Patents

Literature

176 results about "Polyvinyl polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface-functionalized mesoporous carbon materials

ActiveUS9249241B2Effectively and efficiently functionalizedPractical and cost-effective for large scale productionProcess efficiency improvementPolyvinyl polymerSolvent

A functionalized mesoporous carbon composition comprising a mesoporous carbon scaffold having mesopores in which polyvinyl polymer grafts are covalently attached, wherein said mesopores have a size of at least 2 nm and up to 50 nm. Also described is a method for producing the functionalized mesoporous composition, wherein a reaction medium comprising a precursor mesoporous carbon, vinyl monomer, initiator, and solvent is subjected to sonication of sufficient power to result in grafting and polymerization of the vinyl monomer into mesopores of the precursor mesoporous carbon. Also described are methods for using the functionalized mesoporous carbon, particularly in extracting metal ions from metal-containing solutions.

Owner:UT BATTELLE LLC

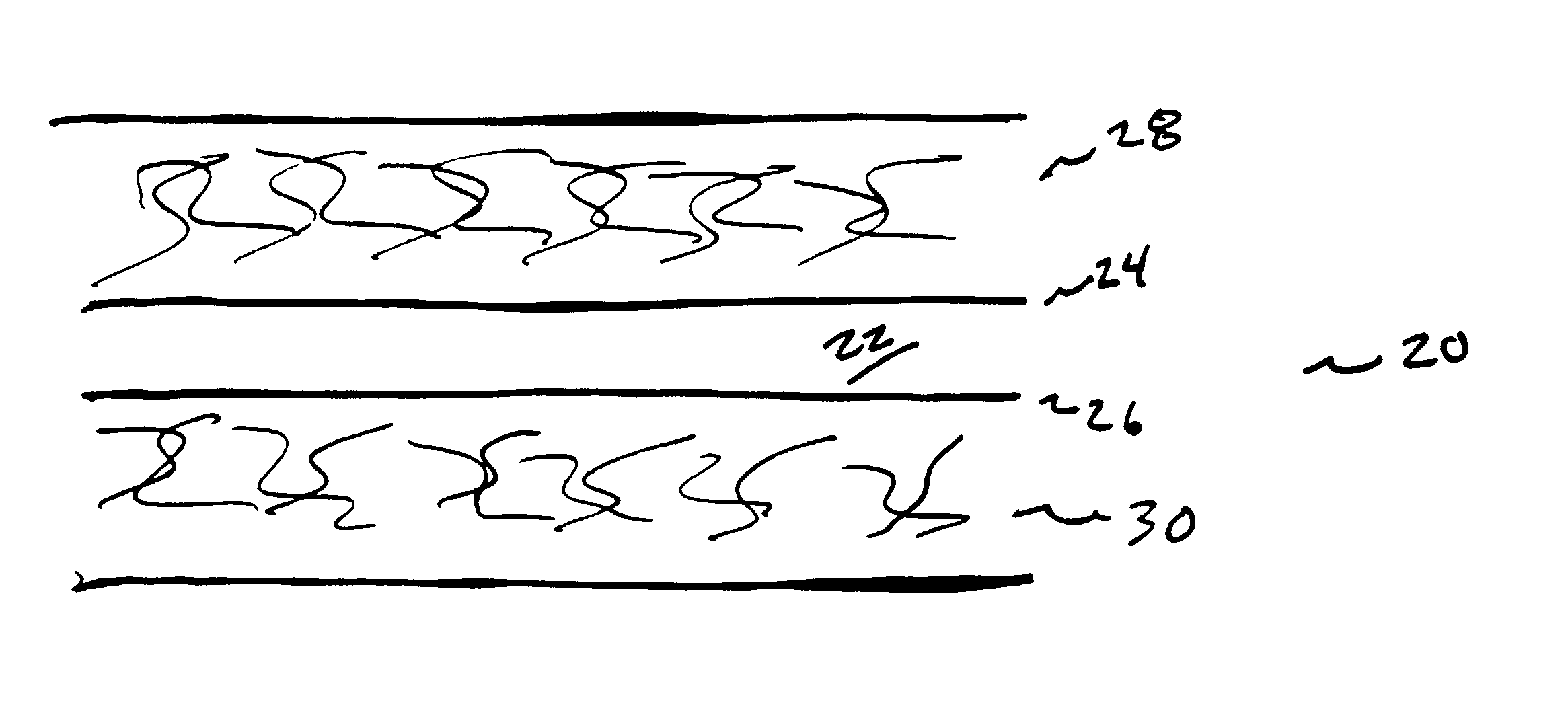

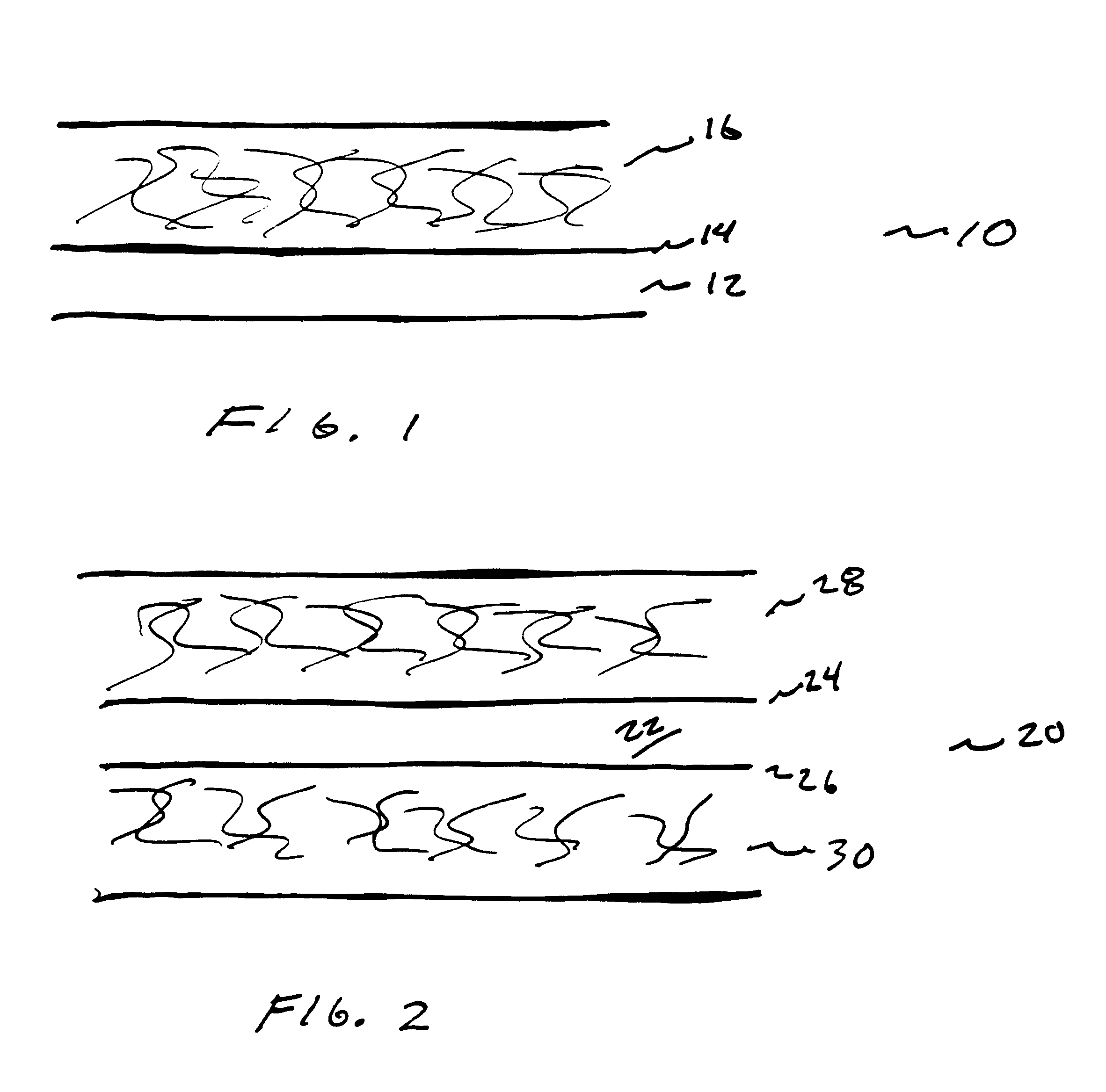

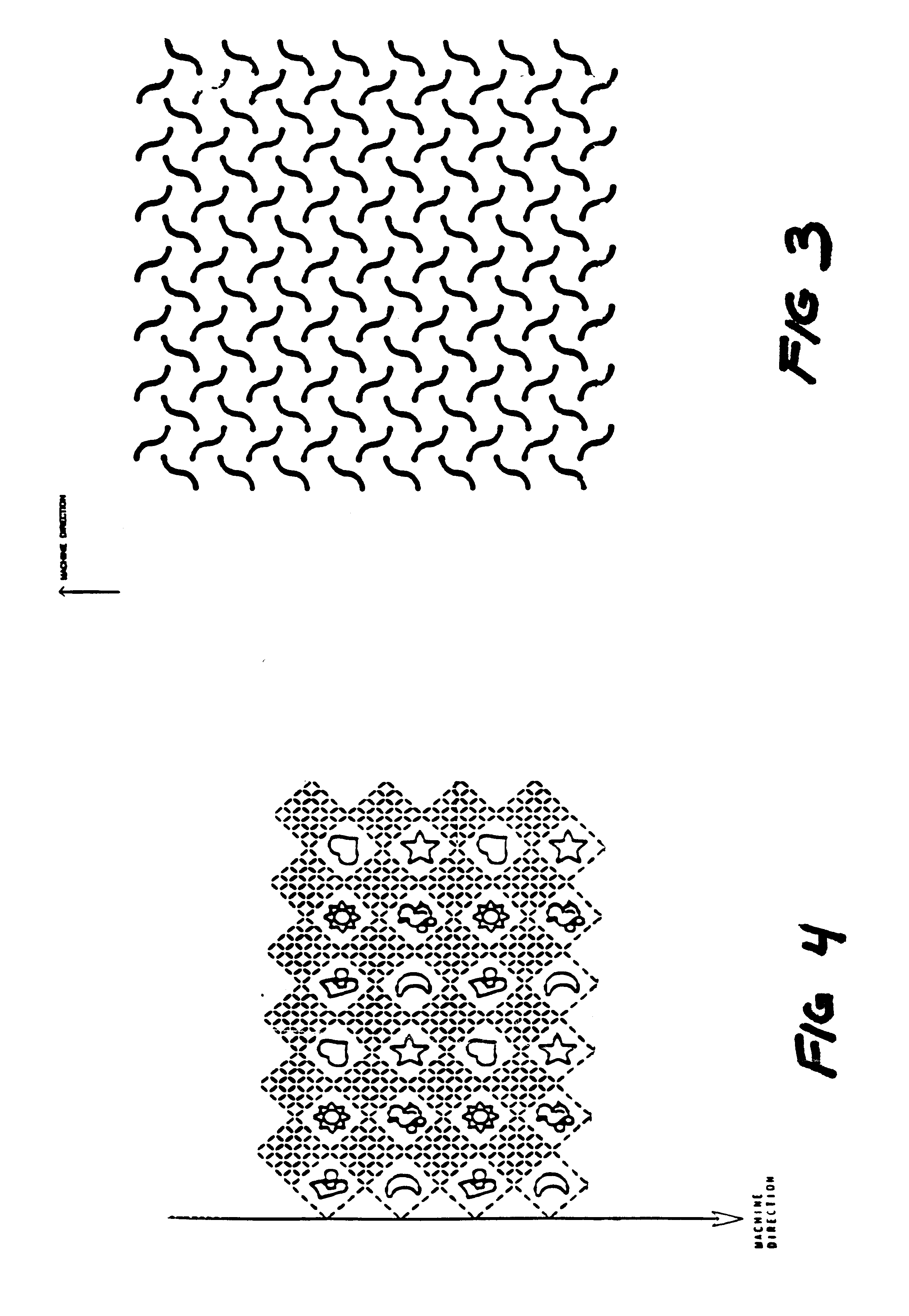

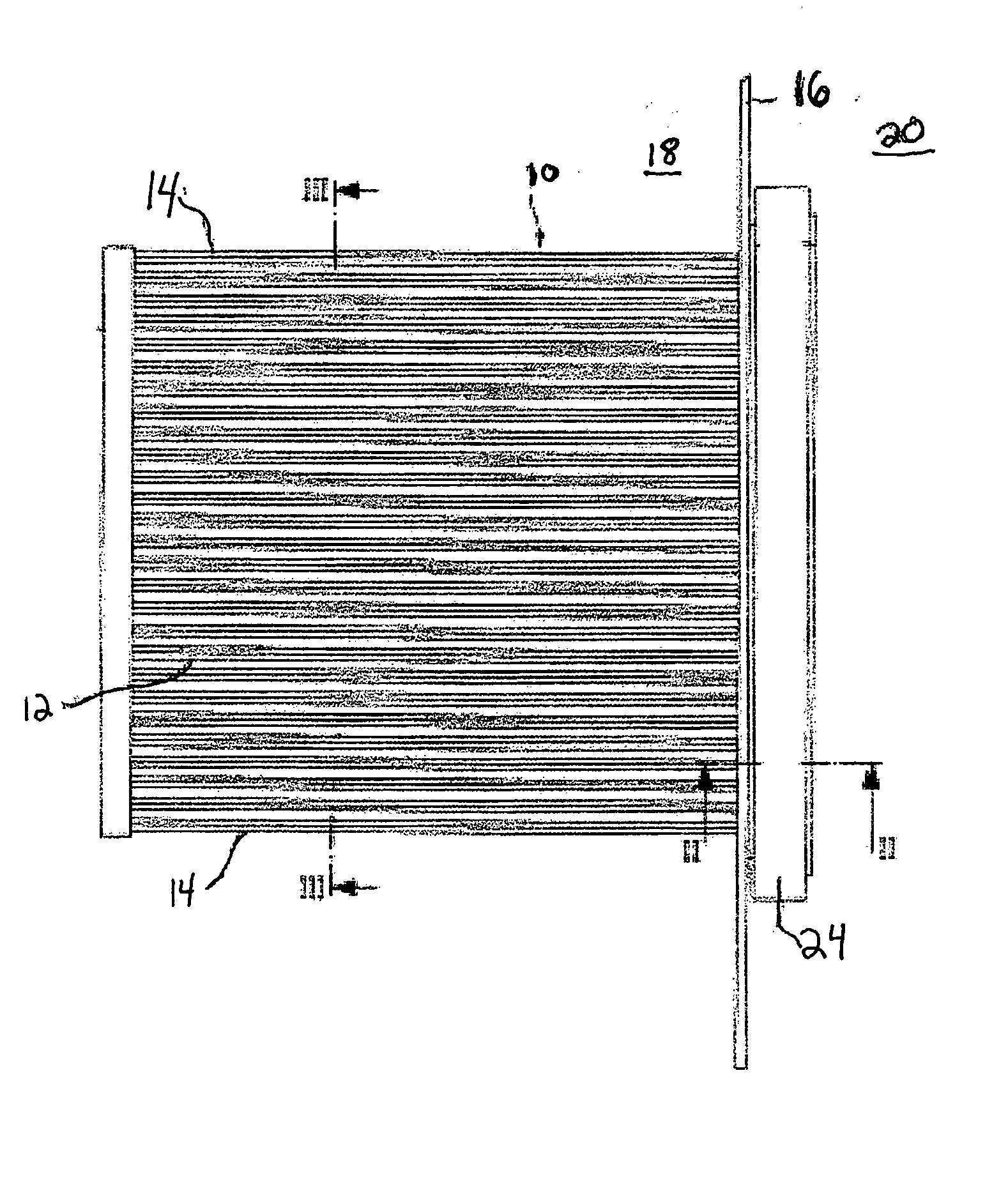

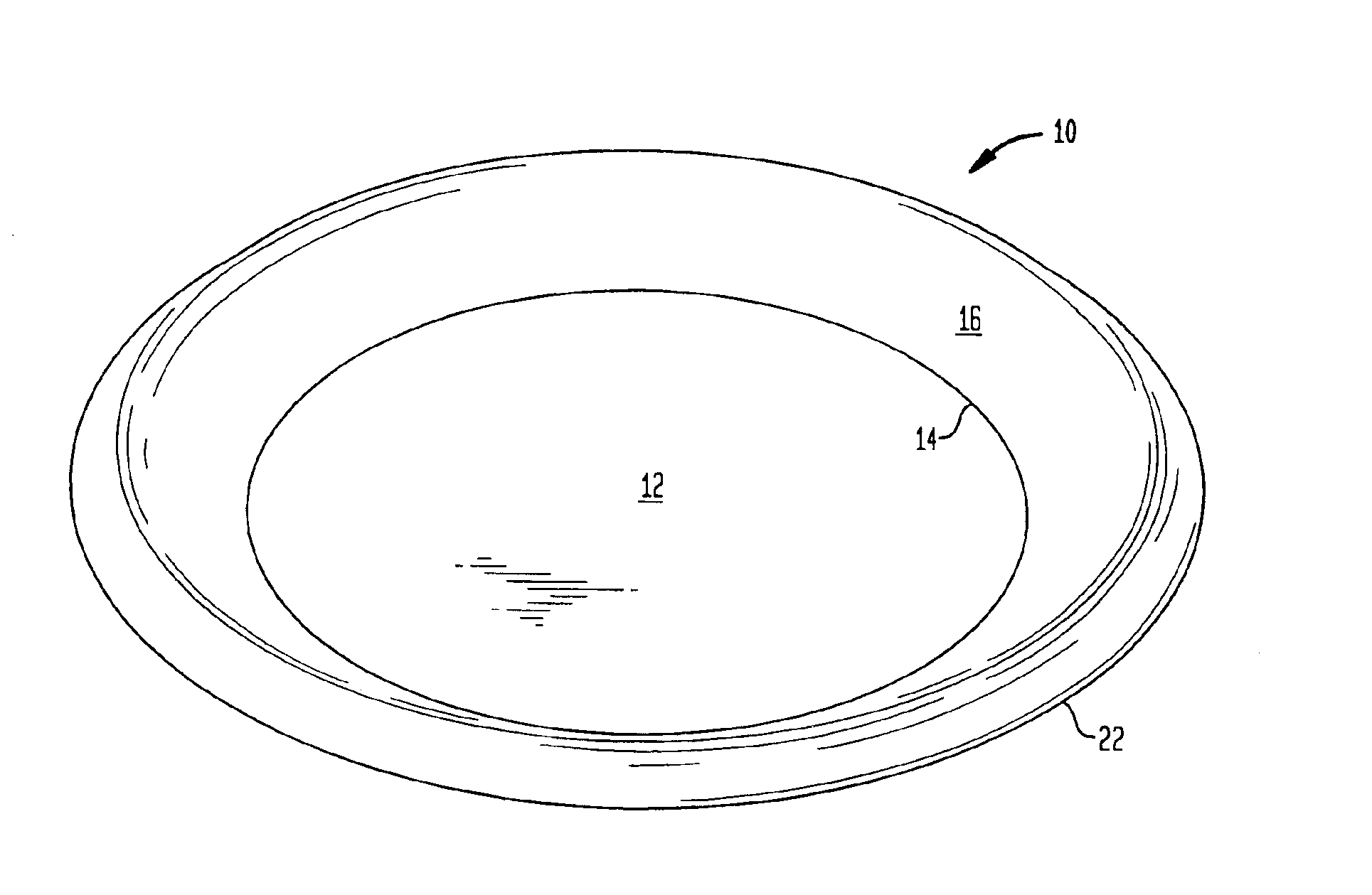

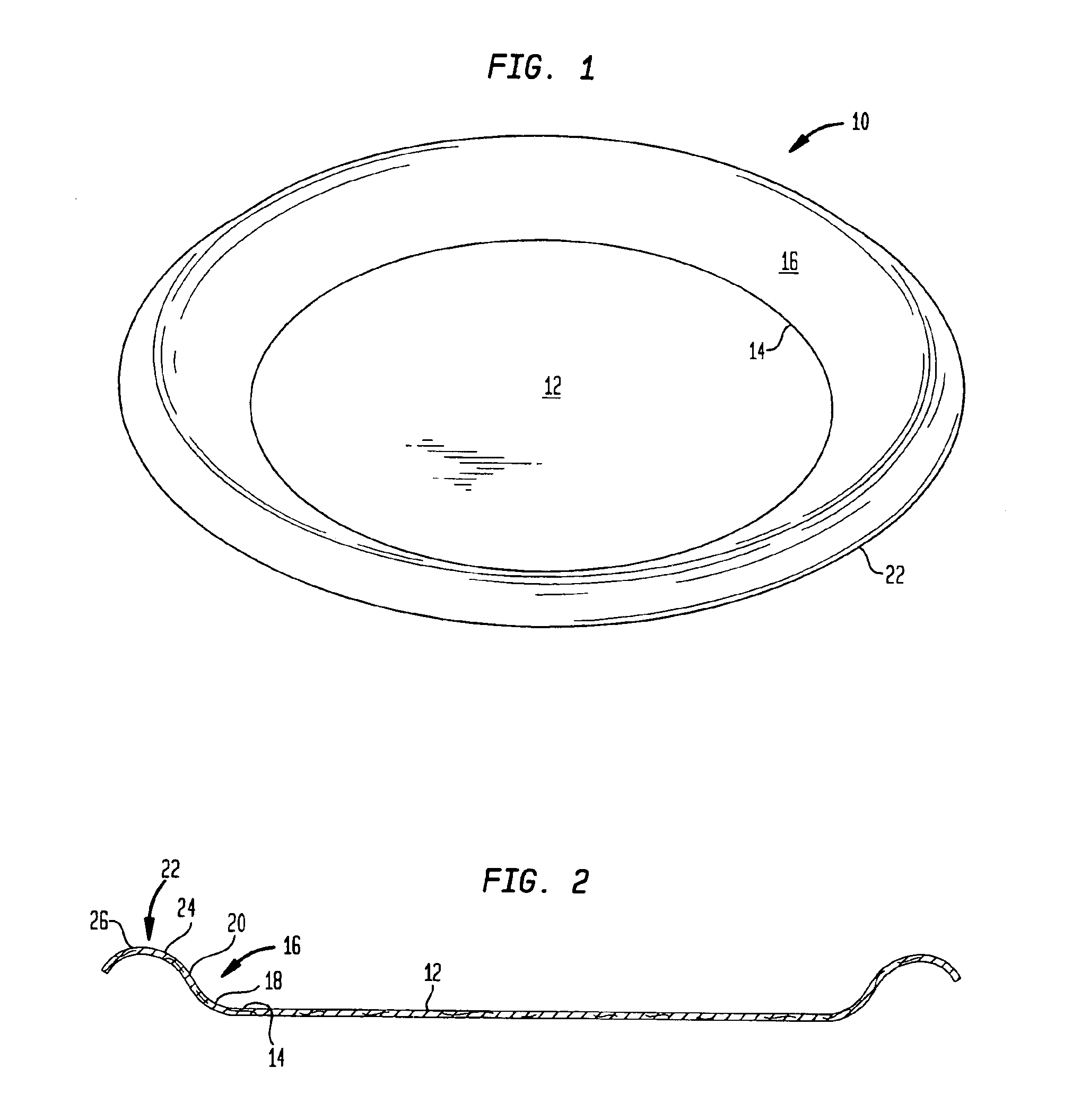

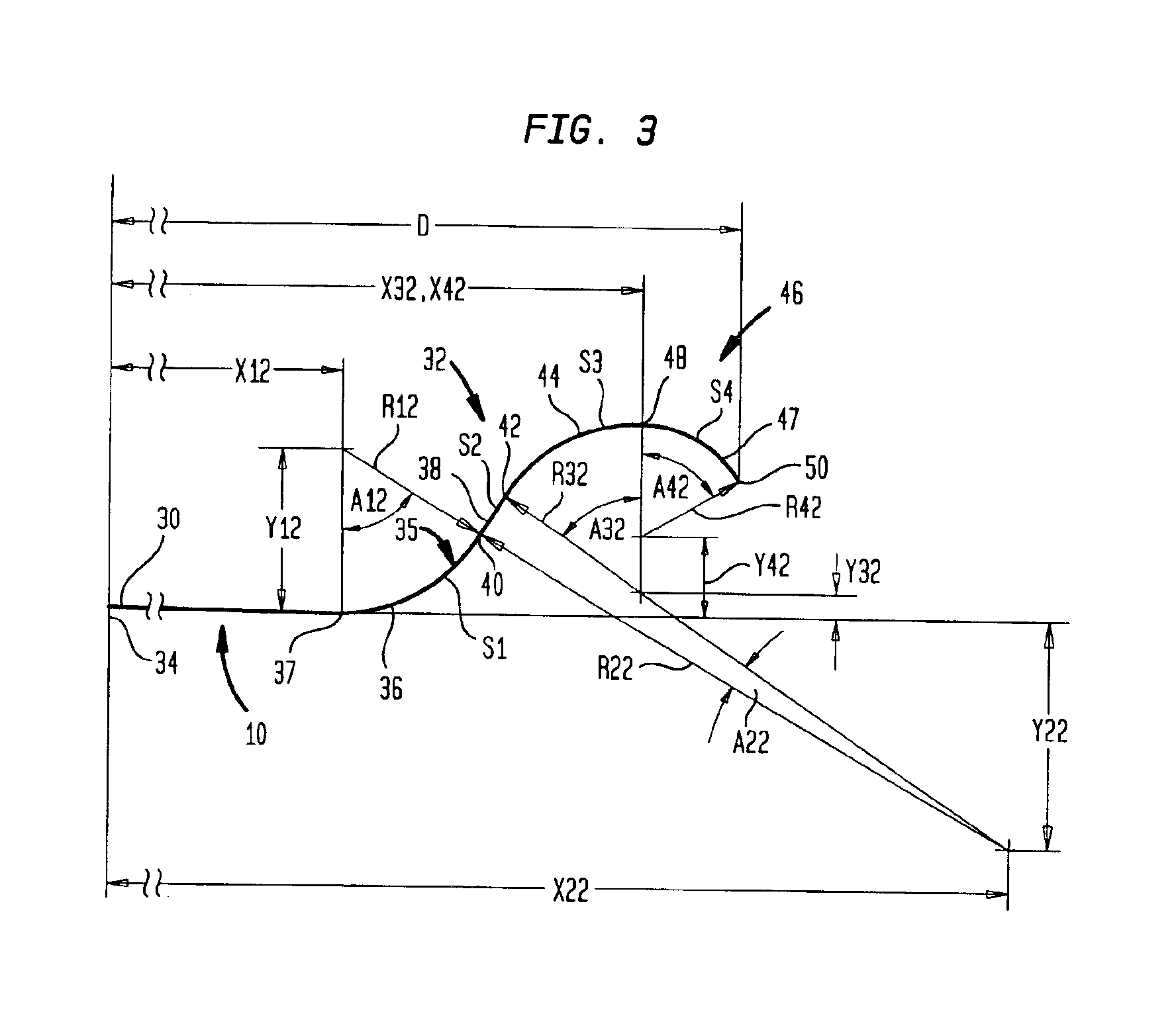

Stable breathable elastic garments

InactiveUS6909028B1Good body conformanceImprove breathabilityPersonal careSynthetic resin layered productsPolyvinyl polymerPolymer science

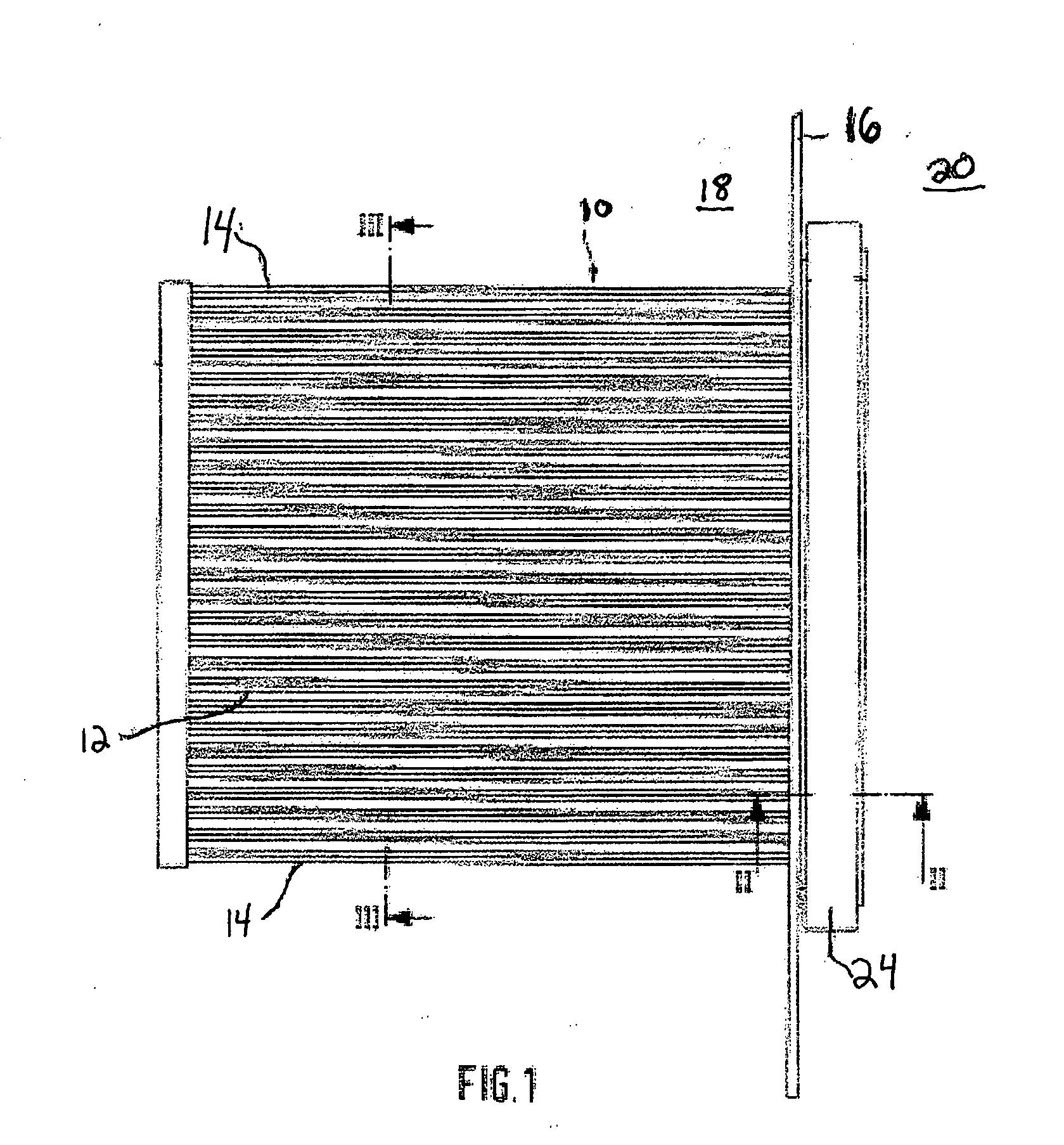

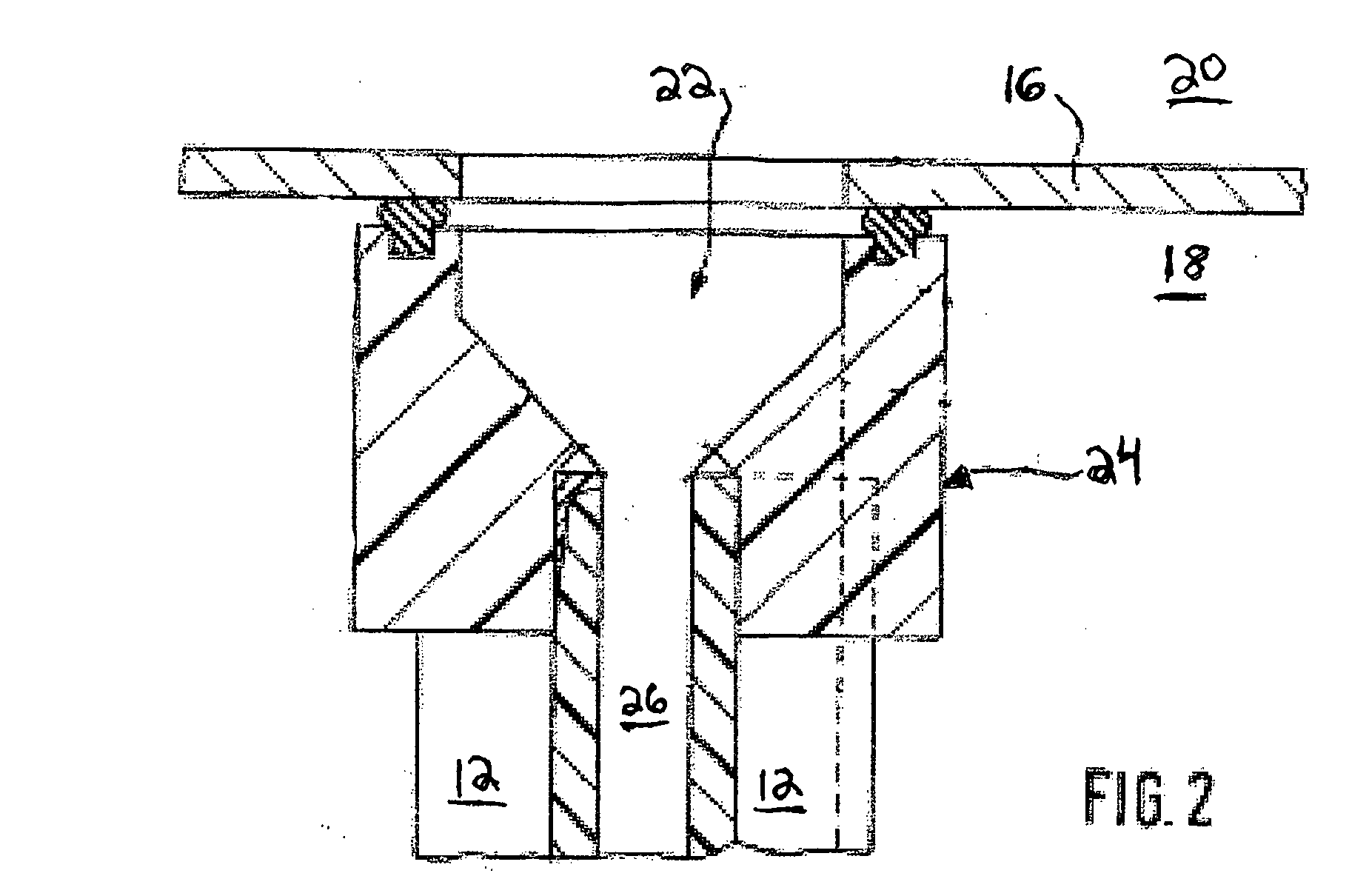

A thermally stable microporous breathable film is provided comprising at least 35% filler, by weight of the filled-film, and a thermoplastic polymer blend of a first polyethylene polymer and a second polyethylene polymer. The first polyethylene polymer comprises 30%-70% by weight of the polymer blend and can have a