Patents

Literature

410results about How to "Prevent thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

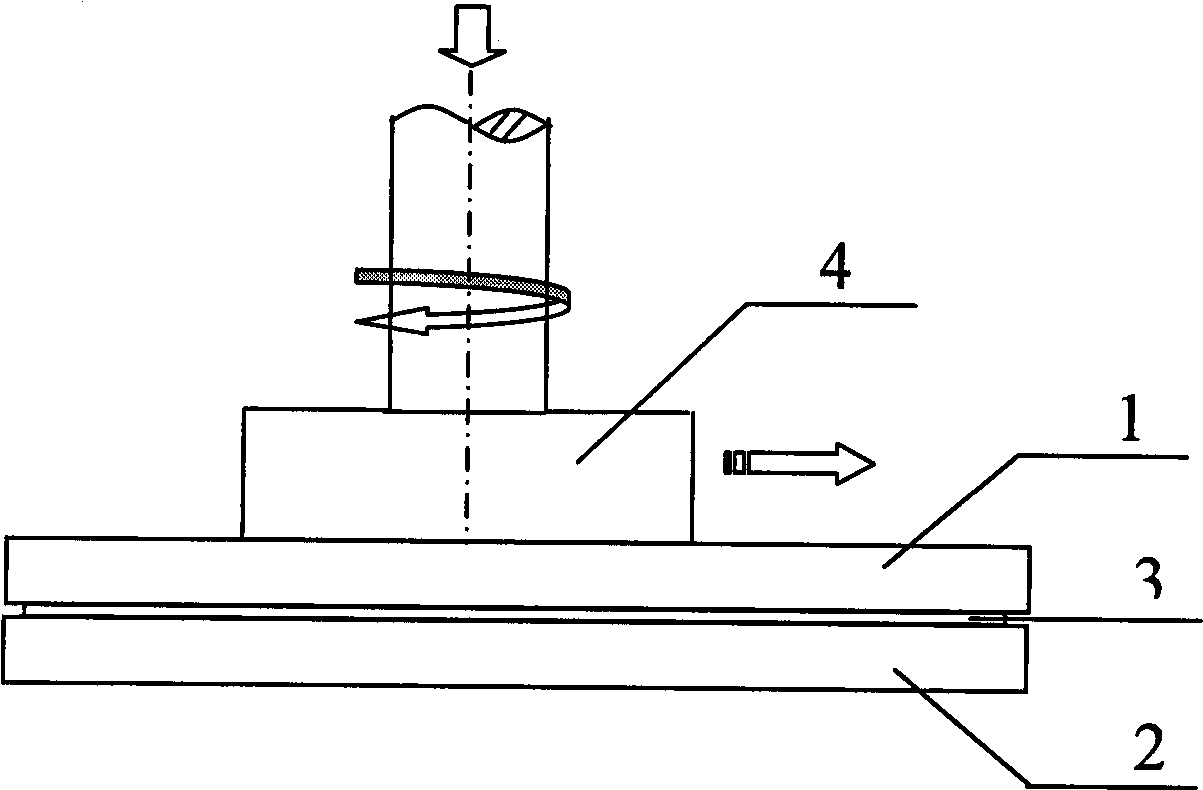

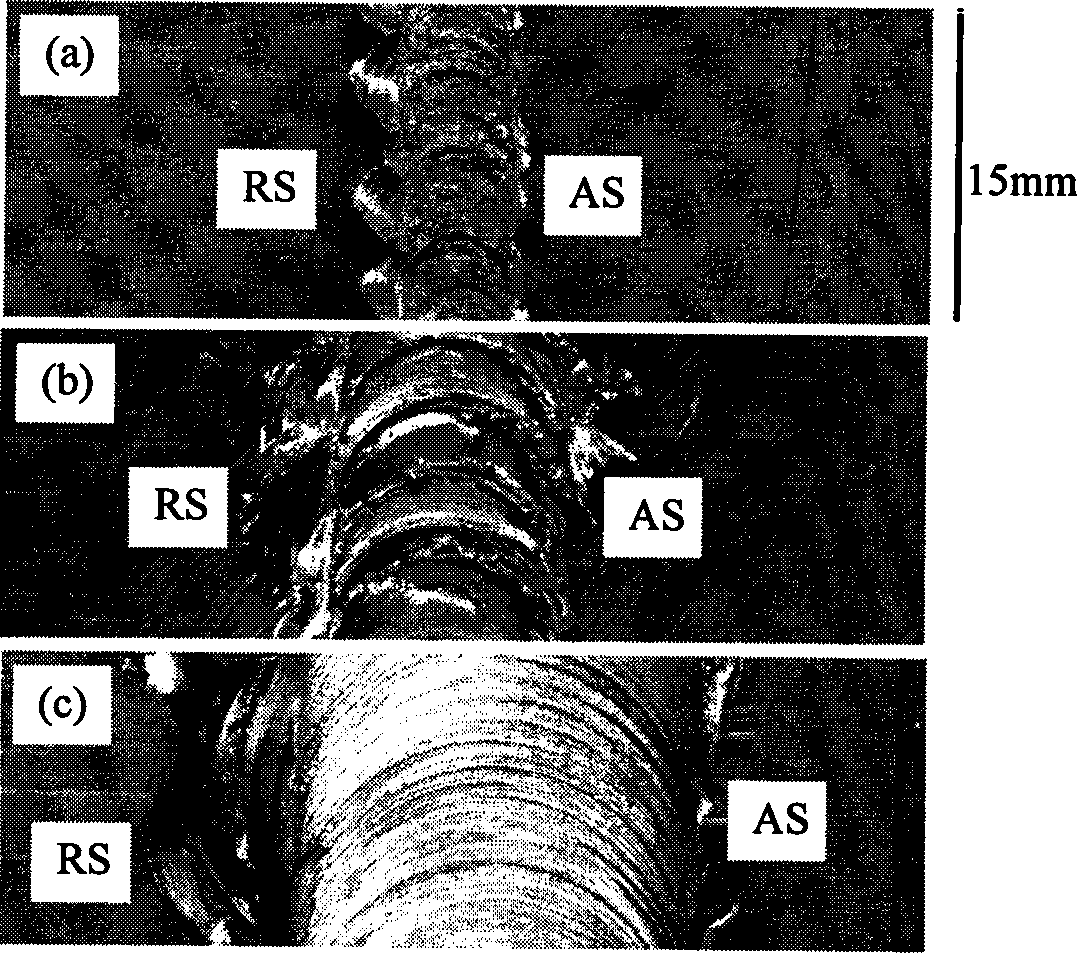

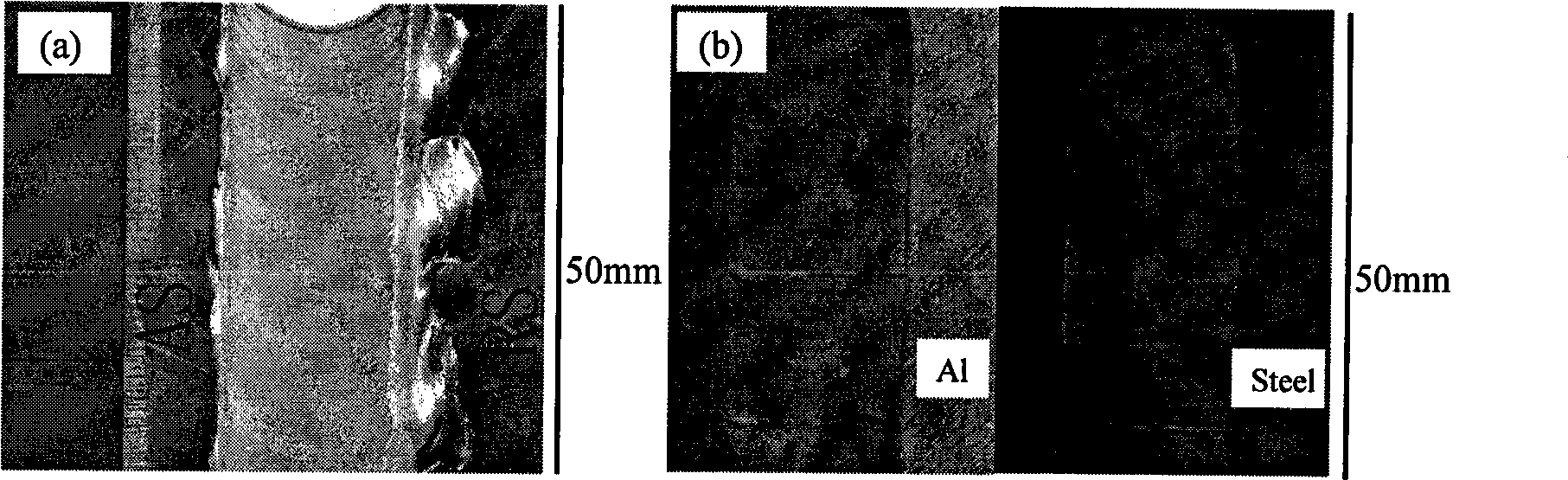

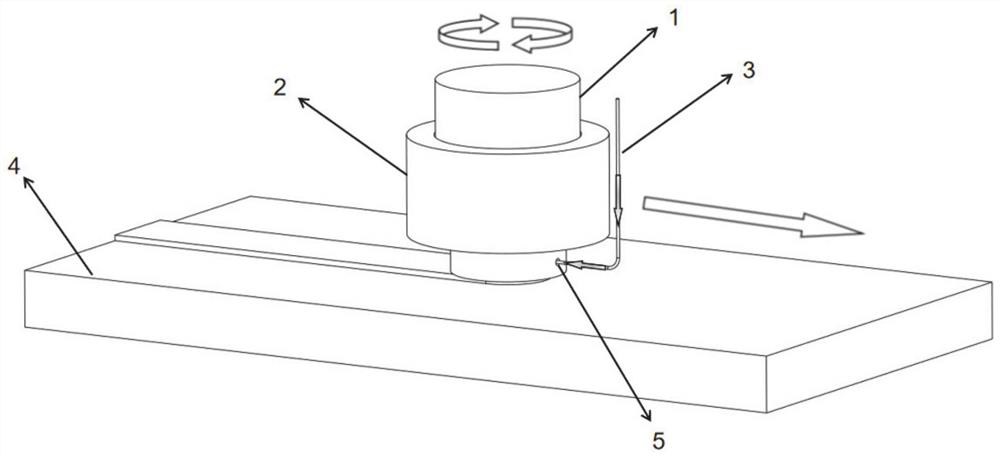

Method for preparing bimetal composite plate by stirring friction braze welding

InactiveCN101530947APrevent thinningAvoid direct contactNon-electric welding apparatusSurface layerShielding gas

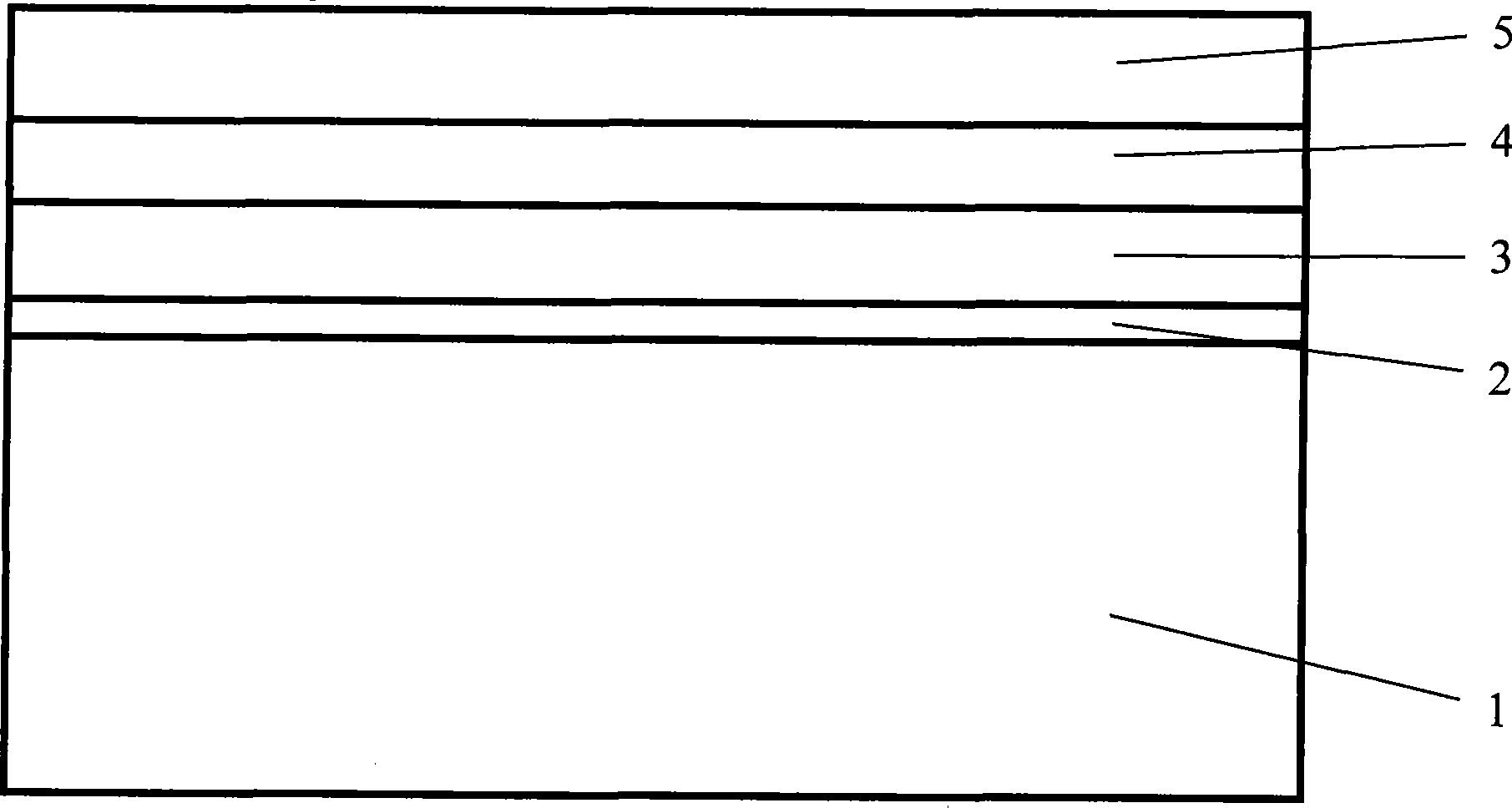

The invention discloses a method for preparing a bimetal composite plate by stirring friction braze welding. The method comprises that: a plate with small hardness is used as a covering layer metal plate; a plate with high hardness is used as a base layer metal plate; the covering layer metal plate and the base layer metal plate are horizontally fixed on a working platform surface in a lap joint mode; solders which can generate eutectic reaction with one of the upper / base layer metal plates are preset between the upper / base layer metal plates; a non-needle type cylinder friction device is arranged over the covering layer metal plate; the non-needle type cylindrical friction device is made to rotate and be pressed to be closely contacted with the surface layer of the covering layer metal plate, but not penetrate the covering layer metal plate, and the non-needle type cylindrical friction device rotates in the original position or moves forward along the surface of the covering layer metal plate while rotating; by utilizing frictional heat to melt the solders, the upper / base layer metal plates are both quickly melted in the solders, thereby achieving excellent interface combination; and the excessive solders are squeezed out, and a thin and dense soldering seam is formed, so that the bimetal composite plate is prepared. Compared with the braze welding in a furnace, the method has the advantages of high efficiency, energy conservation, pressure lead-in, unnecessary soldering flux and gas protection and short holding time at a high temperature.

Owner:XI AN JIAOTONG UNIV

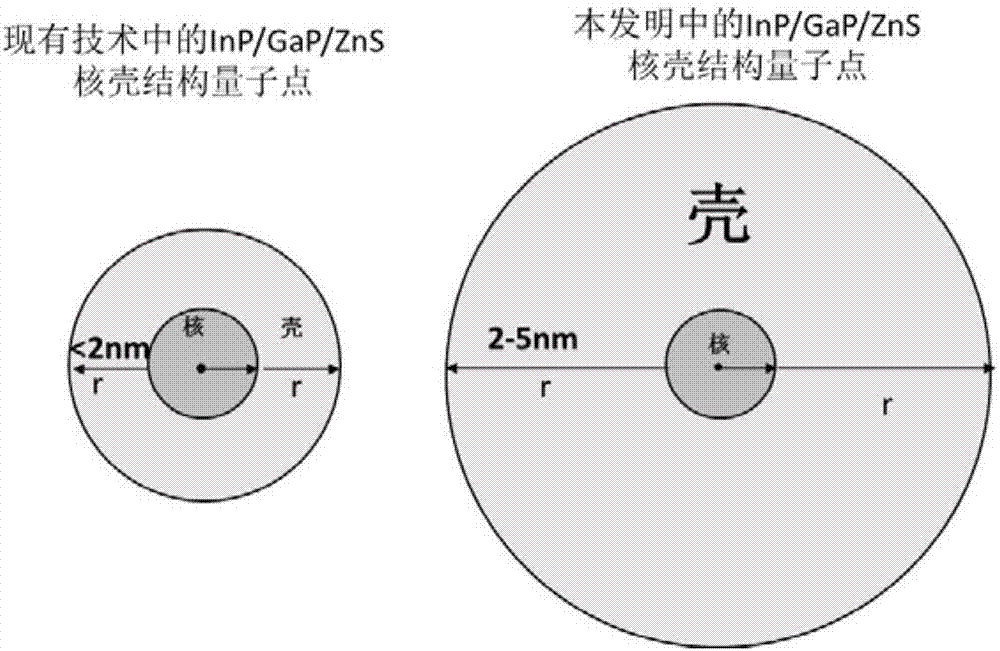

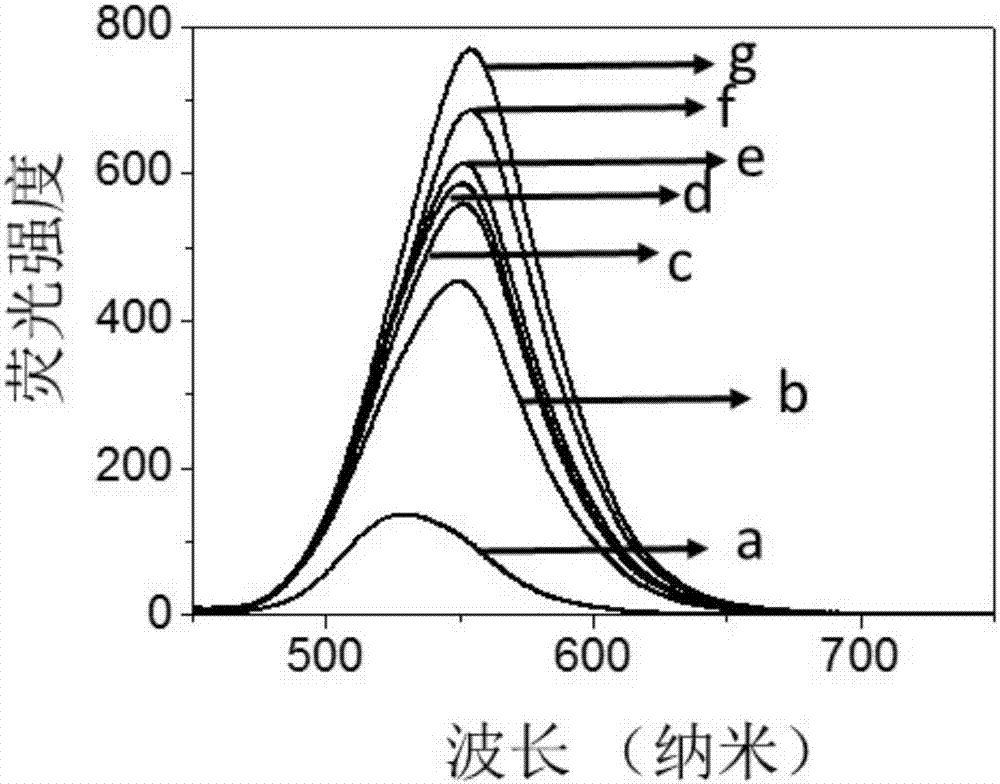

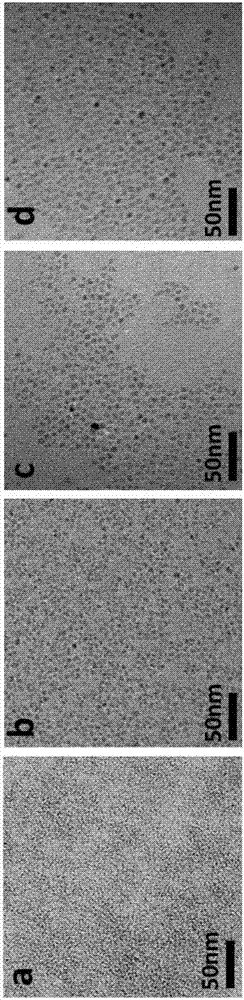

InP/ GaP/ ZnS nucleocapsid quantum dots and preparation method thereof

ActiveCN107338048AReduce lattice differencePromote growthMaterial nanotechnologyNanoopticsQuantum yieldIndium

The invention provides a preparation method of InP / GaP / ZnS nucleocapsid quantum dots. The preparation method comprises the following steps of dissolving an indium precursor, a gallium precursor and a zinc precursor in organic solvent, and obtaining a mixed precursor solution of indium, gallium and zinc; adding a phosphorus precursor to the mixed precursor solution of indium, gallium and zinc, and obtaining an InP / GaP: Zn quantum dot nuclear solution after a reaction; adding a shell material, which is a mixed solution of a zinc salt solution and thiol, into the InP / GaP: Zn quantum dot nuclear solution multiple times at intervals for a reaction, and obtaining the InP / GaP / ZnS nucleocapsid quantum dots. The preparation method is simple in synthesis process, the quantum yield can reach 60-90%, and the fluorescent wavelength range is 510-650 nm; the InP / GaP / ZnS nucleocapsid quantum dots prepared by the preparation method are thick in shell and good in stability.

