Patents

Literature

145results about How to "Eliminate health hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

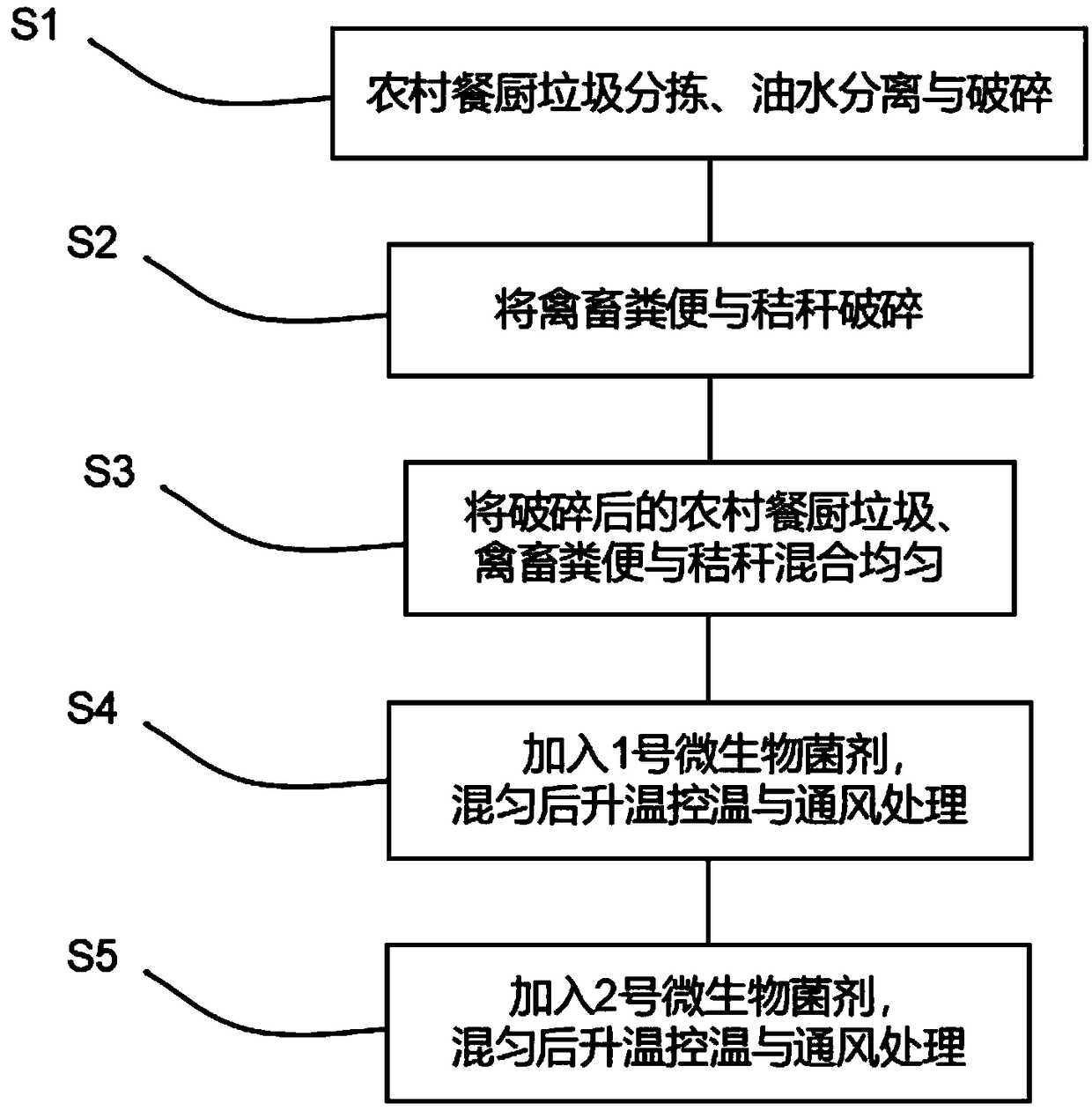

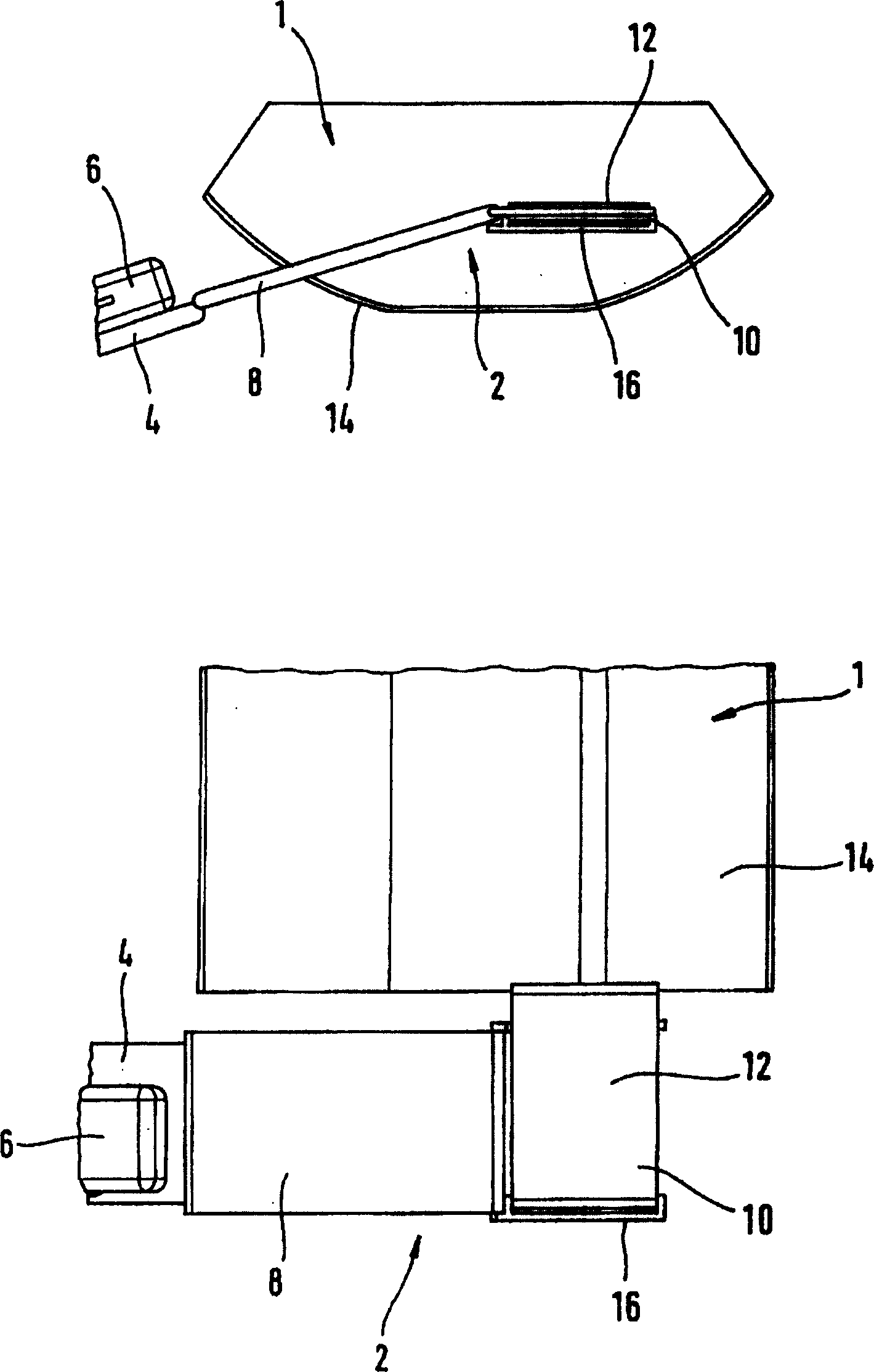

Dental imaging and treatment system

InactiveUS20050202363A1Good precisionShort curing timeImpression capsDental toolsTooth whiteningDental structure

