Patents

Literature

33results about How to "There will be no problem of breaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic temperature-rising power transmission line system

InactiveCN103022947AWon't cause shakingNo load bearingOverhead installationInduction heatingClosed loopEngineering

The invention discloses an automatic temperature-rising power transmission line system comprising a lead wire part, a temperature rising part and a ventilation part, wherein the inner part of the lead wire part is a hollow cavity; the hollow cavity is communicated with the ventilation part; the temperature rising part is fixedly arranged on the lead wire part; the temperature rising part comprises a heating body and two magnetizers which are mutually symmetrical; the heating body is provided with a through hole; the upper ends of the two magnetizers are hinged; convex magnetism-conducting strips are respectively arranged in the middles of the two magnetizers; after the two magnetizers are mutually contacted, a closed loop is formed by the convex magnetism-conducting strips and the two magnetizers; one of the magnetism-conducting strips is wound by a coil; one end of the coil is connected with a first double-metal sheet; and the other end of the coil is connected with the heating body. With the adoption of the structure, a condition of adhering ice and snow on a power transmission line can be prevented and the condition that the pressing force borne by the power transmission line is too large so that the power transmission line shakes and even is cracked can be avoided; and therefore, the normal work of the power transmission line is guaranteed.

Owner:西昌市世通配件加工厂

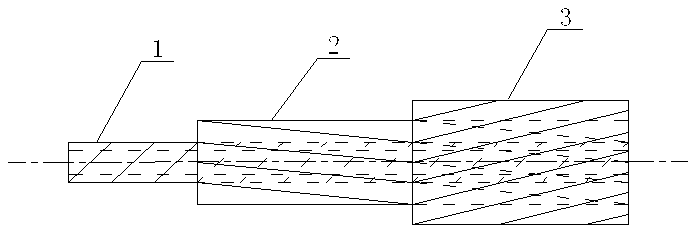

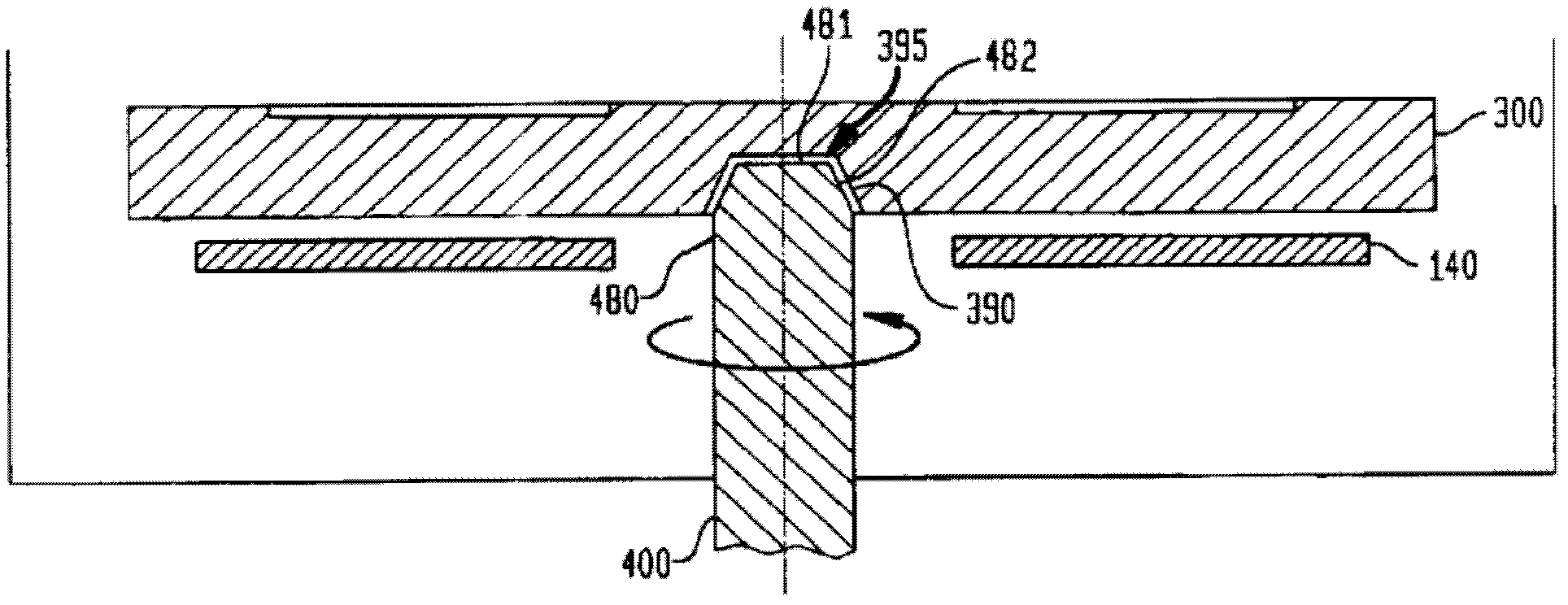

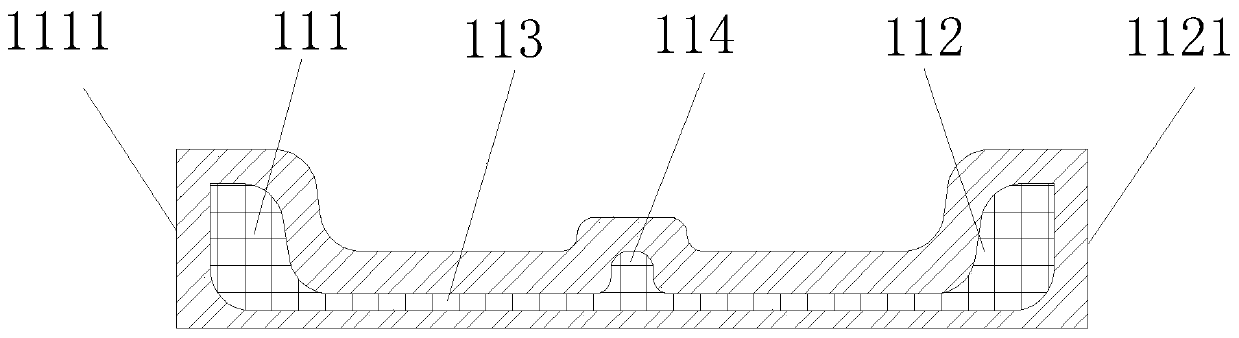

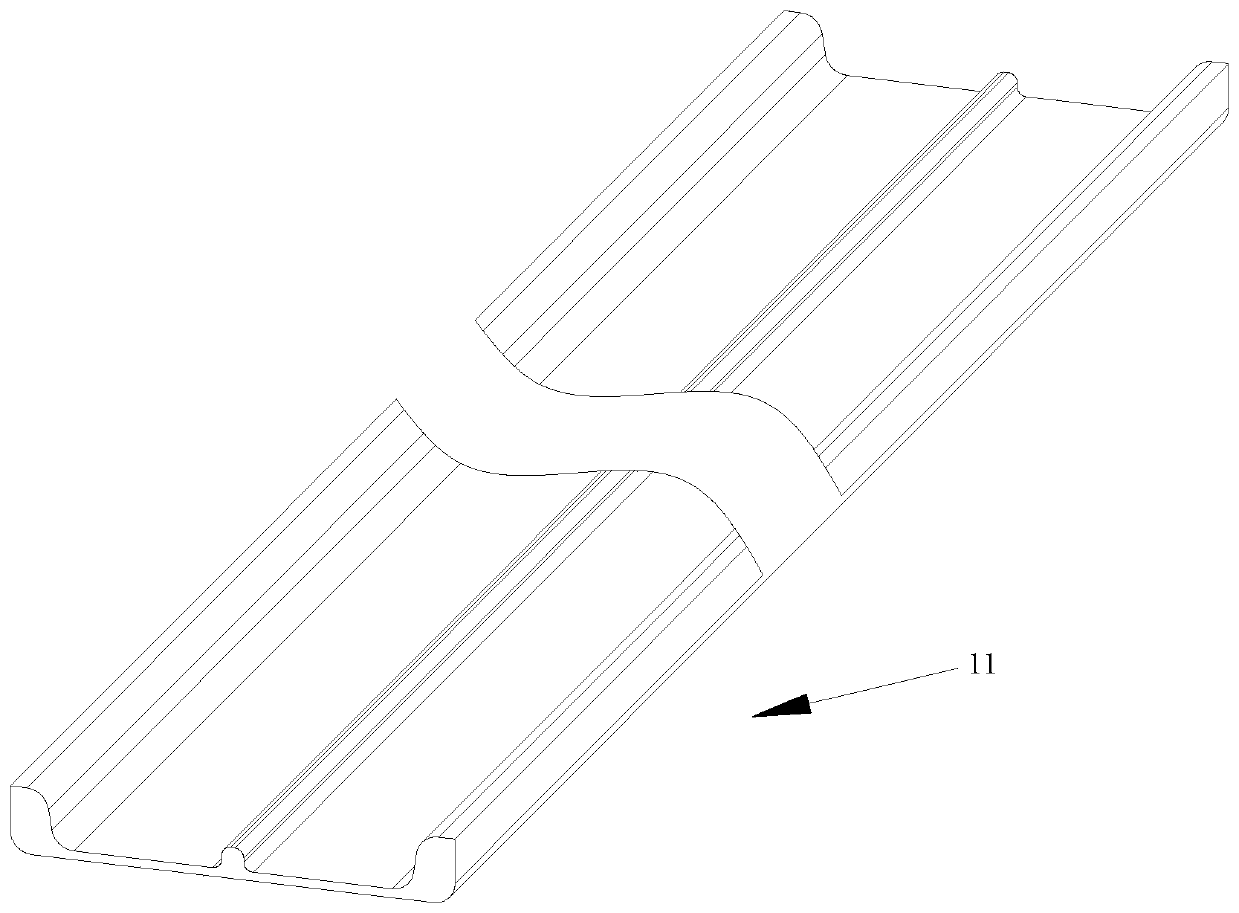

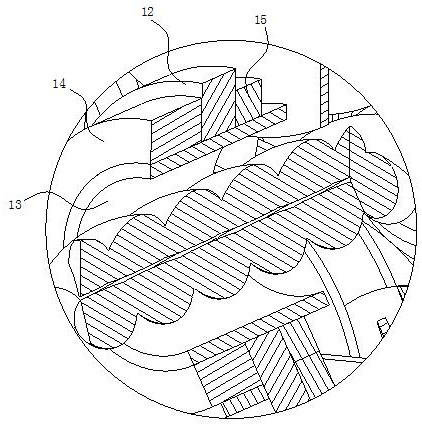

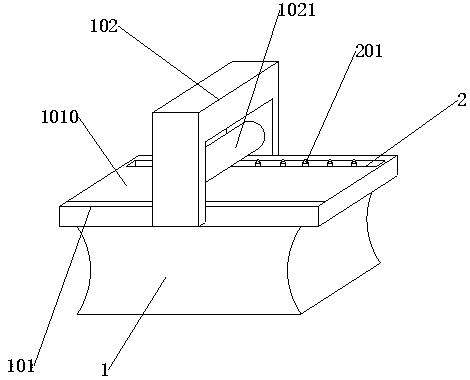

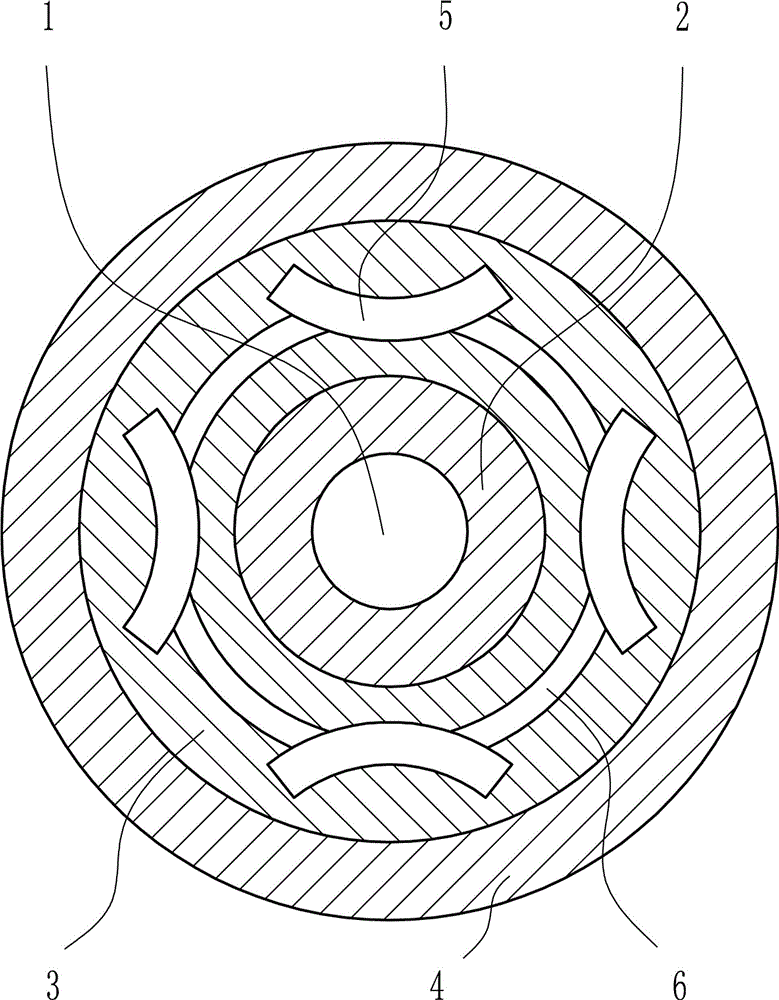

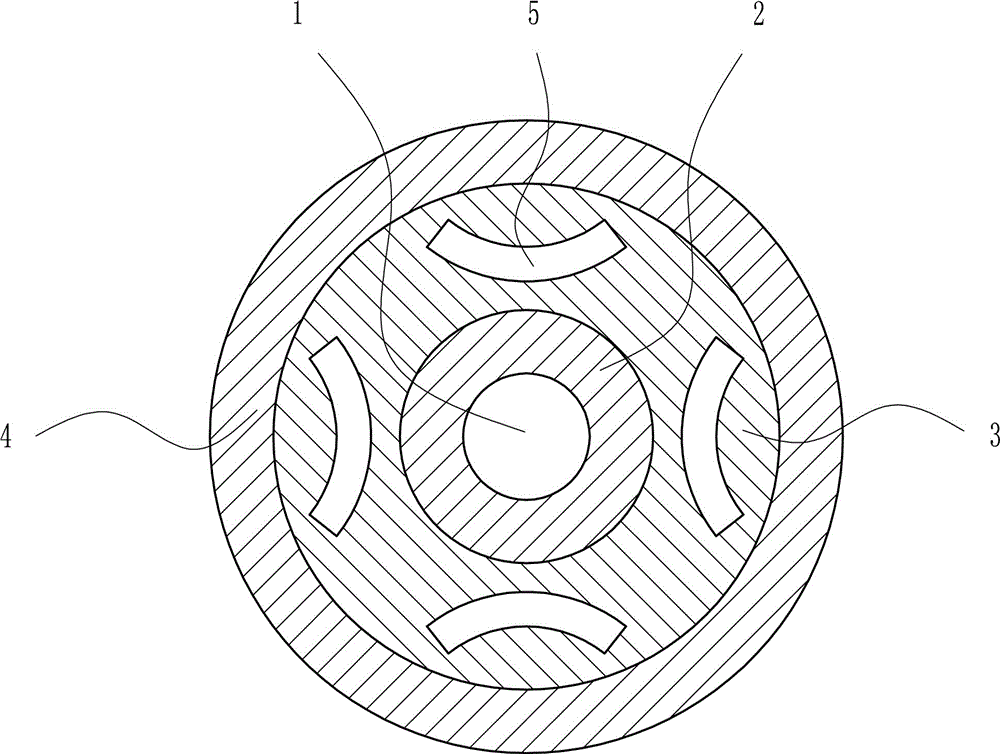

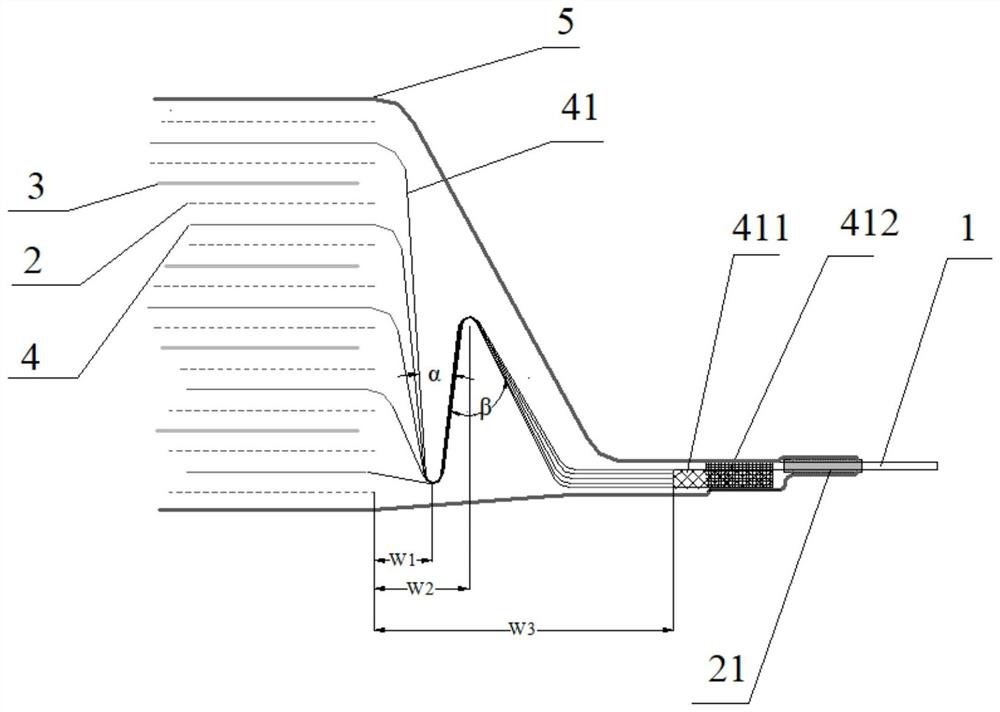

Stirring head for friction stir welding capable of enhancing welding seam material mobility and manufacturing method thereof

InactiveCN104475966AGood for formingAvoid thinningNon-electric welding apparatusWeld seamEngineering

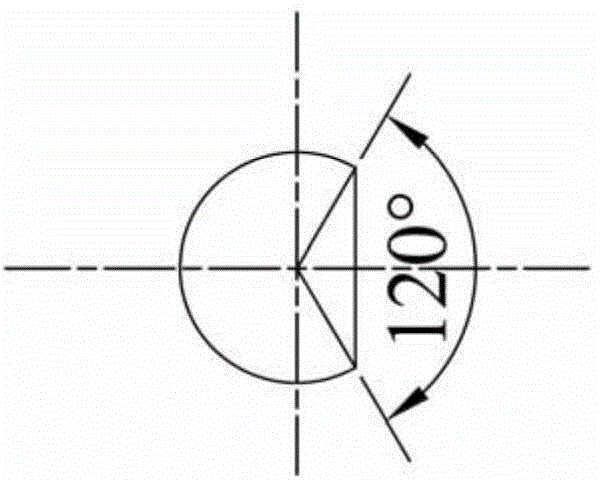

The invention discloses a stirring head for friction stir welding capable of enhancing welding seam material mobility and a manufacturing method thereof and relates to the stirring head and the manufacturing method thereof. The problems of defects, such as ditches and holes formed in a welding seam by a material with relatively poor mobility are solved. A device is of the structure that a stirring needle is connected to a shaft shoulder of the stirring head; right-handed threads and a plane parallel to the axial line direction are machined on the side surface of the stirring needle; the central angle corresponding to an arc section truncated from the plane is 120 degrees. The method comprises the following steps of 1, determining the size of the stirring head; 2, determining the using length of the stirring needle; 3, forming an Archimedes spiral groove with the equation that rho is equal to b plus a theta in the shaft shoulder; 4, machining the right-handed threads and the plane on the side surface of the stirring needle; 5, fixing to-be-welded workpieces; 6, positioning the stirring head; 7, performing friction stir welding on the first to-be-welded workpiece and the second to-be-welded workpiece. The stirring head is applied to friction stir welding.

Owner:HARBIN INST OF TECH

Integrated dual-layer spring cushion

The invention discloses an integrated dual-layer spring cushion. The integrated dual-layer spring cushion comprises first cloth, second cloth, third cloth and multiple groups of springs, wherein multiple transverse seams are formed among the first cloth, the second cloth and the third cloth, the first cloth and the second cloth are mutually separated and folded to form multiple corresponding vertical seams, a plurality of first independent cloth bags are continuously formed between the third cloth and gaps between the adjacent vertical seams in the first cloth, and a plurality of second independent cloth bags are continuously formed between the third cloth and gaps between the adjacent vertical seams in the second cloth; and each group of springs comprises two springs correspondingly packaged in the first independent cloth bag and the second independent cloth bag in a lamination state. According to the integrated dual-layer spring cushion, a traditional structural form of a spring cushion of adhering through glue is abandoned, and the glue adhesion manner is not adopted, so that the problem of the traditional spring cushion that adhering joints are broken after long-term use is avoided, and the stability of the spring cushion is higher.