Owner:深圳天吉新创科技有限公司

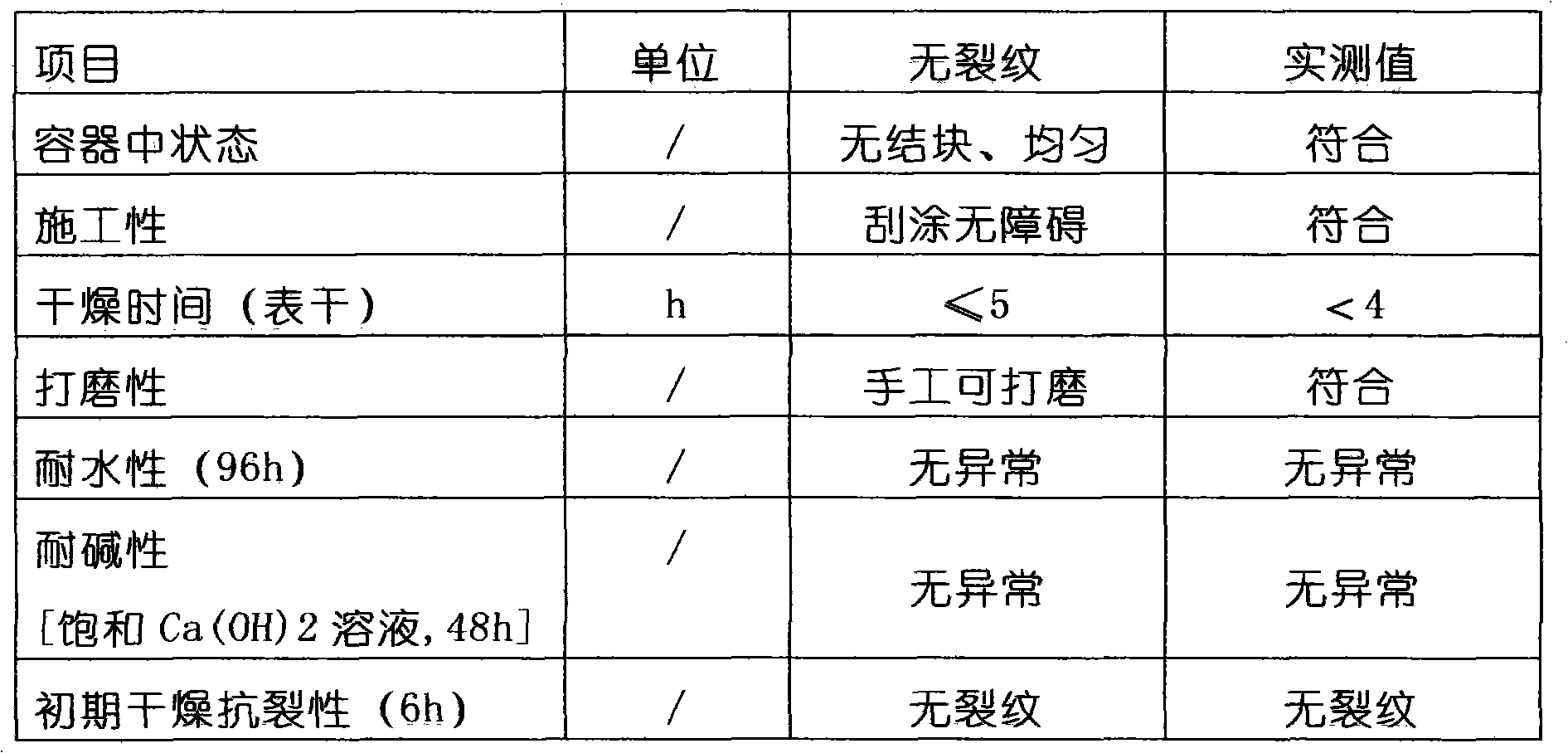

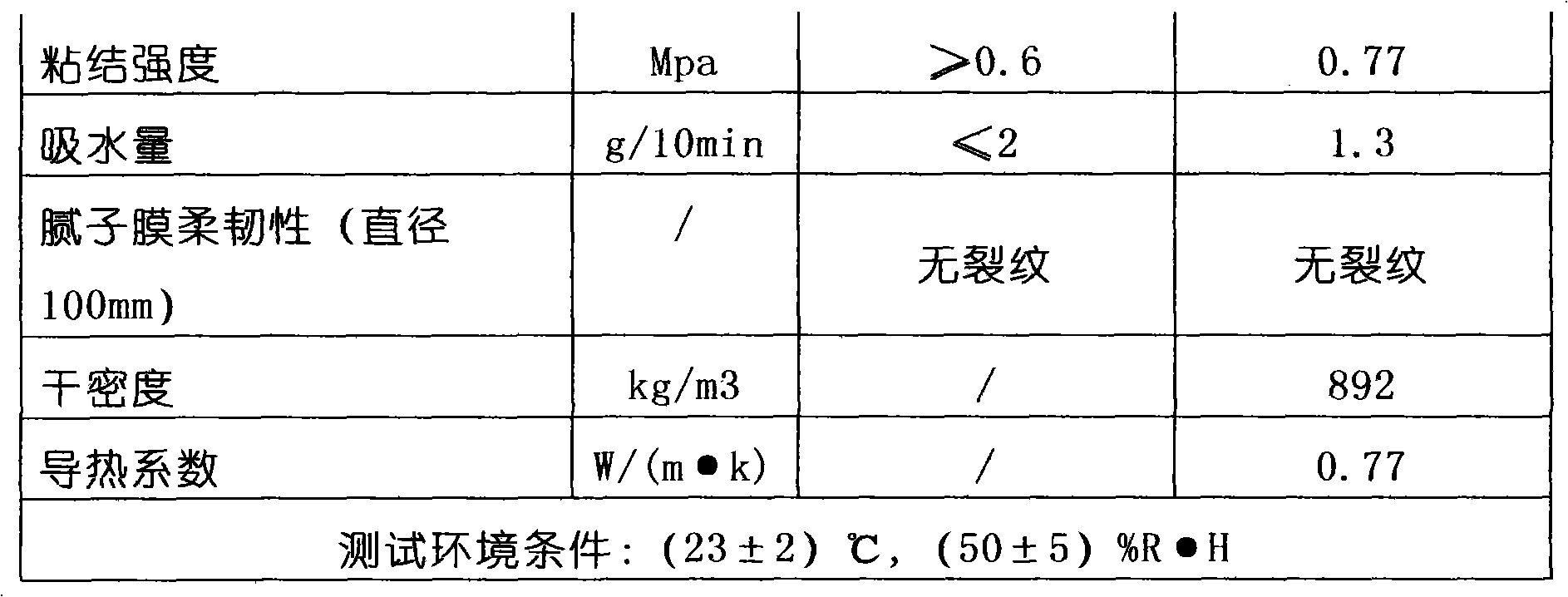

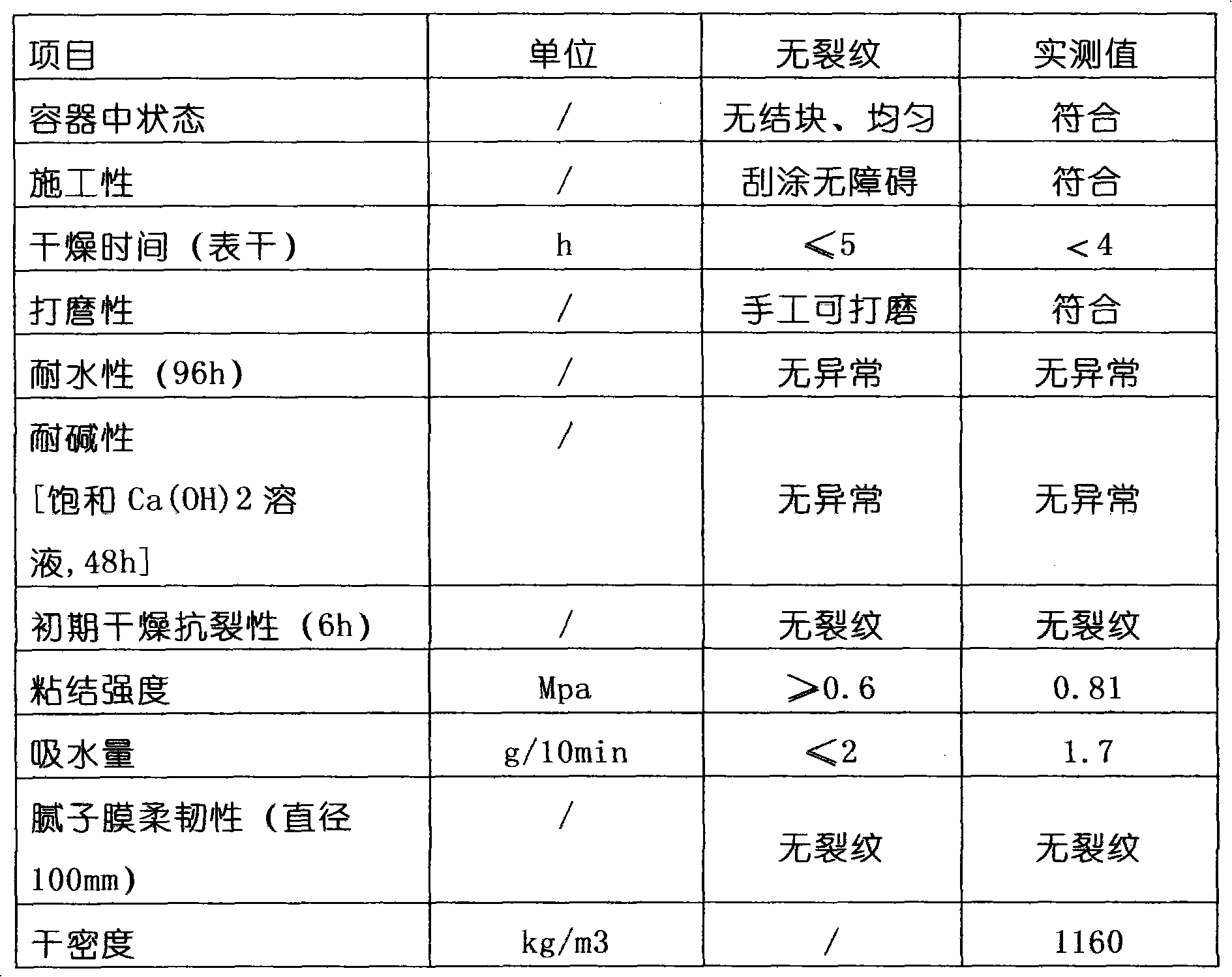

Energy-saving leveling putty powder

The invention relates to energy-saving leveling putty powder, which is characterized by being prepared from the following raw materials in percentage by weight: 20 to 30 percent of white cement, 5 to 10 percent of gray calcium powder, 40 to 60 percent of heavy calcium carbonate powder, 5 to 15 percent of 50 to 100-mesh light sand, 0.1 to 1 percent of reinforcing fiber, 0.1 to 1.5 percent of polyvinyl alcohol, 0.1 to 1.8 percent of cellulose and 1 to 3 percent of polymer powder, wherein the light sand is polyphenyl particles, vitrified micro bubbles or expanded perlite; the reinforcing fiber is 2-mm polypropylene fiber; and the cellulose is carboxymethyl cellulose. The energy-saving leveling putty powder has the characteristics of high strength, high water resistance, no toxicity or odor, yellowing resistance and the like; moreover, by adding the light sand with heat preservation and thermal insulation function, the putty powder has the obvious characteristics of light weight, heat preservation, high thermal insulation, abrasion resistance, corrosion resistance, high electric insulating performance, radiation protection and the like, while the basic performance is ensured.

Owner:陈文光

Clay foam stabilizing complex additive for foam flooding as well as preparation method and application of clay foam stabilizing complex additive

ActiveCN103694983AIncrease foam volumeExtended half-lifeFluid removalDrilling compositionHalf-lifeSolid particle

The invention relates to a clay foam stabilizing complex additive for foam flooding as well as a preparation method and an application of the clay foam stabilizing complex additive. The clay foam stabilizing complex additive comprises the following raw materials in parts by weight: 0.2-0.9 part of sodium dodecyl benzene sulfonate, 1-10 parts of clay particles and 100 parts of water, wherein the particle sizes of the clay particles range from 25mu m to 100mu m. The hydrophobic clay particles are added into the clay foam stabilizing complex additive for foam flooding, provided by the invention to ensure that the solid particles are attached on the surface of a liquid film and in a liquid film layer to form a rigid compact shell, so that the strength of the foam liquid film is enhanced, the liquid drainage of the liquid film is inhibited, the liquid film is prevented from thinning, and furthermore, the bubbling volume of the foam is increased, and the half-life period of the foam is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

