mop bucket

A mop bucket and bucket body technology, applied in the field of mop buckets, can solve the problems of wasting space, many dead corners in the bucket, occupying a large space, etc., and achieve the effects of not easy to damage, scientific and reasonable design, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

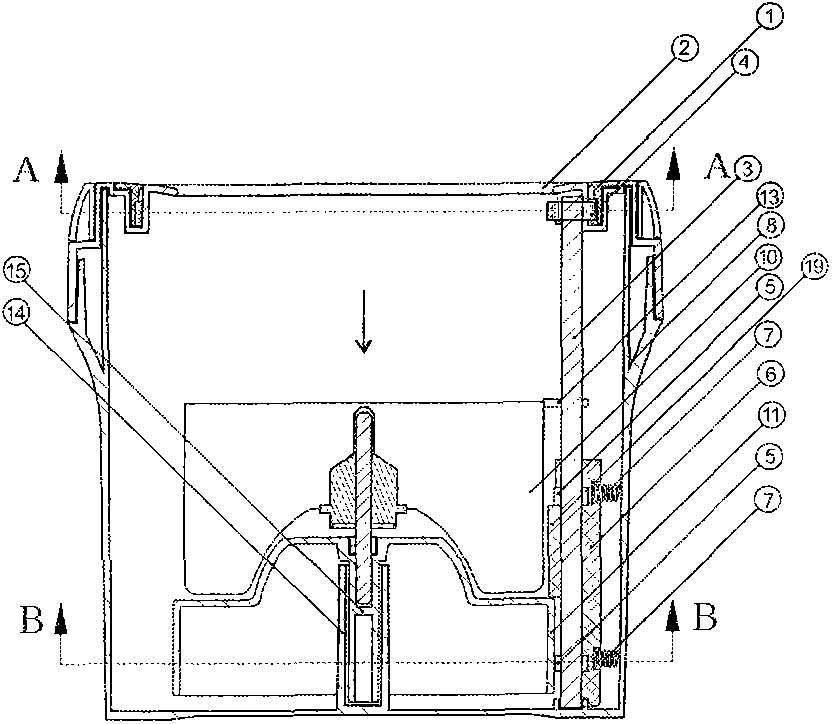

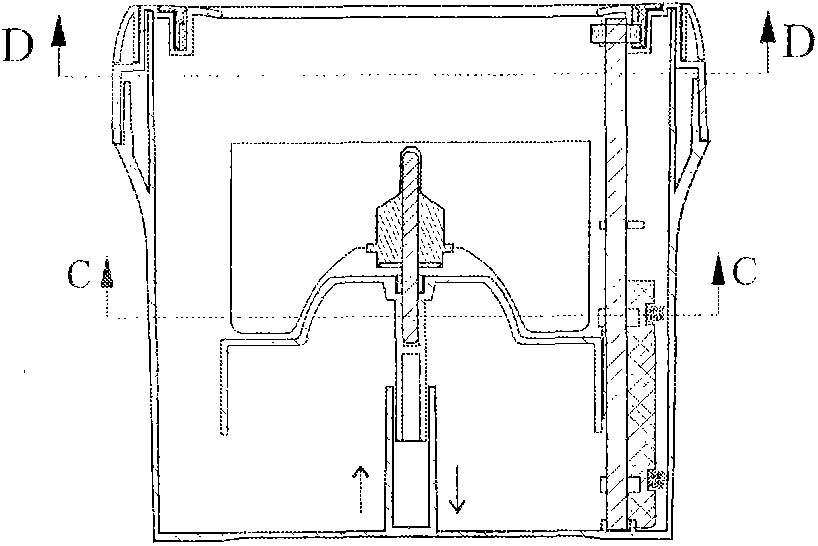

[0043] refer to Figure 1-7To describe one of the preferred solutions of the present invention, a mop bucket includes a bucket body 8, a dehydration basket 10, and a top cover 2. The dehydration basket is located in the bucket body, and the top cover is located on the top edge of the bucket body; Limiting system 16, float 11, the float is located under the dehydration basket 10; the positioning system for lateral movement includes a vertical shaft 3, an eccentric wheel 5, and a support slider 6 for limiting movement in the lateral direction; There is an eccentric wheel chute 17 and a return spring 7 on the position support slider 6; the vertical shaft 3 is clamped and fixed vertically in the barrel, the eccentric wheel 5 passes through the vertical shaft 3 and is located in the eccentric wheel chute 17, and the return spring 7 is located in the horizontal direction Swimming is fixed on the position-limiting support slide block 6, and lateral movement is fixed between the posit...

Embodiment 2

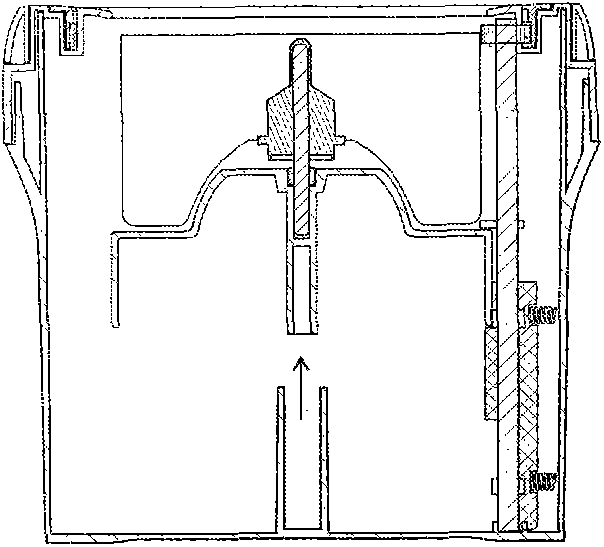

[0046] Such as Figure 8 As shown, the positioning insert 14 and the positioning clip 15 are different from those in Embodiment 1, and the rest are as shown in Embodiment 1.

Embodiment 3

[0048] Such as Figure 9 As shown, the buoy is a fully enclosed hollow structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com