High-temperature-resistant and aging-resistant thermoplastic elastomer material

A thermoplastic elastomer and anti-aging technology, which is applied in the field of thermoplastic elastomers, can solve the problems of greatly affecting production efficiency, insufficient high temperature resistance, and accelerated aging speed, so as to improve heat resistance, good mechanical properties, and improve processing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

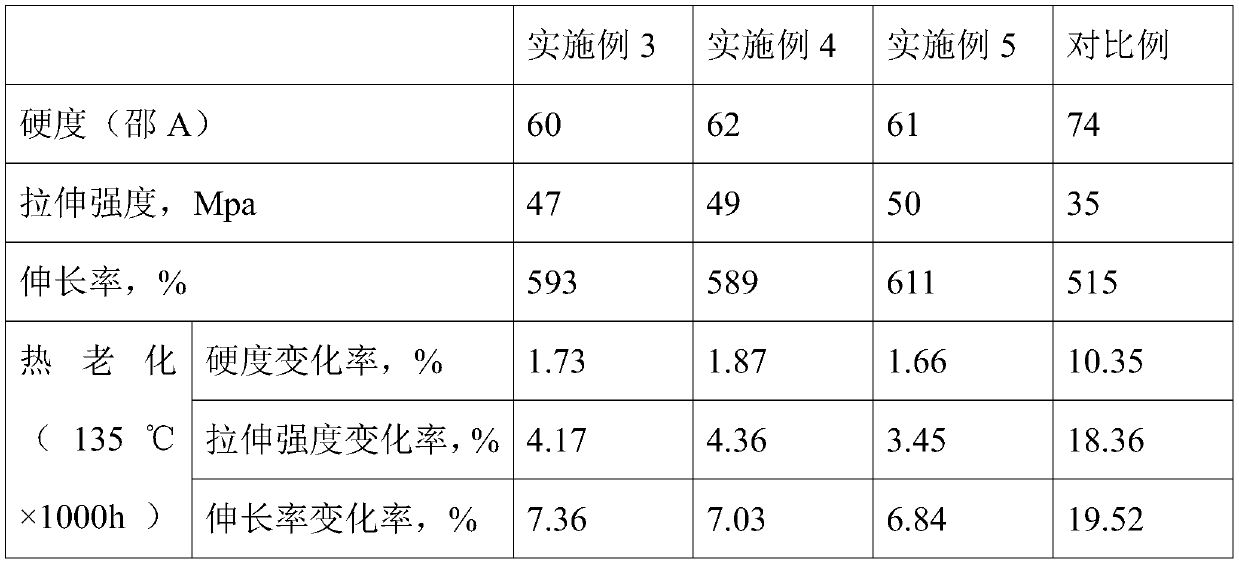

Examples

Embodiment 1

[0025] A thermoplastic elastomer material with high temperature resistance and aging resistance, its raw materials include: thermoplastic elastomer 100kg, nitrile rubber 15kg, phenolic resin 10kg, polypropylene fiber 10kg, carbon nanotube 10kg, maleic anhydride grafted ethylene-octene copolymer Compound 4kg, composite zirconium dioxide 2kg, di-tert-butyl hydroperoxide 2kg, naphthenic oil 1kg, 2-tert-butyl-4-methylphenol 8kg, chlorinated paraffin 0.2kg, benzyl silicone oil 0.8kg.

[0026] The thermoplastic elastomer is composed of thermoplastic polyurethane elastomer rubber and ethylene-butyl acrylate copolymer in a mass ratio of 1:0.6.

[0027] Composite zirconia is prepared by the following process: 10kg of alumina fiber and 5kg of zirconia precursor are mixed, vacuum ground for 1 hour, sent to a high-temperature calcination furnace, calcined at 1300°C for 10 minutes, cooled to room temperature, and pulverized to obtain composite zirconia Zirconia.

[0028] The preparation m...

Embodiment 2

[0034] A thermoplastic elastomer material with high temperature and aging resistance, its raw materials include: 100kg thermoplastic elastomer, 25kg nitrile rubber, 4kg phenolic resin, 40kg polyborate fiber, 2kg maleic anhydride grafted ethylene-ethylene propylene rubber copolymer , 6kg of composite zirconium dioxide, 1kg of dicumyl peroxide, 2kg of naphthenic oil, 4kg of 2-tert-butyl-4-methylphenol, 1kg of chlorinated paraffin, and 1kg of benzyl silicone oil.

[0035] The thermoplastic elastomer is composed of thermoplastic polyurethane elastomer rubber and ethylene-butyl acrylate copolymer in a mass ratio of 1:0.2.

[0036] Composite zirconia is prepared by the following process: 16 kg of alumina fiber and 1 kg of zirconia precursor are mixed, vacuum ground for 2 hours, sent to a high-temperature calcination furnace, calcined at 1250 ° C for 20 minutes, cooled to room temperature, and pulverized to obtain a composite zirconia Zirconia.

[0037] The preparation method of the...

Embodiment 3

[0043] A thermoplastic elastomer material with high temperature resistance and aging resistance, its raw materials include: thermoplastic elastomer 100kg, nitrile rubber 18kg, phenolic resin 8kg, basalt fiber 10kg, nano-cellulose whiskers 15kg, maleic anhydride grafted ethylene-propylene copolymer Compound 3.5kg, composite zirconia 3kg, 1,3-bis(tert-butylperoxyisopropyl)benzene 1.7kg, naphthenic oil 1.2kg, 2,2'-methylenebis(4-methyl-6 -tert-butylphenol) 7kg, polyethylene wax 1.3kg.

[0044] The thermoplastic elastomer is composed of thermoplastic polyurethane elastomer rubber and ethylene-butyl acrylate copolymer in a mass ratio of 1:0.5.

[0045] Composite zirconia is prepared by the following process: 12kg of alumina fiber and 4kg of zirconia precursor are mixed, vacuum ground for 1.3h, sent to a high-temperature calciner, calcined at a temperature of 1280°C for 13min, cooled to room temperature, and pulverized to obtain a composite zirconium dioxide.

[0046] The preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com