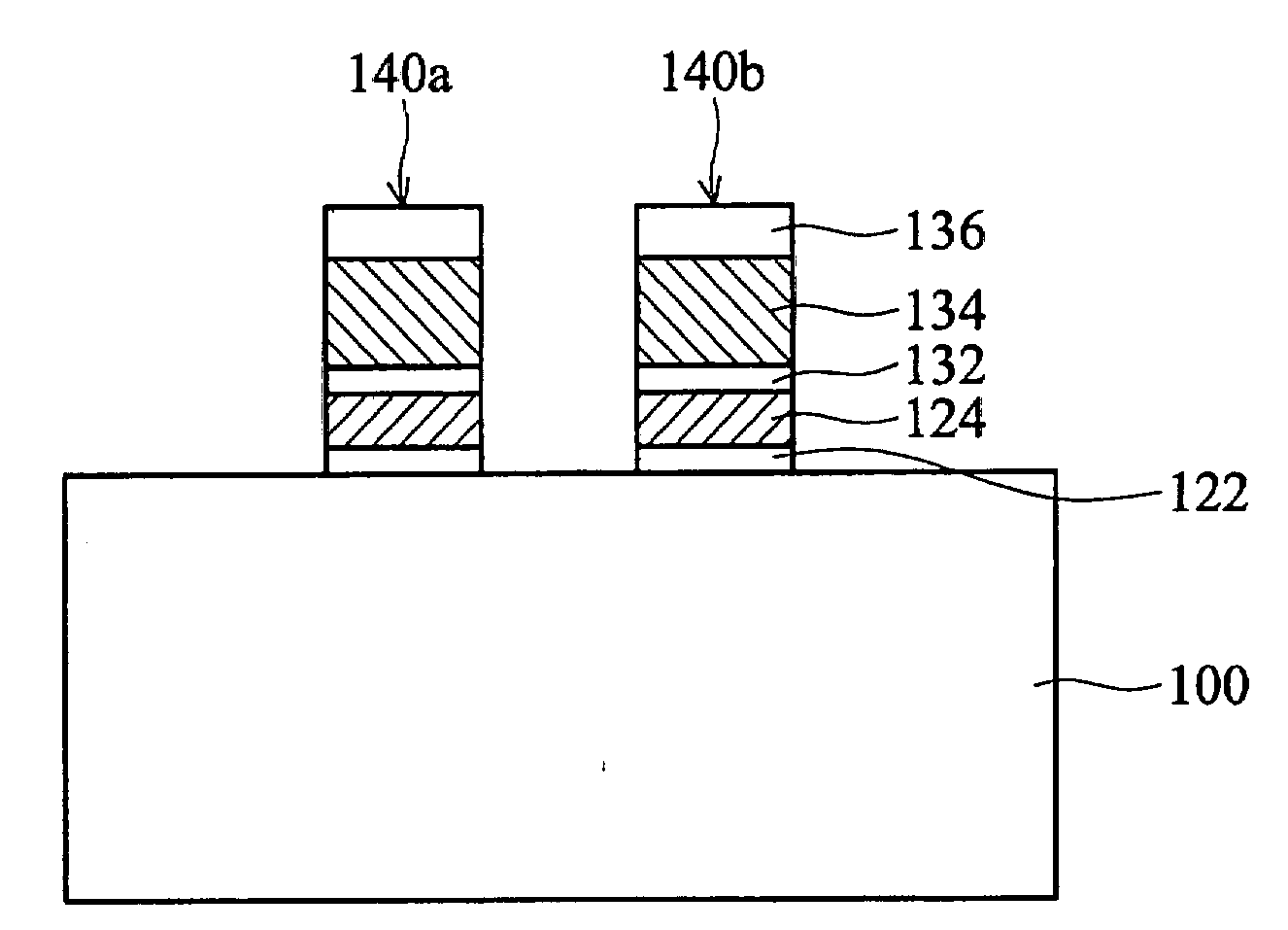

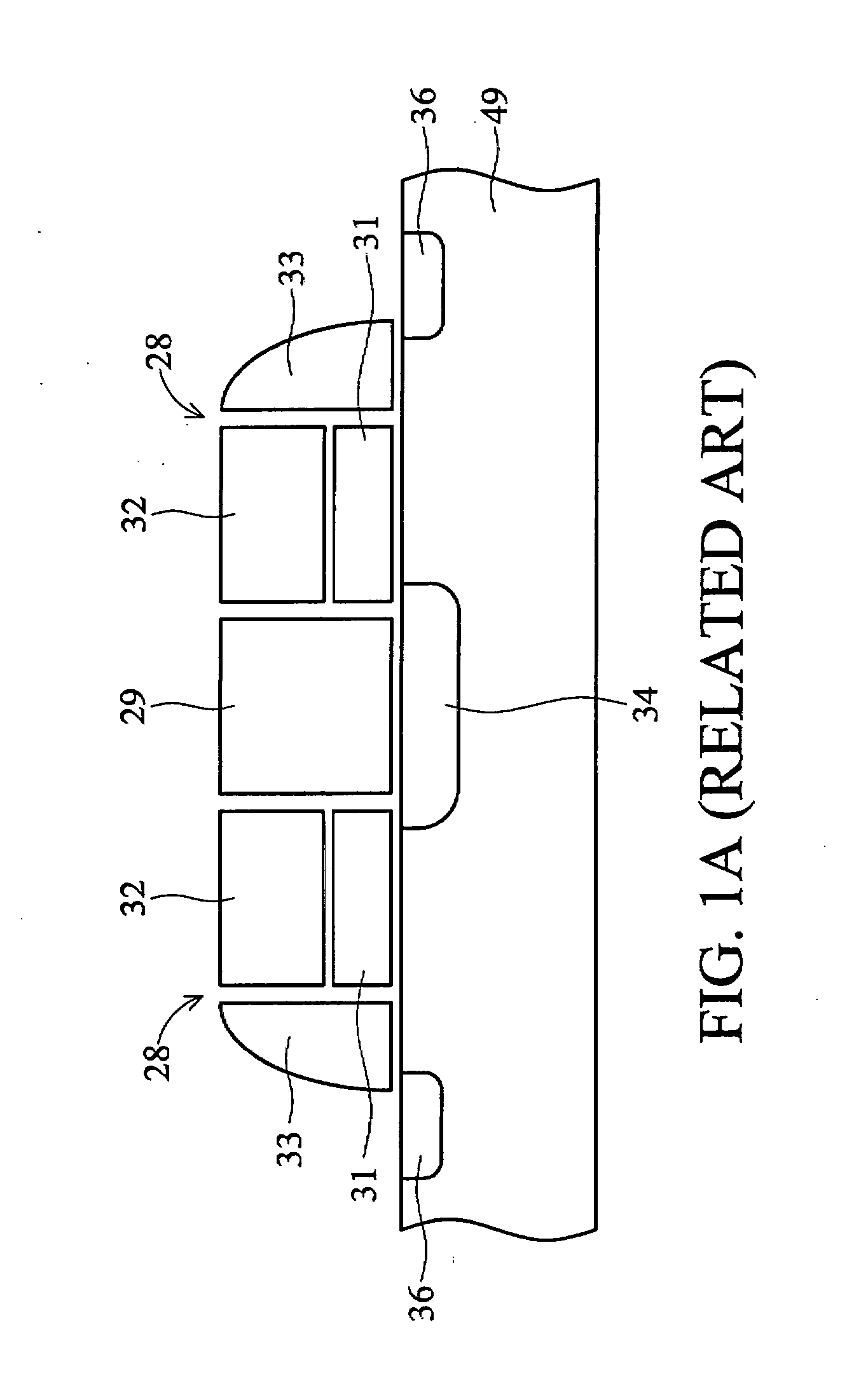

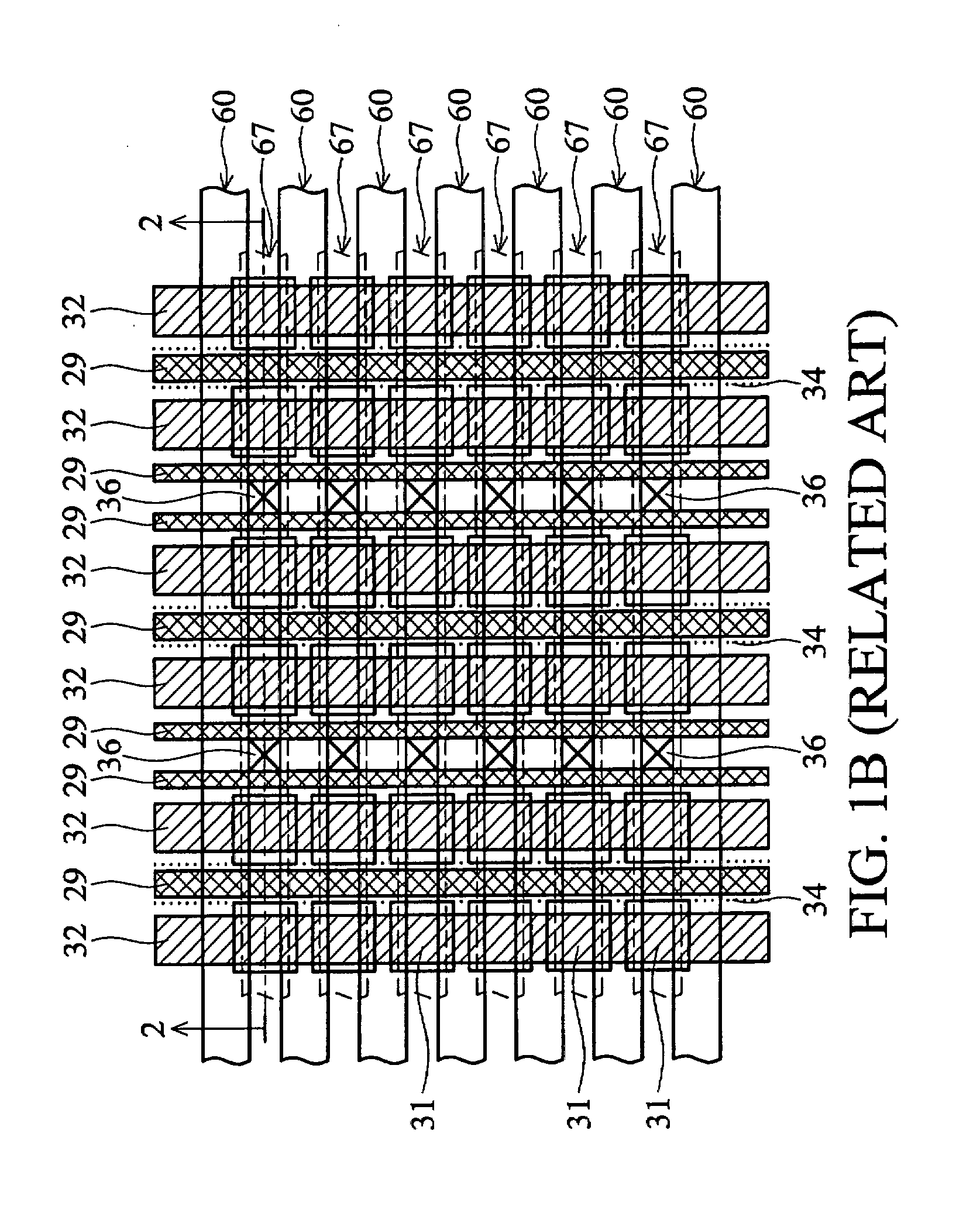

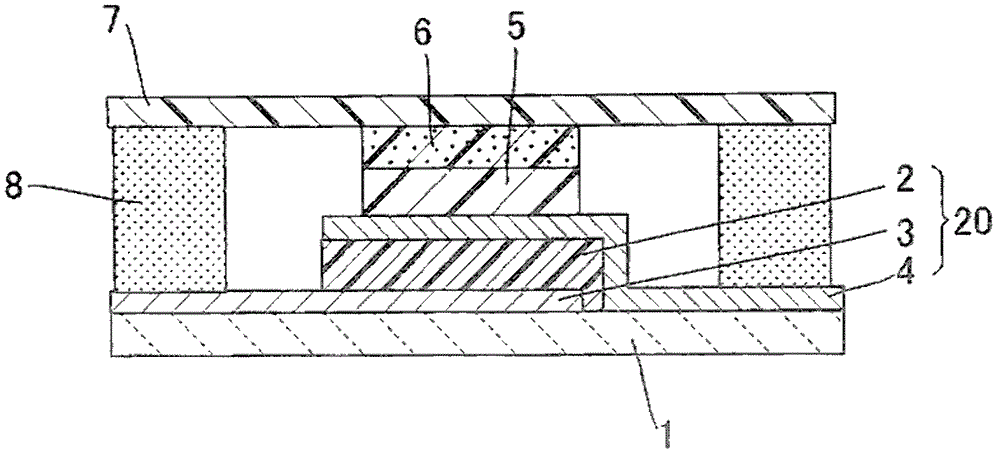

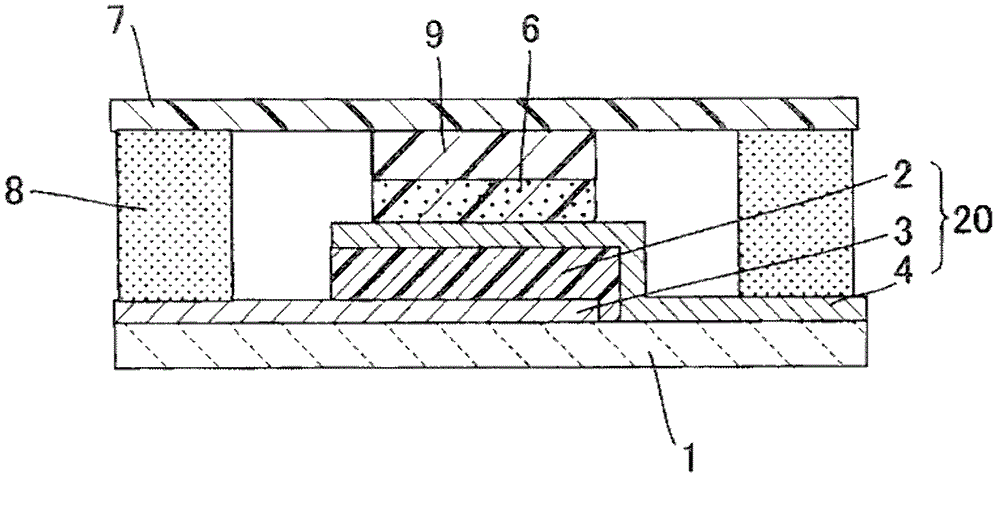

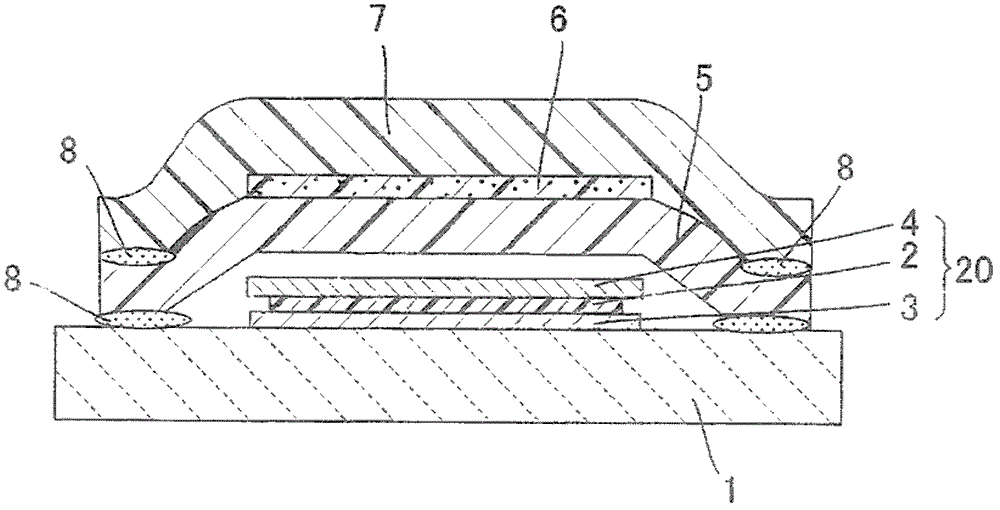

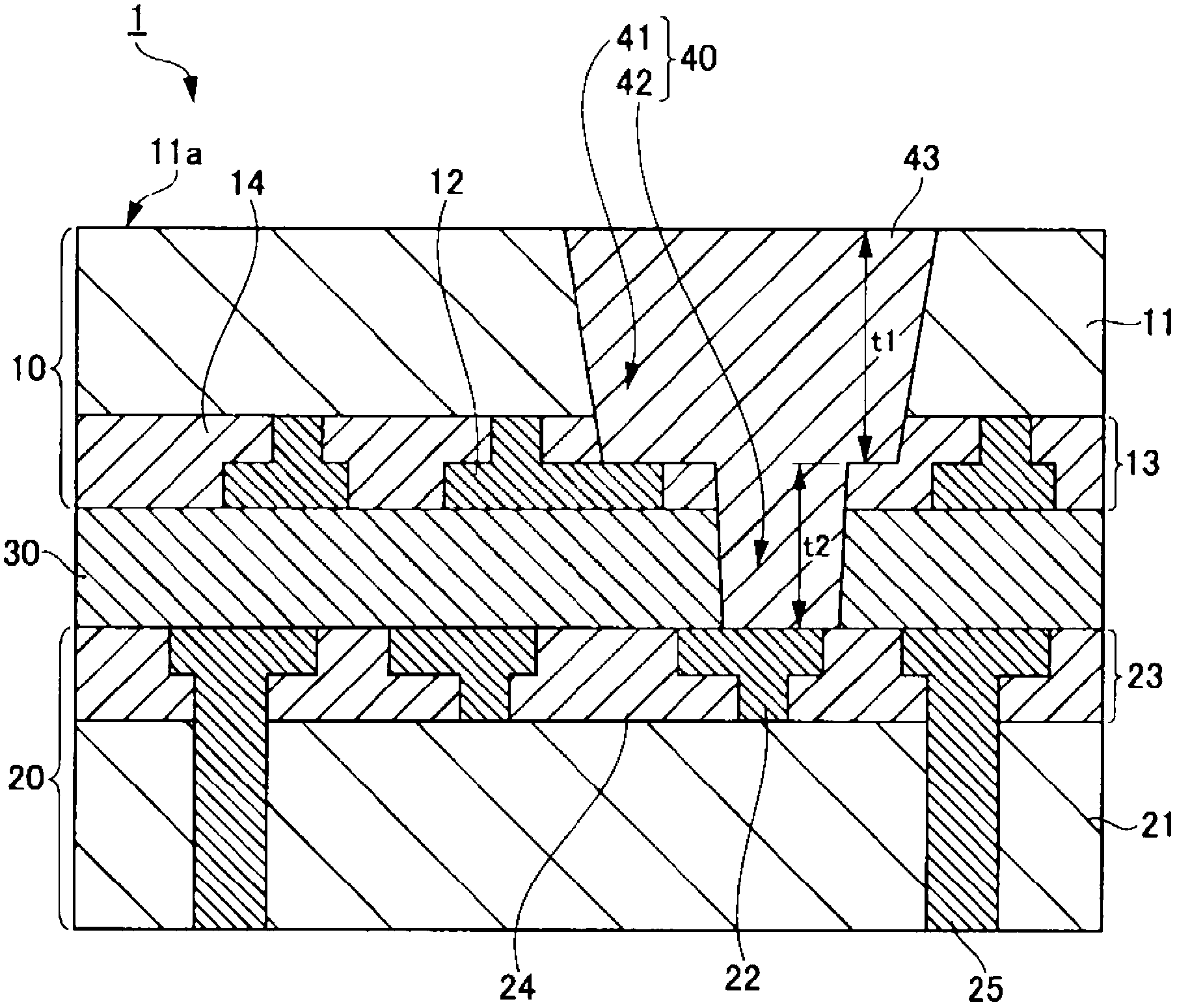

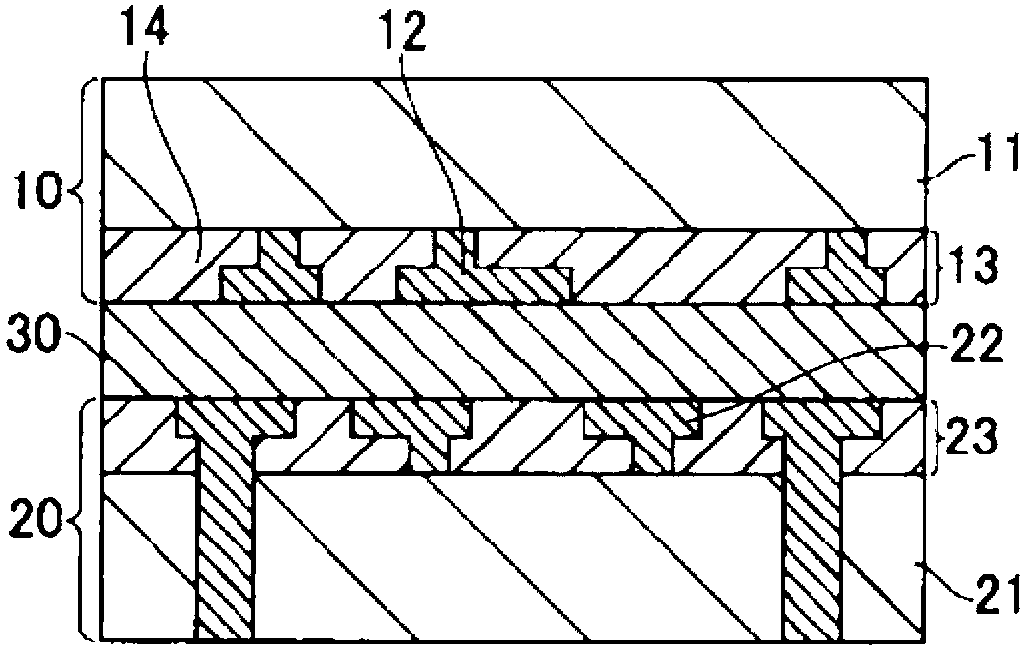

Split-gate memory cells and fabrication methods thereof

Split-gate memory cells and fabrication methods thereof. A split-gate memory cell comprises a plurality of isolation regions formed on a semiconductor substrate along a first direction, between two adjacent isolation regions defining an active region having a pair of drains and a source region. A top level of the active regions is lower than a top level of the isolation regions. A pair of floating gates is disposed on the active regions and aligned with the isolation regions, wherein a passivation layer is disposed on the floating gate to prevent thinning from CMP. A pair of control gates is self-aligned with the floating gates and disposed on the floating gates along a second direction. A source line is disposed between the pair of control gates along the second direction. A pair of select gates is disposed on the outer sidewalls of the pair of control gates along the second direction.

Owner:TAIWAN SEMICON MFG CO LTD

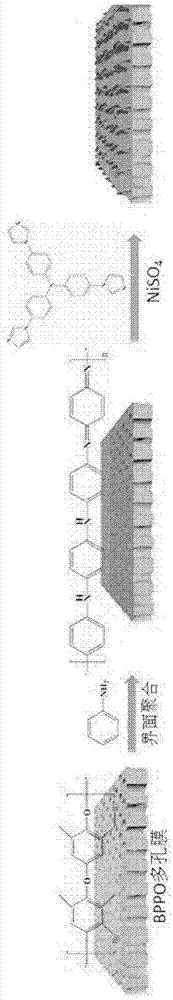

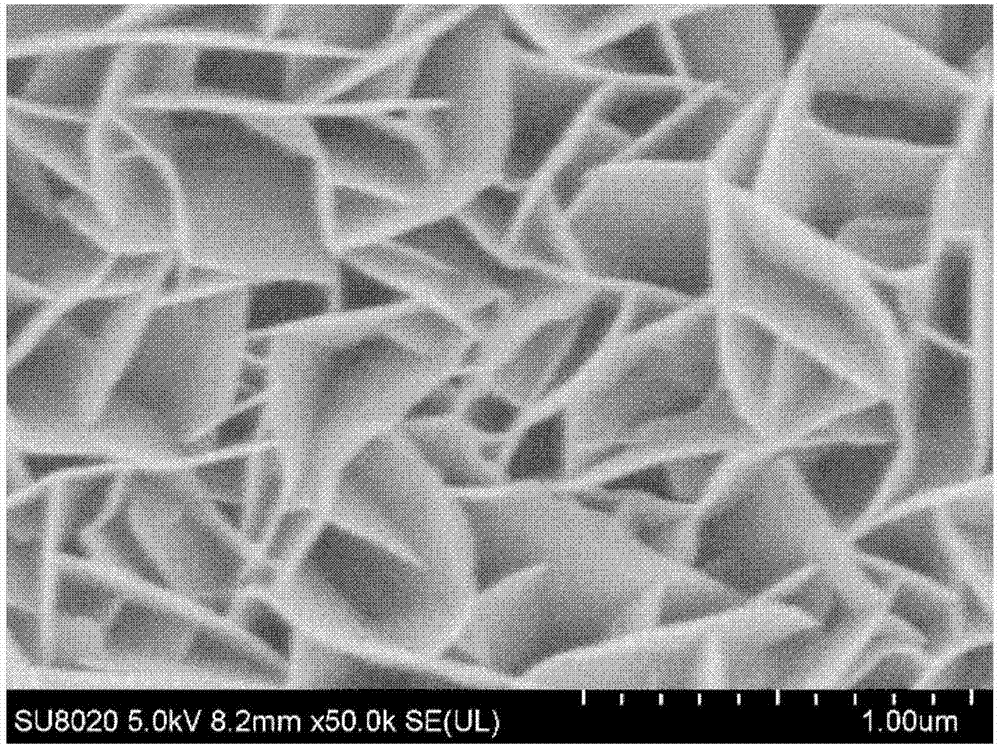

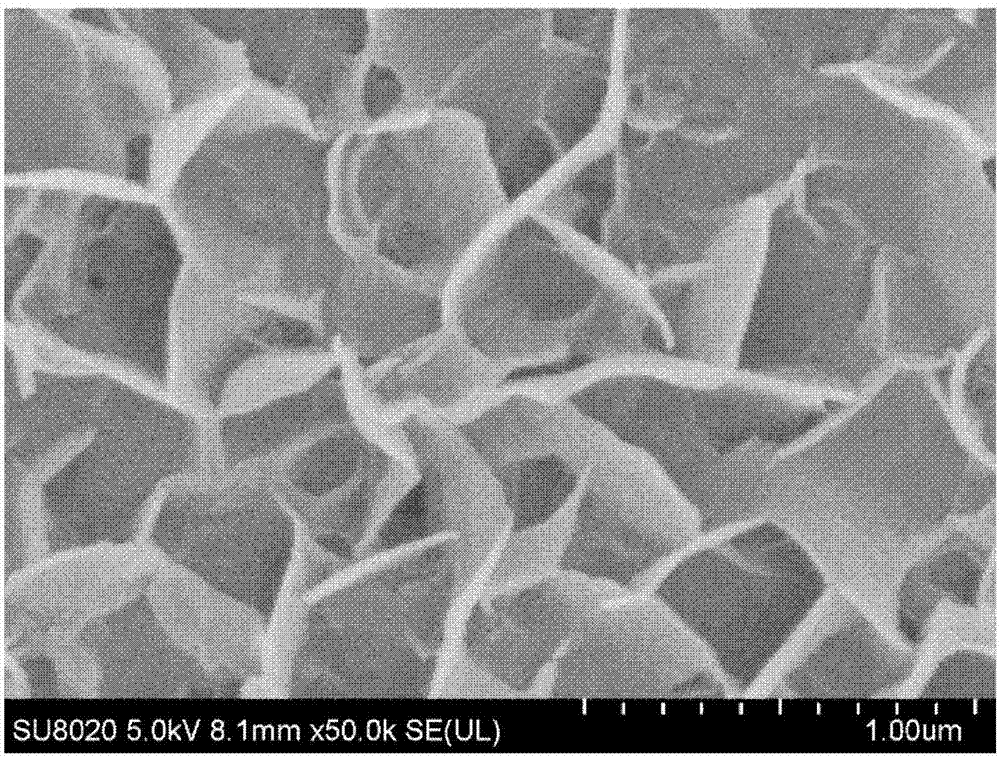

MOF (metal-organic framework) separating layer film and preparation method thereof

ActiveCN107398186AThe preparation method is simple and controllableHigh throughputMembranesSemi-permeable membranesSurface modificationChemistry

The invention provides an MOF (metal-organic framework) separating layer film and a preparation method thereof. The preparation method comprises the following steps: a surface modification layer is formed on the surface of a base film through an interfacial polymerization reaction; an MOF separating layer grows secondarily on the surface modification layer, and preparation of the MOF separating layer film is completed. A preparation method of a positively charged MOF separating layer film further comprises the step that acid radical ions in the MOF separating layer film are removed by soaking the prepared MOF separating layer film in methyl alcohol. The MOF separating layer grows secondarily on the surface modification layer, and by means of the pore diameter screening action and a frame charging effect, the MOF separating layer film can effectively realize the effect of selective ion separation; layers of the MOF separating layer film are not formed through simple physical bonding, and accordingly, the defect of separation is overcome.

