Patents

Literature

253results about "N-vinyl-pyrrolidone polymer adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filtering rod for cigarette and preparing method

InactiveCN101023811AGood filterabilityImprove mechanical propertiesTobacco smoke filtersN-vinyl-pyrrolidone polymer adhesivesPolyesterChemistry

The present invention relates to a polylactic acid filter rod for cigarette. It is made up by using polylactic acid tow for cigarette through the processes of opening, adhesive bonding, bundling, cutting and after-treatment, its filament linear density is 2-8 dtex, its tow linear density is 3-6 ktex and its crimp ratio is 15-30 / 25 mm. The contacted parts of adjacent fibers are mutually bound and all fibers in the rod are cohesive together to form communicated 3-D network structure.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

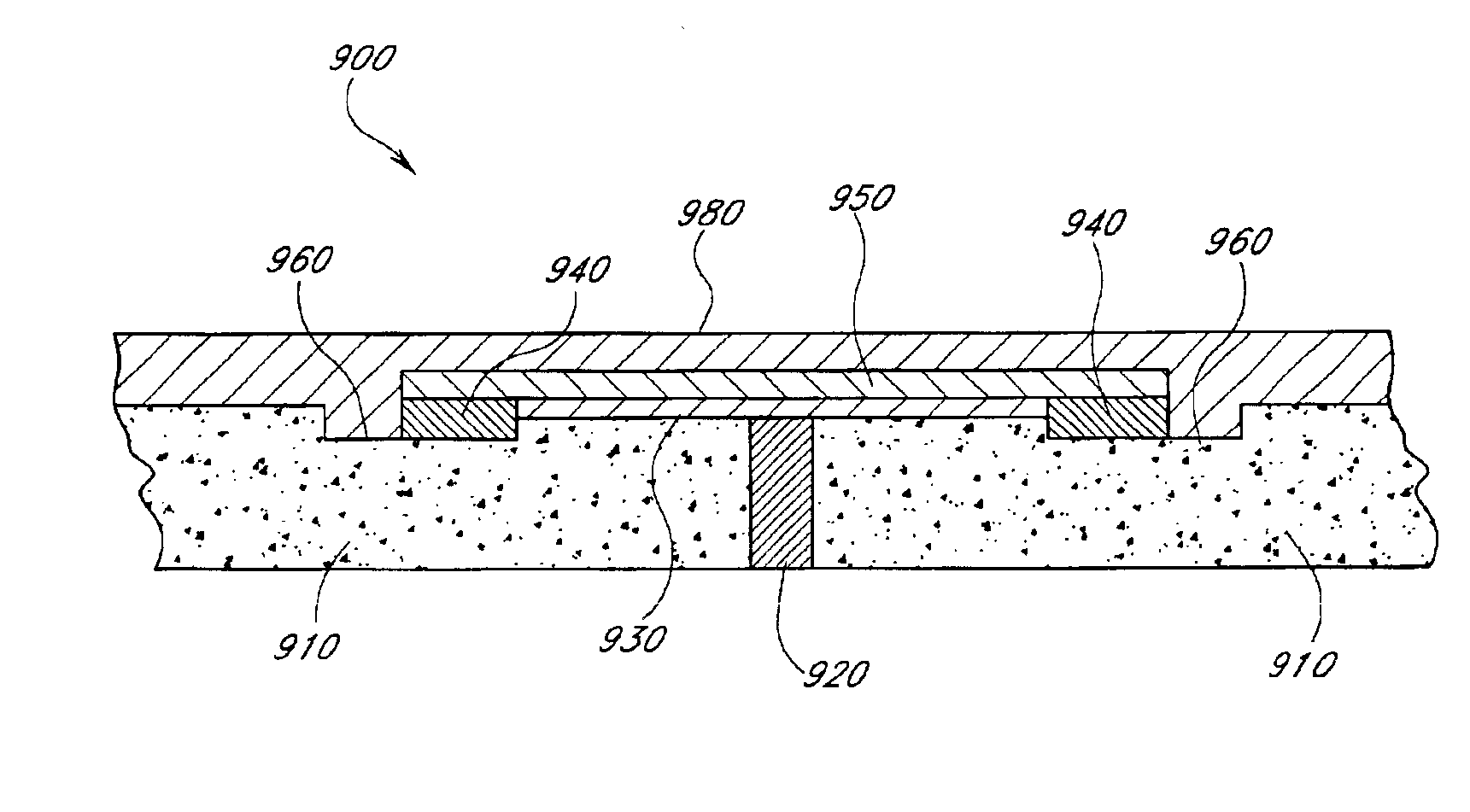

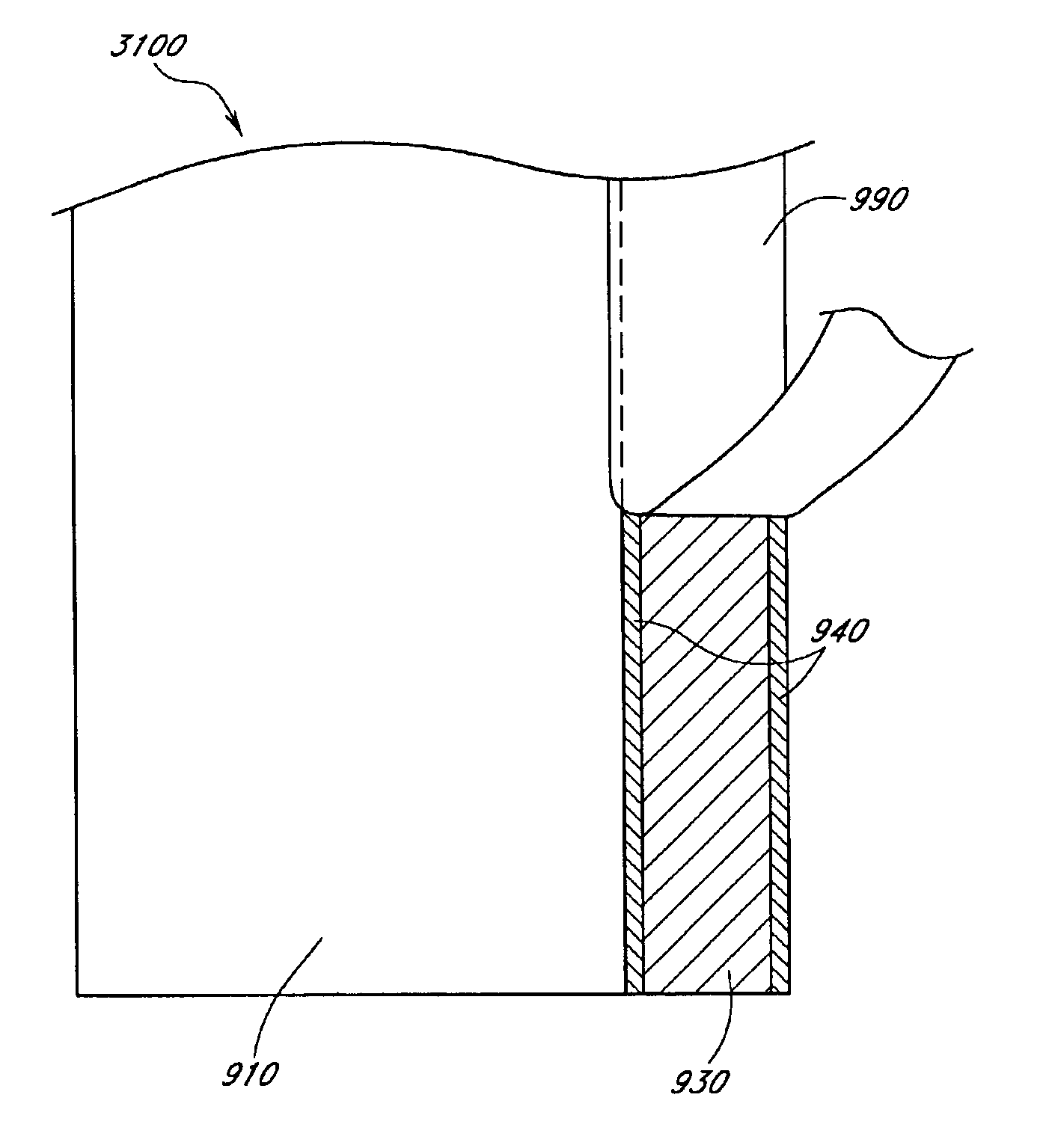

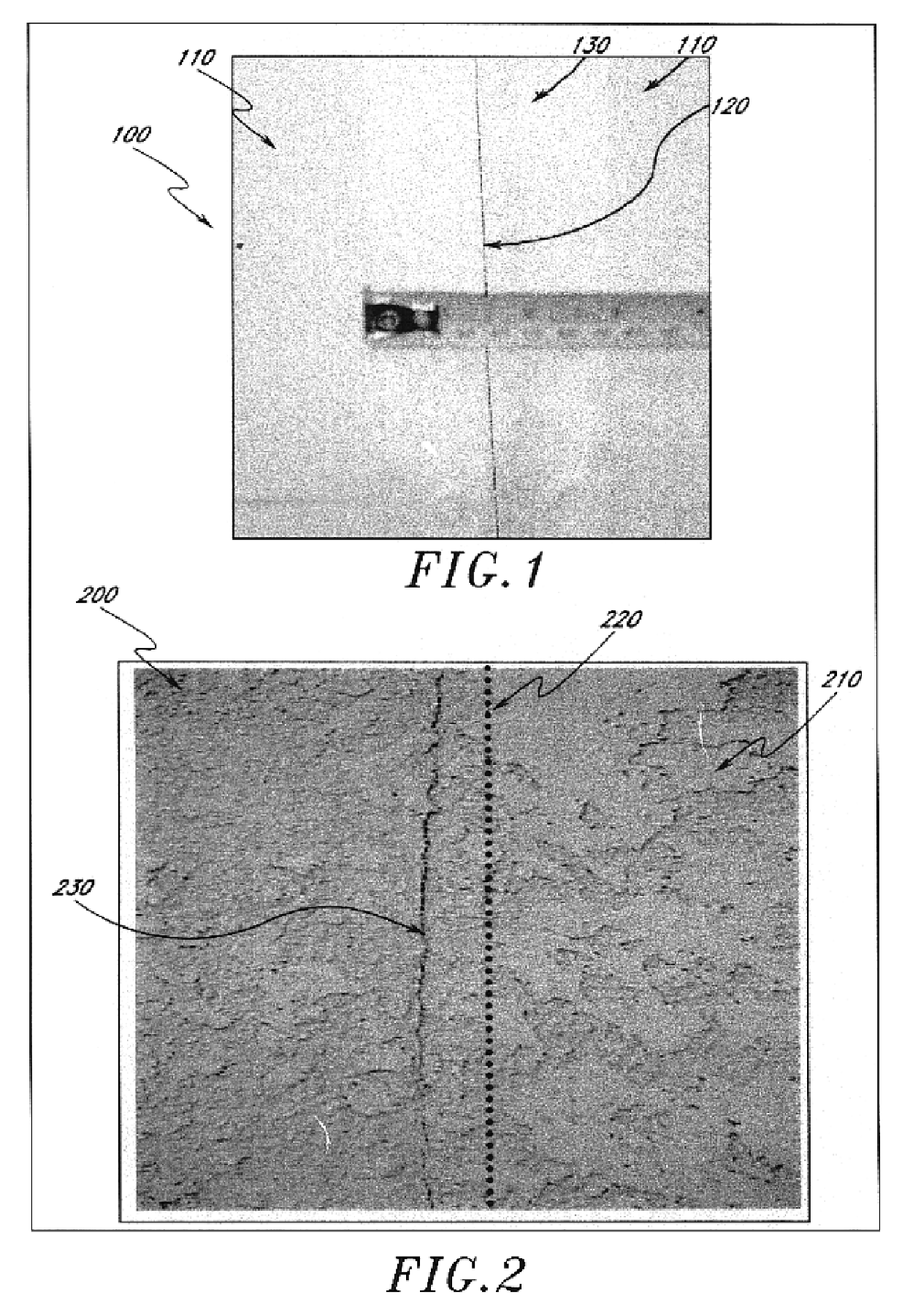

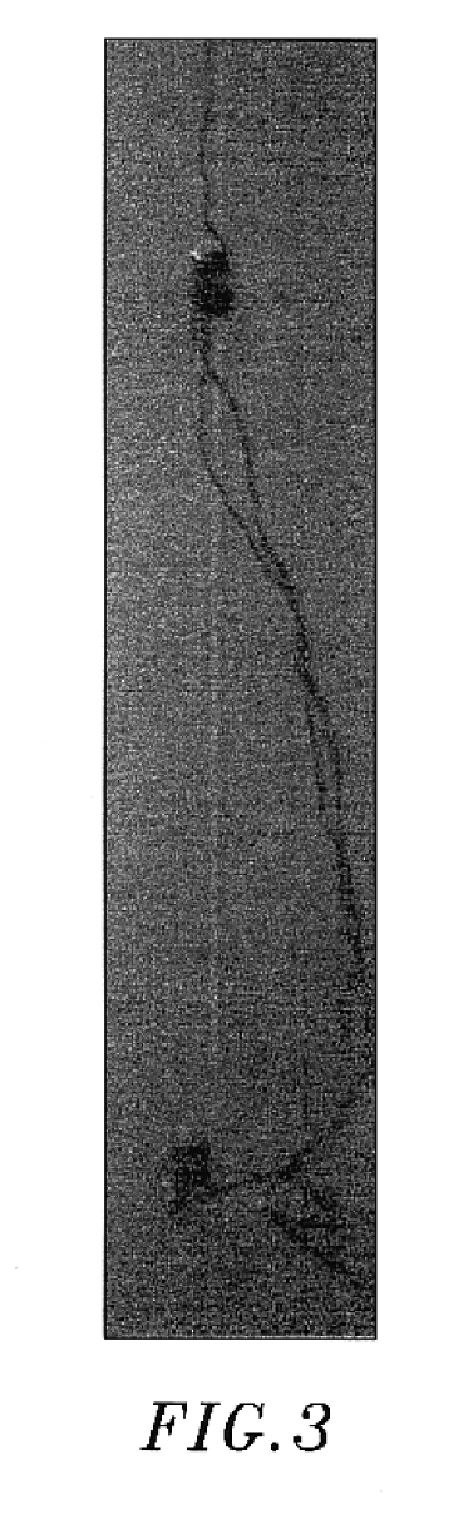

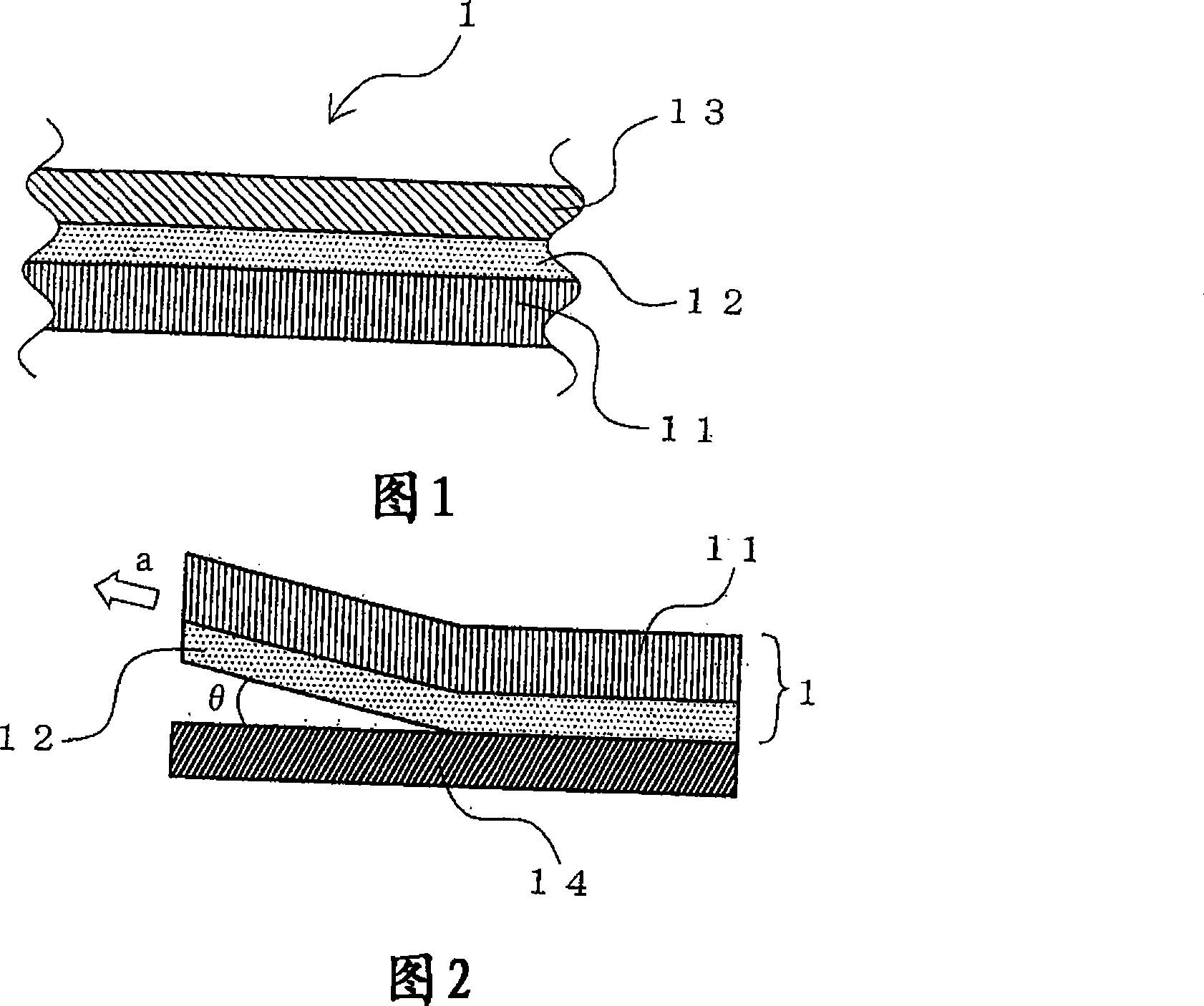

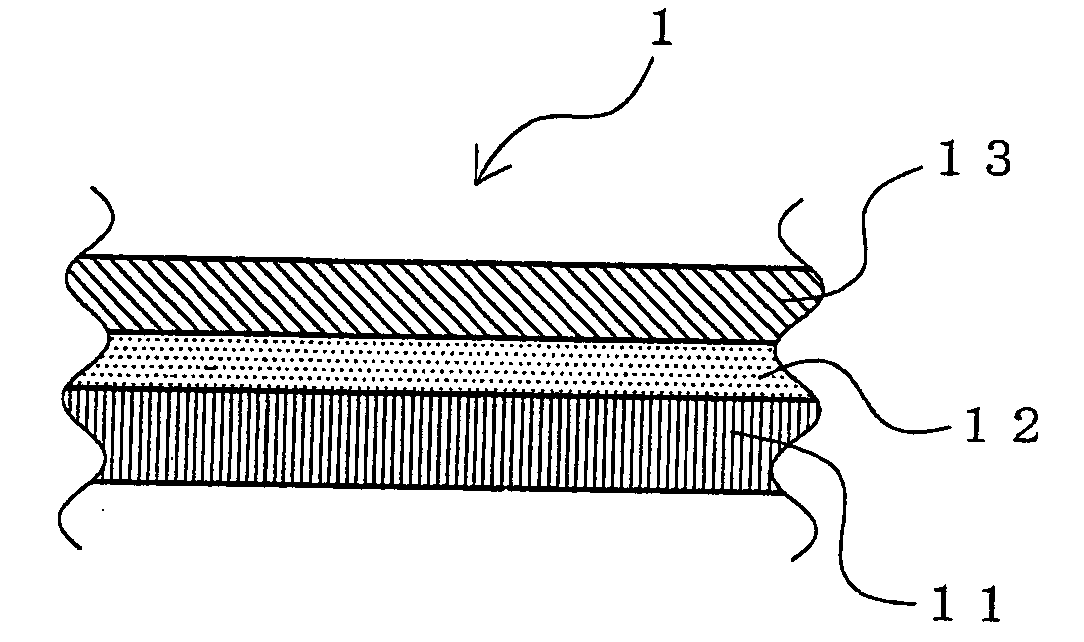

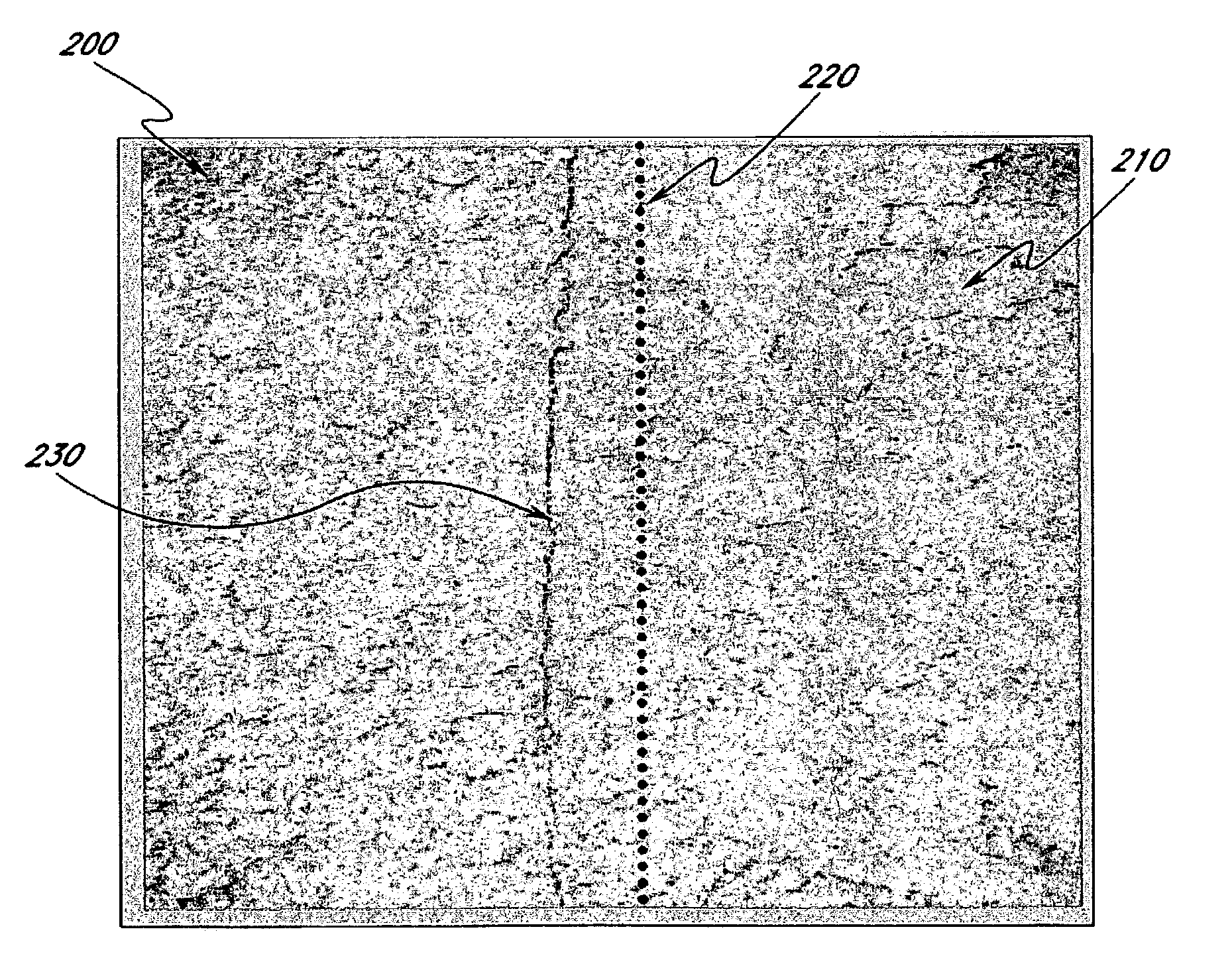

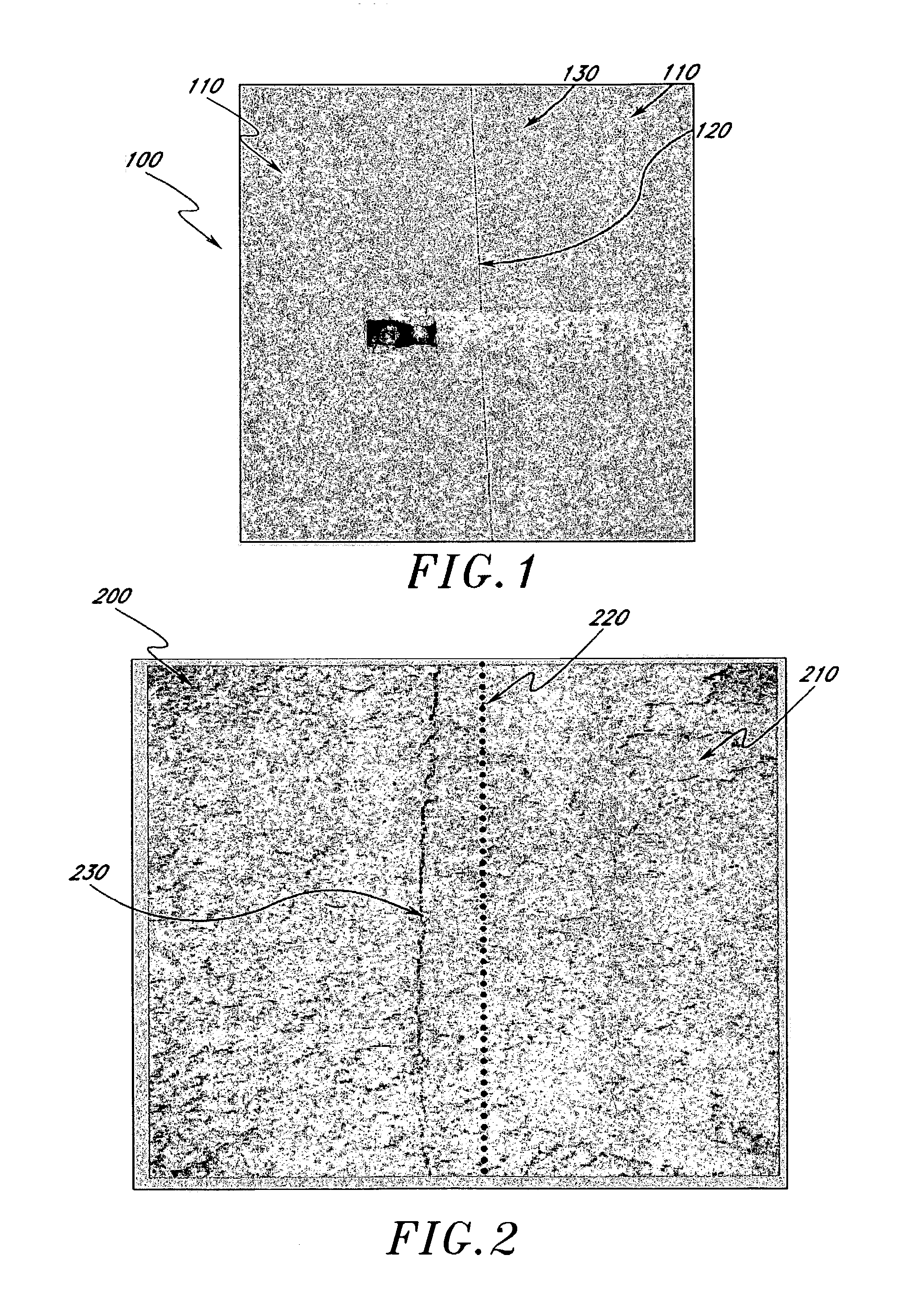

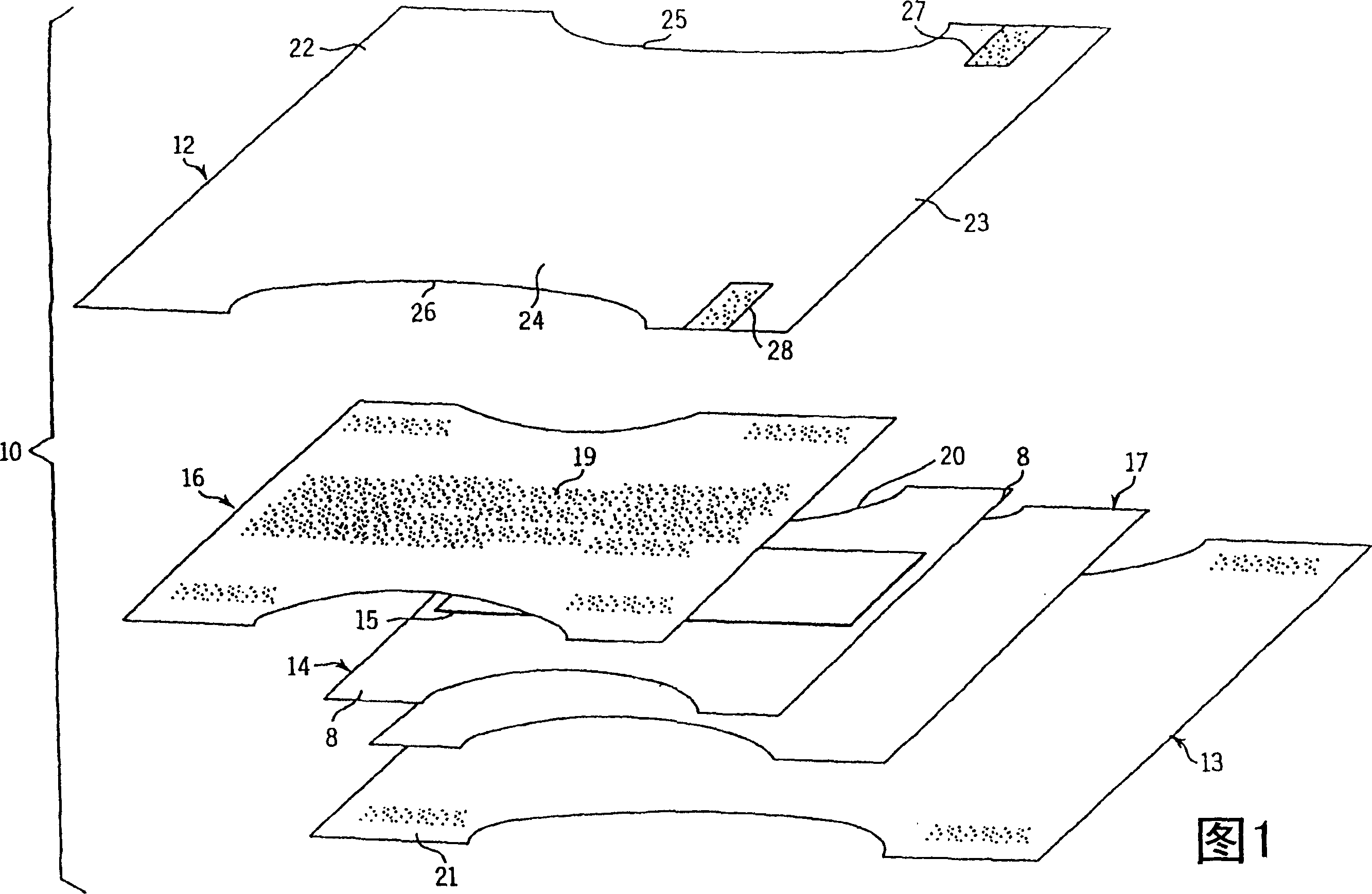

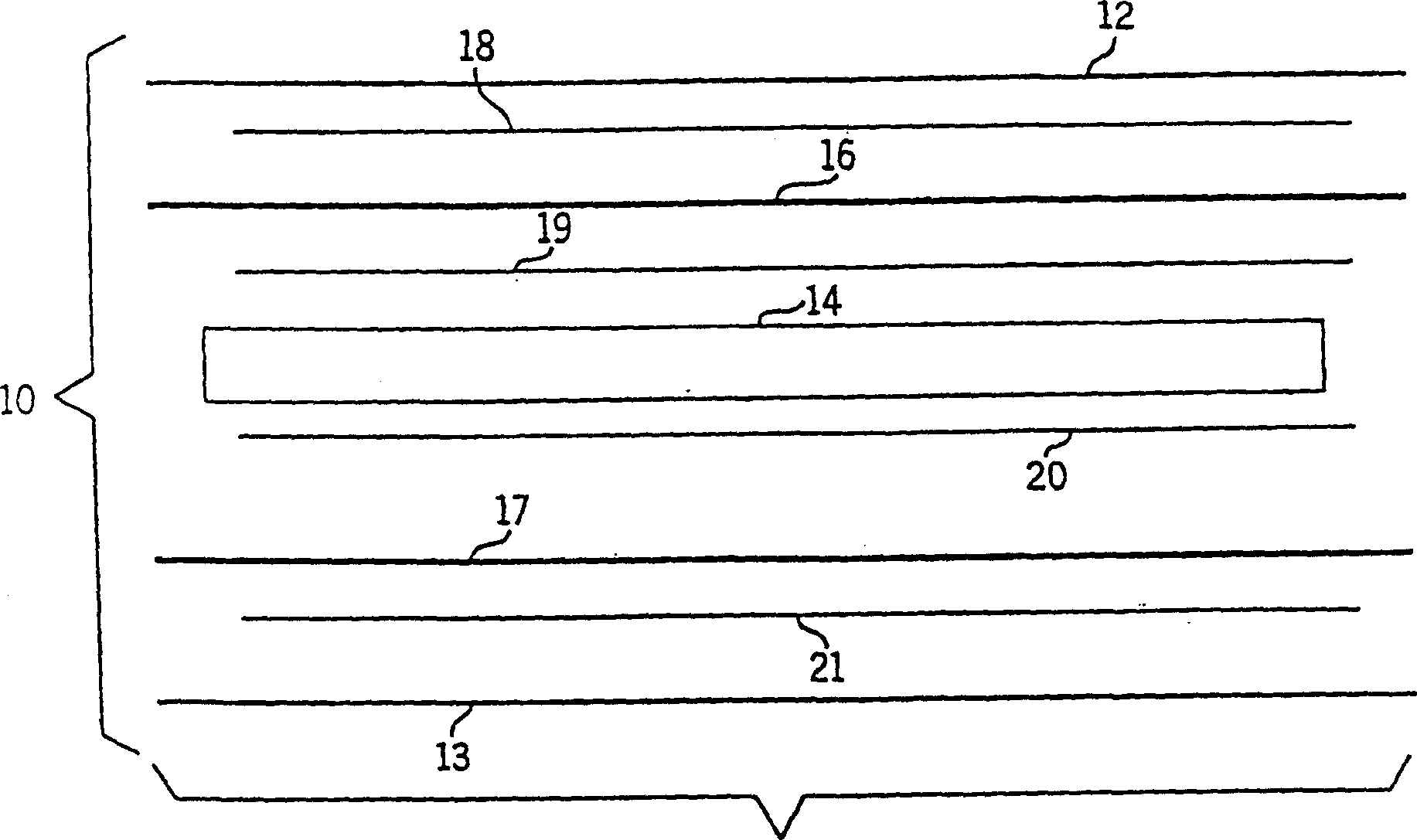

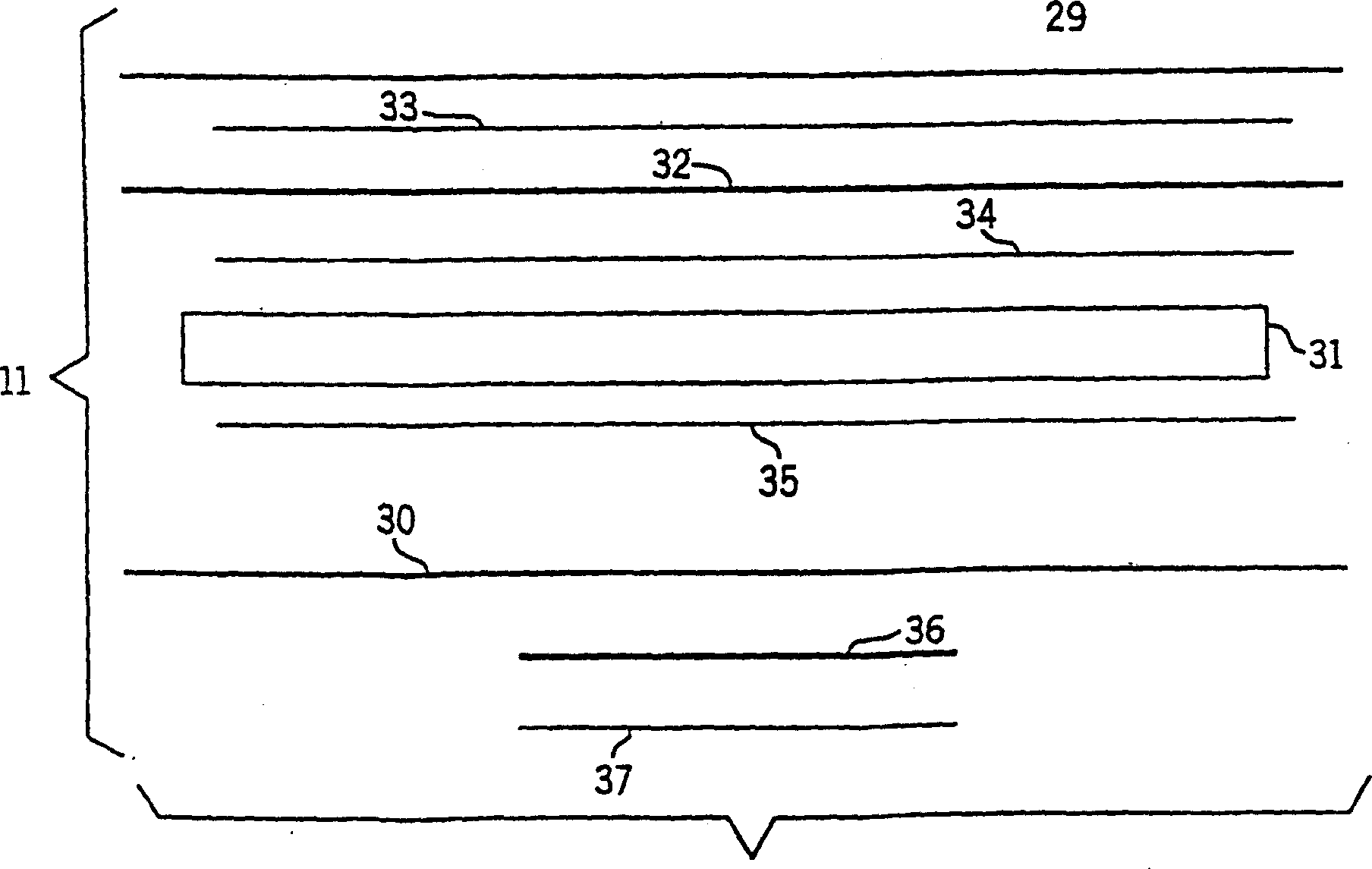

Panelized wall system utilizing trough-edge building panels

Disclosed herein are panelized wall systems and methods for their construction, wherein the wall systems have elastomeric joints that are resistant to cracking. The walls are constructed with trough-edge building panels. The trough-edge building panels are preferably fiber cement. The front surface of each panel has a trough adjacent to an edge of the panel. Panels are fastened to a frame with the trough-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape fall within the troughs of the adjacent panels. The wall is then finished with an elastomeric finish.

Owner:JAMES HARDIE TECH LTD

Panelized wall system utilizing adhesive-edge building panels

Disclosed herein are panelized wall systems and methods for their construction, wherein the wall systems have elastomeric joints that are resistant to cracking. The walls are constructed with adhesive-edge building panels. The adhesive-edge building panels are preferably fiber cement. The front surface of each panel has an adhesive preapplied to an edge of the panel. Panels are fastened to a frame with the adhesive-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape adhere to the adhesive-edges of the adjacent panels. The wall is then finished with an elastomeric finish.

