Water self-adhesive film and manufacturing method of false eyelashes with water self-adhesive film

A manufacturing method and technology for false eyelashes, which are applied in the field of false eyelashes manufacturing, can solve problems such as being unable to be used in the field of beauty makeup, and achieve the effect of being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

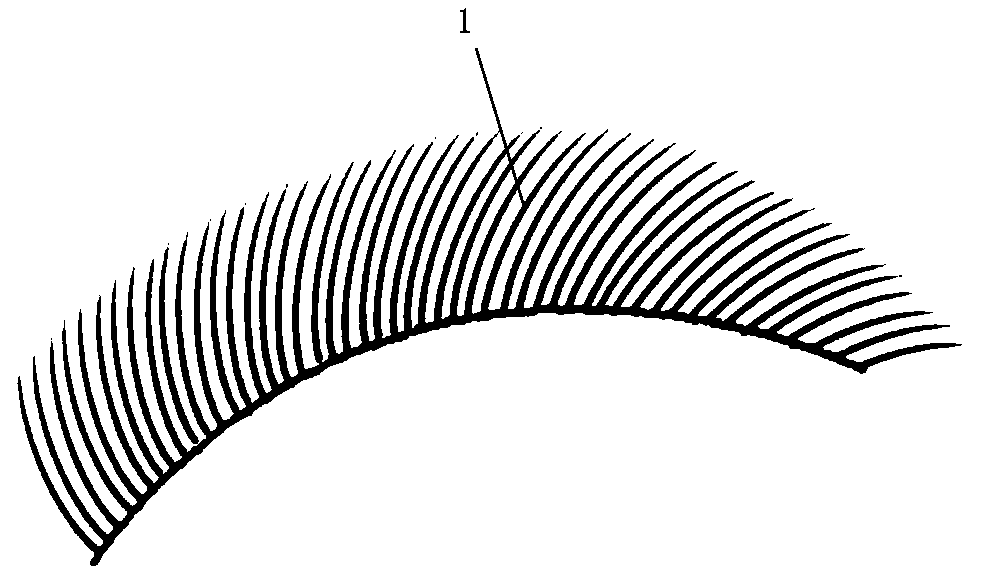

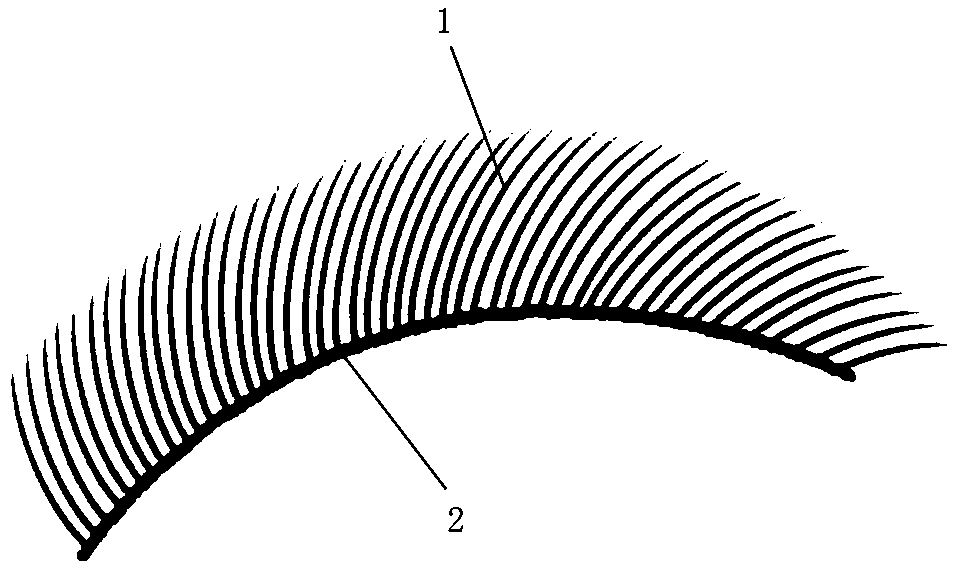

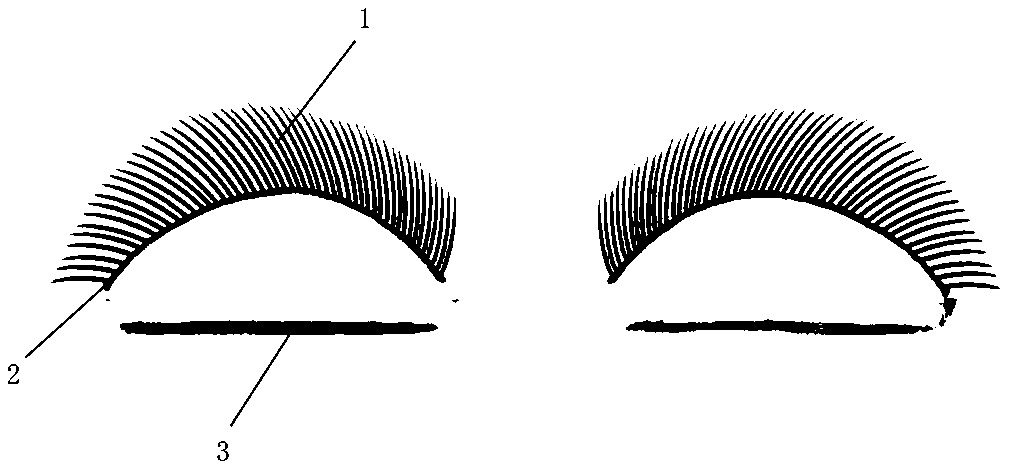

Image

Examples

Embodiment 1

[0043] A water self-adhesive film comprising the following percentages of components:

[0044] Gum Arabic (CAS No. 9000-01-5) 18%

[0045] Casein (CAS No. 9000-71-9) 12%

[0046] Polyvinyl alcohol (CAS No. 9002-89-5) 4.5%

[0047] Polyvinylpyrrolidone (CAS No. 9003-39-8) 5.5%

[0048] Polyvinyl ether (CAS No. 36812-63-2) 6%

[0049] Polyacrylate (CAS No. 25549-84-2) 4%

[0050] Water 50%.

[0051] A kind of manufacture method of the false eyelashes of band water self-adhesive film, comprises the following steps:

[0052] A. Apply the above-mentioned water self-adhesive adhesive film evenly on the eyeliner 2 part of the false eyelashes 1 with a silver needle, and then hang it upside down and dry it once, and the drying time is 3 hours;

[0053] B. The false eyelashes 1 obtained in step A is sterilized once, and the first sterilizing treatment is high-temperature steam sterilization, and the time is 20 minutes;

[0054] C. Apply the above-mentioned water self-adhesive fil...

Embodiment 2

[0060] A water self-adhesive film comprising the following percentages of components:

[0061] Gum Arabic 16%

[0062] Casein 10%

[0063] Polyvinyl alcohol 5%

[0064] Polyvinylpyrrolidone 6%

[0065] Polyvinyl ether 5%

[0066] Polyacrylate 6%