Owner:徐尚柔

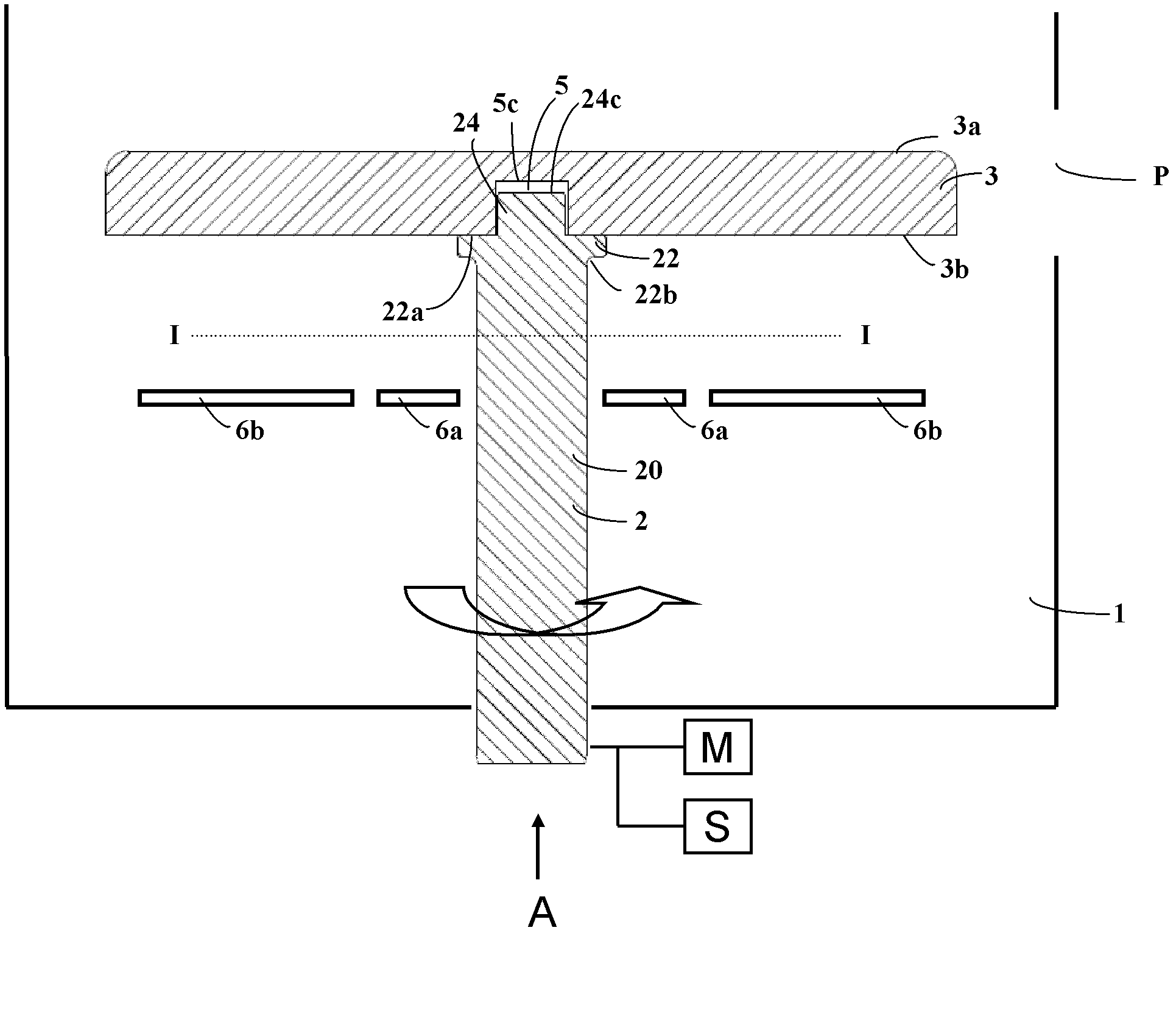

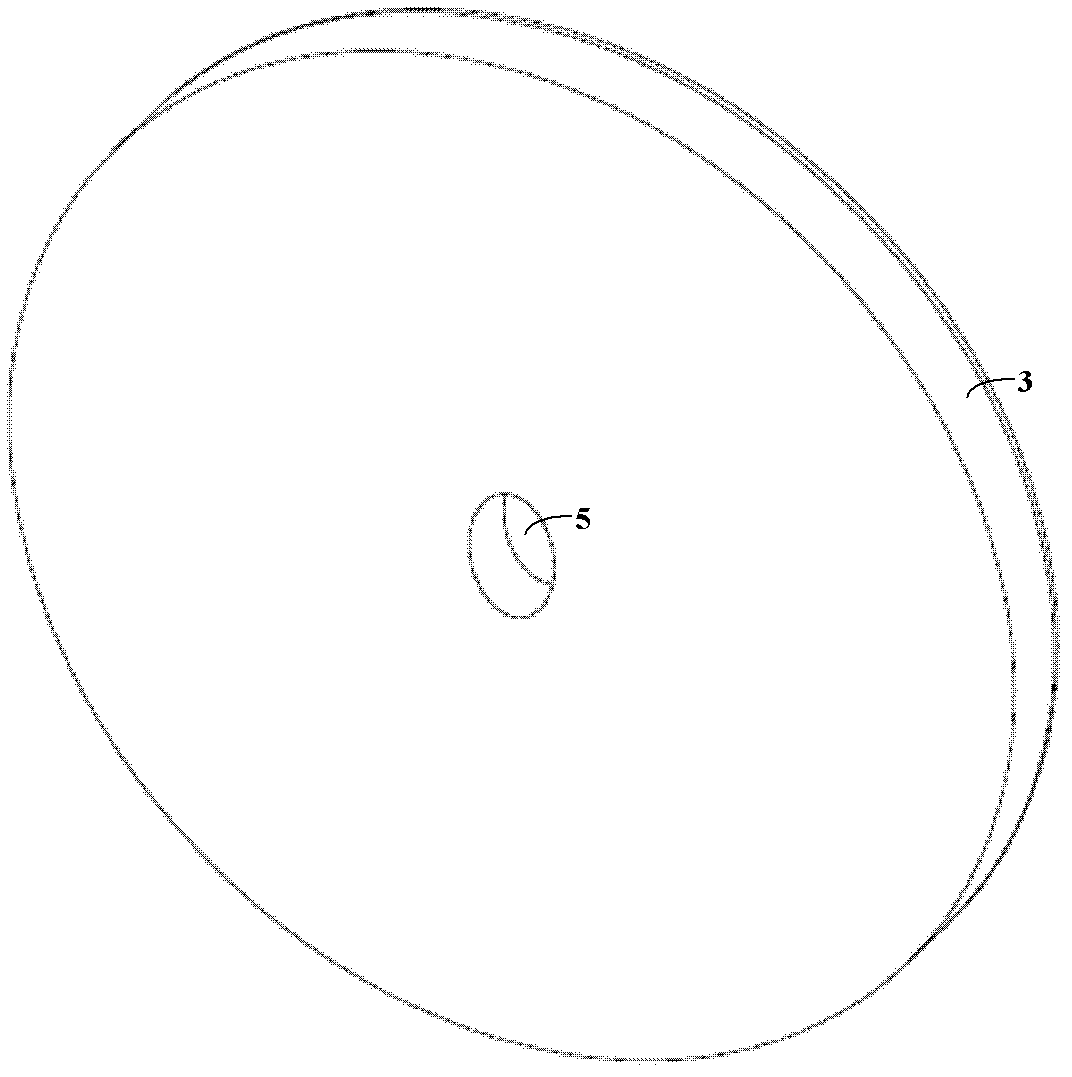

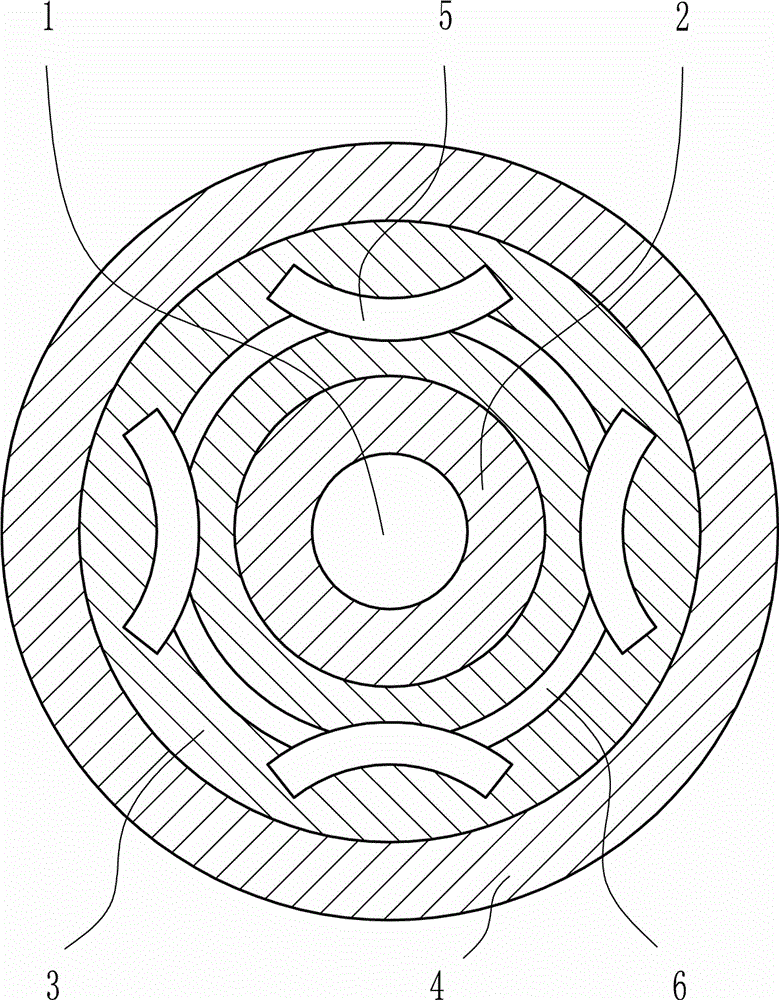

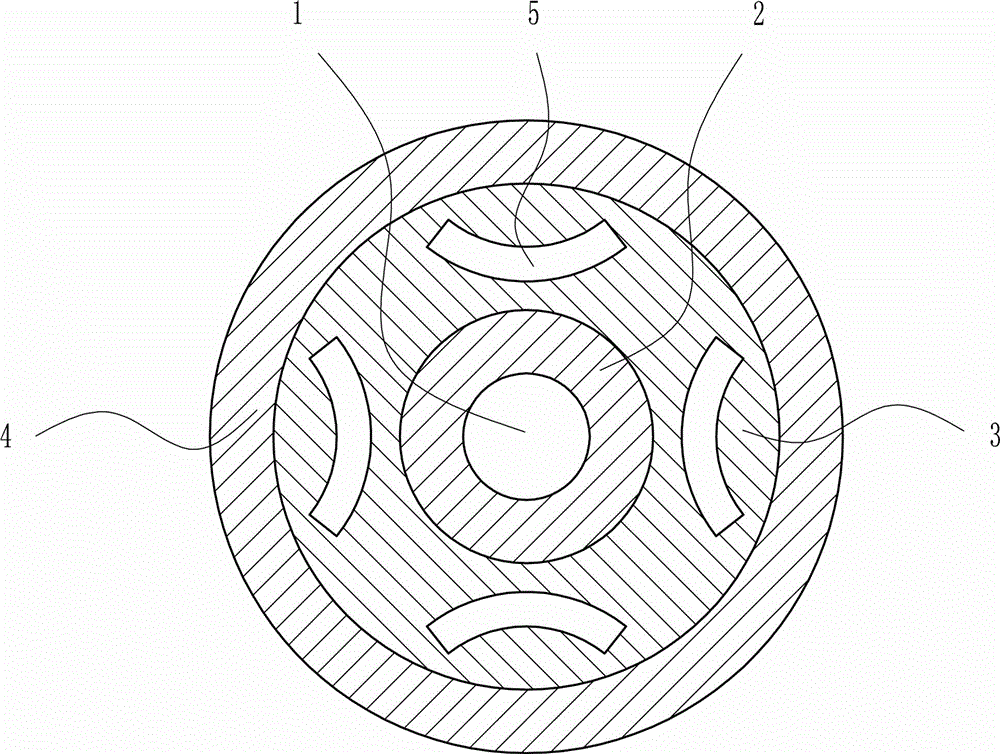

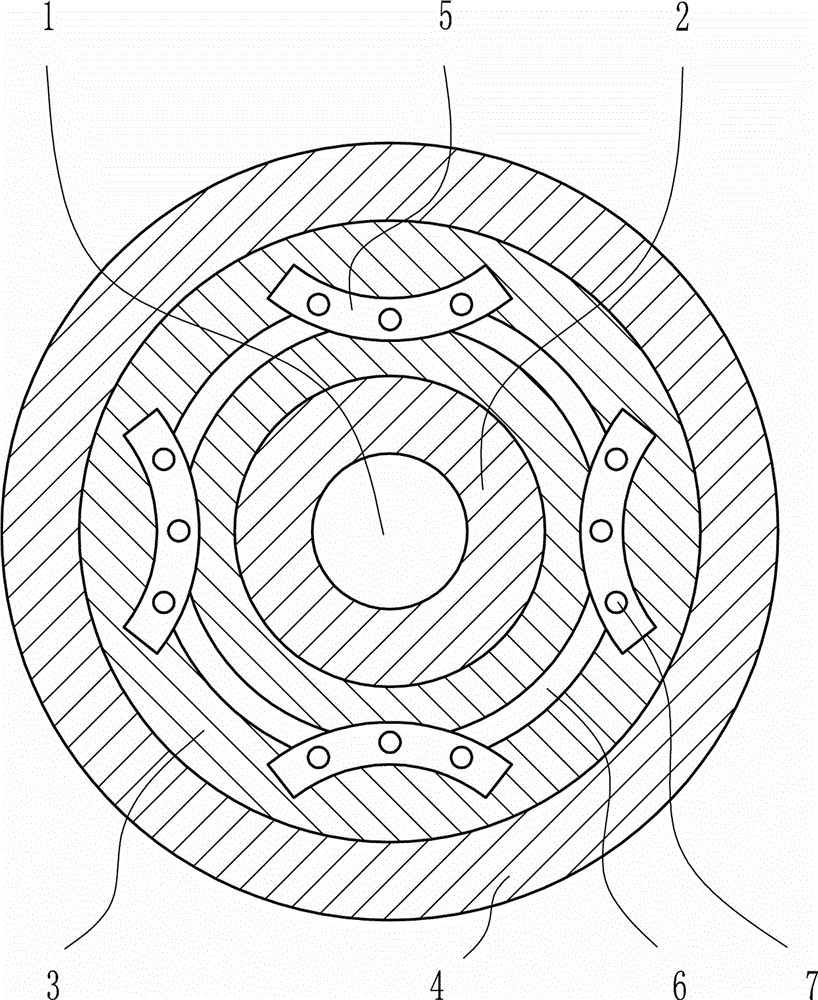

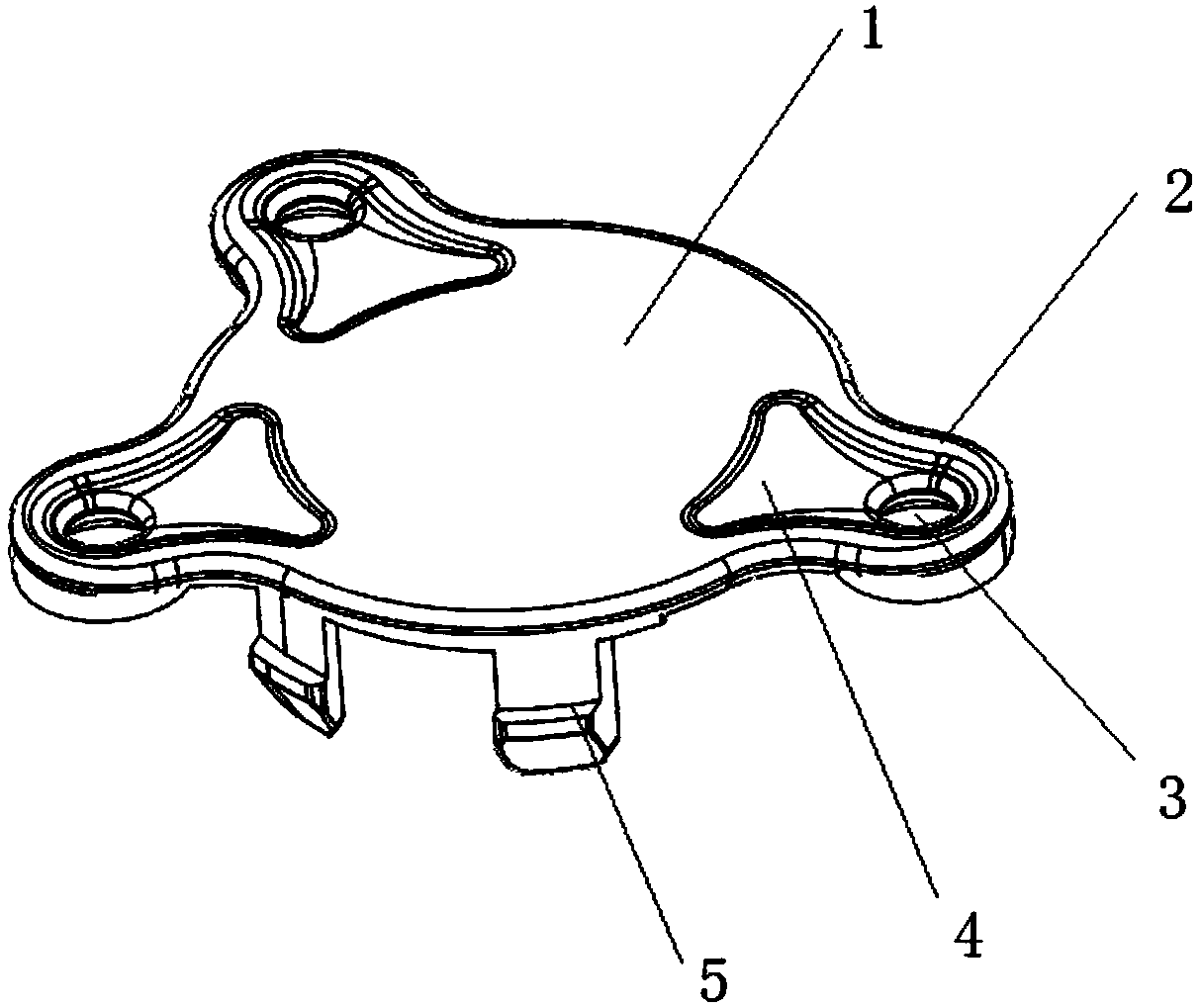

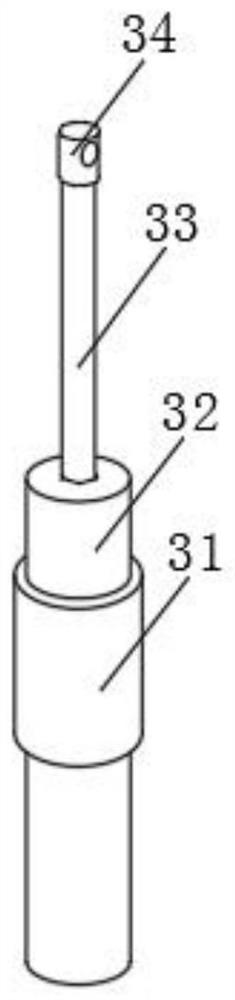

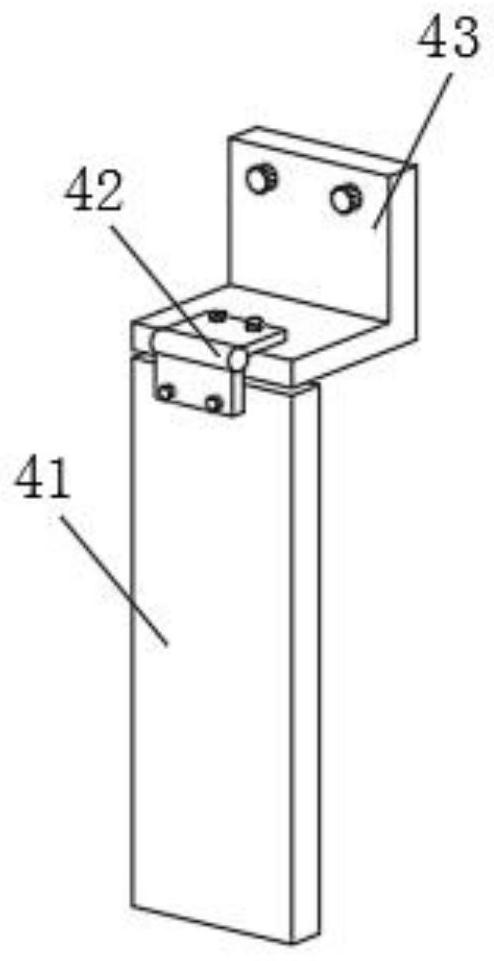

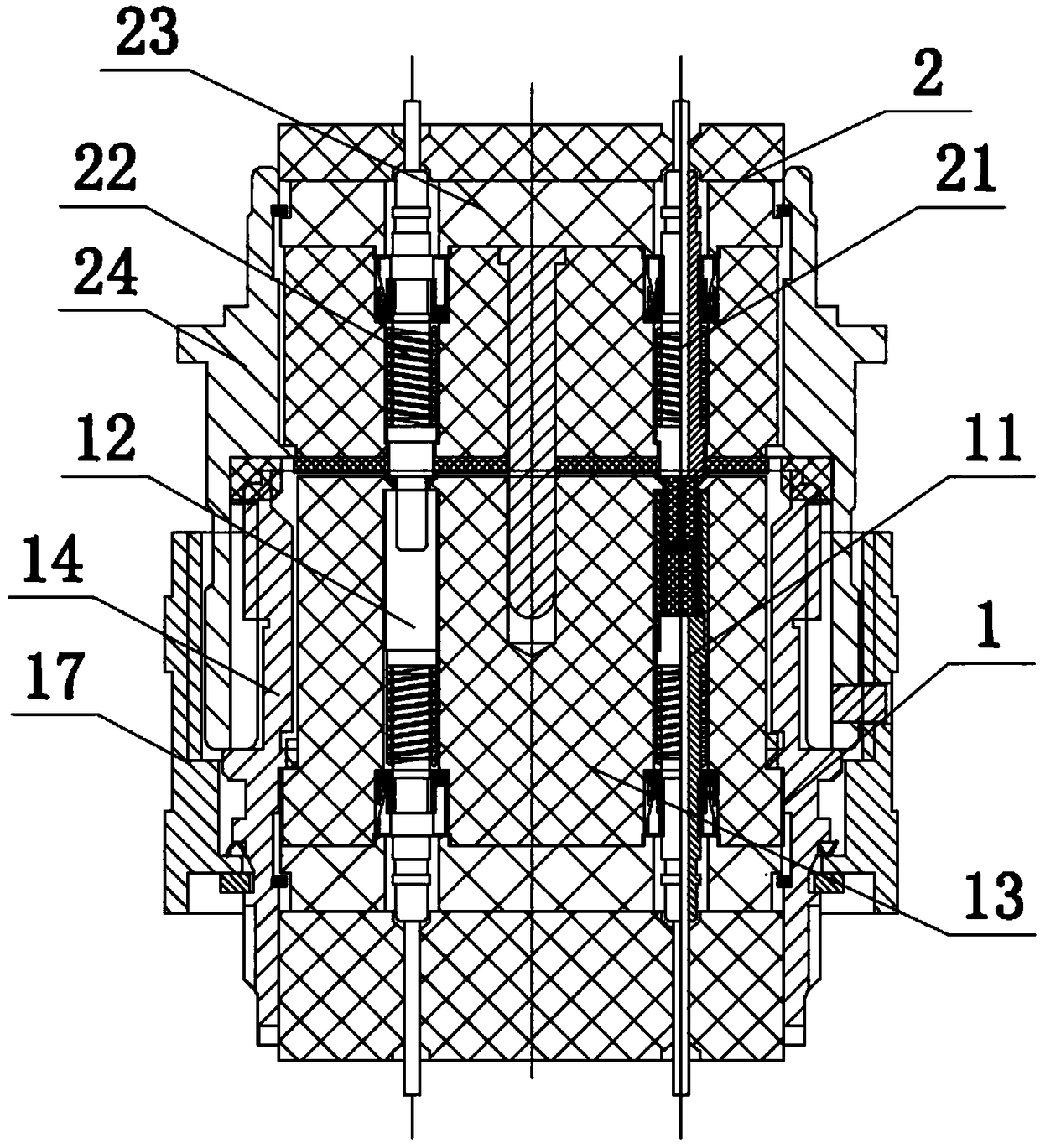

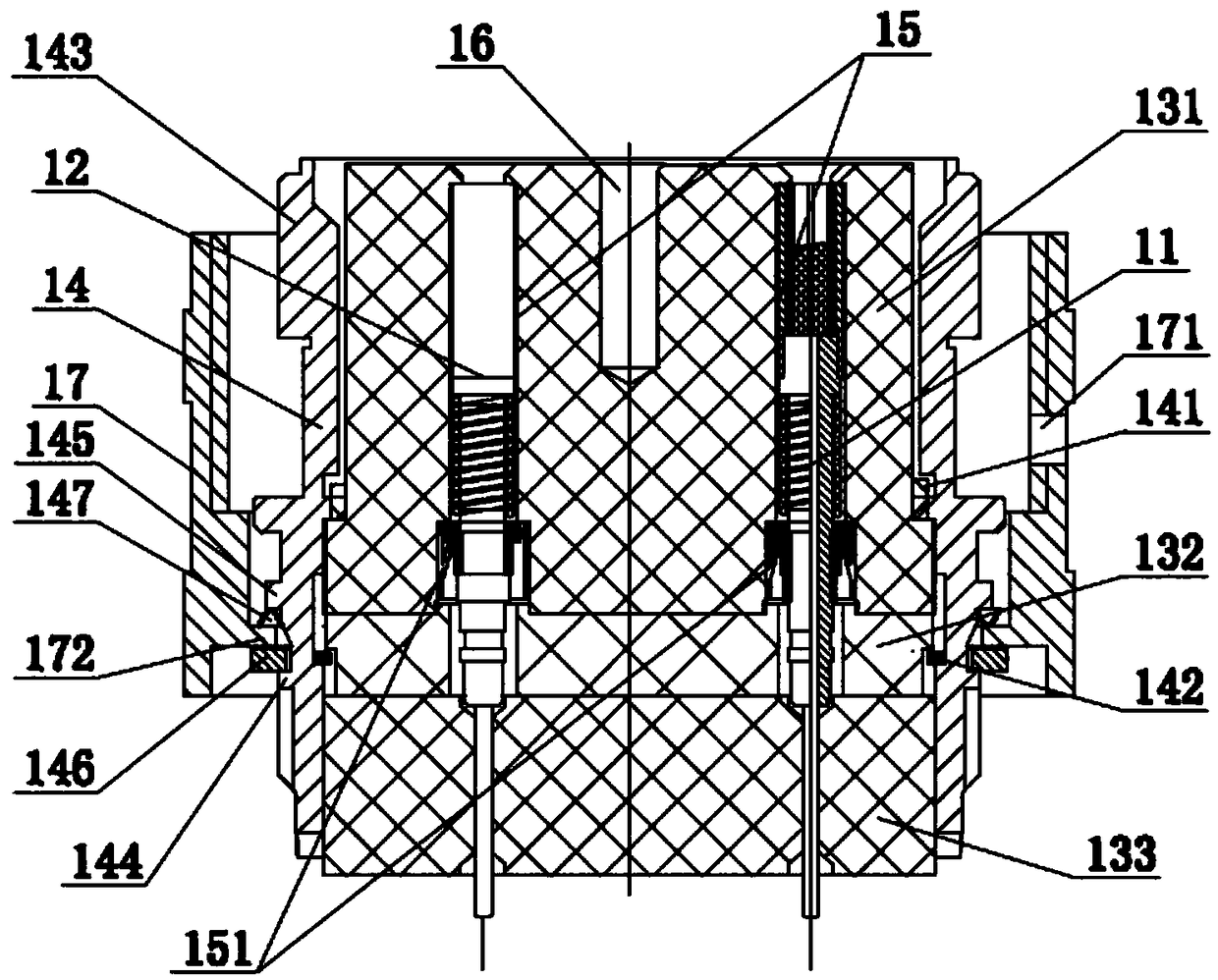

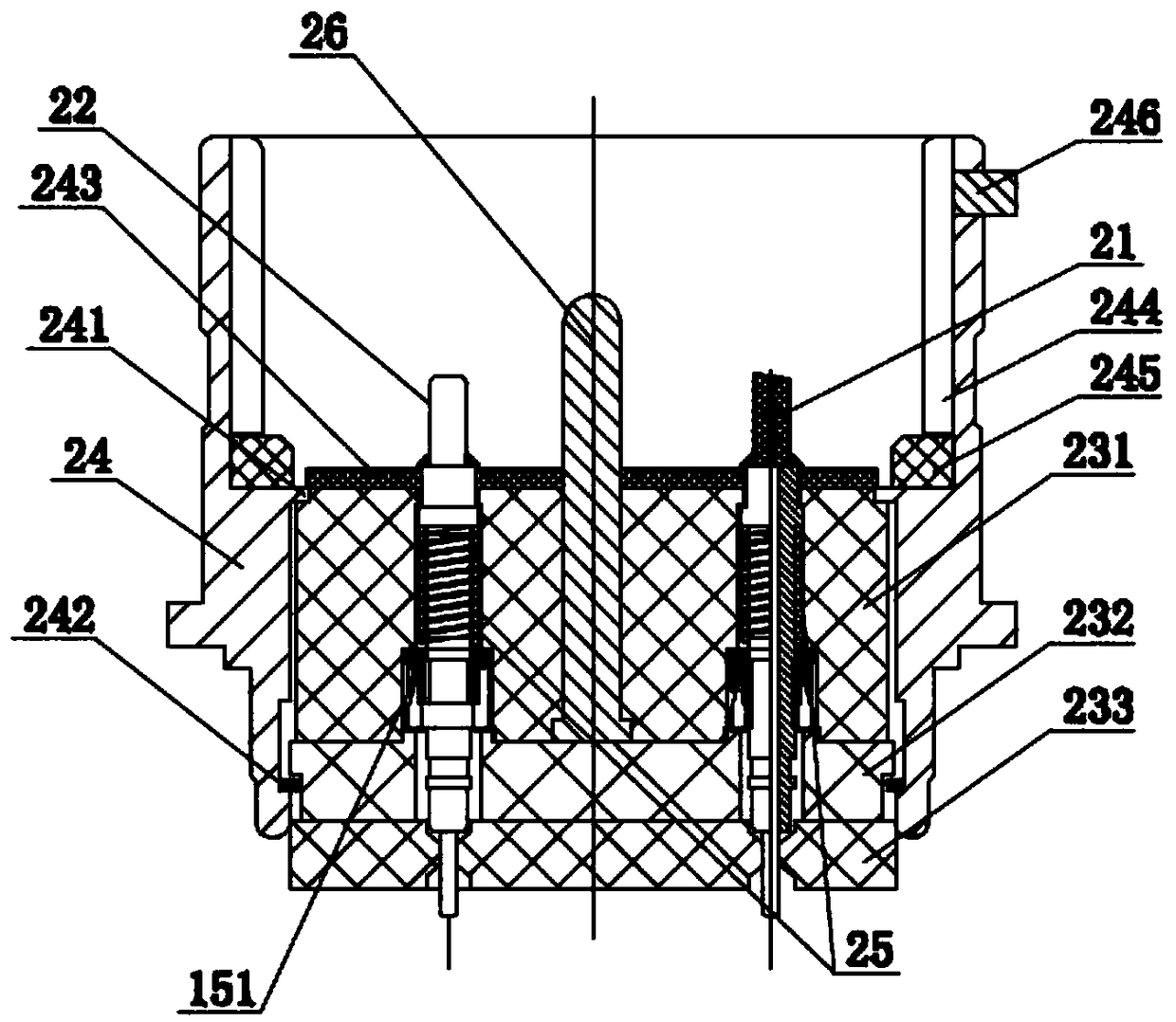