Owner:JAMES HARDIE INT FINANCE BV

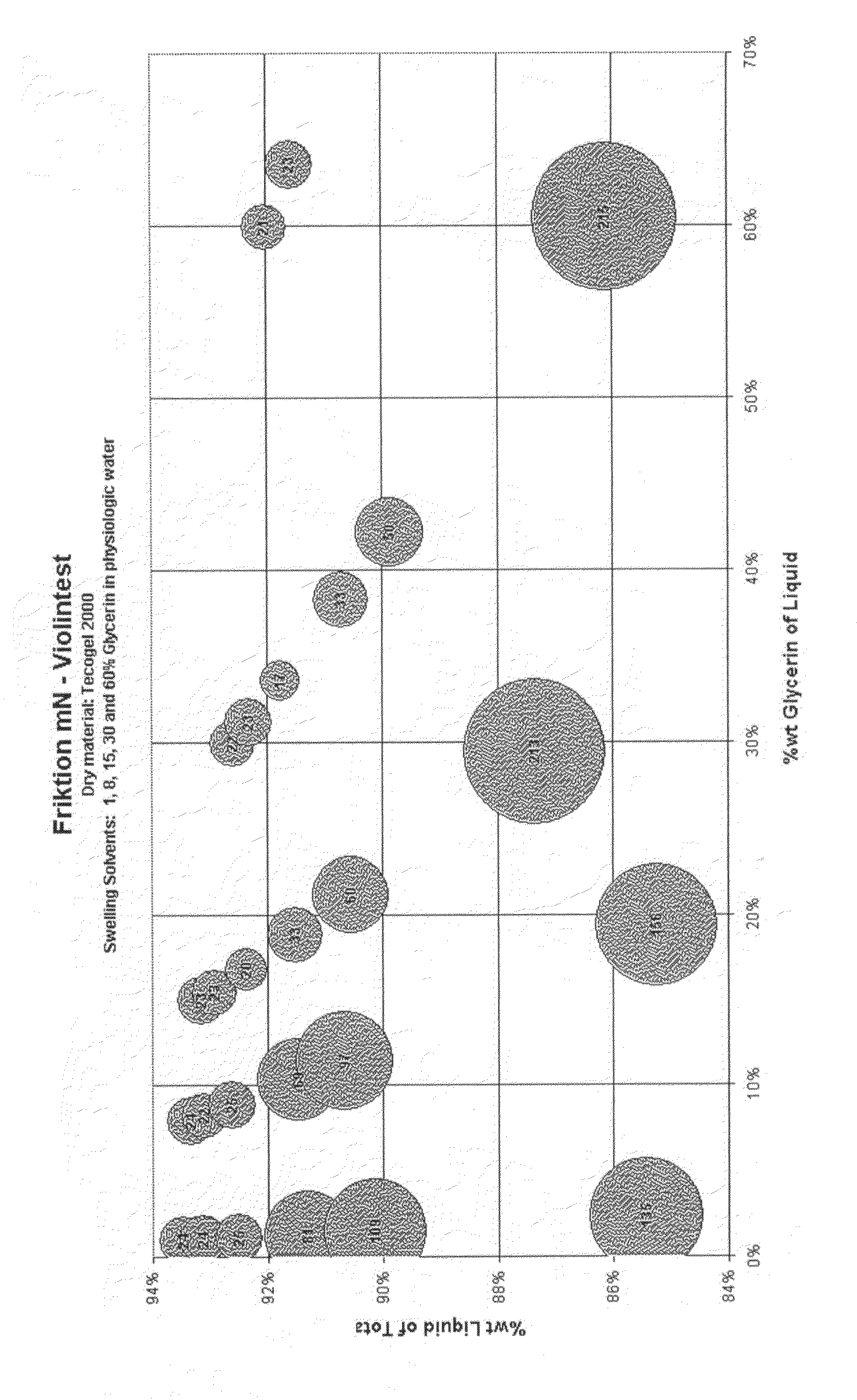

Medical Device Having a Wetted Hydrophilic Coating

InactiveUS20090012208A1Reduce frictionExtended maintenance periodSurgical adhesivesVinyl aromatic copolymer adhesivesHydrophilic coatingHydrophilic polymers

The present invention relates to a medical device having a wetted hydrophilic coating comprising:a coating composition containing a hydrophilic polymer anda wetting agent comprising water and one or more lubricant(s).

Owner:COLOPLAST AS

Acrylic Compositions Adhering to Low Surface Energy Substrates

ActiveUS20120171915A1Toxic reductionMaintain good propertiesFilm/foil adhesivesSynthetic resin layered productsSolubilityAlcohol

In general, the invention features a pressure sensitive adhesive that comprises the reaction product of:(a) from about 25 to about 95 parts by weight of at least one acrylic acid ester of a monohydric alcohol whose homopolymer has a Tg less than 0° C.,(b) from 0 to about 75 parts by weight of at least one non-polar ethylenically unsaturated monomer whose homopolymer has a solubility parameter of no greater than 10.50 and a Tg greater than 15° C.; and(c) from about 5 to about 35 parts by weight of at least one polar ethylenically unsaturated monomer whose homopolymer has a solubility parameter of greater than 10.50 and a Tg greater than 15° C.The pressure sensitive adhesives adhere to substrates having a low surface energy and / or high surface energy.

Owner:AVERY DENNISON CORP

Removable pressure-sensitive adhesive composition and pressure-sensitive adhesive tape or sheet

ActiveCN101195734AEasy to removeReduced bond strengthSolid-state devicesSemiconductor/solid-state device manufacturingAcrylic polymerPolymer

The present invention relates to a removable pressure-sensitive adhesive composition containing an acrylic polymer, a photopolymerization initiator and a crosslinking agent, in which the acrylic polymer and the photopolymerization initiator each are chemically bonded to the crosslinking agent. The present invention also relates to a removable pressure-sensitive adhesive composition containing an acrylic polymer and a photopolymerization initiator, the composition further containing a crosslinking agent having a reactive functional group which is capable of reacting with a reactive functional group of the acrylic polymer and a reactive functional group of the photopolymerization initiator.

Owner:NITTO DENKO CORP

Film forming polymeric sealant for medical use

ActiveUS20080195037A1Inhibition of colonizationReduction of tissue morbidityAntibacterial agentsPowder deliverySealantBiomedical engineering

The invention provides a polymeric film-forming medical sealant. The medical sealant is useful for application to the tonsils and adenoids, wherein the sealant performs at least one of the following functions, a) inhibit the colonization of bacteria, b) inhibit the binding of bacteria to tissue, c) reduction of tissue morbidity, d) hemostasis, e) coating and protection of tissue during healing. e) promotion of healing, and f) reduction of pain.

Owner:MEDTRONIC XOMED INC

Removable pressure-sensitive adhesive composition and pressure-sensitive adhesive tape or sheet

InactiveUS20080138618A1Inhibit migrationReduced adhesion strengthSolid-state devicesSemiconductor/solid-state device manufacturingAcrylic polymerPolymer

The present invention relates to a removable pressure-sensitive adhesive composition containing an acrylic polymer, a photopolymerization initiator and a crosslinking agent, in which the acrylic polymer and the photopolymerization initiator each are chemically bonded to the crosslinking agent. The present invention also relates to a removable pressure-sensitive adhesive composition containing an acrylic polymer and a photopolymerization initiator, the composition further containing a crosslinking agent having a reactive functional group which is capable of reacting with a reactive functional group of the acrylic polymer and a reactive functional group of the photopolymerization initiator.