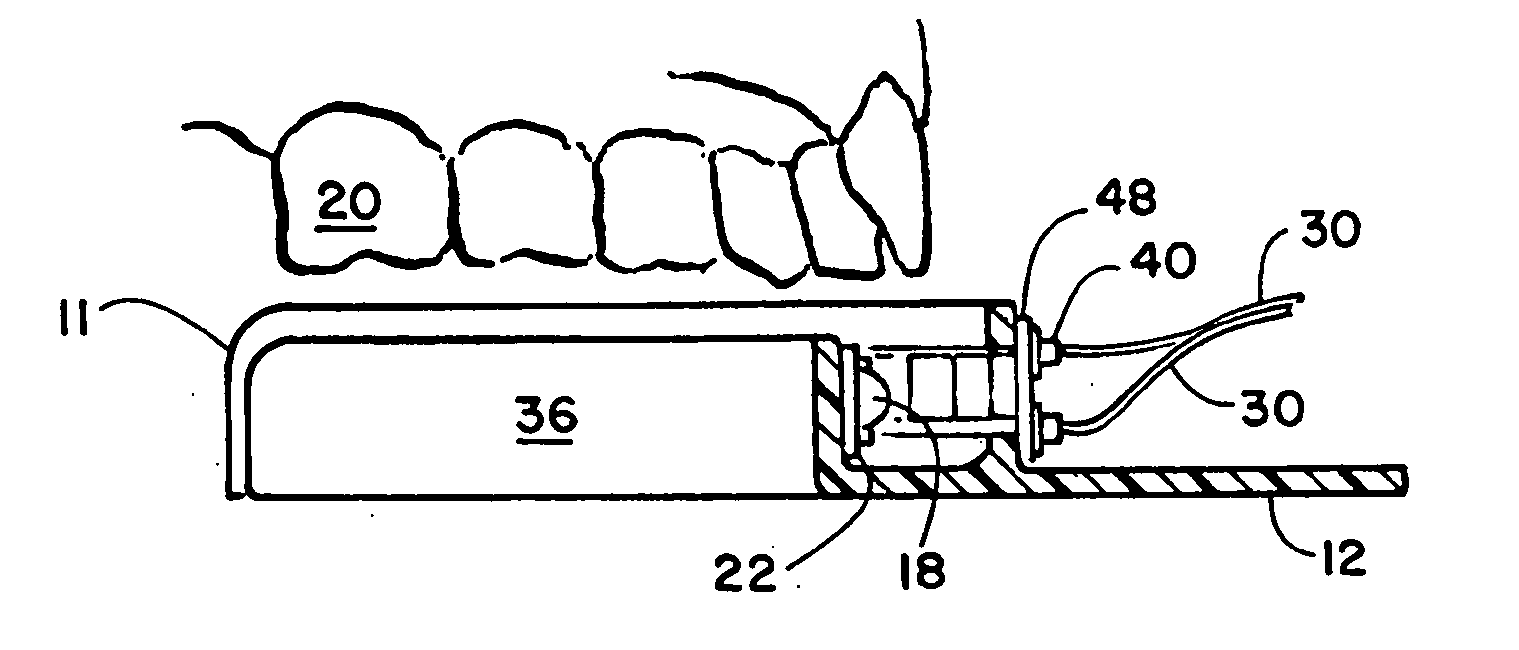

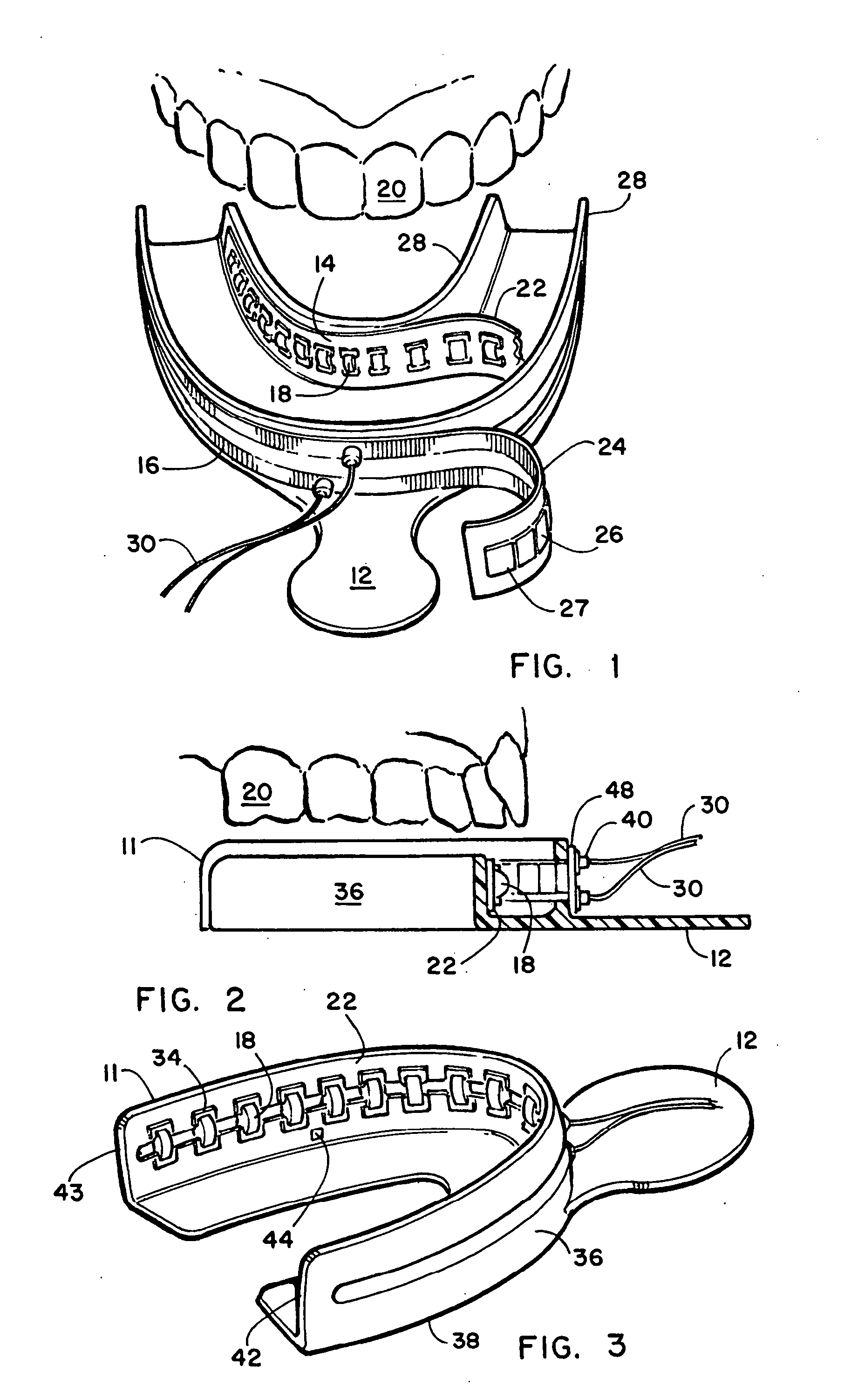

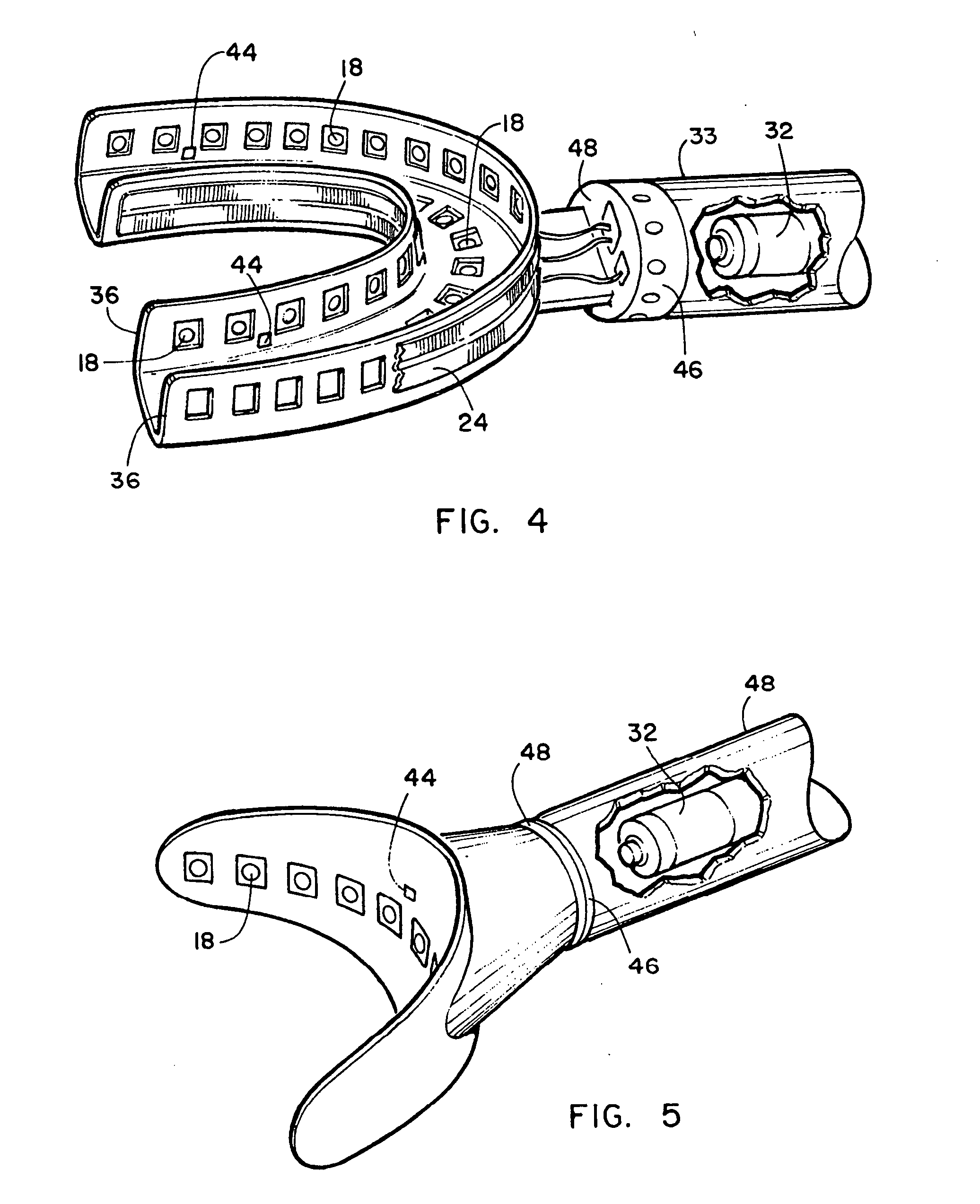

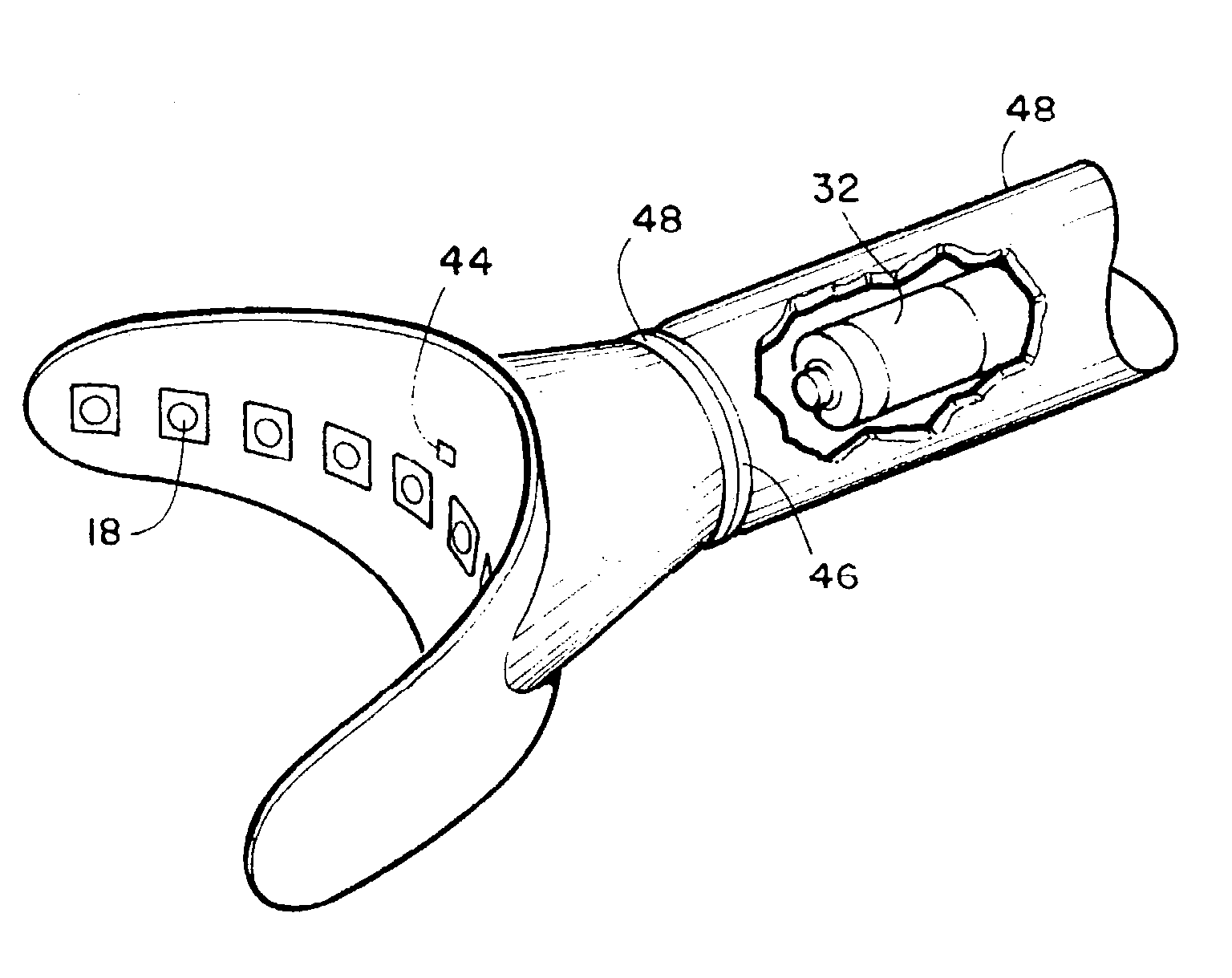

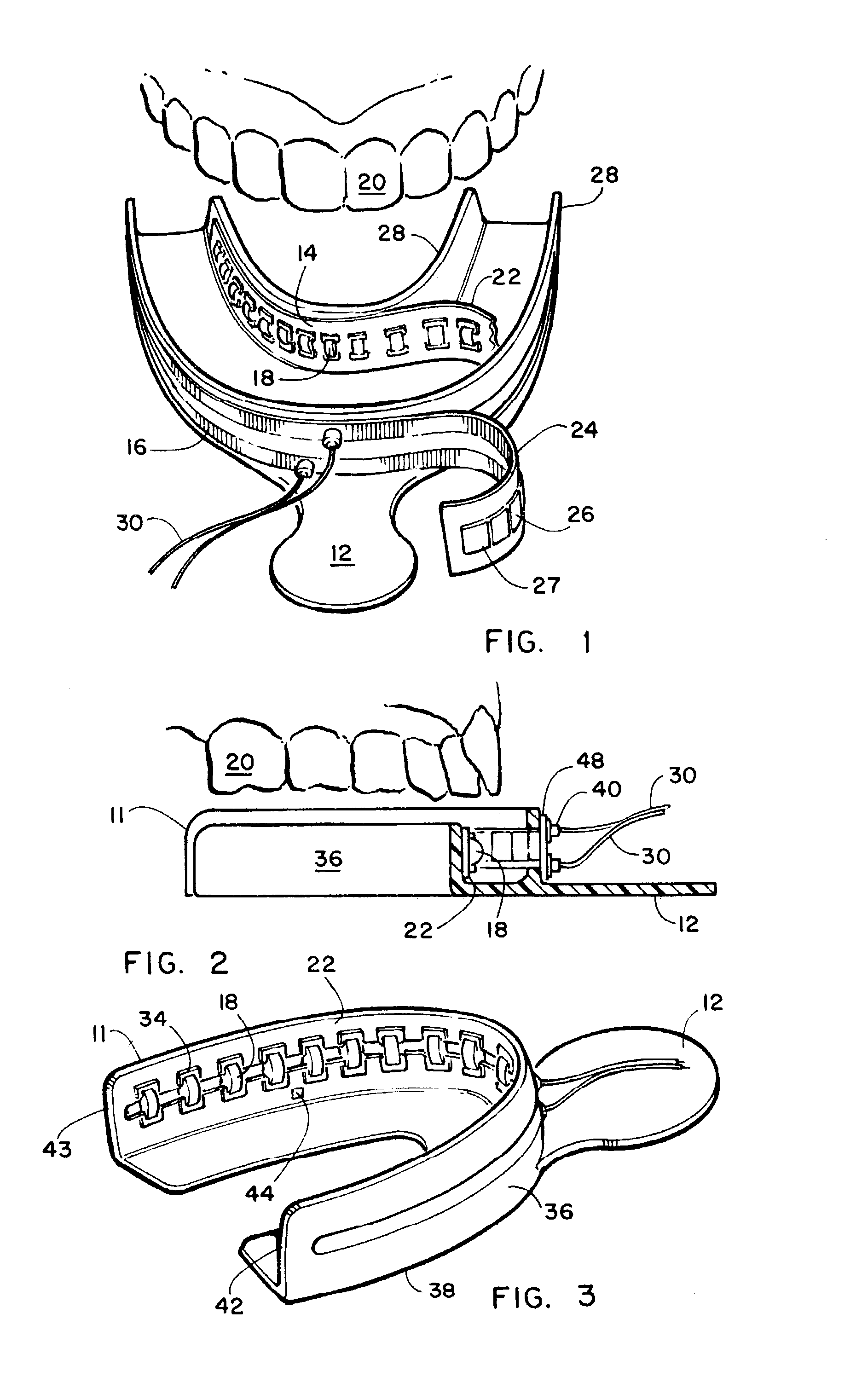

An intra-oral dental irradiation device for use in dental procedures for whitening teeth, imaging teeth, and making impressions of tooth structures of a patient. The device features one or a plurality of LED devices mounted to an arched shaped structure which project light upon or through teeth. In the whitening mode the light of the proper spectrum to activate enamel whitening material is projected. In the imaging mode light projected by the LED devices is received by a charged coupled device which communicates the image of the light passing through the teeth from the LED devices, to a computer. In making dental impressions, the device projects light in a spectrum that provides the catalyst to material that hardens when exposed to that spectrum thereby hardening dental impression material when inserted over the teeth of a patient.