Owner:UNIV OF SCI & TECH OF CHINA

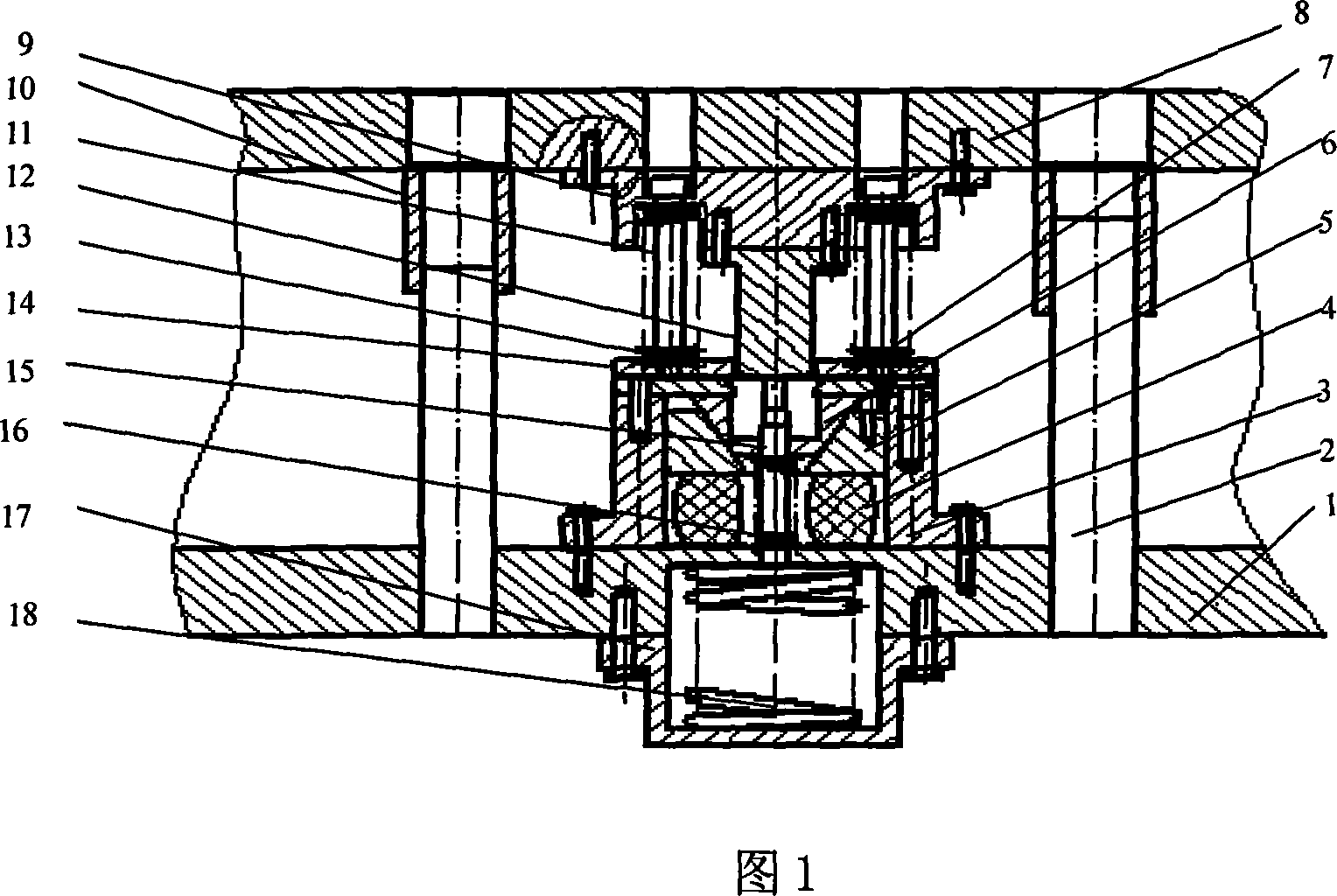

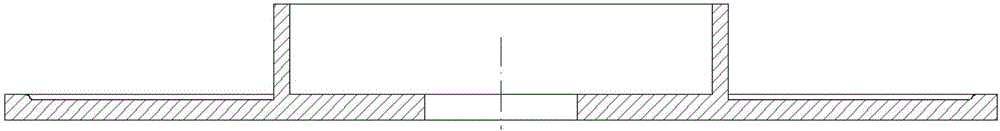

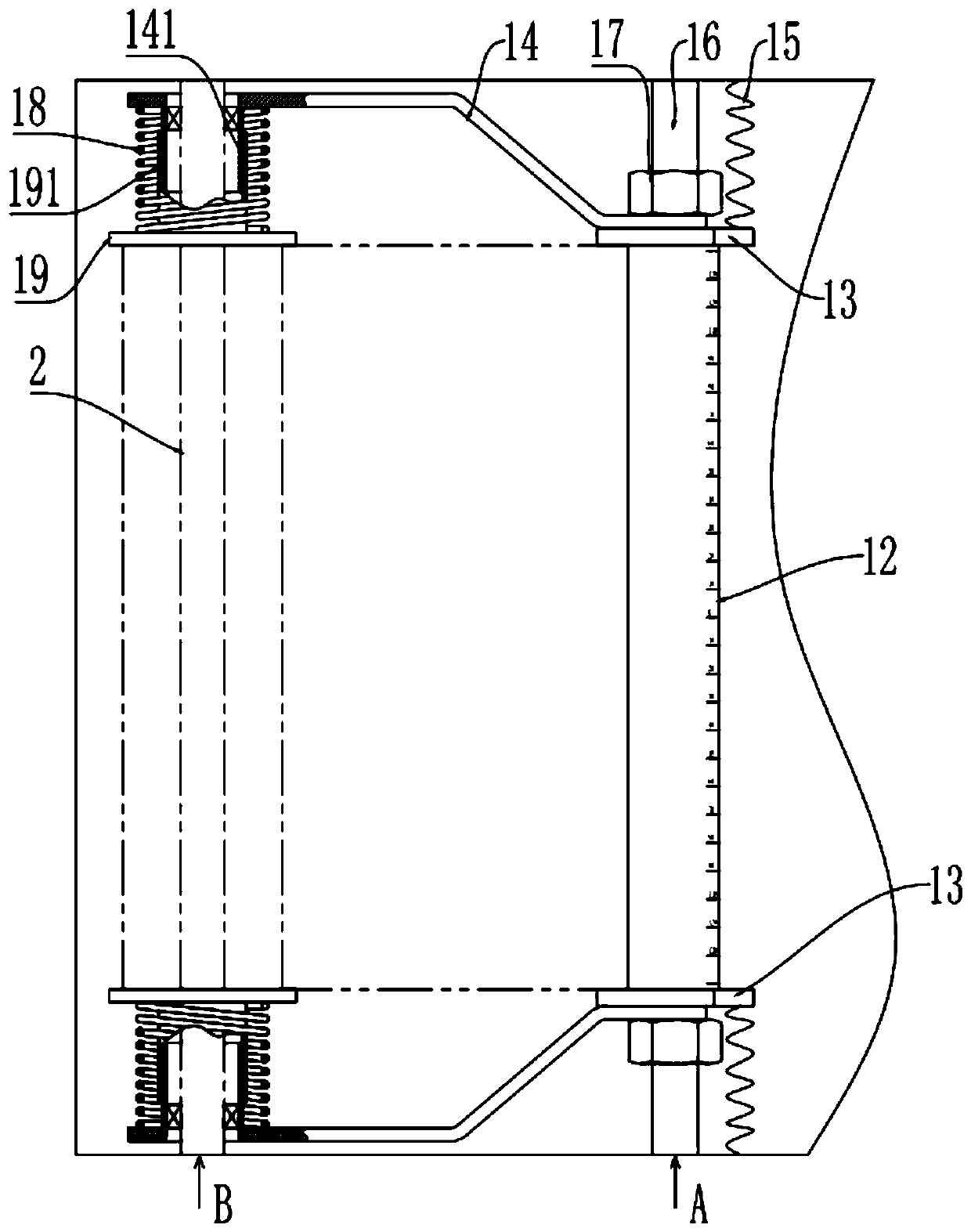

Mold and shaping technique for metal sheet material deep-drawing cup shell

The invention discloses a die assembly of metal plate deep-drawing cup shells and shaping process. The invention comprises an upper die holder and a lower die holder, wherein a punch and a cavity die which are mutually corresponded are respectively arranged on the upper die holder and the lower die holder, a discharging screw which is connected with the upper die holder and a flanging spring which is sleeved on the discharging screw are arranged on the outer side of the punch, a blank holder is arranged on the lower end of the discharging screw, a holding frame which is fixedly connected with the lower die holder is arranged on the outer side of the cavity die, a conical pushing block and a rubber pad are arranged in turn in the holding frame from top to bottom, a conical enclasping element which is matched with the punch is arranged in the conical pushing block, a spring holder is arranged on the lower end of the lower die holder, a material squeezing spring is arranged in the spring holder, and a push rod which is extended through the rubber pat, the conical pushing block, and a conical clamping element is arranged on the upper end of the material squeezing spring. The invention carries out enclasping along the side-wall direction during the deep-drawing process of cup shells, material flowing tendency can be changed flexibly and actively, which enables wall thickness to be changed evenly, maximum thinning-out quantity on a dangerous cross portion during the process for drawing can be minimized and drawing breakage can be avoided.

Owner:SHAANXI UNIV OF SCI & TECH

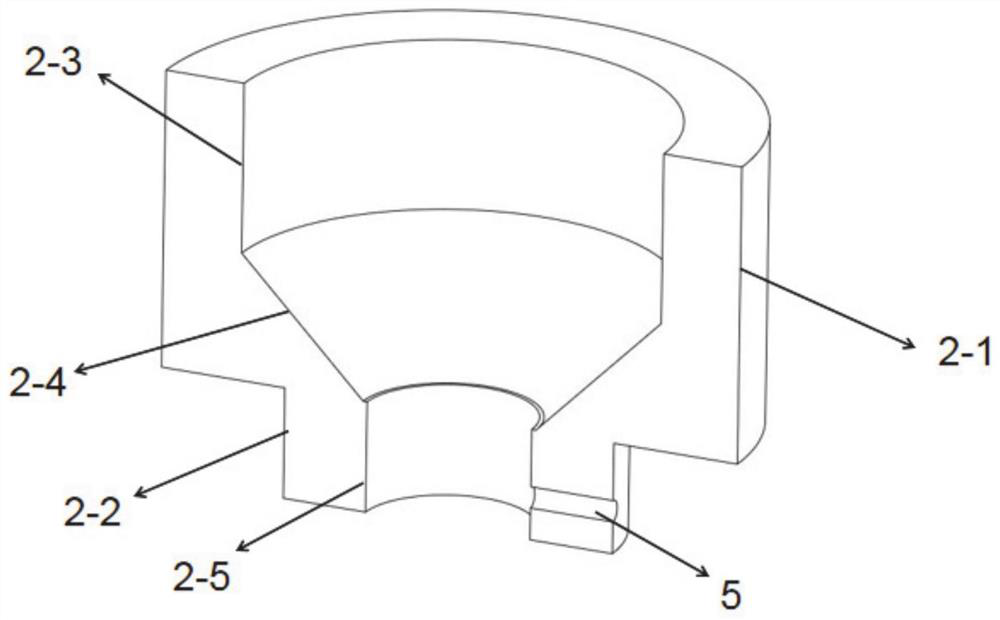

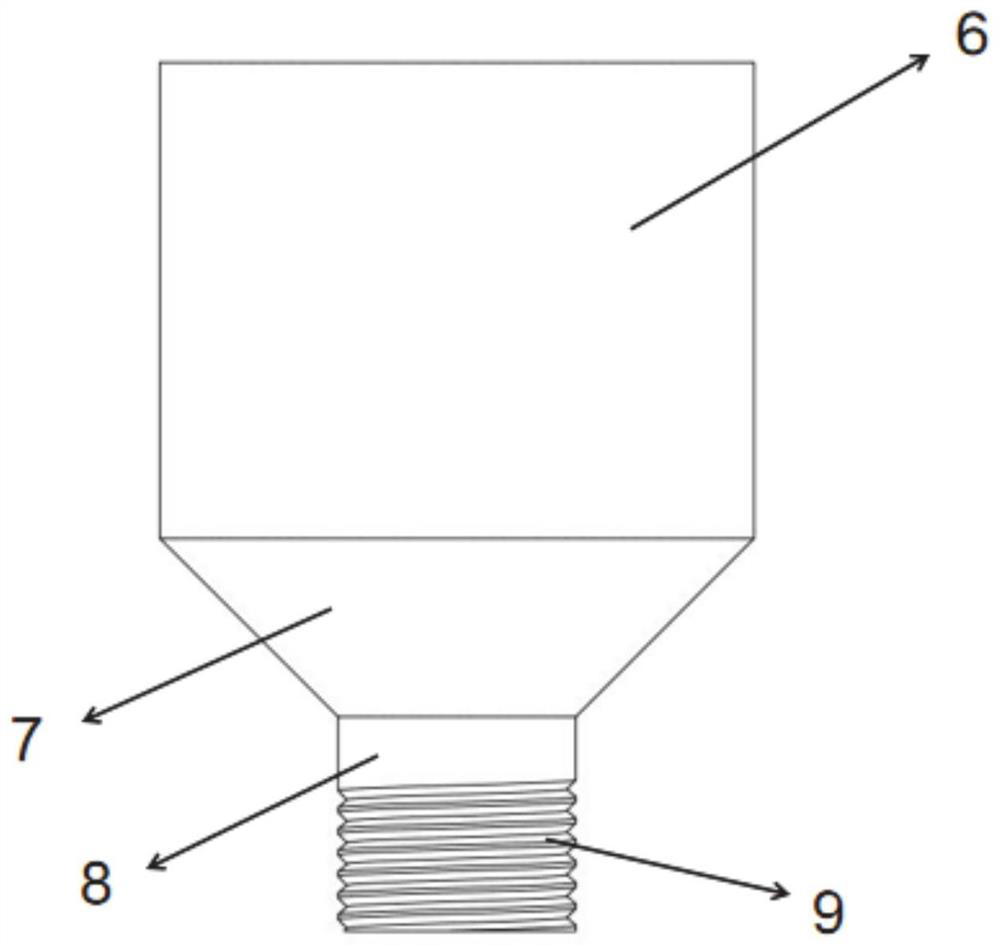

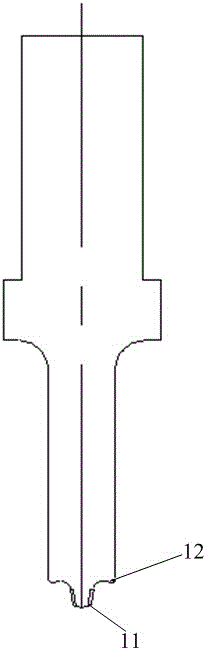

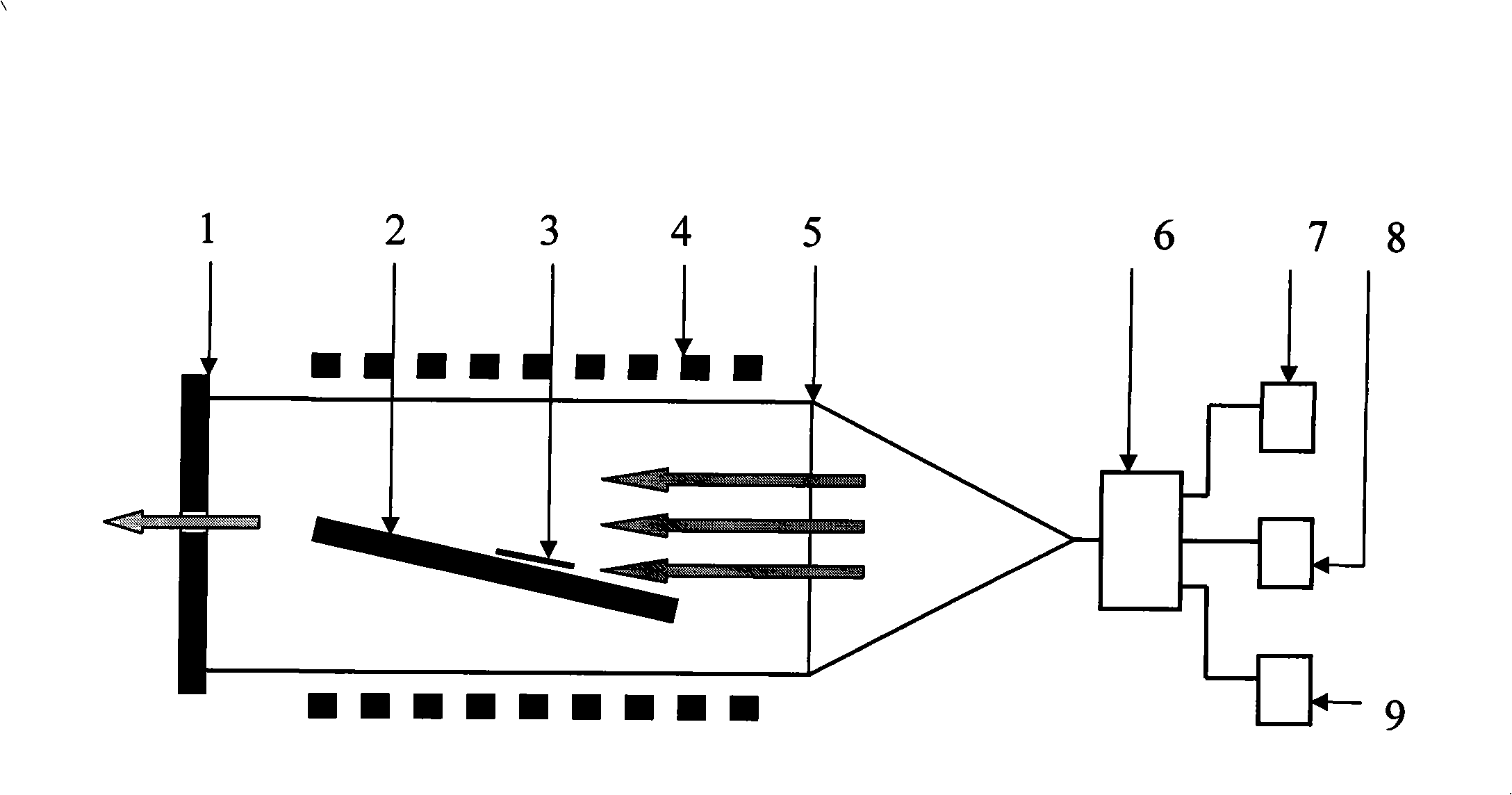

Filler wire static shaft shoulder friction stir welding and additive manufacturing device and method

PendingCN112958902AImprove mechanical propertiesEnabling Additive ManufacturingAdditive manufacturing apparatusNon-electric welding apparatusScrew threadMechanical property

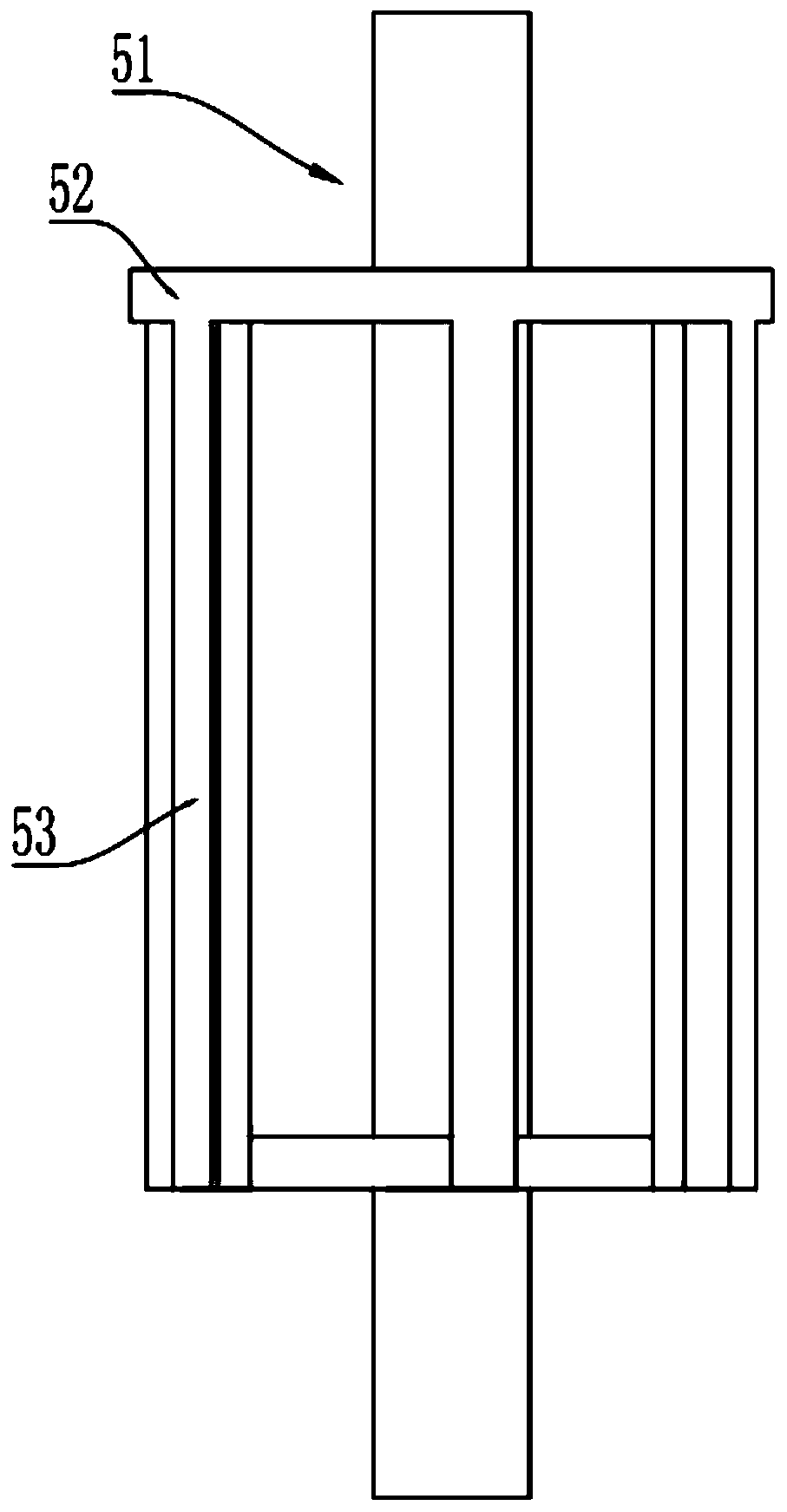

The invention relates to a filler wire static shaft shoulder friction stir welding and additive manufacturing device and method. The filler wire static shaft shoulder friction stir welding and additive manufacturing device comprises a stirring head, the periphery of the stirring head is sleeved with a static shaft shoulder, the stirring head and the static shaft shoulder are configured to synchronously move along a machining track, and the stirring head can rotate around the axis of the stirring head. A threaded groove is formed in the peripheral face of the machining end of the stirring head, the static shaft shoulder is provided with a wire feeding hole, and the wire feeding hole is used for feeding wires to the space between the part, provided with the threaded groove, of the stirring head and the hole face of a through hole formed in the static shaft shoulder. When the device is used for additive manufacturing, the interface bonding defects are avoided, and the bonding strength is guaranteed. And the mechanical property of additive manufacturing parts is greatly improved.

Owner:SHANDONG UNIV

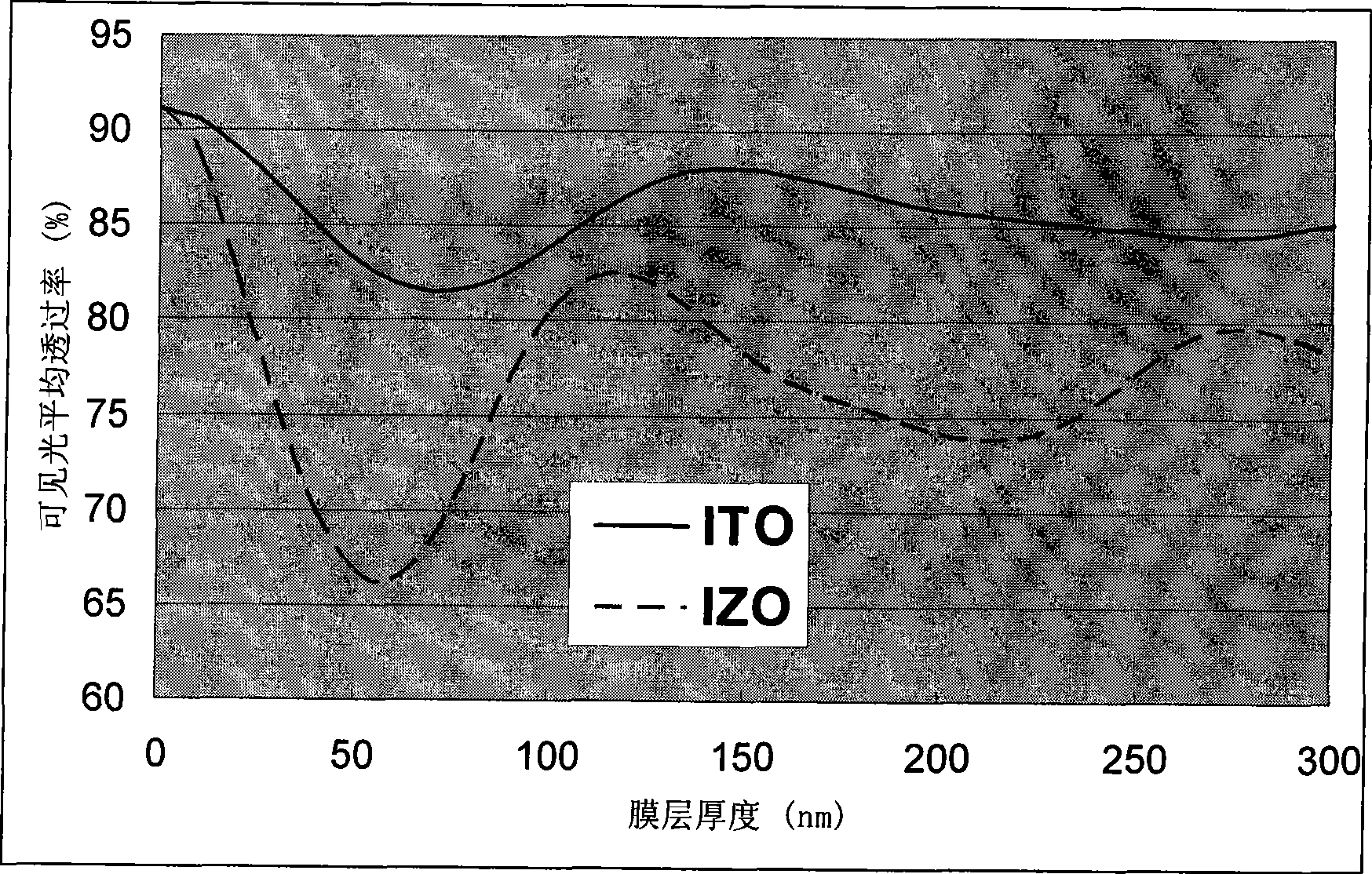

Transparent conductive film production method

InactiveCN101429640AHigh resistivityPrevent thinningStatic indicating devicesVacuum evaporation coatingGas phaseRefractive index

The invention discloses a preparation method for a transparent conductive film. Through the deposition on a transparent base plate in a physical vapor deposition mode, the preparation method prepares a multilayer film consisting of at least a transparent conductive film layer with a high refractive rate and at least a transparent conductive film layer with a low refractive rate; and the transparent conductive film layers are alternated. The visible light transmission rate of the transparent conductive film is improved through the multilayer film consisting of alternated high-refractive-rate films and low-refractive-rate films. Moreover, the multilayer transparent conductive film can have greater thickness and can have lower square resistance under the condition of higher resistivity.