Owner:NITTO DENKO CORP

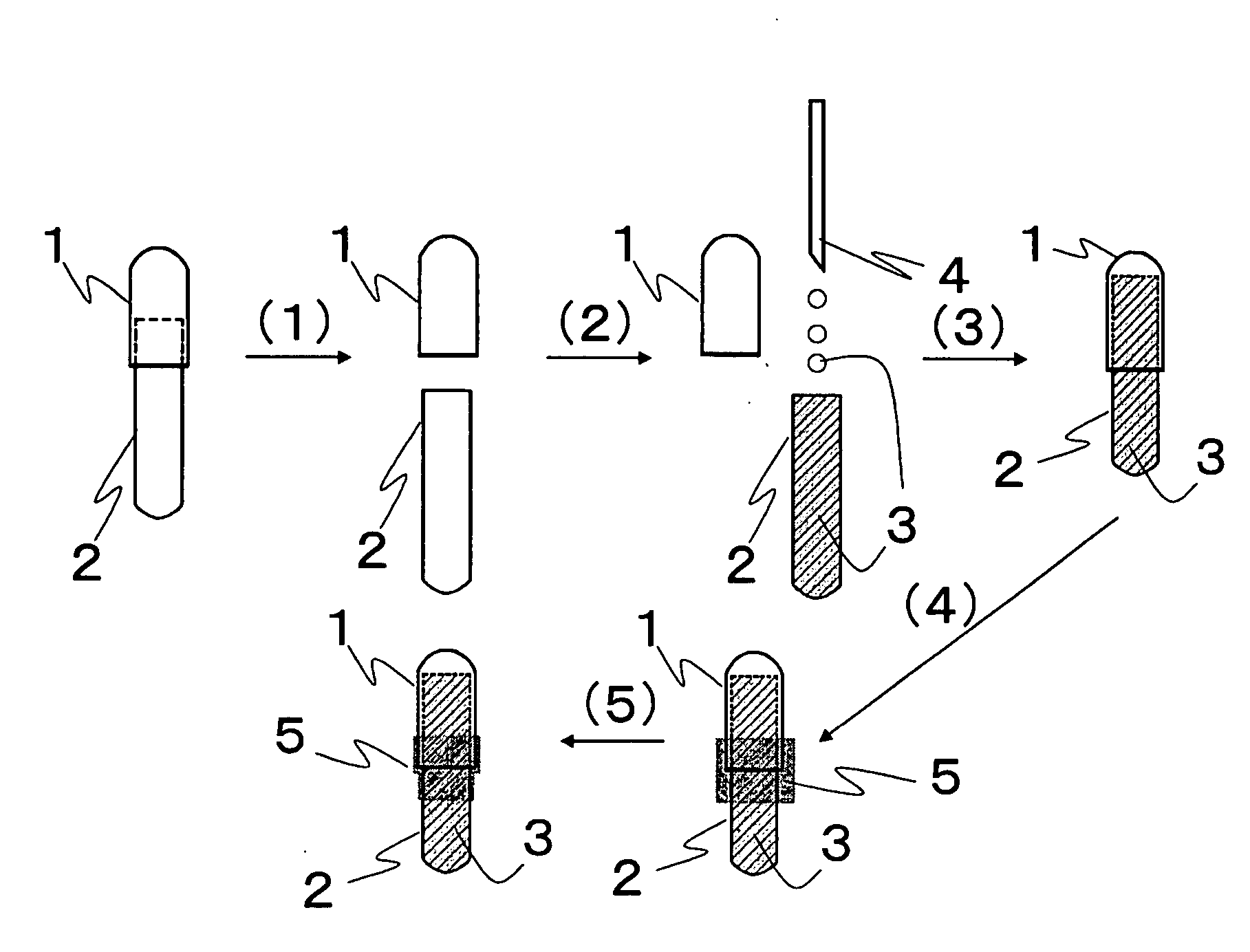

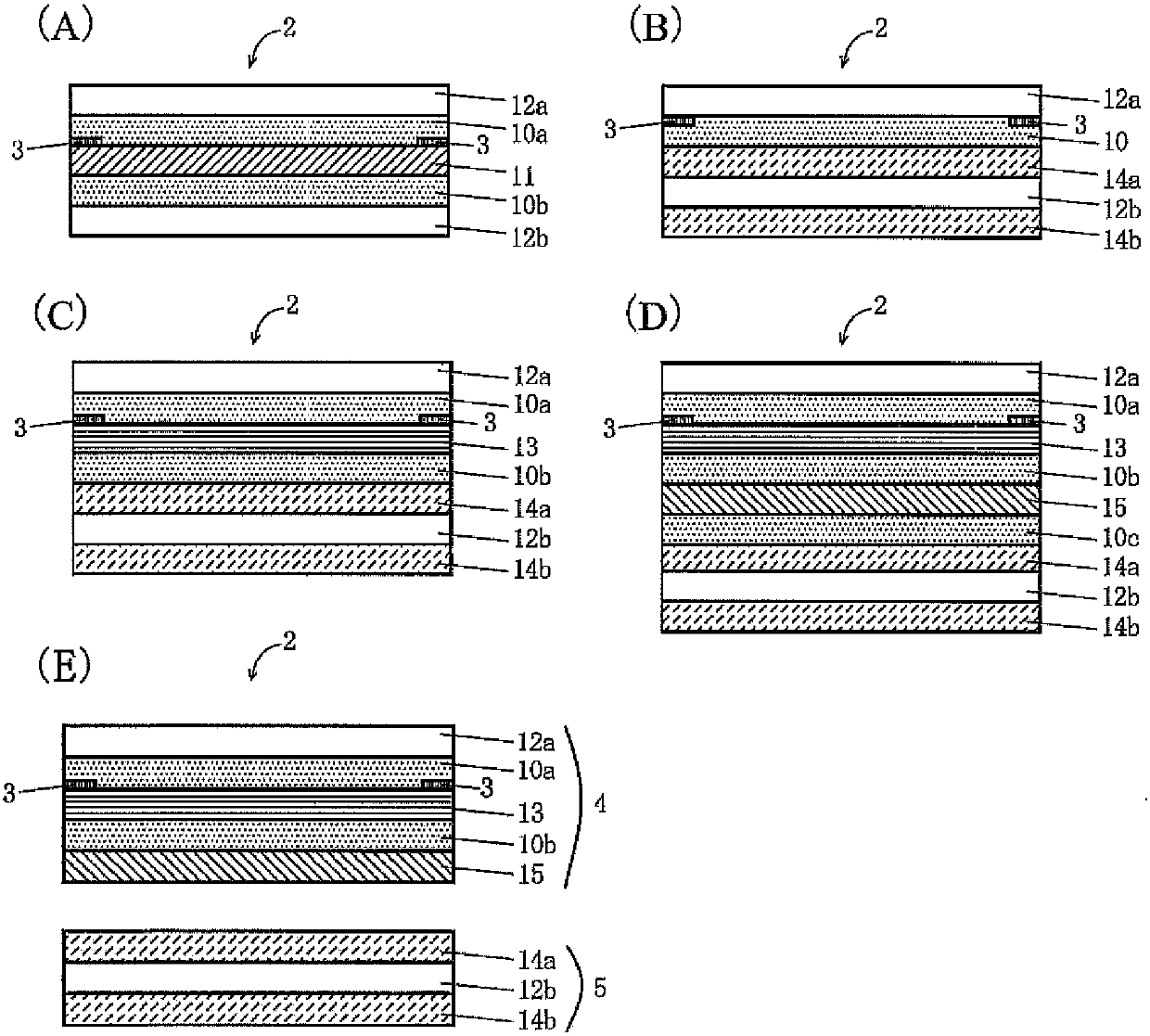

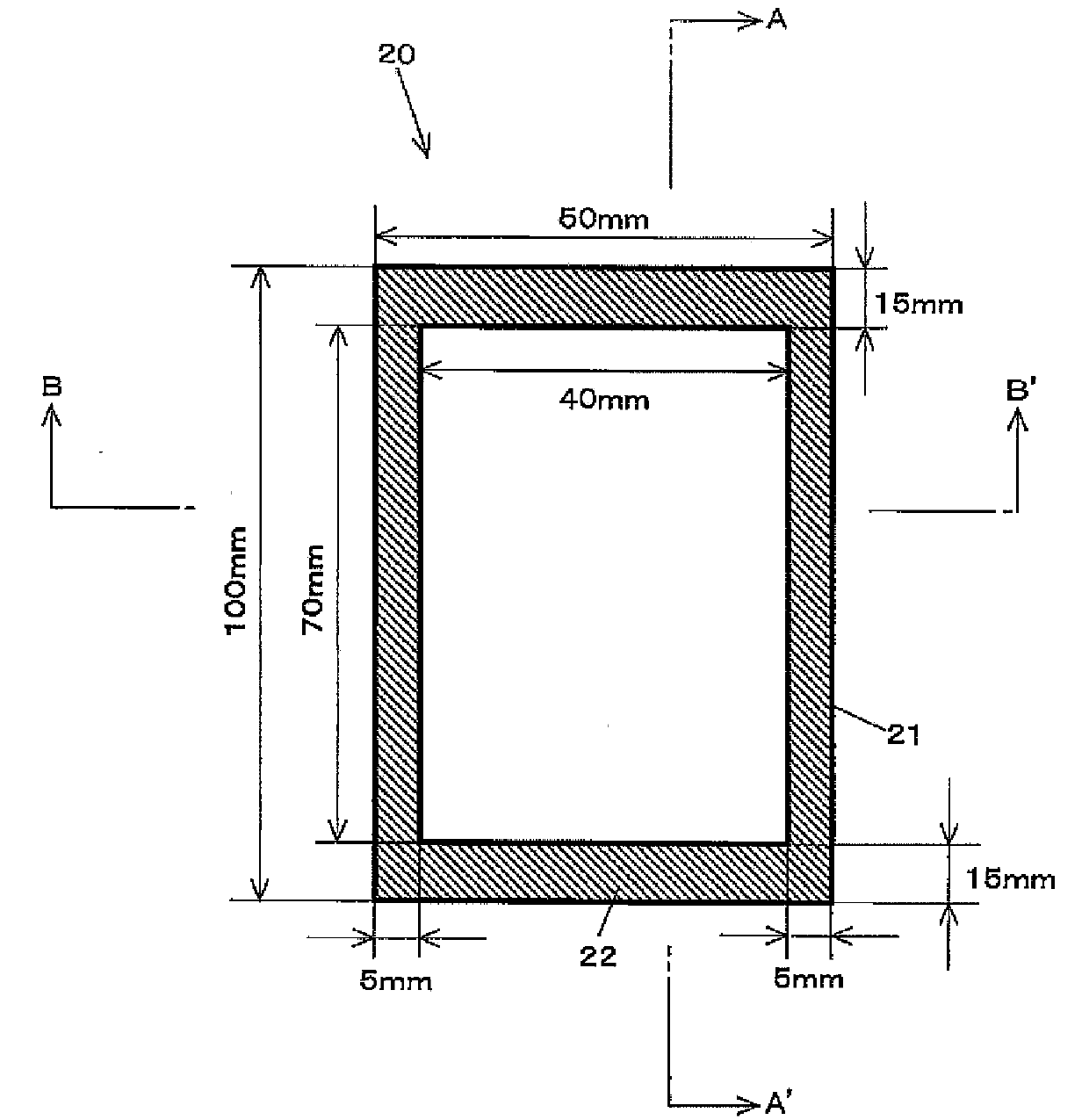

Band-Seals For Hard Capsules

InactiveUS20080008750A1Low production costShorten production timeN-vinyl-pyrrolidone polymer adhesivesCapsule deliveryPullulanMedicine

The present invention has as its object to provide a band-seal to manufacture a leak-tight, stable hard capsule preparation not being susceptible to deformation after having filled pharmaceuticals, foods, healthy foods, etc. in a hard capsule comprising a polyvinyl alcohol copolymer or pullulan as a base, and in more particular, relates to a band-seal intended for use in the hard capsule comprising a polyvinyl alcohol copolymer or pullulan as a base, characterized in that the band-seal is incorporated with at least one or not less than two of the below-described (a) to (c): (a) A polyvinylpyrrolidone with a molecular weight of 100,000 to 4,000,000, (b) A polyvinylpyrrolidone with a molecular weight of 10,000 to 80,000 in the proportion of not more than 90% by weight against the total weight of the band-seal; and (c) A copolymer from 1-vinyl-2-pyrrolidone and vinyl acetate.

Owner:QUALICAPS CO LTD

Pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, pressure-sensitive adhesive sheet, optical component and touch panel

ActiveCN103992753AHigh transparencyImprove corrosion resistanceNon-macromolecular adhesive additivesLayered productsAcid groupTouch panel

Provided are an optical component having an excellent corrosion inhibition effect while maintaining a high level of adhesion reliability and transparency, as well as a pressure-sensitive adhesive composition and a pressure-sensitive adhesive sheet that can produce such an optical component efficiently and at a low cost. The pressure-sensitive adhesive composition according to the present invention includes a rust inhibitor and a base polymer, characterized in that the base polymer does not or substantially does not contain an acid group-containing monomer as a constituent monomer component. Further provided is a pressure-sensitive adhesive sheet having a pressure-sensitive adhesive layer formed from such pressure-sensitive adhesive composition.

Owner:NITTO DENKO CORP

Blue solid glue stick with color being changed after application and preparation method thereof

InactiveCN102134460AGood adhesionExtended shelf lifeMonocarboxylic acid ester polymer adhesivesStarch adhesivesAdhesiveColloid

The invention discloses a blue solid glue stick with the color being changed after application and a preparation method thereof. The blue solid glue stick comprises adhesives, humectant, excipient and visualization reagents and is characterized in that a body of the solid glue stick is blue; when in use, a coating is initially blue and then faded quickly to be colourless; and raw materials comprise the following components in percentage by weight: 4 percent to 50 percent of adhesives, 1 percent to 20 percent of humectant, 2 percent to 20 percent of excipient, 0.01 percent to 5 percent of visualization reagents, 0.1 percent to 3 percent of sodium hydroxide and 20 percent to 75 percent of water, and the total content of the components is 100 percent. When coated on paper, the blue solid glue stick is initially blue and then faded in a short time to be colourless; and the blue solid glue stick has the advantages of high adhesive force, long shelf life and stable glue color after long-term storage.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Allochroic solid adhesive and preparation method thereof

InactiveCN101608103ASimple recipeEasy to produceEster polymer adhesivesN-vinyl-pyrrolidone polymer adhesivesTO-18Phenolphthalein

The invention discloses a high-stability allochroic solid adhesive and a preparation method thereof. The allochroic solid adhesive is prepared by the method according to the following steps: adding all the following raw materials in portion by weight into a reaction kettle of which the temperature is between 50 and 100 DEG C: 50 to 75 portions of dispersant water, 10 to 45 portions of bonding agent such as polyvinyl pyrrolidone, 5 to 18 portions of excipient such as sodium stearate, 5 to 15 portions of humectant such as glycerol, 0.1 to 1 portion of developer phenolphthalein, and proper amount of color stabilizer; stirring the raw materials at a temperature of between 80 and 100 DEG C for one hour, and then adjusting the pH to between 9 and 11; and then standing the mixture at a constant temperature, and bottling the mixture to obtain a purple solid adhesive. The allochroic solid adhesive has a reasonable and simple formulation, easy manufacture and production and low cost; the colloid is purple when the allochroic solid adhesive is coated on a substrate material, and the purple disappears in a short time to meet the requirements in specific fields; besides, the allochroic solid adhesive has the most prominent characteristic that the color is stable during storage and is basically unchanged for more than two years.

Owner:NINGBO SONGHE STATIONERY

Novel amyloid cigarette adhesive containing synthetic polymer

ActiveCN103773269AMeet normal production needsIncrease stickinessNon-macromolecular adhesive additivesStarch adhesivesPolymer scienceSucrose

The invention relates to a novel amyloid cigarette adhesive containing s synthetic polymer. The amyloid cigarette adhesive comprises, by weight, 35%-85% of water, 5%-50% of pyrolyzed dextrin, 5%-50% of sucrose, 0.1%-20% of the synthetic polymer, 0.05%-1% of a preservative, 0.05%-1% of a defoaming agent and 0-5% of auxiliary agents. The cigarette adhesive provided by the invention has good viscosity, fluidity and stability, can be stably stored for more than three months at a room temperature, can be used as any adhesive such as lap adhesive, tipping adhesive, filter rod central line adhesive, packaging adhesive and aluminum foil laminated adhesive in cigarette production, and is applicable to any cigarette machine, particularly a cigarette machine with a single-gun speed higher than 7,000 cigarettes / minute and a highly speed cigarette machine with a speed higher than 10,000 cigarettes / minute. The cigarette adhesive provided by the invention can be also applied in situations such as paper bindings, bottle labels and packing boxes which relate to paper bonding.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Environmental protection type transparent solid glue and preparation method thereof

ActiveCN102321443AColor transparentHigh hardnessNon-macromolecular adhesive additivesN-vinyl-pyrrolidone polymer adhesivesSodium stearatePreservative

The present invention discloses environmental protection type transparent solid glue. The glue comprises the following components, by weight, 40-50 parts of deionized water, 6-10 parts of an activator, 0.5-2 parts of an antifoaming agent, 15-20 parts of a lubricant, 20-30 parts of a moisturizing agent, 6-10 parts of sodium stearate, 20-30 parts of polyvinylpyrrolidone and 0.2-1 parts of a preservative. In addition, the present invention further provides a preparation method for the environmental protection type transparent solid glue. Compared to the prior art, the environmental protection type transparent solid glue provided by the present invention has characteristics of transparent color, high hardness, good moisture retention, smooth coating without dreg dropping, good oxidation resistance, environmental protection and no toxicity.

Owner:JIANGSU XINGDA STATIONERY GRP

Adhesive additive

InactiveUS20130005867A1Increase stickinessReduce processPaper coatingOrganic dyesCellulosePolymer science

A lignocellulosic-based composite composition comprising an adhesive and a water soluble polymer that increases the tack of the composition.

Owner:SOLENIS TECH CAYMAN

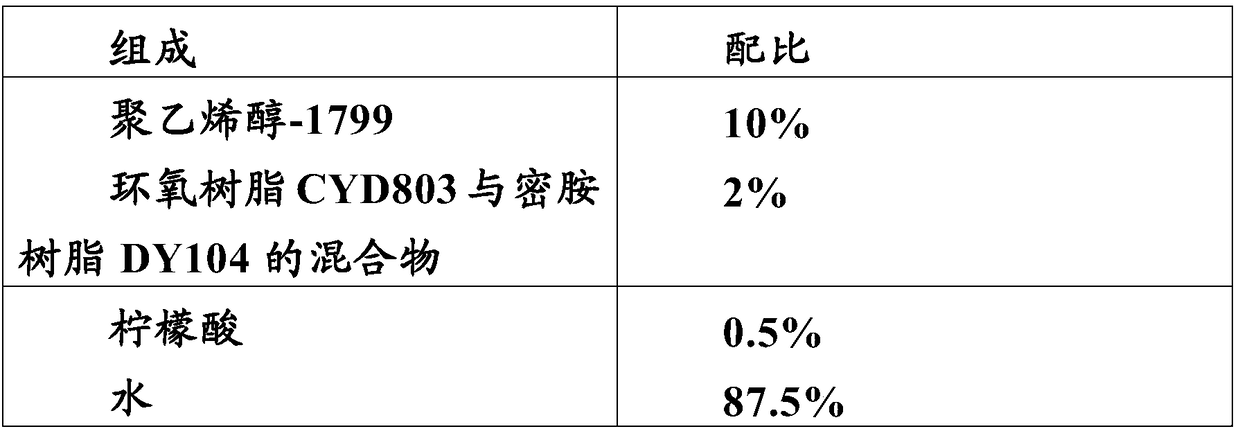

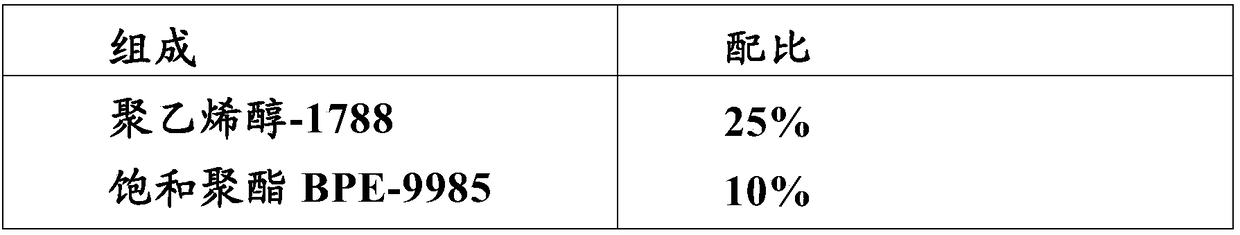

High-barrier water-based adhesive

ActiveCN109161363ALow costNo emissionsNon-macromolecular adhesive additivesLamination ancillary operationsAdhesive cementPolymer science

The invention relates to the field of packaging materials, in particular to a high-barrier water-based adhesive as well as a preparation method and an application of the water-based adhesive. The invention further relates to a composite film, a preparation method and an application of the composite film and a package comprising the composite film. The composite film comprises an adhesion barrier layer formed by the water-based adhesive.