density between about 0.86 g / cm3 and 0.89 g / cm3 and the second polyethylene polymer can have a density between about 0.90 g / cm3 and 0.92 g / cm3. The filled-film can be uniaxially or biaxially oriented to form a microporous film and / or film laminate having good body conformance and which retains a high WVTR at 37° C. and above.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Film with improved self-adhesive properties

InactiveUS6261278B1Formed easily and efficientlyFilm/foil adhesivesAdhesive dressingsPolyvinyl polymerPolymer science

A film that comprises a mixture of a block copolymer and a polyethylene polymer. One embodiment of such a film is a film comprising a block copolymer selected from the group consisting of poly(styrene)-co-poly(ethylene-butylene)-co-poly(styrene) copolymer and poly(styrene)-co-poly(ethylene-butylene) copolymer, and a polyethylene polymer. The film exhibits improved self-adhesive properties and is suitable for use in a disposable absorbent product intended for the absorption of fluids such as body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Polyethylene Molding Powder and Porous Articles Made Therefrom

The present invention relates to a new molding powder comprising polyethylene polymer particles. The molecular weight of the polyethylene polymer is within the range of from about 600,000 g / mol to about 2,700,000 g / mol as determined by ASTM 4020. The average particle size of the particles of the polyethylene polymer is within the range of from about 5 microns to about 1000 microns and the polyethylene has a powder bulk density in the range of from about 0.10 to about 0.30 g / cc. Also disclosed is a process for molding a shape from a molding powder comprising the inventive polyethylene polymer particles, as well as porous articles made in accordance with the process. The articles have excellent porosity and good strength for porous and porous filtration applications.

