Ultrafiltration membrane and preparation method thereof

A technology of ultrafiltration membrane and membrane casting solution, which is applied in the field of ultrafiltration membrane, which can solve the problems of long production cycle, inability to fundamentally solve the alkali resistance of the membrane, and the complexity of the overall process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

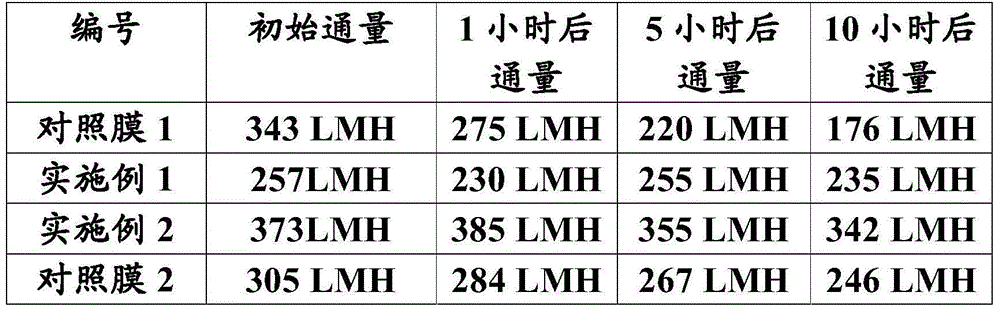

Examples

Embodiment Construction

[0050] The casting solution of the present invention can be applied to the non-woven fabric by methods and devices in the prior art, the methods and devices disclosed in CN1176608A can be used, and the method of spraying can also be used. In a specific embodiment of the present invention, the coating method and device used are the same as those disclosed in CN1176608A.