Owner:NOVA RANGER

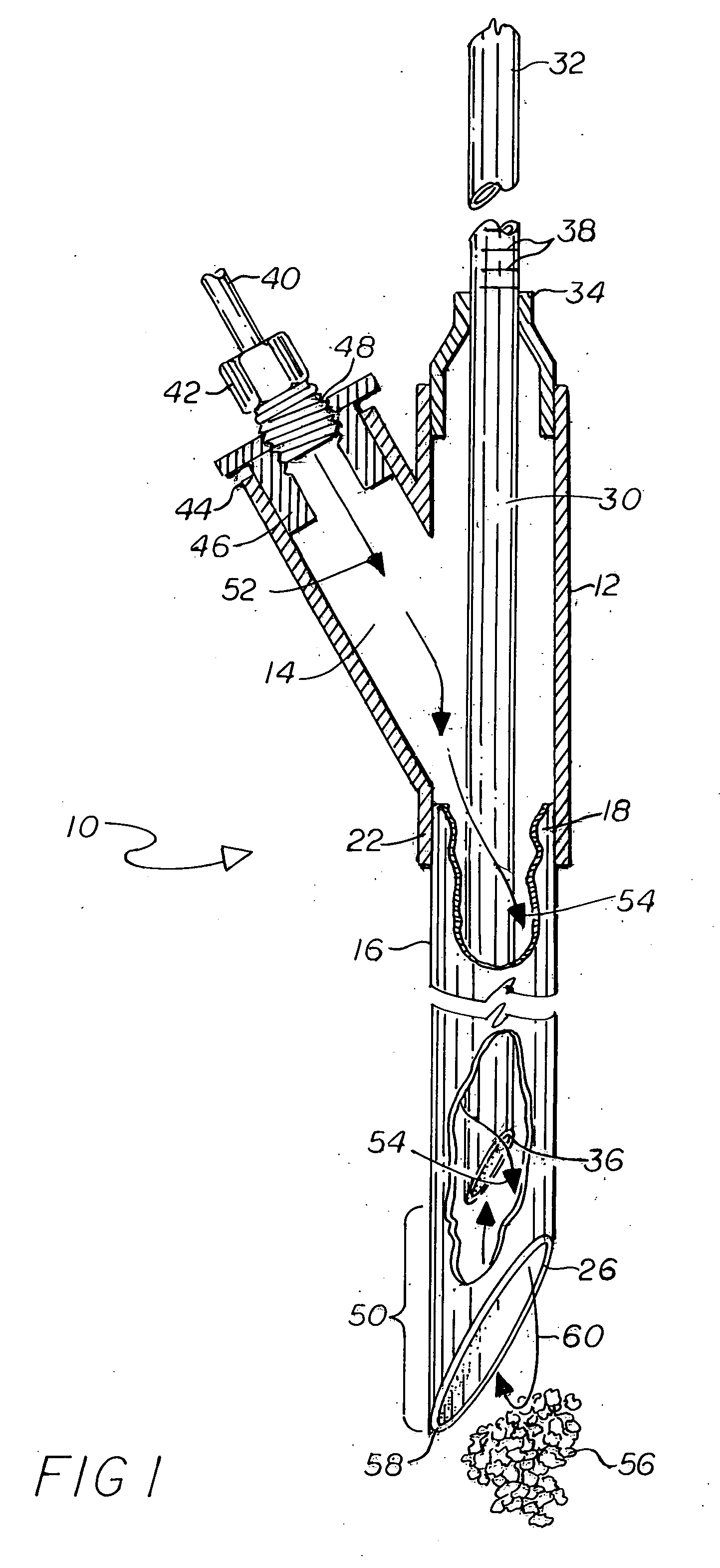

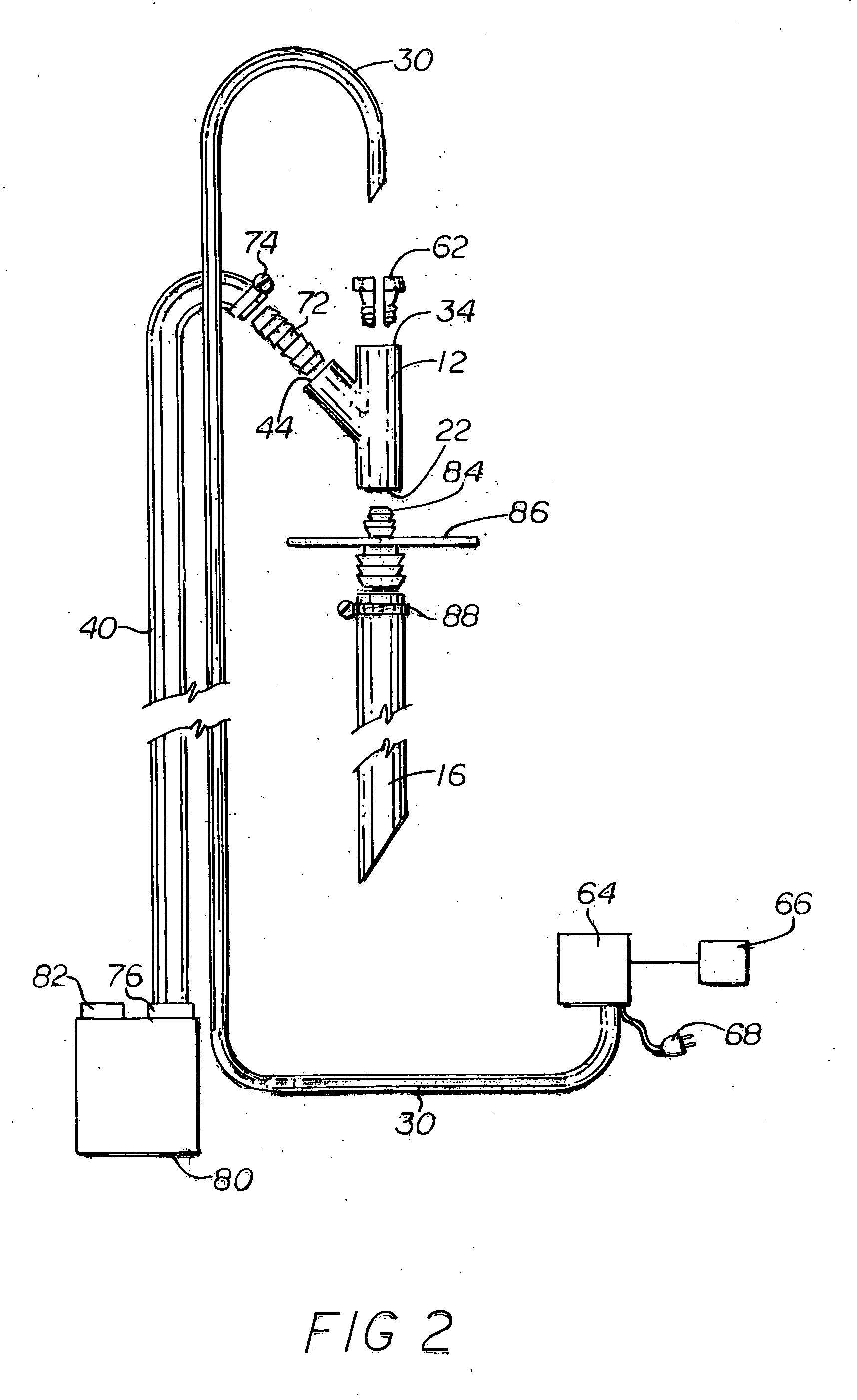

Intra oral dental irradiation device for material curing and dental imaging

InactiveUS6976841B1Eliminate health hazardsStrong specificityImpression capsDental toolsDental impression materialDental procedures

An intra-oral dental irradiation device for use in dental procedures for whitening teeth, imaging teeth, and making impressions of tooth structures of a patient. The device features one or a plurality of LED devices mounted to an arched shaped structure which project light upon or through teeth. In the whitening mode the light of the proper spectrum to activate enamel whitening material is projected. In the imaging mode light projected by the LED devices is received by a charged coupled device which communicates the image of the light passing through the teeth from the LED devices, to a computer. In making dental impressions, the device projects light in a spectrum that provides the catalyst to material that hardens when exposed to that spectrum thereby hardening dental impression material when inserted over the teeth of a patient.

Owner:NOVA RANGER

Environmentally compatible processes compositions and materials treated thereby

InactiveUS20040170742A1Cause and induce damageAvoid premature germinationBiocideInorganic active ingredientsEnvironmental resistanceWorkspace

Environmentally friendly processes for prevention of qualitative deterioration and quantitative loss of plant matter and foodstuffs, during all stages of storage and handling, including pre- and post-harvest, pre- and post-planting, distribution and marketing involves the use of H2O2 compositions including Ag and at least one of Cu and Zn ions. The processes can also be used to prevent sprouting and rooting, and to promote fecundity of certain plant matter, and can also be used to eliminate or reduce quantities of harmful organisms and substances from soil, other growth media and substrates, equipment, materials water, workspaces and surfaces.