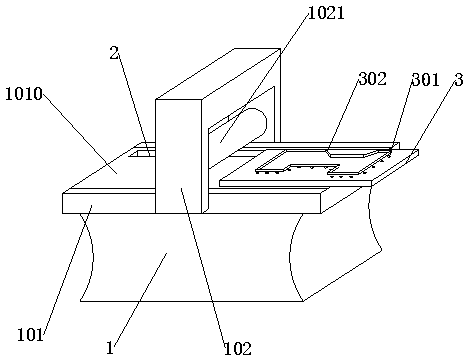

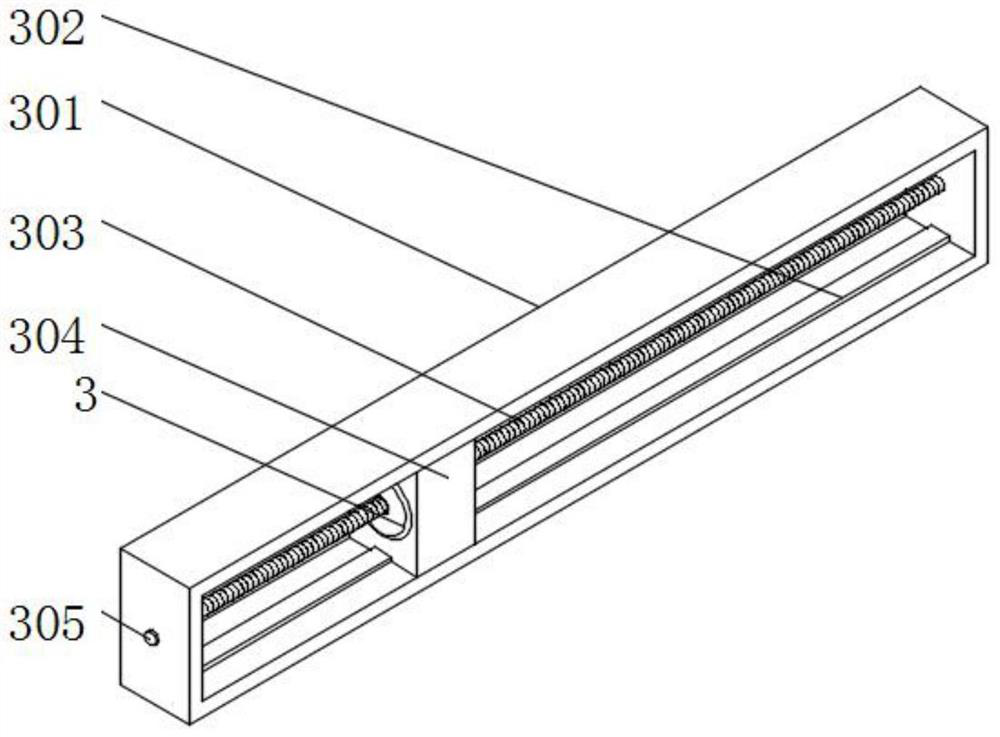

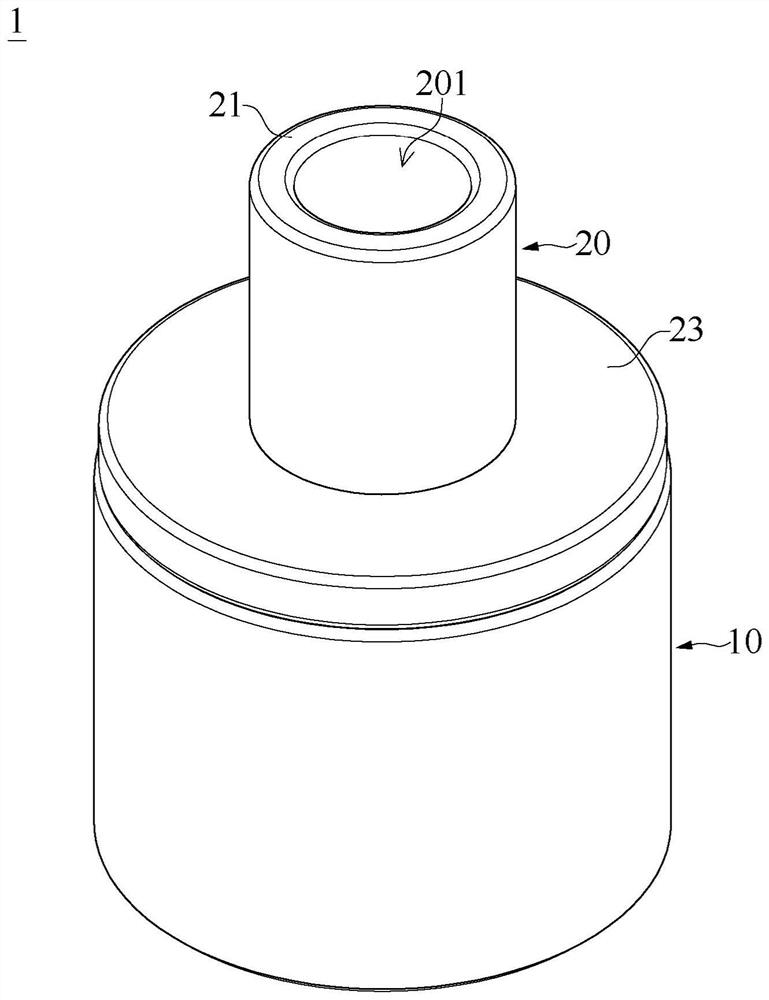

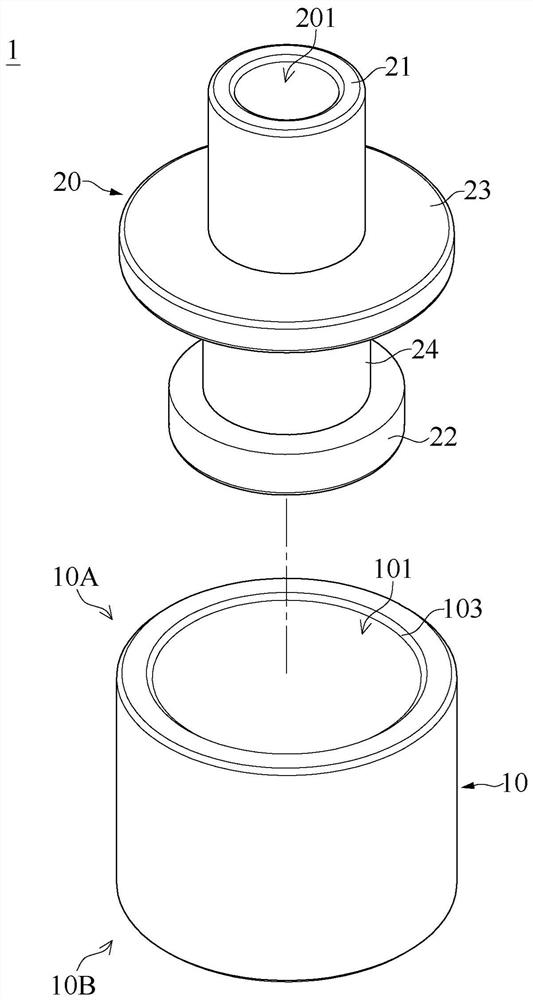

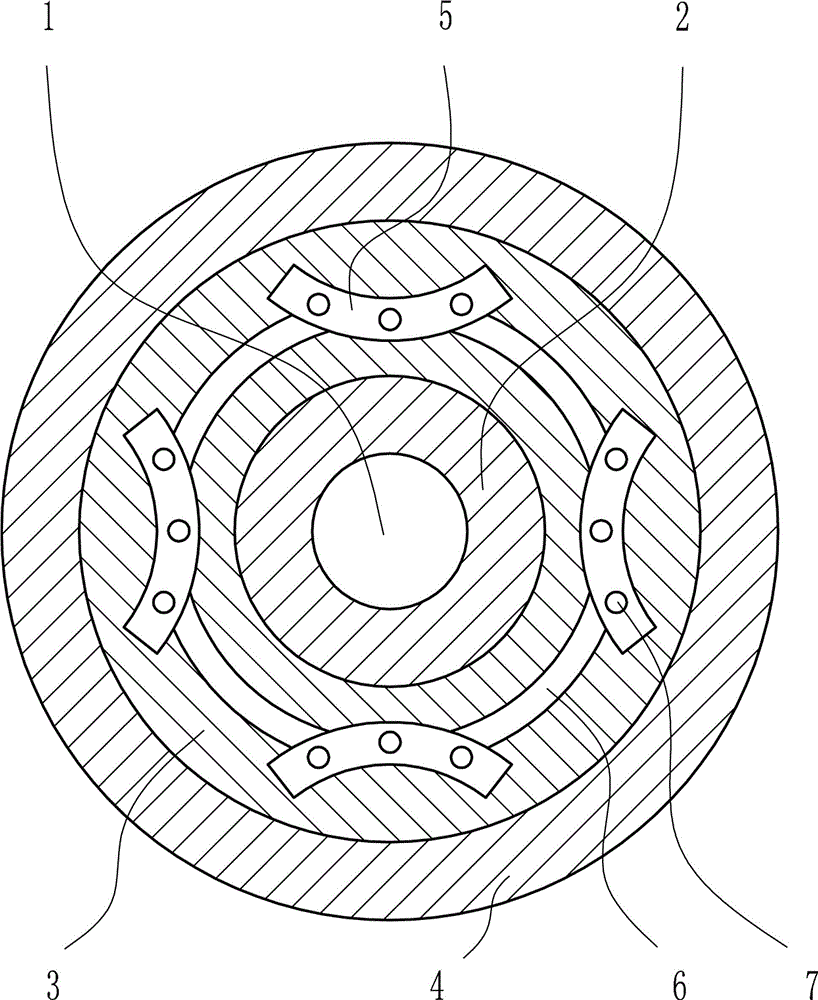

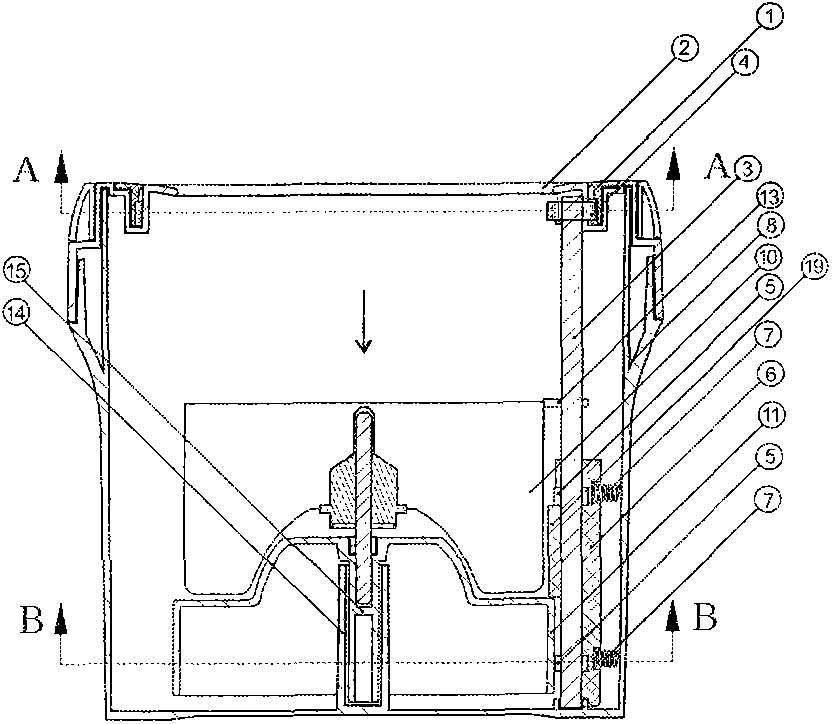

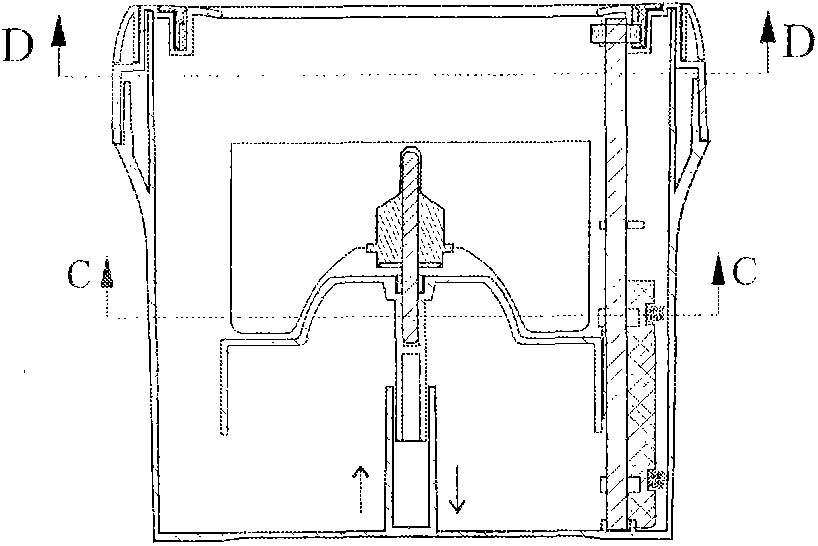

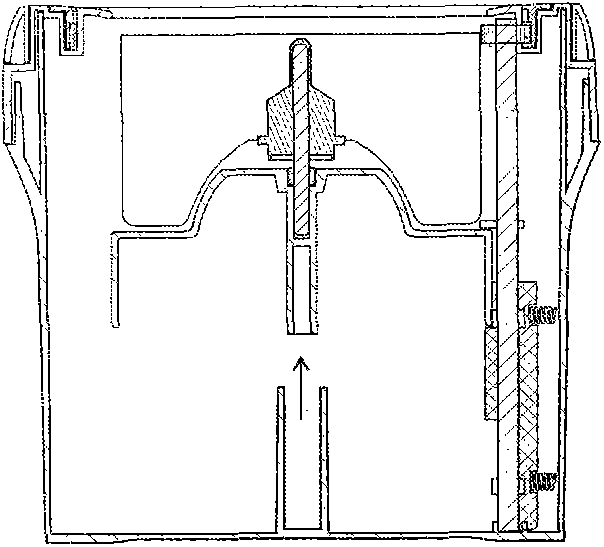

Chemical vapor deposition reactor or epitaxial layer growth reactor and support device thereof

