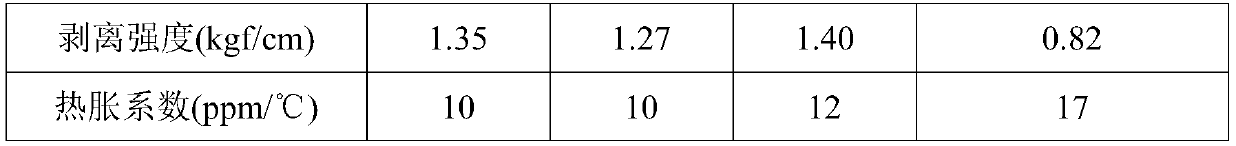

Patents

Literature

64results about "Unsaturated ether polymer adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

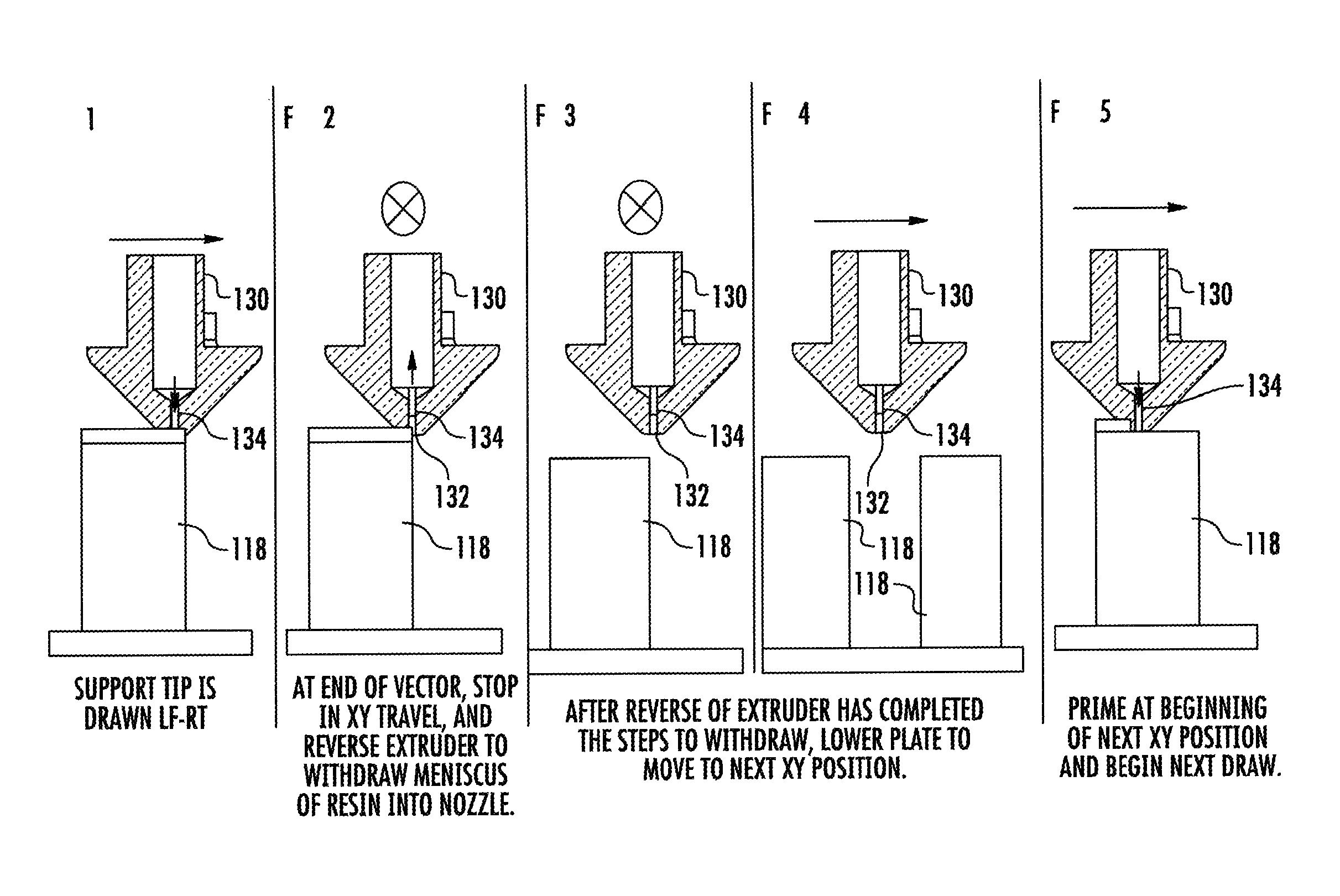

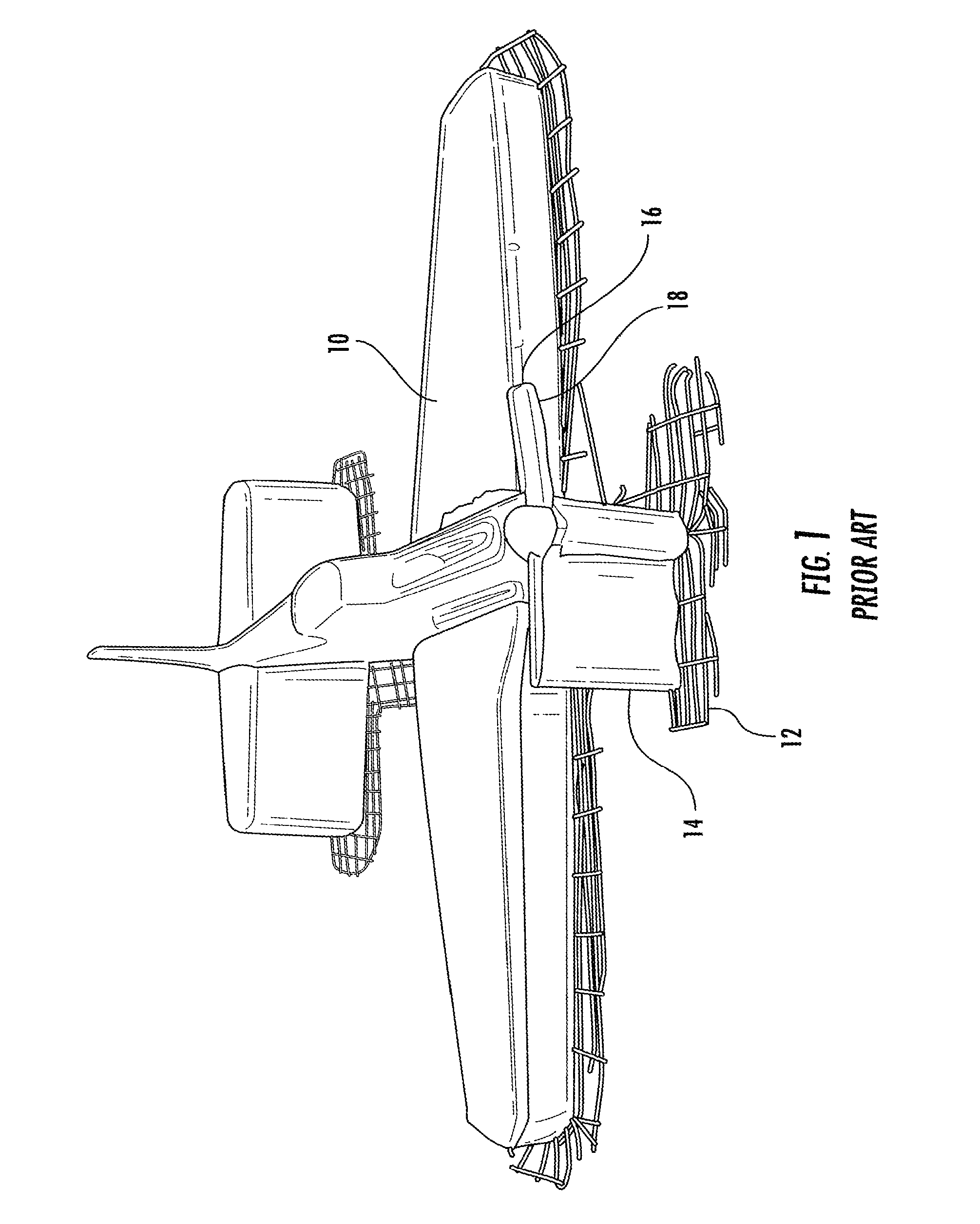

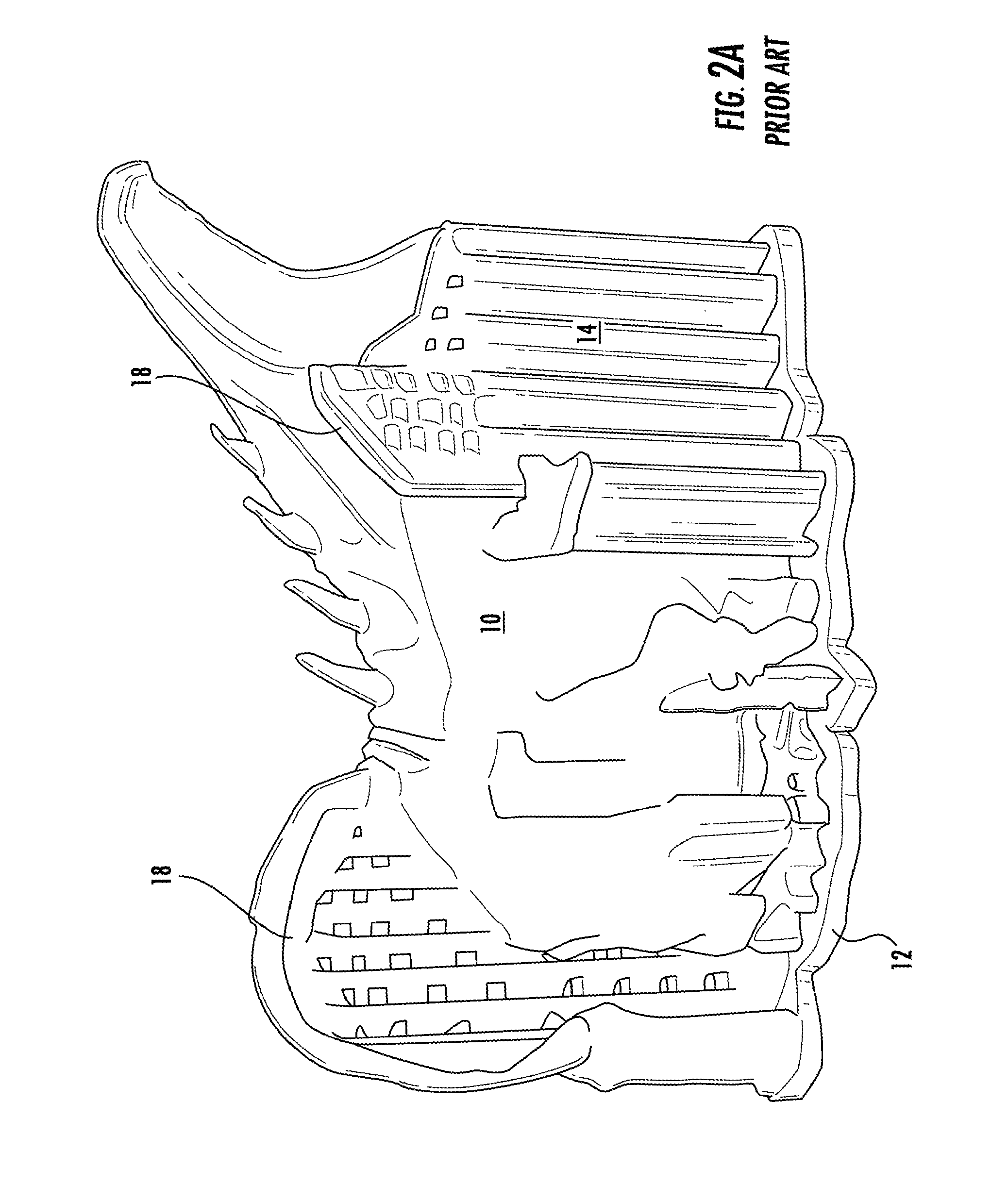

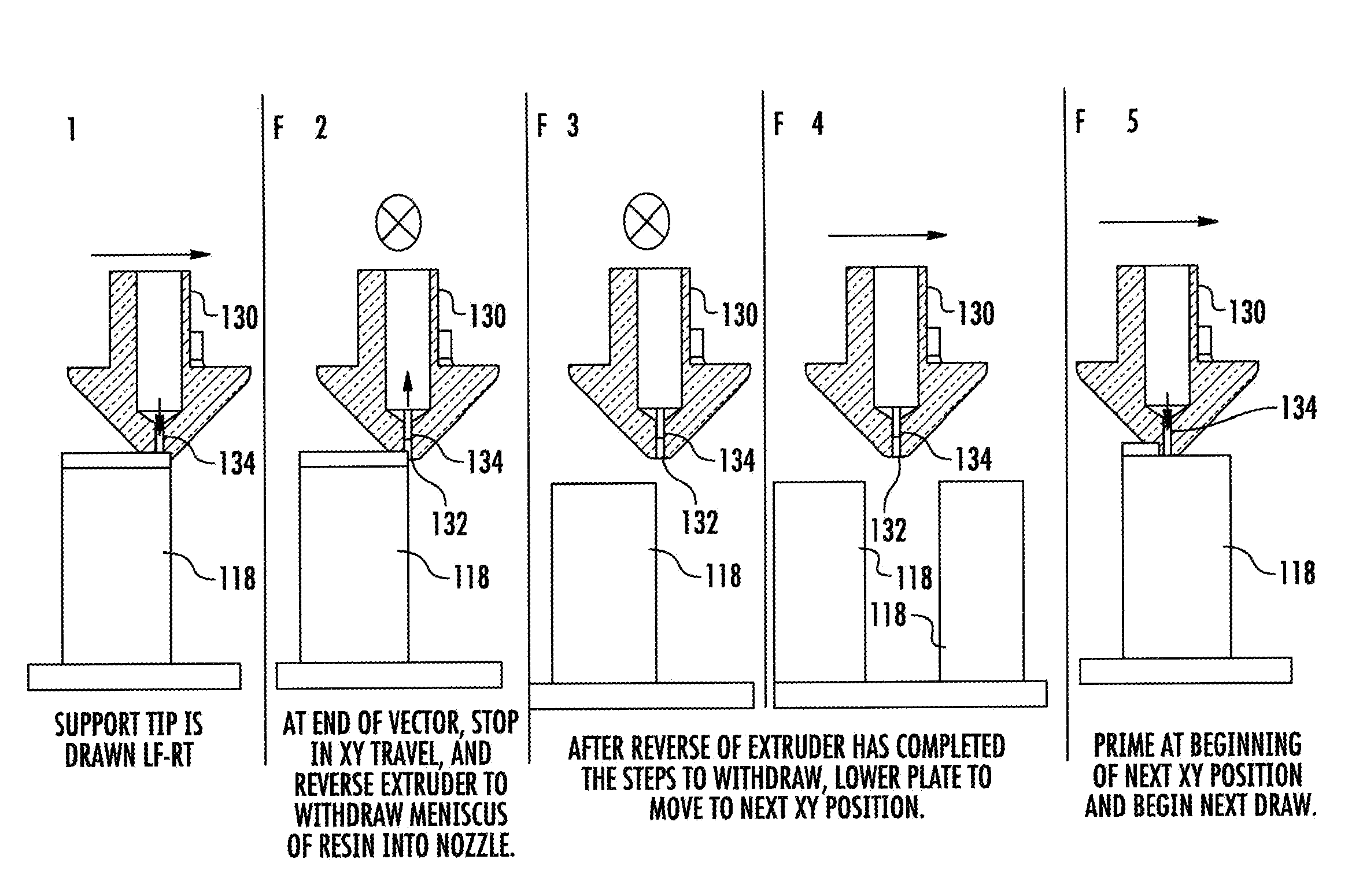

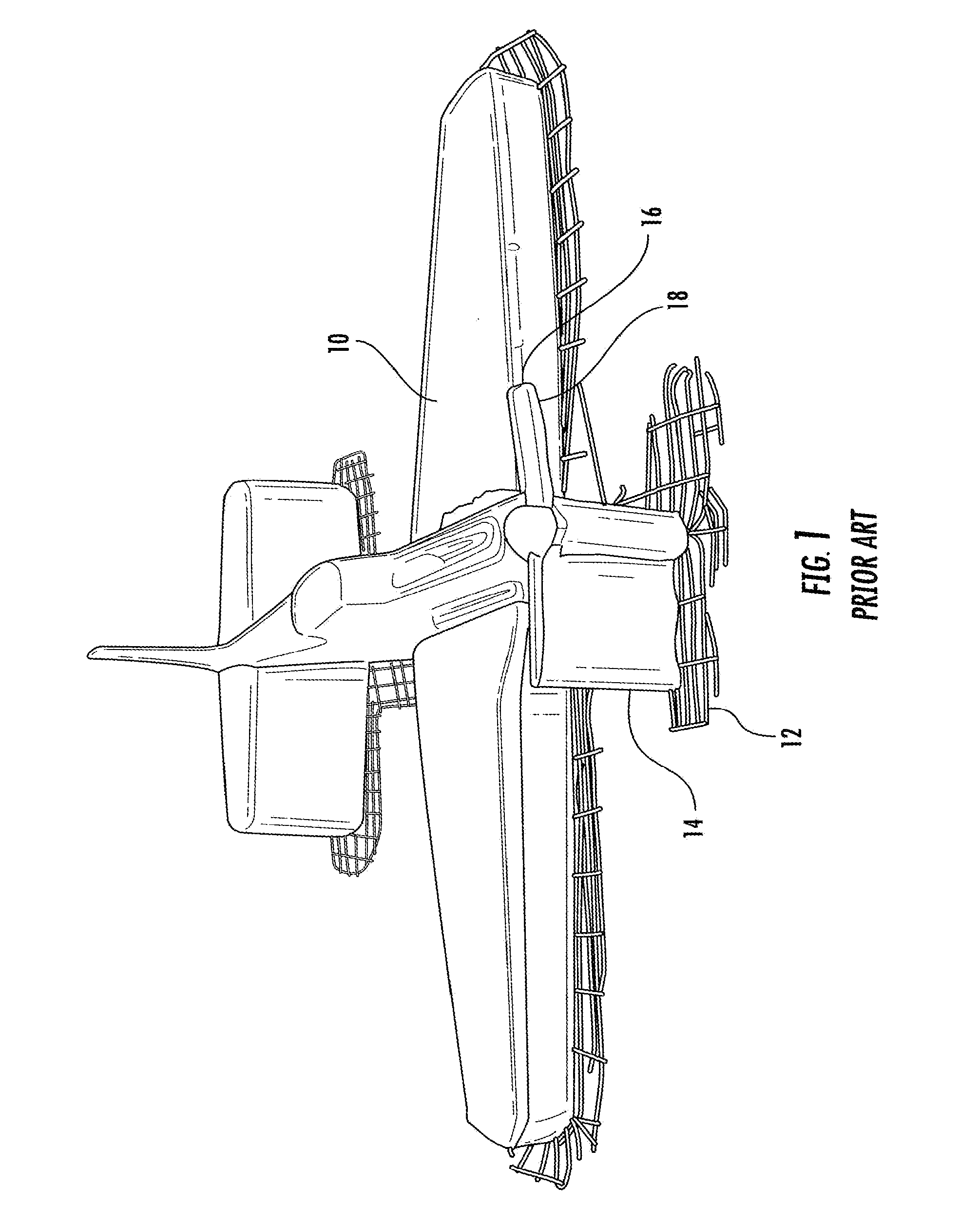