Owner:北京东方新材科技有限公司

Thinning-free one-time brush-molded latex paint finishing coat and preparation method thereof

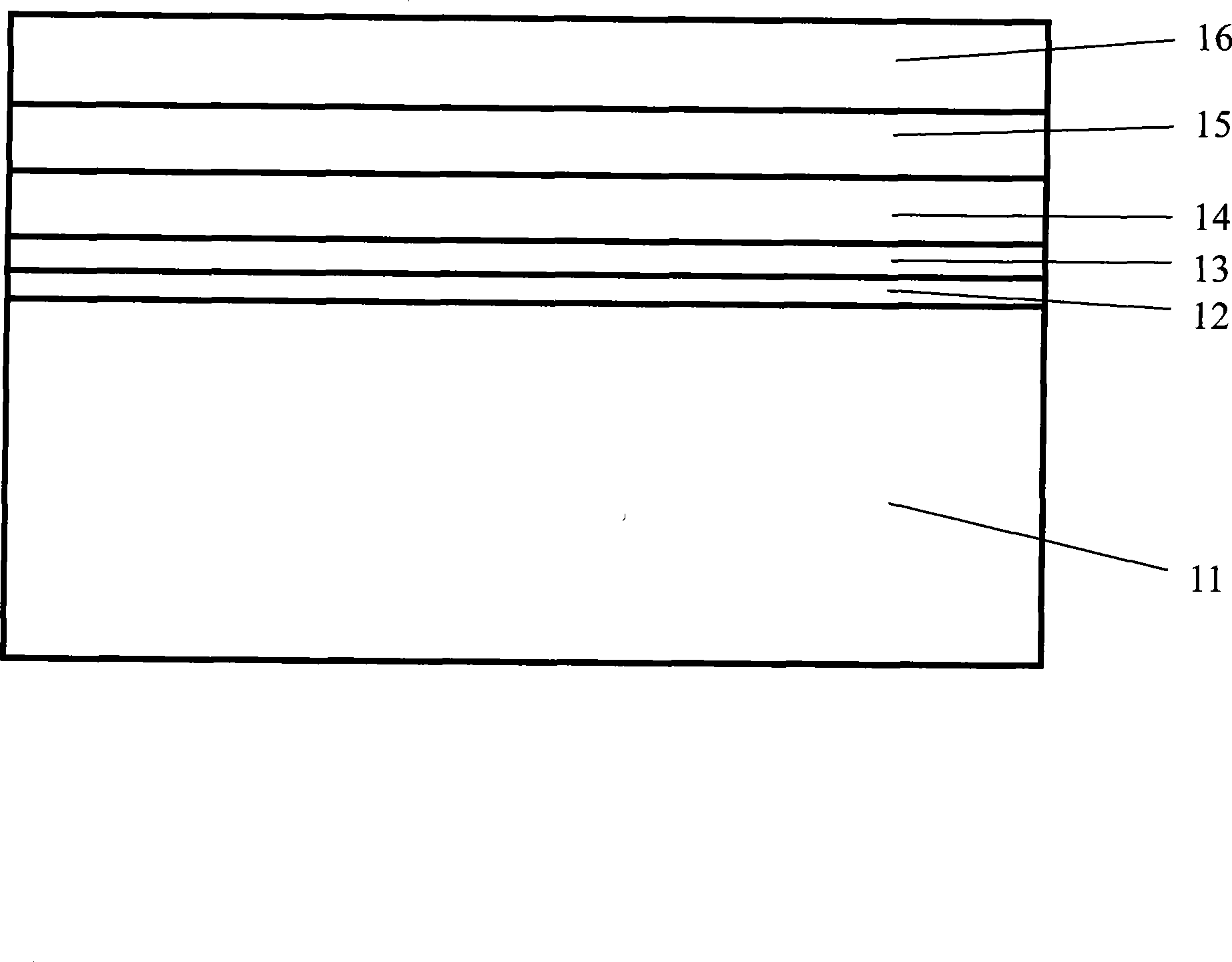

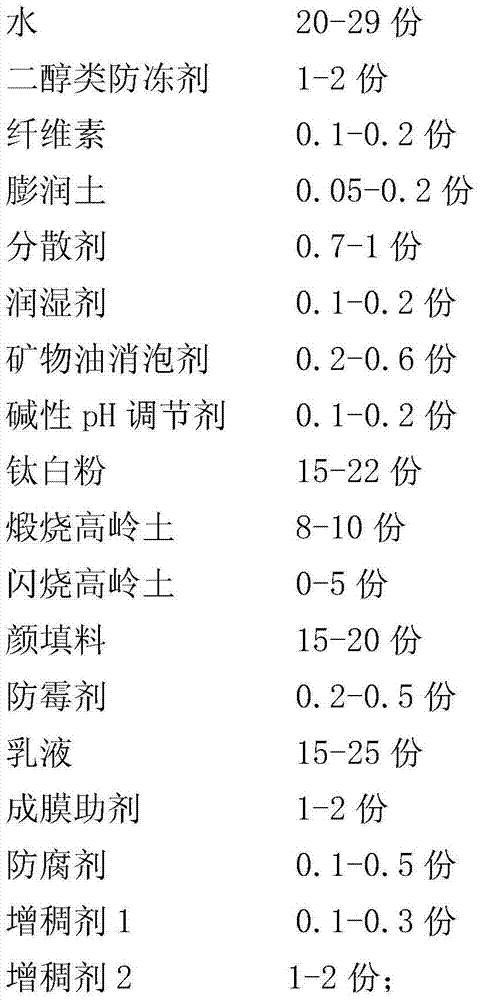

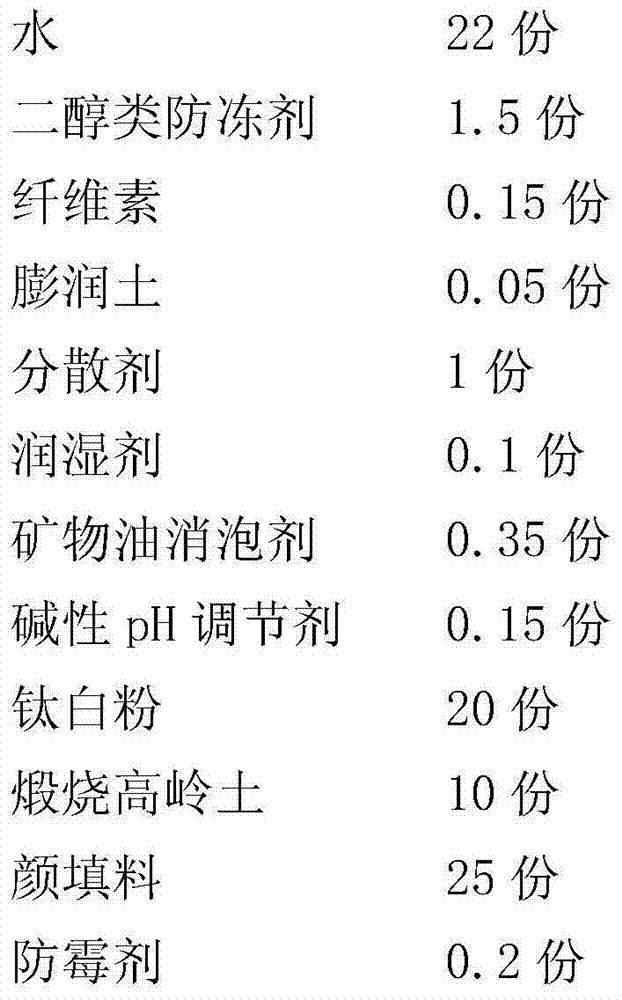

The invention relates to latex paint finishing coat and a preparation method thereof, and in particular relates to a thinning-free one-time brush-molded latex paint finishing coat and a preparation method thereof, belonging to the field of coatings for architectural decoration. The latex paint finishing coat is prepared from the following raw materials in parts by weight: 20-29 parts of water, 1-2 parts of a glycol anti-freezing agent, 0.1-0.2 part of cellulose, 0.05-0.2 part of bentonite, 0.7-1 part of a dispersing agent, 0.1-0.2 part of a wetting agent, 0.2-0.6 part of a mineral oil anti-foaming agent, 0.1-0.2 part of an alkaline pH regulator, 15-22 parts of titanium dioxide, 8-10 parts of calcined kaolin, 0-5 parts of flash-burned kaolin, 15-25 parts of pigment / filler, 0.2-0.5 part of mildew preventive, 15-20 parts of emulsion, 1-2 parts of a coalescing agent, 0.1-0.5 part of antiseptic, 0.1-0.3 part of a thickening agent 1 and 1-2 parts of a thickening agent 2.

Owner:SKSHU PAINT

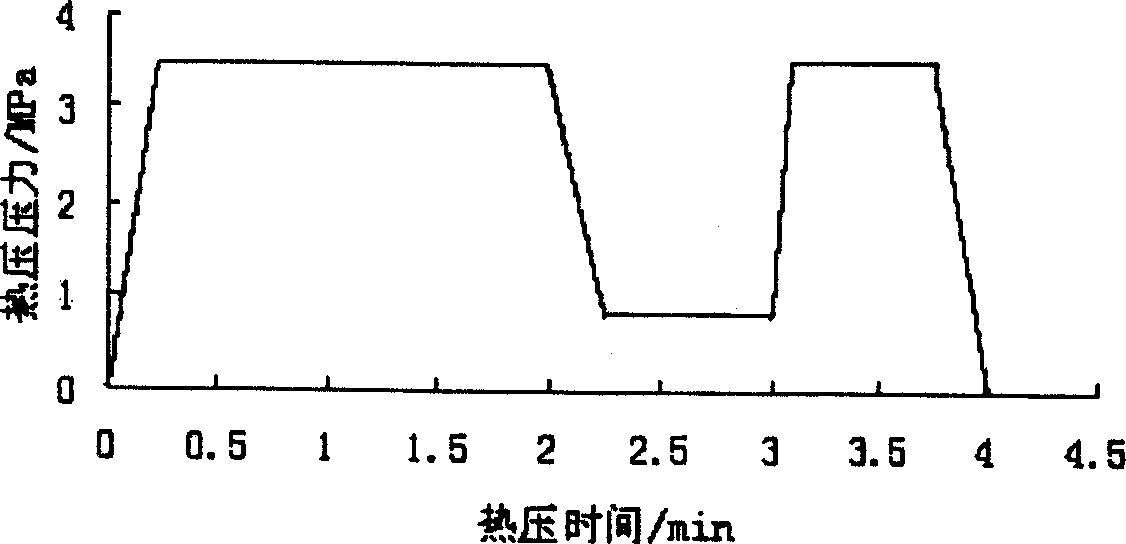

Method for manufacturing glue-less fiber board by leak-free type hot pressing technology

The present invention is sealed hot pressing technological process of producing no-glue fiber board with wood, bamboo or herbaceous plant as material, and solves the technological problems of lowering hot press pressure and expanding the product thickness and density range. The technological process includes the steps of: separating the material into wet fiber and applying paraffin emulsion; drying and spreading; pre-pressing; sealed and heated pressing the board blank inside sealing frame in a hot press to form the no-glue fiber board. The hot pressing step consists of hydrolysis section, air exhausting section and plasticizing section, and the sealing frame is heat resistant and airtight and in the shape of formed board.

Owner:ZHEJIANG FORESTRY UNIVERSITY

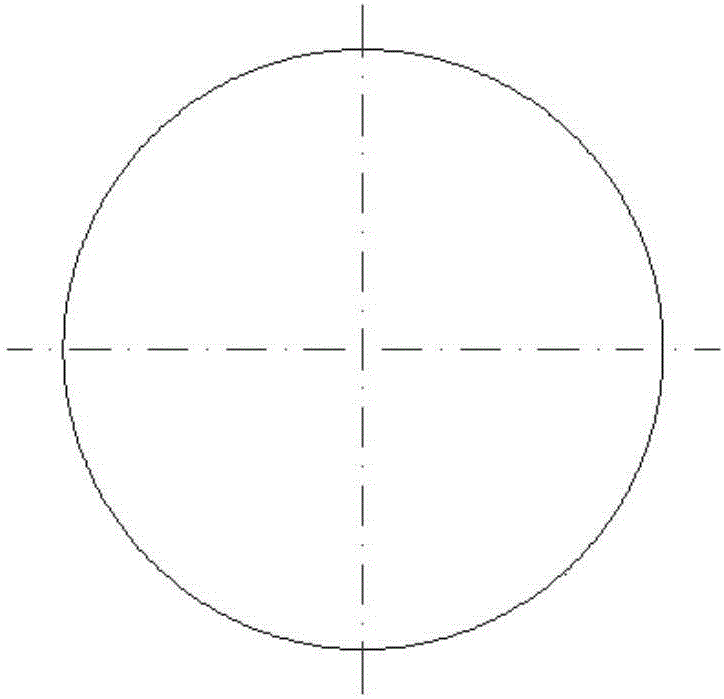

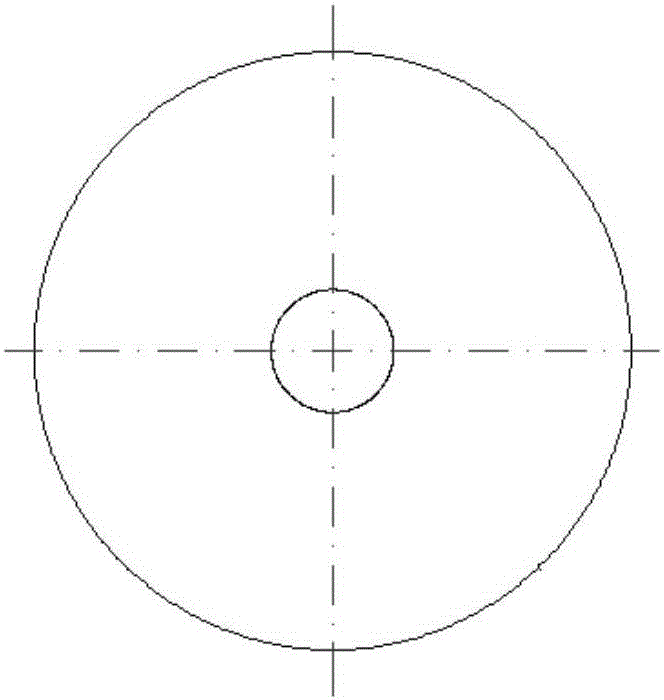

Integral spinning forming method of silicone oil damper housing of crankshaft

ActiveCN106514154AUniform force makes the growth process stable during the shoveling processStable growthBarrel ShapedFlanging

The invention discloses an integral spinning forming method of a silicone oil damper housing of a crankshaft. The method comprises the following steps: a, blanking; b, punching a center hole; c, performing shovel spinning to increase the thickness, wherein a first shovel spinning wheel and a second shovel spinning wheel on a numerically controlled spinning machine are synchronously operated to perform shovel spinning on a circular board so as to form an inner barrel on the circular board; d, performing stretching and spinning to obtain an outer barrel, namely, flanging the circular board through a flanging wheel on the numerically controlled spinning machine, and performing spinning through a spinning flattening wheel, so as to form the outer barrel on the circular board, wherein the outer barrel is concentric with the inner barrel; e, performing spinning to obtain teeth; and f, machining. The integral spinning forming method of the silicone oil damper housing of the crankshaft is high in adaptability; the silicone oil damper housing, manufactured by the method, of the crankshaft, is high in sealing performance, easy in quality control, and long in service life; meanwhile, a good spinning die design scheme and a good forming scheme are provided for other shovel spinning parts, stretching and spinning flanging parts and double-barrel shaped parts with different sizes. Therefore, the method has a great guiding significance.

Owner:NANTONG FULEDA AUTOMOBILE FITTINGS

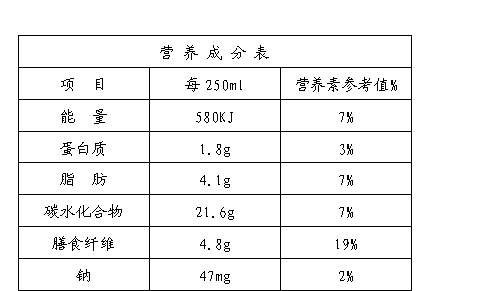

Walnut vegetable protein drink and method for producing same

InactiveCN102696770AEnhance memoryImprove memory functionMilk substitutesGlyceryl monostearateVegetable Proteins

The invention discloses a walnut vegetable protein drink and a method for producing the same. The walnut vegetable protein drink is produced from the following components in percentage by weight: 3-5% of walnut kernel, 1-2% of peanut kernel, 1-2% of brown rice, 5-10% of white granulated sugar, 0.03-0.1% of glyceryl monostearate, 0.05-0.1% of sodium alginate, 0.05-0.1% of agar, 0.01-0.03% of sodium hexametaphosphate and 0.01-0.05% of food essence, and the balance of purified water. The reasonable raw material constitution enables the product to have balanced comprehensive nutrition. The production technology does not filter the raw materials, so the raw materials are utilized to the maximum extent, a superfine technology is adopted, so the grain raw materials which contain under bark are subjected to the processing of a colloid mill, and the drink has fine mouthfeel, developmental nutrition, thicker concentration, and is the drink which is natural, nutrient and healthy.

Owner:厦门粗粮王饮品科技有限公司

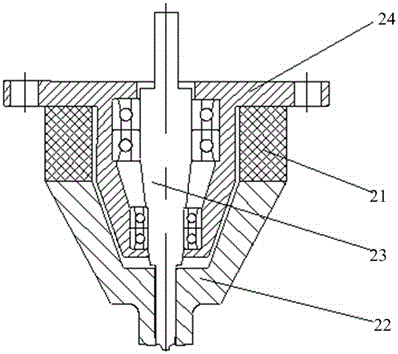

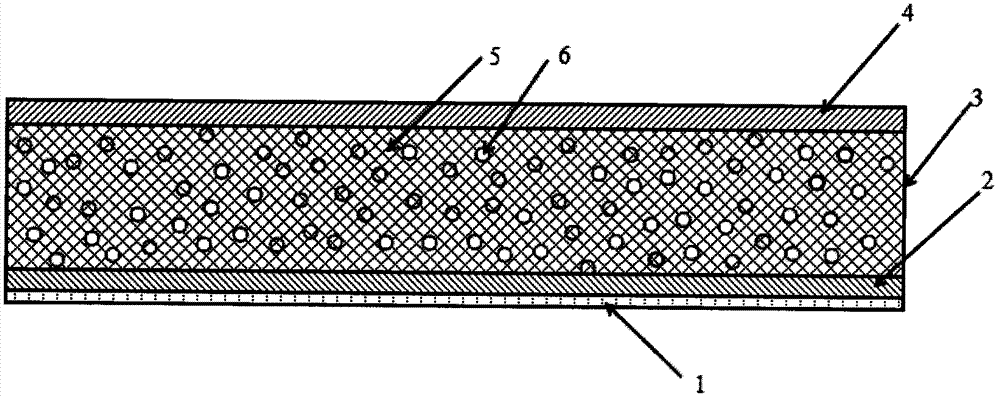

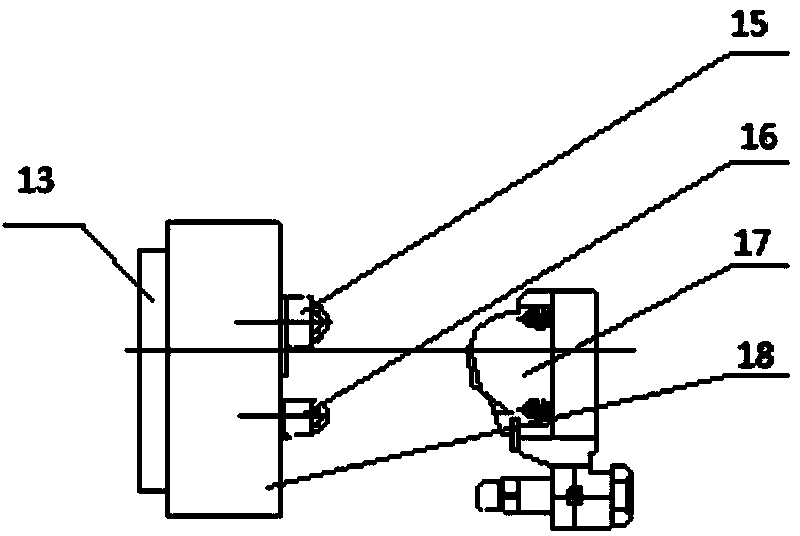

Friction-stir welding device and method thereof

InactiveCN106563878ASimple structurePrevent thinningNon-electric welding apparatusEngineeringHigh frequency vibration

The invention provides a friction-stir welding device. The friction-stir welding device comprises an ultrasonic generator, a variable-amplitude static shaft shoulder, a stirring needle and a mounting base, wherein the ultrasonic generator is in a hollow cylinder shape; the variable-amplitude static shaft shoulder is provided with a mounting opening in one end and coaxially and rigidly connected with the ultrasonic generator; the stirring needle, the ultrasonic generator and the variable-amplitude static shaft shoulder are coaxially mounted, and the non-operating end of the stirring needle is connected with a machine head spindle of the friction-stir welding device; and the mounting base is rigidly fixed to the ultrasonic generator. The invention further provides a method for conducting friction-stir welding on a workpiece through the friction-stir welding device. According to the method for conducting friction-stir welding on the workpiece through the friction-stir welding device, thinning of a weld joint can be effectively avoided through the non-rotational variable-amplitude static shaft shoulder; through high-frequency vibration of the variable-amplitude static shaft shoulder, welding flanges can be completely eliminated; and power ultrasounds are input into weld joint metal through the variable-amplitude static shaft shoulder, the structure of the weld joint can be optimized, and the mechanical performance of the weld joint is improved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