Owner:PIMI AGRO CLEANTECH

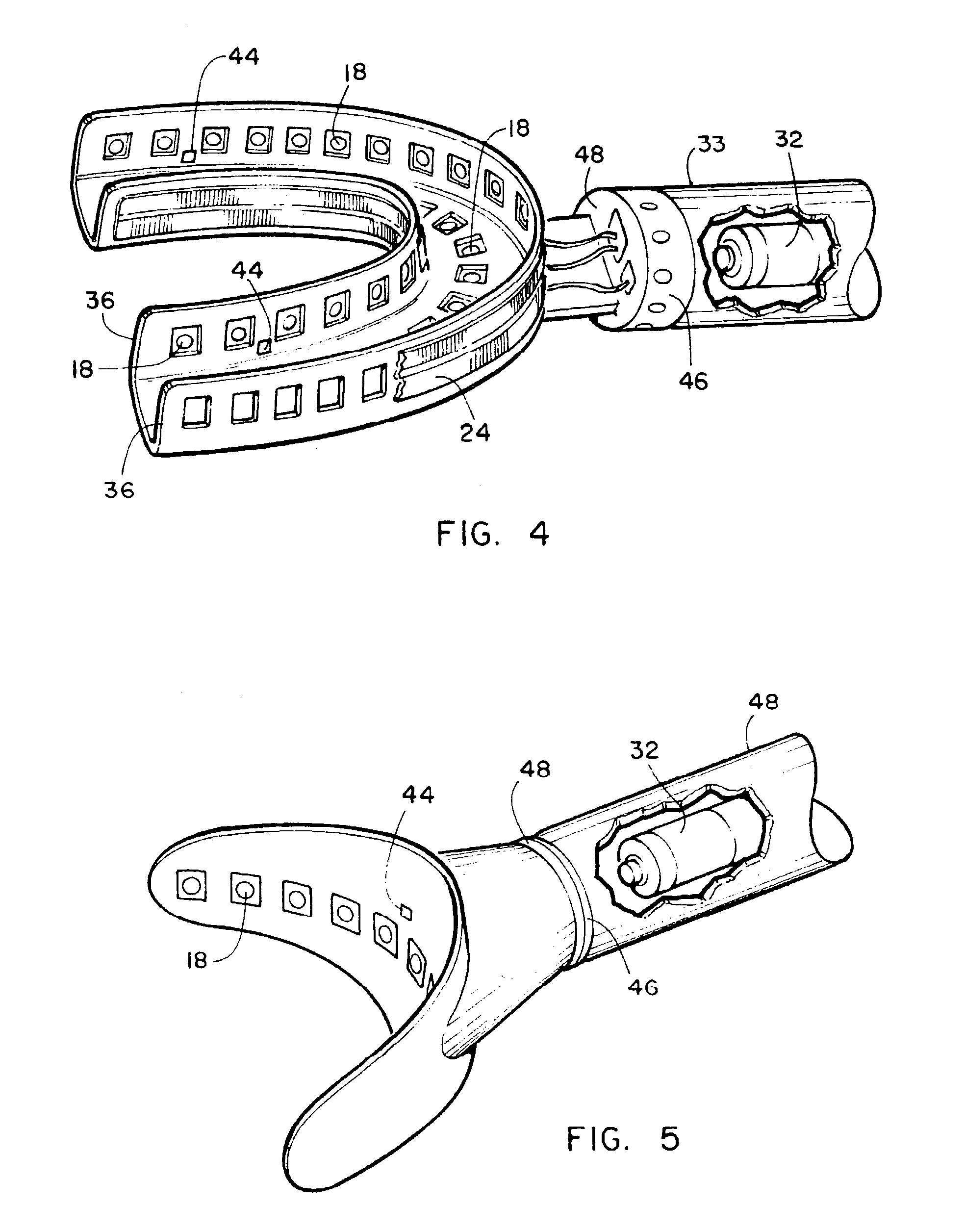

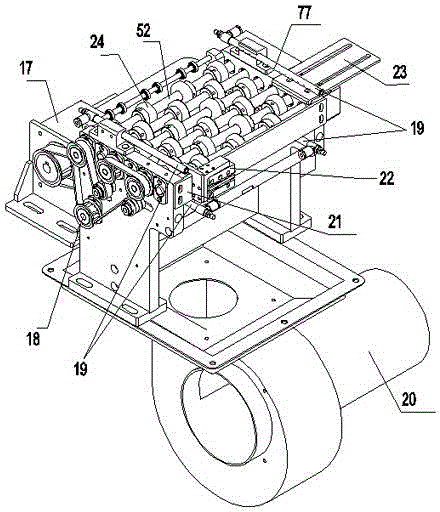

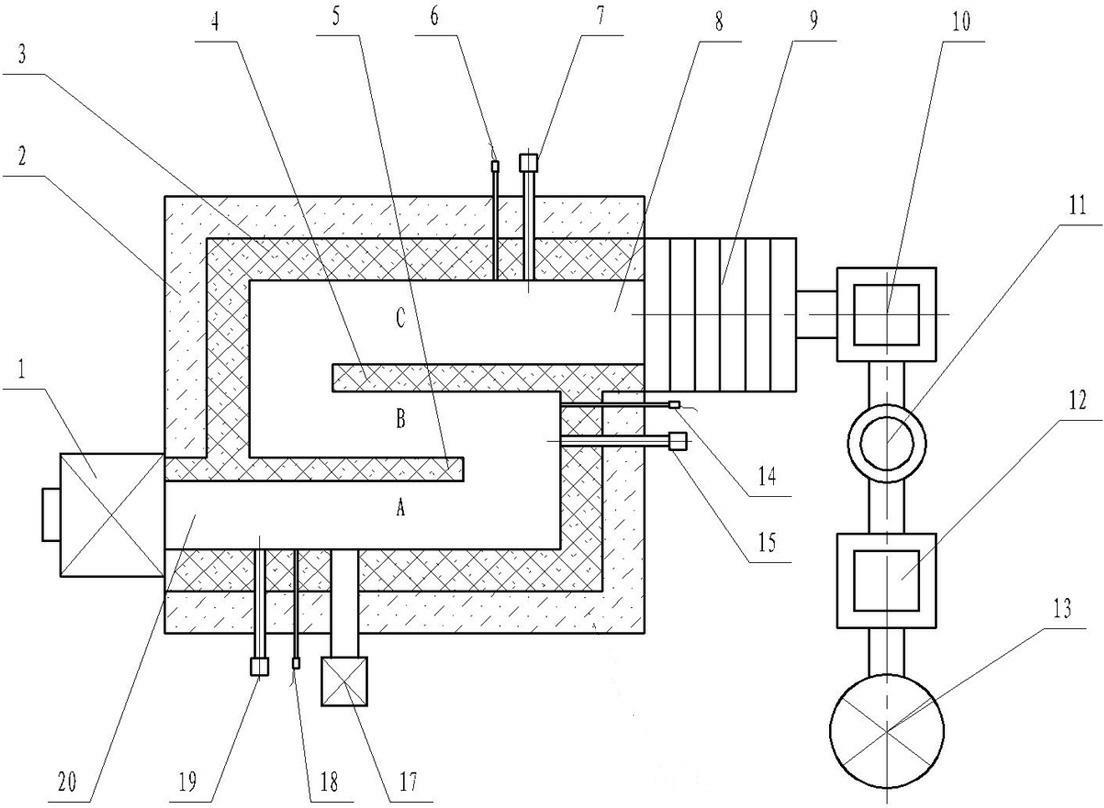

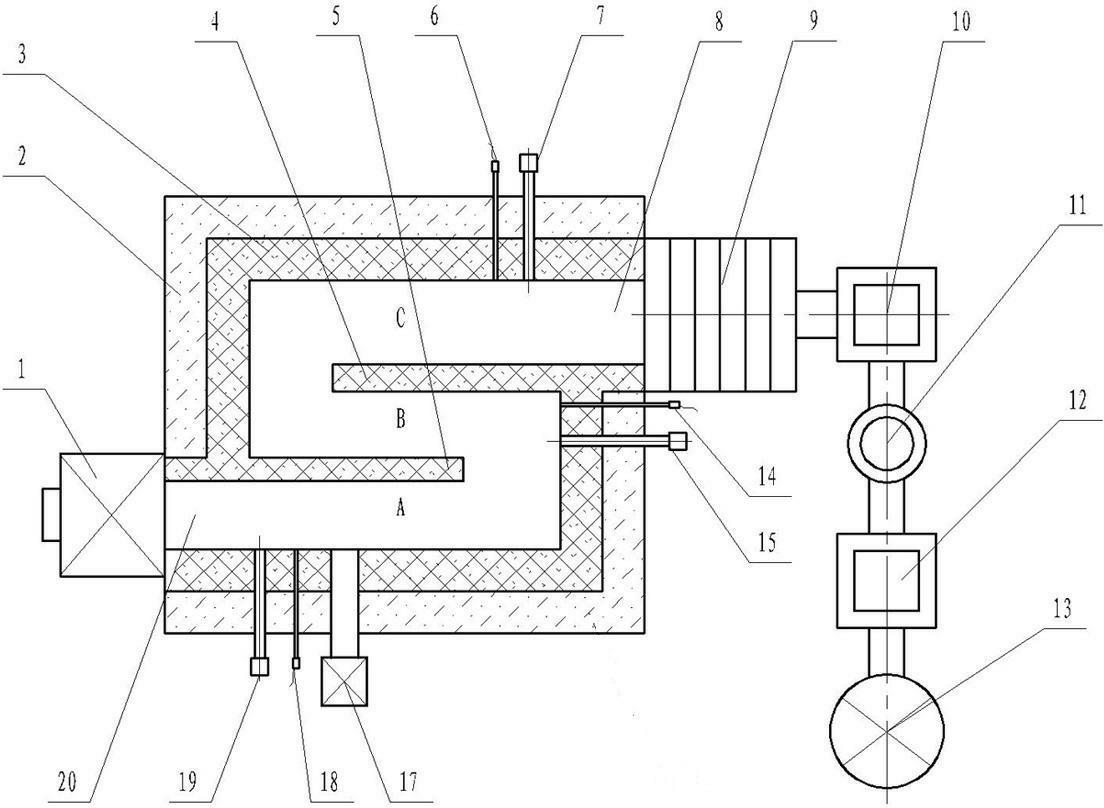

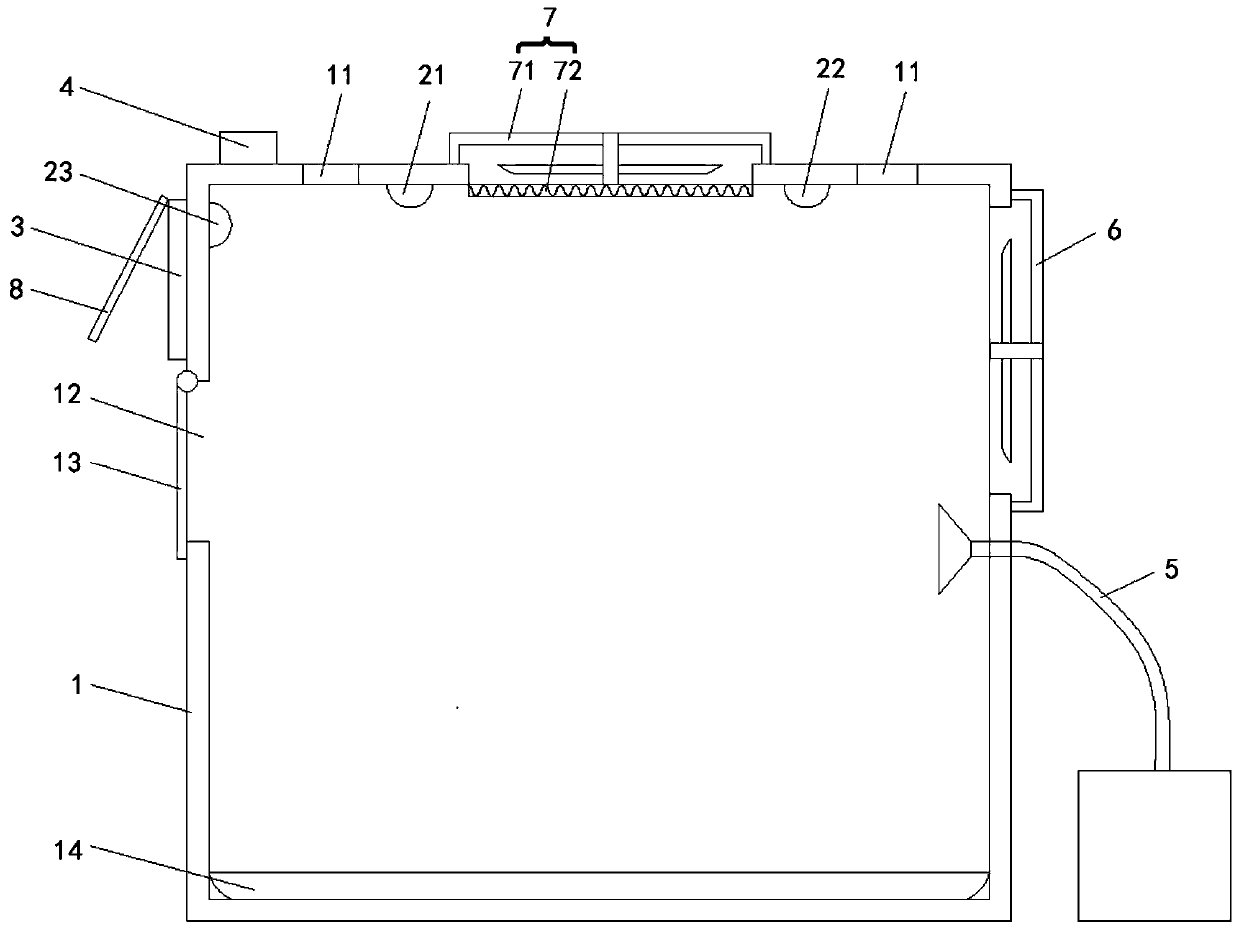

Automatic surface wiping and cleaning device and automatic cleaning machine

ActiveCN104624590AEliminate health hazardsIncrease frictionFlexible article cleaningEngineeringTouchscreen

The invention relates to an automatic surface wiping and cleaning device and an automatic cleaning machine which are used for cleaning the surface of a touch screen of a mobile phone. A platform rotating mechanism is arranged at the center of a bottom plate of a power distribution cabinet, a feeding conveying line is arranged at the starting end of the cleaning machine, the feeding conveying line, a blowing conveying line, a feeding and discharging mechanical arm and a discharging conveying line are sequentially connected in a front-back mode and fixed to the front end of the bottom plate of the power distribution cabinet, the far end of the feeding and discharging mechanical arm is connected with the platform rotating mechanism, a first cleaning head mechanism and a second cleaning head mechanism are arranged beside the platform rotating mechanism, the cleaning head mechanisms are provided with cleaning press plates used for cleaning materials according to sine wave tracks, and the cleaning press plates are connected with ethyl alcohol spraying mechanisms. The automatic surface wiping and cleaning device and the automatic cleaning machine have the advantages of eliminating health hazards of manual operation and greatly improving cleaning work efficiency and cleaning quality.

