Elastic strip forming machine

A technology of forming machine and elastic strip, which is applied to forming tools, feeding devices, positioning devices, etc., can solve the problems of no temperature detection device, no forming temperature control, low automation level, etc. in the punch press, so as to improve the internal quality and mechanical properties. , convenient for waste heat quenching, and the effect of improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below according to the drawings and embodiments.

[0036] The present invention includes a molding system, a feeding manipulator, and an automatic centering system.

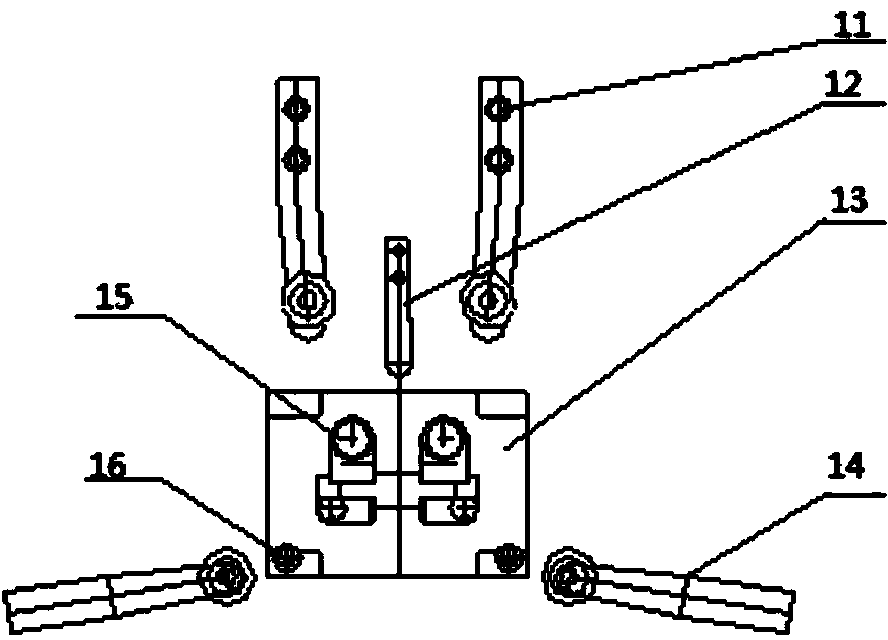

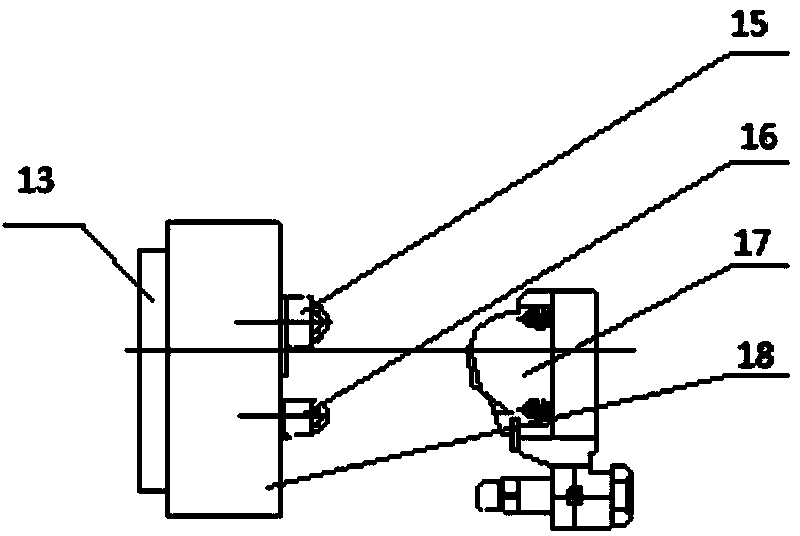

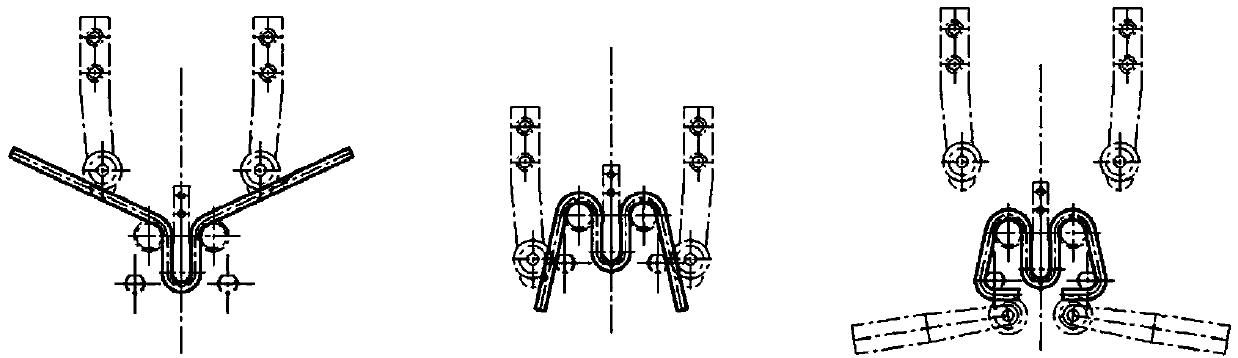

[0037] refer to figure 1 , figure 2 , the one-time forming system of the elastic strip forming machine, including an upper mold 17, a lower mold 13, an upper positioning column 15, a lower positioning column 16, a middle push arm 12, two side push arms 11, and two limb push arms 14;

[0038] Wherein, the surface of the upper mold 17 is facing the surface of the lower mold 13;

[0039] Two upper positioning columns 15 and two lower positioning columns 16 are provided. The above two upper positioning columns 15 are symmetrically fixed above the surface of the lower mold 13, and the above-mentioned lower positioning columns 16 are symmetrically fixed below the surface of the lower mold 13. The distance between the positioning columns 15 is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com