Integrated dual-layer spring cushion

A spring pad, an integrated technology, applied in the field of pocket spring pads, can solve the problems of high production cost, cumbersome and complicated production process, and fracture of bonding parts, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

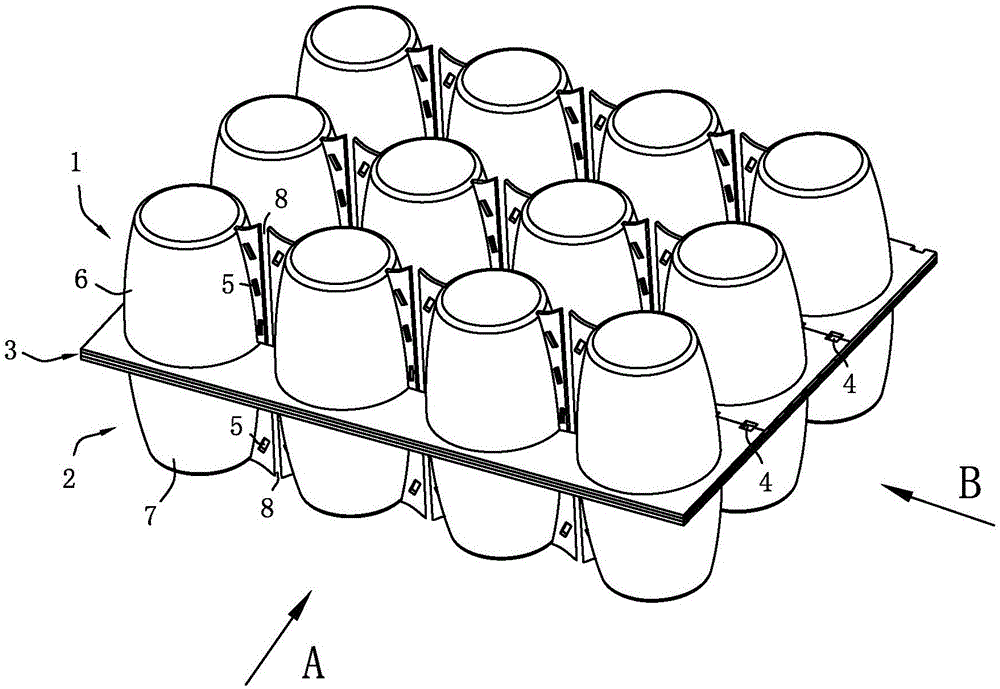

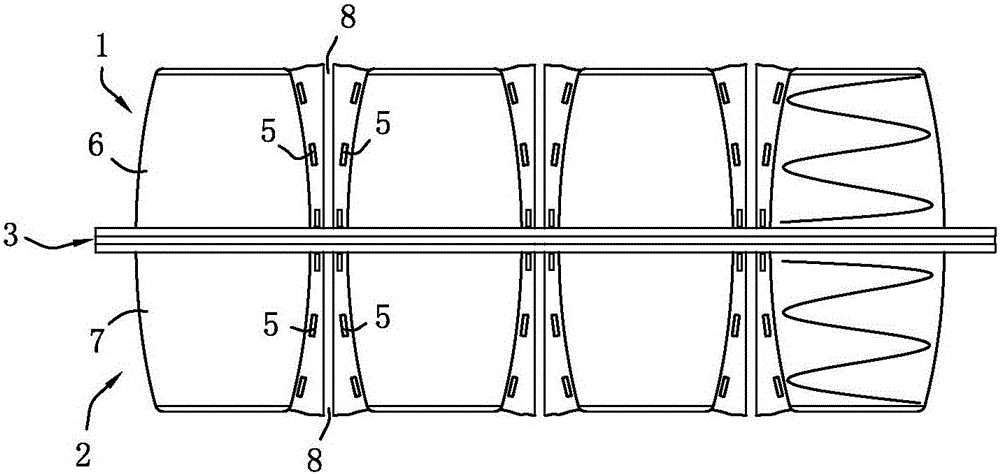

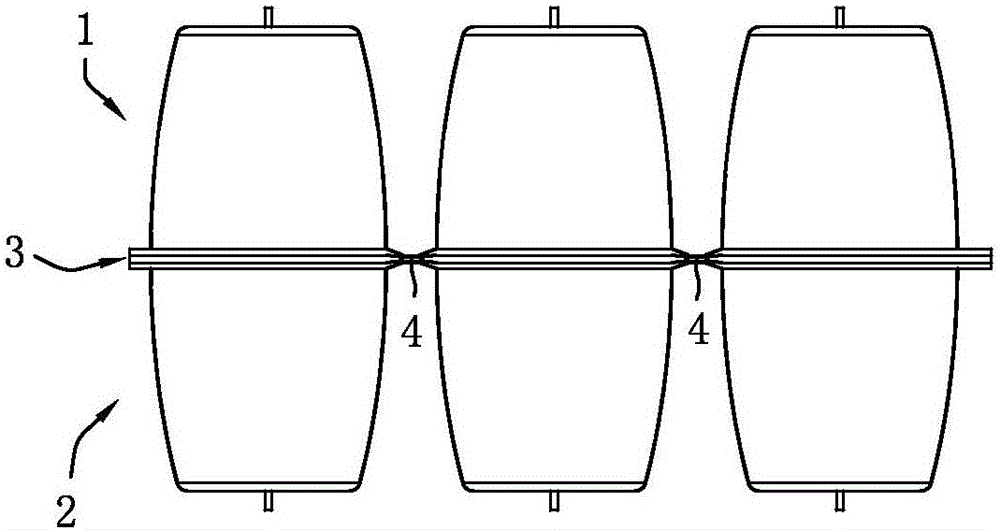

[0015] refer to Figure 1 to Figure 4 , an integrated double-layer pocket spring pad of the present invention, comprising a first cloth 1, a second cloth 2, a third cloth 3 and multiple groups of springs, between the first cloth 1, the second cloth 2 and the third cloth 3 Multiple horizontal seams 4 are formed, the third fabric 3 is between the first fabric 1 and the second fabric 2, the first fabric 1 and the second fabric 2 are separated from each other and folded in half, and multiple vertical seams 5 are formed correspondingly. The gap between the adjacent vertical seams 5 on the first cloth 1 and the third cloth 3 form a plurality of continuous first independent cloth bags 6, the gap between the adjacent vertical seams 5 on the second cloth 2 and the third cloth 3 The fabric 3 constitutes a plurality of continuous second independent cloth bags 7, and each group of springs includes two springs respectively wrapped in the first independent cloth bag 6 and the second indepen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com