ActiveCN103132051AThere will be no problem of breakingThere will be no "friction and slippage" phenomenonFrom chemically reactive gasesChemical vapor deposition coatingChemical vapor depositionMaterials science

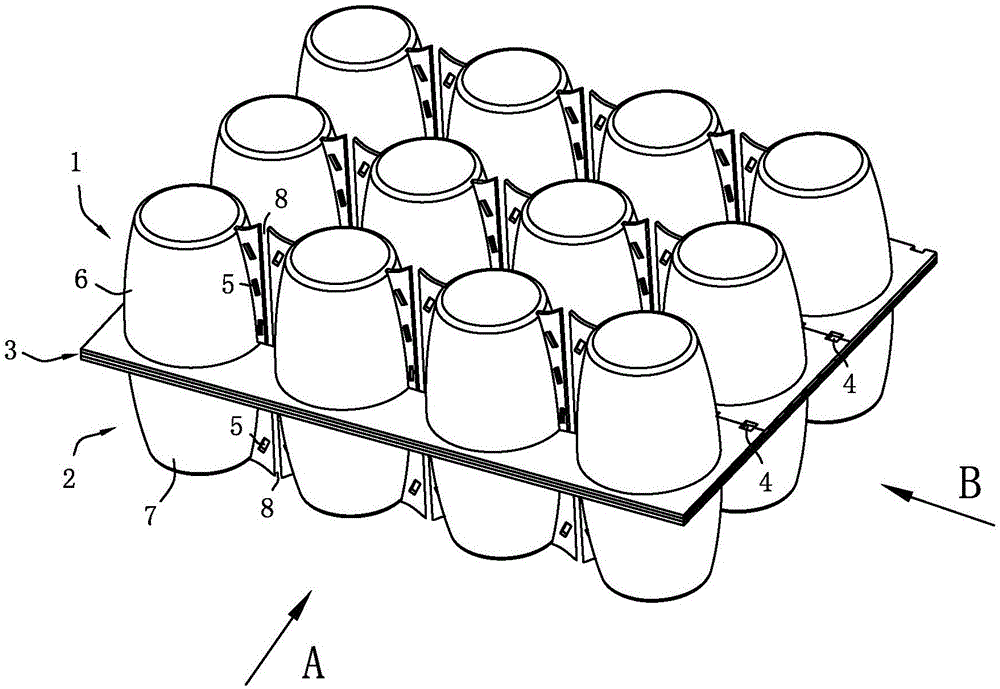

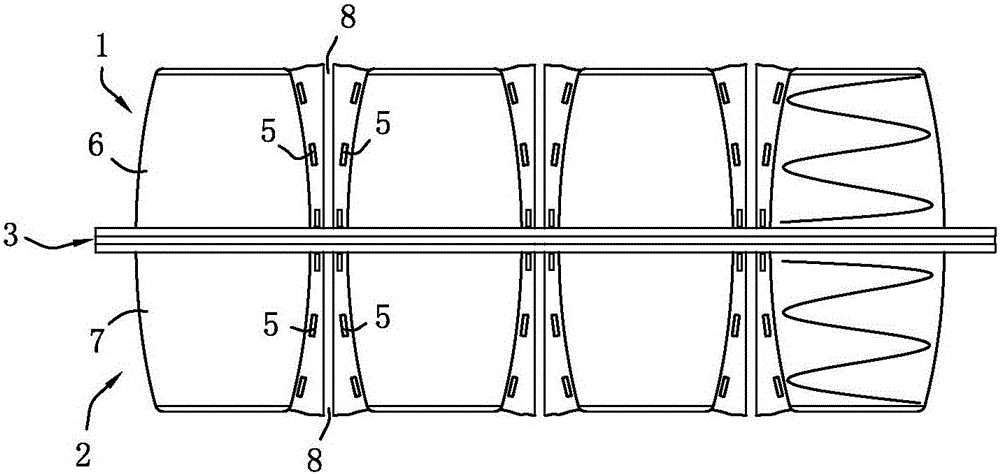

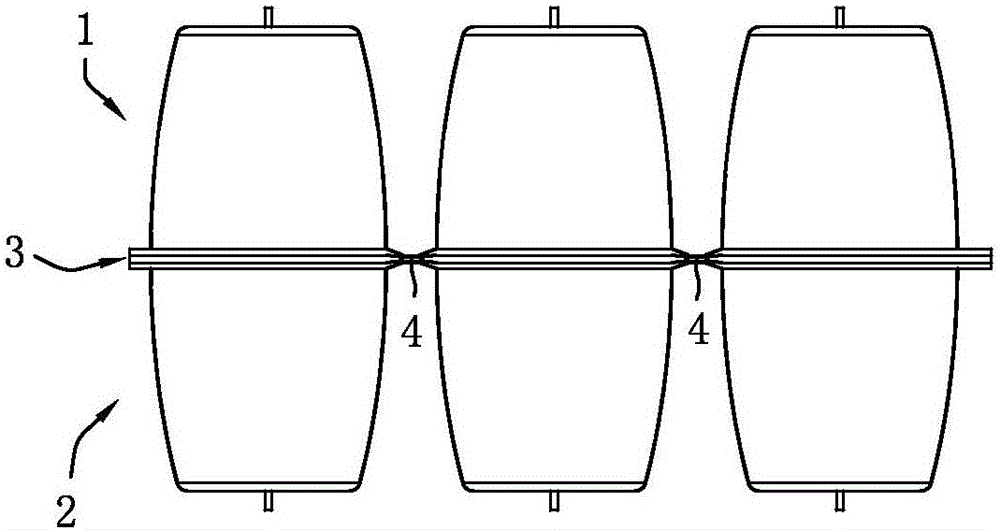

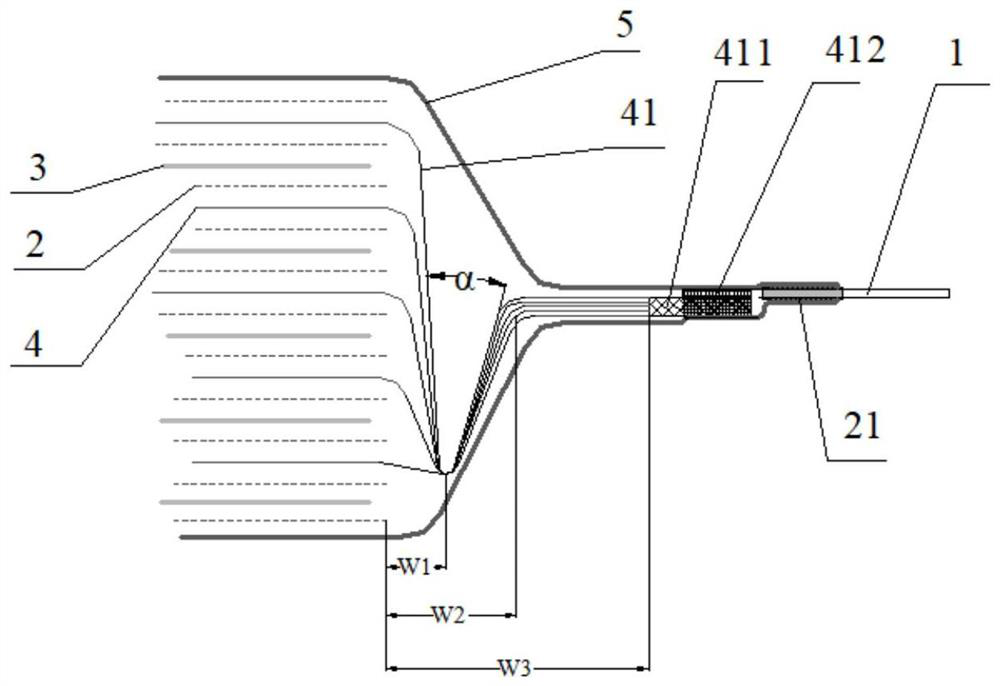

A chemical vapor deposition reactor or an epitaxial layer growth reactor comprises a reaction chamber; at least one substrate bearing rack and a support device for supporting the substrate bearing rack are disposed in the reaction chamber; the substrate bearing rack comprises a first surface and a second surface; the second surface of the substrate bearing rack is provided with at least one recessed part recessing inwards; the support device comprises a main shaft part, a supporting part which is connected with one end of the main shaft part, extends out along the periphery of the main shaft part, and comprises a supporting surface, and a plugging part which is connected with the main shaft part, and extends to a height along a direction towards the first surface of the substrate bearing rack; the plugging part of the support device can be separatedly plugged into the recessed part, so as to allow the substrate bearing rack to be placed on the support device and to be supported by the support device. The substrate bearing rack of the invention can realize balanced and reliable rotation during substrate processing process.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

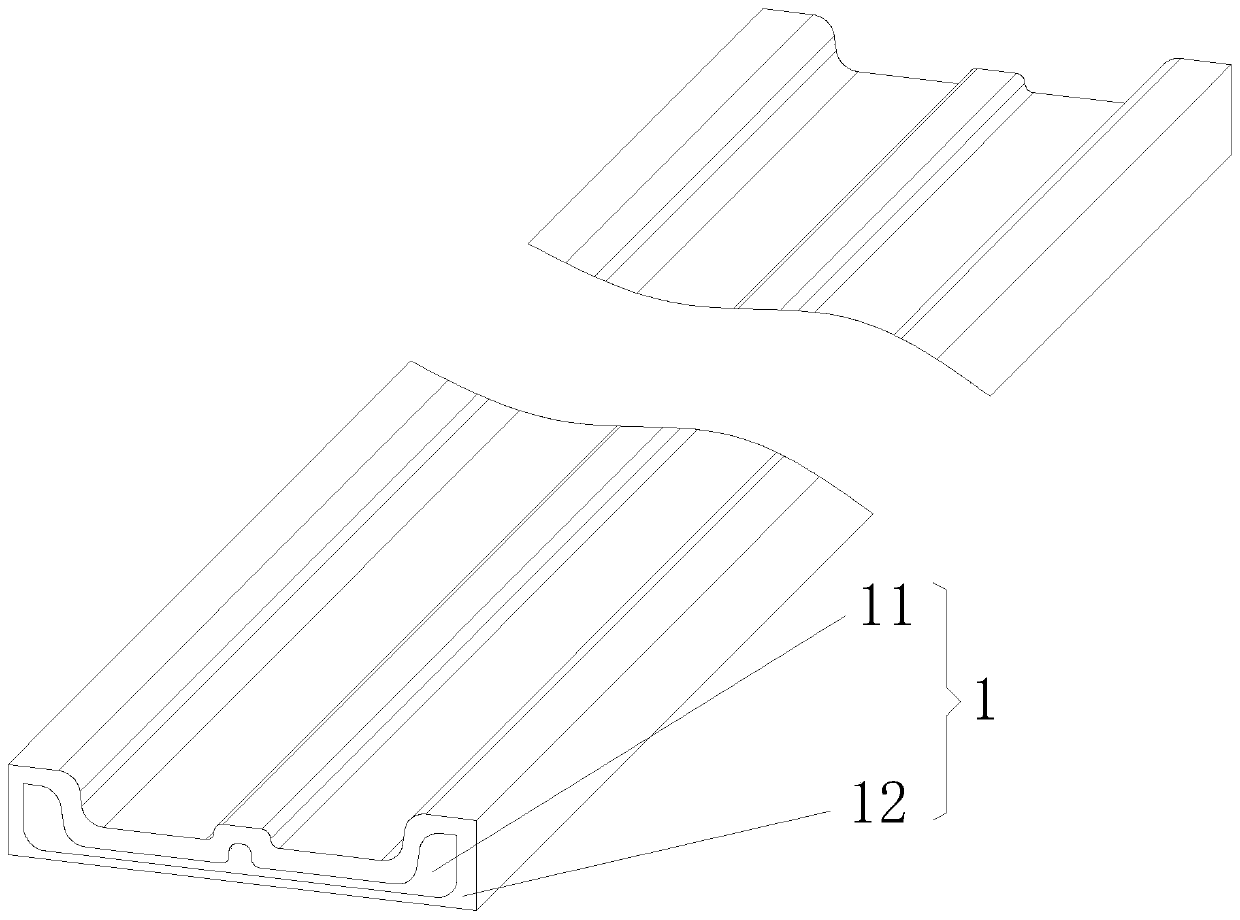

Hot winding solid corrugated pipe, sectional material thereof and manufacturing method thereof

PendingCN110588032AEasy to cool and formIncrease production speedRigid pipesTubular articlesSolid wallShock resistance

The invention relates to a hot winding solid corrugated pipe, and a sectional material and manufacturing method thereof. The sectional material of the hot winding solid corrugated pipe comprises a first sectional material and a second sectional material; the first sectional material comprises a supporting rib and a first hot coating layer; the first sectional material comprises a connecting strip,a first half wave crest strip and a second half wave crest strip; the second sectional material comprises a buckle plate and a second hot coating layer; a buckling groove is formed in the middle partof the second sectional material; and the shape and size of the buckling groove are matched with the shape and size of the outer wall of a small wave crest structure formed by splicing the first halfwave crest strip and the second half wave crest strip. The sectional material adopts the first sectional material and the second sectional material which are solid wall structures, and the sectionalmaterial can facilitate the cooling forming of a pipe, the production speed of the pipe is increased and the welding quality of the pipe can be improved. The solid corrugated pipe is of a solid wall structure, and is high in ring stiffness, good in impact resistance and destruction resistance, and excellent in ring flexibility. The manufacturing method of the corrugated pipe adopts hot winding tocompound all units together, the welding strength is high and the residual stress problem basically does not exist.

Owner:萍乡市大地新材料科技有限公司

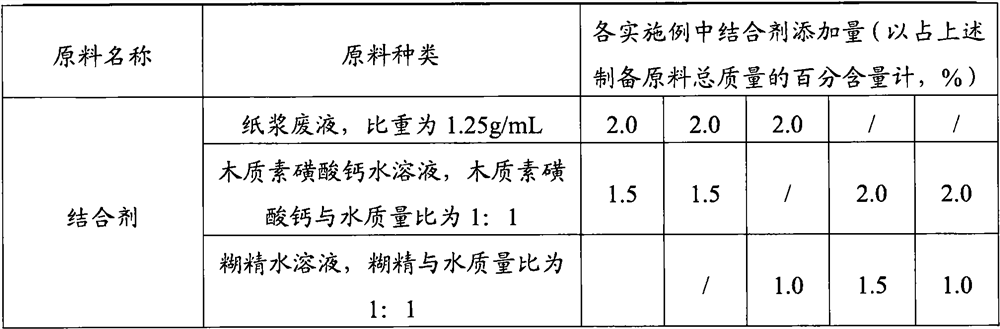

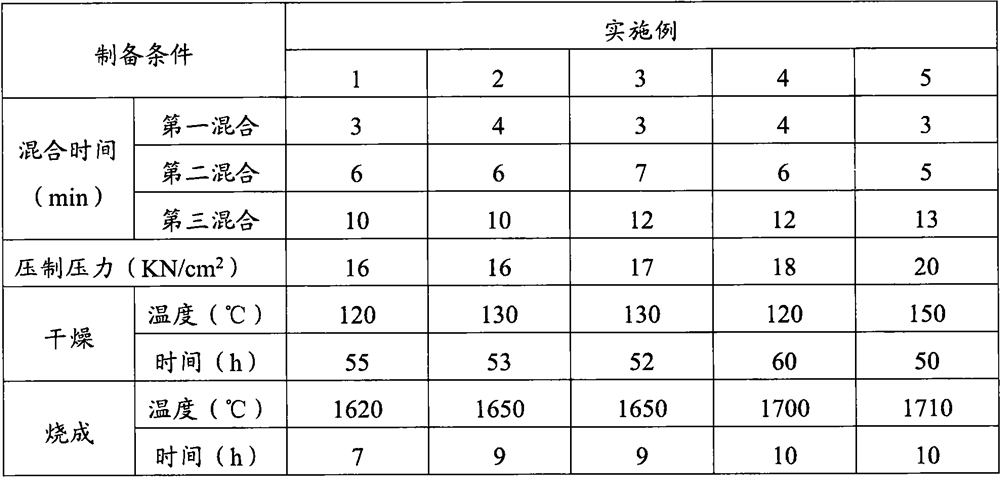

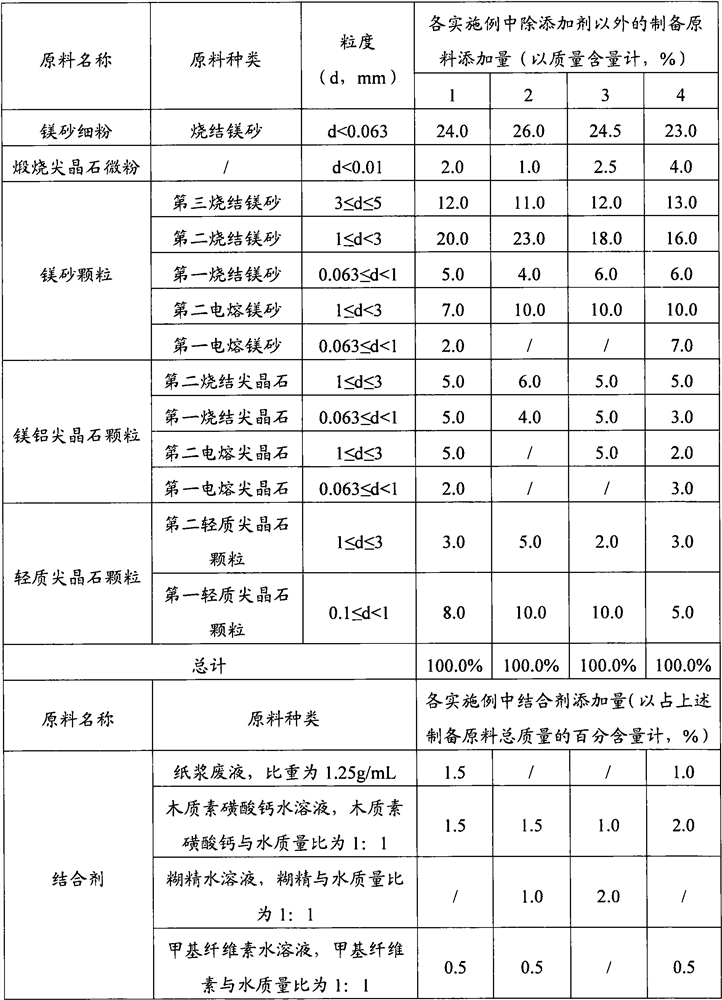

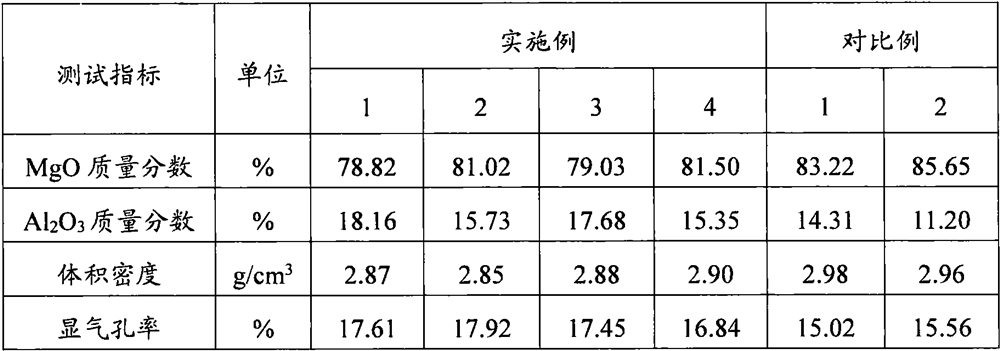

Low-thermal-conductivity spinel refractory homogeneous brick as well as preparation method and application thereof

The invention provides a low-thermal-conductivity spinel refractory homogeneous brick as well as a preparation method and application thereof, and belongs to the technical field of refractory materials. The low-thermal-conductivity spinel refractory homogeneous brick provided by the invention is prepared from the following raw materials: magnesia particles, magnesia fine powder, magnesium aluminate spinel particles, light hollow spheres, additive micro powder and a binding agent. The low-thermal-conductivity spinel fire-resistant homogeneous brick provided by the invention is uniform in material, the hidden danger that weak parts are easy to appear in a composite structure formed by different materials is avoided, and the problem that the composite brick is broken in the use process is avoided. Meanwhile, the low-thermal-conductivity spinel refractory homogeneous brick provided by the invention takes a periclase-spinel system as a matrix, is stable in high-temperature performance, is resistant to corrosion of alkali metals, volatile salts and the like, and is suitable for severe environments of rotary cement kilns or lime calcining kilns.

Owner:MARVELS REFRACTORIES ANSHAN CO LTD

Manufacturing method of carbon-silver composite target for curved touch screen

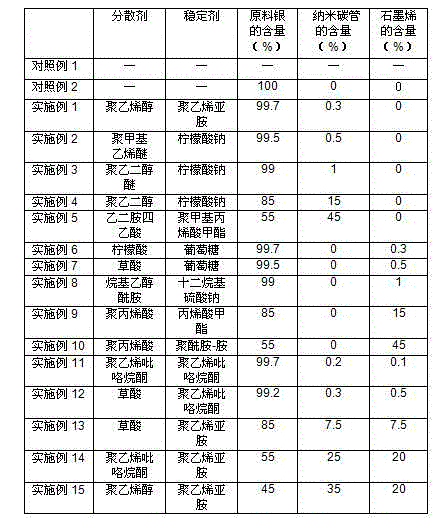

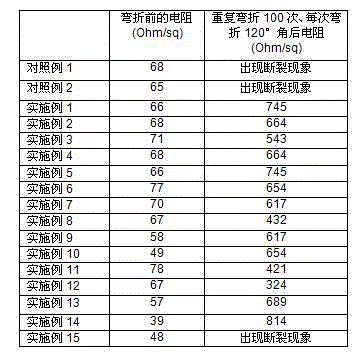

ActiveCN104651784AAccelerate the speed of mixing into high-temperature molten liquid silverImprove dispersion uniformityVacuum evaporation coatingSputtering coatingSilver pasteCarbon nanotube

The invention provides a manufacturing method of a carbon-silver composite target for a curved touch screen. The manufacturing method comprises the following steps: adding a silver salt, a dispersant and a stabilizer to a carbon material aqueous solution to prepare carbon material powder on the surface of which nanosilver particles are adsorbed; next, feeding the carbon material powder into silver paste to obtain high-temperature mixed paste, wherein based on the total mass of the carbon material powder and raw material silver, 0.3-45% of the carbon material powder and 55-99.7% of the raw material silver are put; finally, molding the high-temperature mixed paste to obtain the carbon-silver composite target, wherein the carbon material is made from carbon nanotubes, graphene, or a mixture containing the carbon nanotubes and the graphene. The carbon-silver composite target can be used for preparing the curved touch screen having the excellent buckling resistance; the manufactured curved touch screen is convenient to transport; a favorable condition is created for batch production of the large-size touch screens.

