High-barrier water-based adhesive

An adhesive and barrier technology, which is used in the field of preparing the composite film, composite film, water-based adhesive, and high-barrier water-based adhesive, and can solve the problems of volatile organic compound emission, environmental damage, and lack of bonding function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

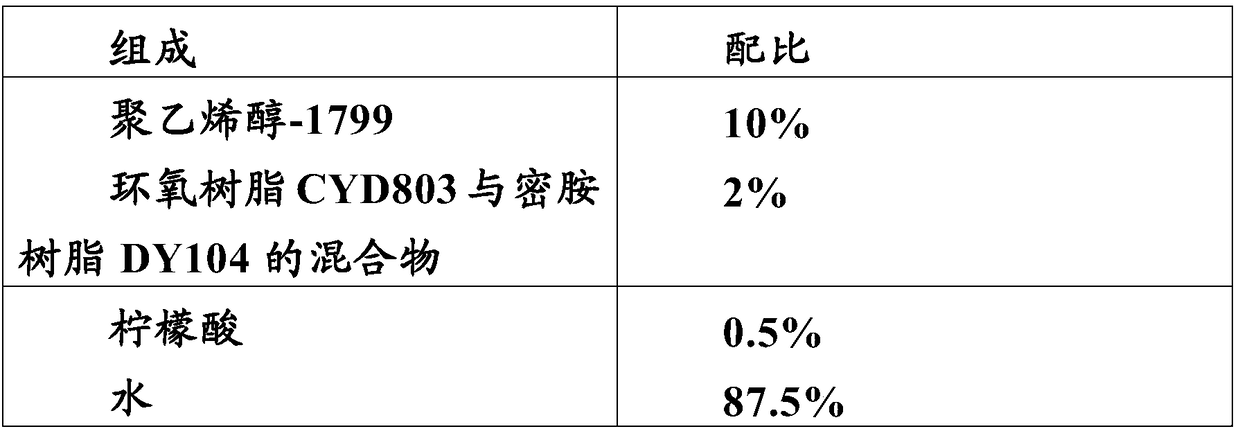

[0190] According to the following ratio, add polyvinyl alcohol-1799 and water into a heatable reaction vessel, and heat to 80°C-90°C under stirring to dissolve completely. After the temperature drops to 35°C-10°C, add a mixture of epoxy resin and melamine resin (0.3:1 weight ratio), stir and mix thoroughly, heat to 40°C-45°C and keep it warm for 8 hours, then drop to room temperature (25°C-15°C), the high-barrier water-based adhesive main agent is obtained after filtration, the main agent does not produce gel phenomenon when stored at 10°C-40°C for 70 days, and has good storage stability. Add citric acid and stir thoroughly before use to obtain a high-barrier water-based adhesive.

[0191]

[0192] Use the prepared high-barrier water-based adhesive to compound BOPP film and PE film. The process is as follows: On the dry laminating machine, the BOPP film with a thickness of 20 μm is placed on the main unwinder, and the high-barrier water-based adhesive is coated on the BOPP ...

Embodiment 2

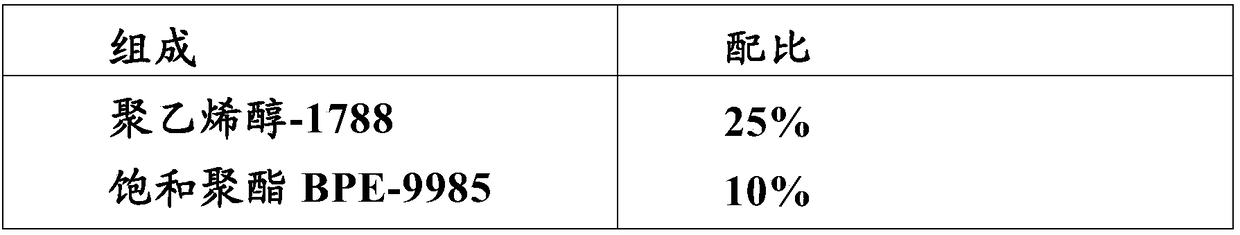

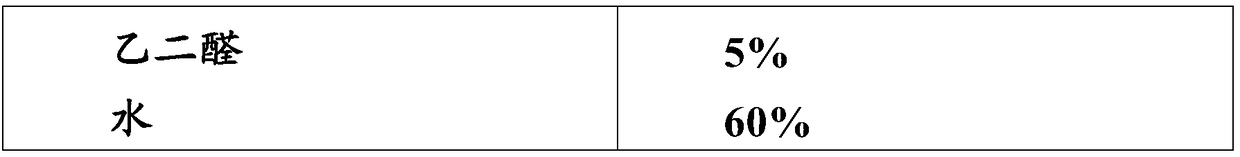

[0195] According to the following ratio, add polyvinyl alcohol-1788 and water into a heatable reaction vessel, and heat to 60°C-70°C under stirring to dissolve completely. After the temperature drops to 20°C-10°C, add saturated polyester, stir and mix thoroughly, heat to 50°C-70°C, keep warm for 12 hours, then drop to normal temperature (15°C-10°C), filter to obtain high barrier Water-based adhesive main agent, the main agent does not produce gel phenomenon when stored at 10°C-40°C for 70 days, and has good storage stability. Add glyoxal and stir thoroughly before use to obtain a high-barrier water-based adhesive.

[0196]

[0197]

[0198]Use the prepared high-barrier water-based adhesive to compound BOPA film and PE film. The process is as follows: On the dry laminating machine, place a BOPA film with a thickness of 15 μm on the main unwinder, and apply the high-barrier water-based adhesive on the BOPA film. The amount of glue is 8 grams per flat. Dry the glue after ...

Embodiment 3

[0201] Add the mixture of polyvinyl alcohol and polyvinylpyrrolidone (1:0.5 weight ratio) and water into a heatable reaction vessel according to the following ratio, and heat to 80°C-90°C under stirring to dissolve completely. After the temperature drops to 30°C-20°C, add polyurethane, stir and mix thoroughly, heat to 45°C and keep it warm for 7 hours, then drop to normal temperature (29°C-20°C), and filter to obtain the main agent of water-based adhesive. It does not produce gel phenomenon when stored at 10°C-30°C for 30 days, and has good storage stability. Add the oxazoline polymer and stir thoroughly before use to obtain the water-based adhesive.

[0202]

[0203] Use the prepared high-barrier water-based adhesive to compound BOPP film and CPP film. The process is as follows: On the dry laminating machine, the BOPP film with a thickness of 15 μm is placed on the main unwinder, and the high-barrier water-based adhesive is coated on the BOPP film. The amount of glue is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com