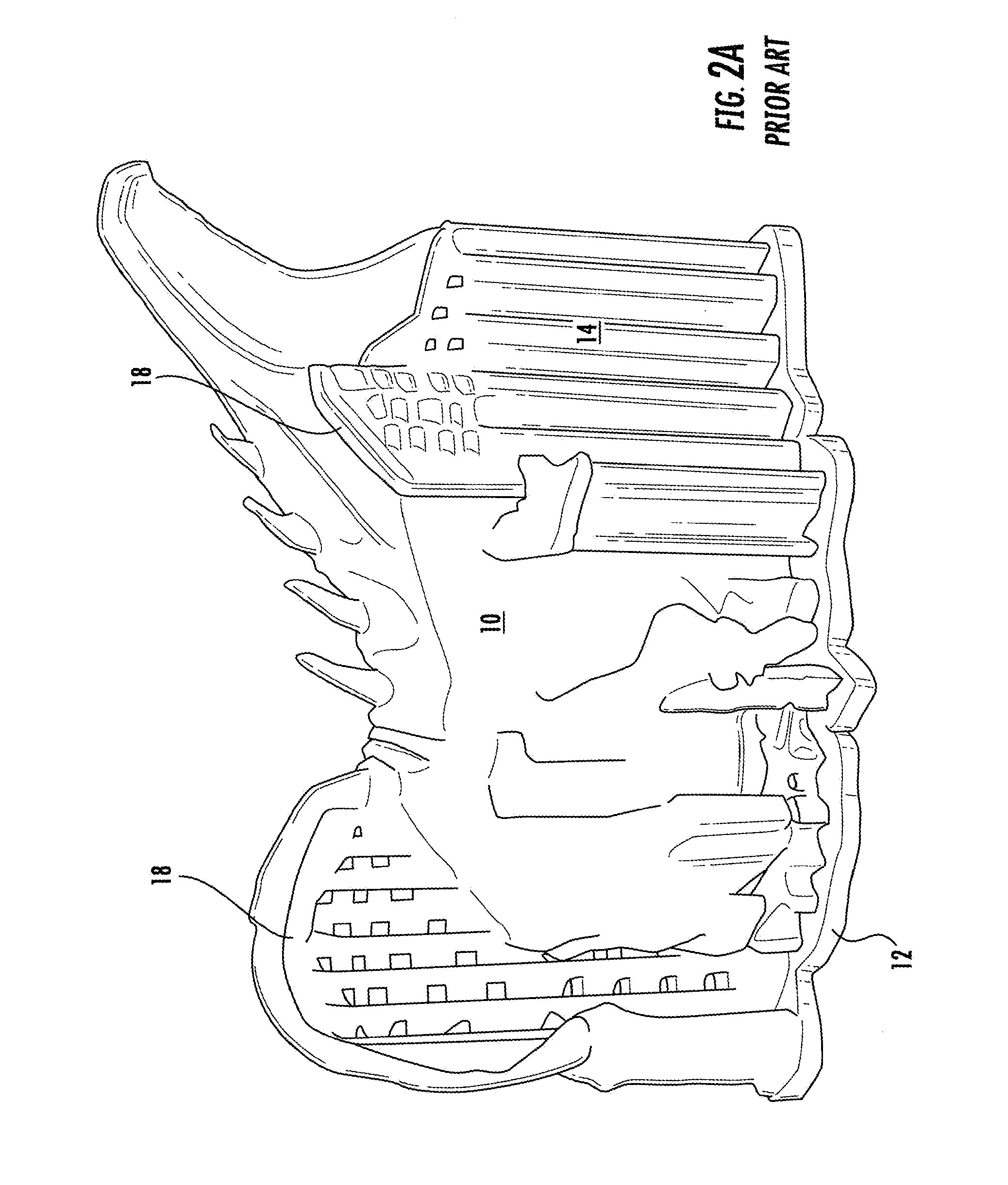

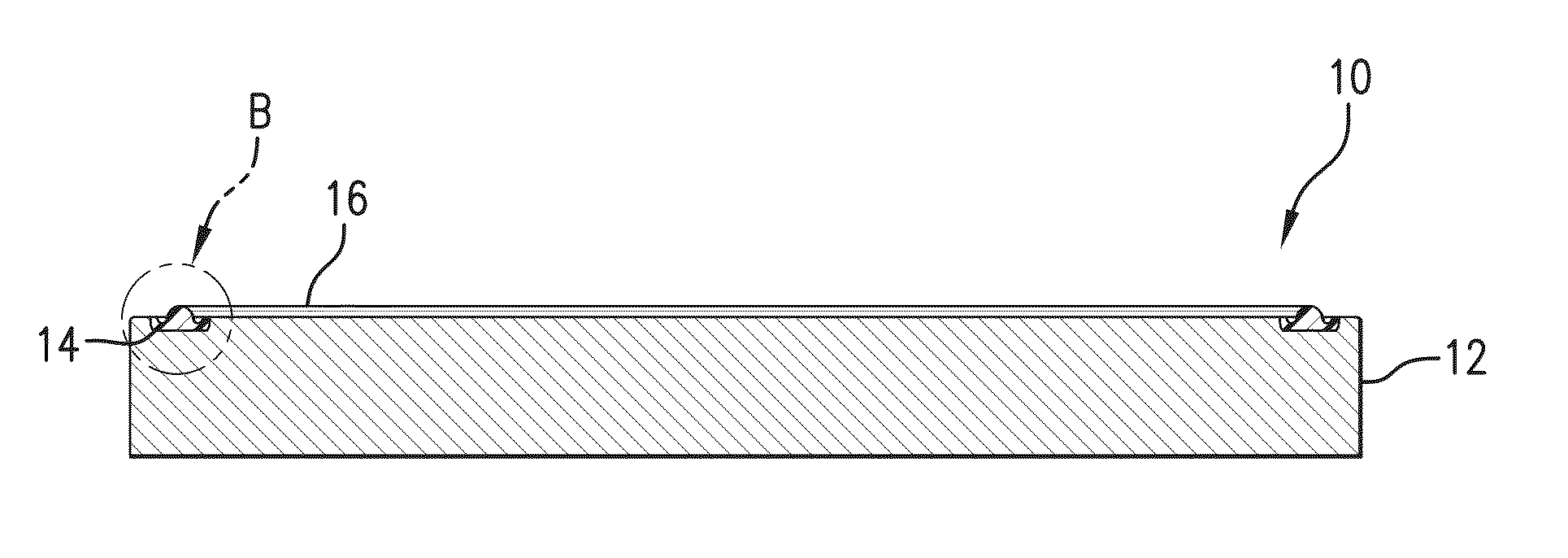

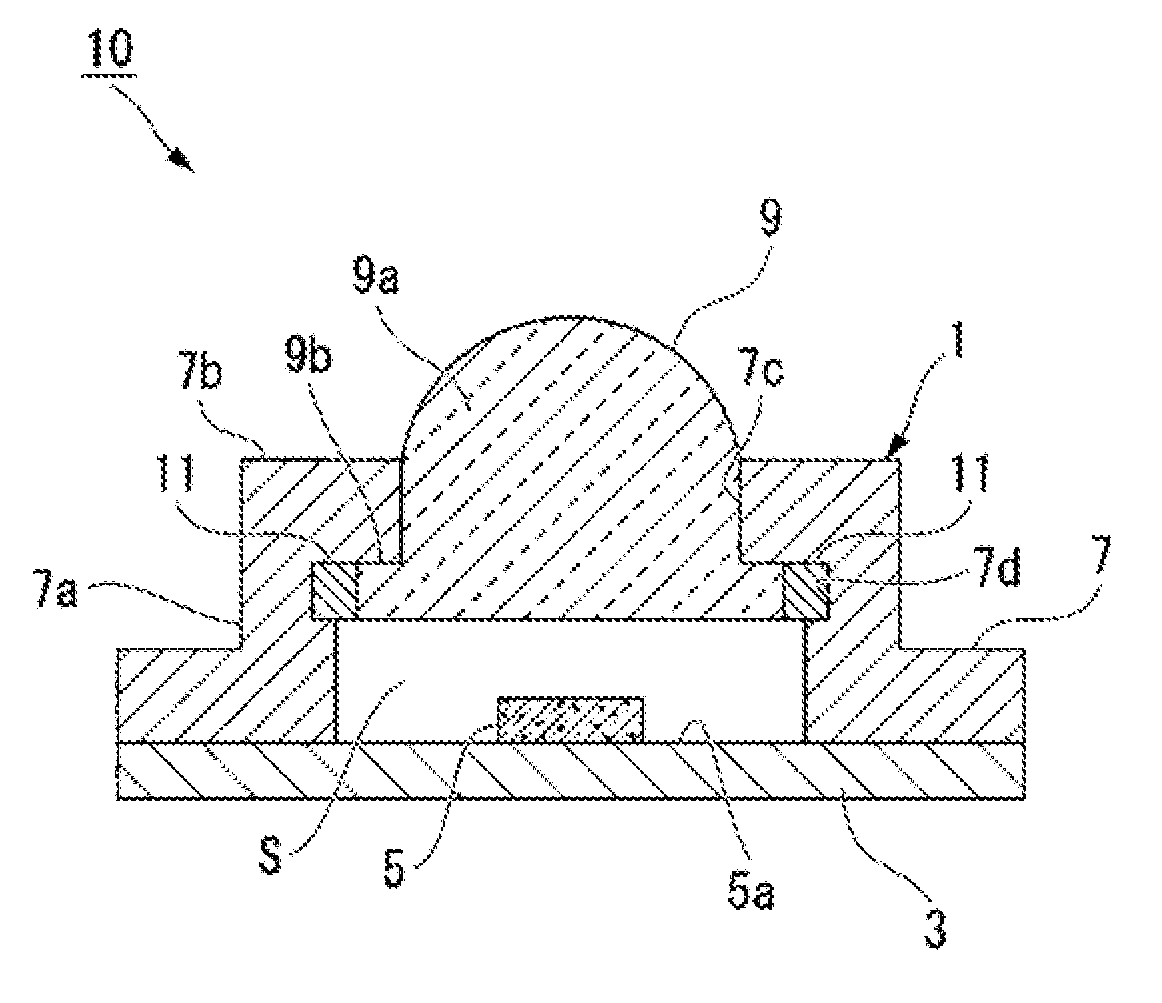

Support structures and deposition techniques for 3D printing

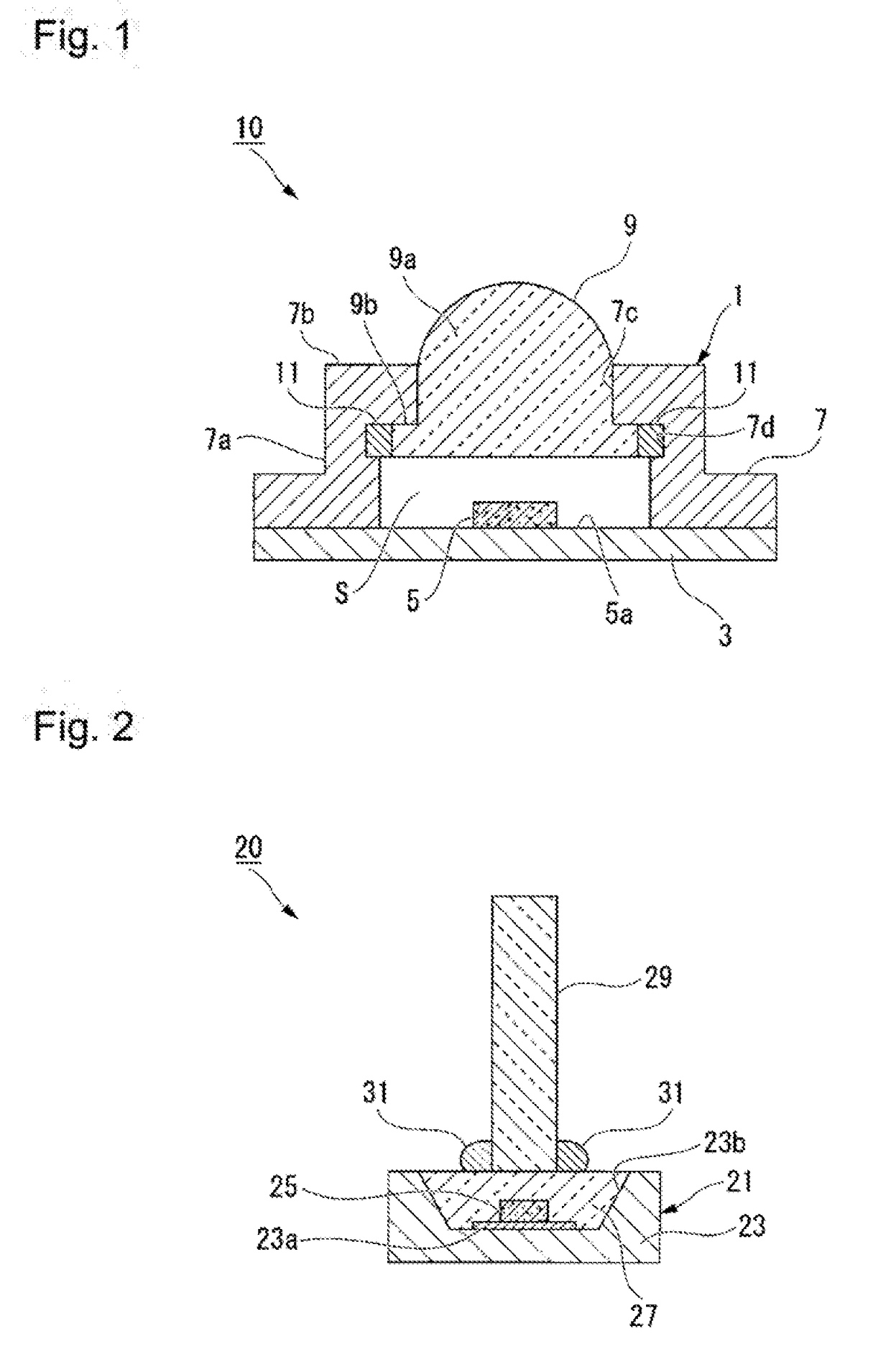

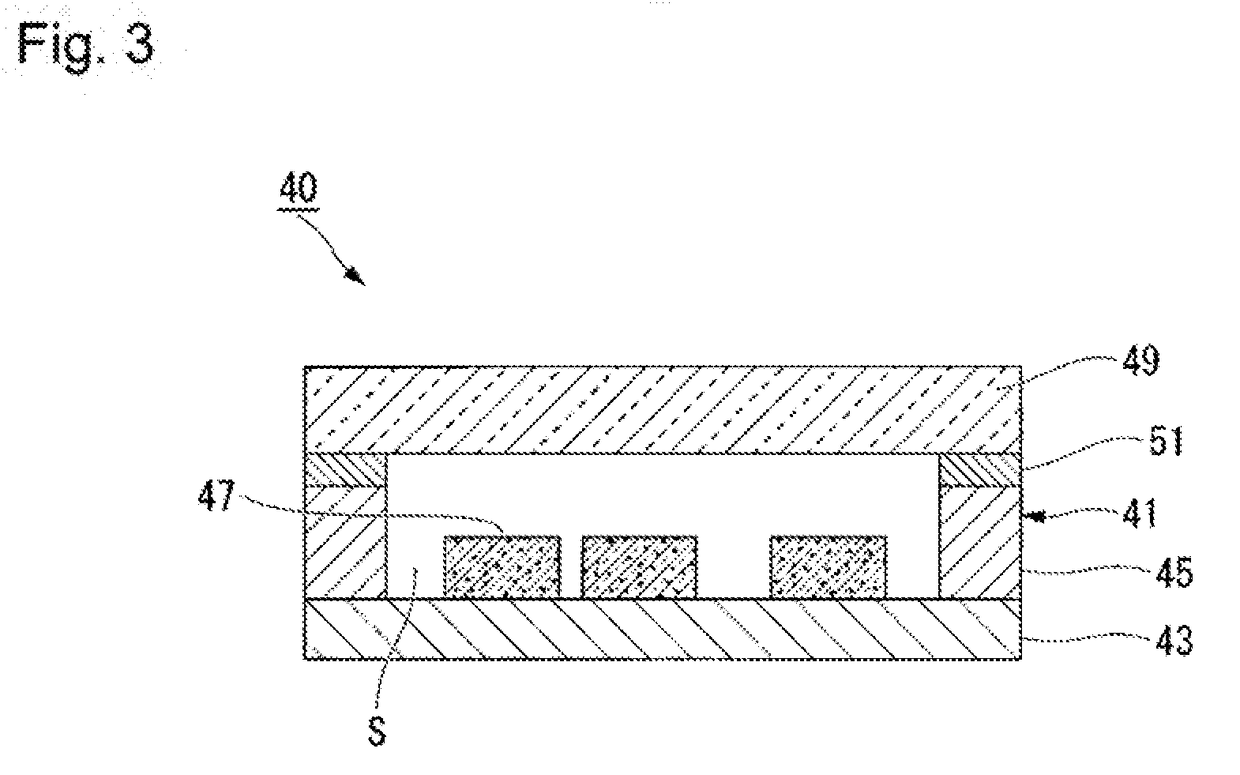

ActiveUS9469057B2Easy to separateFine surfaceManufacturing