Owner:福建省诺希科技园发展有限公司

Novel sound absorption panel structure

InactiveCN108035450ANo warpingThere will be no problem of breakingSound proofingLong lastingAcoustic board

The invention discloses a novel sound absorption panel structure which comprises an outer plate, a first keel support and a second keel support. A sound insulation plate is fixedly connected with theinner wall of the outer plate. An inner layer plate is fixedly connected with the inner wall of the sound insulation plate. A circular groove is formed in the inner wall of the outer plate. A first limiting groove is formed in one side of the inner wall of the inner layer plate. A second limiting groove parallel to the first limiting groove is formed in the other side of the inner wall of the inner layer plate. The first keel support is connected with the second limiting groove through a key groove. The second keel support is connected with the first limiting groove through a key groove. The exterior of the first keel support and the exterior of the second keel support are filled with silencing cotton. The novel sound absorption panel structure is reasonable in structure; the keel structures for long-lasting fixing are installed in the novel sound absorption panel structure; the upwarp and breakage problems of a panel can not appear after long-term use; due to the dual-layer panel design, the product quality can be greatly improved, and the sound absorption effect is better facilitated.

Owner:成都德顺泓沥科技有限公司

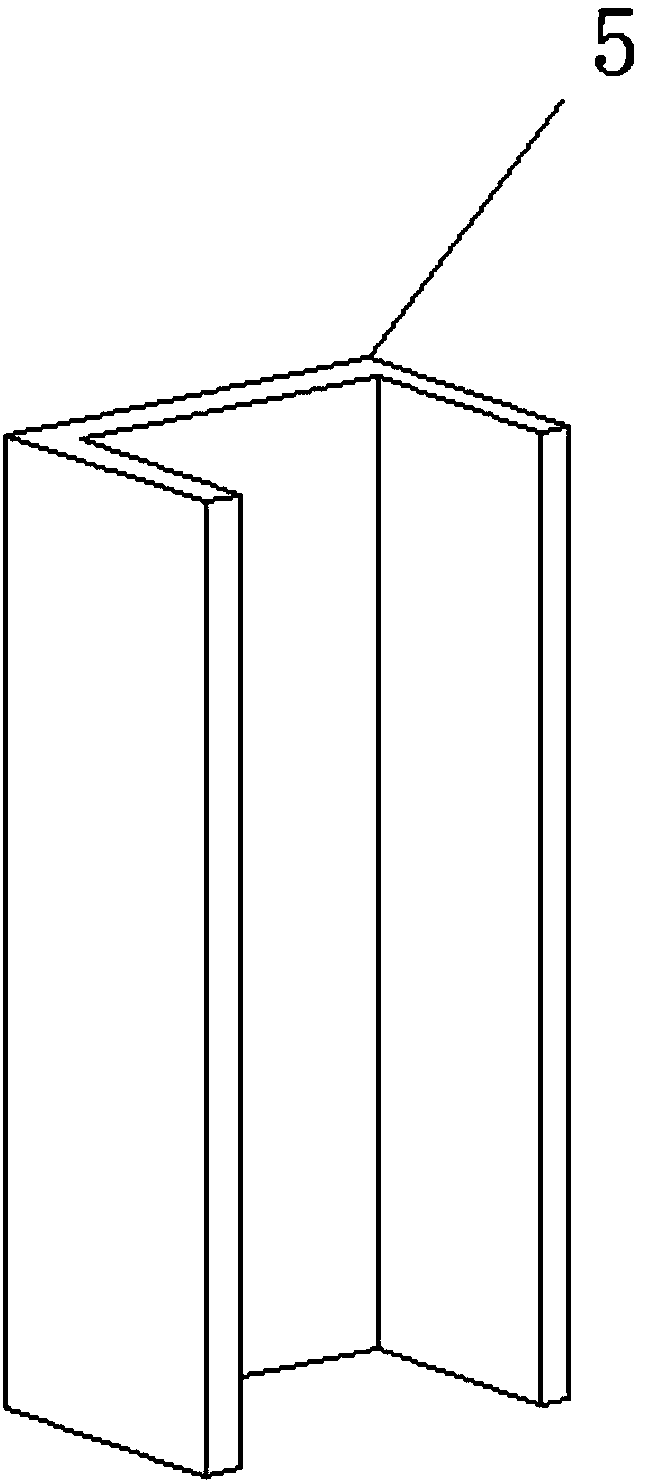

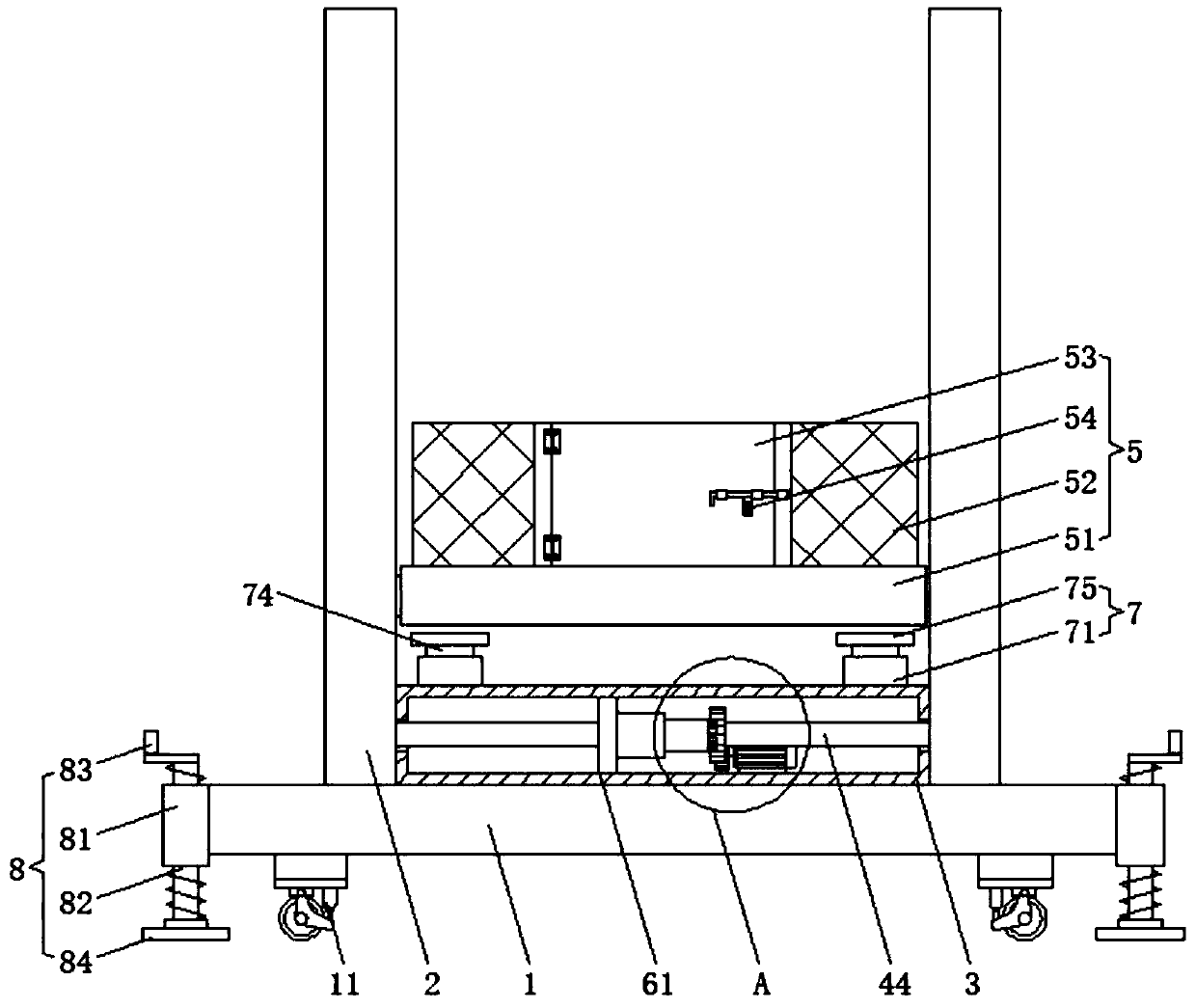

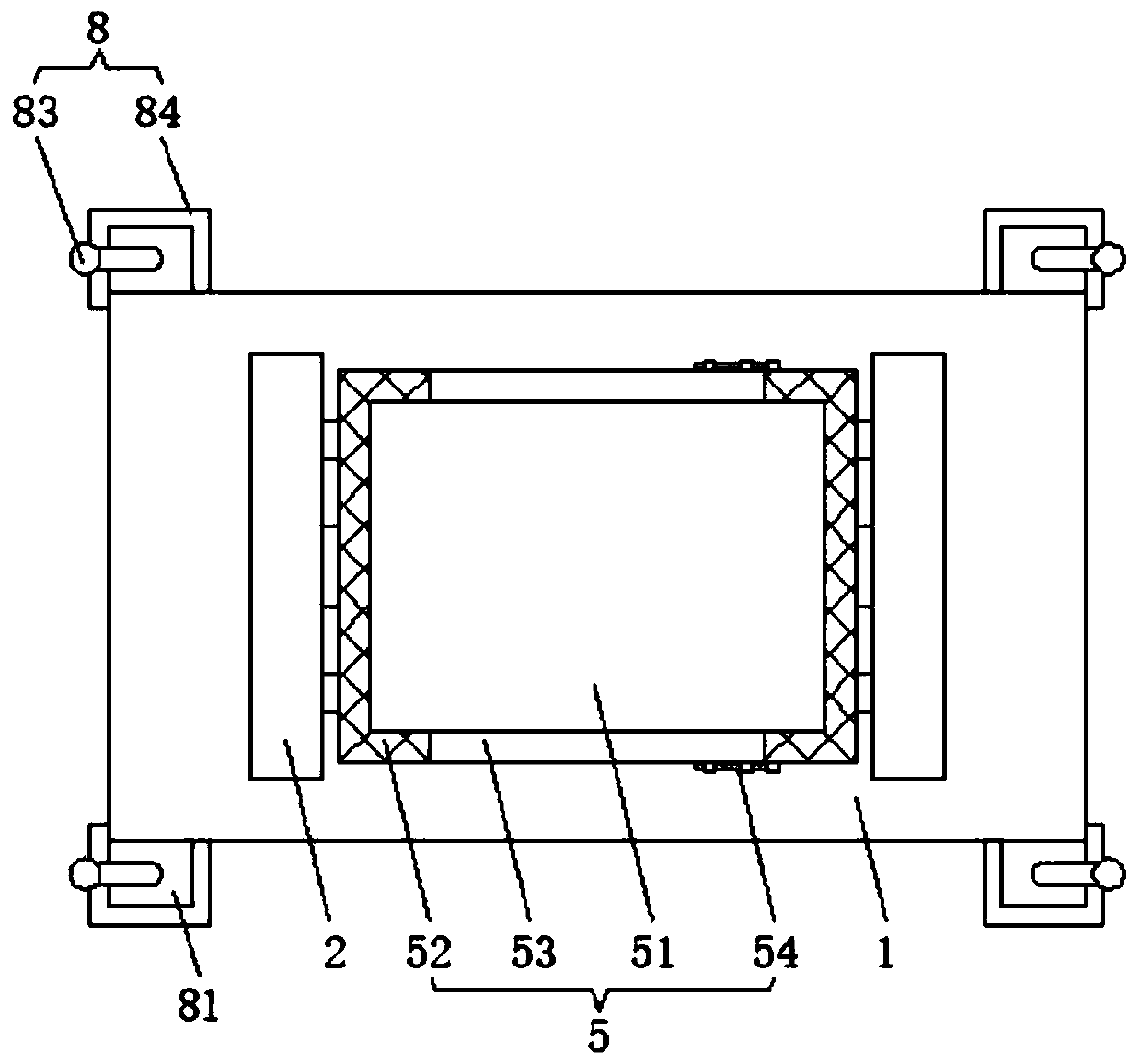

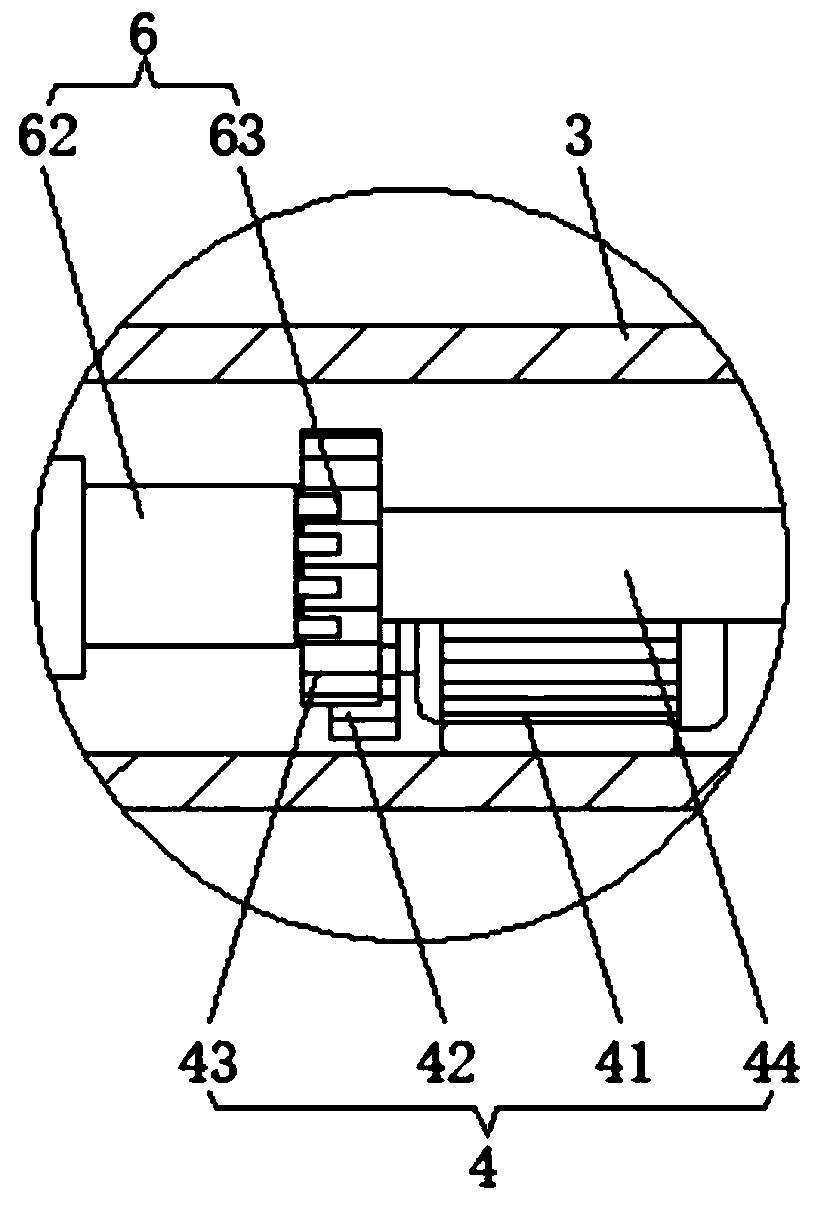

High-safety material lifting device for building construction

InactiveCN110642183AEnsure safetyThere will be no problem of breakingSafety devices for lifting equipmentsLifting framesArchitectural engineeringSteel rope

The invention discloses a material lifting device. The material lifting device comprises a bottom plate, a bearing assembly, a driving mechanism, a positioning mechanism, one or more elastic buffer assemblies, one or more sliding rods, wheels, and a plurality of support assemblies, wherein the bearing assembly comprises a bearing plate which is positioned above the bottom plate and is used for bearing materials; the driving mechanism is connected with the bearing plate to drive the bearing plate to move up and down; the positioning mechanism is used for locking the driving mechanism when the bearing plate moves to a preset height; the elastic buffer assemblies are arranged on the bottom plate and face the bottom of the bearing plate; the sliding rods are vertically fixed to the bottom plate and are sleeved with sliding sleeves capable of sliding, and the sliding sleeves are fixedly connected with the bearing plate; the wheels are arranged at the bottom of the bottom plate; the plurality of support assemblies comprise feet which can move between an extended position and a retracted position; and the feet contact the ground when in the extended position, and the feet are lifted off the ground when in the retracted position such that the material lifting device can be supported on the ground only by the wheels. According to the material lifting device, the problem of poor stability and safety of a traditional steel cable pulley type material lifter is solved.

Owner:CHINA FIRST METALLURGICAL GROUP

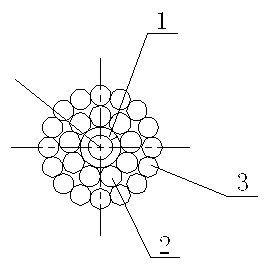

High-flexibility copper-clad steel wire

The invention belongs to the technical field of copper-clad steel wire, and specifically relates to a high-flexibility copper-clad steel wire. The high-flexibility copper-clad steel wire comprises a low carbon steel layer, a pure iron layer, a copper plating layer, outer arc-shaped bending plates and inner arc-shaped bending plates; the pure iron layer is arranged at the outer part of the low carbon steel layer and wraps the low carbon steel layer; four outer arc-shaped bending plates which are prepared from 304 stainless steel are uniformly arranged in the pure iron layer in the circumference direction; the copper plating layer is arranged at the outer part of the pure iron layer and wraps the pure iron layer; the low carbon steel layer contains 0.2 to 0.25% of carbon; the pure iron layer contains 0.02 to 0.03% of carbon content. According to the high-flexibility copper-clad steel wire, the outer arc-shaped bending plates and the inner arc-shaped bending plates are provided to improve the flexibility and the fatigue resistance; the social benefit and economic benefit are increased.

