Stirring head for friction stir welding capable of enhancing welding seam material mobility and manufacturing method thereof

A technology of friction stirring and material flow, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of materials not being well combined, grooves, holes, and small volume of materials, so as to avoid poor flow Visible, avoid thinning, best results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

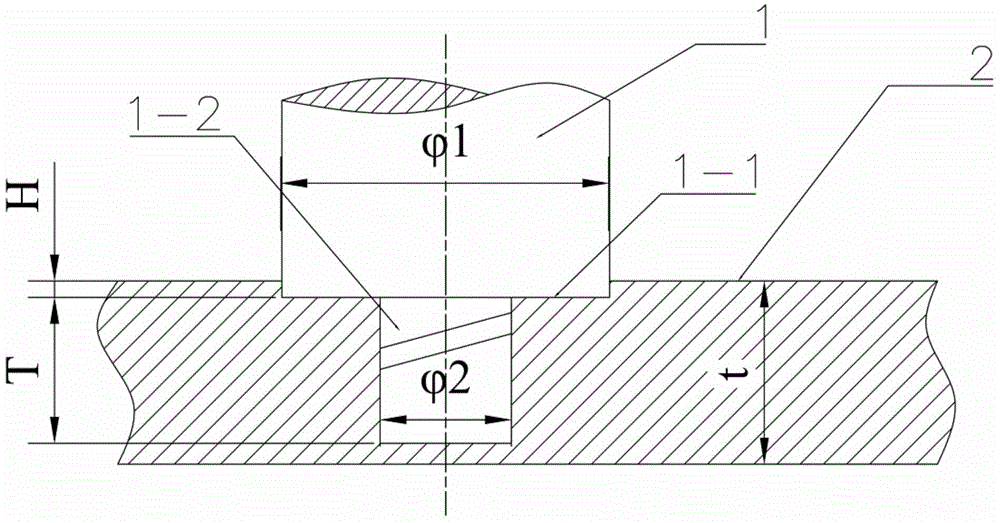

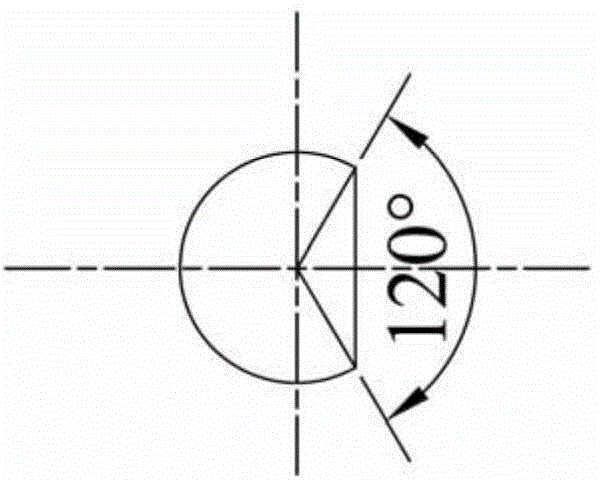

[0027] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the stirring head of this embodiment comprises stirring head shoulder 1-1 and stirring needle 1-2, and stirring needle 1-2 is fixedly connected on the lower end face of stirring head shoulder 1-1, and stirring needle 1- The diameter of 2 is smaller than the diameter of the stirring head shaft shoulder 1-1, and the side of the stirring needle 1-2 is processed with a right-handed thread and a plane parallel to the axis direction, and the central angle corresponding to the cut-off arc segment of the plane is 120°. The manufacturing method of the stirring head is realized through the following steps: Step 1, determination of the size of the stirring head: determine the diameter of the upper shaft shoulder and the diameter of the stirring needle according to the thickness of the first welded workpiece 2 and the second welded workpiece 3: the shoulder The diameter φ1 is 2.75 to 3 time...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 To illustrate this embodiment, in step 1 of this embodiment, the shoulder diameter φ1 is 3 times the thickness t of the workpiece to be welded, and the diameter φ2 of the stirring pin is 1 time the thickness t of the workpiece to be welded. The size of the above stirring head can ensure the stability of the weld formation. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 1 To describe this embodiment, the use length T of the stirring needle in step 2 of this embodiment is 0.2 mm smaller than the thickness t of the workpiece. The above values give the best results for friction stir welding. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com