platforms/substratesUnsaturated ether polymer adhesivesComputer Aided DesignEngineering

Owner:3D SYST INC

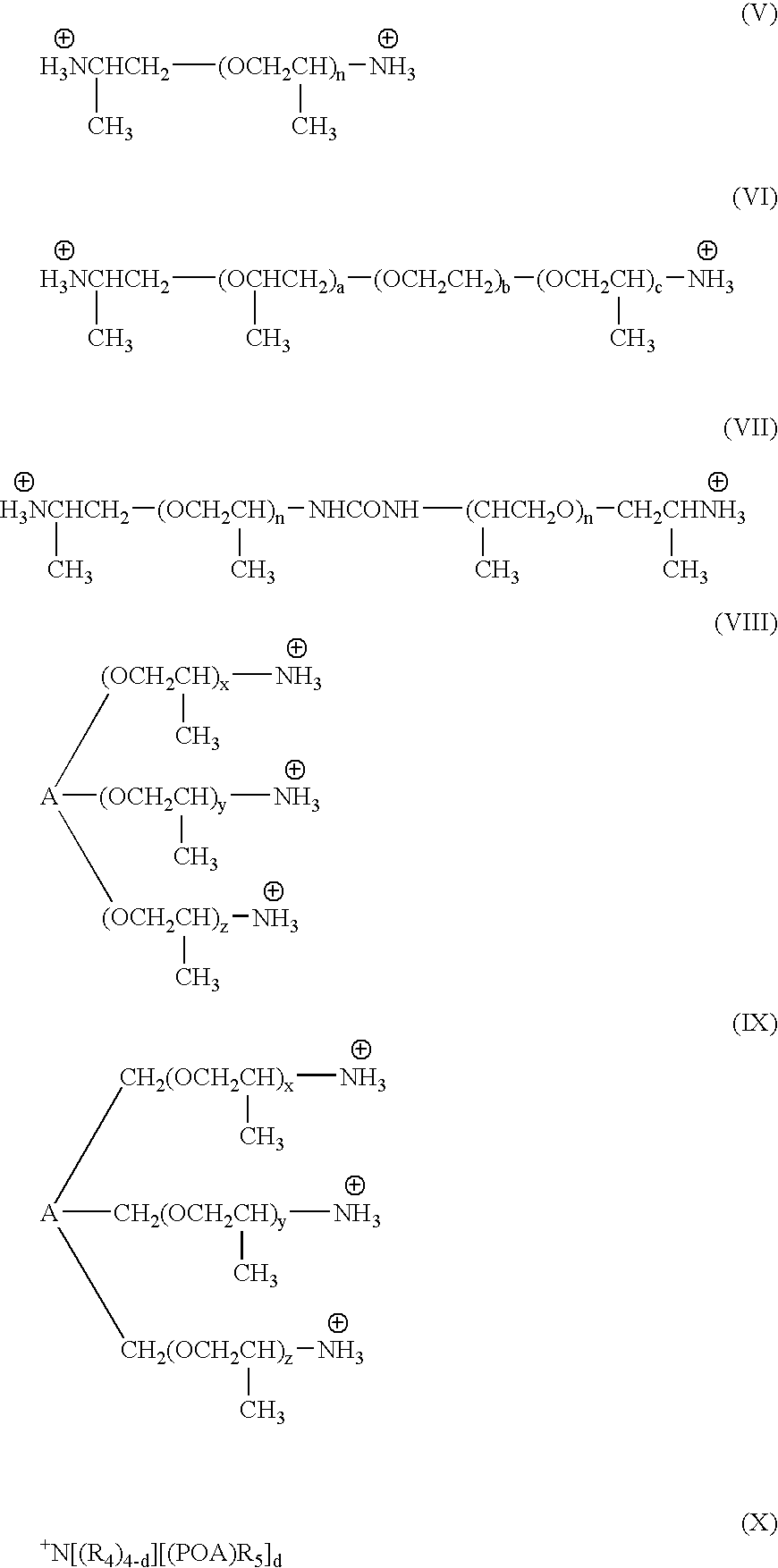

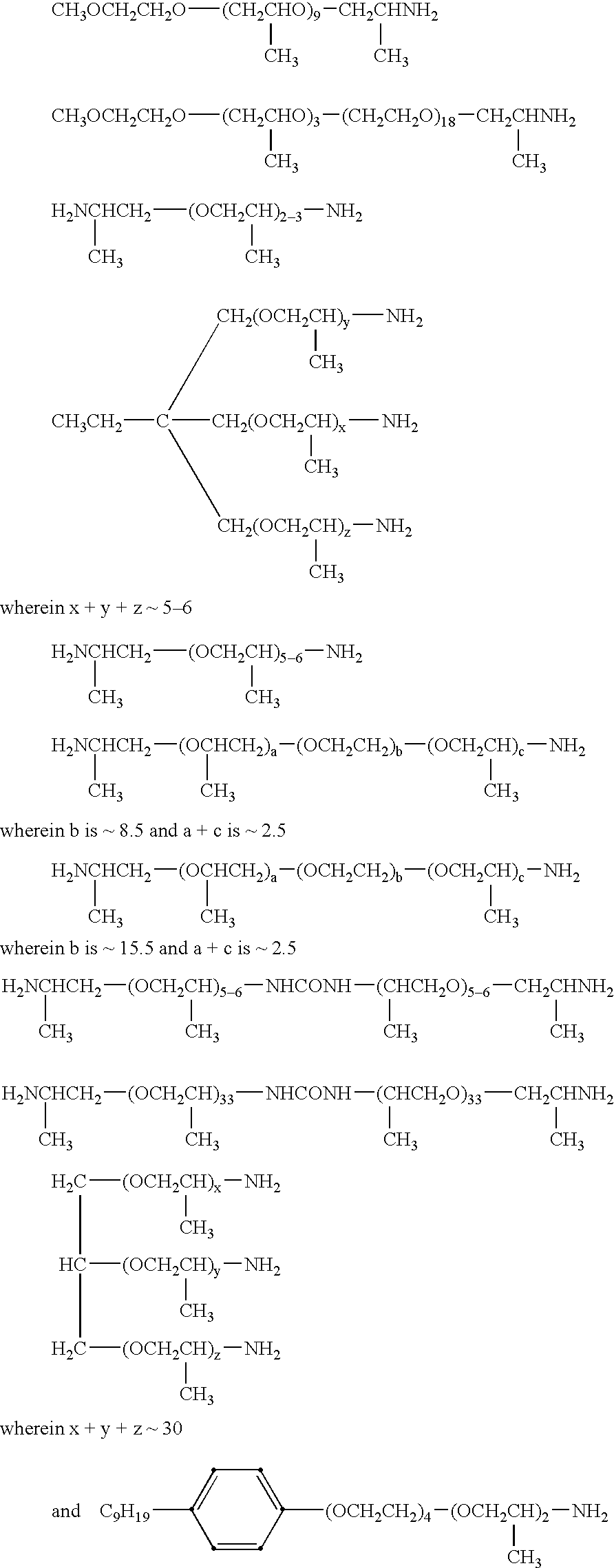

Optically clear and antistatic pressure sensitive adhesives

InactiveUS20070141329A1Natural rubber adhesivesNon-macromolecular adhesive additivesAntistatic agentPolymer chemistry