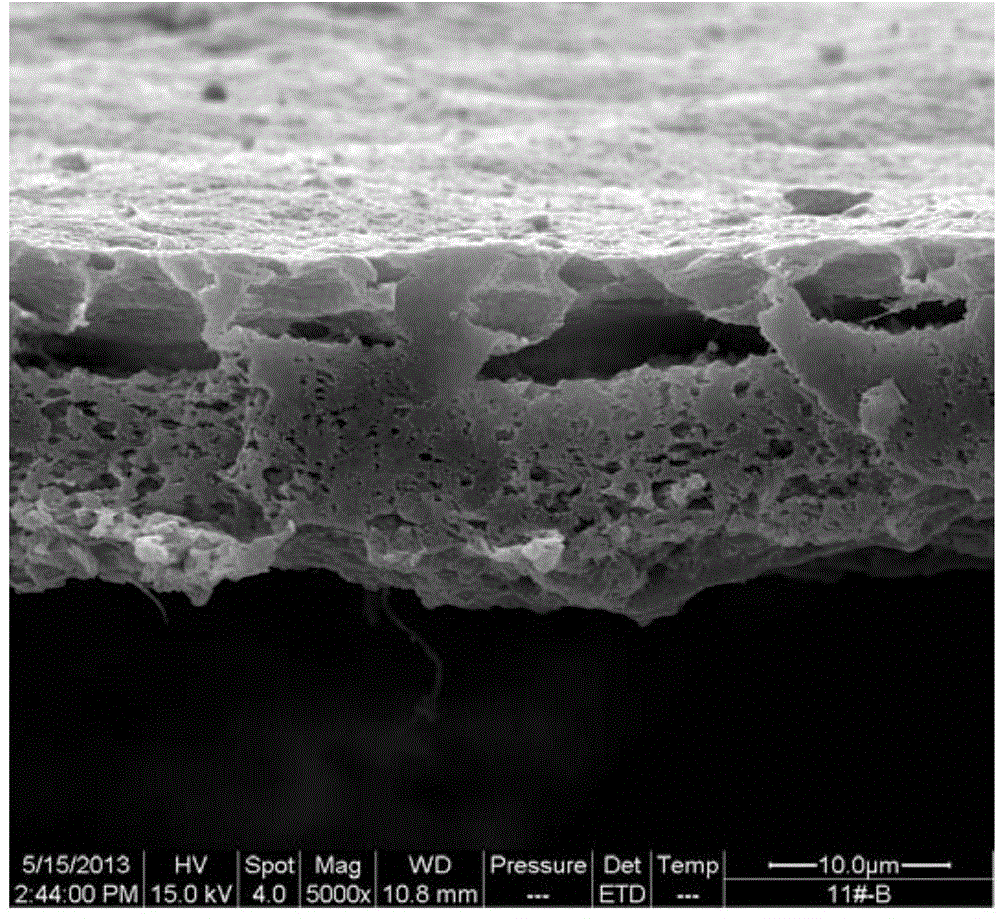

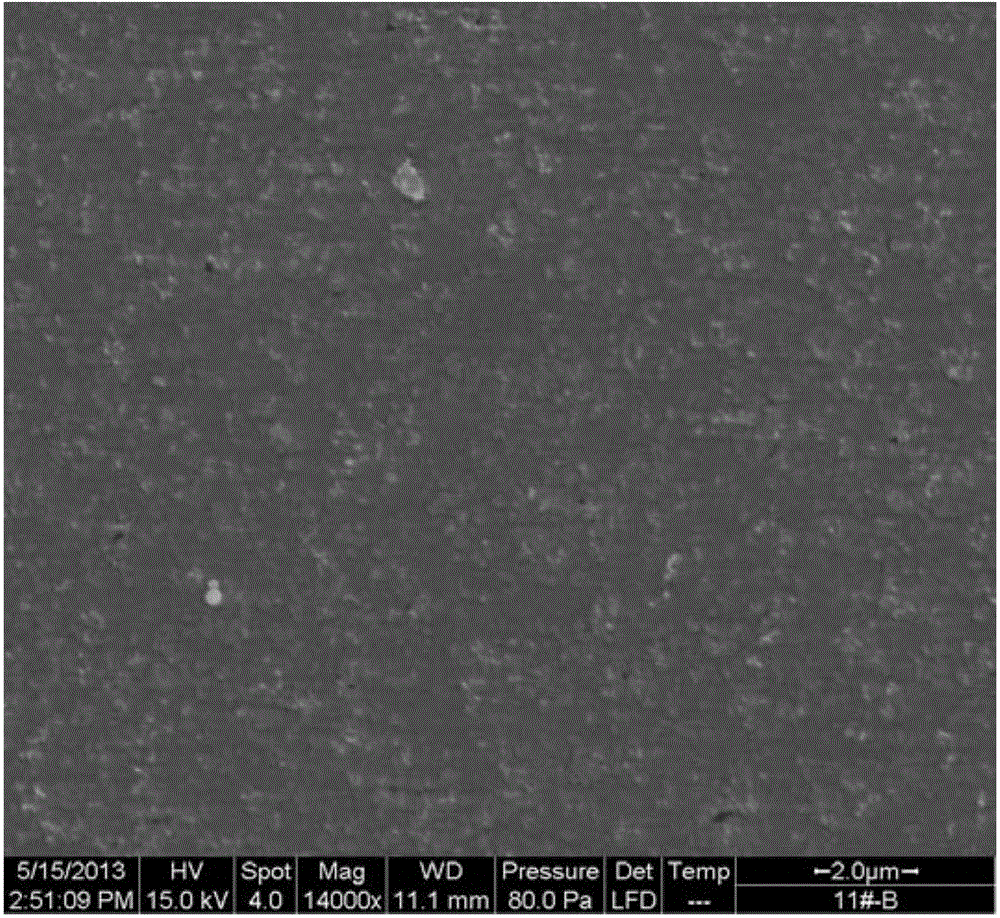

[0051] Cross-linked cellulose ultrafiltration membrane of the present invention mainly solves the alkali resistance of cellulose ester, and its preparation process comprises two parts:

[0052] 1. First, the preparation and hydrolysis process of cellulose ester (the hydrolysis process is equivalent to the deacetylation process). Cellulose ester (such as cellulose acetate, cellulose triacetate, cellulose nitrate, cellulose acetate butyrate and cellulose acetate propionate, etc.) 10-25wt%, solvent (such as acetone, formamide, dioxane, N-methylpyrrolidone, N,N-dimethylformamide, N,N-dimethylacetamide, etc.) 65-9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com