Owner:JINGGANGSHAN JIDA METAL

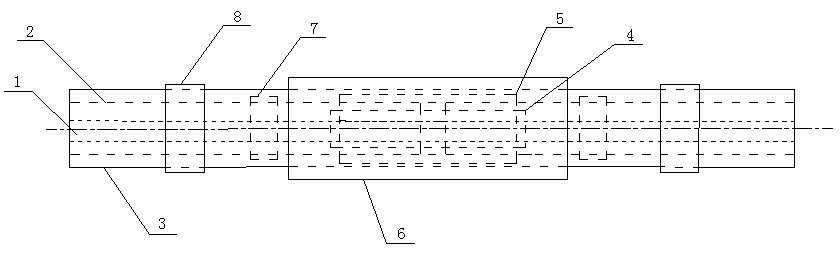

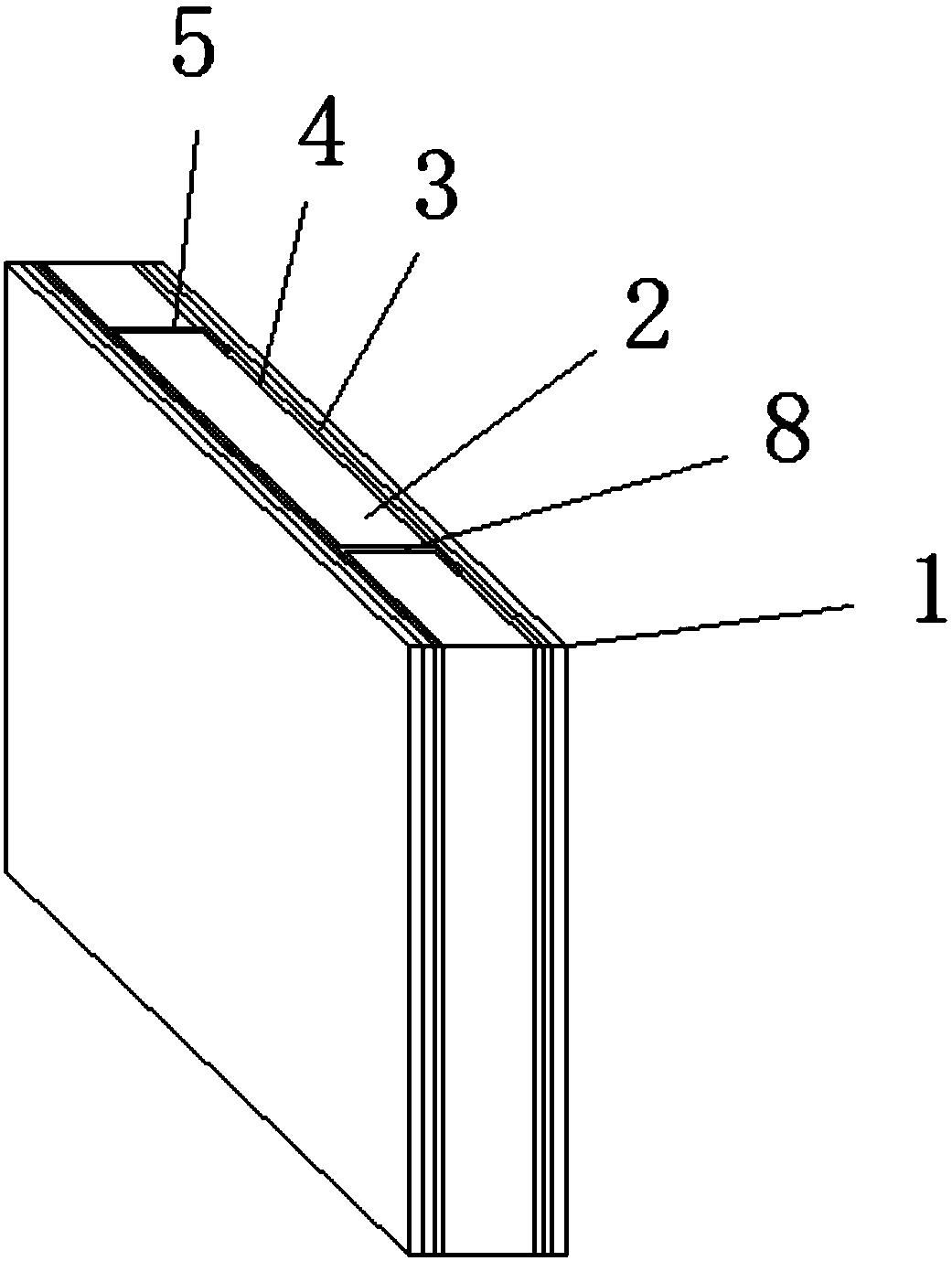

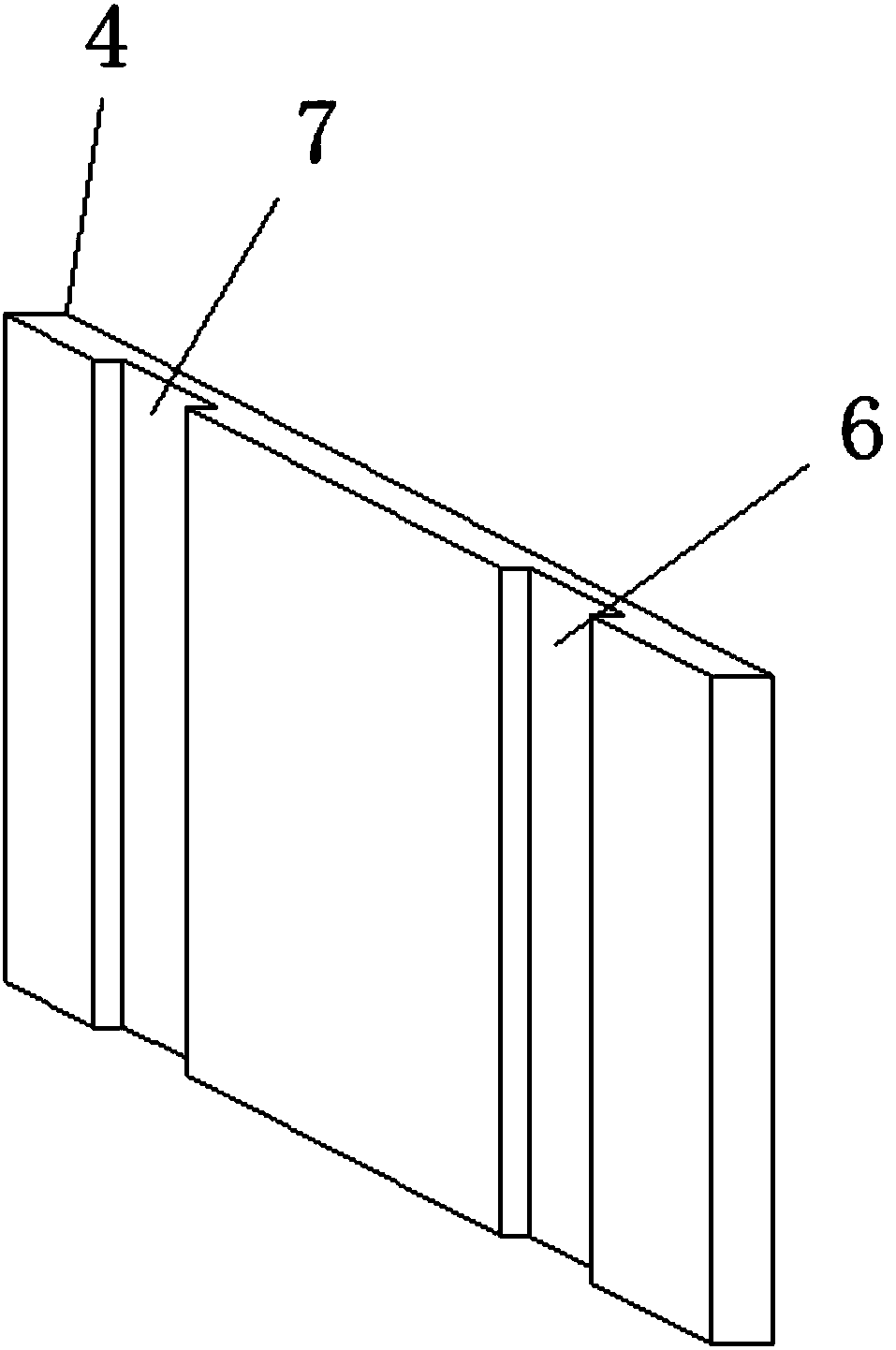

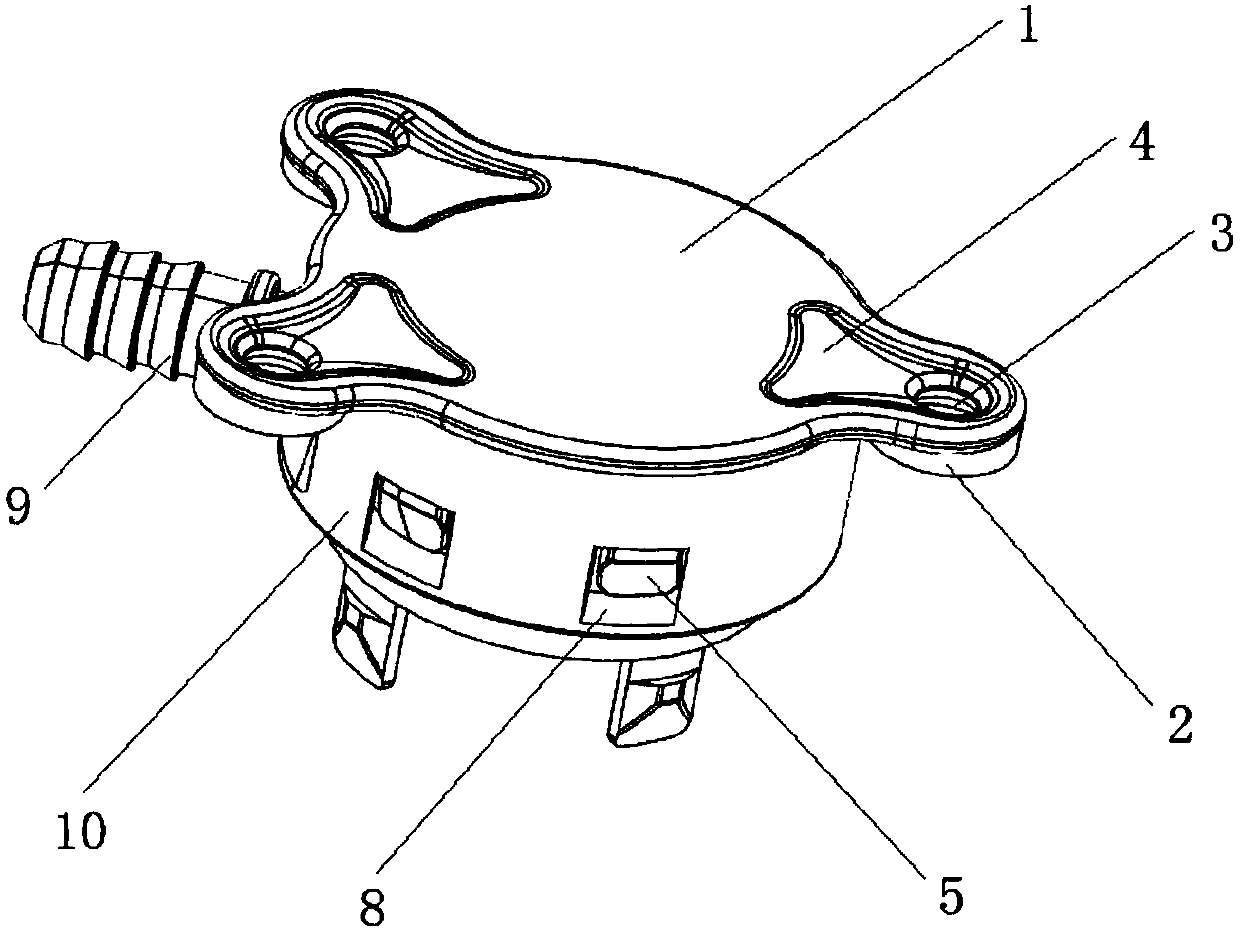

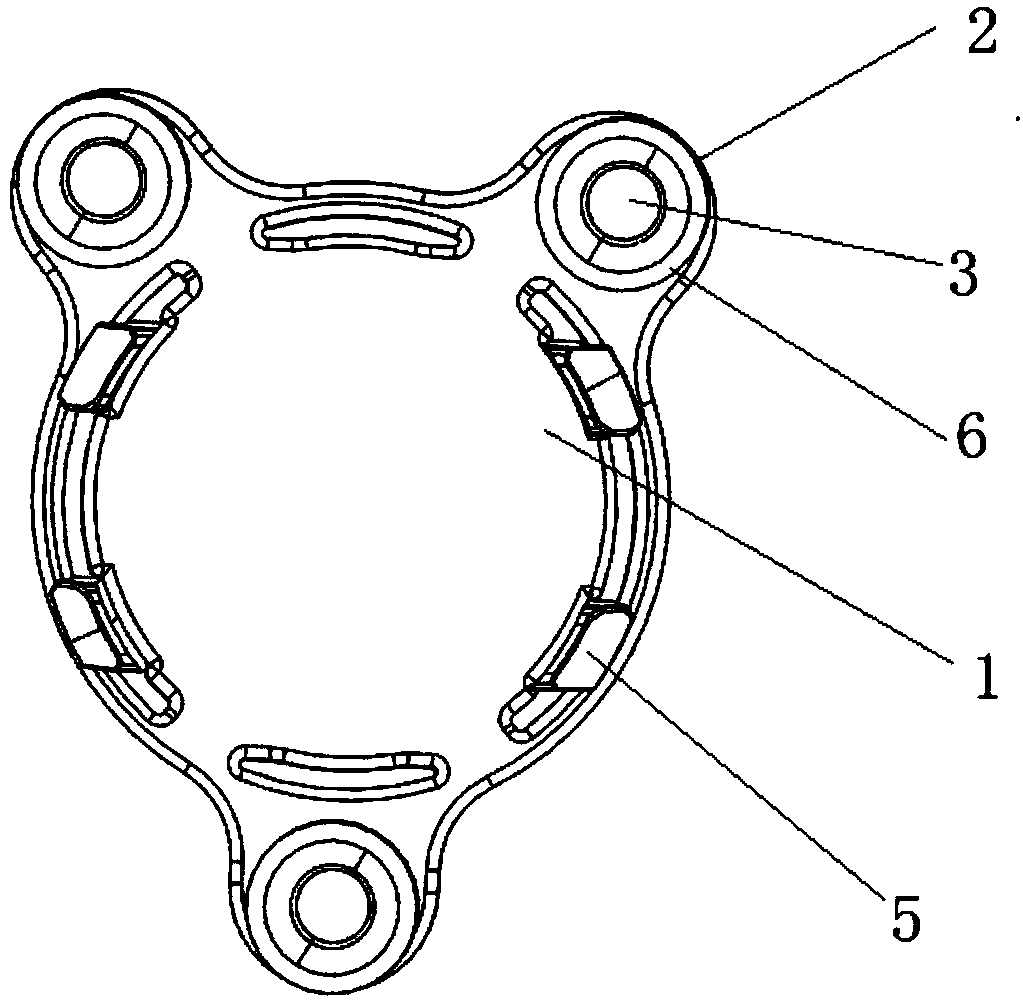

Riveting type oil tank internally-arranged connection part

PendingCN107791830AImprove stabilityUniform connection forceUnderstructuresFuel supplyPetroleum engineeringStructural engineering

The invention discloses a riveting type oil tank internally-arranged connection part. The riveting type oil tank internally-arranged connection part comprises a bottom plate (1), at least three protruding parts (2) are evenly arranged at the edge of the bottom plate (1), a through hole (3) is formed in each of the protruding parts (2), the protruding parts (2) and the bottom plate (1) are of an integrally formed structure, round chamfering treatment is conducted on the edges of the through holes (3), and a plurality of grooves (7) are vertically formed in the inner walls of the through holes (3). The riveting type oil tank internally-arranged connection part overcomes the defects that the connection mode of a fitting and the inner wall of an oil tank is poor in reliability and the firmnessis not perfect existing in the prior art.

Owner:WUHU SHUNRONG AUTOMOBILE PARTS

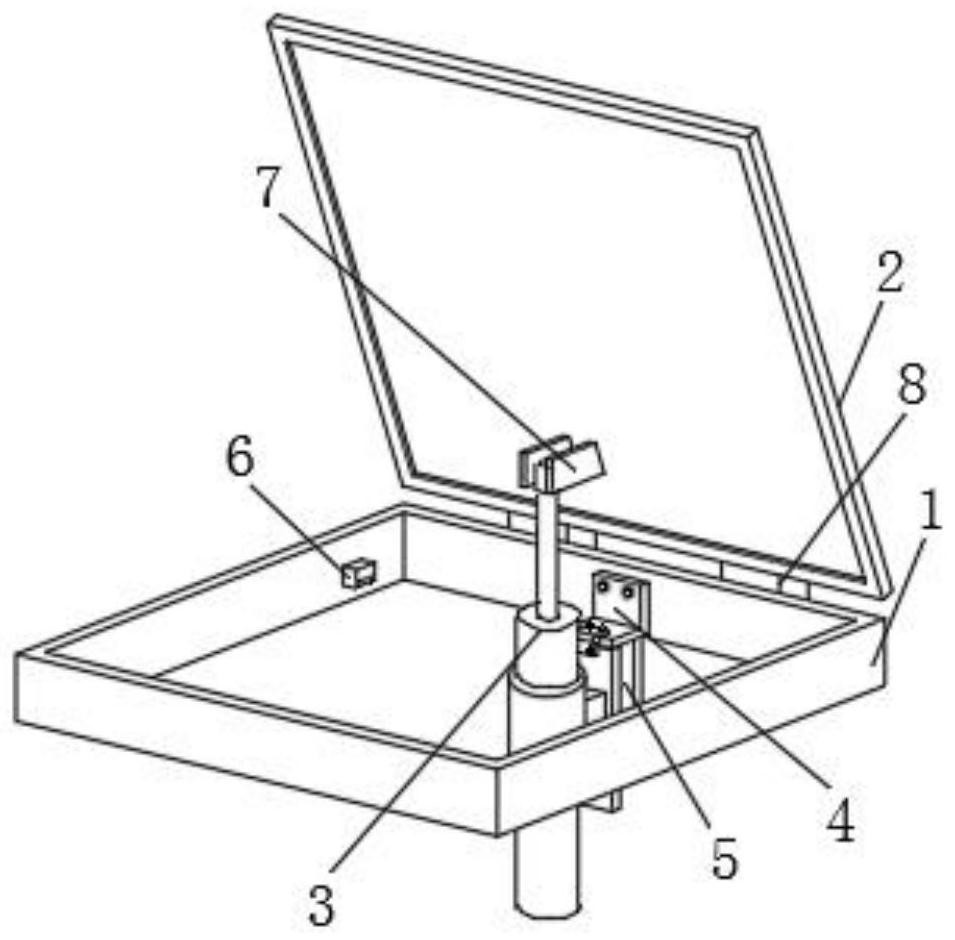

Automatic lifting rainwater well lid

PendingCN114809102AChange inclineReduce forceArtificial islandsUnderwater structuresClassical mechanicsStructural engineering

The invention provides an automatic lifting rainwater well lid which comprises a jacking mechanism and a protection mechanism, the jacking mechanism comprises an air cylinder assembly, a connecting assembly is arranged on one side of the air cylinder assembly, a horizontal transmission assembly is arranged on the other side of the connecting assembly, the connecting assembly comprises a vertical plate and a fixing plate, the vertical plate is arranged below the fixing plate, and the horizontal transmission assembly is arranged below the vertical plate. When the horizontal transmission assembly operates, the horizontal transmission assembly pushes the connecting assembly to incline and drives the air cylinder assembly to incline, and relates to the technical field of hydraulic well lids, the connecting assembly and the horizontal transmission assembly are arranged on one side of the air cylinder assembly, and the connecting assembly comprises a vertical plate and a fixing plate; the horizontal transmission assembly pushes the connecting assembly to move, the vertical plate inclines, and therefore the inclination degree of the air cylinder assembly is changed, the acting force between the control assembly and the well lid body is small when the well lid is opened, the fluorescent screen is arranged on the surface wall of the control assembly, and therefore the position of the control assembly can be determined through the fluorescent screen even in a dark place.

Owner:安徽省臻实机械制造有限公司

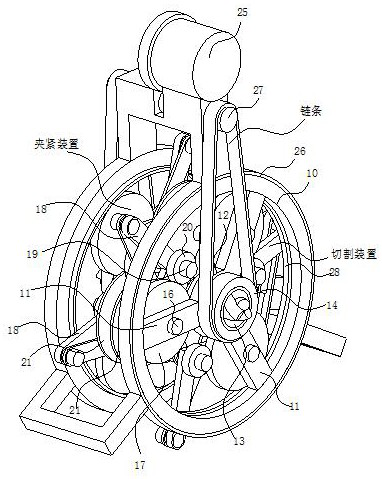

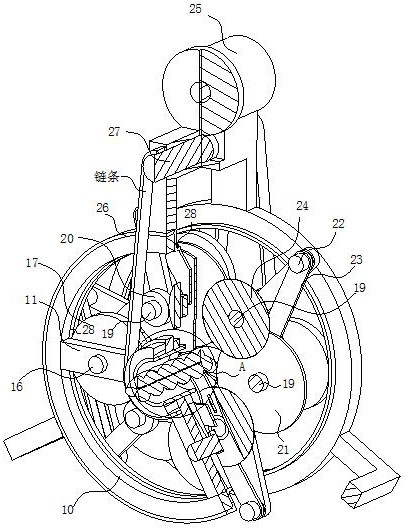

Cutting device for wire and cable processing and cutting method thereof

ActiveCN114589273AControl feed forceNo out of round phenomenonElectronic waste recyclingStructural engineeringSprocket

The invention discloses a cutting device for wire and cable processing in the technical field of cutting for wire and cable processing, the cutting device comprises a clamping device and a cutting device, the clamping device comprises a revolution ring plate, and a plurality of mounting frames are fixedly arranged between the inner walls of the revolution ring plate around the axis of the revolution ring plate in an annular array mode; a fixed ring plate is fixedly arranged at the end, away from the revolution ring plate, of each mounting frame, and a hollow power bearing shaft is rotationally arranged on the inner wall of each fixed ring plate. A clamping chain wheel is coaxially and fixedly arranged on the outer wall of the power bearing shaft located on the side wall of the fixed annular plate. The cable cutting device solves the problems that in the cable cutting process, a pincerlike cutting tool is used for directly cutting a cable, due to the fact that the two sides of the cable are stressed, the end face of the cut cable is in a flat shape, a sharp shearing face can appear, and operators are extremely prone to being scratched in the later construction process; and the flat notch is not beneficial to direct butt joint of the annular cable connector, so that the working progress is influenced.

Owner:永新县宏展电线电缆有限公司

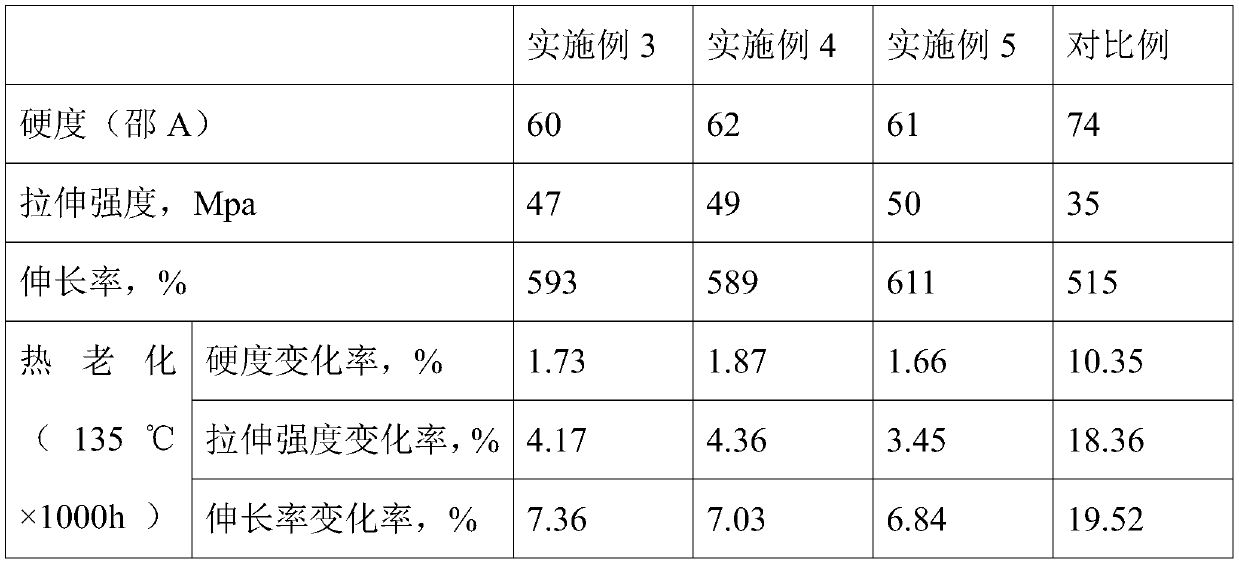

High-temperature-resistant and aging-resistant thermoplastic elastomer material

The invention discloses a high-temperature-resistant and aging-resistant thermoplastic elastomer material. The material comprises the following raw materials in parts by weight: 100 parts of a thermoplastic elastomer, 15-25 parts of butadiene-acrylonitrile rubber, 4-10 parts of phenolic resin, 20-40 parts of a reinforcing agent, 2-4 parts of an interfacial compatibilizer, 2-6 parts of composite zirconium dioxide, 1-2 parts of a peroxide vulcanizing agent, 1-2 parts of naphthenic oil, 4-8 parts of an antioxidant and 1-2 parts of a lubricant. The thermoplastic elastomer comprises thermoplastic polyurethane elastomer rubber and an ethylene-butyl acrylate copolymer; the reinforcing agent is at least one of polypropylene fibers, carbon nanotubes, basalt fibers, polyborate fibers and nanocellulose whiskers; the interfacial compatibilizer is at least one of a maleic anhydride grafted ethylene-vinyl acetate copolymer, a maleic anhydride grafted ethylene-propylene copolymer, a maleic anhydridegrafted ethylene-octene copolymer and a maleic anhydride grafted ethylene-ethylene-propylene rubber copolymer.

Owner:六安市叶集区聚诚高分子材料有限公司

Anti-fog type automobile front windshield glass

InactiveCN109133658ACause harmImprove sexual functionWindowsWindscreensIrritationPolyethylene glycol

An anti-fog type automobile front windshield glass belongs to the technical field of glass materials. The glass comprises, by weight, the following components: 3-13 parts of borax, 2-10 parts of sodium hydroxide, 1-7 parts of limestone, 2-8 parts of glass fiber, 15-25 parts of silicon dioxide, 2-8 parts of zinc oxide, 3-13 parts of sodium carbonate, 2-12 parts of curing agent, 2-5 parts of dispersing agent, 1-5 parts of emulsifier, 1-3 parts of polyethylene glycol and 2-3 parts of propylene glycol. The automobile glass has the advantages of high structural strength, long service life and the like, a problem of breakage does not occur in the use process, the structural strength of the glass material is strengthened, and the service life is prolonged; the strength is high, the glass is capable of resisting strong impact, effectively blocking sun irritation, protecting skin from being injured, effectively preventing fog, and adding safety to driving.