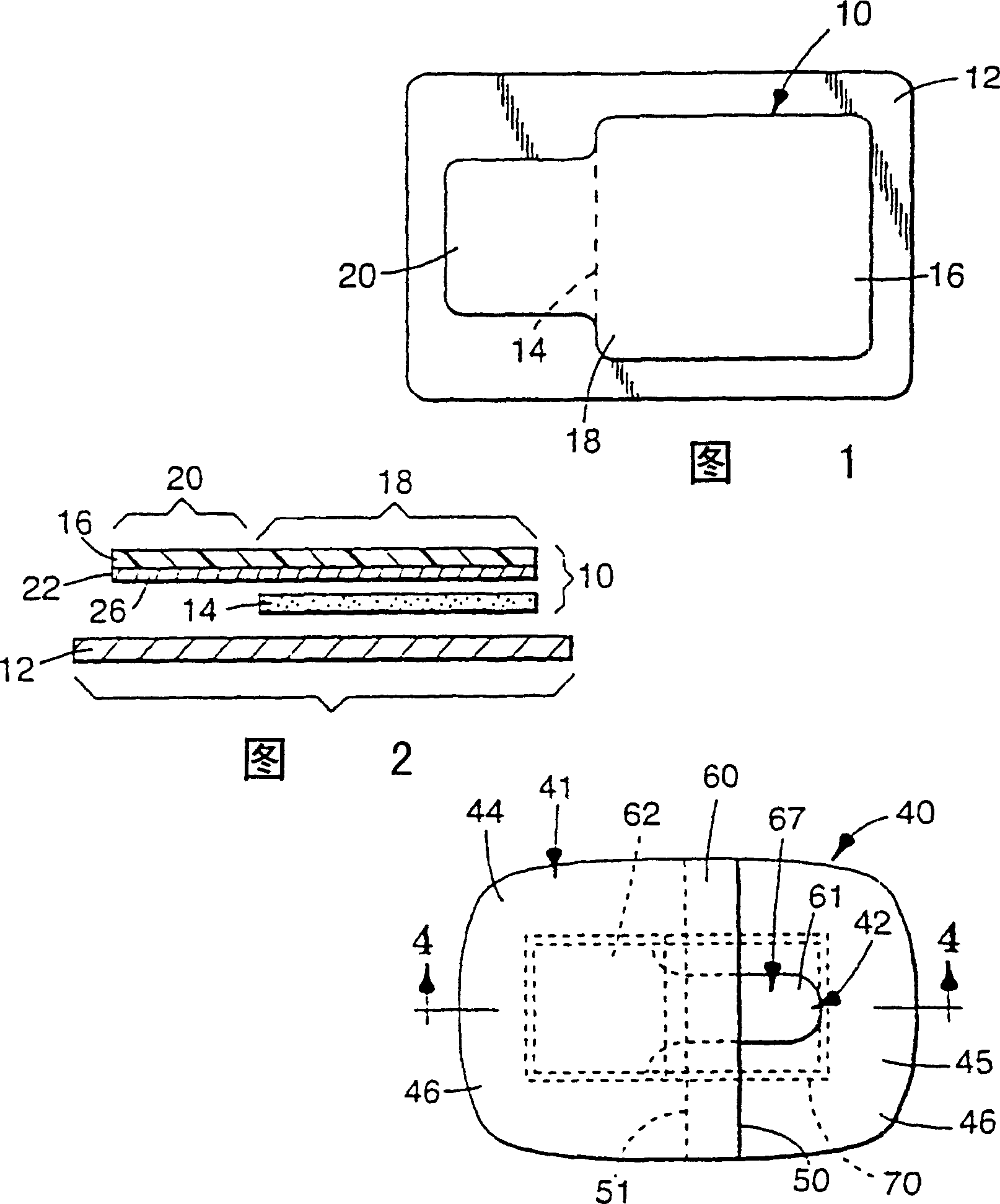

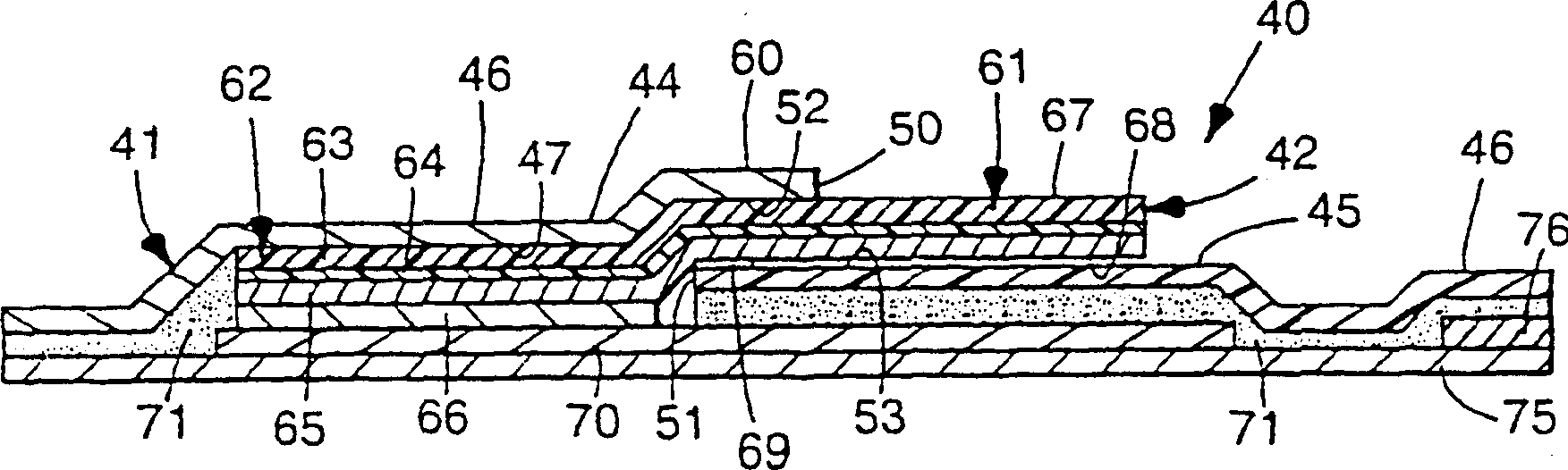

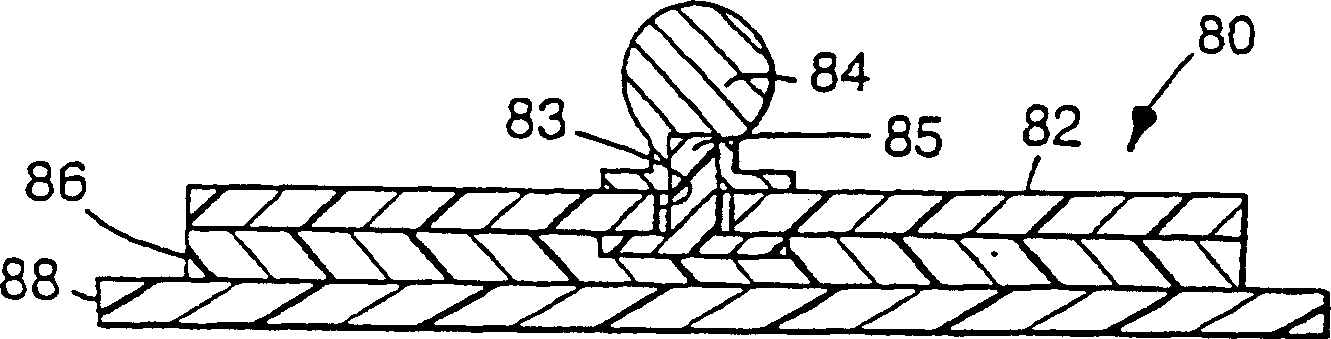

Pressure sensitive conductive adhesive having hot-melt properties and biomedical electrodes using same

InactiveCN1402768APrevent thinningHigh application speedUnsaturated ether polymer adhesivesAdhesive dressingsHot meltPressure sensitive

A skin-compatible, hot-melt processible, pressure sensitive adhesive is disclosed. A thermo-reversible cross-linking is achieved, permitting advantages in processibility and the reduction of waste.

Owner:3M INNOVATIVE PROPERTIES CO

Rice crust containing red tea and corn

InactiveCN103564340AExtension of timeIncrease concentrationFood ingredient functionsFood preparationFlavorEdible oil

The invention relates to the technical field of foods, in particular to rice crust containing red tea and corn. The rice crust is prepared from the following raw materials in parts by weight: 30-50 parts of corn, 20-40 parts of wheat, 1-5 parts of salt, 1-3 parts of red tea powder, 5-8 parts of red tea leaves, 1-5 parts of chicken essence, 10-15 parts of edible oil, 50-80 parts of water and 0.01-0.03 part of sorbic acid. A preparation method for the rice crust comprises the following steps: (1) adding the red tea leaves into the water for boiling and soaking for 15-30 minutes, cooling, and filtering out the leaves to obtain a raw red tea solution; (2) putting the corn and the wheat into the raw solution obtained from the step (1) for soaking for 18-24 hours, taking out, adding the salt, the chicken essence and sorbic acid, and beating into paste for later use; (3) pressing the paste into slices by a mould, sprinkling the red tea powder outside the slices, frying in a pan of 160-180 DEG C by the edible oil for 5-10 minutes, and carrying out vacuum packaging by plastic bags. The rice crust is rich in tea fragrance, unique in taste, full in flavor and suitable for popularization and eating.

Owner:NINGBO CITY YINZHOU FENGMING IND PROD DESIGN

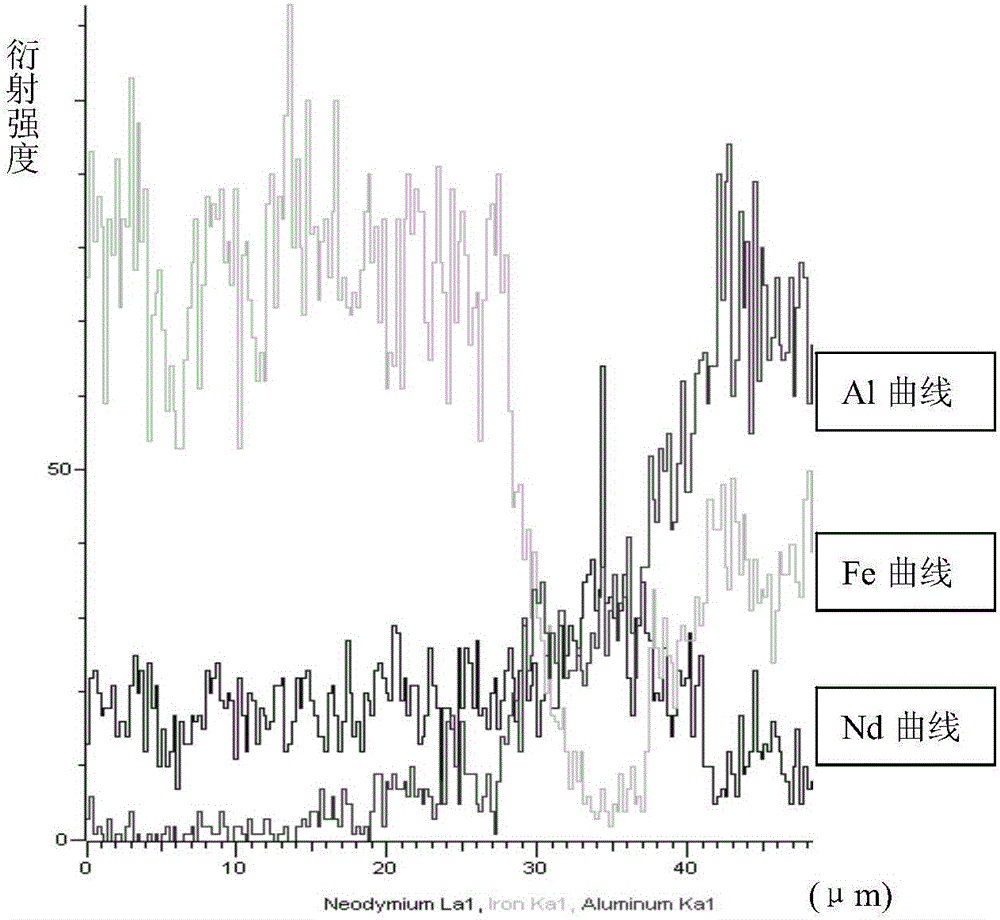

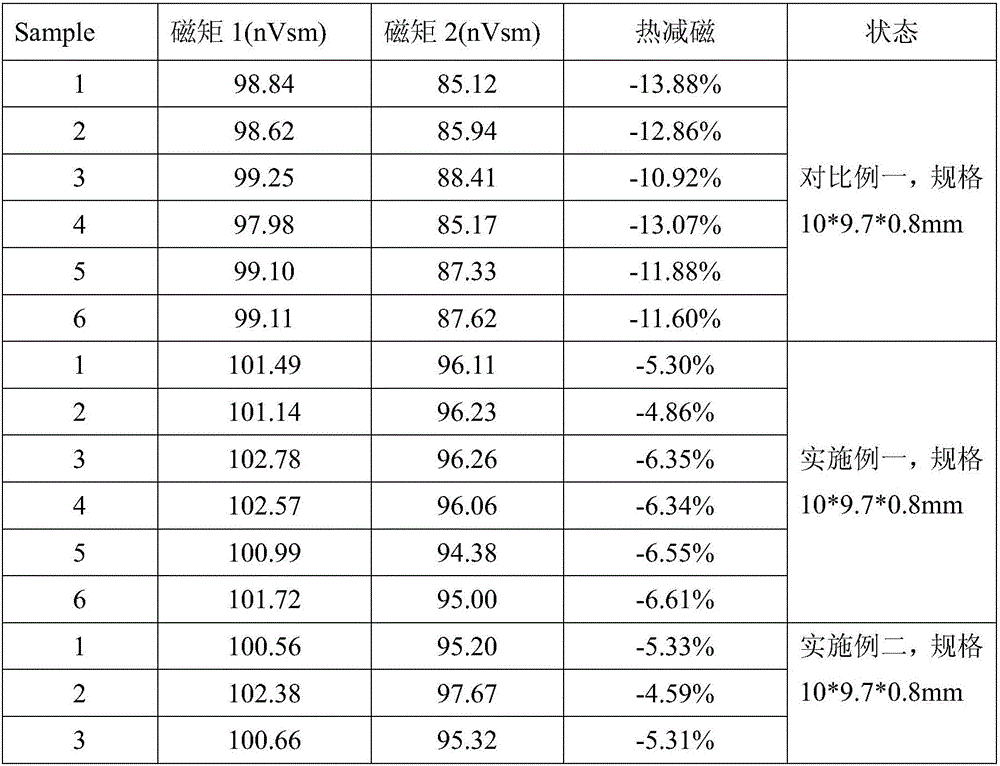

Preparation method of sintering neodymium iron boron sheet magnet

ActiveCN106783131AReduce direct contactReduce Hard Magnetic CouplingInductances/transformers/magnets manufactureMagnetic materialsMetal foilTerbium

The invention discloses a preparation method of a sintering neodymium iron boron sheet magnet. The preparation method comprises the following steps of manufacturing a sintering neodymium iron boron blank into a sheet blank with thickness of 0.4 to 1.0mm by a mechanical processing technology; when grains at the surface layer of the sheet blank are damaged, cleaning and drying the surface of the sheet blank, packaging a black sheet by a metal bag or metal foil paper, putting into a vacuum sintering furnace, and performing heat treatment under a vacuum state; then, performing vibration, grinding and chamfering, and pickling surface activation. The preparation method has the advantages that excessive noble elements, such as cobalt, dysprosium and terbium, do not need to be added, so that the material cost of a component is hardly increased; the size critical point of the component thinning corresponding to the size fining of the grains is avoided; the cost is lower, the difficulty in technology manufacturing is little, and the degrading of anti-magnetic decay ability caused by damage to the surface grains is relieved.

Owner:NINGBO YUNSHENG +2

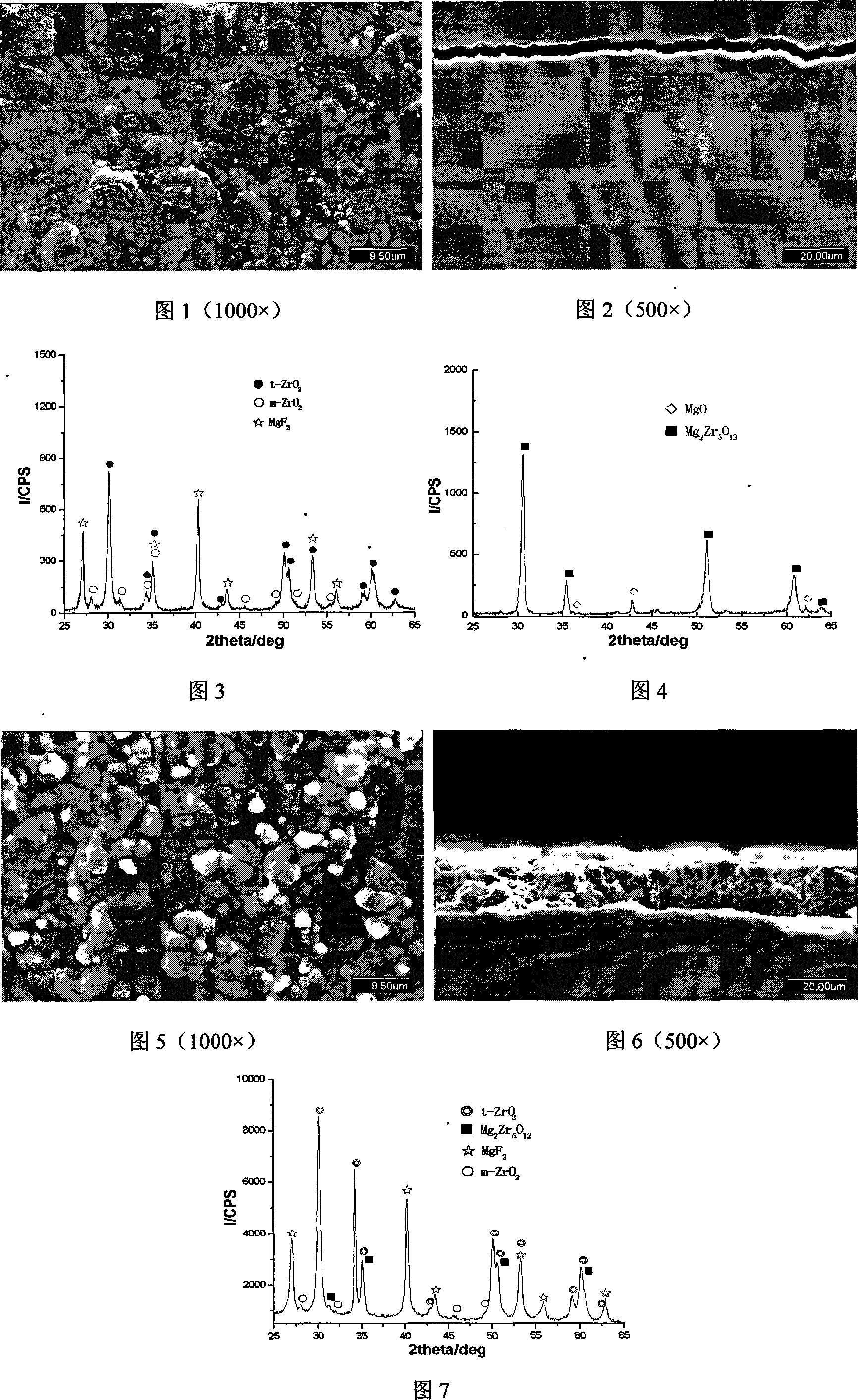

Magnesium radical differential arc oxidization electrolytic solution and its differential arc oxidation process

InactiveCN101113529AProcess stabilitySimple ingredientsAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a magnesium matrix microarc oxidation electrolyte liquid and a microarc oxidation method thereof. The electrolyte liquid comprises: 3 - 40g / L of fluozicronate, 0.5 - 10 g / L of oxalate, 2 - 20 g / L of phosphoric acid, 1 - 20 g / L of acetate, 3 - 30 g / L of phosphate, 0.5 - 10 g / L of fluoride. The operation method is that: a magnesium workpiece is taken as anode, stainless steel is taken as cathode, a pulse power supply is adopted, constant voltage is 350 - 650V, frequency is 50 - 2000Hz, duty ratio is 10 - 40 percent, and the electrolyte liquid is oxidated through microarc under the condition that the distance between a cathode plate and an anode plate is 8 - 12 cm, the temperature of the electrolyte liquid is kept for 10 - 40 DEG C with the treatment time of 5 - 90min. the electrolyte liquid of the invention does not comprise Cr6+, thus having not too large pollution to environment; the obtained film layers which consists of anti-corrosive substances have the advantages of smooth surface, ceramics appearance, strong combination, comparatively larger thickness, high density and little pores, high hardness, etc.

Owner:XI AN JIAOTONG UNIV

Sweet corn beverage and preparation method thereof

The invention discloses a sweet corn beverage and a preparation method thereof. The sweet corn beverage is made from the following components in percentage by weight: 15-20% of sweet corn kernel, 2-5% of coconut extract, 5-10% of white granulated sugar, 0.5-1% of sodium caseinate, 0.05-0.1% of microcrystalline cellulose, 0.05-0.1% of gellan gum, 0.05-0.1% of carrageenan, 0..05-0.1% of xanthan gum, 0.03-0.1% of glycerin monostearate, 0.01-0.5% of baking soda and the balance of purified water. According to reasonable raw materials collocation, the product is balanced and comprehensive in nutrition. In the preparation process, the raw materials are not filtered, so that the raw materials are furthest utilized, and an ultrafine technology is used to ensure that the bast-containing grain raw materials have fine and smooth taste, rich nutrition and thicker concentration after being processed by a colloid mill, so that the sweet corn beverage is a natural, nutritive and healthy beverage.

