Power battery current collector tab shaping method and battery thereof

A power battery and tab shaping technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of not clearly adopting specific technical means of folding, and not involving current collector tab shaping, etc., and achieves the level of folding The effect of smooth, reasonable processing and shaping steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

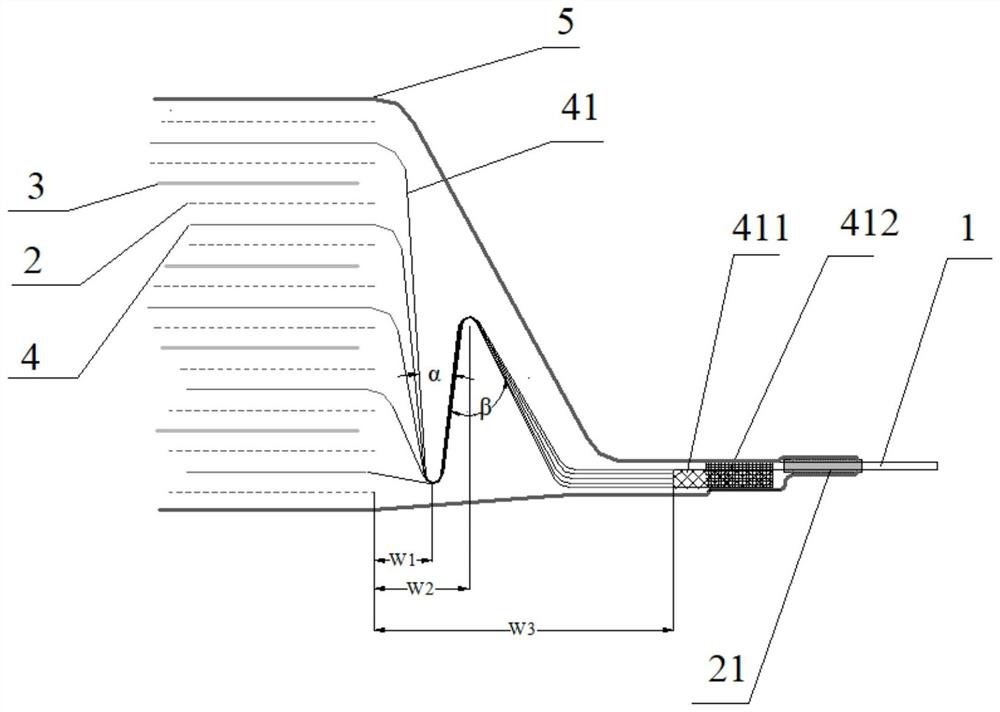

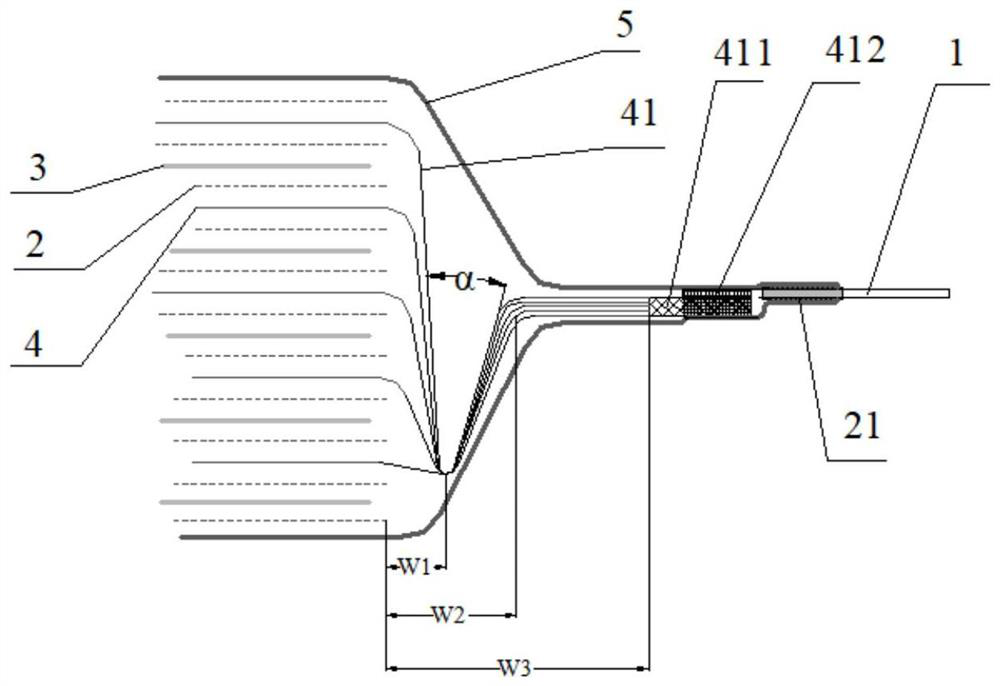

[0038] The power battery of the present invention is composed of a positive electrode sheet 3, a negative electrode sheet 4, a diaphragm 2, a positive electrode ear, a negative electrode ear, an electrolyte and an outer packaging material. The positive electrode sheet 3 or the negative electrode sheet 4 is formed by coating a positive electrode or negative electrode active material on a metal foil which is a positive electrode current collector or a negative electrode current collector. The size of the negative electrode active material coating area of the negative electrode sheet 4 is larger than that of the positive electrode active material coating area, and the size of the separator 2 is larger than that of the negative electrode active material coating area. The negative electrode sheet 4, the separator 2, and the positive electrode sheet 3 are laminated or wound to form the cell of the battery.

[0039] like figure 1 As shown, a power battery current collector tab sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com