Owner:景有超

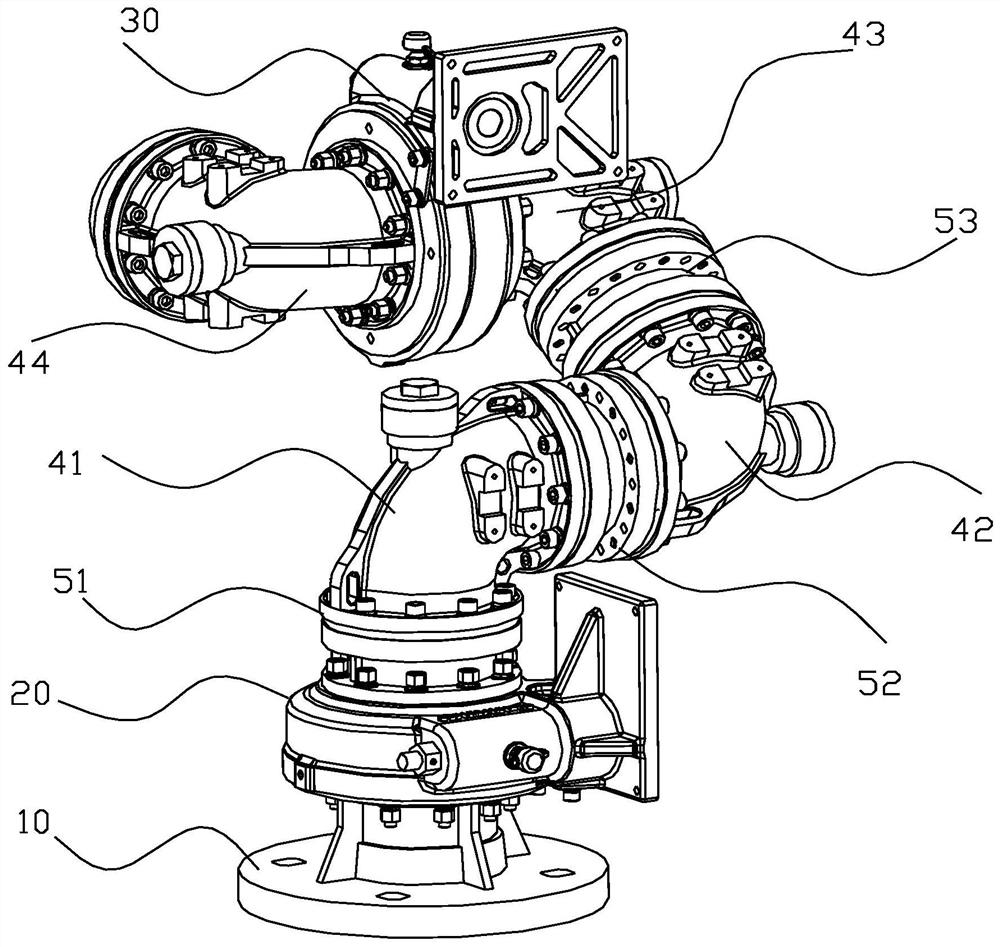

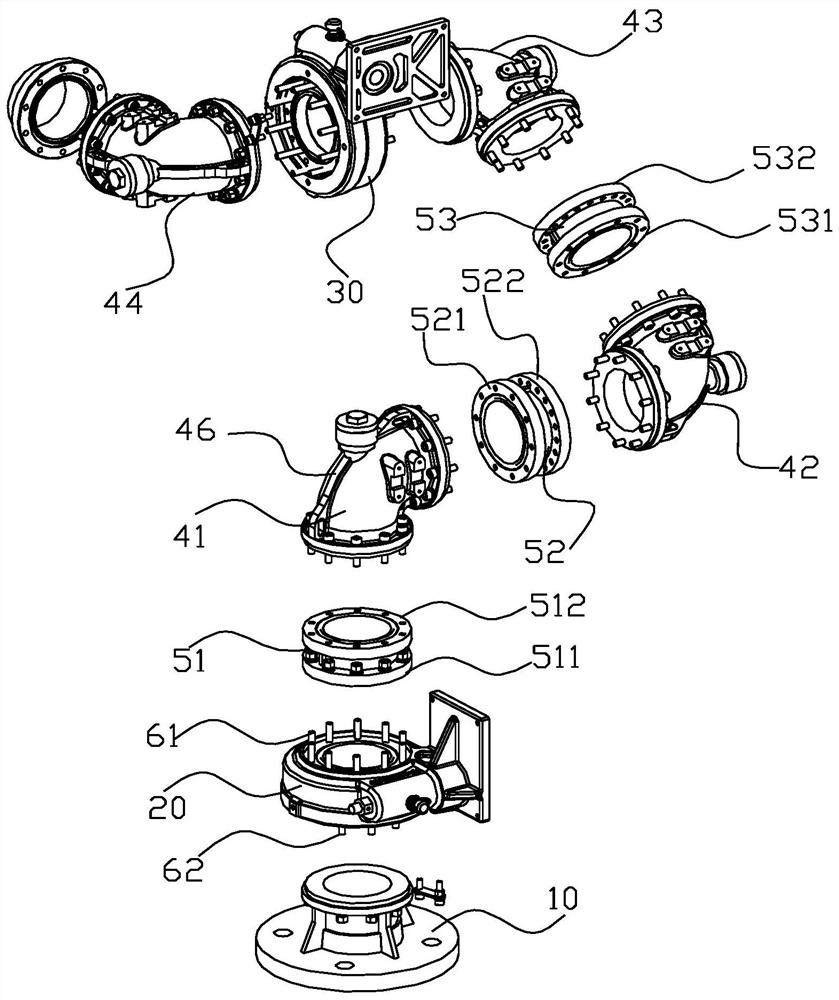

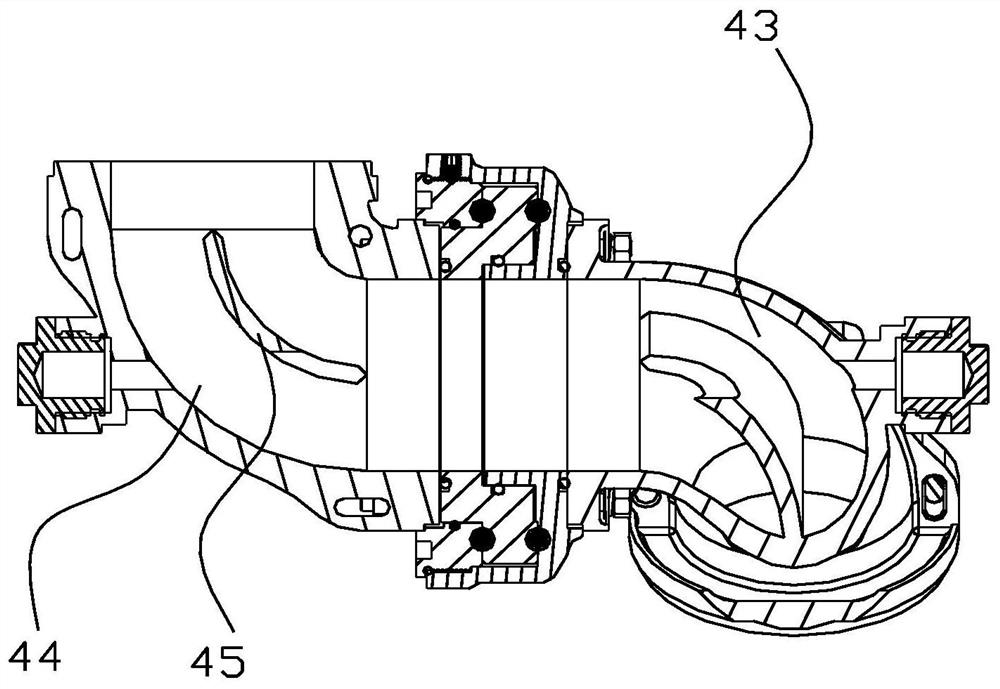

Fire water monitor body and fire water monitor

ActiveCN112843575AAchieve lengthImplementation angleFire rescueStructural engineeringMechanical engineering

The invention relates to a fire water monitor body and a fire water monitor. The fire water monitor body comprises a water inlet base; a first worm and gear assembly and a second worm and gear assembly; a plurality of bent pipes which comprise a first bent pipe, a second bent pipe, a third bent pipe and a fourth bent pipe, wherein the first worm and gear assembly is installed on the water inlet base, the first bent pipe is installed on the first worm and gear assembly, the first bent pipe is connected with the second bent pipe through a first compensation pipe, the second bent pipe is connected with the third bent pipe, the third bent pipe is installed on the second worm and gear assembly, and the second compensation pipe is connected with the third bent pipe; and the second worm and gear assembly is connected with the fourth bent pipe. According to the invention, the interchangeability and maintainability of parts of a cannon body can be improved, the pressure loss of a cannon body runner is reduced, and the characteristics of high structural strength, small processing error, good assembly consistency and the like are achieved.

Owner:高邮市盛鑫消防科技有限公司

Novel automobile anti-fog glass

The invention discloses novel automobile anti-fog glass. The glass comprises the following components in parts by weight: 20-30 parts of silicon dioxide, 8-12 parts of alkyl benzene sulfonic acid, 10-12 parts of alkanolamide, 2-8 parts of glycerol, 5-15 parts of glass fibers, 2-10 parts of silicone oil, 1-5 parts of calcium oxide, 2-6 parts of methyl methacrylate, 2-10 parts of aluminum oxide, 1-5parts of polyethylene glycol and 1-10 parts of superfine powder. The glass has good water resistance and wiping resistance, is applied to automobile assembling, can effectively solve the fogging phenomenon of automobile glass caused by large temperature difference between the inside and the outside of an automobile, and improves the use safety.

Owner:JIANGSU FANHUA GLASS CO LTD

Dual-mode optical cable connector

PendingCN108646355AReduce use costReduced installation effortCoupling light guidesDual modeEngineering

The invention discloses a dual-mode optical cable connector. The connector comprises a plug and a socket; the plug is provided with single-mode optical fiber female pins and multi-mode optical fiber female pins, the socket is provided with single-mode optical fiber male pins and multi-mode optical fiber male pins, the single-mode optical fiber female pins correspond to the single-mode optical fiber male pins, and the multi-mode optical fiber female pins correspond to the multi-mode optical fiber male pins. According to the dual-mode optical cable connector, the simultaneous connection of dual-mode optical cables with single-mode optical fibers and multi-mode optical fibers can be achieved, the use cost and installation workload of the connector are reduced, and the screen cabinet space occupied by the connector is reduced; the abutment joint precision is improved, and the pins are not easily fractured.

Owner:慈溪市南瑞电器有限公司

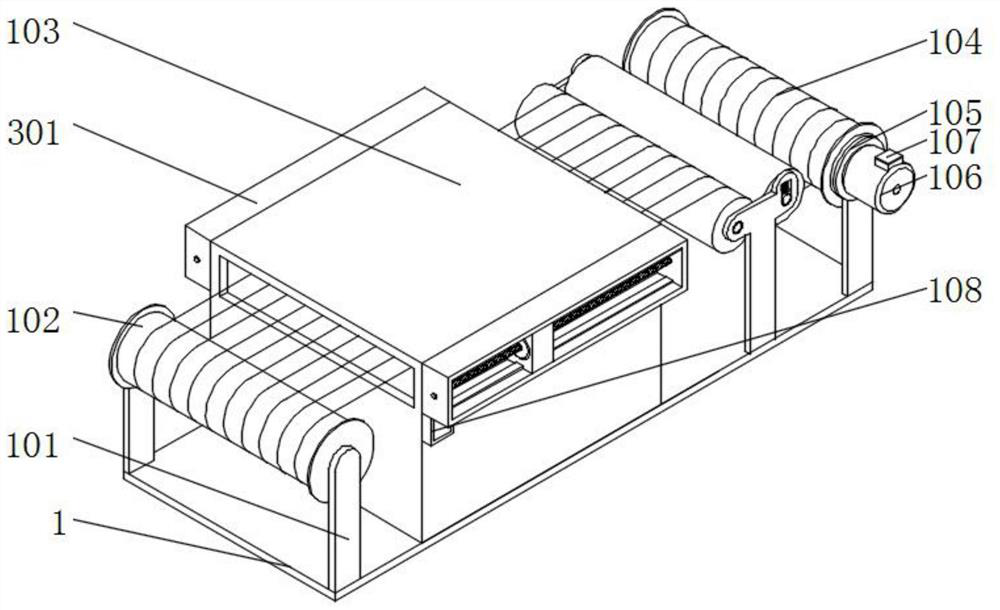

An indentation machine for preventing cardboard from sticking

ActiveCN109664549BAvoid LeakageAvoid manual removalPaper-makingBox making operationsPaperboardConveyor belt

The invention relates to a paperboard adhesion-preventing creasing machine which comprises a fixed base, an operating platform, a cutting knife, a conveying pipe and a connecting valve. The operatingplatform is welded to the top end of the fixed base; a conveyor belt is rotatably connected to the middle of the inner side of the operating platform; a support stand is welded to the middle of the upper part of the operating platform; a grinding roller is rotatably connected to the inner side of the support stand; a movable groove is embedded into one side of the top end of the operating platform; a support shaft is horizontally welded to the inner side of the movable groove; and pulleys are rotatably connected to two ends of the support shaft. The paperboard adhesion-preventing creasing machine provided by the invention has the advantages that through arranging parts such as a connector, a spill plate, an air nozzle and a connecting valve, during corrugated paper cutting, when the phenomenon of adhesion occurrs due to incomplete cutting, corrugated paper is blown and separated by utilizing the function of air pressure, so that follow-up manual removal is avoided; and the internal spill plate part is ensured to be at a closed state when the connecting valve does not enter, so that the occurrence of the phenomenon of internal air pressure leakage is avoided.

Owner:浙江骏驰纸制品有限公司

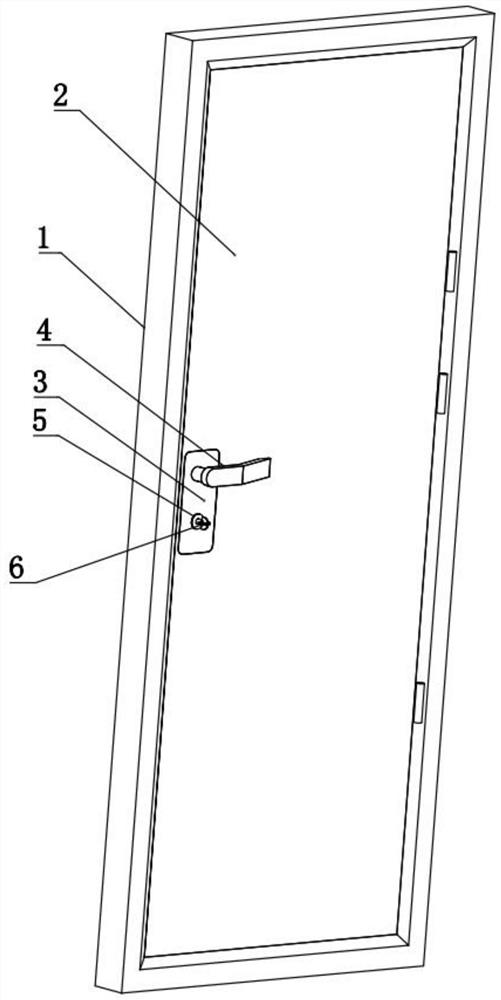

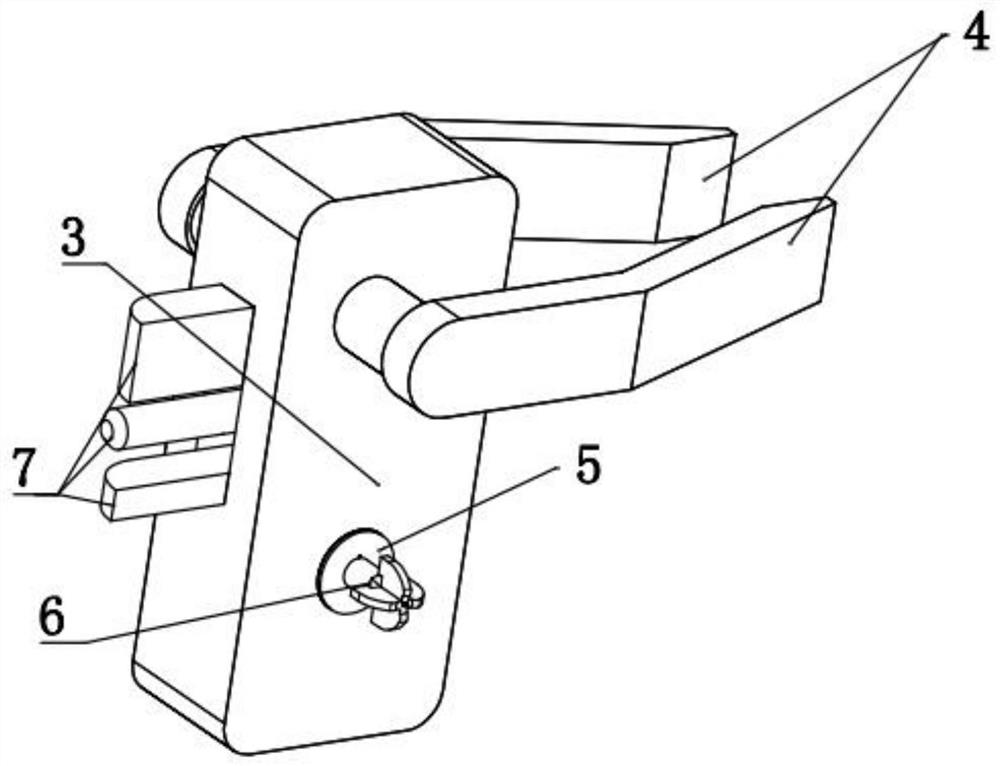

An electromagnetic anti-theft door

ActiveCN113622751BThere will be no problem of breakingExtended service lifeBurglary protectionWing handlesStructural engineeringControl circuit

The invention relates to the technical field of anti-theft doors, and discloses an electromagnetic anti-theft door, which includes a door frame, a door leaf and an anti-theft lock on the door leaf. The anti-theft lock includes a lock body and a key. The lock body includes at least one bolt and a lock fixed in the lock body. The expansion and contraction of the lock bolt is controlled by the energization or de-energization of the first electromagnet, and the energization or de-energization of the first electromagnet is controlled by the first control circuit. There is a slot recessed on the side of the lock cylinder facing the outside of the door. , a control module that can connect or disconnect the control circuit is arranged in the lock cylinder, and the control module includes N (N≥8) through slots that are recessed in the inner wall of the slot along its circumferential direction and / or axial direction. A contact module fixedly arranged at one end of the through slot away from the slot and a telescopic member elastically and telescopically arranged in each through slot, the key includes an insertion rod and a first control circuit that can be telescopically arranged on the outer ring wall of the insertion rod Connected unlocking parts, thieves can't open the security door at all by using the traditional crochet and tin foil filling unlocking methods.

Owner:浙江星月安防科技有限公司

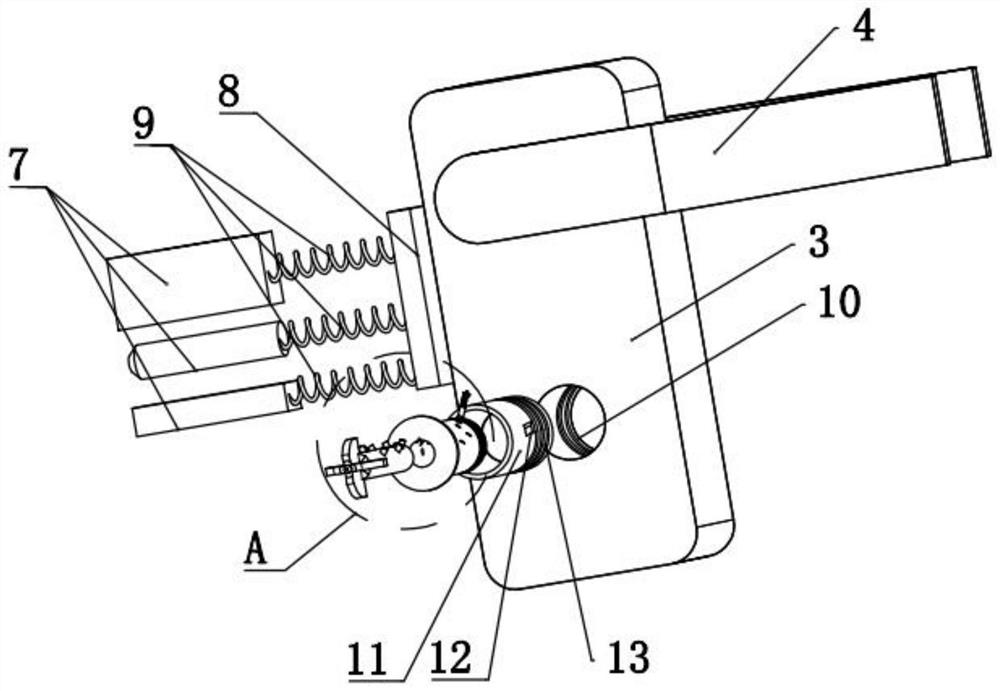

Knotting-preventing thread layer carding device for textile machine

ActiveCN114575012AGuaranteed stabilityPrevent kinkingFibre cleaning/openingTextile disintegration and recoveryYarnStructural engineering

The knotting-preventing thread layer carding device for the textile machine comprises a bearing table and a tension frame, a carding box is installed at the top of the bearing table, the tension frame is installed at the top of the bearing table and located on the back face of the carding box, and limiting frames are installed on the two sides of the carding box; a lead frame is mounted on the inner side of the carding box; a supporting plate is mounted on the inner side of the carding box; the two sides of the interior of the carding box are each provided with two sets of installation frames, and the inner side of the carding box is provided with a plurality of sets of concentration frames. By mounting the concentration frame, knotting caused by yarn staggering can be effectively prevented, and the situation that normal processing is affected by knotting of the device is reduced to a great extent.

Owner:江苏合源纺织科技有限公司

Sunscreen heat-resistance hollow side windshield for vehicle

InactiveCN109133655AImprove structural strengthExtended service lifeSilicon dioxideMaterials science

The invention discloses a sunscreen heat-resistance hollow side windshield for a vehicle, and belongs to the technical field of glass materials. The windshield is of a hollow dual-layer structure andis prepared from, by weight, 3-13 parts of quartz sand, 2-10 parts of sodium hydroxide, 1-7 parts of limestone, 2-8 parts of glass fibers, 15-25 parts of silicon dioxide, 2-8 parts of zinc oxide, 3-13parts of sodium carbonate, 2-12 parts of anti-ultraviolet agent, 2-5 parts of magnesium oxide and 1-5 parts of reinforcing agent. The prepared windshield for the vehicle has the advantages of being high in structural strength, long in service life and the like; in the using process, the situation that the windshield is broken cannot occur, the structural strength of the material of the windshieldis improved, and the service life is prolonged; the windshield has high strength, and can resist strong impact, effectively stop sun illumination to protect the skin against hurt, and effectively prevent fog to improve safety for driving.

