Fire water monitor body and fire water monitor

A water cannon and fire-fighting technology, which is applied in fire rescue and other directions, can solve the problems of inability to change and adjust the overall structure, high maintenance cost, poor maintainability, etc., and achieve reduced maintenance costs, enhanced local structural strength, and stress dispersion and uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

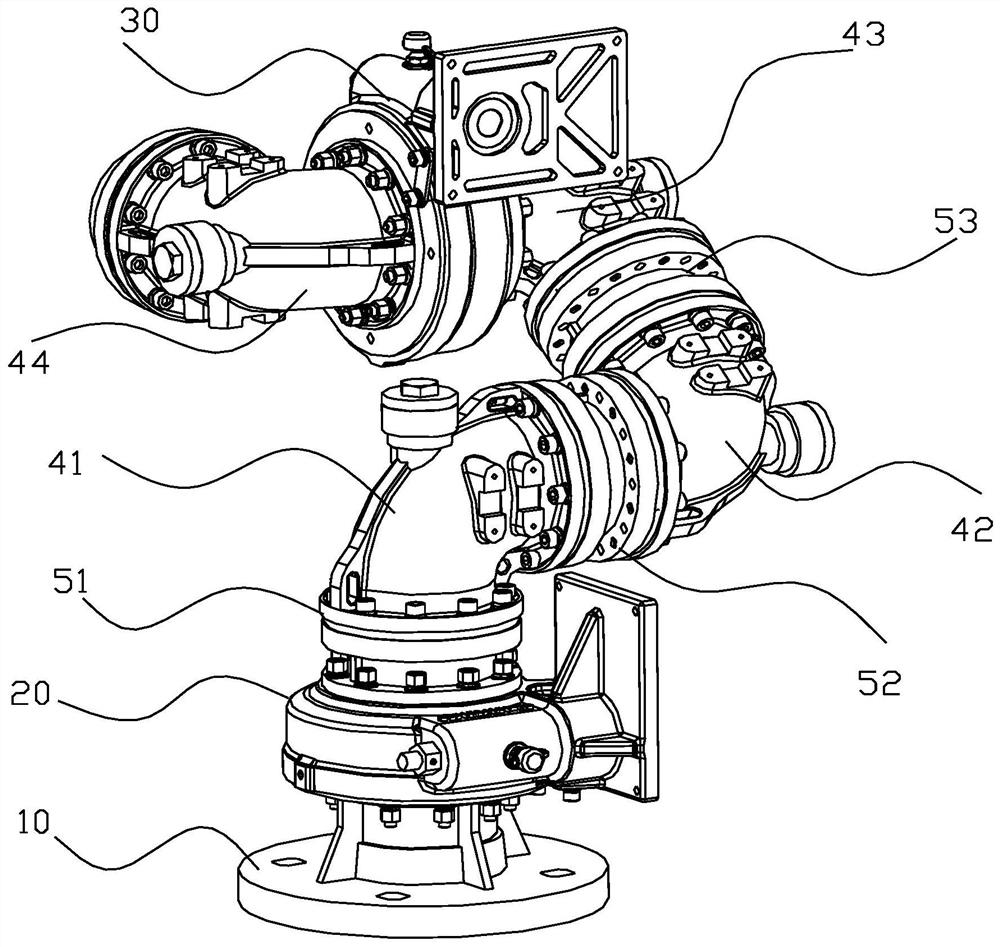

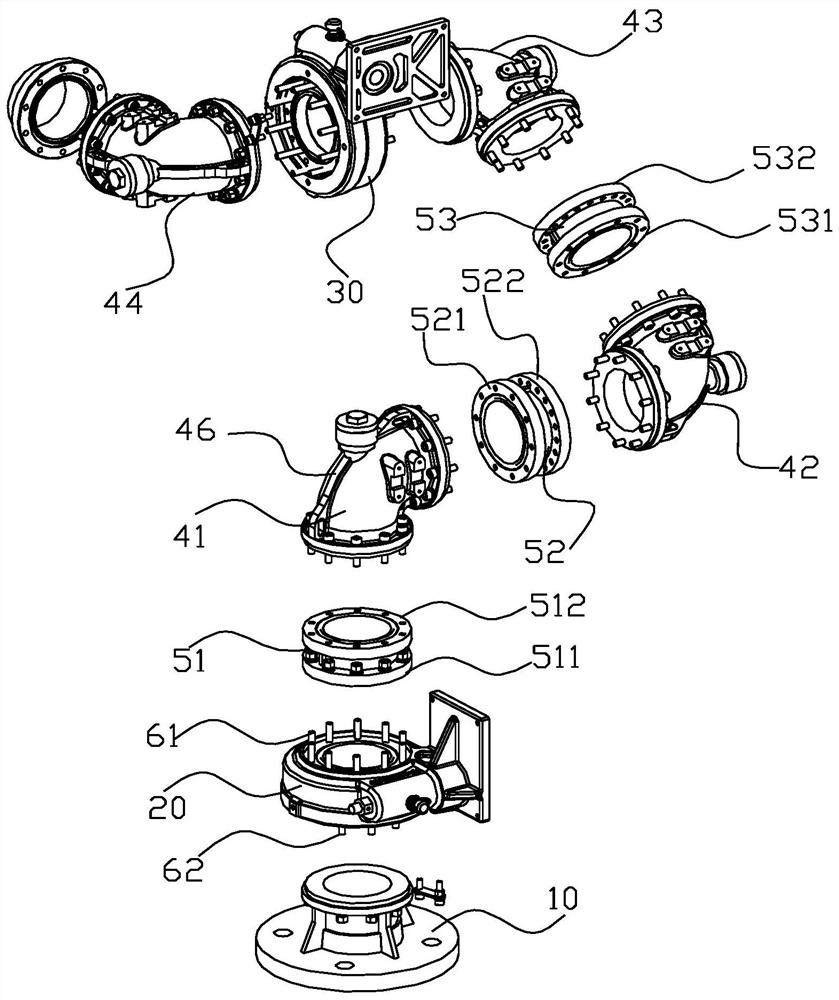

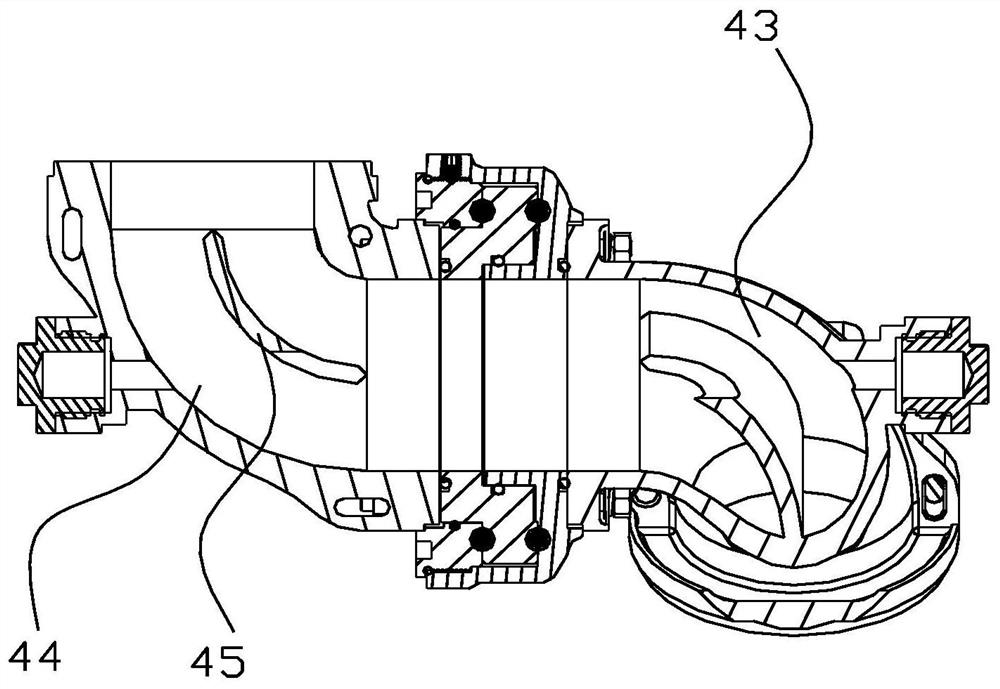

[0031] Such as figure 1 with figure 2 As shown, the present embodiment provides a fire-fighting water monitor body, including: a water inlet base 10; a first worm gear assembly 20 and a second worm gear assembly 30; elbow 41, second elbow 42, third elbow 43 and fourth elbow 44; wherein, the first worm gear assembly 20 is installed on the water inlet base 10, and the first elbow 41 is installed On the first worm gear assembly 20, the first elbow 41 is connected to the second elbow 42 through a first compensation pipe 52, and the second elbow 42 is connected to the third elbow 43, The third curved pipe 43 is installed on the second worm gear assembly 30 , and the second worm gear assembly 30 is connected with the fourth curved pipe 44 .

[0032] The fire water cannon body of this embodiment includes: a water inlet base 10, the water inlet base 10 is used for water inlet; a first worm gear assembly 20 and a second worm gear assembly 30, and the first worm gear assembly 20 can...

Embodiment 2

[0060] This embodiment provides a fire-fighting water monitor, including the fire-fighting water monitor body described in Embodiment 1.

[0061] Since the fire-fighting water monitor described in this embodiment includes the fire-fighting water monitor body described in Embodiment 1, the advantages that Embodiment 1 has, this embodiment also has all of them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com