Owner:TICONA LLC

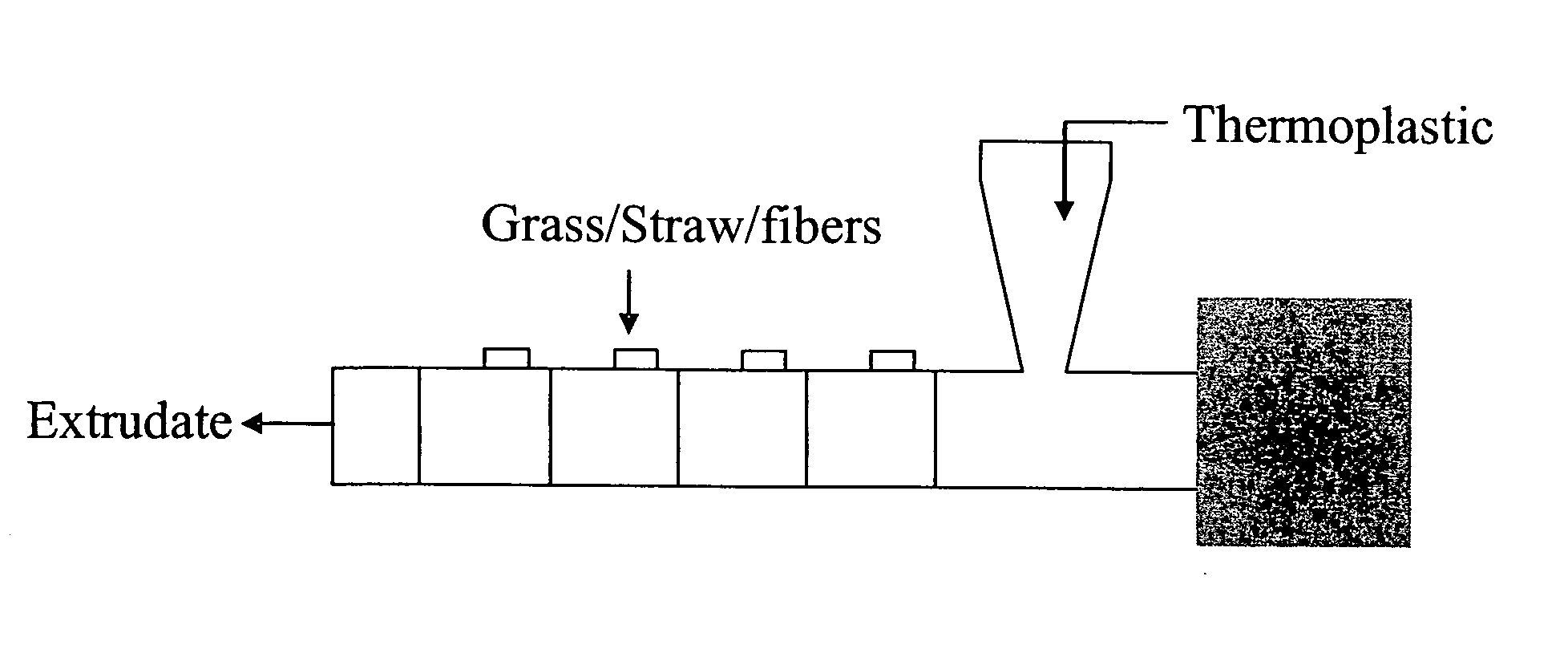

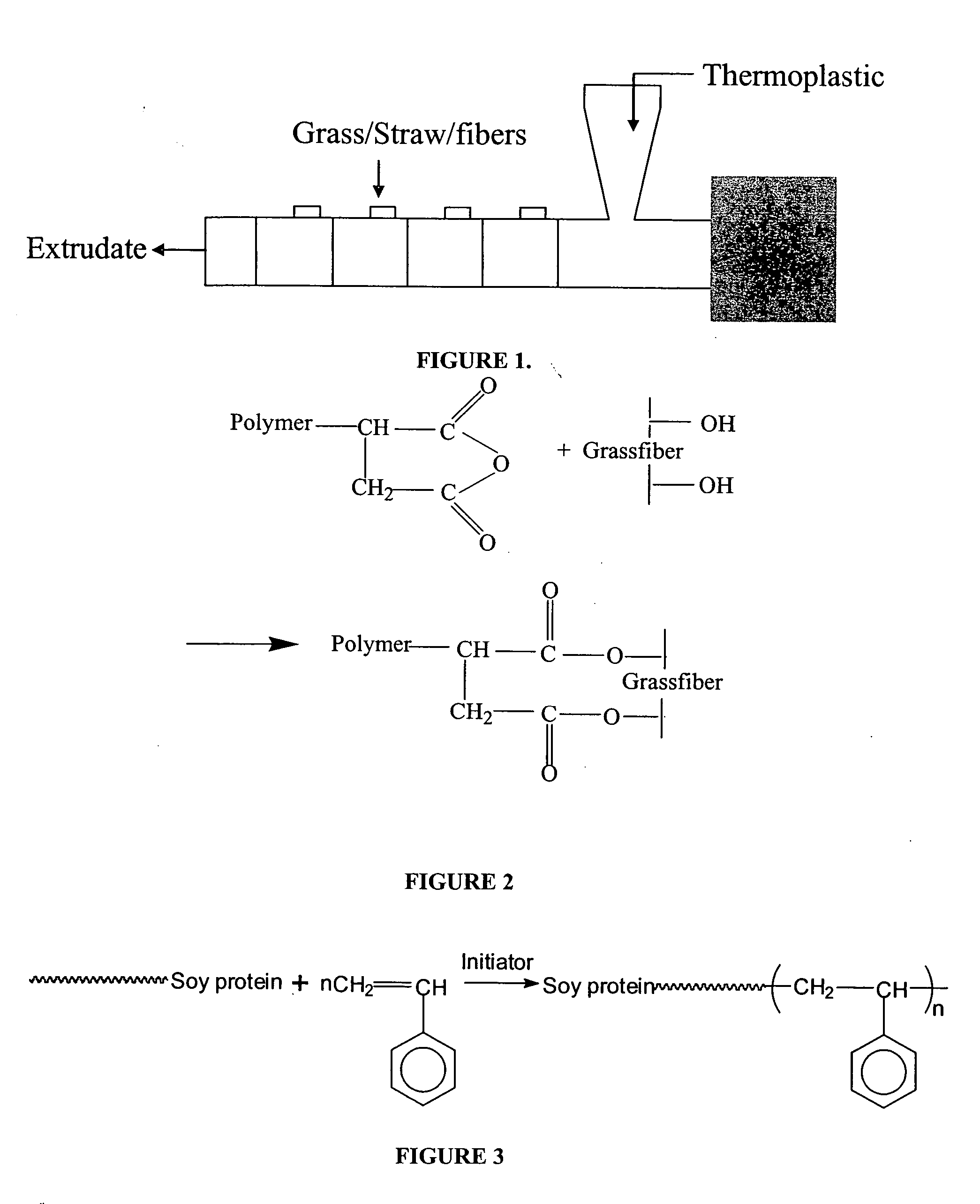

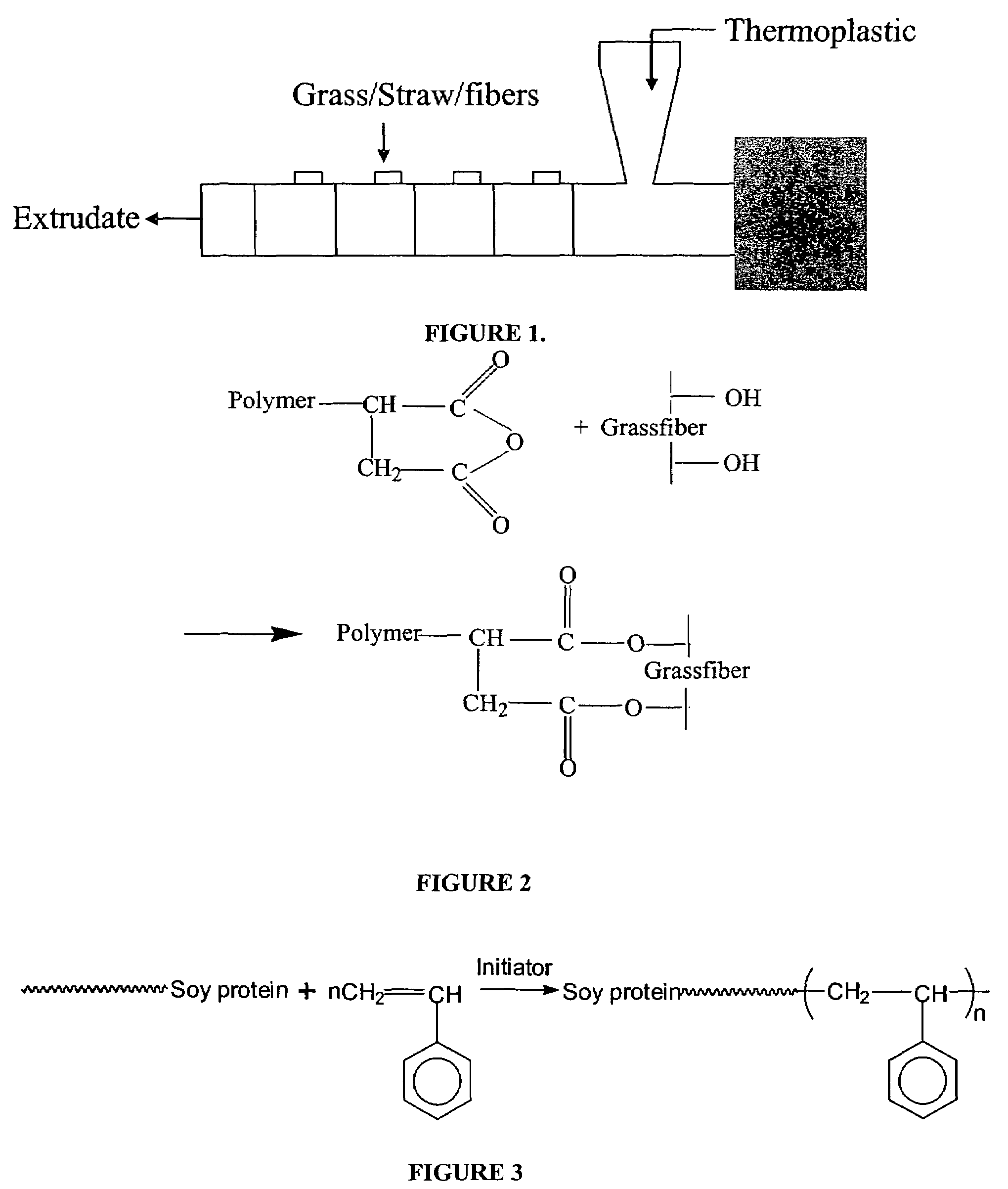

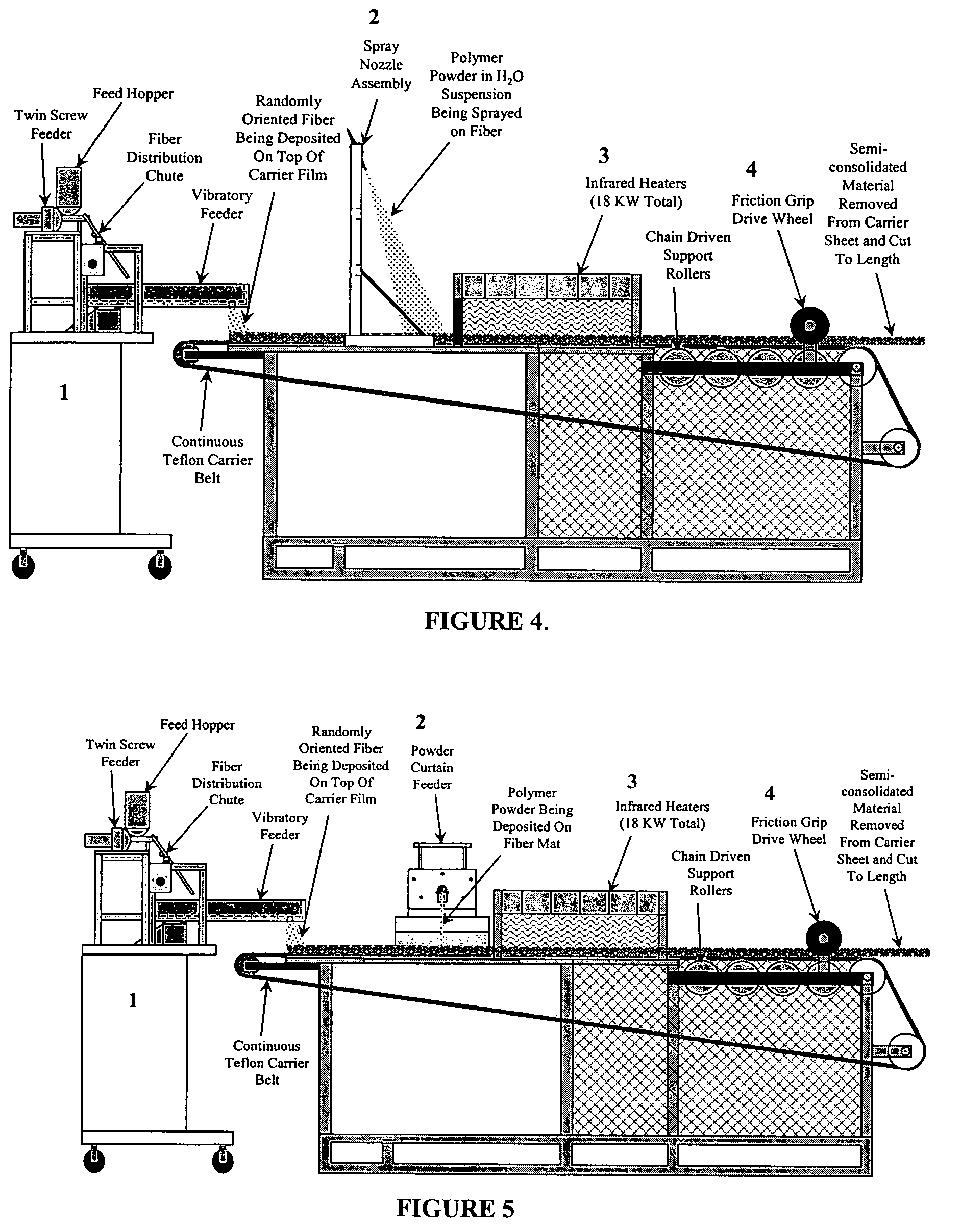

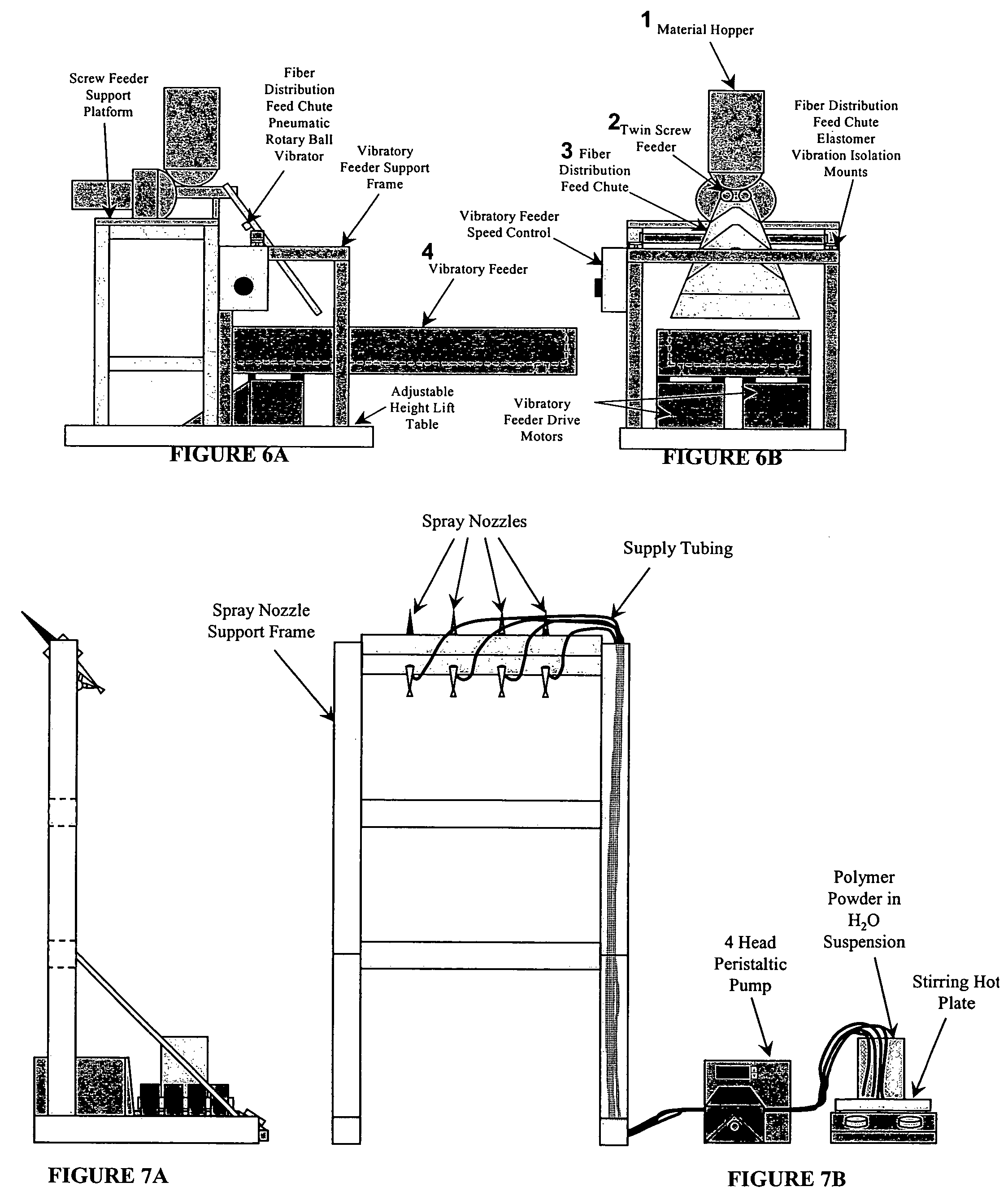

Cellulosic biomass soy flour based biocomposites and process for manufacturing thereof

A process for the manufacture of natural fiber and polymer composites is described. Thermoplastically processed plasticized soy flour based plastics are used with thermoplastic polymers. Polymers of soy flour and an in situ polymerized polyvinyl polymer which links proteins and carbohydrates in the flour to form the polymer are used. The composites are useful in engineering materials.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

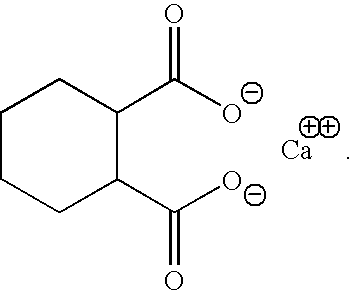

Polyolefin Based Hot Melt Containing a Solid Plasticizer

A hot melt adhesive that is composed of a metallocene catalyzed polyethylene polymer, a hydrogenated styrenic block copolymer, a tackifying resin, and a solid plasticizer. The preferred polyethylene polymer is an ethylene-octene copolymer, and the preferred styrenic block copolymer is a styrene-ethylene-butylene-styrene having less than 30% styrene content. The preferred solid plasticizer is either glycerol tribenzoate or 1,4-cyclohexane dimethanol dibenzoate.