Owner:厦门粗粮王饮品科技有限公司

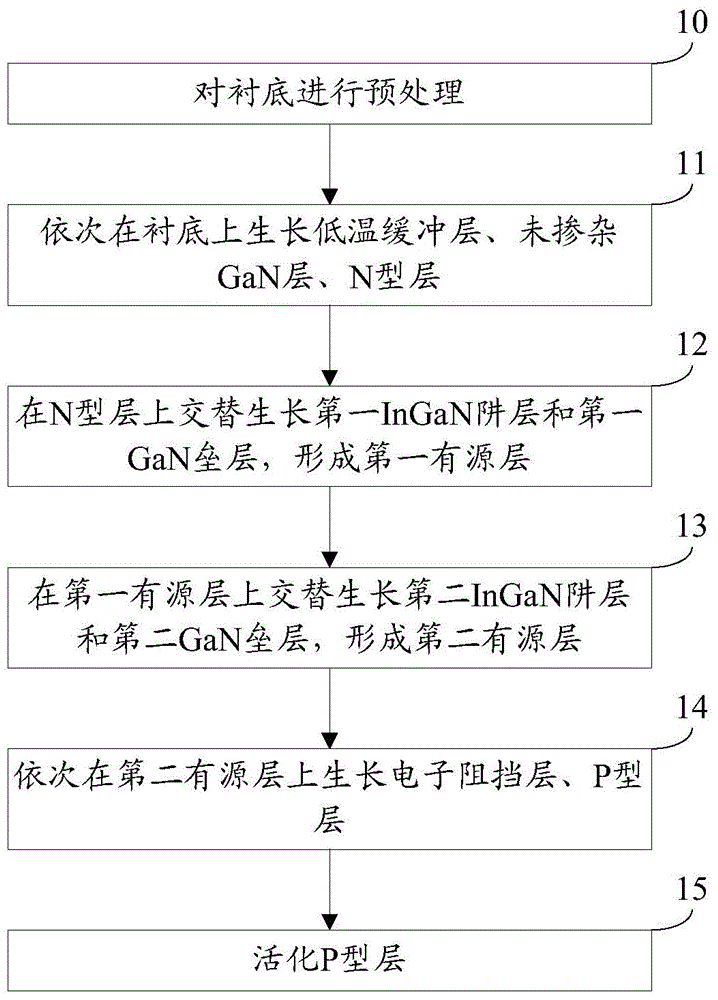

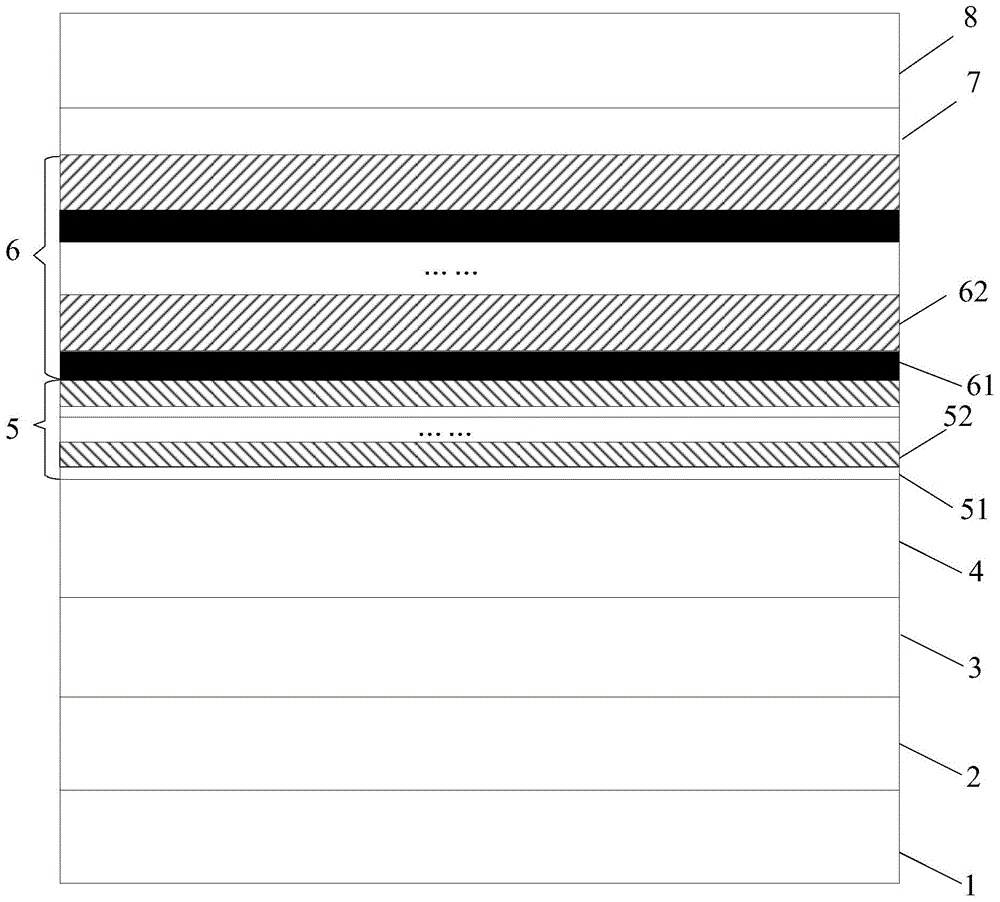

Growth method for light-emitting diode epitaxial wafer and epitaxial wafer

The invention discloses a growth method for a light-emitting diode epitaxial wafer and an epitaxial wafer, belonging to the technical field of a semiconductor. The growth method comprises the following steps of: sequentially growing a low-temperature buffer layer, a non-doped GaN layer and an N-type layer on a substrate; alternatively growing a first InGaN pit layer and a first GaN barrier layer on the N-type layer to form a first active layer; alternatively growing a second InGaN pit layer and a second GaN barrier layer on the first active layer to form a second active layer; and sequentially growing an electron blocking layer and a P-type layer on the second active layer, wherein the growth pressure of the second active layer is lower than the growth pressure of the first active layer, the growth speed of the second active layer is lower than the growth speed of the first active layer, the thickness of the second active layer is smaller than the thickness of the first active layer, and the growth pressure, the growth speed and the thickness of the second InGaN pit layer are gradually reduced, slowed and decreased along the growth direction of the light-emitting diode epitaxial wafer. The epitaxial wafer is high in luminous efficiency.

Owner:HC SEMITEK SUZHOU

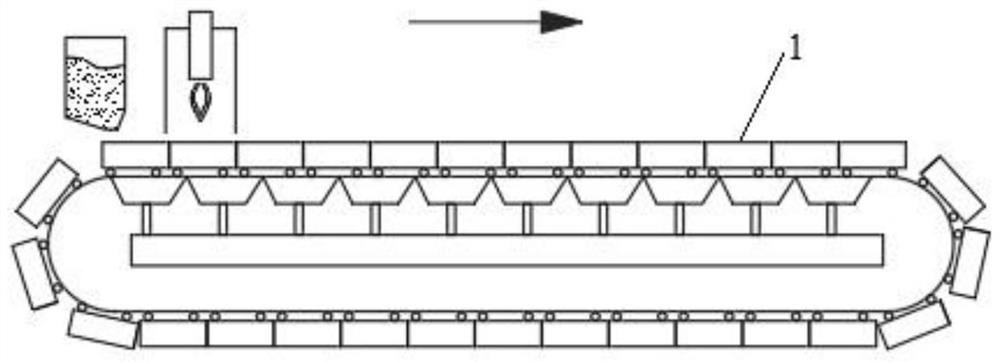

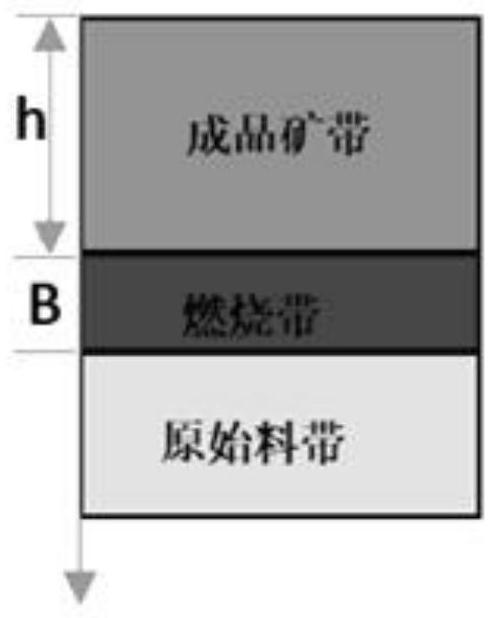

Soaking sintering method based on layered composite heat supply

The invention relates to a soaking sintering method based on layered composite heat supply. The soaking sintering method based on layered composite heat supply comprises the following steps that 1), proportioning is carried out on an iron-containing raw material, a flux, a solid fuel and water, and the proportioned sintering mixture is distributed onto a sintering machine trolley; 2) the sintering mixture distributed to the sintering machine trolley is ignited, and the fact of sintering the surface-layer sintering mixture in the sintering machine trolley is started; 3) high-temperature gas is injected to the material surface of the sintering mixture after ignition, and the high-temperature gas supplies heat to the middle-upper layer sintering mixture; (4) after heat preservation and heat supply, combustible gas is injected to the material surface of the sintering mixture, and the combustible gas is combusted in the material layer to supply heat to the middle-layer sintering mixture; and (5) after gas injection, steam is injected to the material surface of the sintering mixture, and the steam accumulates heat to supply heat to the lower-layer sintering mixture. By adopting the method, the problems of insufficient heat of an upper material layer and excessive heat of a lower material layer in traditional sintering can be effectively solved, and green soaking low-carbon sintering is realized.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

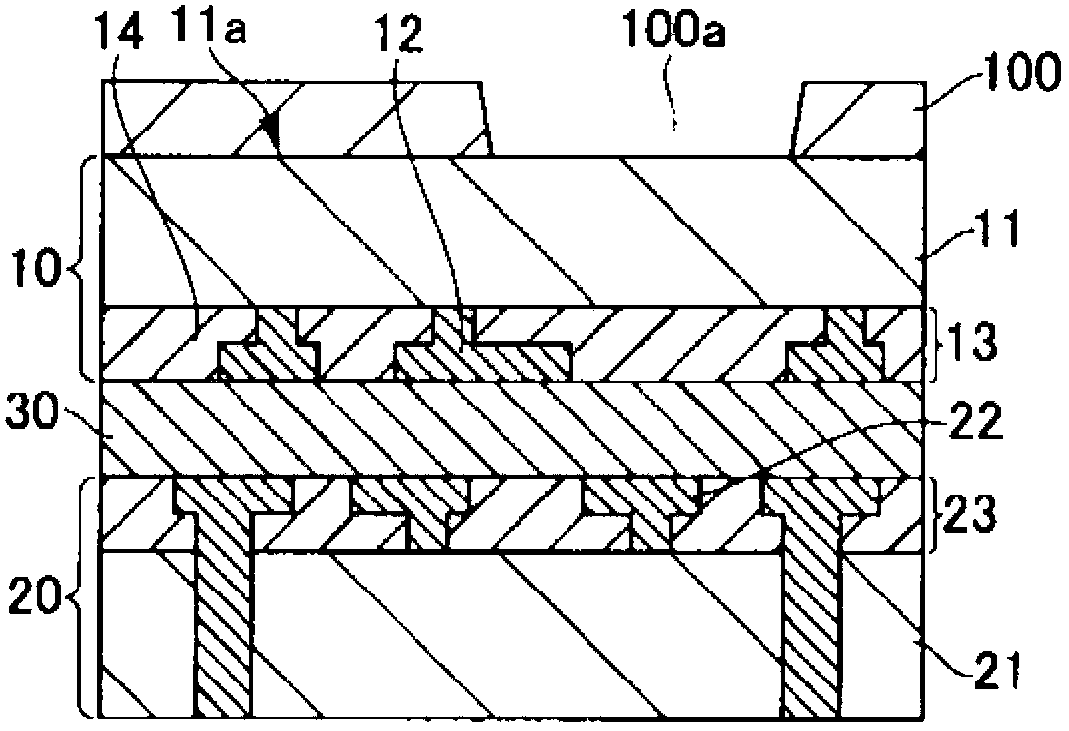

Organic electronic device and method for manufacturing the same

ActiveCN102804440AInhibit deteriorationPrevent thinningFinal product manufactureSolid-state devicesOrganic solar cellScavenger

The invention provides an organic electronic device which does not deteriorate the device performance over a long period of time, for example, a thin film organic solar cell element in which a lowering of the power generation efficiency is suppressed, and a method for manufacturing the organic electronic device. Disclosed is an organic electronic device formed by laminating an organic semiconductor element (B) provided with at least a pair of electrodes, a layer (C) containing a scavenger which absorbs at least one of water and oxygen, and a gas barrier film (d) in this order, wherein one or plural anticorrosion layers (E) is provided between at least one of the pair of electrodes and the layer (C) containing a scavenger which absorbs at least one of water and oxygen; the thickness of the anticorrosion layer (E) is 20 [mu]m or more; the moisture vapor transmission rate (Pe) (g / m2 / day) of the anticorrosion layer (E) in 40 DEG C and 90% RH environment with respect to the moisture vapor transmission rate (Pd) of the gas barrier film (D) in 40 DEG C and 90%RH environment satisfies a condition of 15 g / m2 / day>=Pe>Pd; and the moisture vapor transmission rate (Pd) of the gas barrier film (D) satisfies a condition of 10<->4<=Pd<=10<-1> g / m2 / day.

Owner:MITSUBISHI RAYON CO LTD

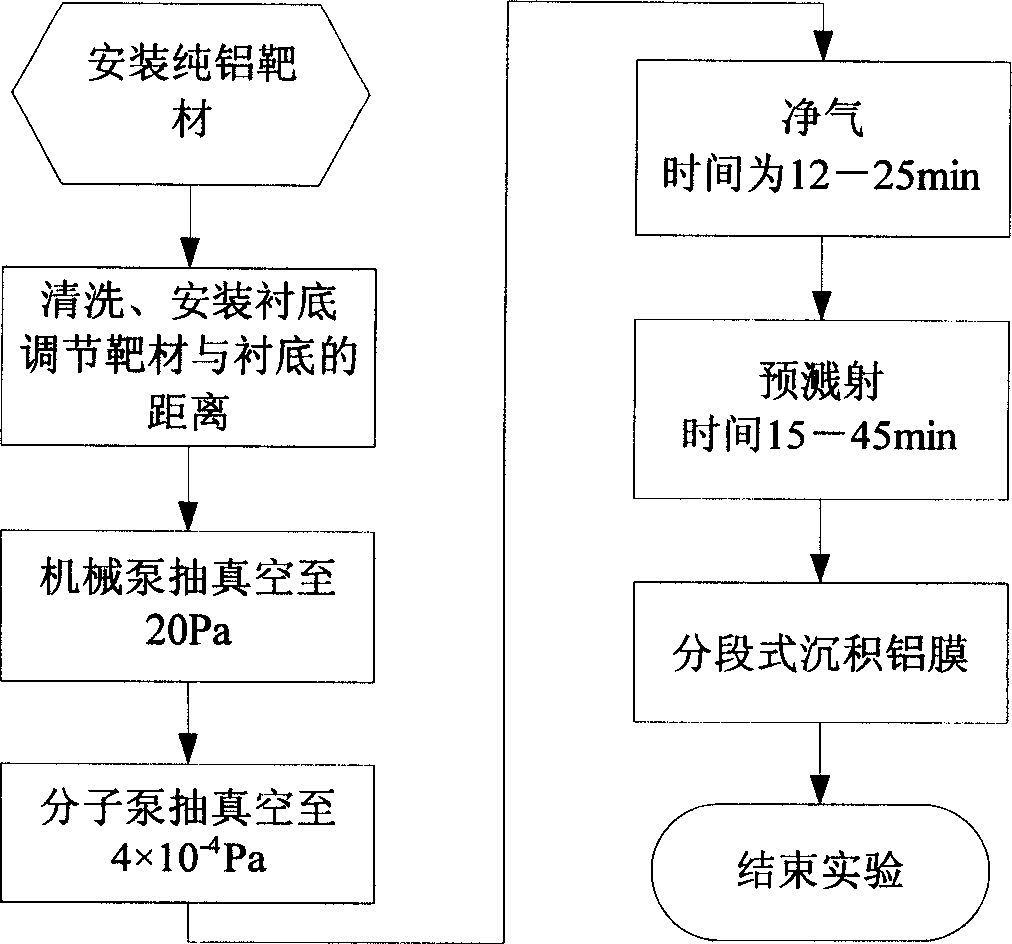

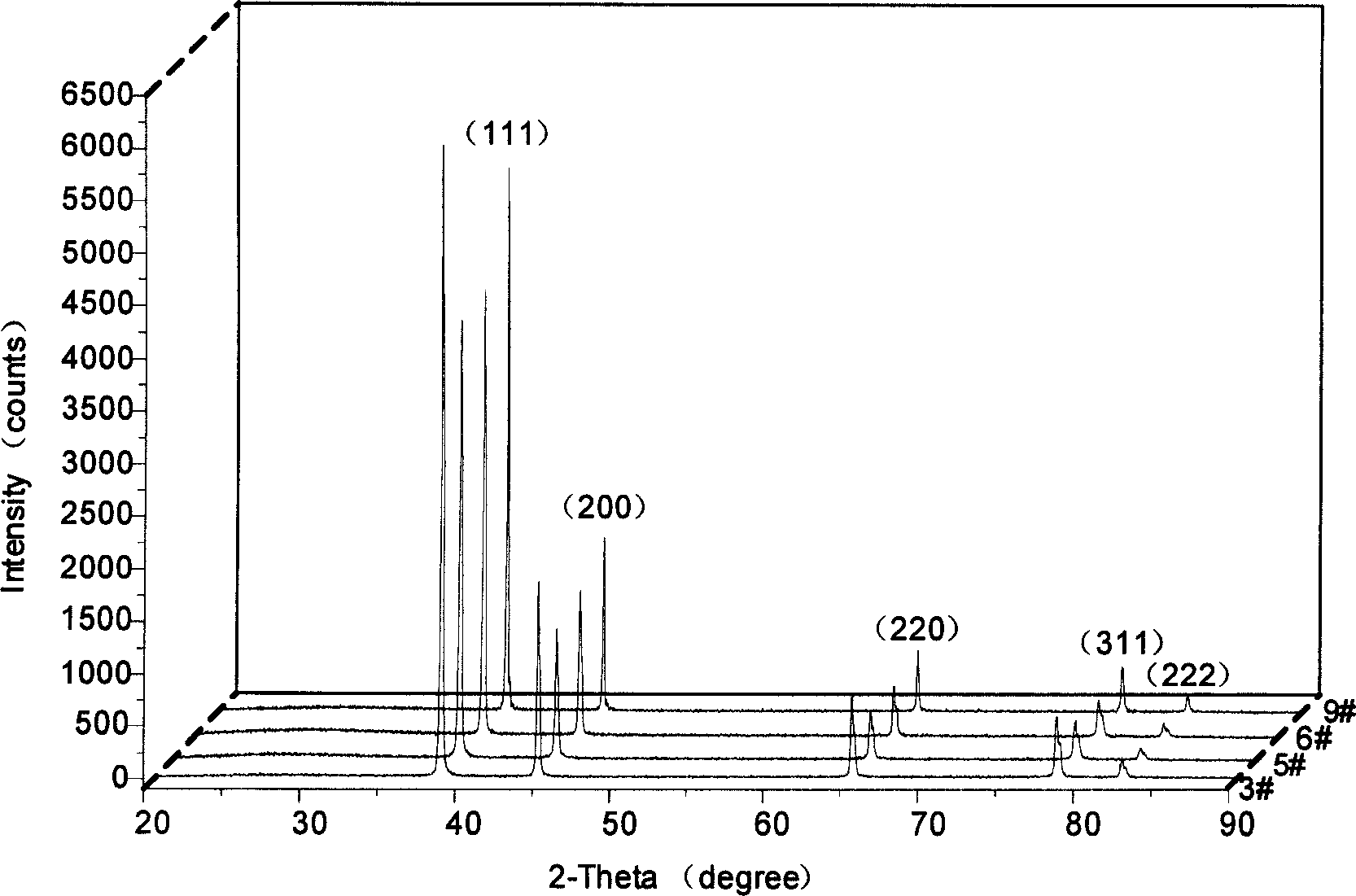

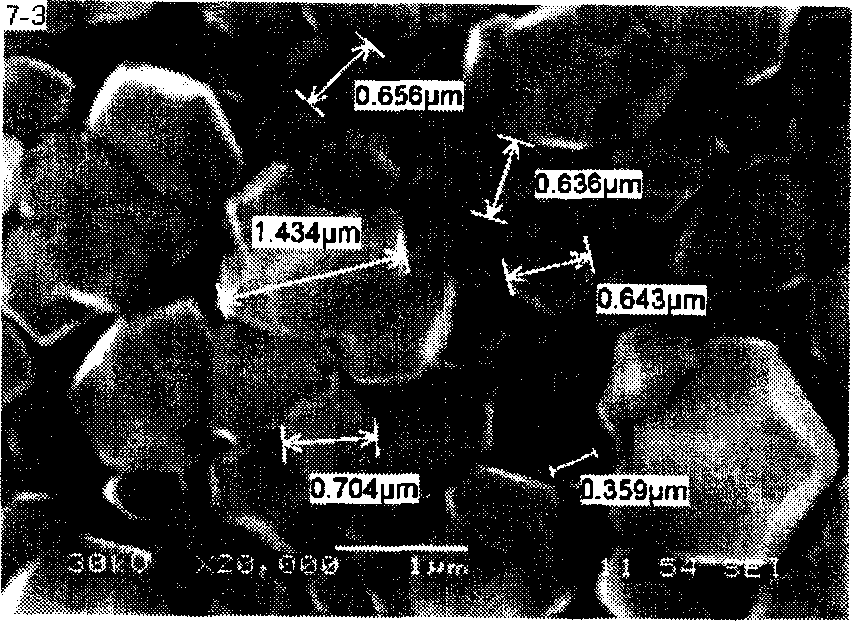

Method for preparing thick film of superfine crystal in pure aluminum through DC magnetism controlled sputtering

InactiveCN1916230APrevent thinningQuality improvementVacuum evaporation coatingSputtering coatingSurface engineeringGranularity

This invention discloses a method for preparing pure aluminum ultrafine crystal thick film by DC magnetron sputtering. The method comprises: (1) selecting pure aluminum target, installing a substrate, and adjusting the distance between the target and the substrate; (2) evacuating, introducing Ar for 12-25 min, and pre-sputtering for 15-45 min; (3) sputtering for deposition under 0.6-0.8 Pa, Ar flow of 20-40 cm3 / s, sputtering current of 0.8-1.6 A and sputtering voltage of 180-300 V; (4) stopping deposition for 10-30 min after sputtering for 5-15 min, and repeating the procedures until desirable thickness of the pure aluminum ultrafine crystal thick film is reached. The method can obtain pure aluminum ultrafine crystal thick film with a thickness above 2 mum. Besides, the thick film also has cuh advantages as good quality, high thickness and small granularity, and can be used as protective coating layer in such fields as surface engineering and microelectronics.

