyoxyethylene ether, acrylic acid, acrylamide and 430 Put part of water in the reaction kettle, stir to dissolve, blow nitrogen for 30 minutes, heat up to 75°C, add dropwise a solution of 0.6 part of ammonium persulfate and 10 parts of water within 1 hour, keep warm for 4 hours, then cool down to below 20°C, by mole ratio n(hydroxypropyl polyamino allyl polyoxyethylene ether):n(NaOH):n(CS 2 )=1:4:3 Add NaOH first, then slowly add CS dropwise 2 , react at 25°C for 3h, and then react at 45°C for 2h to obtain the chelating dispersant. The molecular structure of the chelating dispersant is shown in formu...

Embodiment 2

[0036] A kind of silicone oil softener, its preparation method is: with 60 parts of D 4 , 6 parts of compound emulsifier, 280 parts of deionized water are mixed, emulsified by high-speed shearing, and a pre-emulsion is obtained;

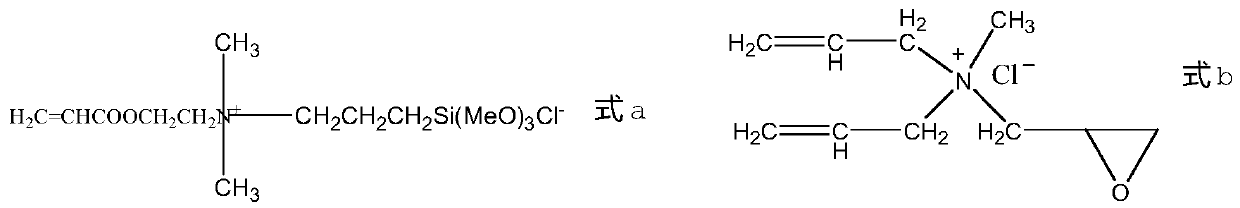

[0037] Add 80 parts of deionized water, 12 parts of dodecylbenzenesulfonic acid, and 3 parts of composite emulsifier into the reaction kettle, raise the temperature to 80°C, and finish adding the pre-emulsion within 1.5 hours; part of quaternary ammonium salt silane coupling agent N,N-dimethyl-acryloyloxyethyl-propyltrimethoxysilane ammonium chloride, then react at constant temperature for 4 hours, and neutralize the pH value with sodium hydroxide; Add a solution of 0.2 parts of initiator and 5 parts of deionized water, 5 parts of diallylmethylglycidyl ammonium chloride, add dropwise for 0.5 hours, then react at constant temperature for 1 hour, and drop to room temperature to obtain silicone oil softener . The composite emulsifier is composed of no...

Embodiment 3

[0040] A kind of silicone oil softener, its preparation method is: with 82 parts of D 4 , 9 parts of compound emulsifier, 280 parts of deionized water are mixed, emulsified by high-speed shearing, and a pre-emulsion is obtained;

[0041]Add 80 parts of deionized water, 12 parts of dodecylbenzenesulfonic acid, and 3 parts of composite emulsifier into the reaction kettle, raise the temperature to 80°C, and finish adding the pre-emulsion within 1.5 hours; part of quaternary ammonium salt silane coupling agent N,N-dimethyl-acryloyloxyethyl-propyltrimethoxysilane ammonium chloride, then react at constant temperature for 4 hours, and neutralize the pH value with sodium hydroxide; Add a solution of 0.2 parts of initiator and 5 parts of deionized water, 5 parts of diallylmethylglycidyl ammonium chloride, add dropwise for 0.5 hours, then react at constant temperature for 1 hour, and drop to room temperature to obtain silicone oil softener . The composite emulsifier is composed of non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com