Owner:景有超

High-temperature-resistance pressure-resistant polymer glass used for vehicles

The invention provides high-temperature-resistance pressure-resistant polymer glass used for vehicles, and belongs to the technical field of glass materials. The glass is prepared from, by weight, 3-13 parts of borax, 2-10 parts of sodium hydroxide, 1-7 parts of zircon powder, 2-8 parts of glass fiber, 15-25 parts of silicon dioxide, 2-10 parts of steel fiber, 3-8 parts of calcium carbonate, 1-2 parts of sodium chloride, 2-8 parts of zinc oxide, 3-13 parts of sodium carbonate, 2-12 parts of curing agent, 5-9 parts o calcium silicate, 6-12 parts of bone charcoal powder, 5-10 parts of nano diamond, 3-8 parts of chromium carbide, 2-8 parts of magnesium borate crystal whiskers and 6-8 parts of additives. The prepared automobile glass has the advantages of high structural strength, long servicelife and the like, breakage does not occur in the use process, the structural strength of the glass materials is enhanced, the compressive capacity is high, the service life is prolonged, the strength is high, and the glass can resist strong impact, effectively block sun radiation and protect the skin from injury.

Owner:景有超

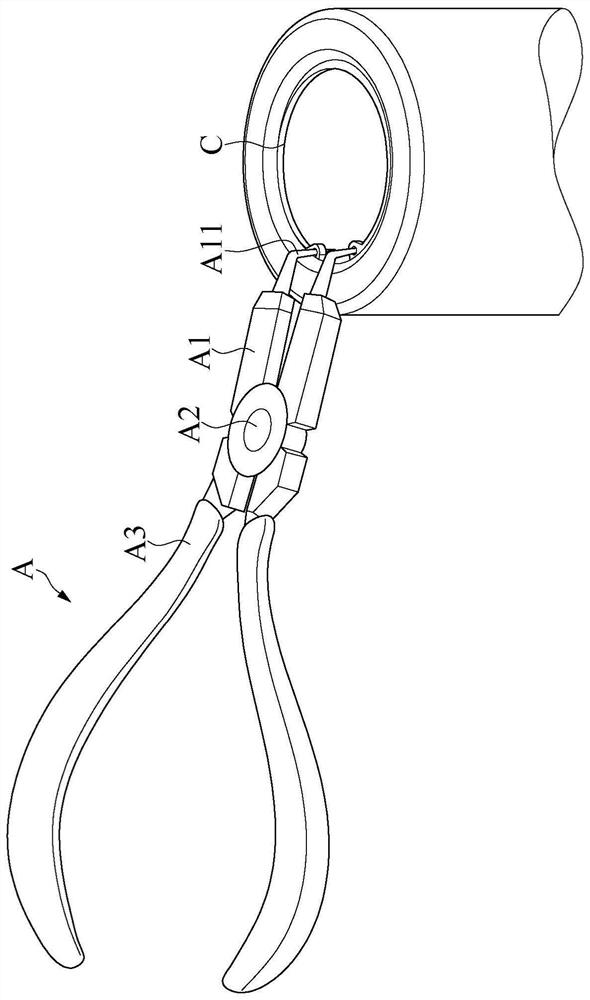

Mounting suite

InactiveCN112405419AThere will be no problem of breakingBroken problem solvedMetal-working hand toolsRetaining ringElectrical and Electronics engineering

The invention discloses a mounting suite. The mounting suite comprises a sleeve and a resisting part, wherein the sleeve is provided with a guide channel; a first opening and a second opening are separately formed in the two ends of the sleeve; the hole diameter of the first opening is greater than that of the second opening; the inner diameter of the guide channel is gradually reduced from the first opening to the second opening; the two ends of the resisting part are separately equipped with a resisting part and a force applying part; and the biggest radial width of the resisting part is smaller than the hole diameter of the second opening. While the force applying part receives external force, the resisting part can resist against a C-shaped buckle ring arranged in the guide channel, sothat the C-shaped buckle ring is extruded by side walls of the guide channel; and the second opening leaves the sleeve to enter a mounting slot of a part to be mounted. The mounting suite can make auser quickly and conveniently mount the C-shaped buckle ring in the mounting slot of the part to be mounted.

Owner:ADATA

A highly flexible copper-clad steel wire

InactiveCN104616716BImprove flexibilityStress reliefMetal/alloy conductorsSocial benefitsCopper plating

Owner:JINGGANGSHAN JIDA METAL

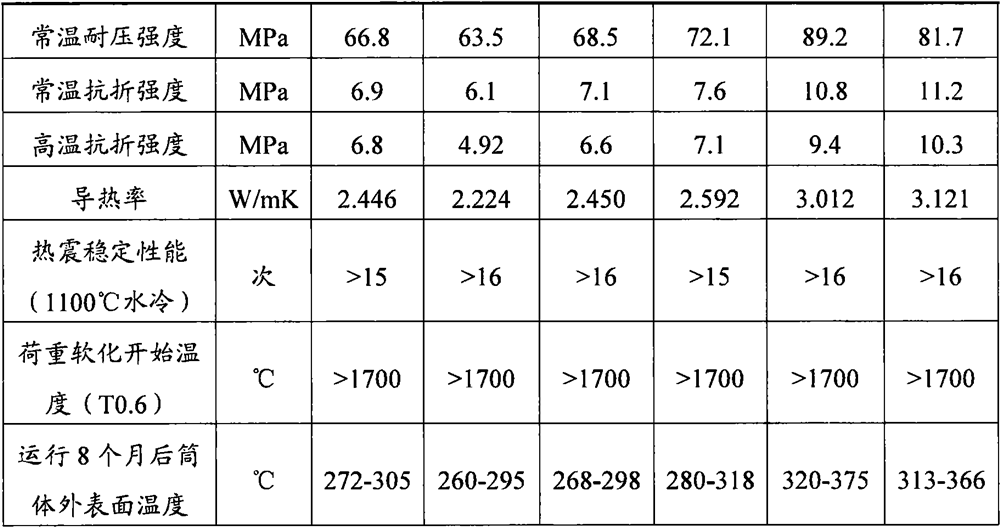

Low-thermal-conductivity refractory material, low-thermal-conductivity refractory brick, preparation method of refractory brick and application

The invention provides a low-thermal-conductivity refractory material, a low-thermal-conductivity refractory brick, a preparation method of the low-thermal-conductivity refractory brick and application, and belongs to the technical field of refractory materials. The low-thermal-conductivity refractory material is prepared from the following raw materials: magnesia particles, magnesia fine powder, magnesium aluminate spinel particles, light spinel particles, calcined spinel micro powder and a binding agent. The low-thermal-conductivity refractory brick prepared by taking the low-thermal-conductivity refractory material as a raw material is stable in high-temperature performance, resistant to corrosion of alkali metals, volatile salts and the like, and suitable for a severe environment of a rotary cement kiln or a rotary lime kiln. Meanwhile, the low-heat-conduction refractory brick avoids the problem of Cr<6+> public nuisance pollution of magnesite-chrome bricks, has the characteristics of high strength, low heat conduction, wear resistance, high-temperature load resistance and the like, can meet the requirements of high-temperature strength and mechanical flexibility in use of a cement rotary kiln or a lime rotary kiln, can effectively reduce the dead weight of a rotary kiln and the temperature of a barrel body, reduces te energy and equipment consumption, and improves the service life of the brick for the rotary kiln.

Owner:MARVELS REFRACTORIES ANSHAN CO LTD

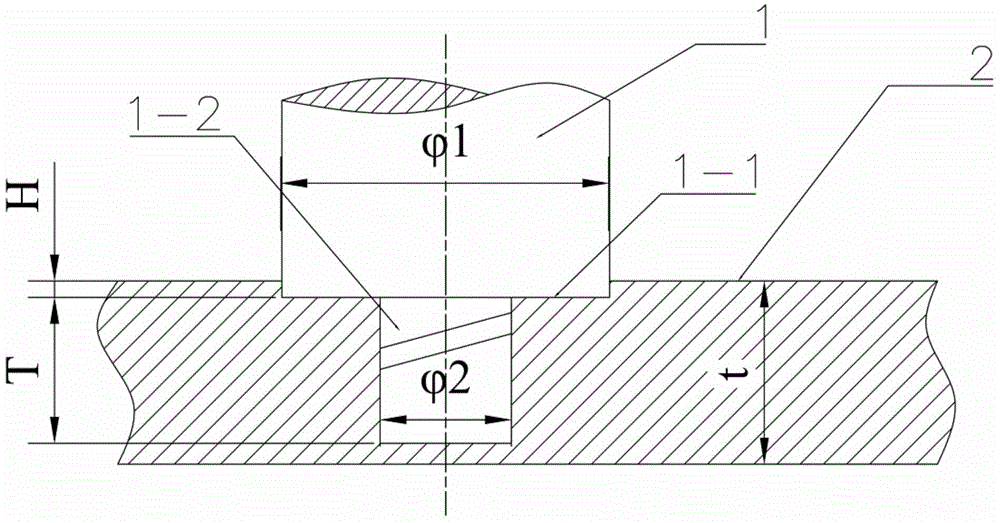

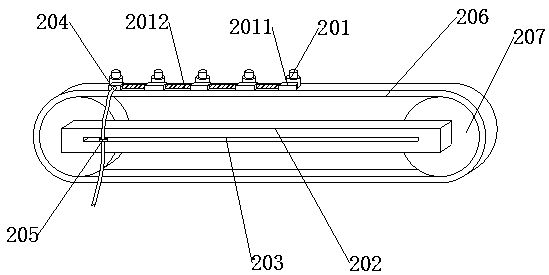

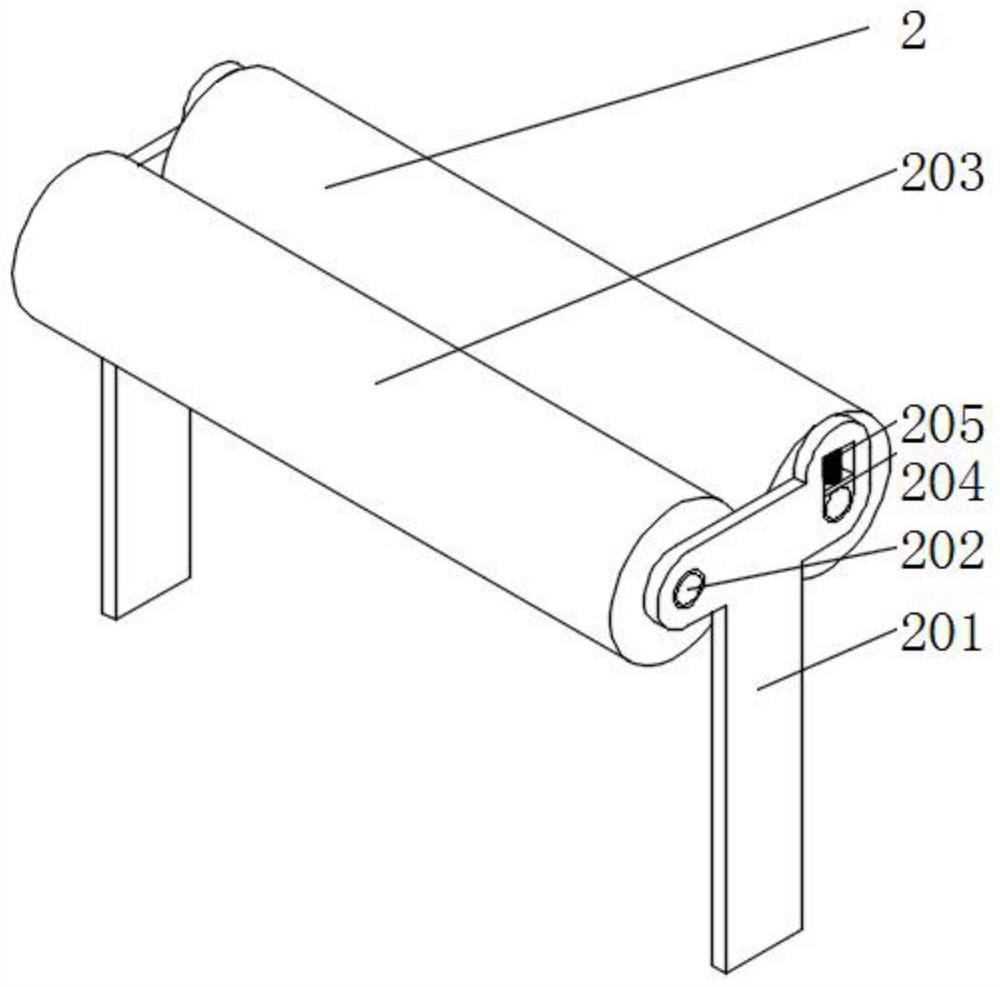

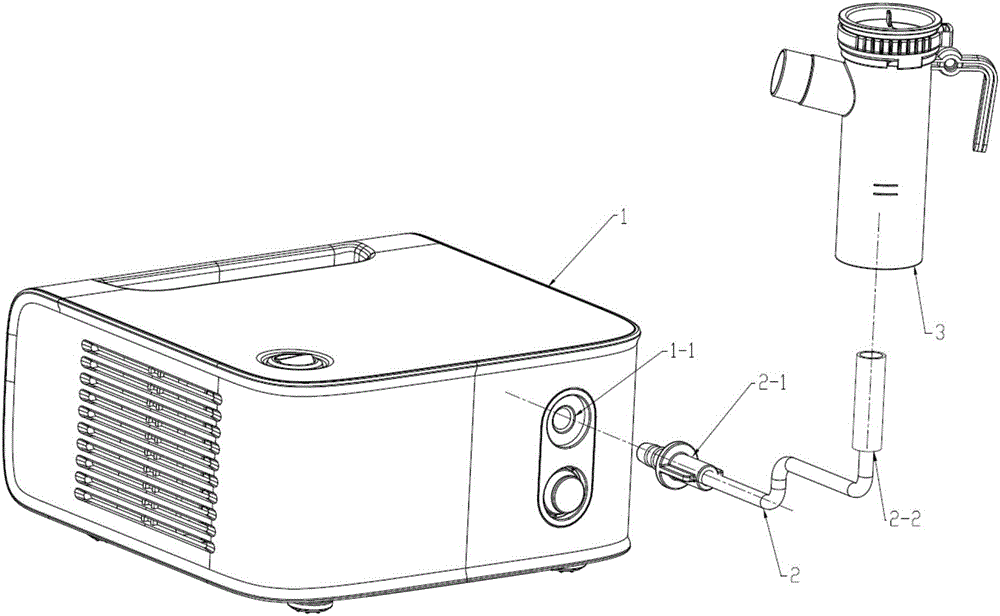

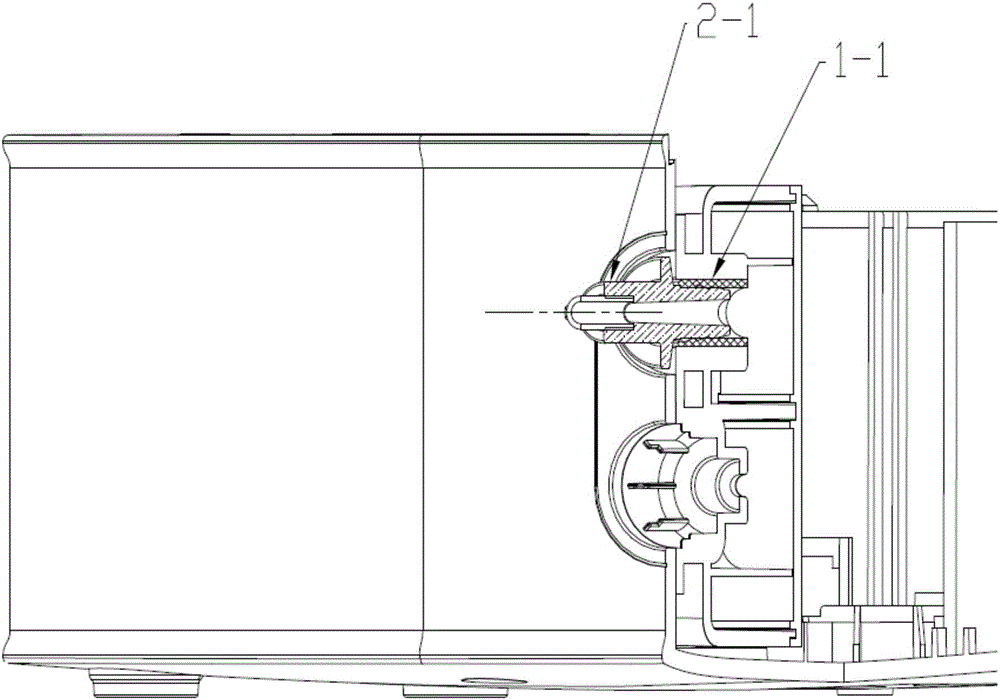

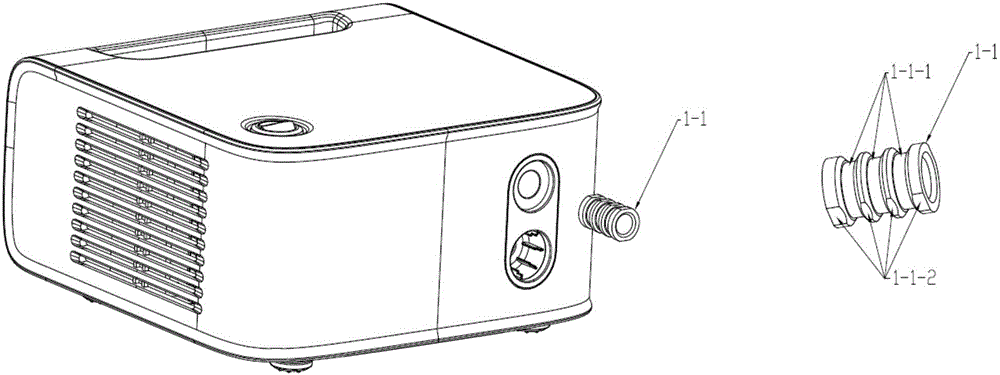

Compressed air atomizer connecting device

InactiveCN106075675AThere will be no problem of breakingUniform bearing surfaceTube connectorsMedical atomisersInhalationElectrical and Electronics engineering

The invention discloses a compressed air atomizer connecting device. The device comprises an atomizer main machine 1, a connecting pipe 2 and an atomizing cup 3, wherein an atomizing nozzle 1-1 is formed in the atomizer main machine 1; the connecting pipe 2 comprises a joint; the atomizing nozzle 1-1 is formed in a body shell of the atomizer main machine 1; the joint comprises a first connector 2-1 and a second connector 2-2; the first connector 2-1 is connected with the atomizing nozzle 1-1; the second connector 2-2 is connected with the external equipment atomizing cup 3; and the atomizing nozzle 1-1 is connected with the first connector 2-1 in an internal wrapping manner. The device has the beneficial effects that the problem of atomizing nozzle rupture caused by inserting and pulling out the joint of the connecting pipe multiple times is solved, thus obviously prolonging the service lives of compressed air atomizers, especially the compressed air atomizers which have high frequency of use and are used in hospitals, and avoiding the problem that atomization inhalation can not be carried out because of atomizing nozzle rupture.

Owner:JIANGSU YUYUE MEDICAL EQUIP&SUPPLY CO LTD +3

mop bucket

InactiveCN103549930BNot easy to damageEven by forceCarpet cleanersFloor cleanersWater savingEngineering

The invention relates to a mop barrel, belongs to the field of daily necessities, and overcomes the defects that an existing mop barrel is large in space occupation, easy to damage and wasteful in water and space, and more dead corners exist inside the barrel. The two-in-one mop barrel which is convenient to use and integrated with functions of cleaning and dewatering comprises a barrel body, a dewatering basket and a top cover, the dewatering basket is located in the barrel body, and the top cover is located at the side edge at the top end of the barrel body; the mop barrel further comprises a horizontal-movement positioning and limiting system and a buoy which is located under the dewatering basket; the horizontal-movement positioning and limiting system comprises a vertical shaft, an eccentric wheel and a horizontal-movement positioning and limiting supporting slider; the horizontal-movement positioning and limiting supporting slider is provided with an eccentric wheel sliding groove and reset springs; the vertical shaft is located in the barrel body, the eccentric wheel penetrates the vertical shaft to be located in the eccentric wheel sliding groove, and the reset springs are located on the horizontal-movement positioning and limiting supporting slider and between the horizontal-movement positioning and limiting supporting slider and the barrel body. The mop barrel is scientific and reasonable in design, different from the design principle of the existing rotating mop barrel, simple, less prone to damage, small in space occupation, energy saving, water saving and suitable for popularization and application.

Owner:金广成

Enhanced heat-resistant automobile glass

The invention relates to enhanced heat-resistant automobile glass, and belongs to the technical field of glass materials. The glass is prepared from, by weight, 3-13 parts of borax, 2-10 parts of sodium hydroxide, 1-7 parts of limestone, 2-8 parts of glass fiber, 15-25 parts of silicon dioxide, 2-10 parts of steel fiber, 3-8 parts of calcium carbonate, 1-2 parts of sodium chloride, 2-8 parts of zinc oxide, 3-13 parts of sodium carbonate, 2-12 parts of curing agent and 5-9 parts of calcium silicate. The prepared automobile glass has the advantages of being high in structural strength, long in service life and the like, the problem that breakage occurs in the using process is avoided, the structural strength of the glass material is enhanced, the service life is prolonged, and the glass hashigh strength and can resist strong impact, effectively prevent sun irradiation and protect skin from being harmed.

Owner:景有超

Power battery current collector tab shaping method and battery thereof

PendingCN114367554AAvoid damageSolve crackingMetal-working feeding devicesCell component detailsPower batteryMetal foil

The invention relates to the technical field of power batteries, in particular to a power battery current collector tab shaping method and a battery thereof, and the shaping method comprises the following steps: S1, pressing; s2, primary shaping; s3, carrying out secondary shaping; s4, the current collector tab metal foil shaped in the step S3 is leveled horizontally; and S5, welding. By shaping the tabs, the tab foil is tightly attached to the battery cell body, an elastic body is formed between the welding area and the battery cell body, the stress of the current collector tab metal foil is changed from single stress to multi-layer simultaneous stress when the positive tab or the negative tab is bent, and the problem of breakage of the current collector tab metal foil under assembly and working conditions is effectively solved.

Owner:WANXIANG 123 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com