Owner:刘建林

Pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, pressure-sensitive adhesive sheet, optical component and touch panel

InactiveUS20140226085A1Good corrosion inhibitionHigh level of adhesion reliabilitySynthetic resin layered productsN-vinyl-pyrrolidone polymer adhesivesAcid groupTouch panel

Provided are an optical component having an excellent corrosion inhibition effect while maintaining a high level of adhesion reliability and transparency, as well as a pressure-sensitive adhesive composition and a pressure-sensitive adhesive sheet that can produce such an optical component efficiently and at a low cost. The pressure-sensitive adhesive composition according to the present invention includes a rust inhibitor and a base polymer, characterized in that the base polymer does not or substantially does not contain an acid group-containing monomer as a constituent monomer component. Further provided is a pressure-sensitive adhesive sheet having a pressure-sensitive adhesive layer formed from such pressure-sensitive adhesive composition.

Owner:NITTO DENKO CORP

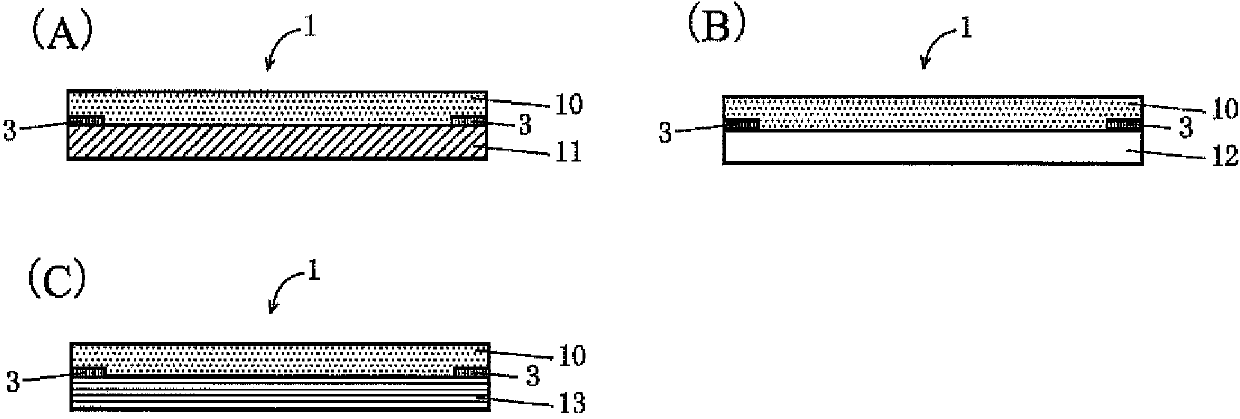

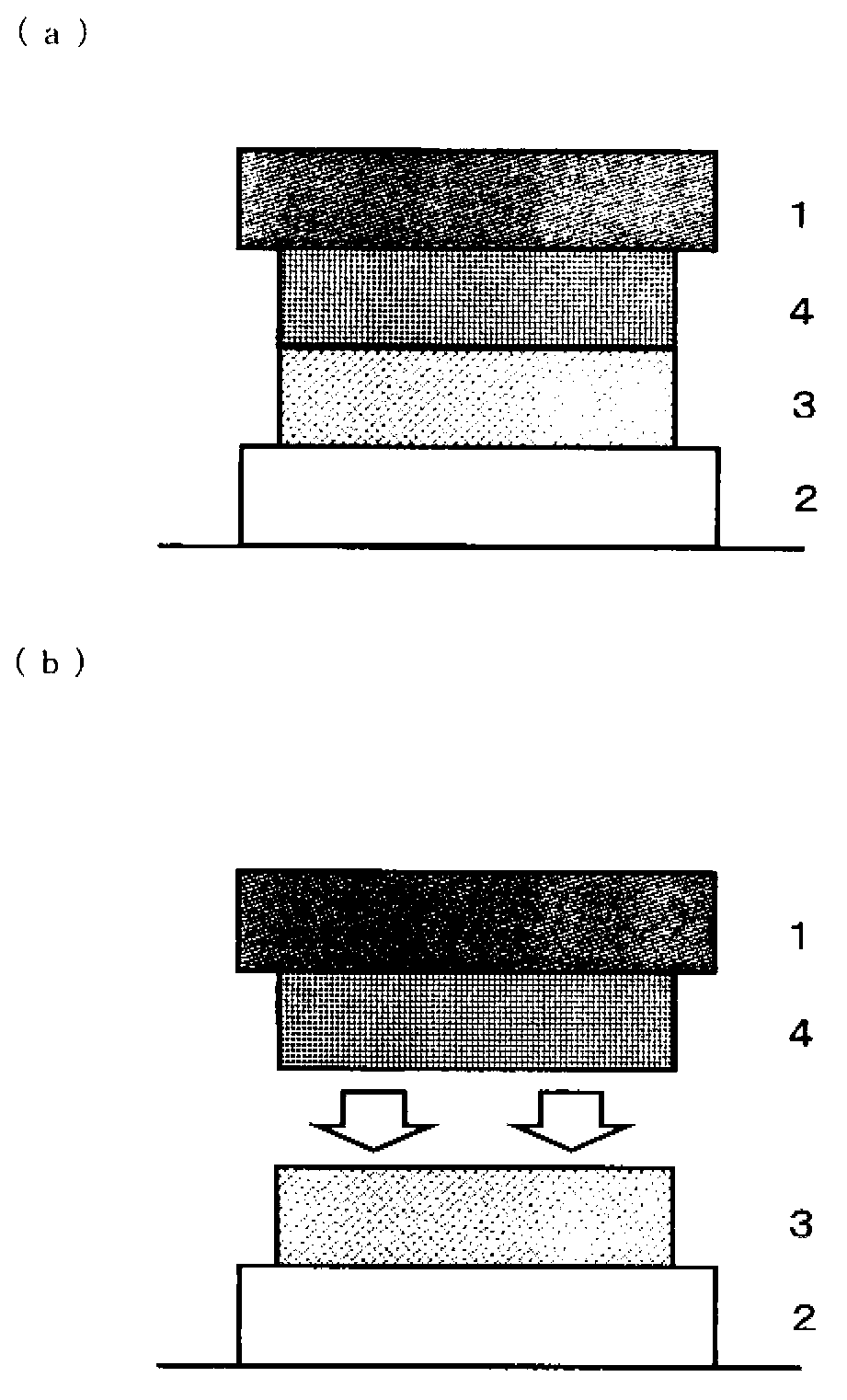

Protective film composition for wafer dicing

ActiveCN102077326AEnhanced adhesionDoes not break related issuesSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solventWafer dicing

Disclosed is a protective film composition for wafer dicing, comprising at least one resin selected from the group consisting of polyethyloxazoline and polyvinylpyrrolidone, at least one component selected from the group consisting of a water-soluble resin and an alcoholic monomer, and a solvent, such as water or a mixture of water and an organic solvent.

Owner:DONGWOO FINE CHEM CO LTD

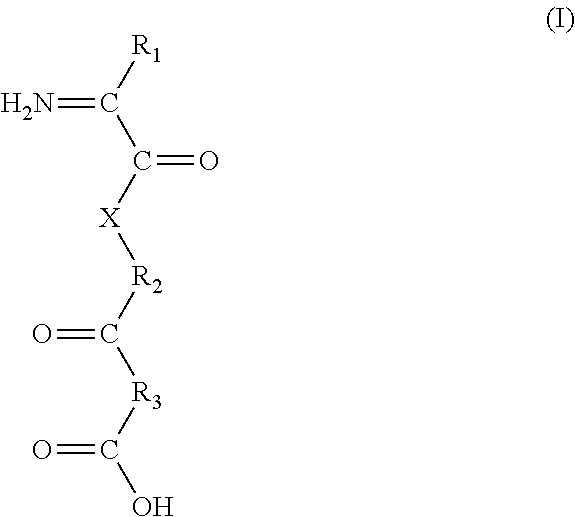

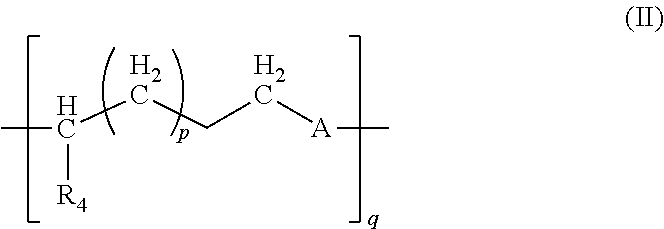

Adhesive composition

An adhesive composition is described which has improved initial tack, long-term adhesion, water uptake and translucency characteristics and may be prepared by melt extrusion. Uses of these compositions are also described, for example, their use as blister pads and wound dressings.

Owner:CORIUM INT +1

Thermoplastic hydrophilic adhesive compositions for attachment on dry and wet surfaces and with increased water adhesion stability

InactiveUS20050032952A1Monocarboxylic acid ester polymer adhesivesNon-fibrous pulp additionPersonal careThermoplastic

The present invention relates to the thermoplastic hydrophilic adhesive compositions having an increased adhesion capability and stability on moist or wet surfaces. The adhesive compositions comprise a thermoplastic hydrophilic homogeneous polymeric matrix having selected liquid absorption capacity, liquid absorption rate, and rheology. The adhesive compositions of the present invention are particularly suitable as topical adhesives for skin adhesion of articles such as disposable waste management articles, disposable absorbent articles, and personal care articles.

Owner:THE PROCTER & GAMBLE COMPANY

Trough-edge building panel and method of manufacture

Disclosed herein is a trough-edge building panel used in the fabrication of panelized wall systems with elastomeric joints that are resistant to cracking. The panels are preferably fiber cement. The front surface of each panel has a trough adjacent to an edge of the panel. Panels are fastened to a frame with the trough-edges adjacent to each other. A joint tape is applied to the seam between the panels such that the edges of the joint tape fall within the troughs of the adjacent panels. The wall is then finished with an elastomeric finish. Also disclosed is a method of manufacturing the trough-edge panels.

Owner:JAMES HARDIE TECH LTD

Solid glue stick and method for producing the same

InactiveCN101220252AImprove mechanical propertiesImprove performancePolyureas/polyurethane adhesivesN-vinyl-pyrrolidone polymer adhesivesSodium stearatePolyurethane adhesive

The invention discloses a solid glue stick, and is prepared with watercraft polyurethane latex as a major glue component, water as solvent, sodium stearate as gel, and polyvinyl alcohol and polyethylene pyrrole azululanone as accessory ingredients, and moderate glycerol added as humectant, wherein a self-emulsion method is adopted for the preparation of the watercraft polyurethane latex. The invention has the advantages that coated surface of the watercraft polyurethane adhesive adopted in preparing the solid glue stick is not easy to be damaged; the mechanical property is excellent; the modification is easy; the compatibility with paint is good; the prepared solid glue stick has obvious advantages in properties of assigned model, hardness, coating, and splicing, etc.; the exterior is pure white; the feeling is subtle; the splicing property is good; the drying speed is high; time for paper tearing is less than one minute; the hydrating period is as long as one year; the reserve property is fine.

Owner:ZHONGBEI UNIV +1

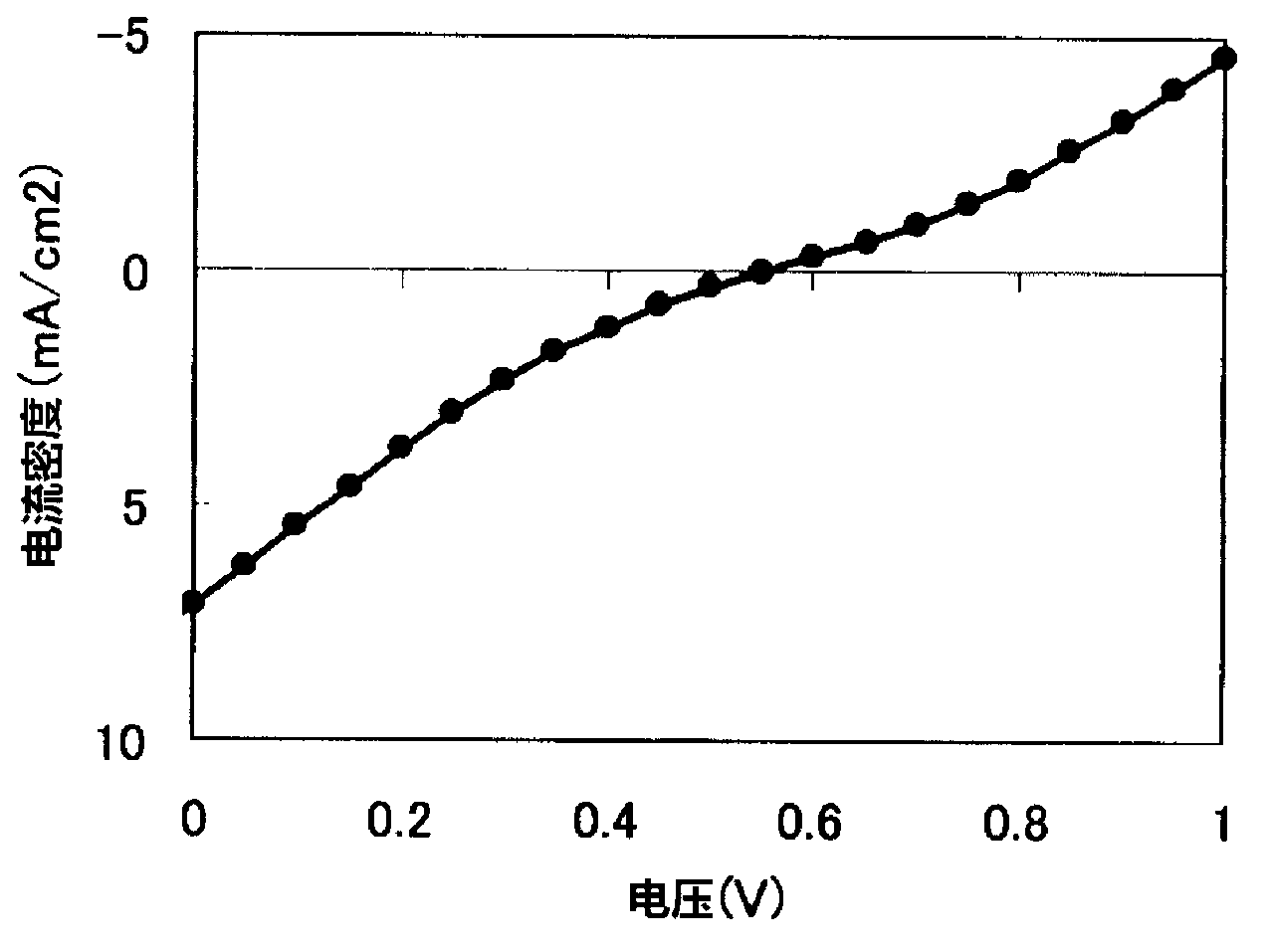

Conductive adhesive composition, electronic device, positive electrode laminate, and method for manufacturing electronic device

ActiveCN103189463AHigh transparencyReduce surface resistanceNon-macromolecular adhesive additivesFinal product manufactureSimple Organic CompoundsAlcohol

The present invention provides a conductive adhesive composition that has superior adhesive properties and low surface resistance and is capable of use as a buffer layer foran electronic device. This conductive adhesive composition contains a water-soluble polyvinyl polymer (A), organic additive (B), and conductive high molecular weight organic compound (C). The organic additive (B) is at least one selected from water-soluble polyhydric alcohols, water-soluble pyrrolidones, or hydrophilic aprotic solvents. The conductive high molecular weight organic compound (C) is at least one selected from polyanilines, polypyrroles, or polythiophenes as well as derivatives thereof. Furthermore, the present invention provides an electronic device having a conductive layer formed from this conductive adhesive composition, a positive electrode laminate in which a conductive layer formed from this conductive adhesive composition is laminated, and a method for manufacturing this electronic device.

