Binder composition for electrode of nonaqueous electrolyte battery, and electrode mixture, electrode and battery using same

A non-aqueous electrolyte and battery electrode technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, non-aqueous electrolyte batteries, battery electrodes, etc., can solve problems such as safety is not considered, adhesion is not enough, and danger is increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

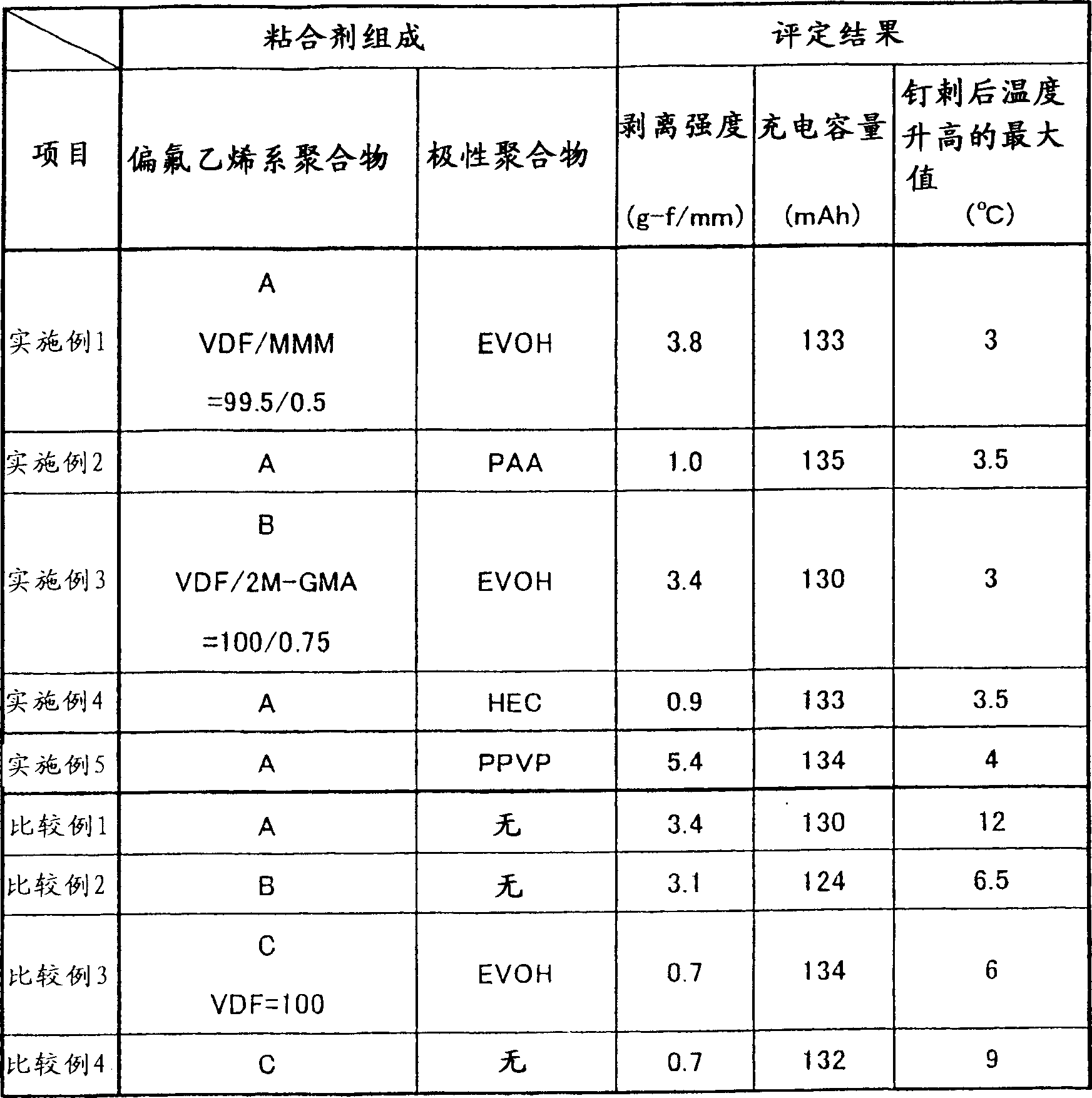

Embodiment 1

[0035] (preparation of positive electrode)

[0036] Add N-methyl-2-pyrrolidone (NMP) to 94 parts by weight of lithium cobaltate ("Cellshid C-5", manufactured by Nippon Chemical Industry Co., Ltd.), 3 parts by weight of vinylidene fluoride polymer C, and 3 parts by weight of carbon black. 43 parts by weight, mixed to prepare a mixture for the positive electrode. The obtained mixture is evenly coated on an aluminum foil with a thickness of 10 μm, so that the thickness of the coating film after drying is 100 μm, and dried at 130° C. for 25 minutes to obtain a positive electrode structure (active material amount: 291 g / m 2 ).

[0037] (preparation of negative electrode)

[0038] For 11 parts by weight of vinylidene fluoride polymer A containing functional groups, 1 part by weight of ethylene-vinyl alcohol copolymer (manufactured by EVOH, クレハ company, "Eval EP-G156B", the molar content of ethylene is 47%), add Composition A of the negative electrode mixture of the present invent...

Embodiment 2

[0051] When preparing the negative electrode, polyacrylic acid (PAA) ("AQUPEC HV-501", manufactured by Sumitomo Seika Chemical Co., Ltd.) was used instead of EVOH. In addition, the same operation as Example 1 was carried out to obtain negative electrode structure B, namely battery B .

[0052] The peel strength of the negative electrode structure B was 1.0 gf / mm, the charging capacity of the battery B was 135 mAh, and the maximum temperature increase in the nail penetration test was 3.5°C.

Embodiment 3

[0054] When preparing the negative electrode, the vinylidene fluoride polymer B containing the functional group is used instead of the vinylidene fluoride polymer A containing the functional group. In addition, the same operation as in Example 1 is carried out to obtain the negative electrode structure C, that is, the battery c.

[0055] The peel strength of the negative electrode structure C was 4.3 gf / mm, the charging capacity of the battery C was 130 mAh, and the maximum temperature increase in the nail penetration test was 3°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com