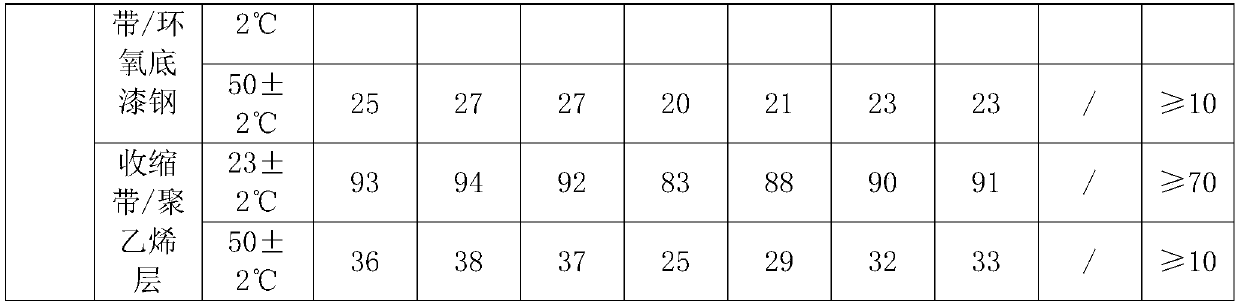

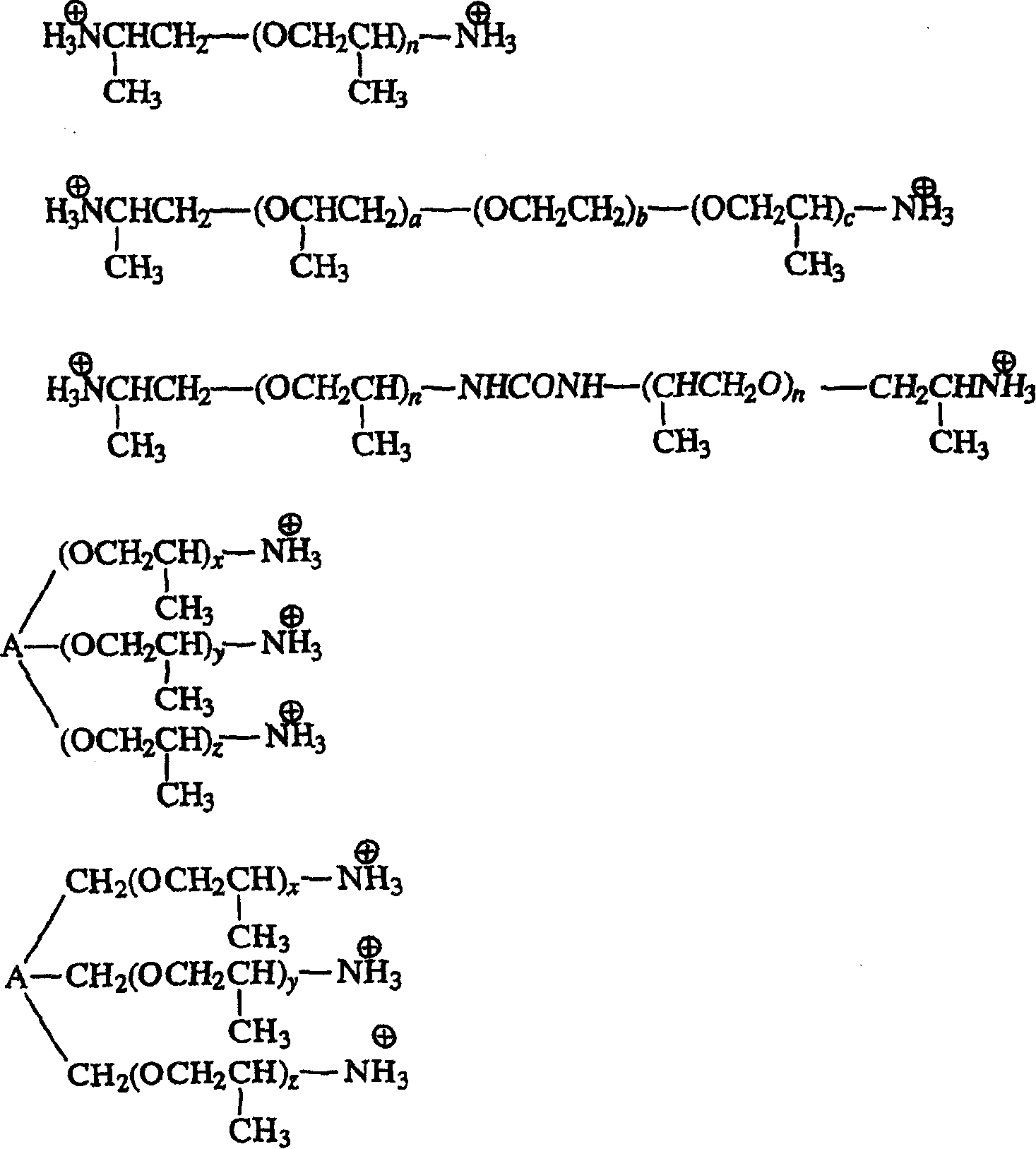

The present invention is directed to an antistatic pressure sensitive adhesive. The antistatic pressure sensitive adhesive comprises a pressure sensitive adhesive, and an antistatic agent comprising at least one organic salt. Certain embodiments of the antistatic pressure sensitive adhesive also have a luminous transmission of greater than about 89% according to ASTM D 1003-95. Additional embodiments of the antistatic pressure sensitive adhesive have a haze of less than about 5% according to ASTM D 1003-95, and in specific embodiments the haze is less than about 2% according to ASTM D 1003-95.

Owner:3M INNOVATIVE PROPERTIES CO

Delayed-tack adhesive composition

InactiveUS6080480AIncrease stickinessImprove the immunityNon-macromolecular adhesive additivesUnsaturated ether polymer adhesivesPolymer sciencePlasticizer

PCT No. PCT / JP96 / 02685 Sec. 371 Date Mar. 25, 1998 Sec. 102(e) Date Mar. 25, 1998 PCT Filed Sep. 18, 1996 PCT Pub. No. WO97 / 12010 PCT Pub. Date Apr. 3, 1997A delayed-tack adhesive composition exhibiting a high tack strength even for adherends made of non-polar materials such as polyethylene and polypropylene, which comprises a (co)polymer prepared by the use of a radical-polymerizable monomer having a straight-chain or branched alkyl group having 9 to 18 carbon atoms and a plasticizer being solid at ordinary temperatures.

Owner:TOYO INK SC HOLD CO LTD

Support Structures and Deposition Techniques for 3D Printing

ActiveUS20130307193A1Easy to separateImproved down-facing surfaceManufacturing platforms/substratesUnsaturated ether polymer adhesivesComputer Aided Design3d print

Owner:3D SYST INC

Aqueous adhesive compositions for bonding elastomers

InactiveUS20030158338A1Improve composite effectImprove securityUnsaturated ether polymer adhesivesSynthetic resin layered productsElastomerAdhesive

The present invention relates to improved compositions for aqueous adhesives and aqueous primers that increase the durability of composites made by adhering elastomers to metal.

Owner:ROHM & HAAS CO

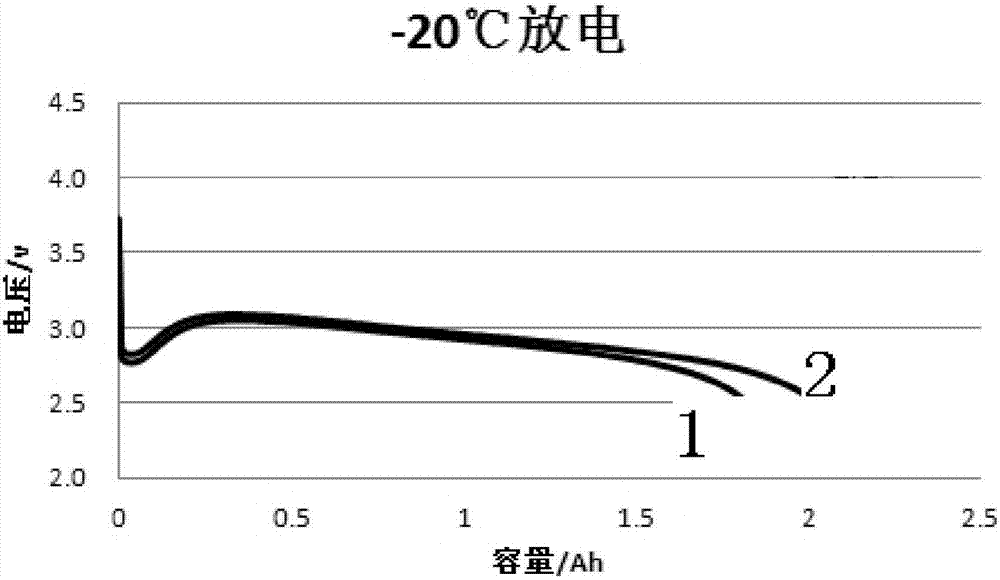

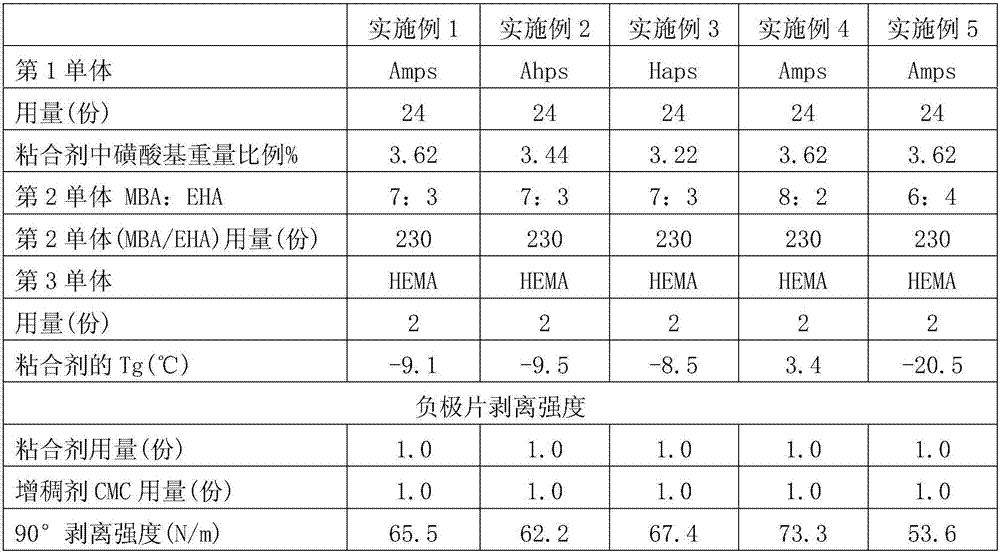

Lithium ion battery negative electrode aqueous adhesive and preparation method thereof

ActiveCN107325225AIncrease energy densitySatisfy the use requirements of the preparationUnsaturated ether polymer adhesivesCell electrodesPolymer scienceDispersed media

The invention relates to a lithium ion battery negative electrode aqueous adhesive and a preparation method thereof, and belongs to the field of energy storage device (battery eg.) manufacturing. The lithium ion battery aqueous adhesive comprises polymer emulsion, which comprises a hydrophilic unit, a hydrophobic unit, and an enhancing unit; wherein the hydrophilic unit comprises sulfonic acid groups accounting for 3.0 to 4.0 wt% of the polymer, and the glass-transition temperature of the polymer is -25 to 5 DEG C. Water is taken as the disperse medium, the adhesive is environmentally friendly, the bonding force of the adhesive is strong, and the using amount of the adhesive for negative electrodes can be reduced. The using amount of the adhesive is only 40% of SBR, the using requirements of battery preparation can be satisfied, and the discharging performance is better at a low temperature (-20 DEG C).

Owner:SICHUAN INDIGO TECH CO LTD

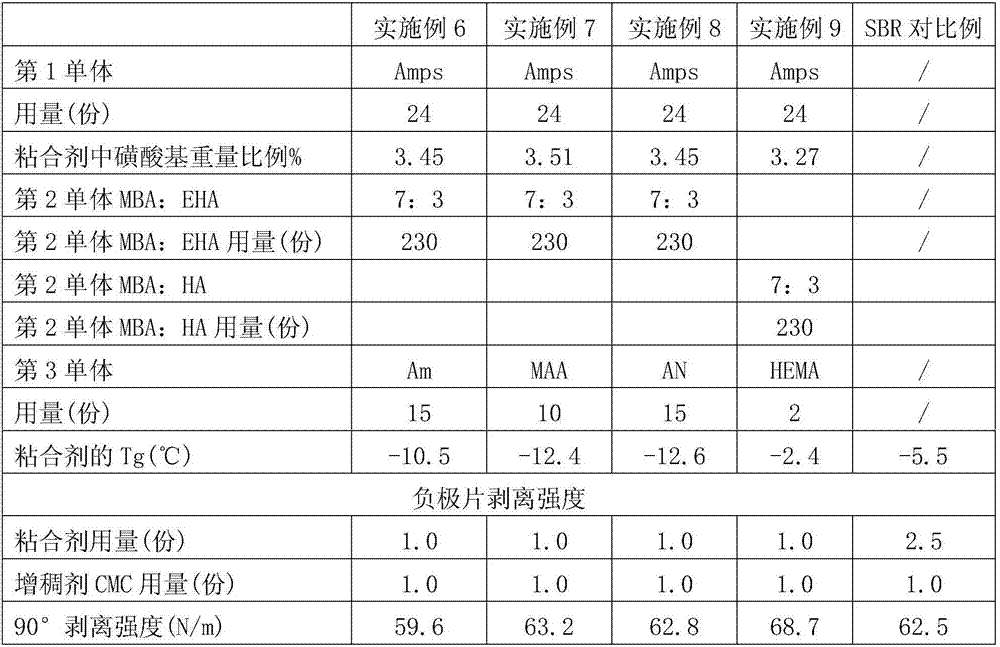

Adhesive composition used for solar energy and preparation method thereof

ActiveCN106675465AExcellent adhesionGood resistance to environmental erosionUnsaturated ether polymer adhesivesEster polymer adhesivesAcrylic resinAdhesive

The invention provides an adhesive composition used for a solar backboard. The adhesive composition is prepared from the following components in percentage by weight: 30% to 50% of polyester modified acrylic resin, 30% to 45% of polyester resin and 5% to 40% of an isocyanate curing agent. 2-methylene-1,3-dioxocycloheptane is used for being reacted with an acrylic monomer, so that modified acrylic resin of which a main chain contains more ester bonds is obtained; the modified acrylic resin can be preferably compatible with polyester, the modified acrylic resin and the polyester are cooperatively used, and the adhesive force of the adhesive for PET films, PVF films or EVA films simultaneously can be greatly improved, so that the using performance of the backboard adhesive is greatly improved.