Owner:BOSTIK INC

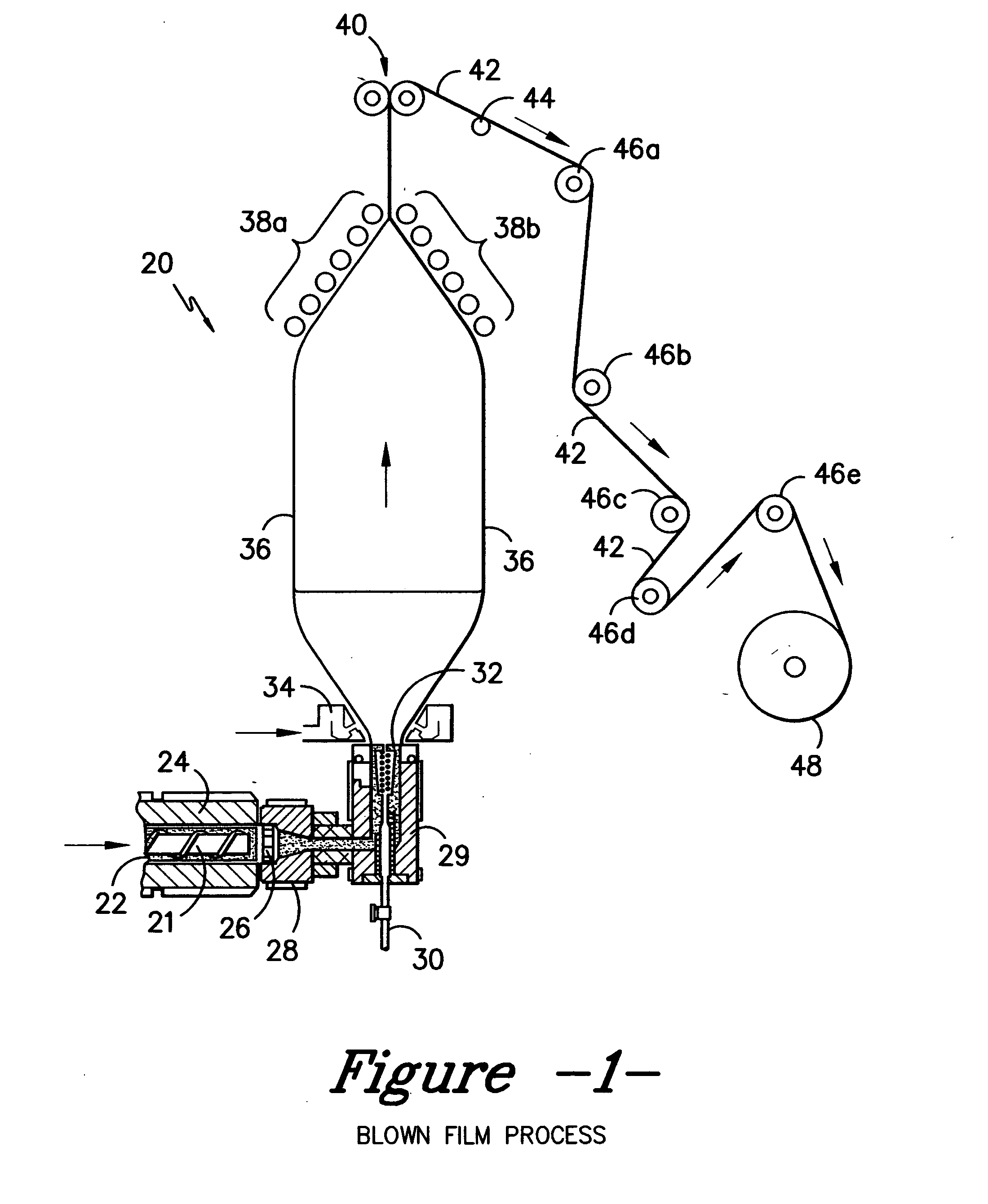

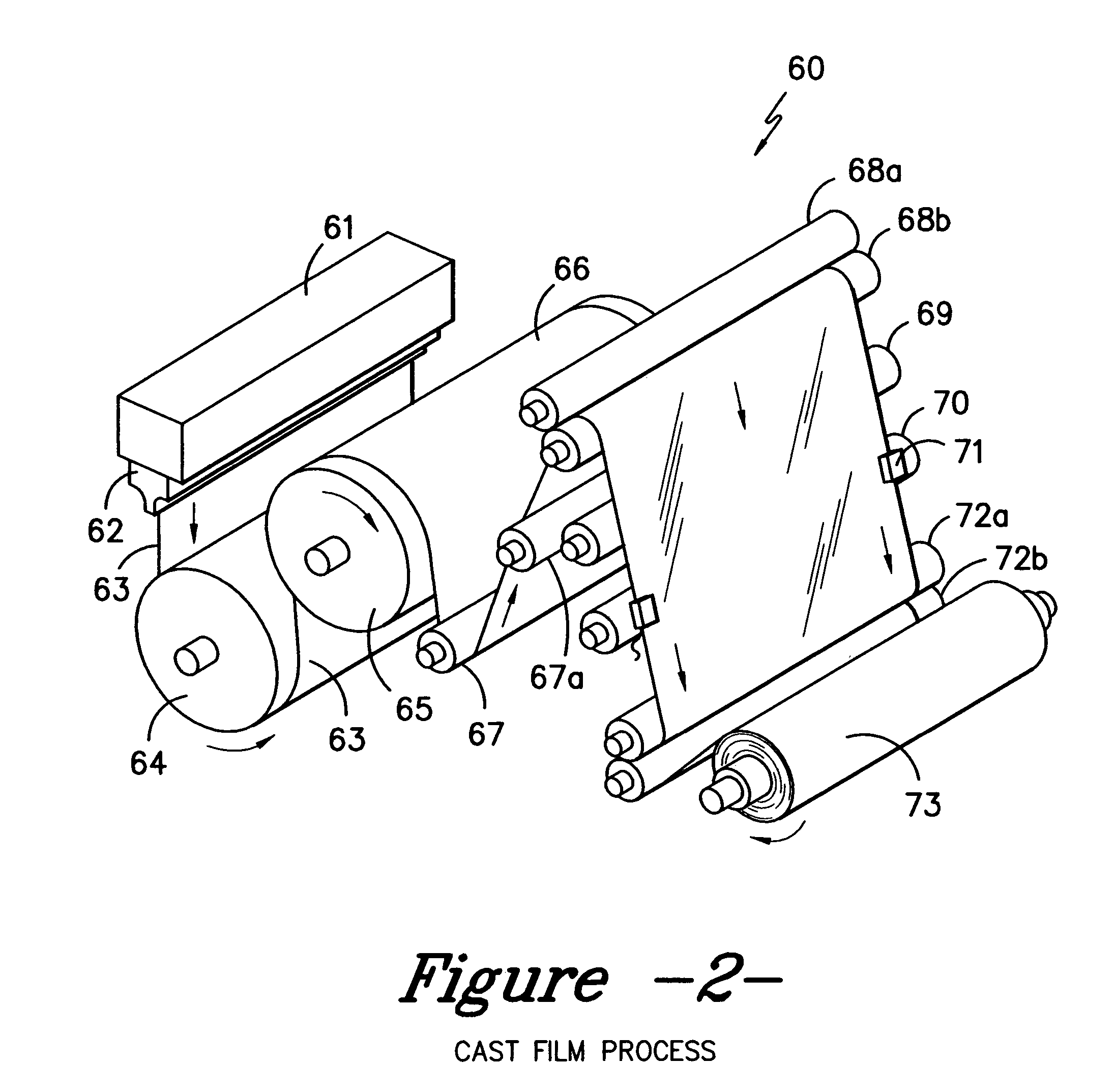

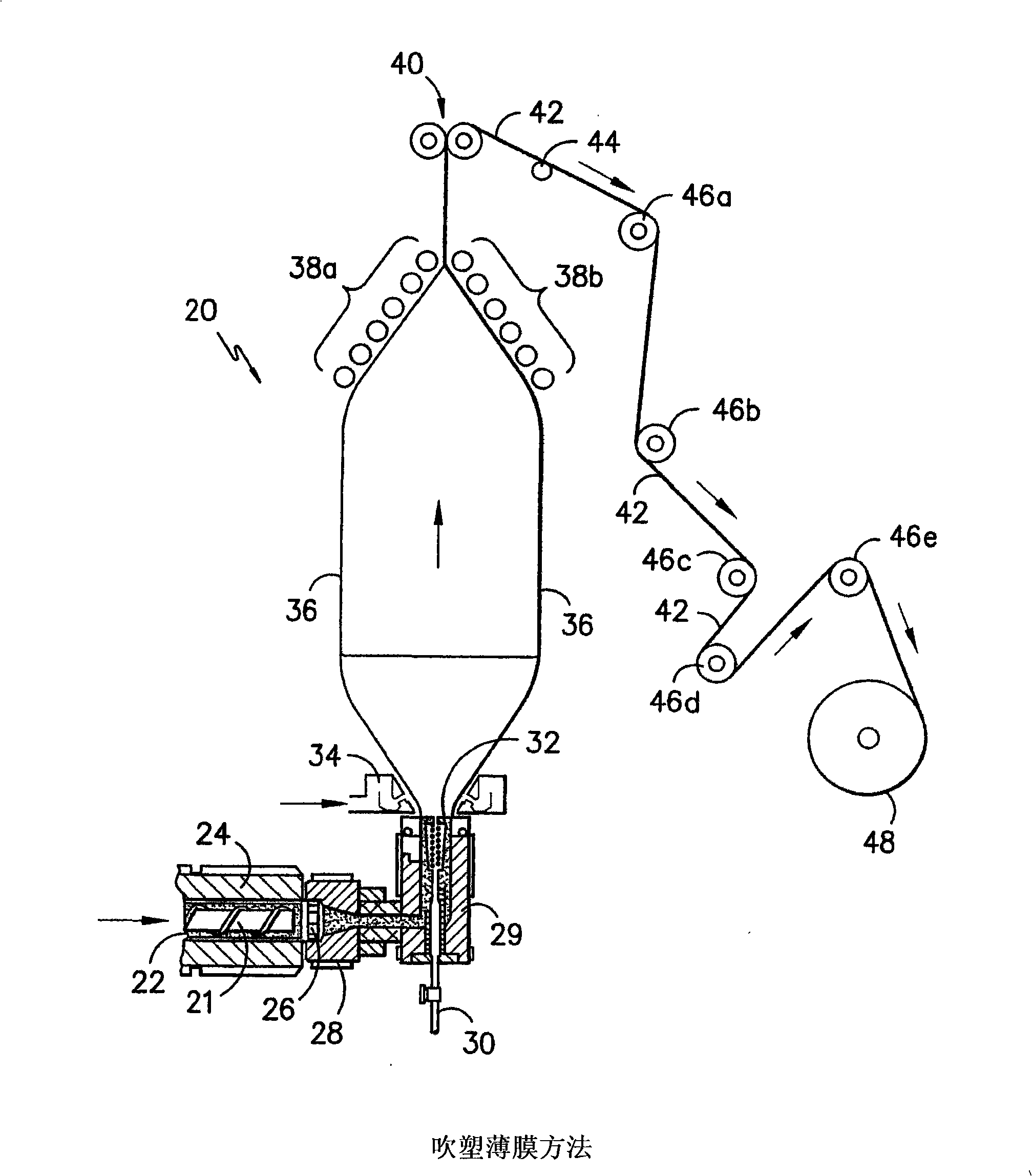

Film and methods of making film

A film article comprising a polyethylene polymer or copolymer and a cycloaliphatic metal salt is disclosed. A method of making a blown and a cast polyethylene film is shown. The film may also include various additives that are employed to improve the properties of the film, including stearate-containing compounds. Additives employed in one embodiment of the invention may reduce the percent haze of film formed in the process, thereby providing desirably low levels of haze. Zinc stearate is one additive that can be employed in making a low haze polyethylene film.

Owner:MILLIKEN & CO

Thermoplastic composition including polyethylene oxide

InactiveUS6110849AEasily and efficiently formed into fiberSynthetic resin layered productsAbsorbent padsPolyesterFiber

A thermoplastic composition that comprises a mixture of a polyethylene oxide polymer, a polyolefin polymer, a polyester polymer, and, optionally, a compatibilizer for the polymers. One embodiment of such a thermoplastic composition is a mixture of polyethylene oxide polymer, poly(lactic acid) polymer, and polyethylene polymer. The thermoplastic composition is capable of being extruded into fibers that may be formed into nonwoven structures that may be used in a disposable absorbent product intended for the absorption of fluids such as body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

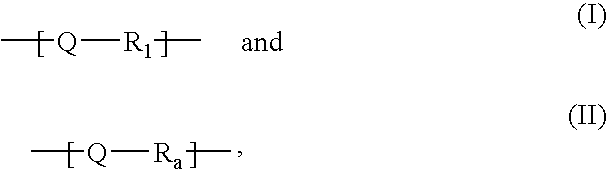

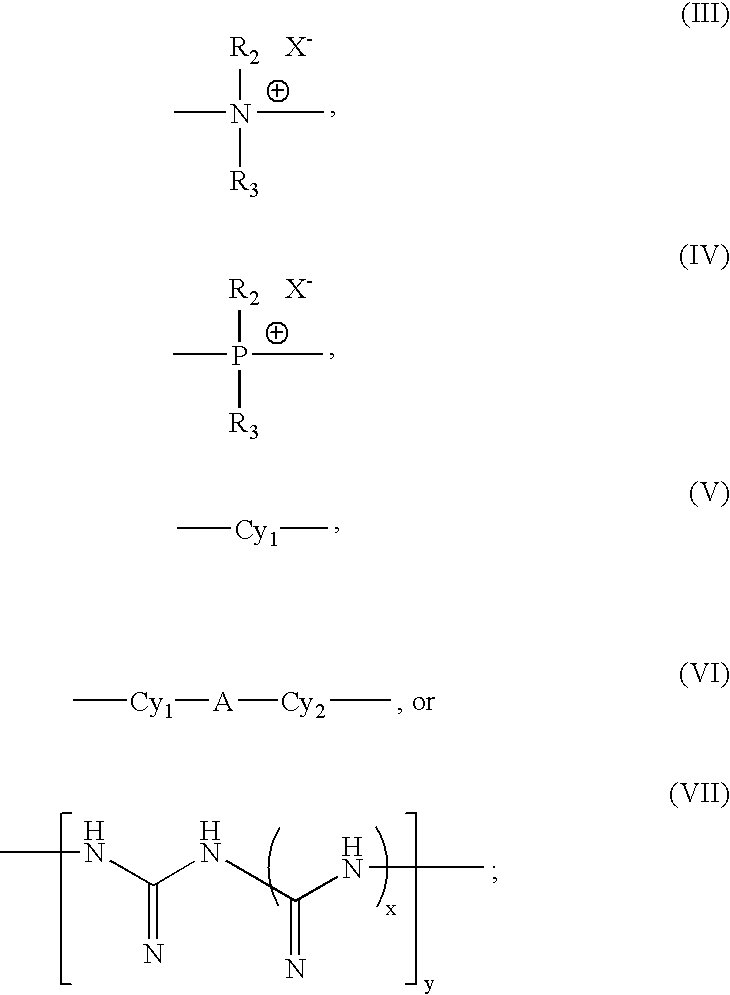

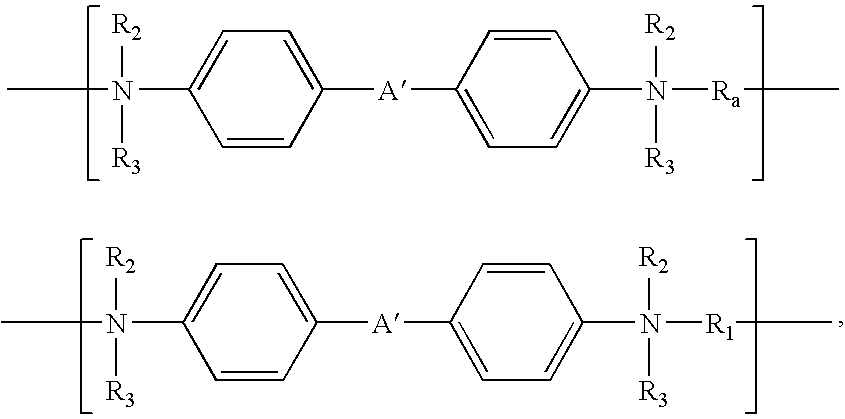

Polyionene polymers with hydrolyzable linkages

InactiveUS20060002889A1Synthetic polymeric active ingredientsCoatingsPolymer sciencePolyvinyl polymer

Ionene polymers are effective antipathogenic agents and can be used as a surface treatment or as a pharmaceutical agent. Ionene polymers typically are persistent in an environment because they degrade slowly, however, it is sometimes desirable to have a polymer that degrades over time. Ionene polymers that have one or more hydrolyzable groups in the polymer backbone represent a type of ionene polymer that degrades with time, and the size of the resulting polymer fragments can be controlled by the placement of the hydrolyzable groups.

Owner:GENZYME CORP

Silver polyamide composite

InactiveUS20100093851A1DegreeDegree of reductionBiocideAntifouling/underwater paintsPolyvinyl polymerBisulfide

A polymer composite comprising a thermoplastic polyamide polymer compounded with an organo-disulfide additive and a silver-based antimicrobial agent is disclosed. The organo-disulfide additive inhibits undesirable discoloration of the thermoplastic polyamide polymer including one or more silver-based antimicrobial agent. Processes for preparing the composite are also disclosed, including compounding the organo-disulfide additive in a polymeric carrier with the silver-based antimicrobial agent, then with the thermoplastic polyamide polymer, or compounding the organo-disulfide additive with the thermoplastic polyamide polymer before adding the silver-based antimicrobial agent.

Owner:EASTMAN KODAK CO

Water-based polyurethane-polyethylene compositions

The present invention provides water dispersible polyurethane-polyethylene compositions (or dispersions) having a sulfonated polyurethane polymer and a polyethylene polymer (second polymer). The polyurethane polymer is a reaction product of a polyisocyanate, and a sulfonated polyol.

Owner:VALSPAR SOURCING INC

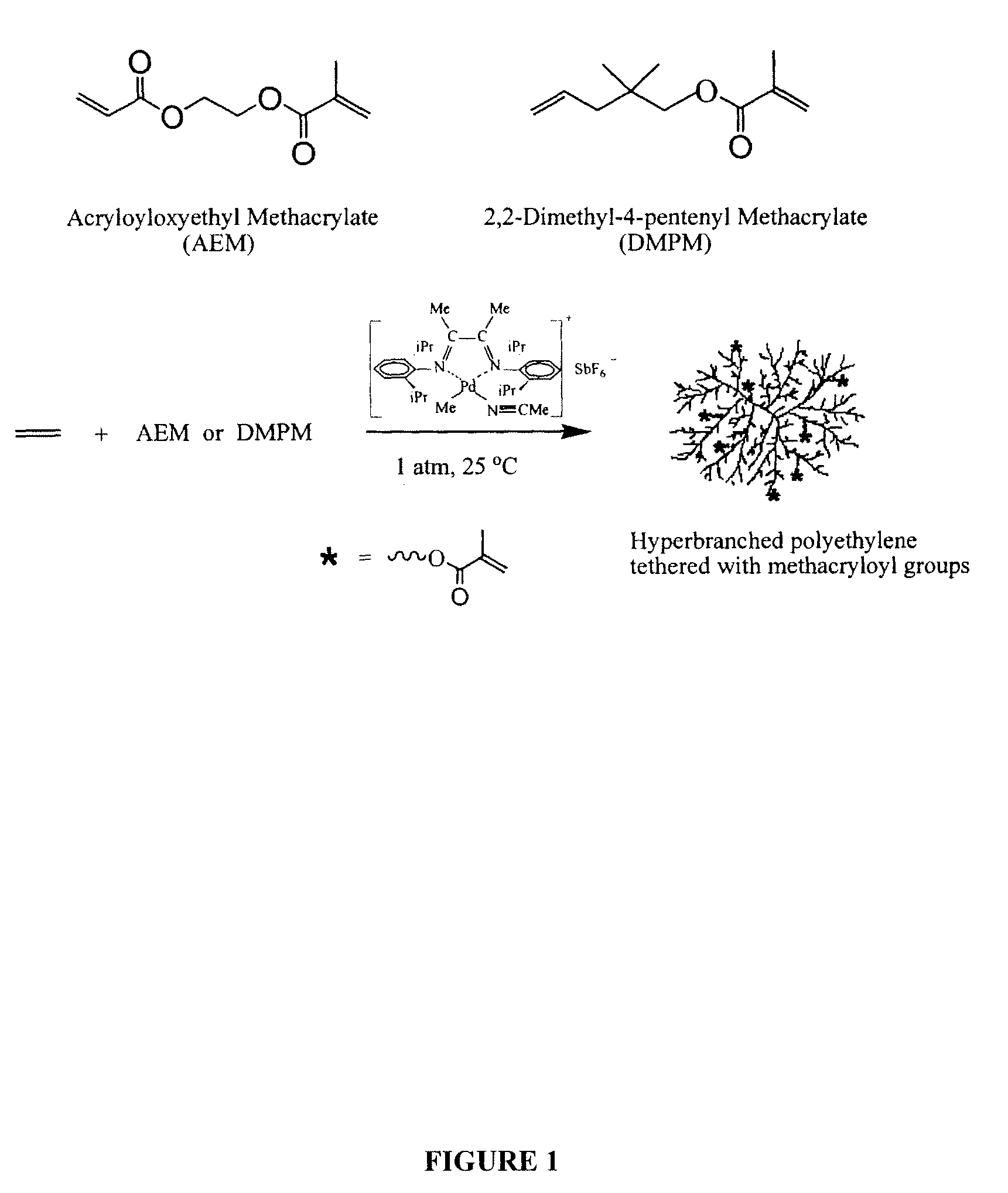

Branched polyolefin polymer tethered with polymerizable methacryloyl groups and process for preparing same