Owner:重庆工学院

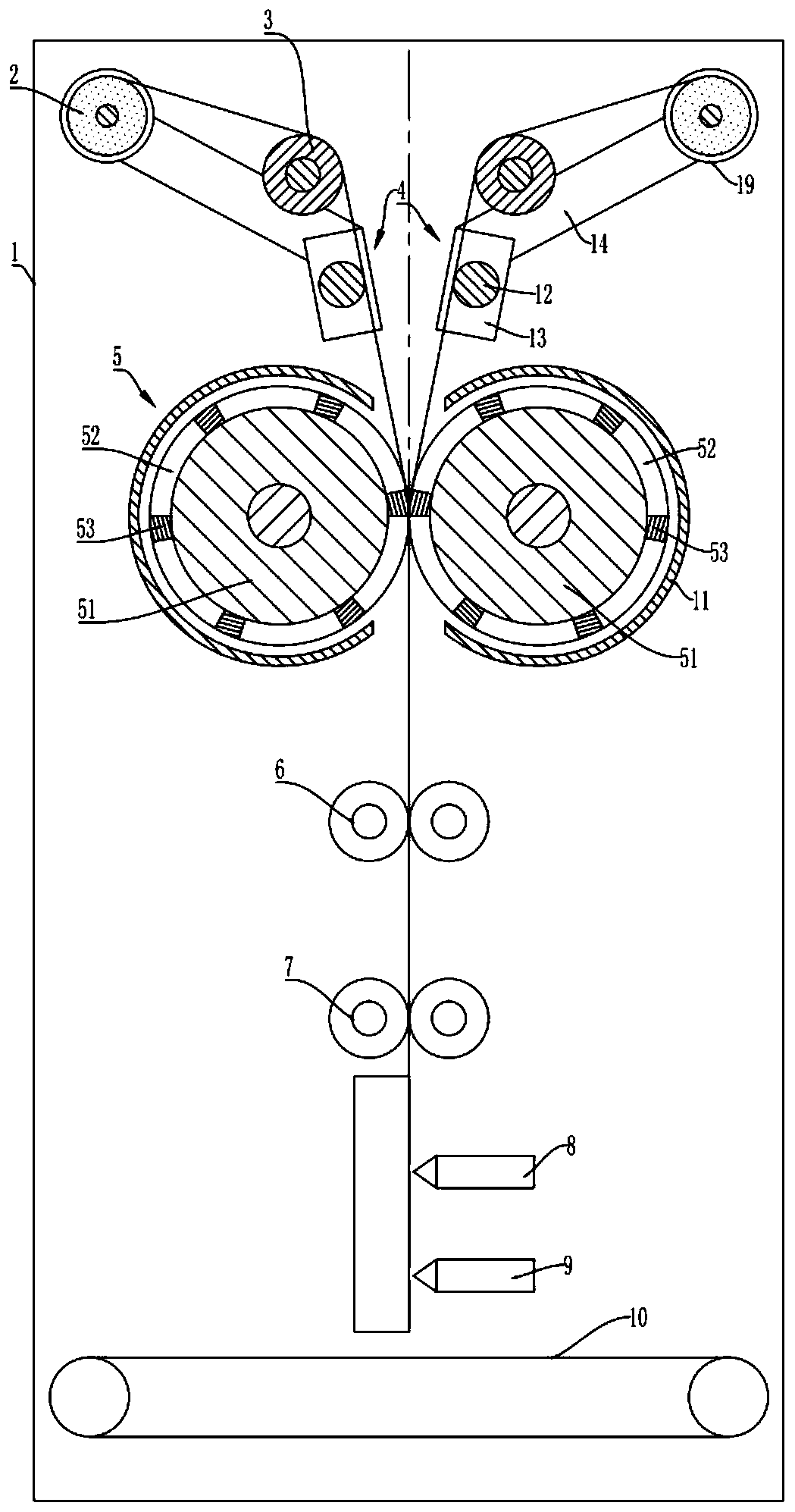

Processing technology for aluminum plastic packaging bags

ActiveCN111086272ARapid cooling and settingEasy to tearBag making operationsPaper-makingPlastic packagingThin membrane

The invention relates to the technical field of packaging, and concretely discloses a processing technology for aluminum plastic packaging bags. The processing technology comprises the step I of unreeling, the step II of guiding, the step III of heat sealing, the step IV of dragging, and the step V of slitting, wherein, in the step I, two thin film rollers around which thin films are respectivelywound are taken, and the two thin film rollers are both rotatably connected onto a frame of a processing device for the aluminum plastic packaging bags, and in the step II, the frame is connected withtwo guiding units symmetrically arranged; each thin film roller corresponds to one guiding unit; the two guide units each comprise two guiding plates; and after being pulled out from the thin film roller, a thin film around each thin film roller enters a position between the two guiding plates of the corresponding guiding unit through a corresponding guiding roller. According to the scheme, the processing technology is used for solving the problems that the quality of the aluminum plastic packaging bags is unstable and the rejection rate of the aluminum plastic packaging bags is high due to the fact that two layers of thin films are attached inaccurately in the edge sealing process of the aluminum plastic packaging bags in the prior art.

Owner:重庆富美包装印务有限公司

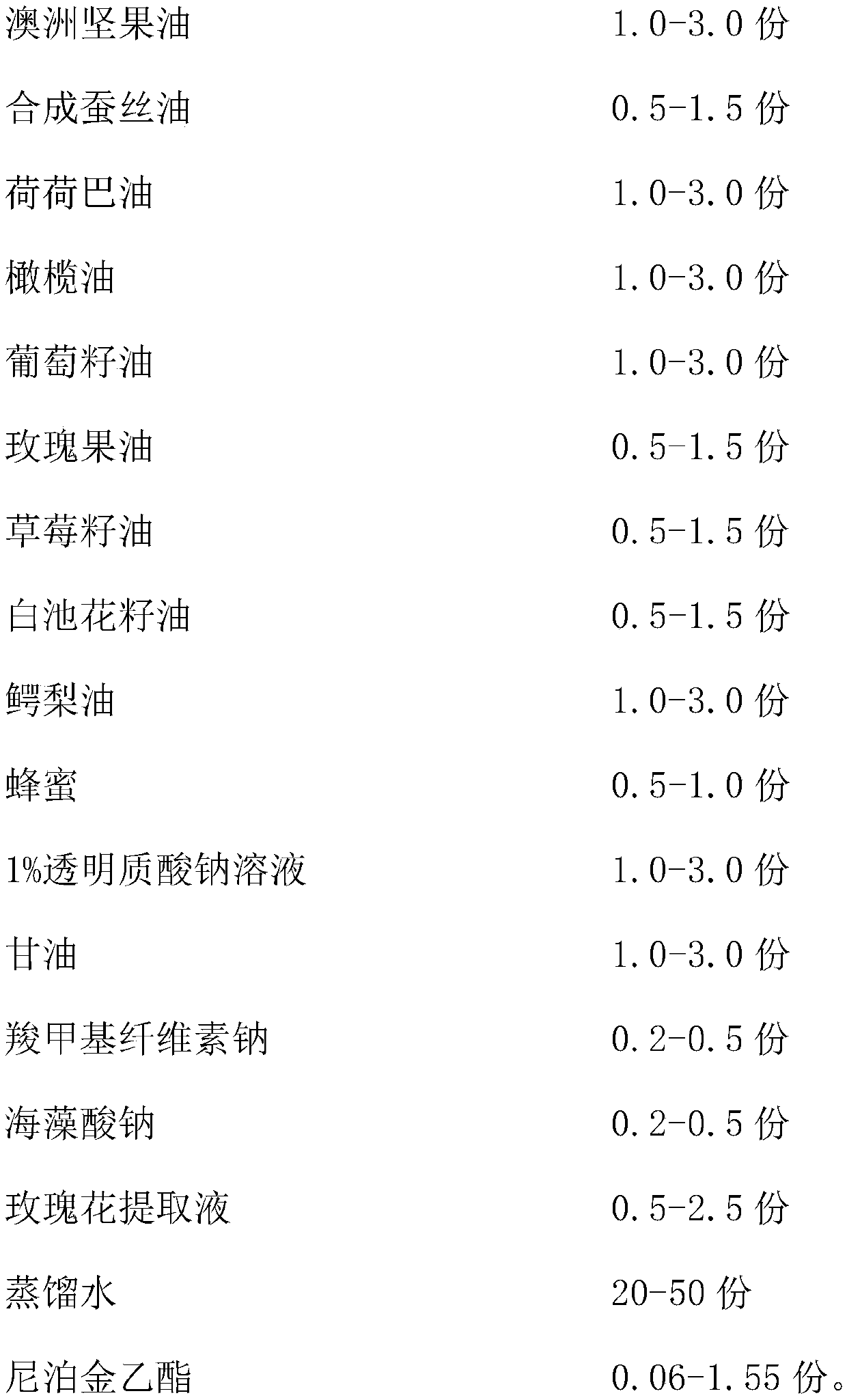

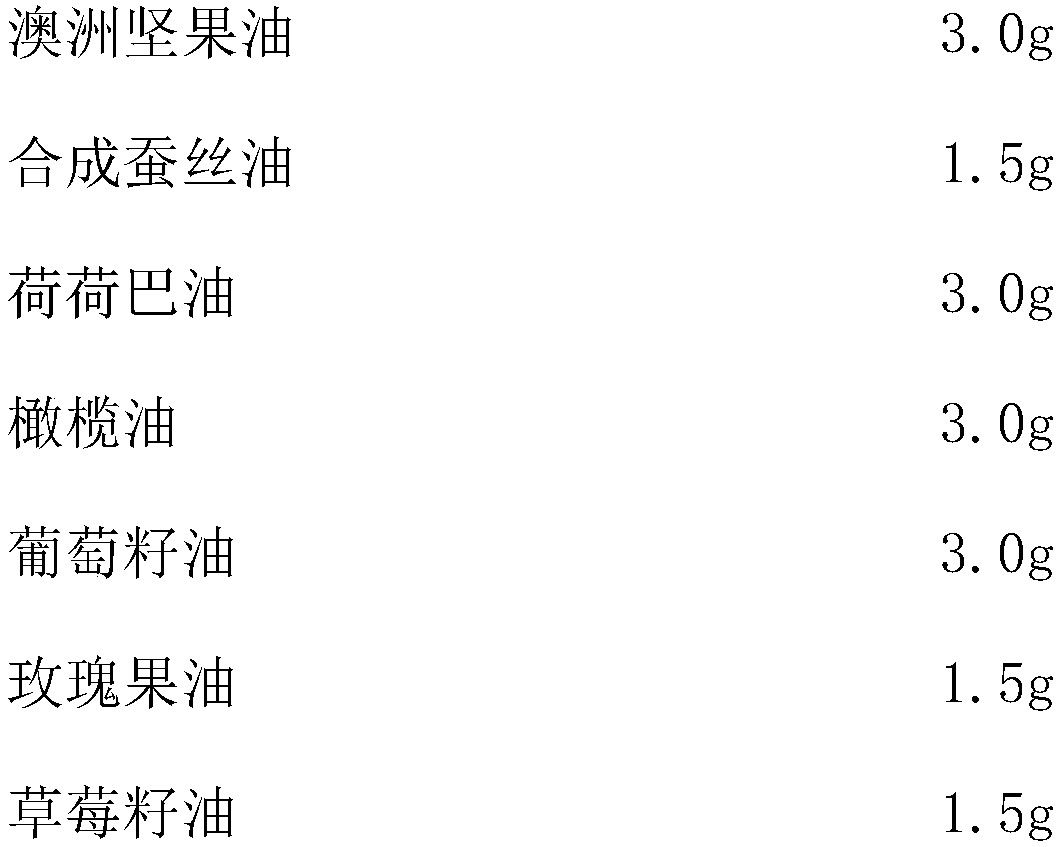

Toxin-free nail-care oil capable of repairing nails and preparation method of toxin-free nail-care oil

ActiveCN107661269AInhibit the production of melaninPrevent dark spotsCosmetic preparationsToilet preparationsChemistryAdemetionine

The invention provides toxin-free nail-care oil capable of repairing nails and a preparation method of the toxin-free nail-care oil. The toxin-free nail-care oil is prepared from the following substances: macadamia nut oil, synthetic silk oil, jojoba oil, olive oil, grape seed oil, rosehip seed oil, strawberry seed oil, meadowfoam seed oil, avocado oil, a rose flower extracting solution, honey, a1 percent sodium hyaluronate solution, glycerol, sodium carboxymethyl cellulose, sodium alginate, distilled water and ethyl 4-hydroxybenzoate. Compared with the prior art, the toxin-free nail-care oilprovided by the invention has stable properties, is moderate, has nourishing and moisture-keeping properties, has no toxin and no harms and is green and natural; the toxin-free nail-care oil can be used for improving a nail structure and nail strength and the elasticity and moisture-keeping degree of nail cuticles and remarkably improving the appearance of nails. Only if one thin layer of the nail-care oil is covered, the nails are bright as if the nails are manicured; meanwhile, the nail-care oil also can be used for nourishing and protecting the nails and protection layers are formed on thesurfaces of the nails to prevent the nails from being invaded by sunlight, so that the surfaces of the nails are smoother and tougher.

Owner:WANNAN MEDICAL COLLEGE

Method for preparing silicon inverse epitaxial wafer and special equipment thereof

ActiveCN101311340APrevent thinningMeet the production requirementsPolycrystalline material growthFrom chemically reactive gasesOptoelectronicsProcess conditions

The invention discloses a manufacturing method of a silicon inversion epitaxial wafer. First, anti-epitaxial equipment specially used for the silicon inversion epitaxial wafer is designed and manufactured; the liquidoid doping technology of epitaxial layer is adopted; the epitaxial process conditions which are suitable for the silicon inversion epitaxial wafer is built. The liquidoid doping technology of the epitaxial layer is that PC13 is added into SiHCL3 and the mixture ratio is suitable for satisfying the resistivity of the epitaxial layer; one kilogram of SiHCL3 is added with 5ml of PC13. The suitable process conditions are that gaseous temperature is 1190 DEG C, gaseous flow is 20 liters per minute, growing temperature is 1180 DEG C and the growing speed is 5Mum per minute. The flatness of the surface of the epitaxial wafer and the lattice integrity of the epitaxial wafer are ensured while the doping concentration of the epitaxial wafer is ensured.

Owner:NANJING GUOSHENG ELECTRONICS

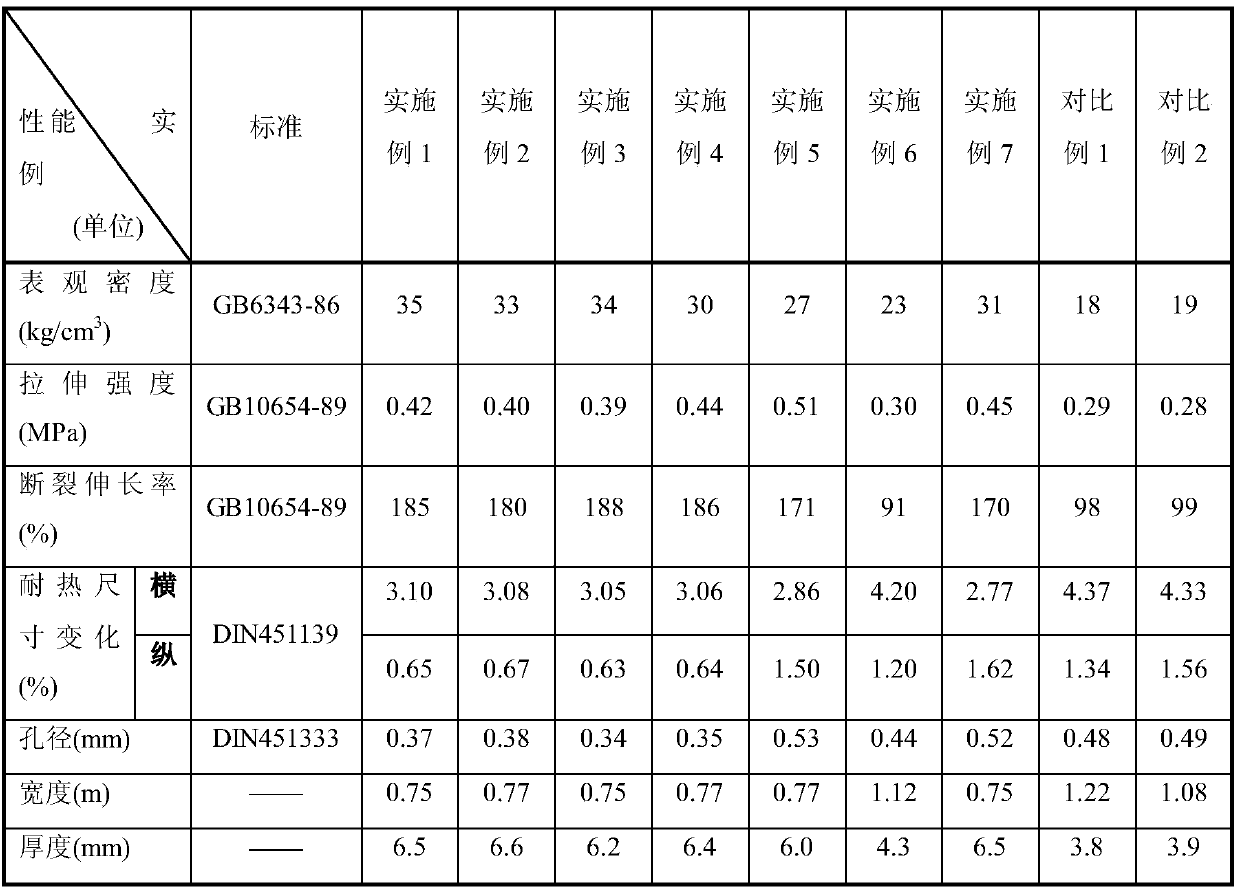

Polyethylene foaming material preparation method and polyethylene foaming material prepared by preparation method

The invention provides a polyethylene foaming material preparation method and a polyethylene foaming material prepared by the preparation method. The preparation method comprises: (a) mixing a matrixresin and a processing aid to form a mixture; (b) extruding the mixture to form a molding billet; and (c) preheating the molding billet at a temperature of 110-150 DEG C for 10-30 min, carrying out cross-linking and foaming on the preheated molding billet at a temperature of 190-230 DEG C under a pressure of 0.05-0.2 MPa, and carrying out cooling shaping on the cross-linked and foamed molding billet at a temperature of 60-80 DEG C under a normal pressure to obtain the polyethylene foaming material, wherein the matrix resin comprises low-density polyethylene, and the processing aid comprises across-linking agent, a foaming agent, a nucleating agent and a surfactant. According to the invention, the preparation method is simple, convenient and easy to operate, the foaming stability of the polyethylene resin can be well controlled, and the polyethylene foaming material prepared by the method is high in foaming ratio, uniform in foam holes, high in size stability, and is suitable for preparing foaming products with high quality.

Owner:PETROCHINA CO LTD

Semiconductor device and manufacturing method of the same

ActiveCN103035615AAvoid over etchingPrevent thinningSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceDevice material

Disclosed herein is a semiconductor device including: a substrate having a first conductive layer and a second conductive layer arranged deeper than the first conductive layer; a large-diameter concave portion having, on a main side of a substrate, an opening sized to overlap the first and second conductive layers, with the first conductive layer exposed in part of the bottom of the large-diameter concave portion; a small-diameter concave portion extended from the large-diameter concave portion and formed by digging into the bottom of the large-diameter concave portion, with the second conductive layer exposed at the bottom of the small-diameter concave portion; and a conductive member provided in a connection hole made up of the large- and small-diameter concave portions to connect the first and second conductive layers.

Owner:SONY CORP

High-rigidity composite pipeline and manufacturing method thereof

InactiveCN106969213AReduce weightAchieve lightweightSynthetic resin layered productsRigid pipesOptoelectronicsResin-Based Composite

Disclosed are a high-rigidity composite pipeline and a manufacturing method thereof. A lining layer, a structure layer, an interlayer structure and a protective layer are arranged sequentially from inside to outside. The lining layer, the structure layer and the protective layer are all prepared from fibers or fabric-reinforced resin-based composites through a winding process. The surface of the structure layer is coated with the interlayer structure through warp-knitted spacer fabrics soaked with resin, and the hollow interlayer structure is formed through resin curing, or the hollow interlayer structure is filled with light foamed plastics to form a solid interlayer structure. According to the high-rigidity composite pipeline and the manufacturing method thereof, the hollow interlayer structure or the interlayer structure filled with the light foamed plastics is adopted, thus the weight of the pipeline is reduced substantially, and small weight is achieved. Meanwhile, due to the fact that the interlayer structure is adopted, larger pipe wall thickness can be achieved with less materials, the inertia moment of the pipe wall section is improved greatly, the rigidity of the pipeline is improved, and thus high rigidity and low cost are achieved.

Owner:TIANJIN POLYTECHNIC UNIV

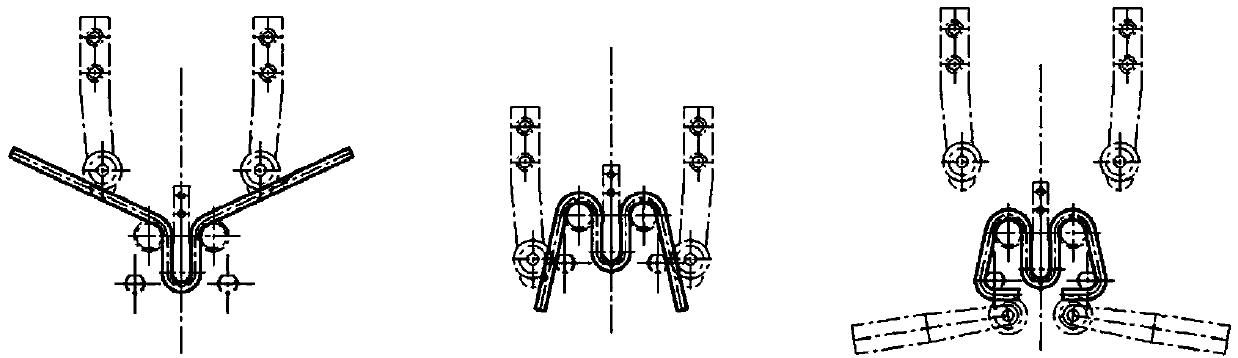

Elastic strip forming machine

ActiveCN103418653AAvoid thinningReduce molding processShaping toolsMetal-working feeding devicesRobot handMolding machine

The invention discloses an elastic strip forming machine which comprises a one-time forming system, a feeding manipulator and an automatic centering system. The one-time forming system comprises an upper die, a lower die, an upper positioning column, a lower positioning column, a middle pushing arm, two lateral pushing arms and two limb pushing arms. The feeding manipulator comprises a grabbing mechanism, a telescoping mechanism, a rotating mechanism and a transverse moving mechanism. The automatic centering system comprises an upper connecting rod, a lower connecting rod, a rotating mechanism, a left material blocking plate, a right material blocking plate and a drive mechanism. The elastic strip forming machine has the advantages of achieving one-time forming production of elastic strips and improving the production efficiency of the elastic strips and the pass percent of products.

Owner:ANHUI CHAOHU CASTING FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com