Environment-friendly aqueous thermoprinting back glue for tipping paper thermoprinting film and preparation method thereof

A technology of hot stamping film and tipping paper, applied in adhesives, rosin adhesives, N-vinylpyrrolidone copolymer adhesives, etc., which can solve problems such as waste, difficult solvent-based adhesives, and small patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

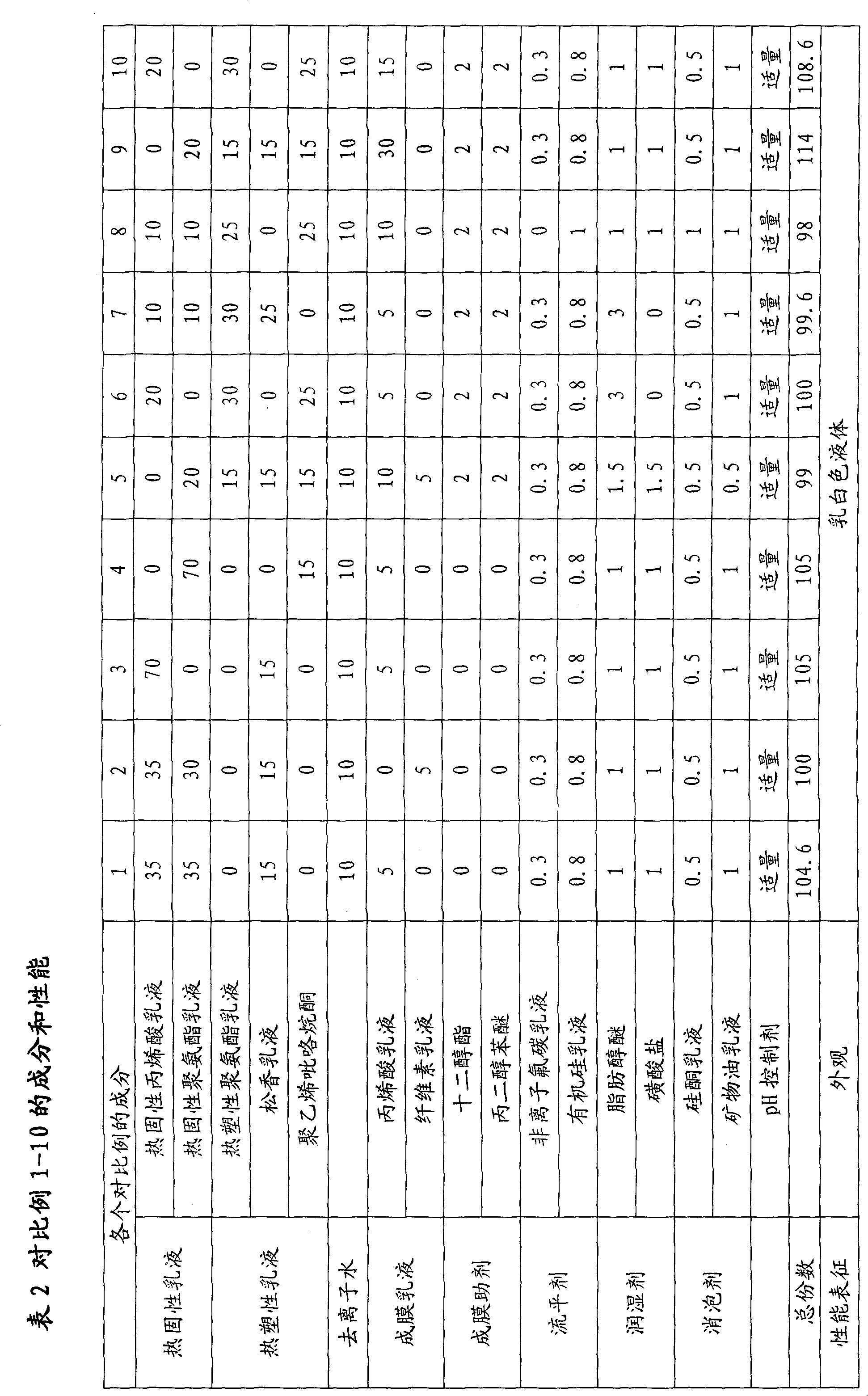

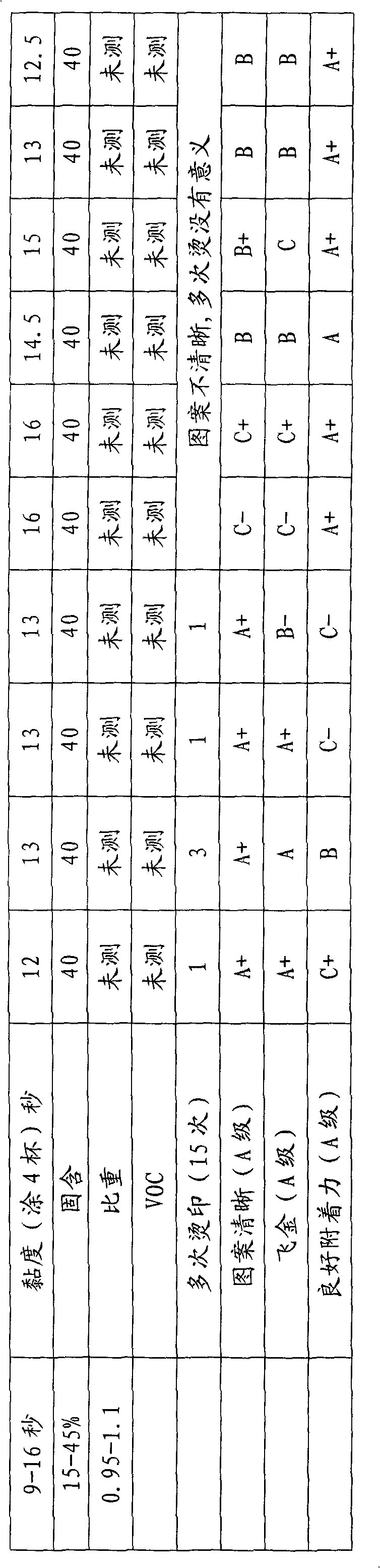

Examples

Embodiment 1

[0054] Raw material ratio (mass %): thermosetting acrylic emulsion (anion, particle size 80 nanometers, viscosity 20 seconds (coating 4 cups), solid content (mass percentage) 40%, molecular weight 80000, Tg25 ° C): 5%; thermosetting polyurethane emulsion (anion, particle diameter 200 nanometers, viscosity 25 seconds (coating 4 cups), solid content (mass percentage) 40%, molecular weight 800000, modulus 80mpa): 15%; thermoplastic polyurethane emulsion (anion, particle diameter 150 nanometers, viscosity 35 Second (coating 4 cups), solid content 40% (mass percentage), molecular weight 50000, modulus 15mpa): 15%; Rosin emulsion (anion, particle diameter 200 nanometers, viscosity 60 seconds (coating 4 cups), solid content (mass Percentage) 50%, molecular weight 8000, softening point 30 ℃): 5%; polyvinylpyrrolidone: 5%; deionized water: 40%; film-forming acrylic emulsion (anion, particle size 20 nanometers, viscosity 15 seconds (coat 4 cups ), solid content (mass percentage) 40%, mo...

Embodiment 2