[0067] Water 52%.

[0068] A kind of manufacture method of the false eyelashes of band water self-adhesive film, comprises the following steps:

[0069] A. Apply the above-mentioned water self-adhesive film evenly on the eyeliner part of the false eyelashes with a silver needle, and then dry it once after inversion, and the drying time is 2 hours;

[0070] B. The false eyelashes gained in step A are sterilized once, and the first sterilizing treatment is high-temperature steam sterilization, and the time is 15 minutes;

[0071] C. Apply the above-mentioned water self-adhesive adhesive film to the eyeliner part of the false eyelashes obtained in step B with a silver needle, and perform secondary drying after inversion, and the ...

Embodiment 3

[0076] A water self-adhesive film comprising the following percentages of components:

[0077] Gum Arabic 20%

[0078] Casein 13%

[0079] Polyvinyl alcohol 4%

[0080] Polyvinylpyrrolidone 5%

[0081] Polyvinyl ether 6.6%

[0082] Polyacrylate 3%

[0083] Water 48.4%.

[0084] A kind of manufacture method of the false eyelashes of band water self-adhesive film, comprises the following steps:

[0085] A. Apply the above-mentioned water self-adhesive film evenly on the eyeliner part of the false eyelashes with a silver needle, and then dry it once after inversion, and the drying time is 4 hours;

[0086] B. The false eyelashes gained in step A are sterilized once, and the first sterilizing treatment is high-temperature steam sterilization, and the time is 30 minutes;

[0087] C. Apply the above-mentioned water self-adhesive adhesive film to the eyeliner part of the false eyelashes obtained in step B with a silver needle, and perform secondary drying after inversion, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com