Owner:苏州瀚海新材料有限公司

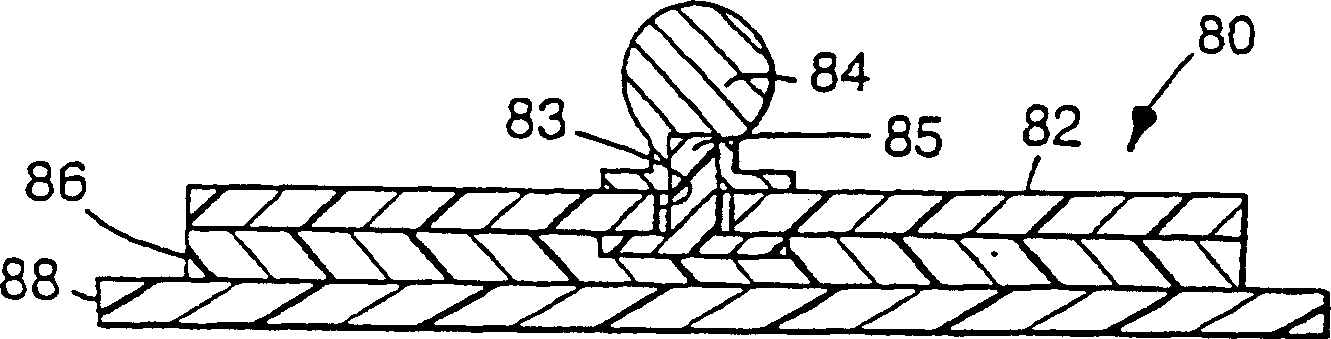

Pressure sensitive conductive adhesive having hot-melt properties and biomedical electrodes using same

InactiveCN1402768APrevent thinningHigh application speedUnsaturated ether polymer adhesivesAdhesive dressingsHot meltPressure sensitive

A skin-compatible, hot-melt processible, pressure sensitive adhesive is disclosed. A thermo-reversible cross-linking is achieved, permitting advantages in processibility and the reduction of waste.

Owner:3M INNOVATIVE PROPERTIES CO

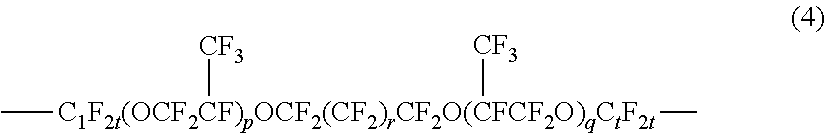

Thermosetting fluoropolyether adhesive composition and adhesion method

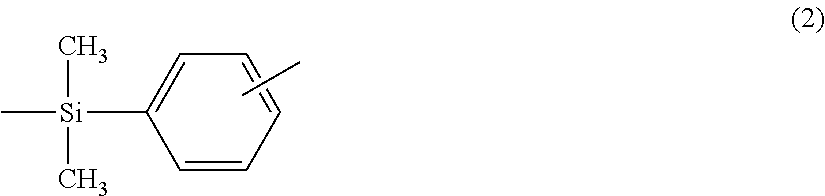

InactiveCN102604581AImprove adhesionExcellent Adhesion DurabilityNon-macromolecular adhesive additivesUnsaturated ether polymer adhesivesEpoxyAryl

Owner:SHIN ETSU CHEM CO LTD

Flame-retardant adhesive for timer and preparation method thereof

InactiveCN101519571AImprove heat resistanceLong-term fire retardantUnsaturated ether polymer adhesivesEster polymer adhesivesEmulsionAdhesive

The invention discloses a flame-retardant adhesive for timer and a preparation method thereof. The adhesive comprises the following compositions in percentage by mass: 80.0 to 85.0 percent of bromocarbon styrene-acrylic emulsion, 1.0 to 2.0 percent of diantimony trioxide, 4.0 to 8.0 percent of chlorinated paraffin, and 10.0 percent of deionized water. The preparation method comprises the following steps: adding a proper amount of the deionized water, the diantimony trioxide, the chlorinated paraffin and the titanium pigment orderly into a multi-purpose dispersion mill for high-speed dispersion for 30 to 60 minutes; reducing the stirring speed, adding the bromocarbon styrene-acrylic emulsion into the mixture, and dispersing the mixture for 20 to 40 minutes once again; and grinding the obtained product to a needed fineness by a cone mill, adding the powder into the multi-purpose dispersion mill to be dispersed for 10 to 20 minutes, and obtaining the flame-retardant adhesive for the timer.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Fluoroelastomer Compositions Having Self-Bonding Characteristics and Methods of Making Same

Owner:GREENE TWEED TECH

Fluoroelastomer compositions having self-bonding characteristics and methods of making same

Self-bonding curable fluoroelastomer compositions are provided wherein the compositions including a) a fluoropolymer composition having at least one curable fluoropolymer; and b) a compound selected from the group consisting of aluminum acrylates, silicon acrylates, and ammonia acrylates, wherein the self-bonding curable fluoroelastomer composition is able to bond directly to a substrate. Bonded structures formed of such self-bonding compositions and a substrate having a surface bonded thereto are also described herein along with a method for bonding a self-bonding curable fluoroelastomer composition to a substrate surface. The fluoroelastomers herein may encompass both non-fully fluorinated (FKM) and fully fluorinated (FFKM) elastomers.

Owner:GREENE TWEED TECH

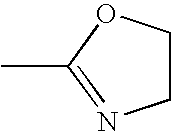

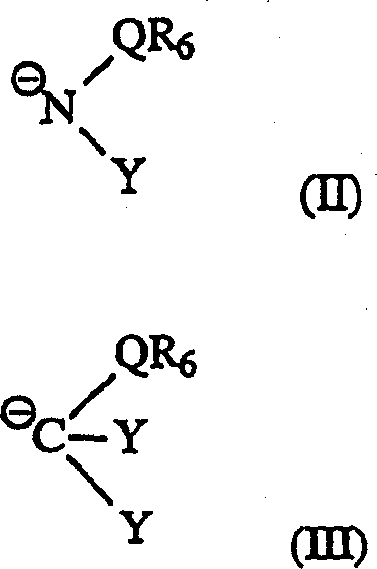

Improved method for producing hydroxyl group-containing vinyl ether polymer

ActiveUS20180179305A1High monomer conversion rateReduce the amount requiredUnsaturated ether polymer adhesivesInksVinyl etherSolvent

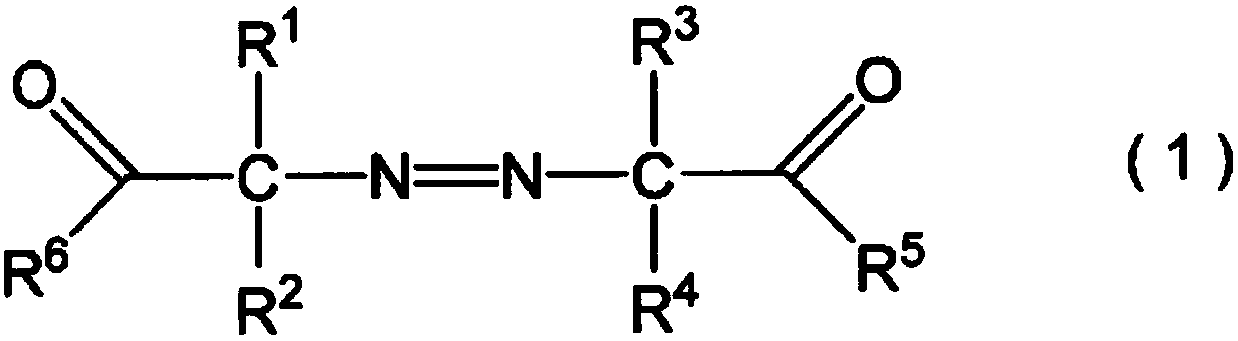

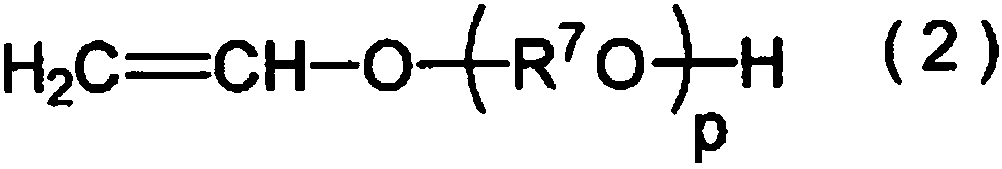

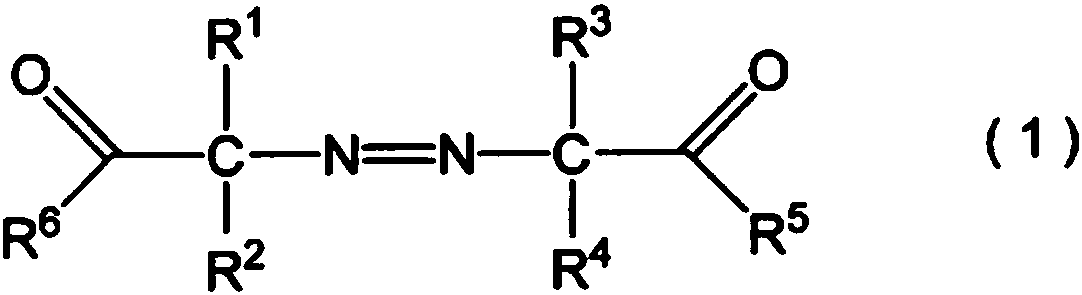

A method for producing a hydroxyl group-containing vinyl ether polymer according to the present invention includes: a step of radical polymerizing at least one vinyl ether selected from vinyl ether having a hydroxyl group represented by the following formula (2):wherein R7 represents an alkylene group which is straight-chained, branched or comprises an alicyclic structure, and p is 1, 2, or 3, in the presence of water as a polymerization solvent and an azo compound represented by the following formula (1) as a polymerization initiator:wherein R1 to R4 each independently represent a hydrogen atom or an alkyl group and R5 and R6 each independently represent an alkoxy group optionally having a substituent group or an alkyl amino group optionally having a substituent group.