[0065] Raw material ratio: thermosetting acrylic emulsion (anion, particle size 100 nm, viscosity 20 seconds (4 cups), solid content (mass percentage) 40%, molecular weight 140000, Tg55°C): 10%; thermosetting polyurethane emulsion: 15%; Thermoplastic polyurethane emulsion (anion, particle size 150 nm, viscosity 35 seconds (4 cups), solid content 40% (mass percentage), molecular weight 100000, modulus 75mpa): 2096; rosin emulsion: 10%; polyvinylpyrrolidone: 5 %; deionized water: 9%; film-forming acrylic emulsion: 10%; cellulose emulsion: 10%; dodecyl carbonate: 3%; propylene glycol phenyl ether: 2%; Emulsion 0.8%; Fatty alcohol ether: 1%; Sulfonate 1%; Silicone emulsion: 0.5%; Mineral oil emulsion: 1%;

[0066] The above materials are not marked with the same embodiment one

[0067] Preparation method

[0068] Same as Example 1

[0069] Application Performance Characterization

[0070] Appearance: milky white liquid; viscosity 13 seconds (4 cups); solid content 30%; specifi...

Embodiment 3

[0072]Raw material ratio: thermosetting acrylic emulsion (anion, particle size 100 nanometers, viscosity 20 seconds (4 cups), solid content (mass percentage) 40%, molecular weight 140000, Tg55°C): 10%; thermosetting polyurethane emulsion: 20%; Thermoplastic polyurethane emulsion: 15%; rosin emulsion (anion, particle size 150 nanometers, viscosity 50 seconds (coated in 4 cups), solid content (mass percentage) 60%, molecular weight 10000, softening point 75°C): 15%; polyvinylpyrrolidone : 10%; deionized water: 5%; film-forming acrylic emulsion: 10%; cellulose emulsion: 5%; dodecyl carbonate: 3%; propylene glycol phenyl ether: 1%; Silicone emulsion 0.8%; fatty alcohol ether: 1.5%; sulfonate 1.5%; silicone emulsion: 0.5%; mineral oil emulsion: 0.5%; ammonia and diethanolamine to adjust the pH to 7.4.

[0073] The above materials are not marked with the same embodiment one

[0074] Preparation method

[0075] Same as Example 1

[0076] Application Performance Characterization

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com