Owner:LINTEC CORP

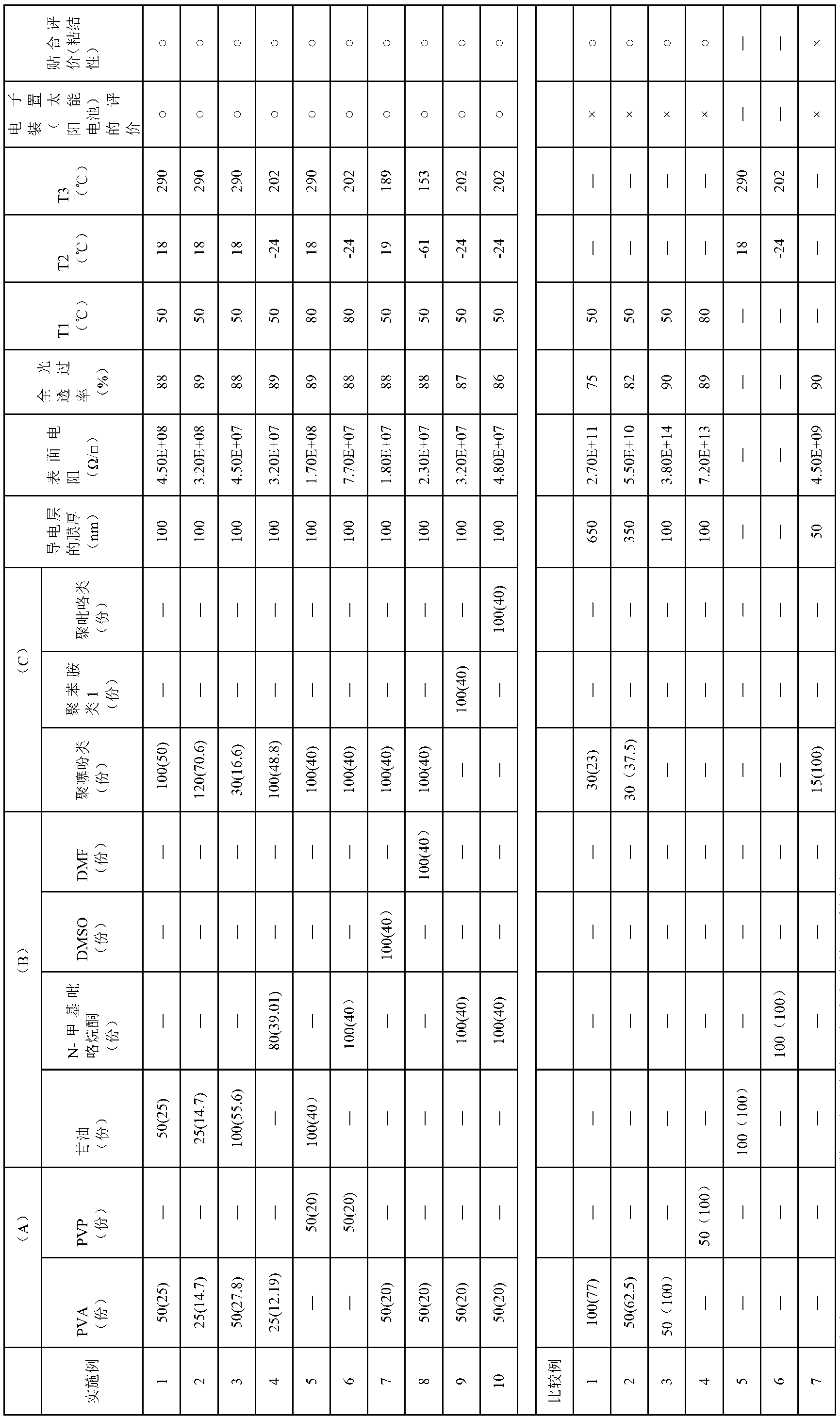

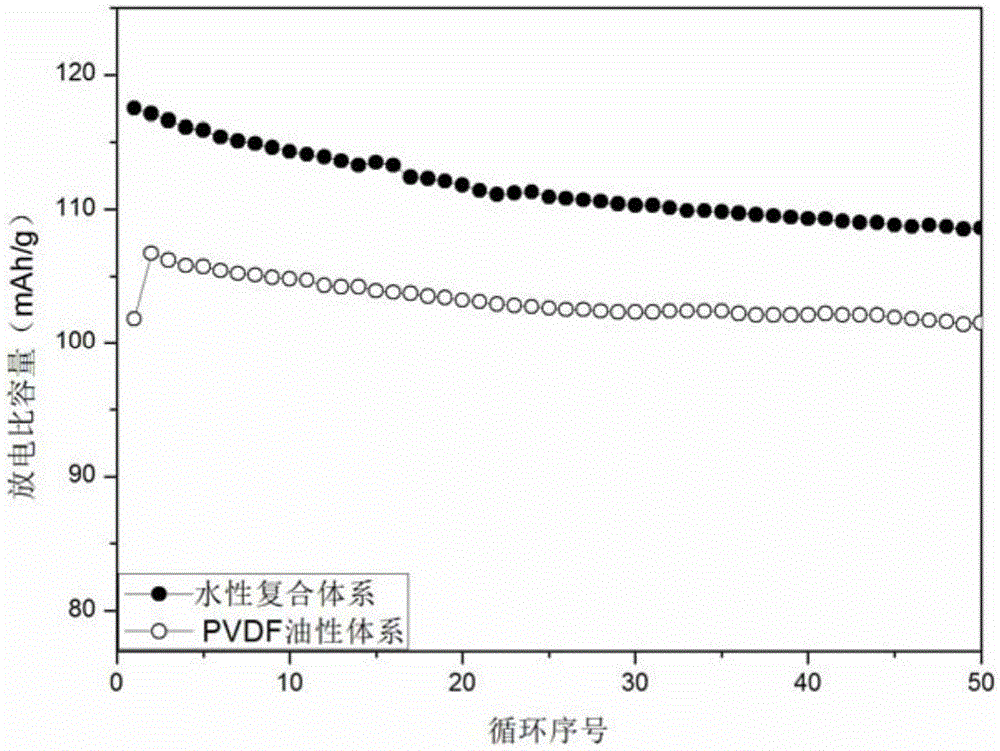

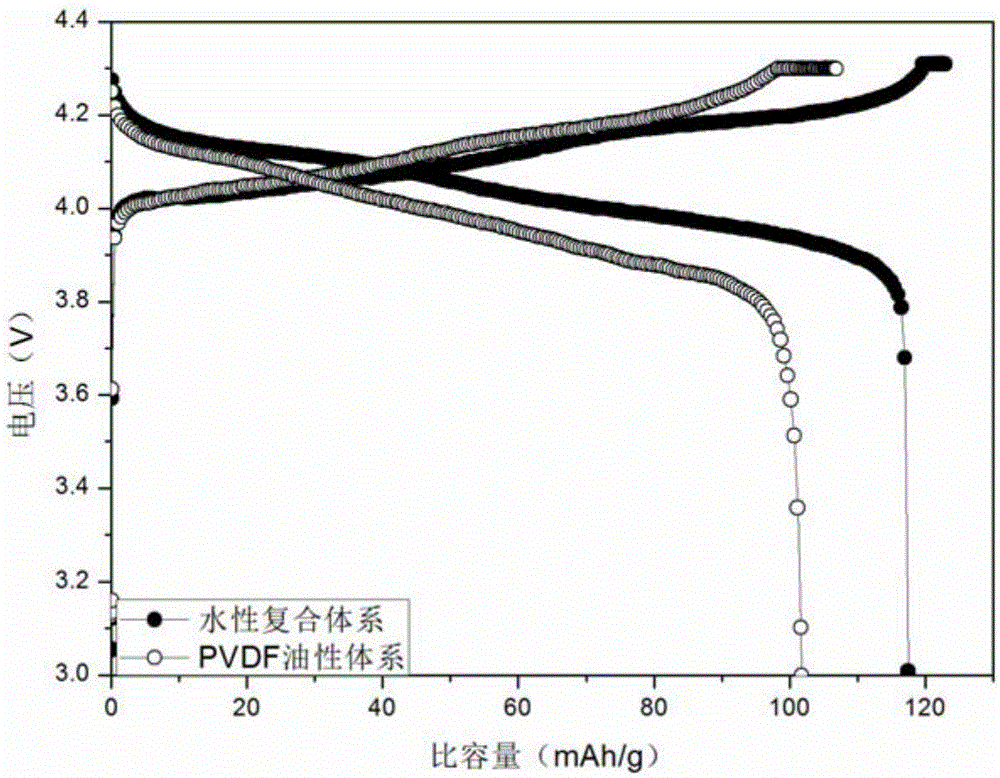

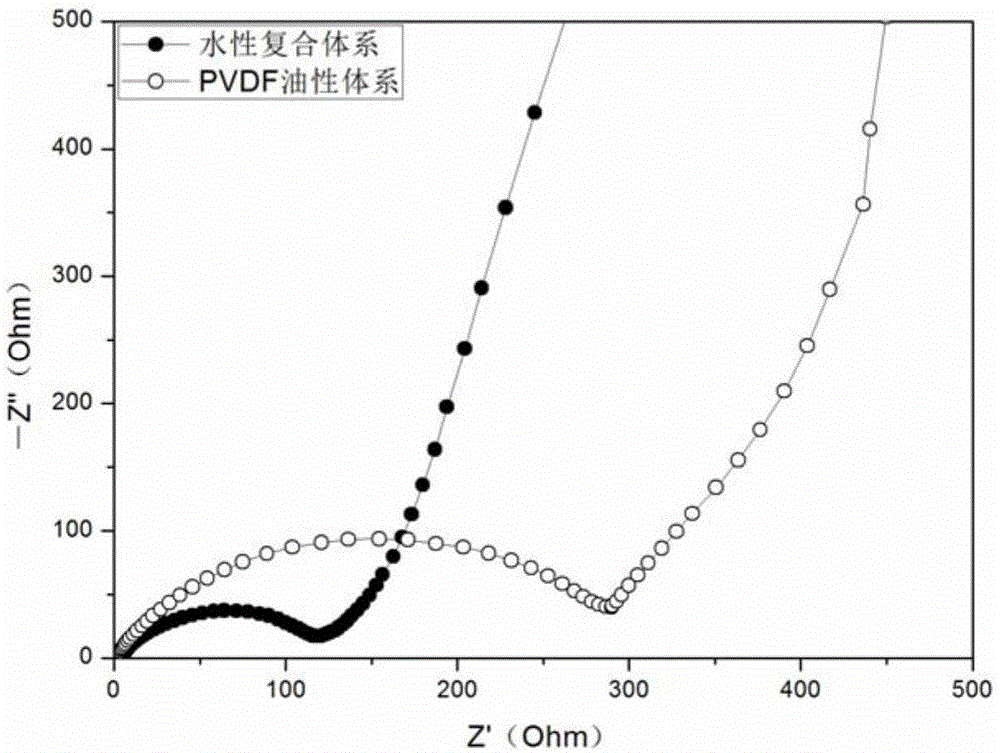

Aqueous composite binder and method for preparing aqueous positive electrode slurry therefrom

ActiveCN105153974AReduce the rate of change in thicknessGuaranteed charge and discharge performanceCell electrodesSecondary cellsCyclic processFlocculation

The invention provides an aqueous composite binder and a method for preparing aqueous positive electrode slurry therefrom. The aqueous composite binder is prepared through blending the ingredients in parts by mass: 65-70 parts of primary binder, 30-35 parts of ionic binder and 1.5 parts of flexibilizer, wherein a -COOLi functional group containing water-soluble polymer, or water-soluble lithium-containing silicate or a water-soluble binder capable of forming a complex with free Li<+> serves as the ionic binder, a long-chain water-soluble polymer with adsorption and flocculation effects serves as the flexibilizer, and a water-soluble polymer serves as the primary binder. The aqueous composite binder and the method for preparing the aqueous positive electrode slurry therefrom have the advantages that the problem that Mn is dissolved in a cycle process of spinel lithium manganate batteries can be effectively solved, and prepared batteries are more environment-friendly and are better in charging and discharging properties.