Owner:MARUZEN PETROCHEMICAL CO LTD

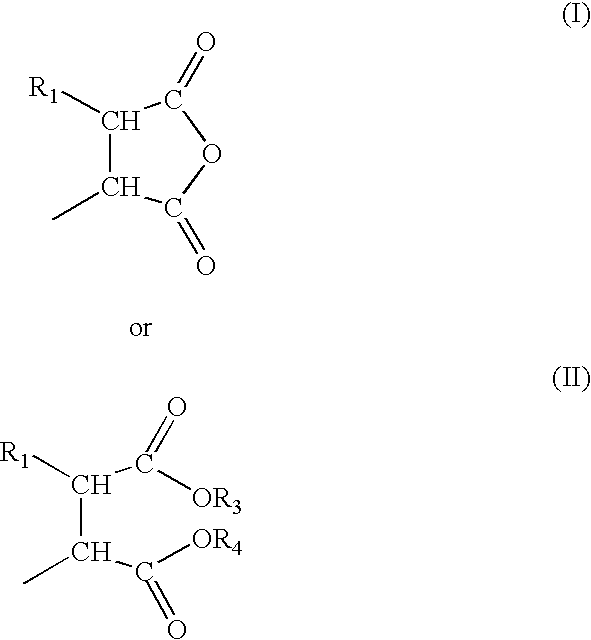

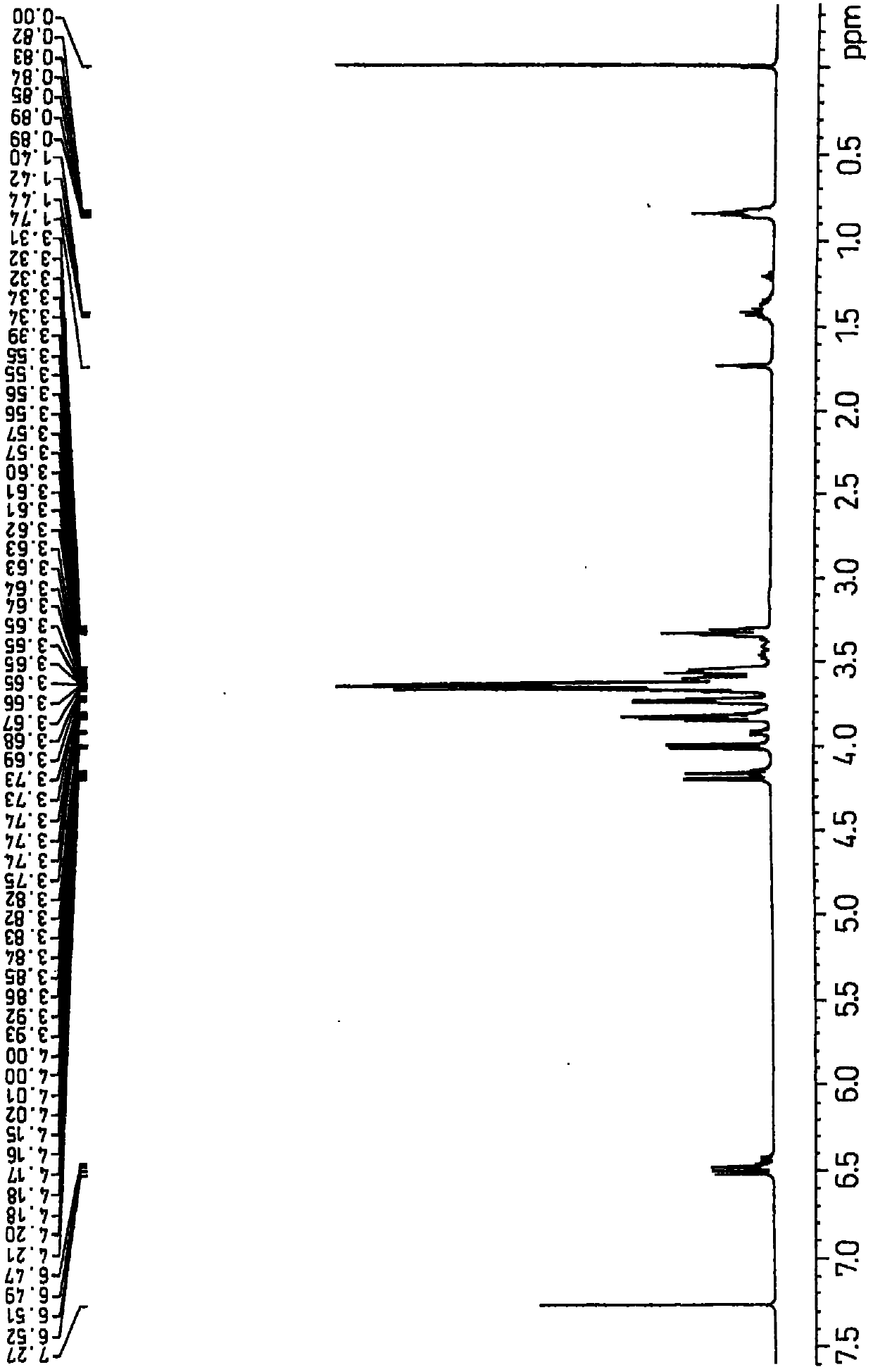

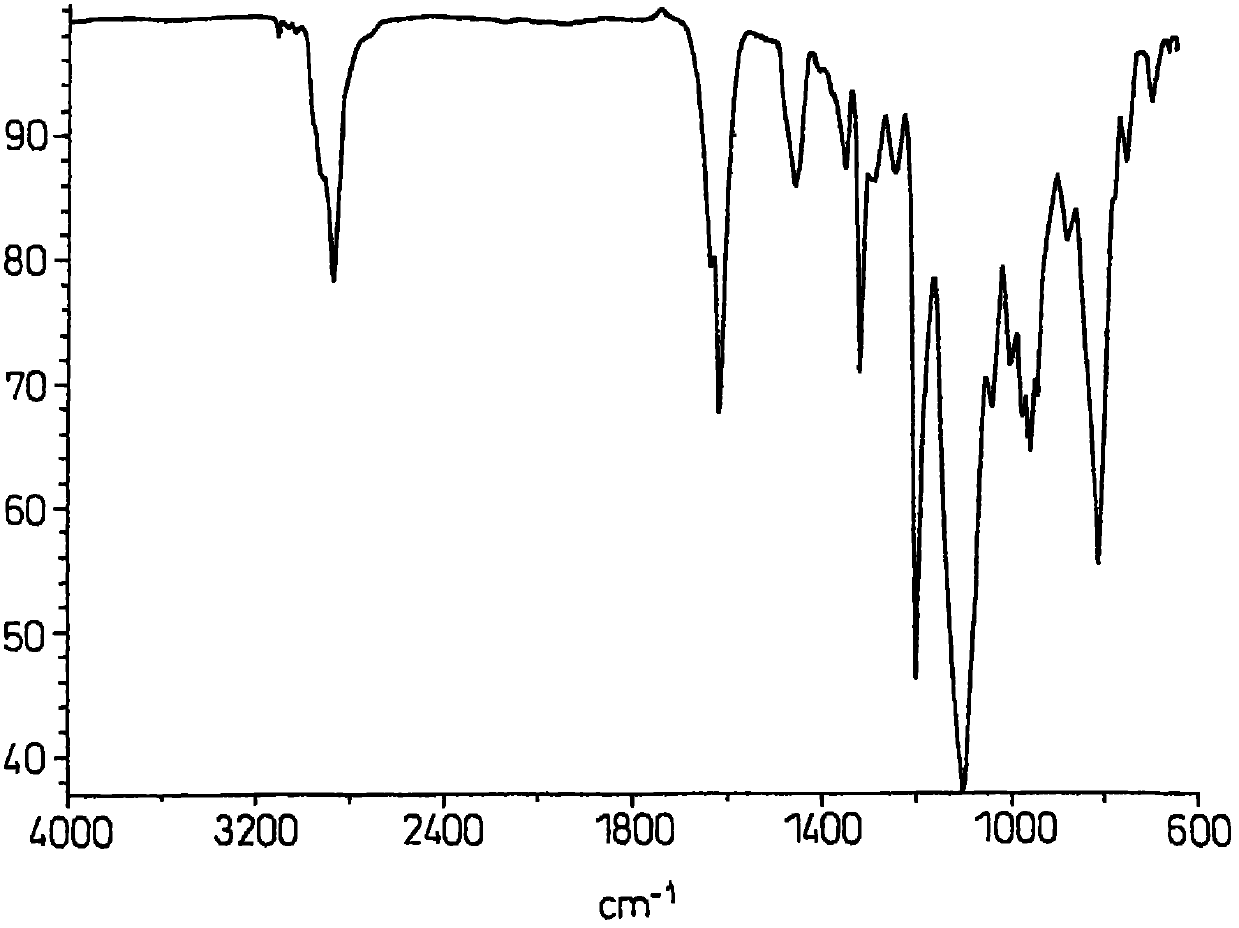

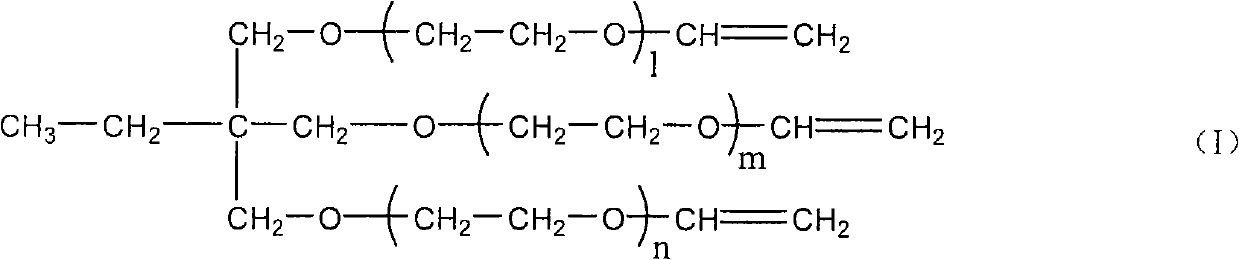

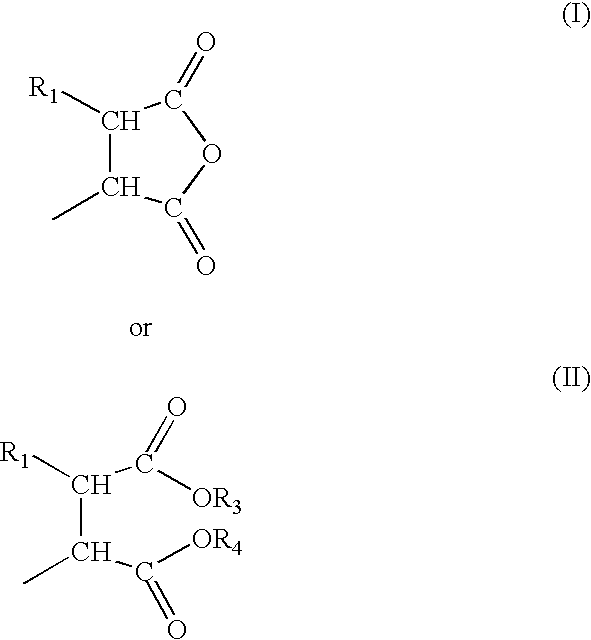

Multifunctional vinyl ether and resin composition containing same

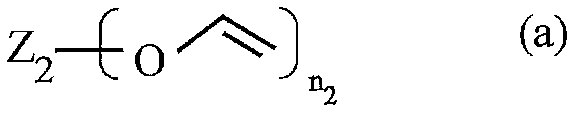

InactiveCN102066437ASkin irritationReduce odorOrganic chemistryUnsaturated ether polymer adhesivesSolubilityResist

The multifunctional vinyl ether represented by formula (I) below produces little skin irritation, is low in odor, has excellent polymerization initiator solubility and curability and is not readily affected by oxygen during curing. Additionally, a resin composition containing said multifunctional vinyl ether can be used in many fields, such as for inks, coating materials, adhesives and resists, since it satisfactorily dissolves polymerization initiators and has excellent curability. l, m and n in the formula (I) are integers that satisfy the relationship l + m + n > 3.

Owner:NIPPON CARBIDE KOGYO KK

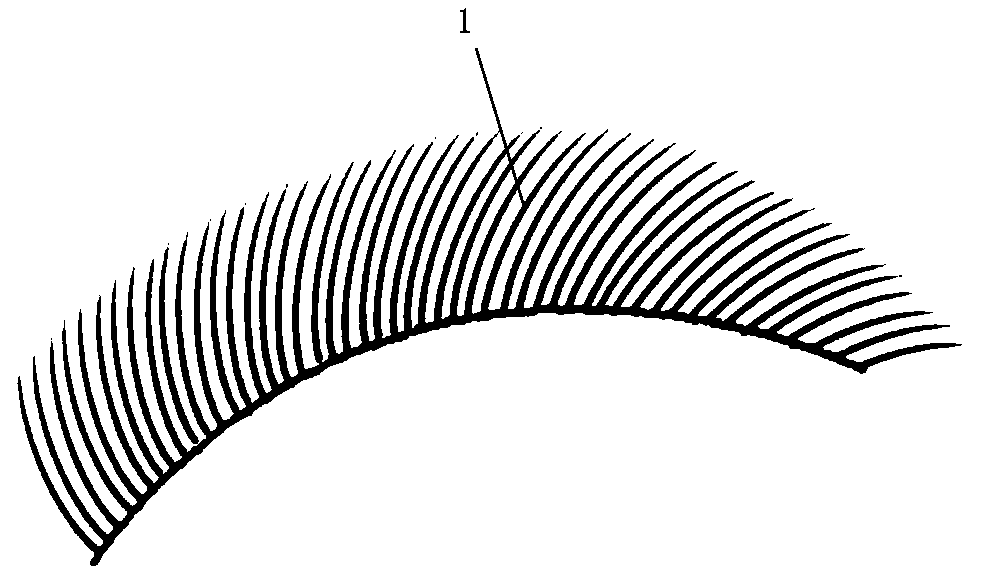

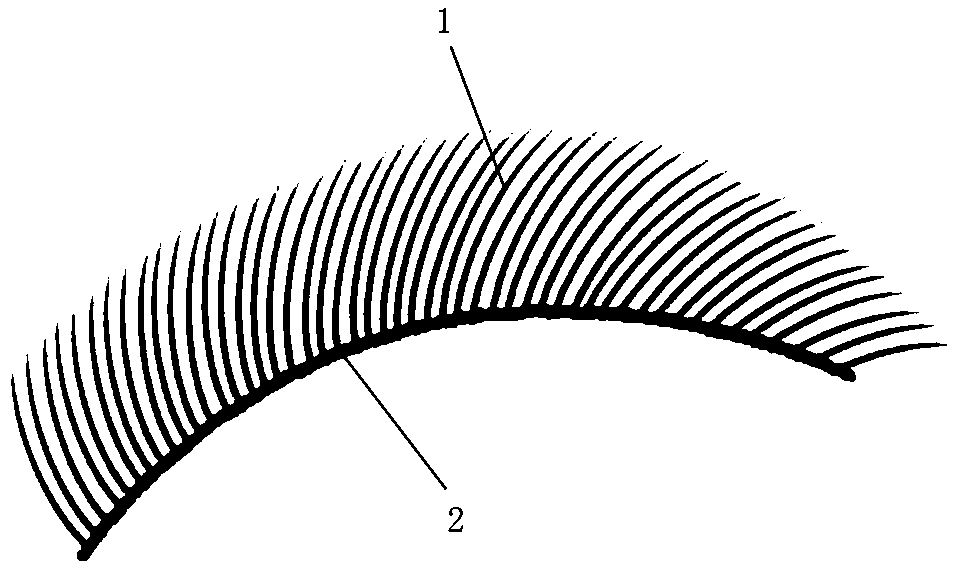

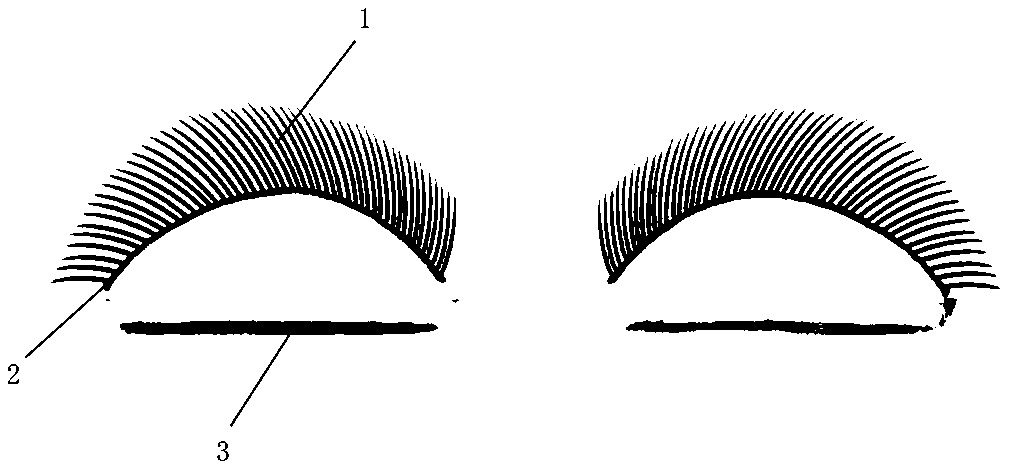

Water self-adhesive film and manufacturing method of false eyelashes with water self-adhesive film

The invention belongs to the technical field of cosmetics, and particularly relates to a water self-adhesive film and a manufacturing method of false eyelashes with the water self-adhesive film. The water self-adhesive film comprises the following components in percentage by weight: 16%-20% of Arabic gum, 10%-13% of casein, 4%-5% of polyvinyl alcohol, 5%-6% of polyvinylpyrrolidone, 5%-6.6% of polyvinyl ether, 3%-6% of polyacrylate and the balance of water. The manufacturing method of the false eyelash with the water self-adhesive film comprises the following steps: A, smearing the water self-adhesive film on the eyeliner part of the false eyelash, and airing for the first time, B, performing primary sterilization treatment on the false eyelashes obtained in the step A, C, smearing the water self-adhesive film on the eyeliner part of the false eyelash obtained in the step B, and airing for the second time, D, smearing the water self-adhesive film on the eyeliner part of the false eyelash obtained in the step C, and airing for three times, and E, performing secondary sterilization treatment on the false eyelashes obtained in the step D. The invention provides the water self-adhesivefilm which has viscosity immediately after being wetted and can be repeatedly adhered.

Owner:青岛蝶妃日用品有限公司

Adhesive for ultraviolet-light-emitting device, and ultraviolet-light-emitting device

ActiveUS20170114253A1Improve adhesionNon-macromolecular adhesive additivesUnsaturated ether polymer adhesivesPolymer scienceAdhesive

Provided is an adhesive for use in an ultraviolet-light-emitting device using ultraviolet light having a wavelength of from 200 to 400 nm as a light source, which can attach adherends made of a polymer having a fluorine-containing alicyclic structure with excellent adhesiveness which is unlikely to be impaired by exposure to such ultraviolet light or heat.An adhesive for forming an adhesive joint in an ultraviolet-light-emitting device, which is either the following adhesive (A) or the following adhesive (B) comprising a fluoropolymer having a fluorine-containing alicyclic structure;the adhesive (A): an adhesive in which the glass transition temperature of the fluoropolymer is from 30 to 100° C., and which does not contain an ultraviolet-shielding agent; andthe adhesive (B): an adhesive comprising the fluoropolymer and an ultraviolet-shielding agent.