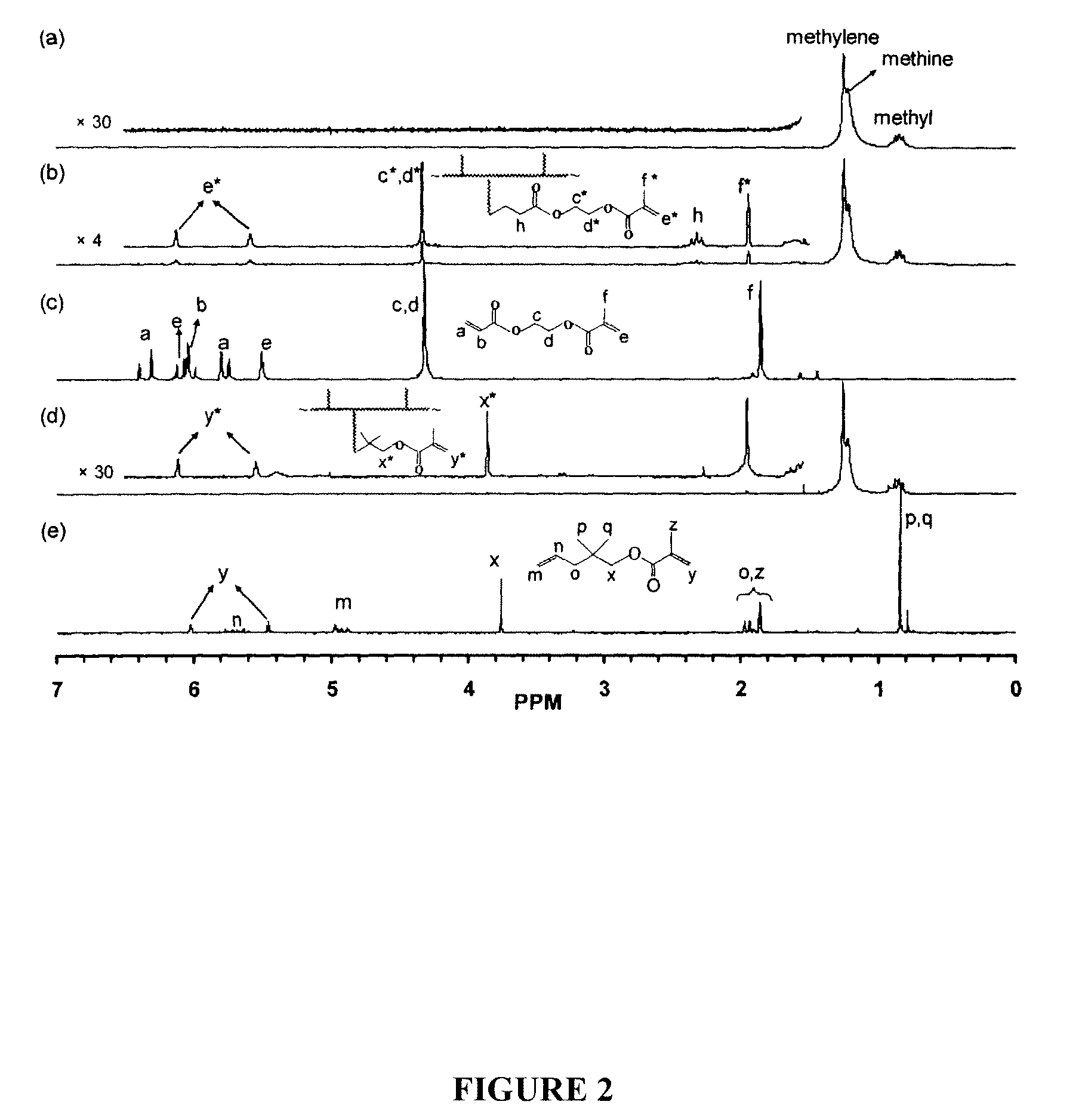

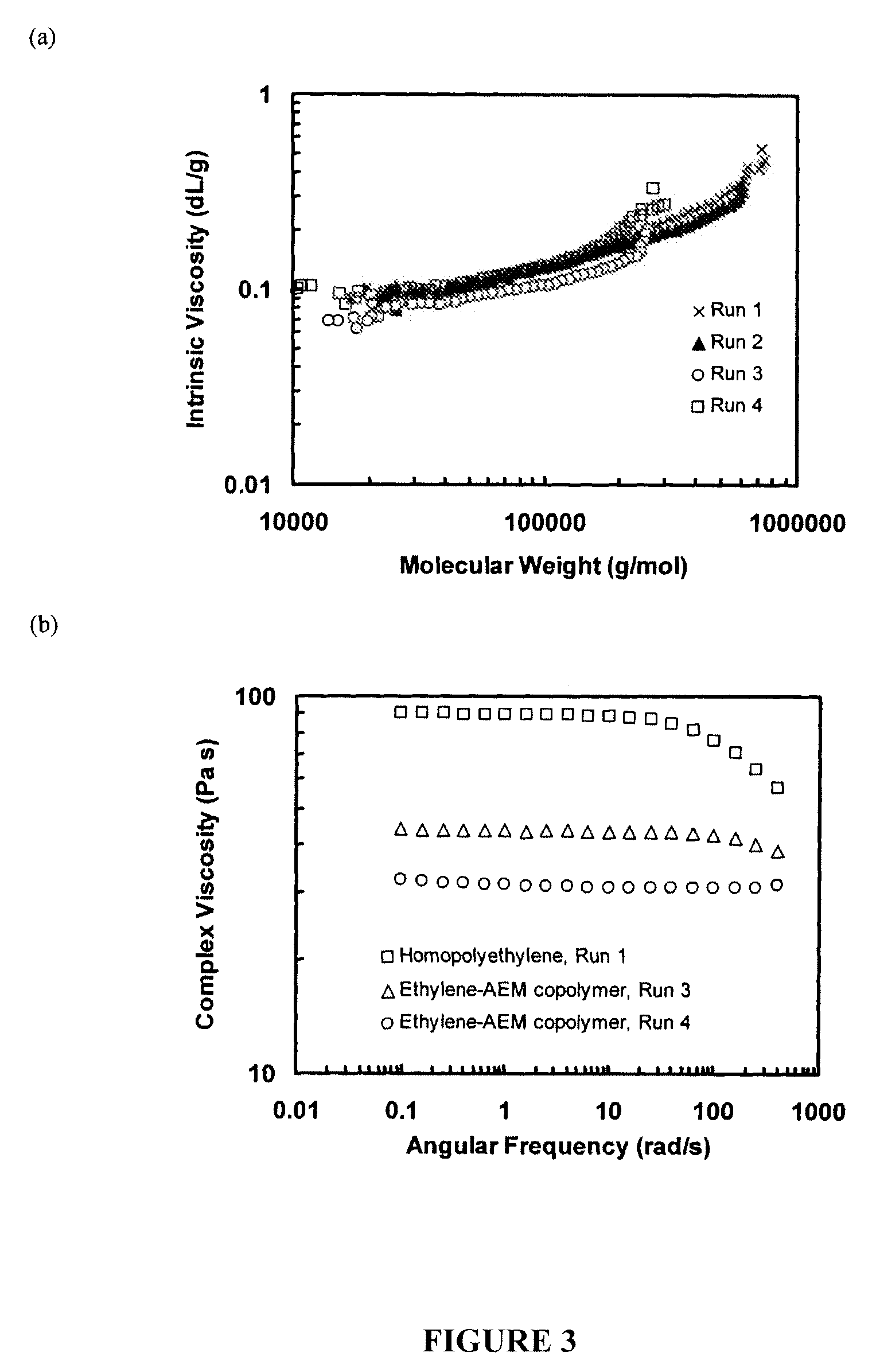

InactiveUS20090253878A1Readily scaled up to industrial scaleSimple and efficientPolyolefinPolyvinyl polymer

A polyolefin polymer comprising one or more terminal polymerizable methacryloyl groups (i.e. tethered to the main body of the polymer) and a novel process for preparing same are herein disclosed. A hyperbranched polyethylene polymer and a process for preparing same are also disclosed. The polymer is prepared by a novel one-pot copolymerization reaction of an olefin, such as ethylene, and a heterobifunctional comonomer comprising a methacryloyl group, catalyzed by a late transition metal α-diimine catalyst which is selectively non-reactive towards methacryloyl groups. The process allows for preparation of polymers with various chain topologies, including linear, branched, and hyperbranched topologies. The terminal methacryloyl groups within the polymer are reactive in further polymerization reactions. Thus, the polymer may be used in materials and applications which require cross-linking or further polymerization, for example, UV / thermal / radical curable crosslinkers for use in thermoset applications.

Owner:YE ZHIBIN +2

Polymer molding compositions

The invention relates to formulated compositions which can be easily formed into bottle caps, without the need for a liner, while still maintaining pressure requirements, such as for carbonated beverages. The compositions may include an ethylene polymer having a density in the range of from about 0.947 to 0.962 g / cm3, a melt index of from about 1 to about 10 g / 10 min., and another ethylene polymer having a density in the range of from about 0.912 to 0.932 g / cm3, a melt index of from about 0.25 to about 6 g / 10 min., wherein the two ethylene polymers have a density difference of equal to or greater than 0.03 g / cm3. In other cases, the composition may include a single component resin with a density in the 0.935-0.955 g / cm3 range with a melt index in the range of 0.3-1.2 g / 10 minutes, and wherein the resin comprises a polyethylene polymer.

Owner:DOW GLOBAL TECH LLC

Multimodal polyethylene for use in single piece beverage bottle caps and closures

The present invention relates to single piece beverage bottle caps containing and / or made from polyethylene polymers, polymer blends, and / or resins. These polymers / blends / resins have a multimodal molecular weight distribution, sufficient physico-chemical characteristics, and superior environmental stress cracking resistance, so as to be ideally suited for articles and applications such as caps and closures.

Owner:EXXONMOBIL CHEM PAT INC

Polymer molding compositions

The invention relates to formulated compositions which can be easily formed into bottle caps, without the need for a liner, while still maintaining pressure requirements, such as for carbonated beverages. The compositions may include an ethylene polymer having a density in the range of from about 0.947 to 0.962 g / cm3, a melt index of from about 1 to about 10 g / 10 min., and another ethylene polymer having a density in the range of from about 0.912 to 0.932 g / cm3, a melt index of from about 0.25 to about 6 g / 10 min., wherein the two ethylene polymers have a density difference of equal to or greater than 0.03 g / cm3. In other cases, the composition may include a single component resin with a density in the 0.935-0.955 g / cm3 range with a melt index in the range of 0.3-1.2 g / 10 minutes, and wherein the resin comprises a polyethylene polymer.