Owner:GUANGZHOU LINKCORE AUTOMATIC EQUIP CO LTD

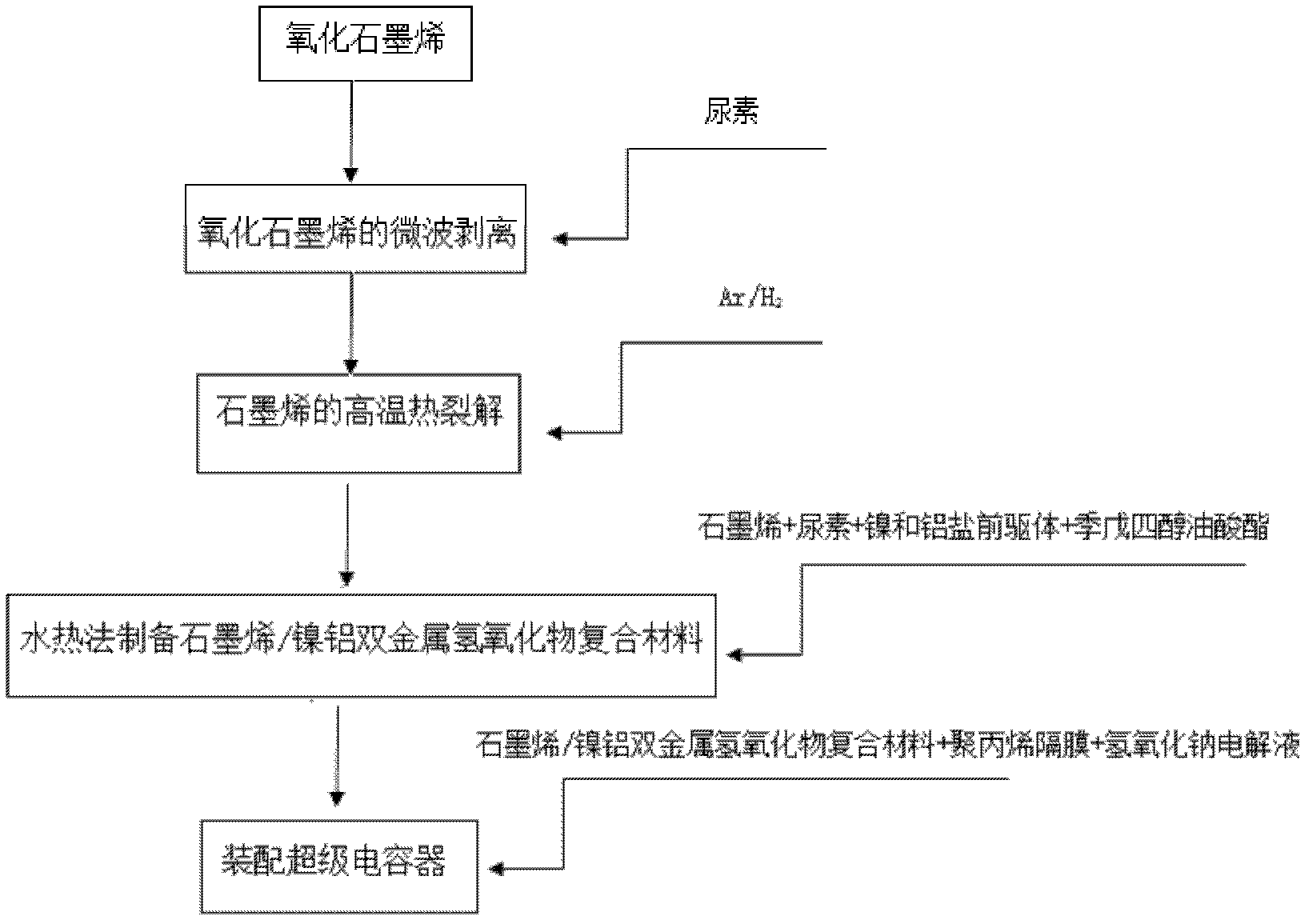

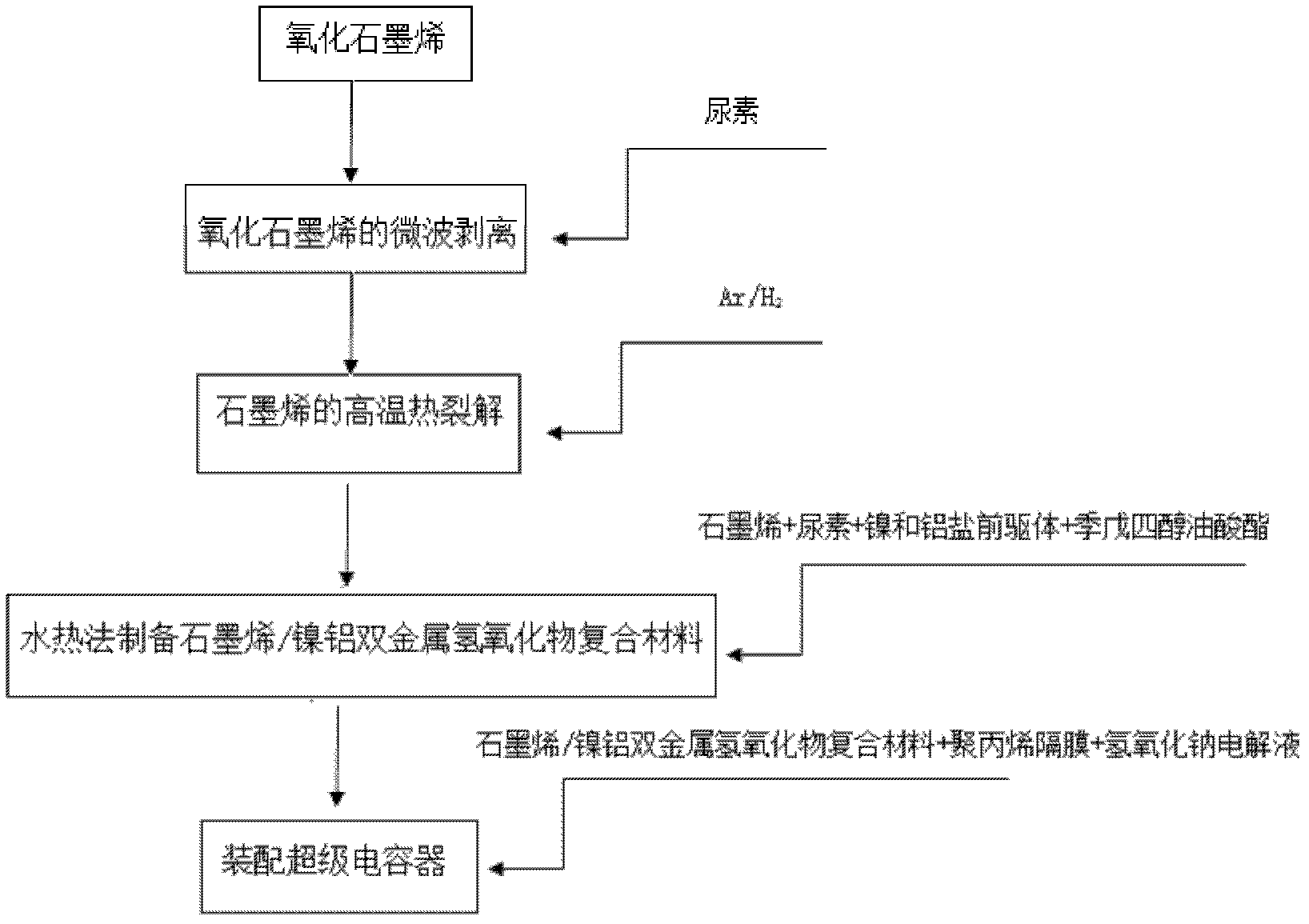

Preparation method of graphene/nickel-aluminum bi-metal hydroxide composite material and application thereof

ActiveCN102496480AGood electronic conductivityGood conductivityElectrolytic capacitorsCvd grapheneEnvironmental chemistry

The invention discloses a preparation method of a graphene / nickel-aluminum bi-metal hydroxide composite material and an application thereof, belonging to the technical field of electrochemistry. The preparation method comprises the following steps of: preparing a mixed solution by a stripping enhancer, oxidized graphene and deionized water, dispersing the mixed solution by ultrasonic wave; decompressing and filtering the mixed solution to obtain a filtering cake, and arranging the filtering cake into a household microwave oven to radiate; placing a graphene filtering cake into a tubular furnace, charging Ar / H2 mixed gas, and executing high-temperature thermal cracking; and adding an alkali source compound, nickel and aluminum salt precursors, a medium regulating agent and the deionized water to prepare a reactant mixing solution, and transferring the reactant mixing solution to a high-pressure reaction kettle to carry out a hydrothermal reaction, and finally obtaining the graphene / nickel-aluminum bi-metal hydroxide composite material. According to the preparation method of the graphene / nickel-aluminum bi-metal hydroxide composite material, disclosed by the invention, toxic chemical agents are not used at two steps of reduction of the graphene, thus damage on the health of a human body and environmental pollution because a large number of harmful chemical agents such as hydrazine hydrate and the like are taken as a strong reducing agent in a chemical reduction method can be eliminated fundamentally.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