Owner:ASAHI GLASS CO LTD

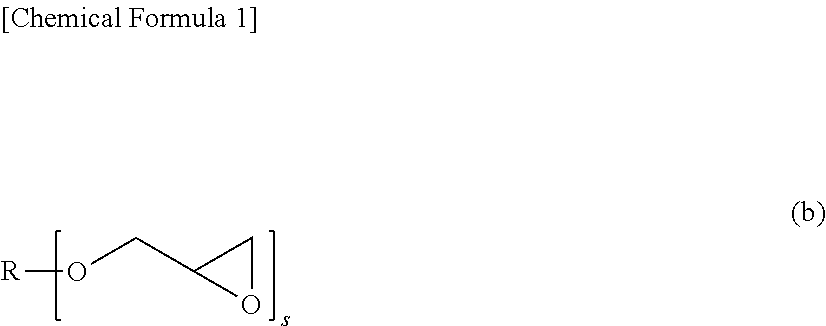

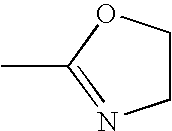

Monomer mixture and curable composition containing same

ActiveUS20200055977A1Low viscosityGood paintabilityAdditive manufacturing apparatusNon-macromolecular adhesive additivesVinyl etherPolymer science

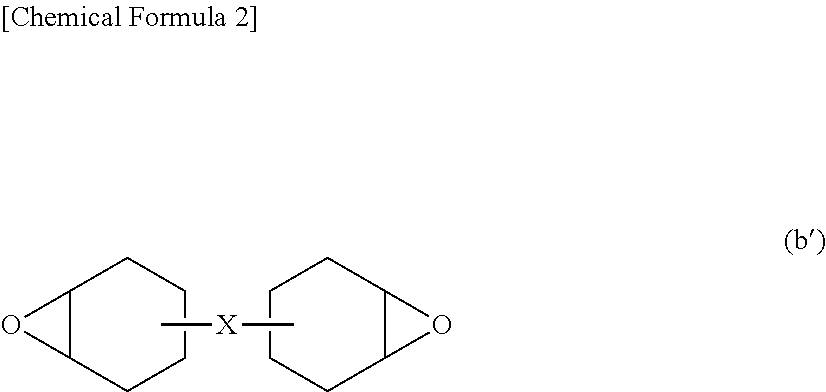

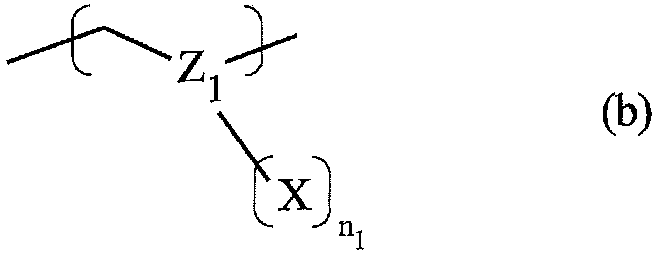

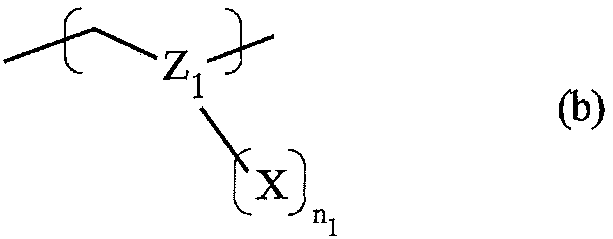

The present invention is to provide a monomer mixture that is cured rapidly even in the presence of oxygen and that forms a cured product having high hardness and excellent adhesion to metals and / or glass. The monomer mixture according to an embodiment of the present invention contains two or more types of cationically polymerizable monomers. As the cationically polymerizable monomers, the monomer mixture contains at least 10 wt. %, based on a total amount of the monomer mixture, of a compound having at least one cationically polymerizable group selected from the group consisting of a vinyl ether group, an epoxy group, and an oxetanyl group, and at least one hydroxy group in a molecule, and at least 5 wt. %, based on the total amount of the monomer mixture, of a compound represented by Formula (b). In the formula, R represents an s-valent straight-chain or branched saturated aliphatic hydrocarbon group or an s-valent group having two or more straight-chain or branched saturated aliphatic hydrocarbon groups bonded to each other through an ether bond, and s represents an integer of 2 or greater.

Owner:DAICEL CHEM IND LTD

Improved method for producing hydroxy group-containing vinyl ether polymer

ActiveCN107835825AEasy and efficient to manufactureReduce usageUnsaturated ether polymer adhesivesInksVinyl etherBoiling point

The invention provides a simple and efficient method for producing a hydroxy group-containing vinyl ether polymer, which does not require a step for removing low-boiling-point impurities such as residual monomers and initiator residues, polyacetals and the like by suppressing the production of polyacetals by improving the monomer conversion rate, while reducing the amount of a polymerization initiator used therefor. A vinyl ether having a hydroxy group represented by formula (2) is radically polymerized in the presence of water, which serves as a polymerization solvent, and an azo compound represented by formula (1), which serves as a polymerization initiator. (In formula (1), each of R1-R4 independently represents a hydrogen atom or an alkyl group; and each of R5 and R6 independently represents an optionally substituted alkoxy group or an optionally substituted alkylamino group.) (In formula (2), R7 represents a linear, branched or alicyclic structure-containing alkylene group; and prepresents 1, 2 or 3.).

Owner:MARUZEN PETROCHEMICAL CO LTD

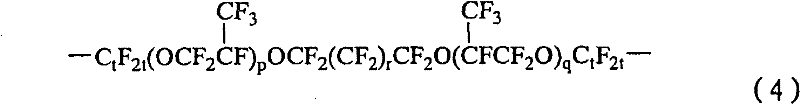

Thermosetting fluoropolyether adhesive composition and adhesion method

ActiveUS20120123049A1Excellent adhesion durabilityImprove adhesionAdhesive processesNon-macromolecular adhesive additivesEpoxyAryl

A thermosetting fluoropolyether adhesive composition is provided. This composition cures at lower than 100° C., and the cured product exhibits good adhesion to various substrates and excellent adhesion durability at a temperature of up to 150° C. A method for adhering the composition to the substrate is also provided. The composition comprises (A) a straight chain polyfluoro compound, (B) a fluorine-containing organohydrogenpolysiloxane containing at least 2 SiH groups and not containing other functional group, (C) a platinum group metal catalyst, (D) a fluorine-containing organohydrogenpolysiloxane containing a fluorine-containing organic group, SiH group, epoxy group and / or tri(organoxy)silyl group, and an aryl group, (E) a polyhydric allyl ester compound, (F) an organosilicon compound having epoxy group and an organoxy group, and not containing SiH group, and (G) an organosilicon compound having SiH group and an aryl group, and not containing epoxy group or a tri(organoxy)silyl group, or a fluorine-containing organic group.

Owner:SHIN ETSU CHEM IND CO LTD

Aqueous adhesive compositions for bonding elastomers

InactiveUS7144630B2Unsaturated ether polymer adhesivesSynthetic resin layered productsElastomerAdhesive

Owner:ROHM & HAAS CO

Adhesive

ActiveCN108137994AGood flexibilityEasy to peelNon-macromolecular adhesive additivesUnsaturated ether polymer adhesivesVinyl etherPolymer science

Provided is an adhesive enabling: adhesion and fixing of an adherend onto a support while maintaining a high adhesive property during when the adherend is required to be fixed onto the support, even in a high temperature environment or an environment in which the temperature changes rapidly; detachment of, when the fixing has become unnecessary, the adherend from the support without causing any damage to the adherend; and easy removal of any residual paste present on the adherend after detachment. The adhesive according to the present invention contains a multivalent vinyl ether compound (A),a compound (B) having two or more constitutional units represented by formula (b), and a thermoplastic resin (C). In the formula, X represents a hydroxy group or a carboxy group.

Owner:DAICEL CORP

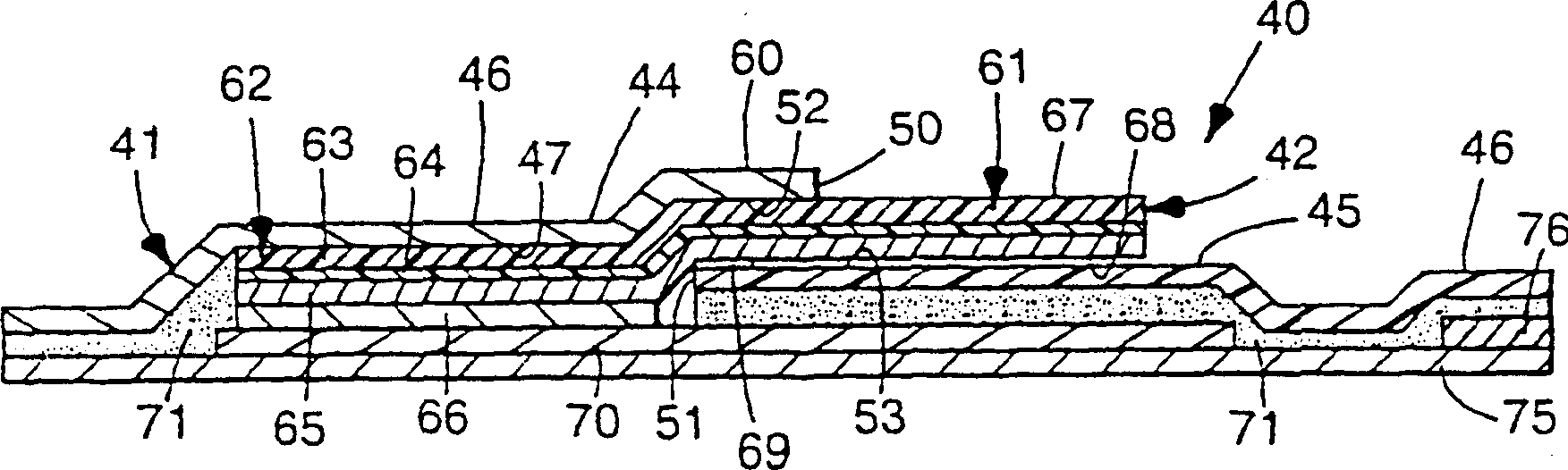

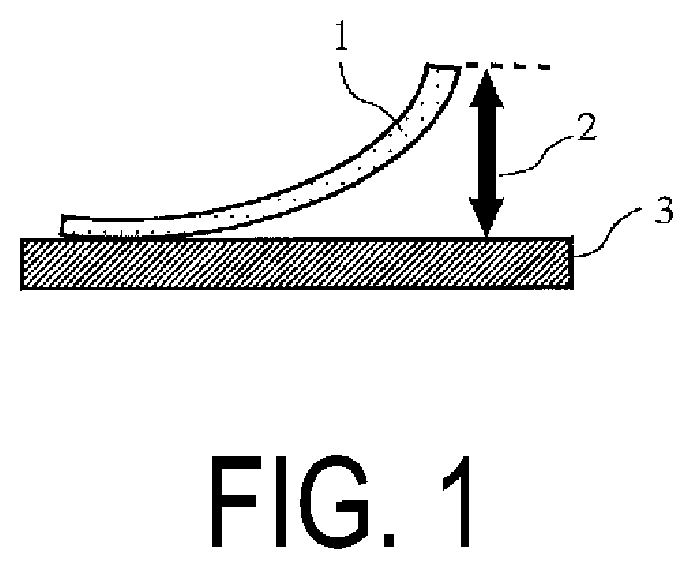

Material for printed circuit board, metal laminate, methods for producing them, and method for producing printed circuit board

ActiveUS20180050516A1Unsaturated ether polymer adhesivesCircuit susbtrate materialsEngineeringPrinted circuit board

To provide a material for a printed circuit board which is less likely to be warped in a high temperature region (from 150 to 200° C.) while maintaining electrical properties, a metal laminate, methods for producing them, and a method for producing a printed circuit board.A material having a fluorinated resin layer is subjected to a heat treatment. The fluorinated resin layer is composed of a composition containing a fluorinated copolymer (a) having at least one type of functional group selected from the group consisting of a carbonyl group-containing group, a hydroxy group, an epoxy group and an isocyanate group, having a melting point of from 280 to 320° C. and a melt flow rate of at least 2 g / 10 min measured at 372° C. under a load of 49 N. The heat treatment is carried out at a temperature of at least 250° C. and lower by at least 5° C. than the melting point of the fluorinated copolymer (a) so that the ratio of the melt flow rate of the fluorinated resin layer after the heat treatment to that before the heat treatment, and the melt flow rate of the fluorinated resin layer after the heat treatment, are respectively within specific ranges.

Owner:ASAHI GLASS CO LTD

Cationic polymerizable adhesive composition and anisotropically electroconductive adhesive composition

InactiveCN1312246CPrinted circuit assemblingUnsaturated ether polymer adhesivesVinyl etherCationic polymerization

In a cationic polymerizable adhesive composition comprising (A) a cationic polymerizable monomer selected from an epoxy monomer, a vinyl ether monomer, or a mixture thereof; (B) a cationic polymerization catalyst; and (C) a solvent for the cationic polymerization catalyst, a mixture of a good solvent and a poor solvent for the cationic polymerization catalyst is used as the solvent.

Owner:3M INNOVATIVE PROPERTIES CO

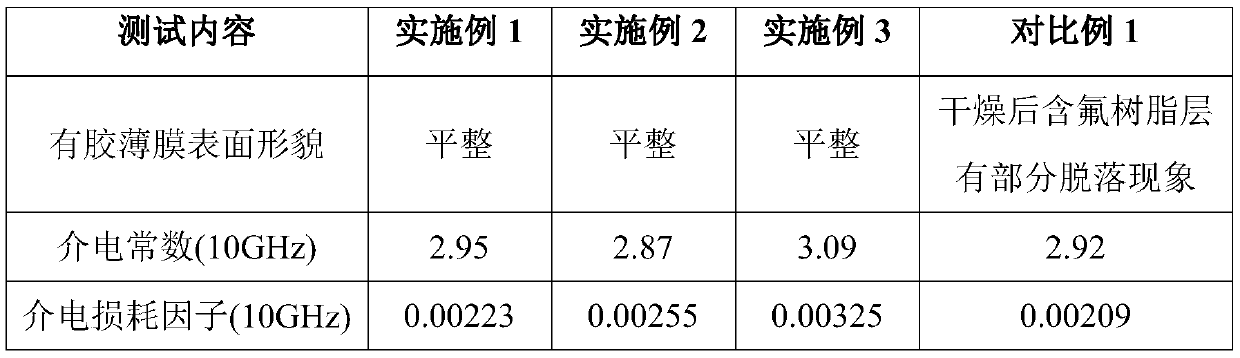

Fluorine-containing resin mixture and copper-clad plate prepared from same

ActiveCN111154433AGood adhesionFlat surfaceNon-macromolecular adhesive additivesUnsaturated ether polymer adhesivesPolymer scienceFilm base

The invention discloses a fluorine-containing resin mixture. The fluorine-containing resin mixture at least comprises a fluorine-containing resin emulsion, a prepolymer of a thermoplastic polymer, andcyanate ester. The mixture can be well coated and attached to a film base material, good dimensional stability can be kept in the processing process, and the water absorption rate is low. Besides, the invention further discloses a copper-clad plate prepared from the fluorine-containing resin mixture, and the copper-clad plate has the characteristics of excellent dielectric property, relatively high peel strength, good dimensional stability and the like, and can meet various comprehensive performance requirements on a substrate material in the field of 5G high-frequency communication.