Owner:DOW GLOBAL TECH LLC

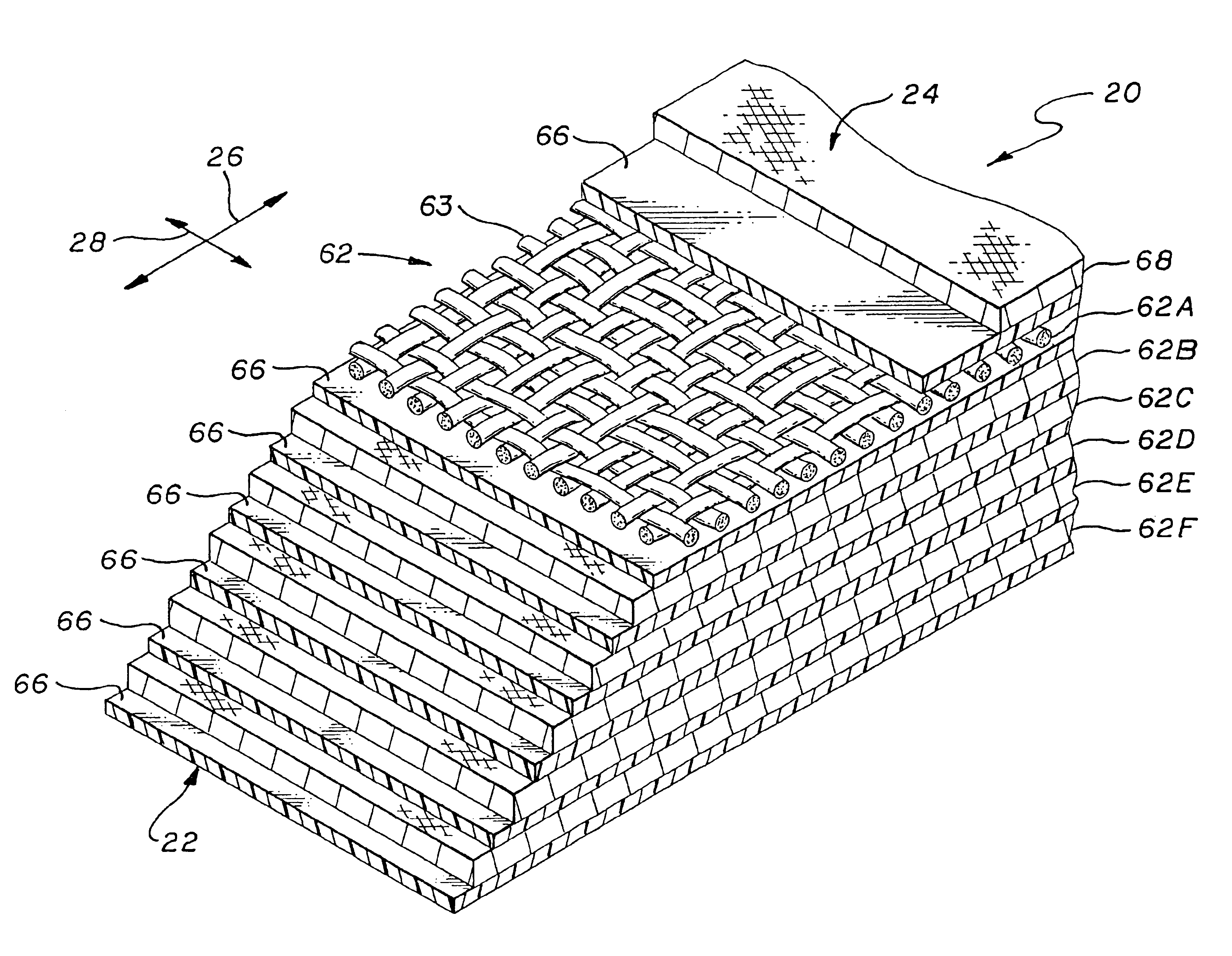

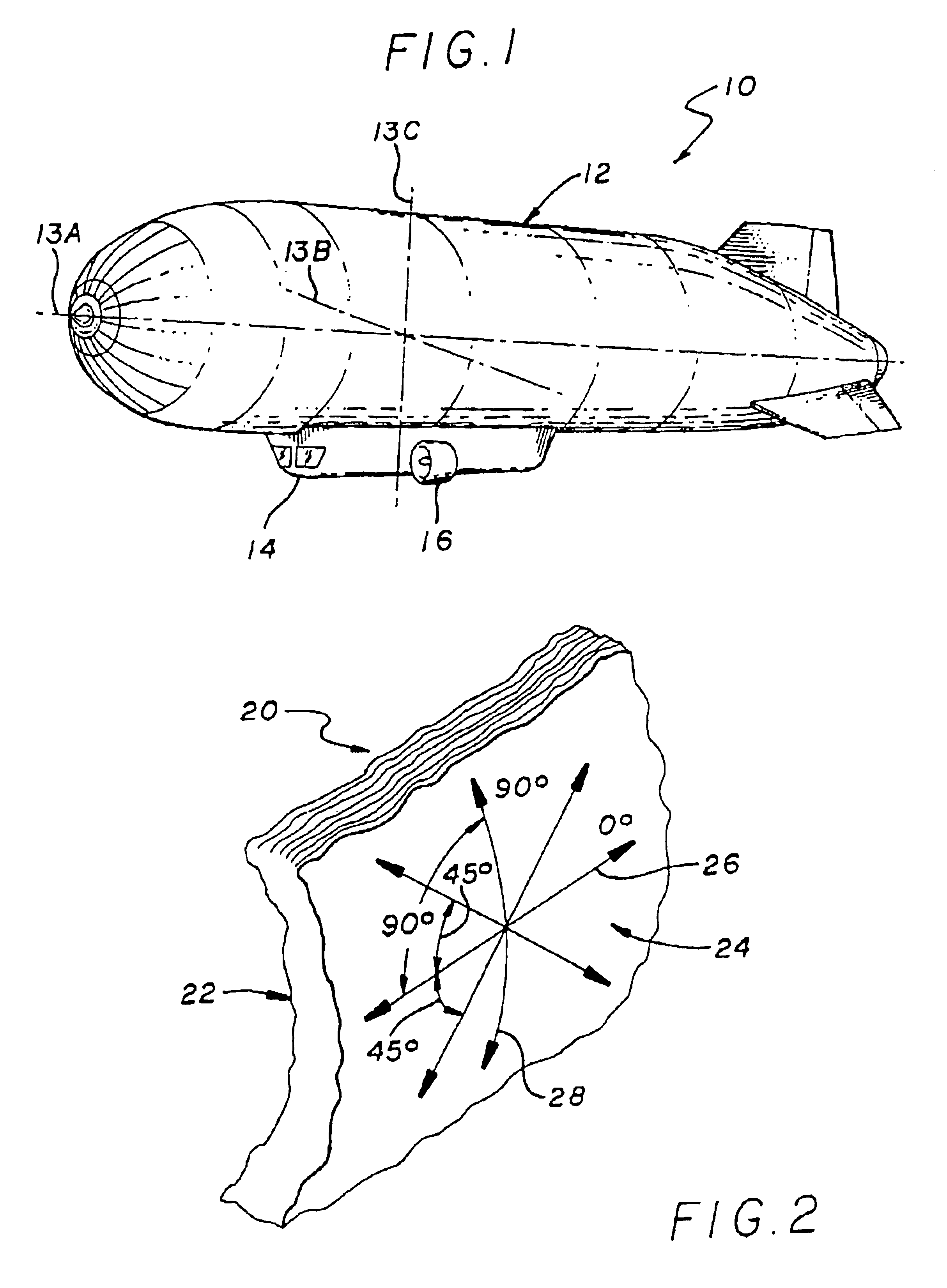

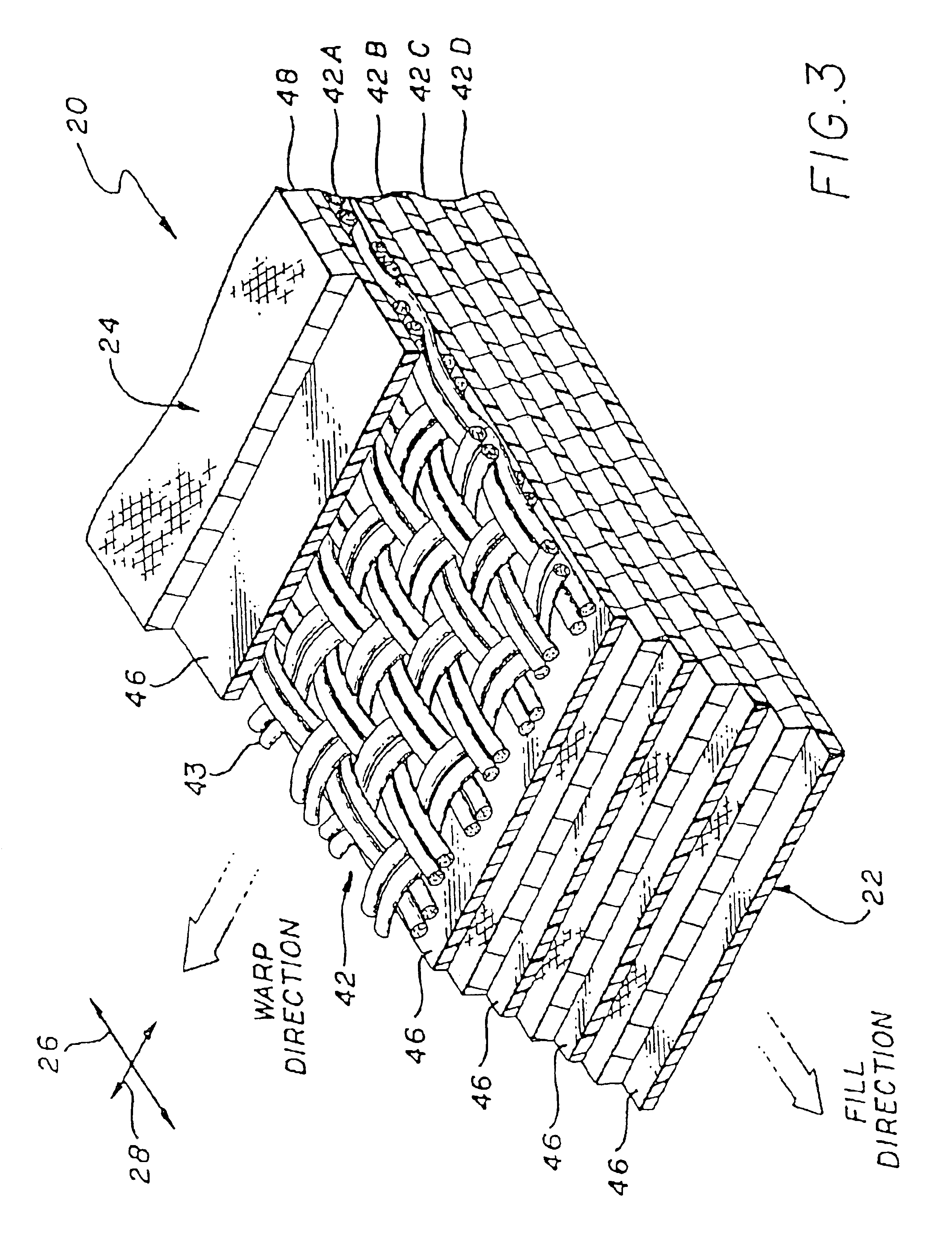

Flexible wall material for use in an inflatable structure

This invention relates to airships, with a volume of 15 to 60 million cubic feet of Helium. More particularly, it relates to improved structural envelope / gas bags or outer covers for lighter-than-air and neutral buoyancy airships. In detail, the material is a multi-layer cloth assembly including at least two plies of fiber cloth, said cloth comprising 56 by 56 yarns / inch with a total weight of 150 to 450 g / m2, with the fiber of the individual cloth layers having a denier generally between 180 and 280 and with the fill of the individual plies at 90 degrees to each other. Preferably, the filaments should be between 200 and 215 denier. The fibers of each layer of cloth are selected from the group consisting of extended chain polyethylene polymer or a thermotropic liquid (melt spun) crystalline polymer. The extended chain polyethylene fiber is a woven modified rip stop weave architecture, while the thermotropic liquid (melt spun) crystalline polymer fiber is a 2×2 basket weave architecture.

Owner:LOCKHEED MARTIN CORP

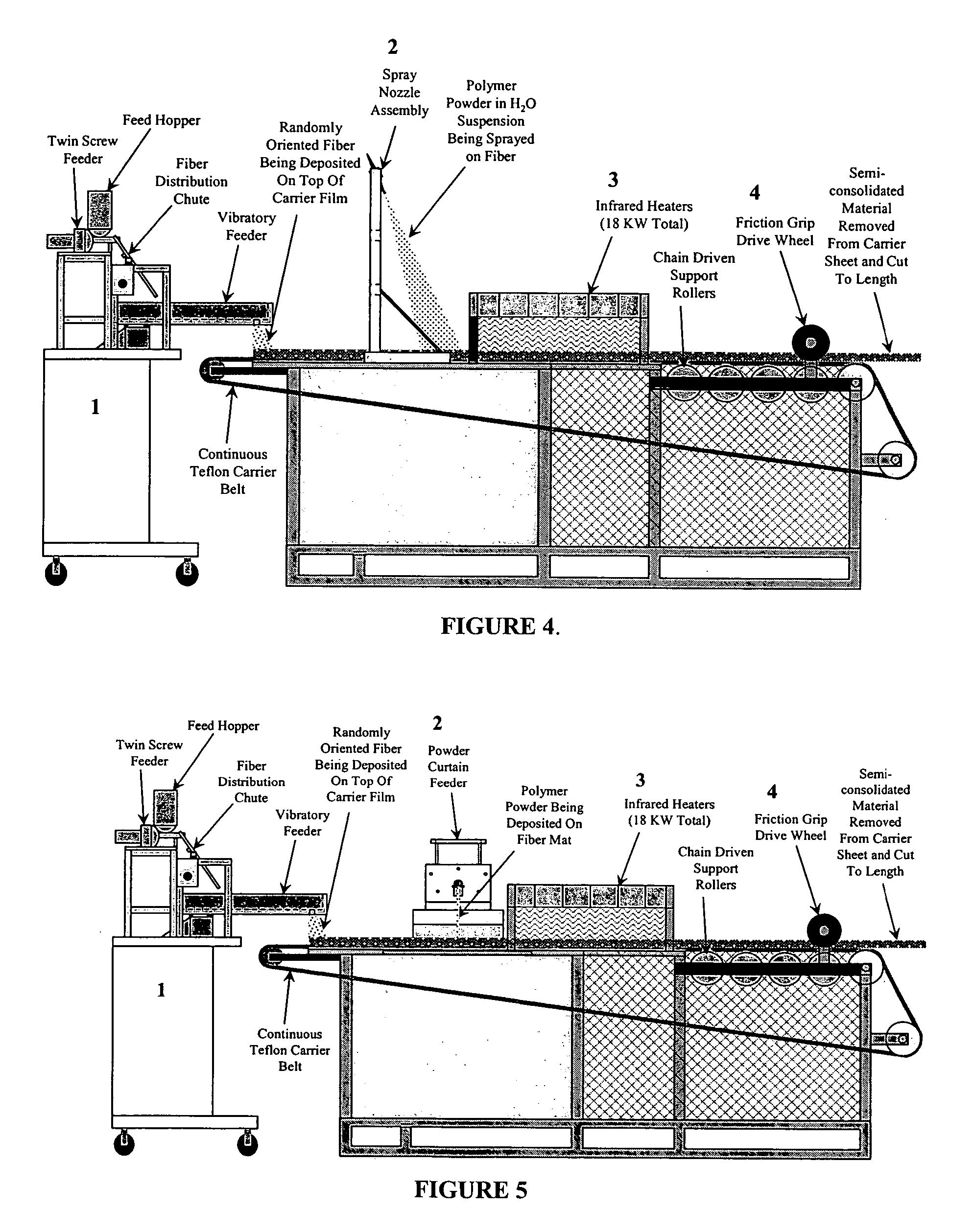

Cellulosic biomass soy flour based biocomposites and process for manufacturing thereof

A process for the manufacture of natural fiber and polymer composites is described. Thermoplastically processed plasticized soy flour based plastics are used with thermoplastic polymers. Polymers of soy flour and an in situ polymerized polyvinyl polymer which links proteins and carbohydrates in the flour to form the polymer are used. The composites are useful in engineering materials.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

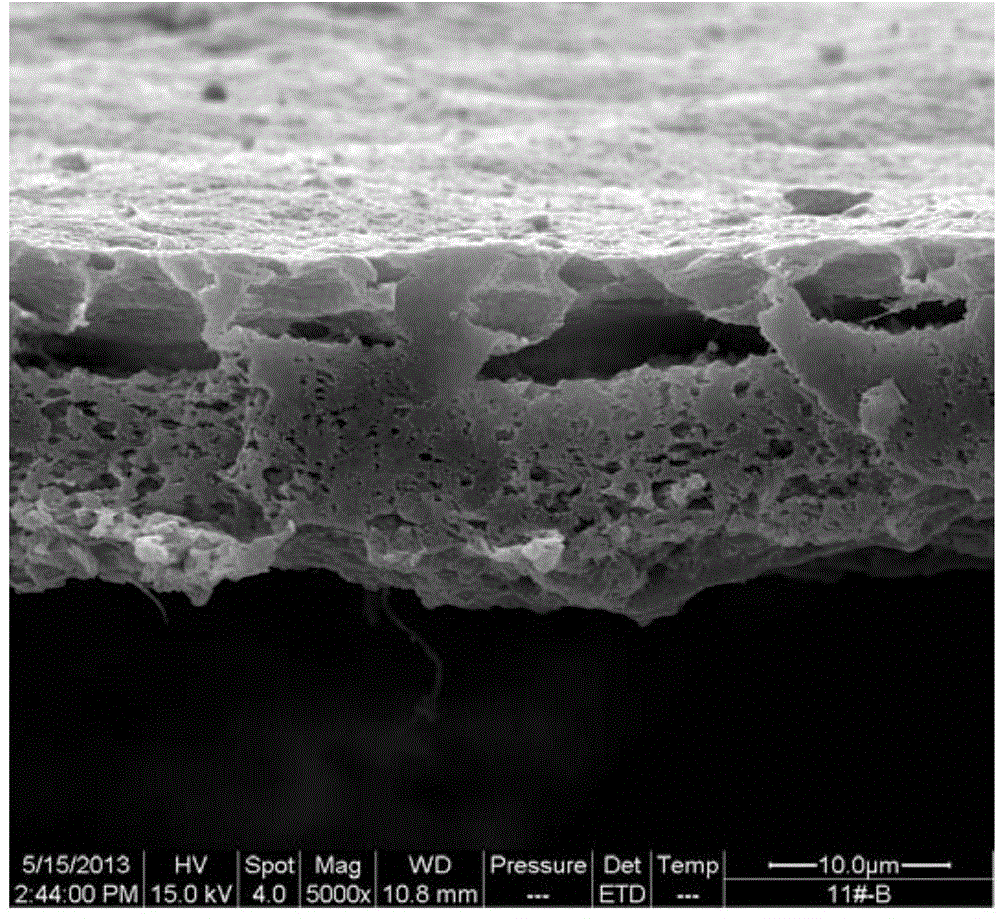

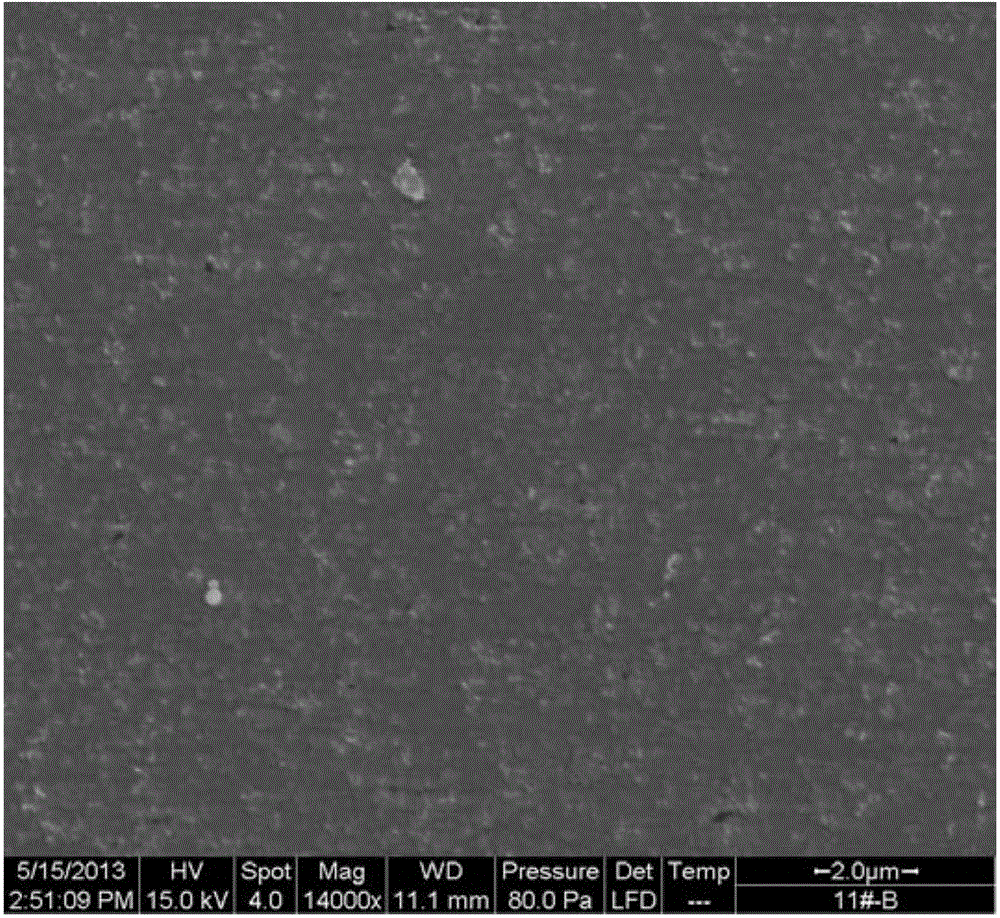

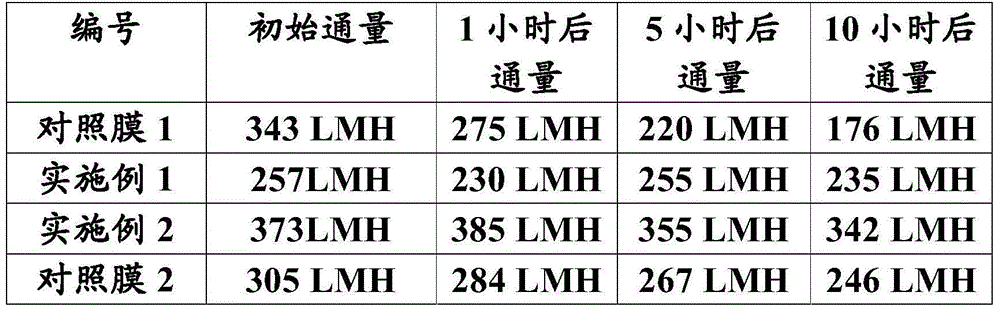

Ultrafiltration membrane and preparation method thereof

ActiveCN103551054AFully hydrolyzedReduce production processSemi-permeable membranesCellulosePolyester

The invention relates to a cross-linking cellulose ultrafiltration membrane and a preparation method thereof. The cross-linking cellulose ultrafiltration membrane comprises a non-woven fabric layer and a cross-linking cellulose layer, wherein the non-woven fabric is selected from a polyester non-woven fabric, a polypropylene non-woven fabric, a polyethylene non-woven fabric and a polypropylene and polyethylene polymer non-woven fabric; the cross-linking cellulose is a product obtained by crosslinking and polymerizing glutaric dialdehyde, cellulose and polyvinyl alcohol. According to the invention, the hydroxy hydrolyzed from cellulose ester and the polyvinyl alcohol are crosslinked by adopting a cross-linking technology and utilizing the characteristics of the cellulose and the polyvinyl alcohol. The process disclosed by the invention is simple in production process, and shortens the production time and reduces the production cost by integrating a cross-linking process and a membrane drying process, thereby realizing the enhancement of alkali resistance property.

Owner:中科瑞阳膜技术(北京)有限公司

Metallocene-produced bery low density polyethylenes or linear low density polyethylenes as impact modifiers

InactiveUS20040152842A1Flexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

In one embodiment, the present invention is directed to an article, such as a blow-molded bottle, formed from a polymer blend composition. In one aspect, the article is formed by blow-molding techniques. In one aspect, the article is a blow-molded container having a Bruceton Mean Drop Height of 3.8 feet or above. In another aspect, the article is a blow-molded container having a volume of 60 fluid ounces or greater. In general, the polymer blend composition comprises polypropylene and an impact modifier of metallocene-produced very low density polyethylene or linear low density polyethylene. In one embodiment, the polypropylene polymer comprises a random copolymer. In one embodiment the metallocene-catalyzed linear very low density polyethylene polymer has one or more of the following: (a) a density of less than 0.916 g / cm<3>, (b) a composition distribution breadth index of 50 to 85% by weight, (c) a molecular weight distribution Mw / Mn of 2.0 to 3.0, (d) a molecular weight distribution Mz / Mw of less than 2.0, and (e) two peaks in a TREF measurement. In one embodiment, the polymer blend composition comprises 5% to 85% of the impact modifier and 95% to 15% of the polypropylene polymer, based on the total combined weight of the polypropylene polymer and the impact modifier. In another embodiment, the polymer blend composition comprises 5% to 35% of the impact modifier and 95% to 65% of the polypropylene polymer, based on the total combined weight of the polypropylene polymer and the impact modifier.

Owner:EXXONMOBIL CHEM PAT INC

Film and method of making film

A film article comprising a polyethylene polymer or copolymer and a cycloaliphatic metal salt is disclosed. A method of making a blown and a cast polyethylene film is shown. The film may also include various additives that are employed to improve the properties of the film, including stearate-containing compounds. Additives employed in one embodiment of the invention may reduce the percent haze of film formed in the process, thereby providing desirably low levels of haze. Zinc stearate is one additive that can be employed in making a low haze polyethylene film.