Owner:TOP CHEM SHENZHEN CO LTD

Antimicrobial hot melt adhesive

Hot melt adhesive compositions suitable for a variety of applications, especially in nonwoven disposable articles, are prepared by blending various adhesive components with a bacteriostat. The bacteriostat is incorporated into the adhesive compositions in sufficient amounts to inhibit the growth of various microorganisms, particularly bacteria. The preferred bacteriostat is triclosan in amounts of 0.0 1 % to 5 % by weight.

Owner:ATO FINDLEY

Transparent solid adhesive

InactiveCN104231969AColor transparentHigh hardnessMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPreservativeActive agent

The invention provides a transparent solid adhesive which comprises the following components in percentage by weight: 4-50% of an adhesive, 1-20% of a humectant, 2-20% of gel, 3-6% of an active agent, 0.5-2% of a defoaming agent, 0.1-1% of a preservative, 0.1-3% of PH adjusting agent and 20-75% of water. Compared with the prior art, the transparent solid adhesive has the beneficial effects that the solid adhesive is transparent in color, high in hardness, good in moisture retention, smooth without reside dropping when being coated, good in oxidation resistance and environment-friendly and non-toxic.

Owner:TIANCHANG EARTHQUAKE OFFICE

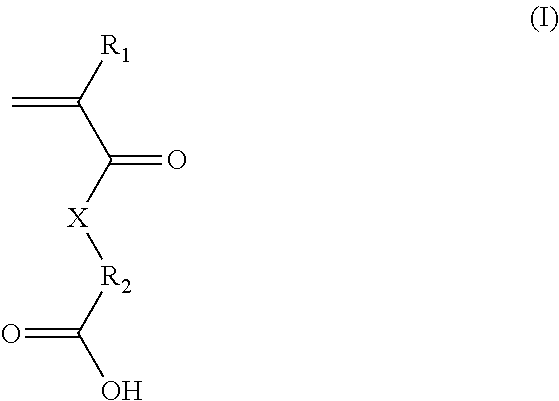

Pressure sensitive adhesive and patch

InactiveUS20060193900A1Good cohesive propertyGood tackinessAdhesive dressingsEster polymer adhesivesMethacrylateMeth-

The present invention is a pressure sensitive adhesive comprising: an ingredient (A) which is a copolymer of a carboxyl group-containing monomer and (meth)acrylic ester; and an ingredient (B) which is a copolymer of a pyrrolidone group-containing monomer and (meth)acrylic ester, wherein the ingredient (A) is crosslinked by at least one crosslinking agent selected from the group consisting of a metal chelate compound, a metal oxide and a metal hydroxide, and the blending ratio of the ingredient (A) is 70 to 90 weight % based on the total amount of the ingredient (A) and ingredient (B).

Owner:HISAMITSU PHARM CO INC

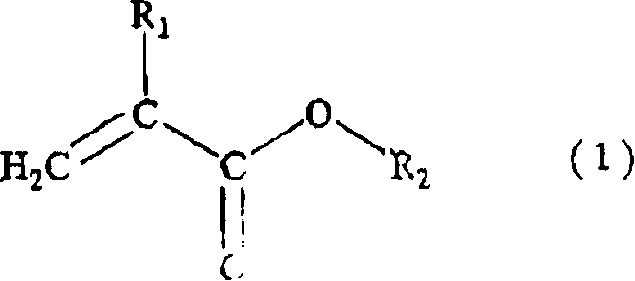

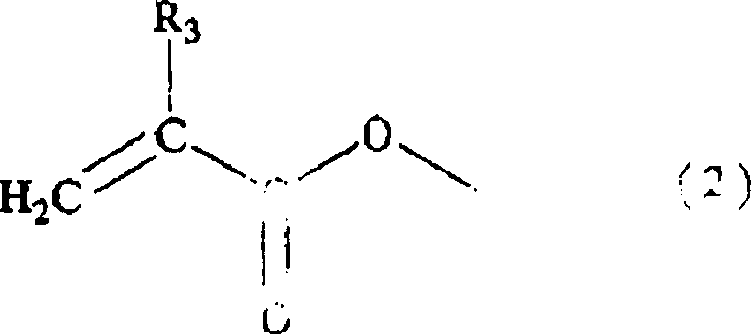

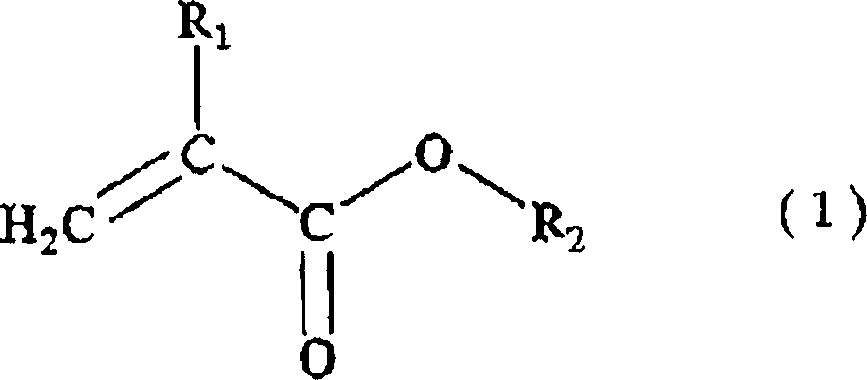

Acrylic resin

InactiveCN1660916AReduce light leakageOperating means/releasing devices for valvesFilm/foil adhesivesHydrogen atomAcrylic resin

The acrylic resin can be obtained by copolymerizing (a), (b), (c) and (d). (a): a (meth)acrylate represented by formula (1), wherein R1denotes hydrogen atom or methyl group; R2denotes a 1-14C alkyl group or aralkyl group. (b): a monomer containing at least two groups represented by formula (2) in the molecule, wherein R3denotes hydrogen atom or methyl group. (c): a monomer containing a heterocycle and one olefinic double bond in the molecule. (d): a monomer containing at least one polar functional group and one olefinic double bond in the molecule.

Owner:SUMITOMO CHEM CO LTD

Optical acrylic pressure-sensitive adhesive composition and optical acrylic pressure-sensitive adhesive tape

InactiveUS20120184680A1High transparencyImprove adhesionFilm/foil adhesivesEster polymer adhesivesMeth-Nitrogen

The present invention relates to an optical acrylic pressure-sensitive adhesive composition, containing: 100 parts by mass of an acrylic polymer (A) which contains a vinylic monomer having a nitrogen atom in a skeleton thereof as a monomer unit and does not substantially contain a monomer containing a carboxyl group; 1-70 parts by mass of a (meth)acrylic polymer (B) having a weight average molecular weight of 1,000 or greater and less than 30,000; and 1-50 parts by mass of a hydrogenated tackifying resin (C), and an optical acrylic pressure-sensitive adhesive tape including a pressure-sensitive adhesive layer containing the optical acrylic pressure-sensitive adhesive composition.

Owner:NITTO DENKO CORP

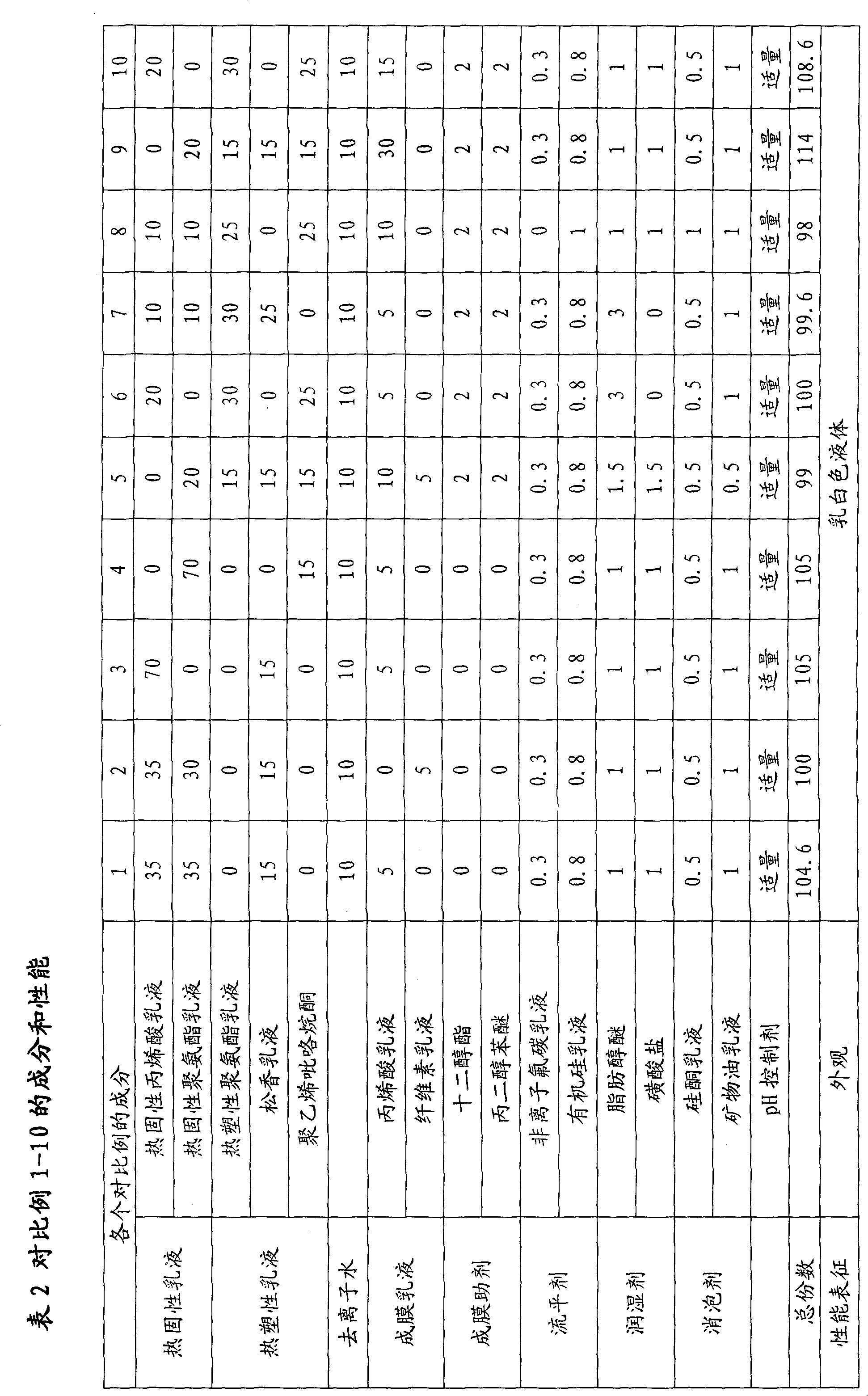

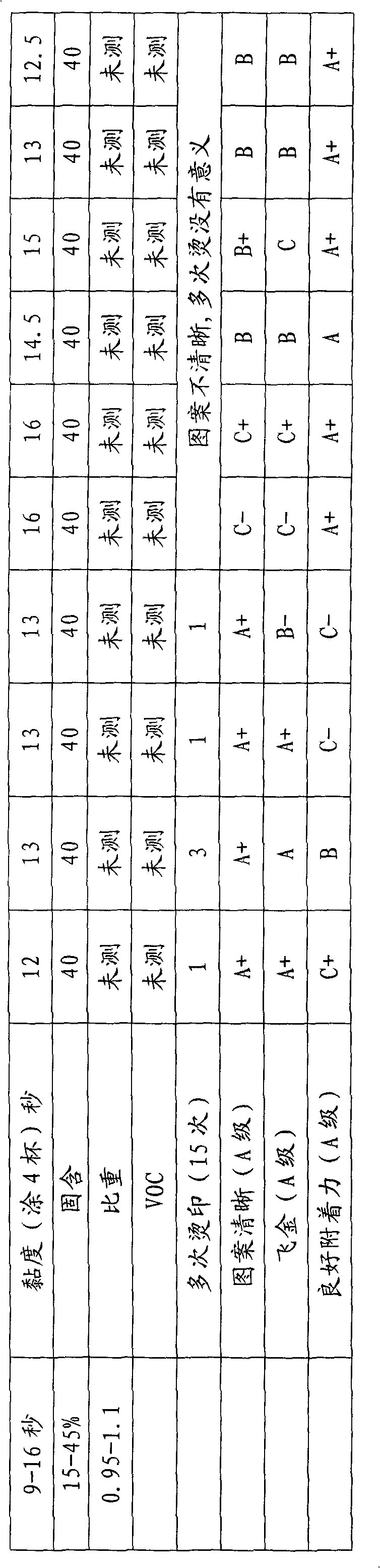

Environment-friendly aqueous thermoprinting back glue for tipping paper thermoprinting film and preparation method thereof

ActiveCN101805571APolyureas/polyurethane adhesivesN-vinyl-pyrrolidone polymer adhesivesPolymer scienceEmulsion

The invention discloses environment-friendly aqueous thermoprinting back glue for a tipping paper thermoprinting film and a preparation method thereof, wherein the formula thereof comprises the following components in mass ratio: 20 to 60 percent of thermosetting emulsion, 10 to 50 percent of thermoplastic emulsion, 5 to 40 percent of deionized water, 5 to 30 percent of film forming emulsion, 0 to 5 percent of film forming auxiliary agent, 0 to 3 percent of flatting agent, 0 to 3 percent of wetting agent, 0 to 3 percent of defoaming agent and a proper amount of pH control agent. The back glue is prepared by adopting a two-step material mixing method, and excellent product stability and uniformity can be obtained through controlling with different stirring speed and stirring time. A totally aqueous material is adopted by the invention, and balance is comprehensively obtained by utilizing the brittleness of the thermosetting emulsion, the flexibility of the thermoplastic emulsion and the film forming property of the film forming emulsion. According to the invention, zero emission can be realized in the production process, and the environment-friendly aqueous thermoprinting back glue for the tipping paper thermoprinting film, which has zero VOC, high solid content, low viscosity, adaptability for high-speed thermoprinting for many times, clear patterns, no metal flying and good adhesive force can be prepared.

Owner:广州天赢化工科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com