An indentation machine for preventing cardboard from sticking

A technology of creasing machine and cardboard, applied in the field of paper products, can solve the problem of incomplete cutting of the creasing machine, and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

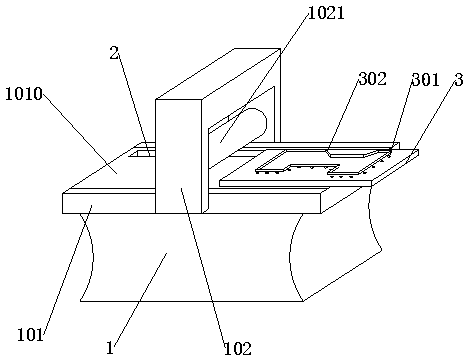

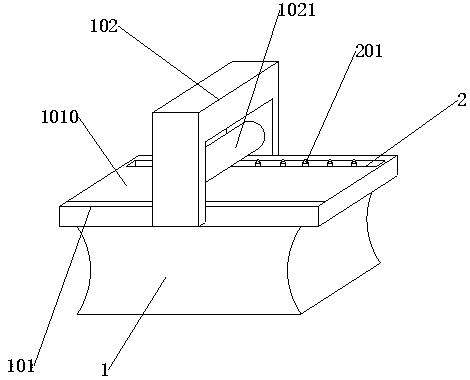

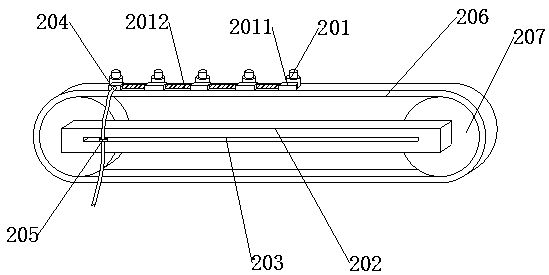

[0026] see figure 1 To attach Figure 6 , an indentation machine for preventing cardboard adhesion, including: a fixed base 1, an operating platform 101, a conveyor belt 1010, a support table 102, a rolling roller 1021, a movable groove 2, an adapter 201, a connecting warehouse 2011, a hose 2012, Anti-overflow plate 2013, support shaft 202, chute 203, air pipe 204, buckle 205, movable belt 206, pulley 207, rolling plate 3, air jet port 301, cutting knife 302, delivery pipe 303, connecting valve 304, described The top of the fixed base 1 is welded with an operating platform 101, the inner middle part of the operating platform 101 is rotatably connected with a conveyor belt 1010, the upper middle part of the operating platform 101 is welded with a support platform 102, and the inner side of the support platform 102 is rotatably connected with a roller. Pressure roller 1021;

[0027] The top side of the operating platform 101 is embedded with a movable groove 2, and the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com