Owner:MILLIKEN & CO

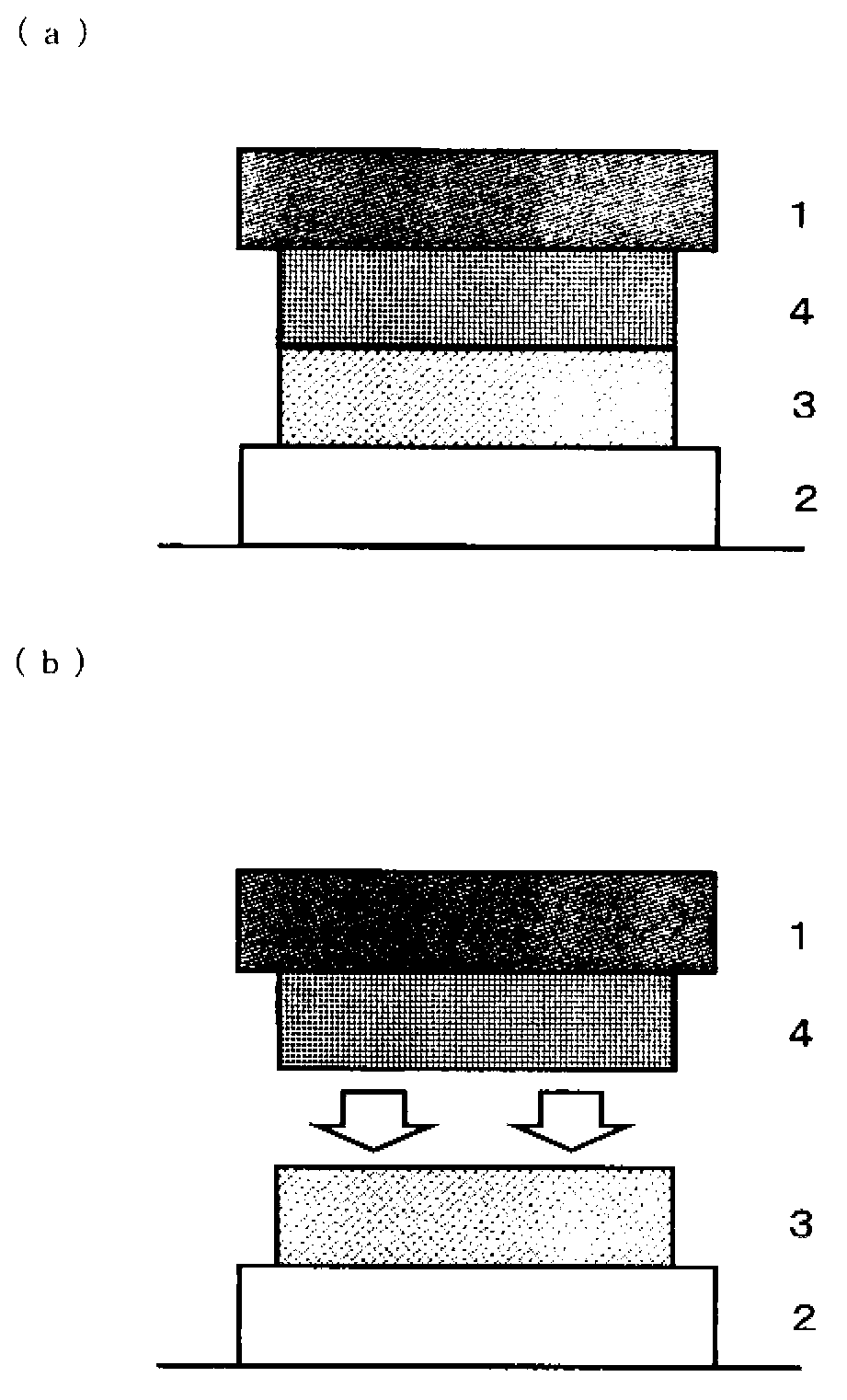

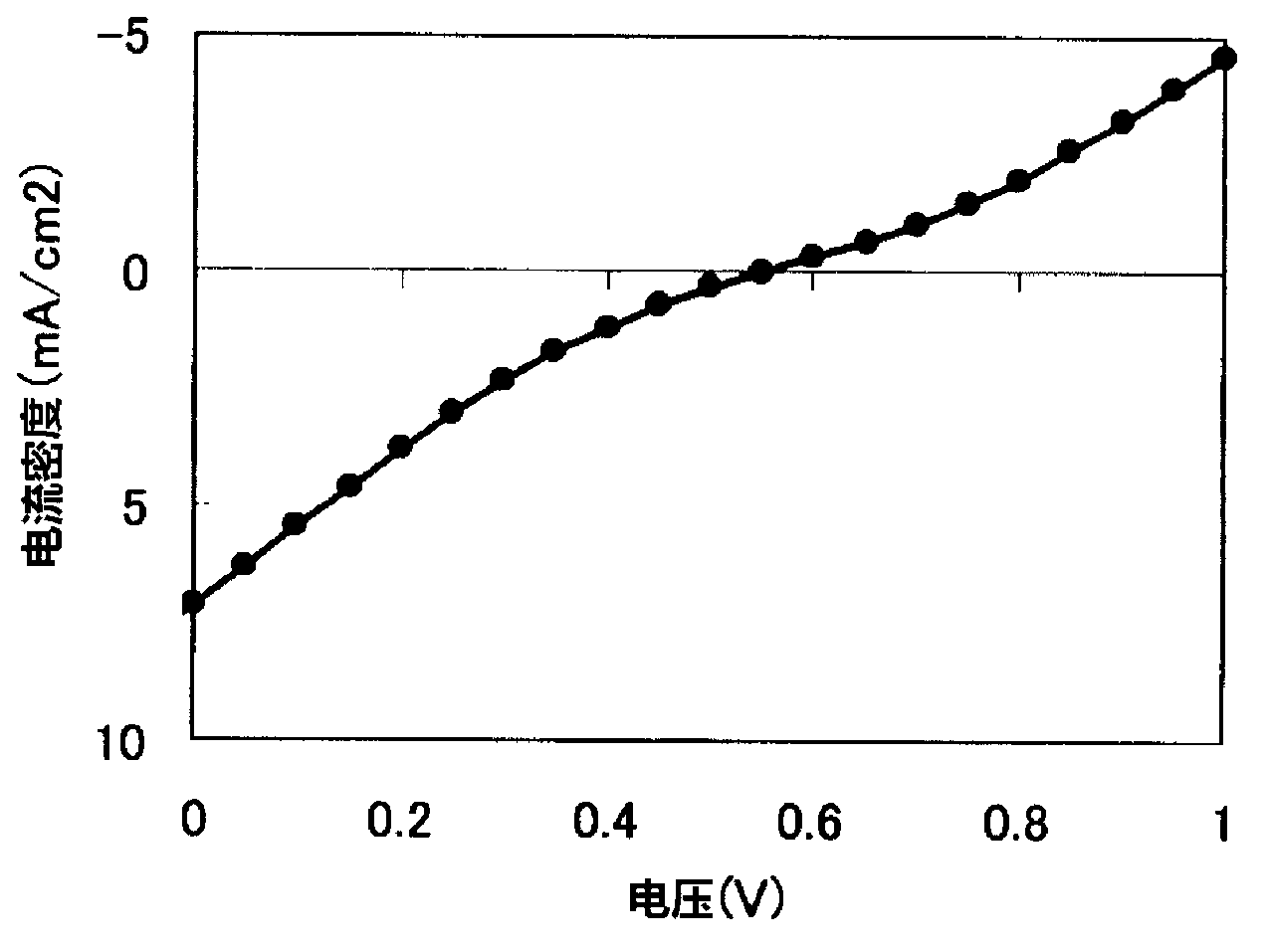

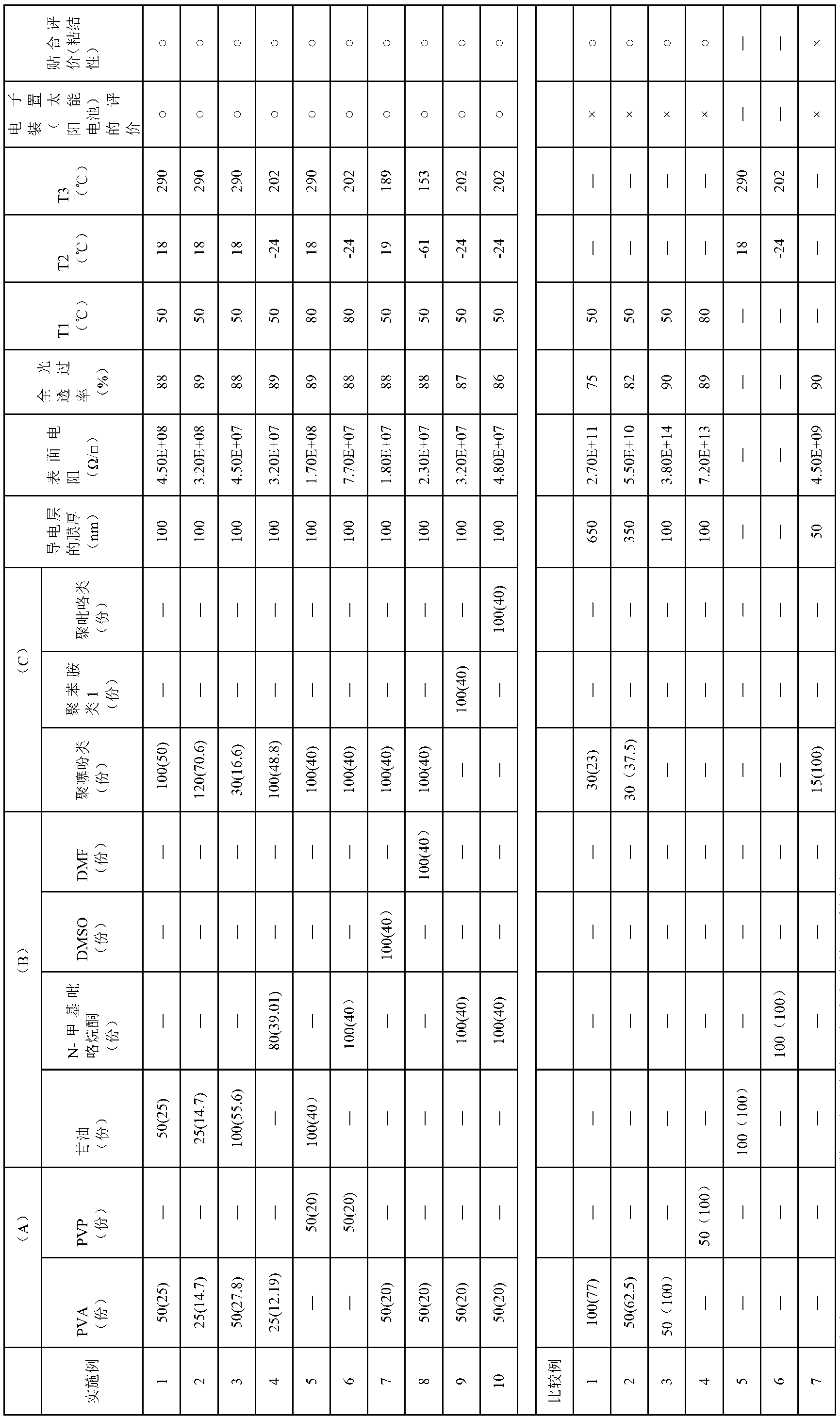

Conductive adhesive composition, electronic device, positive electrode laminate, and method for manufacturing electronic device

ActiveCN103189463AHigh transparencyReduce surface resistanceNon-macromolecular adhesive additivesFinal product manufactureSimple Organic CompoundsAlcohol

The present invention provides a conductive adhesive composition that has superior adhesive properties and low surface resistance and is capable of use as a buffer layer foran electronic device. This conductive adhesive composition contains a water-soluble polyvinyl polymer (A), organic additive (B), and conductive high molecular weight organic compound (C). The organic additive (B) is at least one selected from water-soluble polyhydric alcohols, water-soluble pyrrolidones, or hydrophilic aprotic solvents. The conductive high molecular weight organic compound (C) is at least one selected from polyanilines, polypyrroles, or polythiophenes as well as derivatives thereof. Furthermore, the present invention provides an electronic device having a conductive layer formed from this conductive adhesive composition, a positive electrode laminate in which a conductive layer formed from this conductive adhesive composition is laminated, and a method for manufacturing this electronic device.

Owner:LINTEC CORP

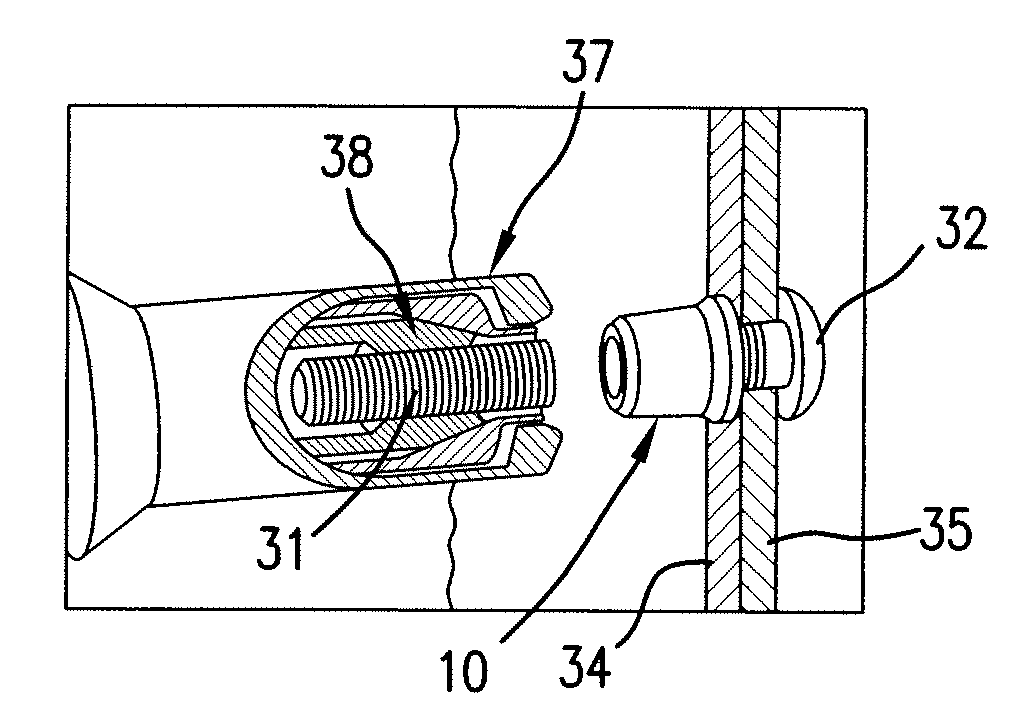

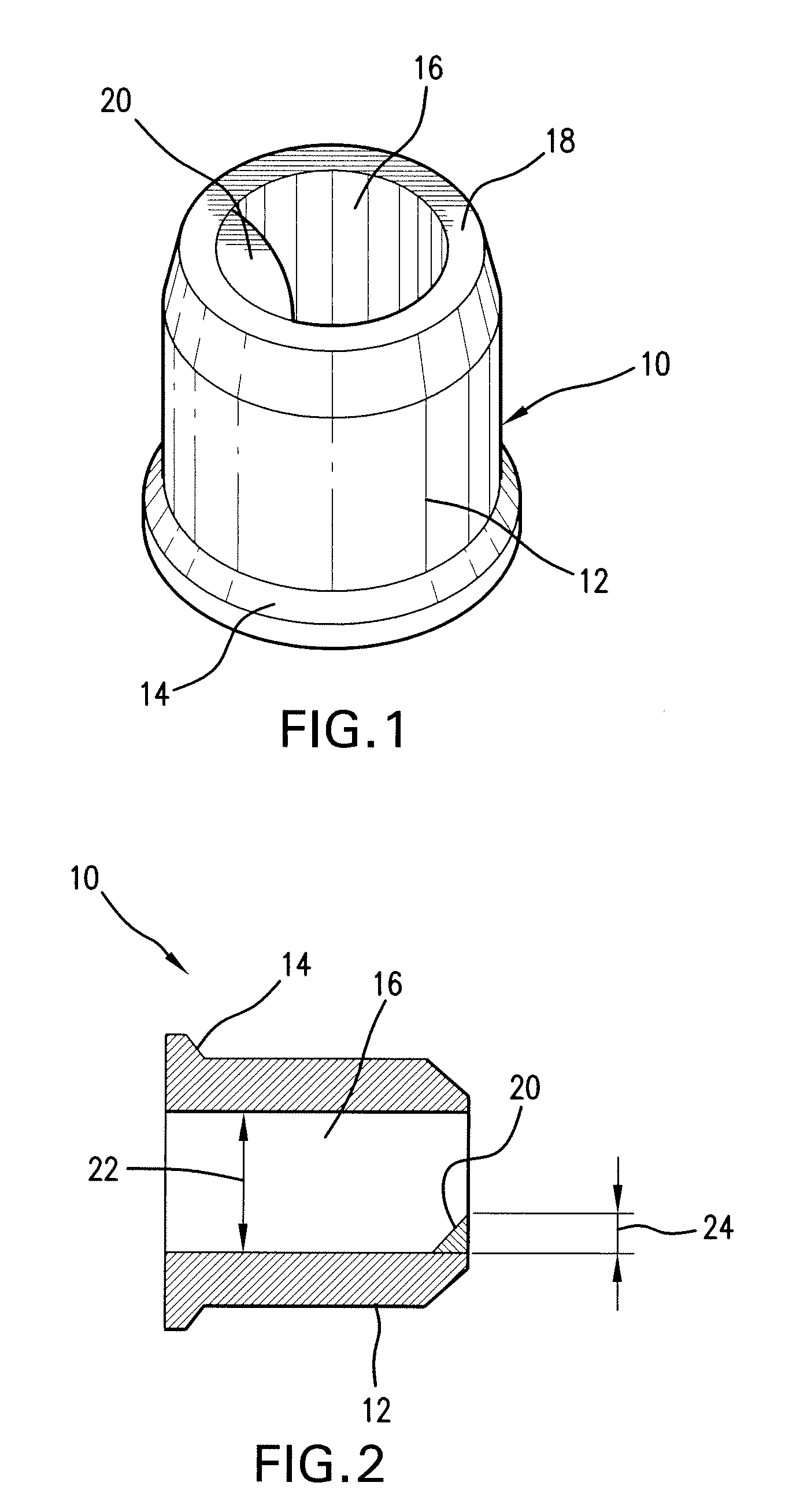

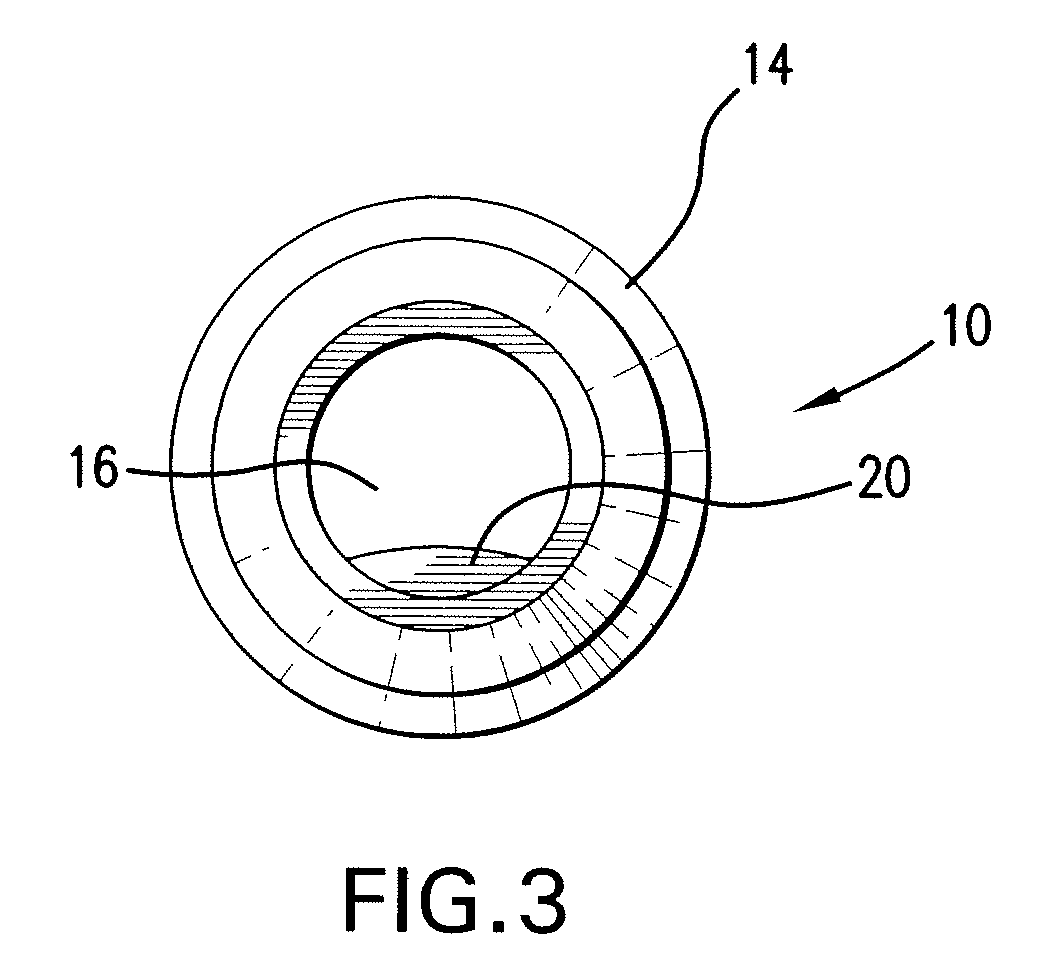

Fastening device having a retention element and method of manufacture

A fastening device such as a rivet collar that includes a retention element is disclosed. The retention element enhances the retention of a fastener within the fastening device by frictionally engaging the fastener. The retention element comprises a heat resistant base polymer, such as a reactive hot melt, an ethylene acrylic acid copolymer, or a polyethylene polymer blend, that does not melt or become tacky even at high temperatures, and therefore has high stability even under extreme storage conditions. Also disclosed is a method of forming such retention element on a fastening device.