Owner:ALLSTAE TECH ZHONGSHAN

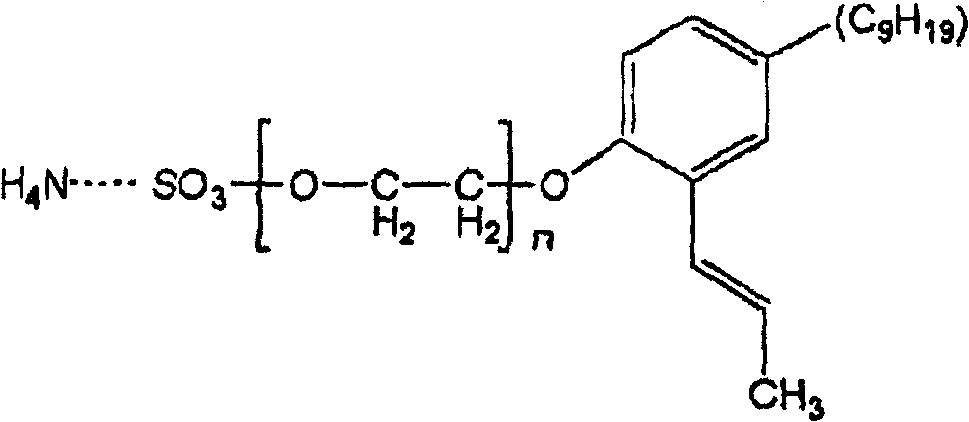

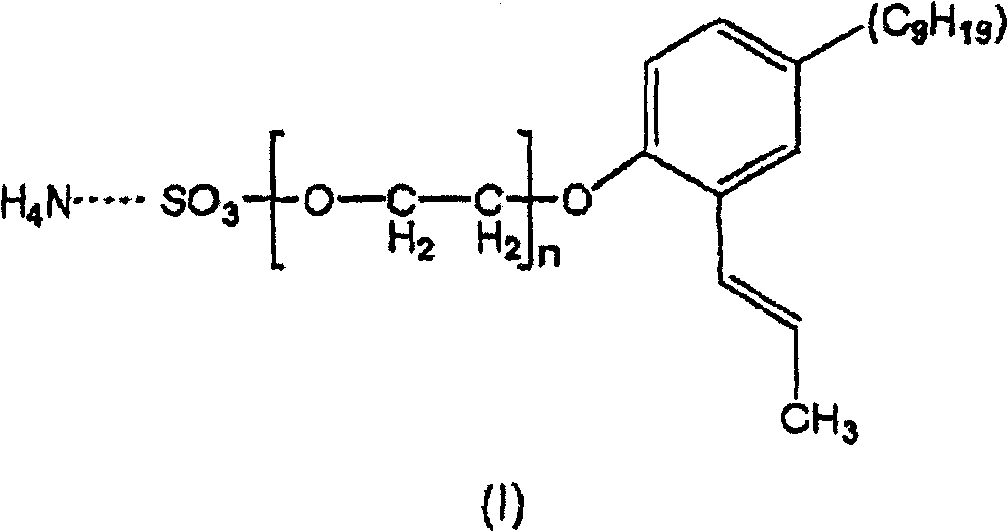

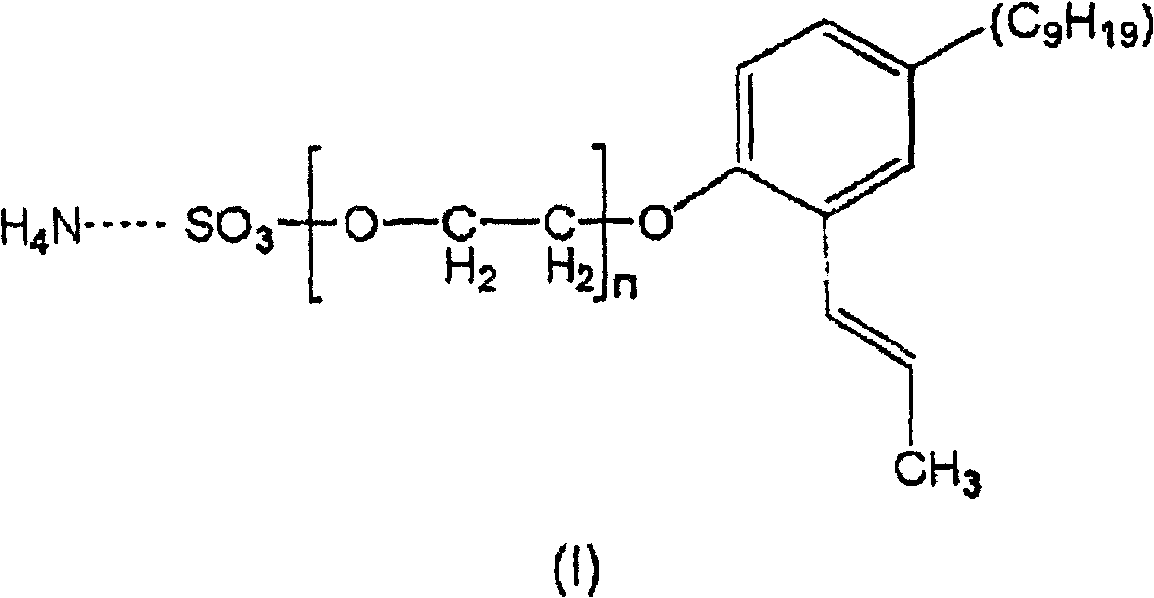

Water-whitening resistant latex emulsion pressure sensitive adhesive and its production

InactiveCN100422280CUnsaturated ether polymer adhesivesEster polymer adhesivesPolymer sciencePolymer chemistry

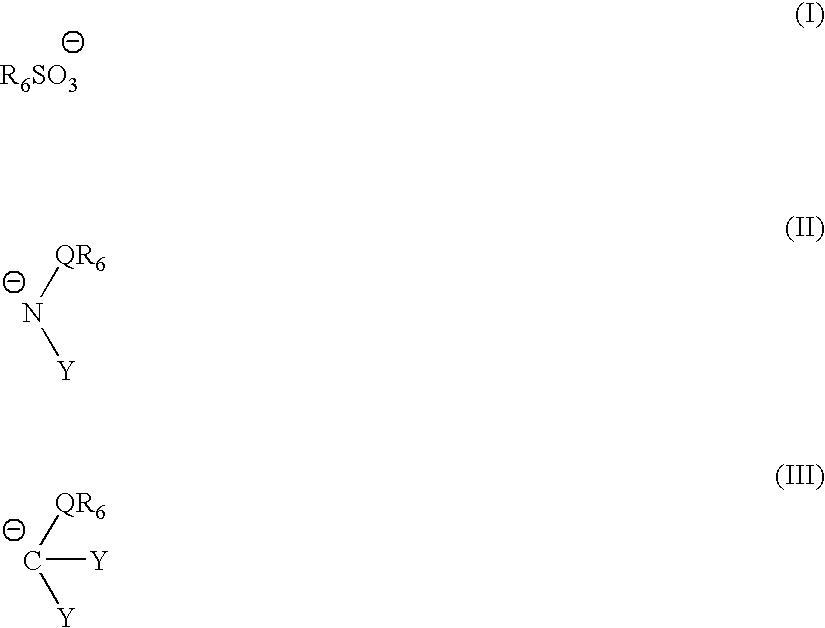

An aqueous, blush-retardant pressure sensitive adhesive (PSA) is made from an aqueous latex emulsion having an average particle size diameter of not substantially above about 100 nm and emulsified in the presence of an emulsifier consisting essentially of: Formula (I) wherein n is an integer ranging from 1-200.

Owner:ASHLAND LICENSING & INTPROP LLC

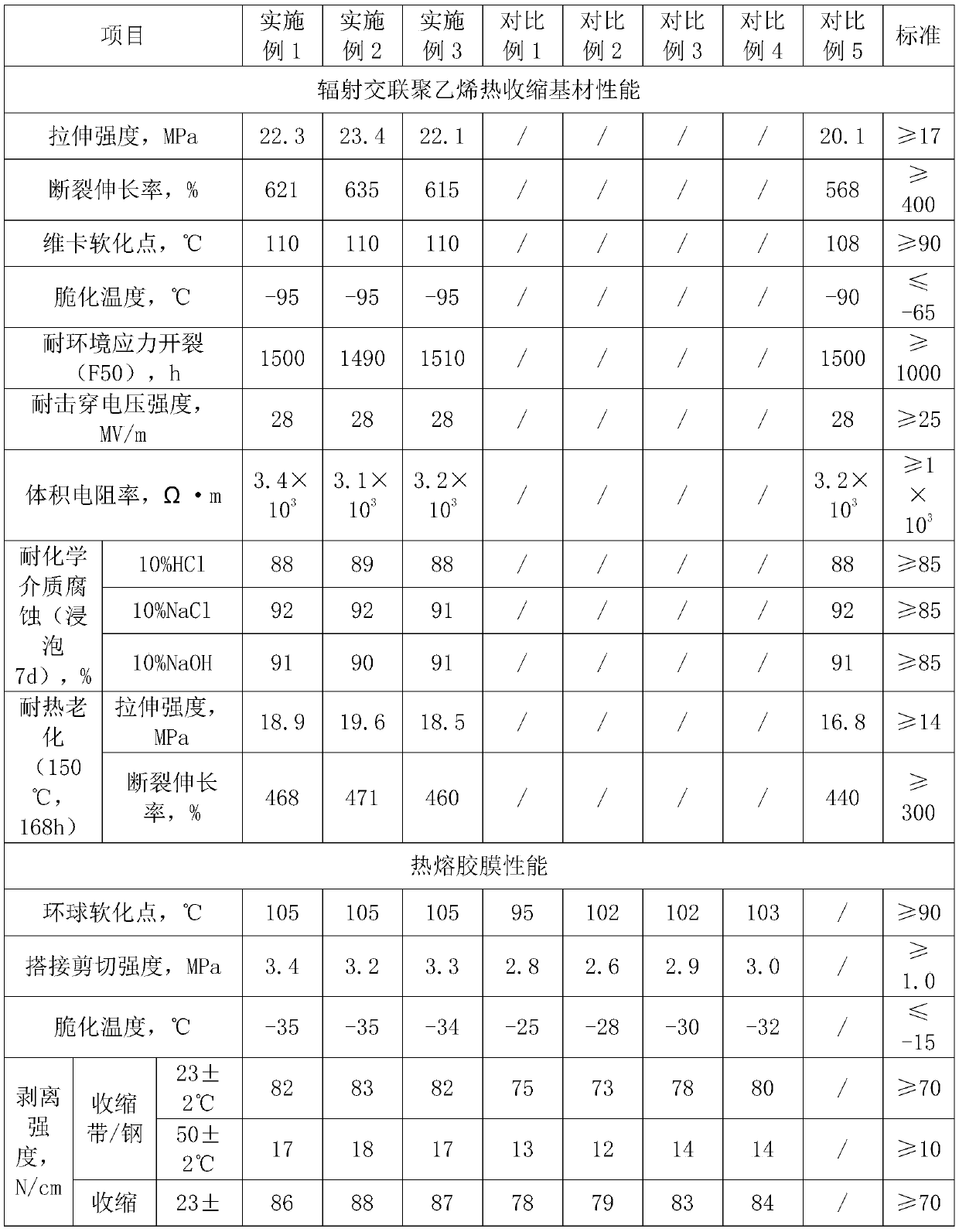

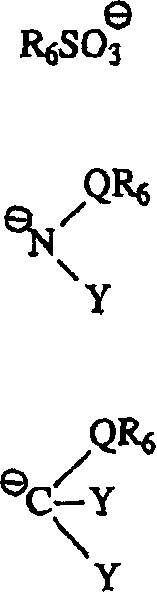

Radiation cross-linked polyethylene heat shrinkable wrap and preparation method thereof

ActiveCN110922900AImprove cold resistanceExcellent low temperature bond strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesVinyl etherPolymer science

The invention discloses a radiation cross-linked polyethylene heat shrinkable wrap and a preparation method thereof, and the key points of the technical scheme are as follows: the radiation cross-linked polyethylene heat shrinkable wrap comprises a radiation cross-linked polyethylene heat shrinkable substrate and a hot melt adhesive film; the hot melt adhesive film is prepared from the following components: an ethylene-ethyl acrylate copolymer, a styrene-isoprene-styrene block copolymer, a polymethyl vinyl ether / maleic anhydride copolymer, a tackifying resin, 6 to 10 parts of a modified argil,a cold-resistant plasticizer, an antioxidant, a lubricant and a silane coupling agent; wherein the modified argil is prepared by acidifying and modifying argil. According to the radiation cross-linked polyethylene heat shrinkable wrap, the ethylene-ethyl acrylate copolymer, the styrene-isoprene-styrene block copolymer and the polymethyl vinyl ether / maleic anhydride copolymer are used as main rawmaterials, and the tackifying resin, the modified argil and the cold-resistant plasticizer are matched, so that the cold resistance of the hot melt adhesive can be improved, and the hot melt adhesivehas excellent low-temperature bonding strength.

Owner:成都环宇热缩材料有限公司

Aluminum silicate ceramic fiber structural adhesive film

ActiveCN109207076AGood flexibilityImprove toughnessUnsaturated ether polymer adhesivesFilm/foil adhesivesFiberAdhesive

The invention discloses an aluminum silicate ceramic fiber structural adhesive film; aluminum silicate ceramic fibers are immersed into a macromolecular adhesive solution, and the structural adhesivefilm is obtained through traction, drying, solvent recovery, cutting and crimping processes; the aluminum silicate ceramic fibers are aluminum silicate ceramic fiber paper, aluminum silicate ceramic fiber cloth or aluminum silicate ceramic fibrofelt with the thickness of 0.2 mm-1.5 mm. The aluminum silicate ceramic fiber structural adhesive film has good flexibility, no fragile cracking in any bending, no chromium layer, and no need of isolating paper or isolating film in folding or coiling of the adhesive film, can be curled and preserved, does not adhere at medium and low temperature, is cured at high temperature, has the advantages of convenient storage, good high temperature resistance, good toughness of the cured adhesive film, high peeling strength greater than 90 N / 2.5 cm, shear strength on 45# steel more than 45 MPa, and good aging resistance, and can be applied in the bonding manufacturing of structural components of high-end equipment such as aerospace, national defense and military industry.

Owner:SHANDONG NORTH MODERN CHEM IND +1

Optically clear and antistatic pressure sensitive adhesives

InactiveCN100351294CNatural rubber adhesivesNon-macromolecular adhesive additivesAntistatic agentPolymer chemistry

The present invention is directed to an antistatic pressure sensitive adhesive. The antistatic pressure sensitive adhesive comprises a pressure sensitive adhesive, and an antistatic agent comprising at least one organic salt. Certain embodiments of the antistatic pressure sensitive adhesive also have a luminous transmission of greater than about 89% according to ASTM D 1003-95. Additional embodiments of the antistatic pressure sensitive adhesive have a haze of less than about 5% according to ASTM D 1003-95, and in specific embodiments the haze is less than about 2% according to ASTM D 1003-95.

Owner:3M INNOVATIVE PROPERTIES CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com