Owner:ND IND INC

Thermoformed food containers with enhanced rigidity

InactiveUS6881937B2Improve rigidityPrevent excessive buildupLayered productsMicrowave heatingPolyvinyl polymerCalipers

A thermoformed disposable food container having a wall caliper of from about 10 to about 80 mils consisting essentially of from about 30 to about 80 percent by weight of a matrix polymer composition consisting predominantly of a polypropylene polymer and optionally including a polyethylene polymer, from about 10 to about 50 percent mica, from about 2.5 to about 25 percent calcium carbonate, and up to about 5 weight percent titanium dioxide, exhibits enhanced rigidity when the calcium carbonate has a mean particle size of less than about 8 microns. The extrudable compositions are likewise useful for film, sheet and injection molding applications.

Owner:GPCP IP HLDG LLC

Polyethylene Polymers and Articles Made Therefrom

Owner:EXXONMOBIL CHEM PAT INC

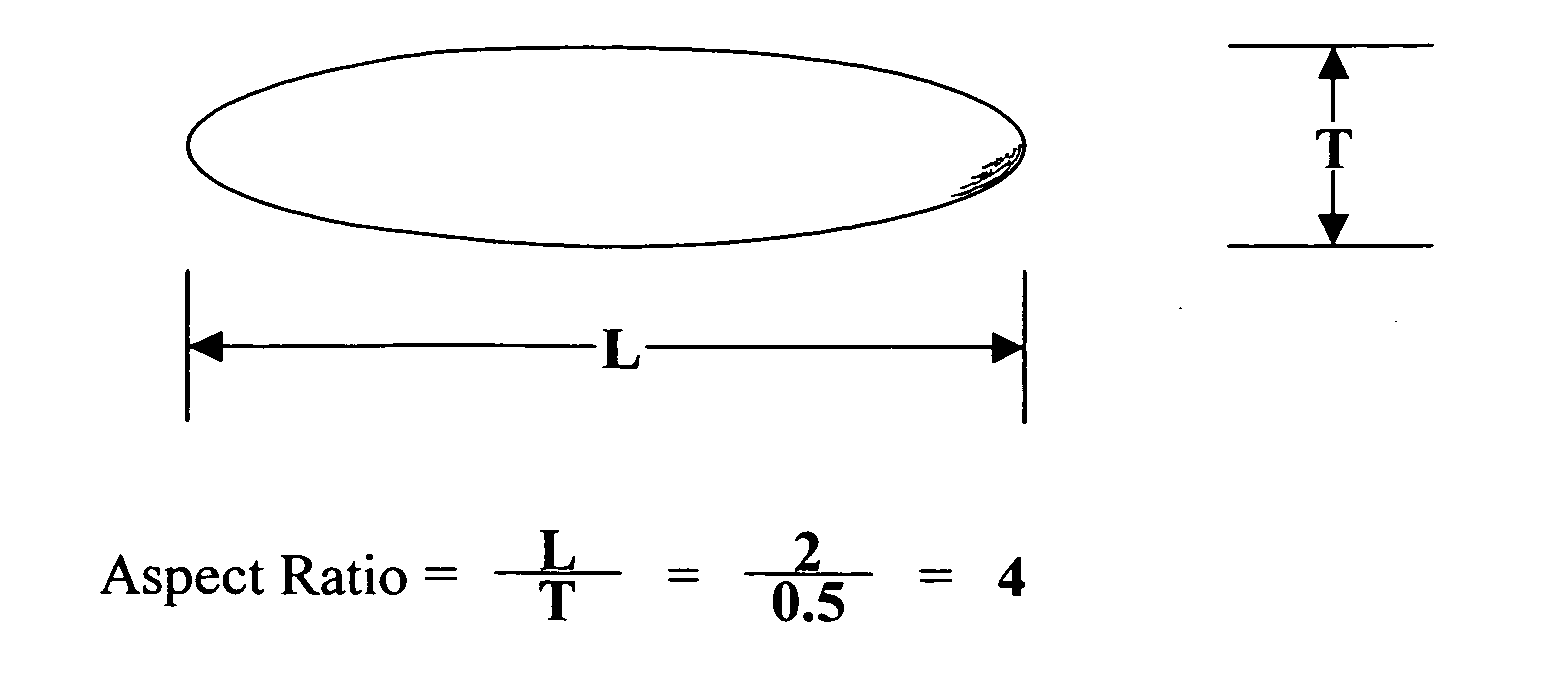

Novel liquid flow facilitator

InactiveUS20060163136A1Improved and optimal level of filtration performanceHigh trafficTreatment involving filtrationWater/sewage treatment by ion-exchangeSolventSand granules

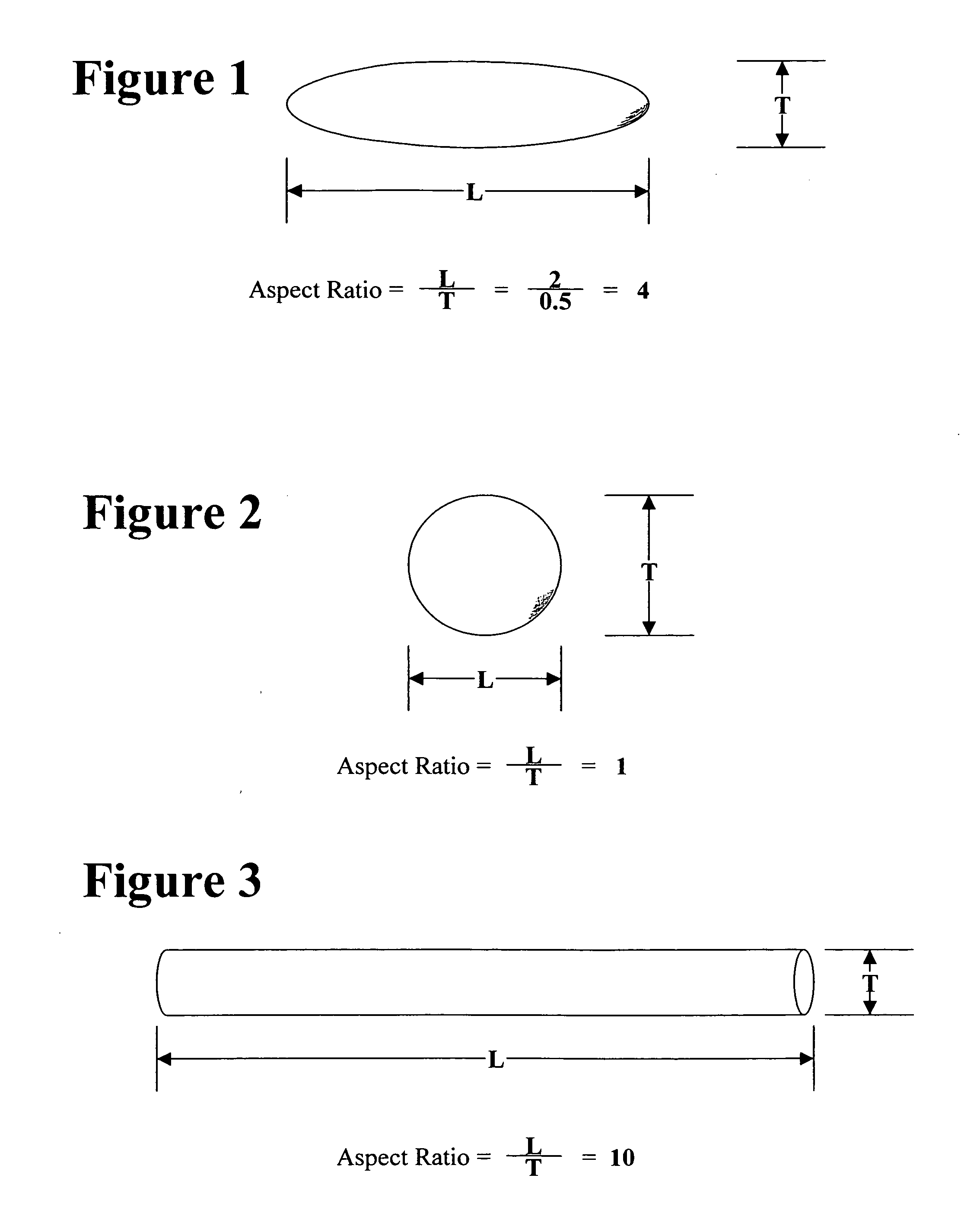

A novel water flow facilitator for granular filter devices that operate under gravity and contain granular particles, further consisting of plastic pellets that are 2 to 100 times, preferably 5 to 20 times larger than the granular particles; the plastic pellets having an aspect ratio of 0.5 to 10, preferably 1 to 4; that comprise about 1 to 50%, preferably 5 to 15% of the weight of the filter media; that have a specific gravity of 0.5 to 2, preferably 0.9 to 1.5. The plastic pellets should contain antimicrobial agents that protect the granular media from microbiological growth. The plastic pellets are made from any of the following plastics: polyolefins, various kinds of polyacrylates, polyvinyl polymers, nylon, polycarbonates etc. The plastic pellets may contain fillers such as calcium carbonate, titania, silica, or alumina. The invented flow facilitator is utilized in a gravity fed granular filter device to remove contaminants such as chlorine, taste and odor-causing compounds, solvents, pesticides, dissolved organic impurities, dissolved heavy metals and non-metallic impurities such as perchlorates. The invented flow facilitator is utilized in a gravity fed granular filter device in which the media consists of activated carbon, synthetic ion exchange resins, silica, alumina, titania, green sands, iron oxides or mixtures thereof.

Owner:RICURA TECH

Polymer composition

The invention relates to novel multimodal polyethylene polymers comprising a low molecular weight fraction and a high molecular weight fraction, and having a MFR5 of greater than 0.10 g / 10 min and less than or equal to 0.22 g / 10 min, and a density of greater than equal to 952 kg / m<3>. The invention also relates to uses of the novel polymers in the production of polymeric articles, especially pipes.

Owner:ボレアリステクノロジーオイ

Solvent method for preparing cellulose mixing fibre and application thereof

InactiveCN101240454AHigh mechanical strengthImprove mechanical propertiesConjugated cellulose/protein artificial filamentsWet spinning methodsPolyvinyl polymerTotal solid content

The invention relates to a method of cellulose blend fiber solvent and an application of the same, the method is: 1) evenly mixing the cellulose, the polyvinyl polymer and the ionic liquid, dissolved 1 to 80 hours in the 25-160[deg.] C, to form a uniform stability spinning dope of 3-40% of total solid content, the quality mixing ratio of the cellulose, the polyvinyl polymer and the ionic liquid is 99.5:0.5 to 60:40; 2) filtering and deaerating for 3-120 hours, the dope thread gushing from spinneret hole by coagulation bath is solidified to form primary cellulose; 3) drawing, washing, bleaching, finish application and drying to obtain the cellulose blend fiber. The invention prepares a blend cellulose fiber by ionic liquid, the method is high efficiency, green and environmental protection, the prepared fiber has satisfactory mechanical behaviors, and that underwear and handkerchief can be made by blend fiber, the spinning may be pure or blended into all kinds of clothing material, and also into the membrane for artificial organs, water processor, etc.

Owner:FUJIAN HONGYUAN GROUP CO LTD

Multimodal polyethylene for use in single piece beverage bottle caps and closures

The present invention relates to single piece beverage bottle caps containing and / or made from polyethylene polymers, polymer blends, and / or resins. These polymers / blends / resins have a multimodal molecular weight distribution, sufficient physico-chemical characteristics, and superior environmental stress cracking resistance, so as to be ideally suited for articles and applications such as caps and closures.

Owner:EXXONMOBIL CHEM PAT INC

Thermoset Cross-Linked Polymeric Compositions And Method Of Manufacture

Embodiments of the present invention include a heat-shrinkable article, comprising a thermoset cross-linked polymeric composition, wherein the cross-linked polymeric composition comprises at least one polypropylene polymer, and at least one polyethylene polymer, wherein the composition has a polypropylene content of less than about 50 percent by weight, and a polyethylene content of less than about 50 percent by weight, based on the total weight of the cross-linked polymeric composition. A method for making the heat-shrinkable article comprises melt mixing the at least one polypropylene polymer with the at least one polyethylene polymer and at least one additional ingredient, extruding the composition blend to form an extruded material, cross-linking the extruded material to produce a thermoset cross-linked material, stretching the cross-linked material at a temperature at or above a melting point of the material, and cooling the stretched material to maintain a form of the stretched material.

Owner:BERRY PLASTICS CORP

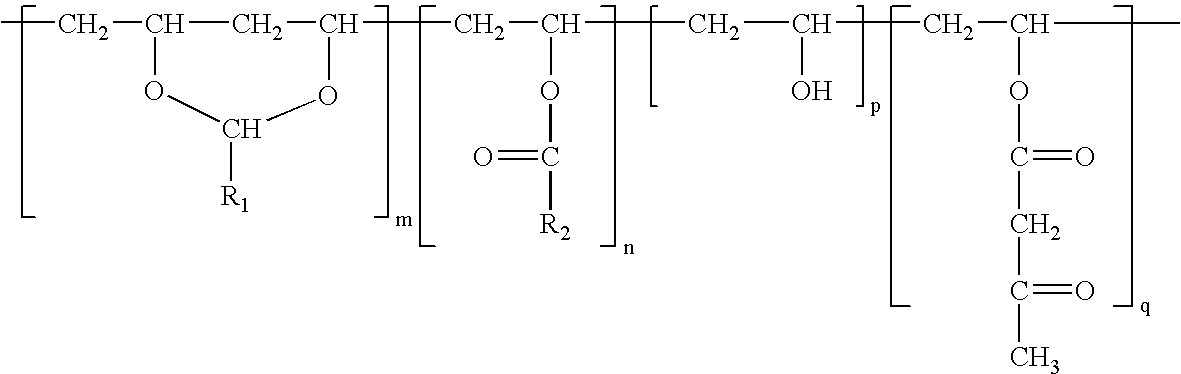

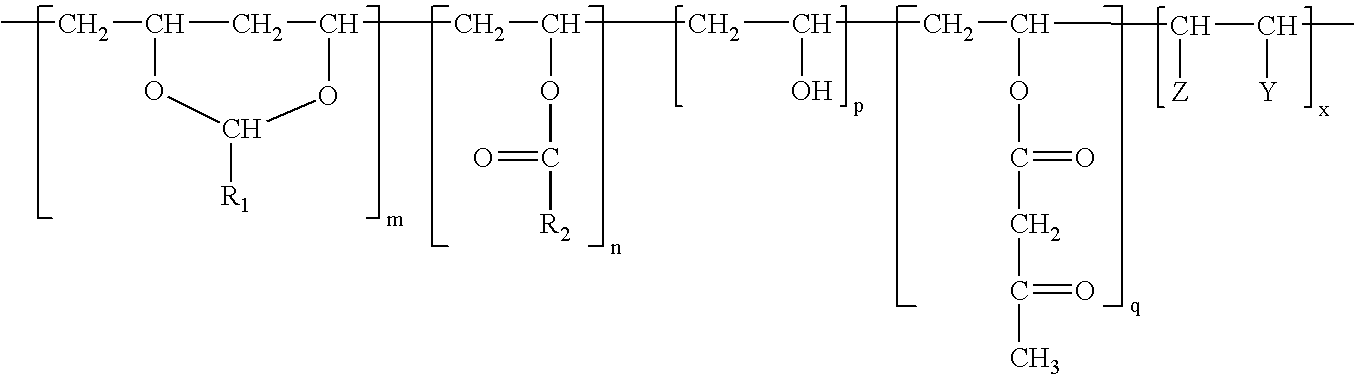

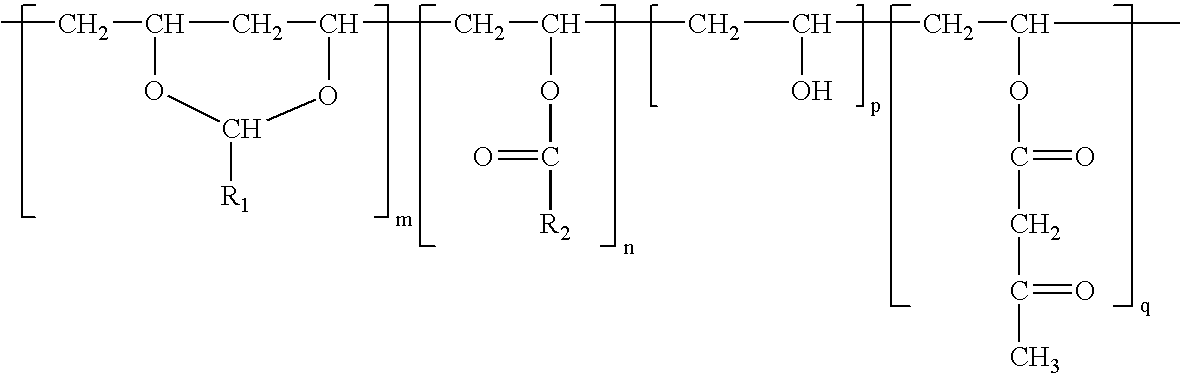

Acetoacetylated polyvinyl polymers and curable coating compositions made therefrom

The present invention relates to curable coating compositions containing acetoacetylated polyvinyl polymers obtained from polyvinyl polymers, such as polyvinyl butyrals. These coating compositions are especially suitable for use as wash primers in automotive OEM and refinish coating applications.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com