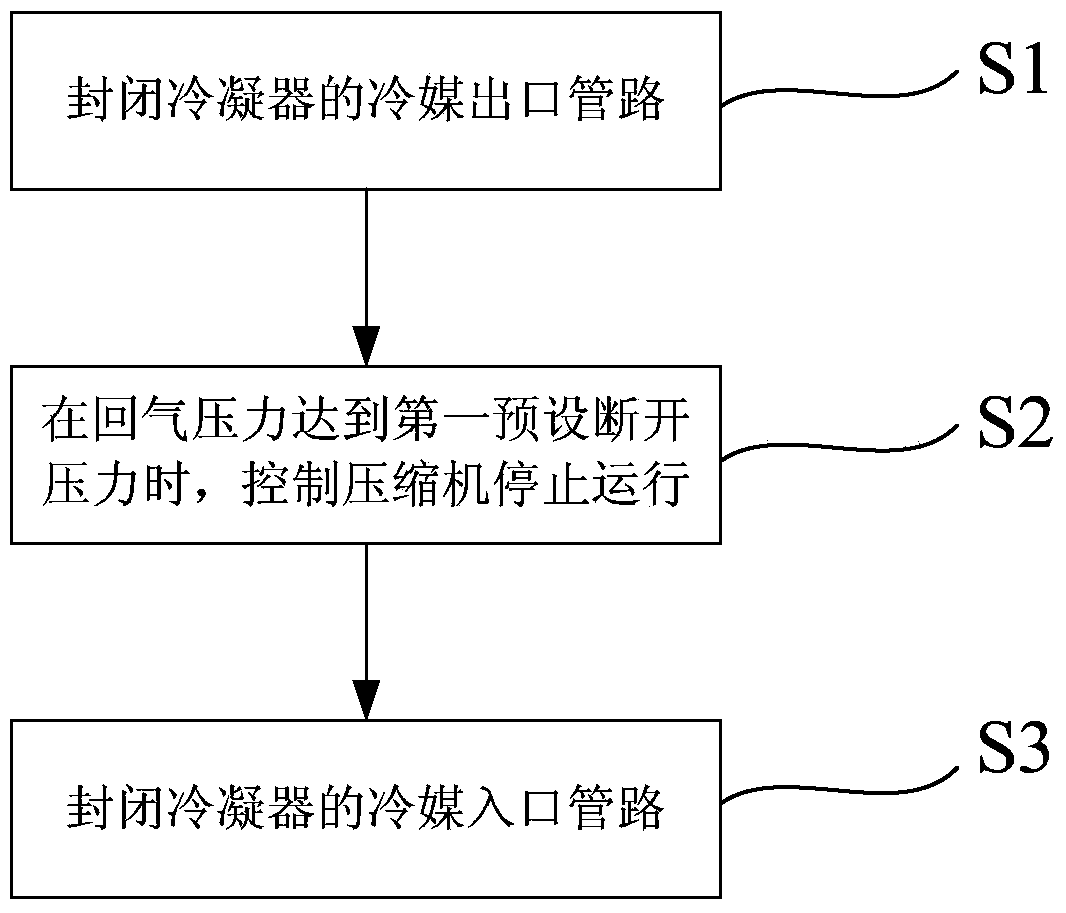

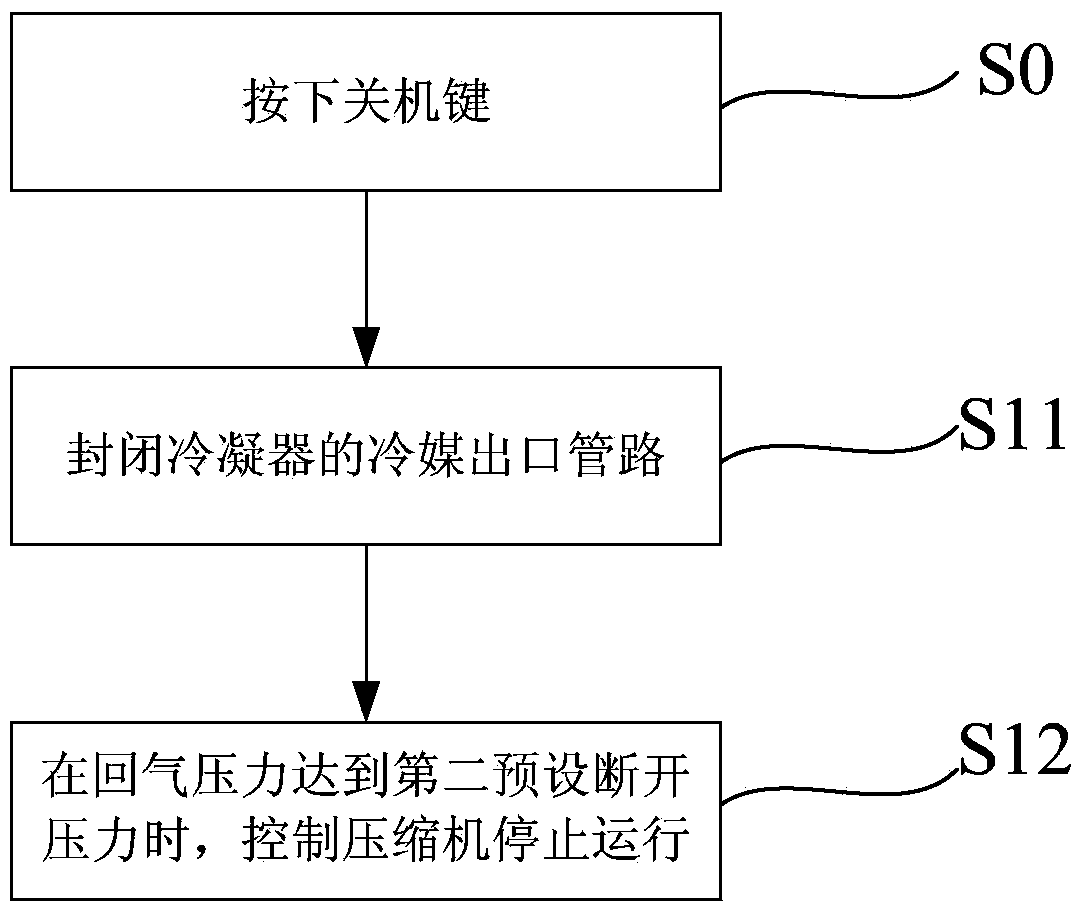

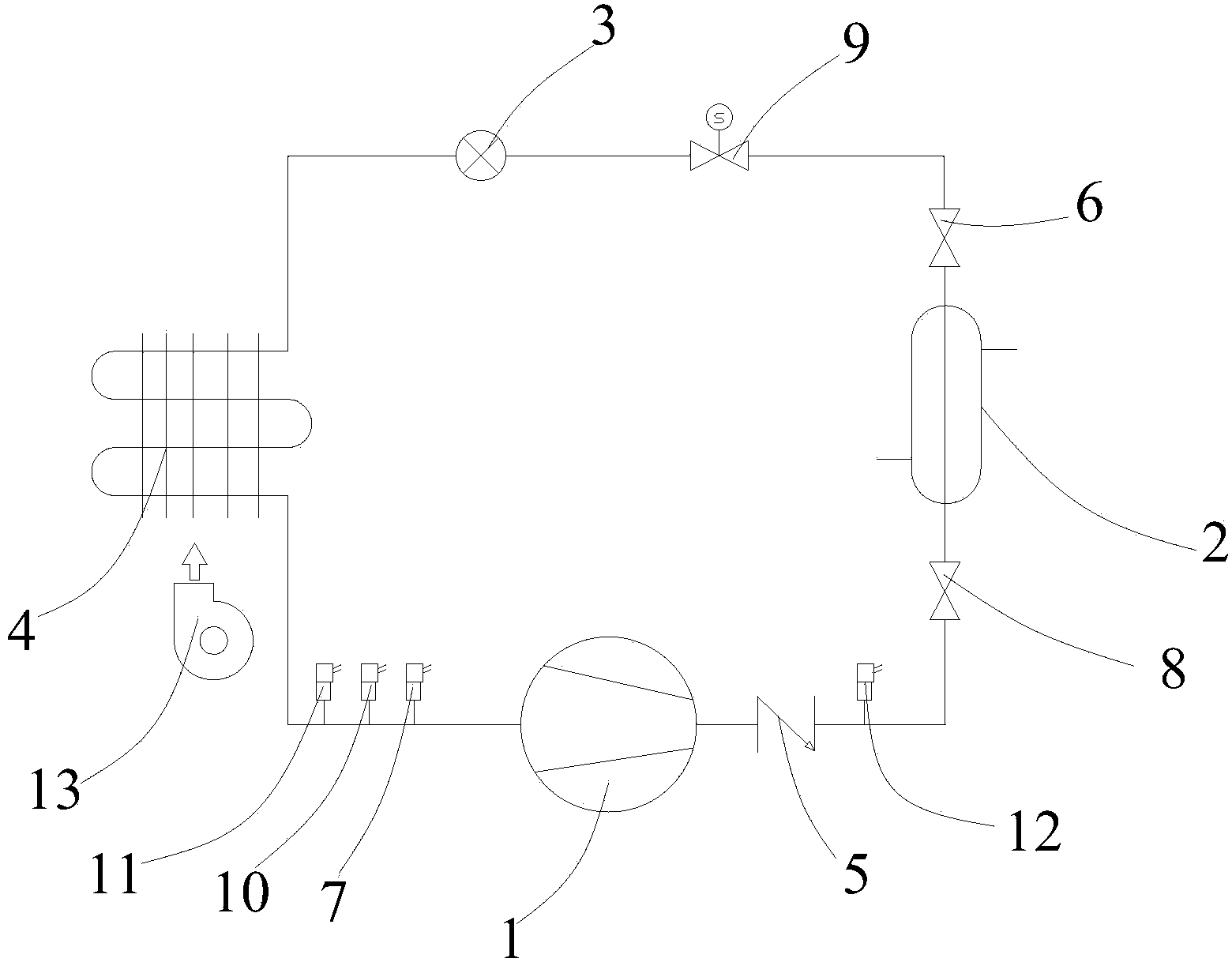

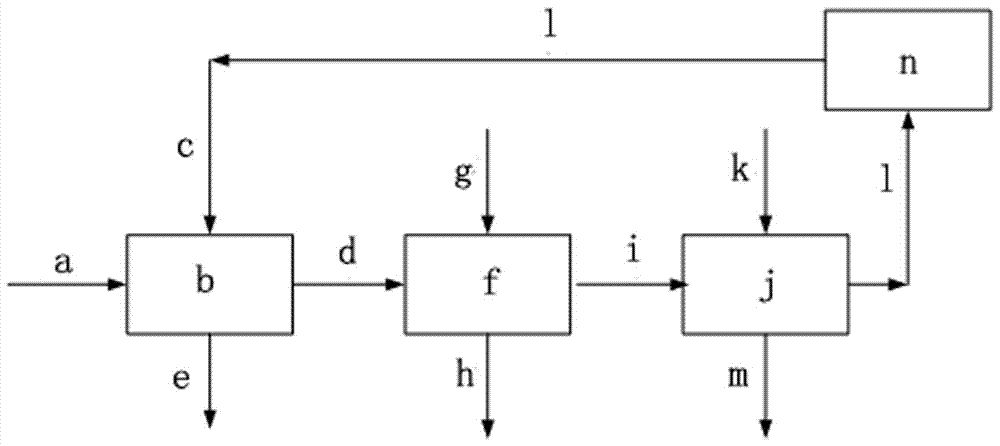

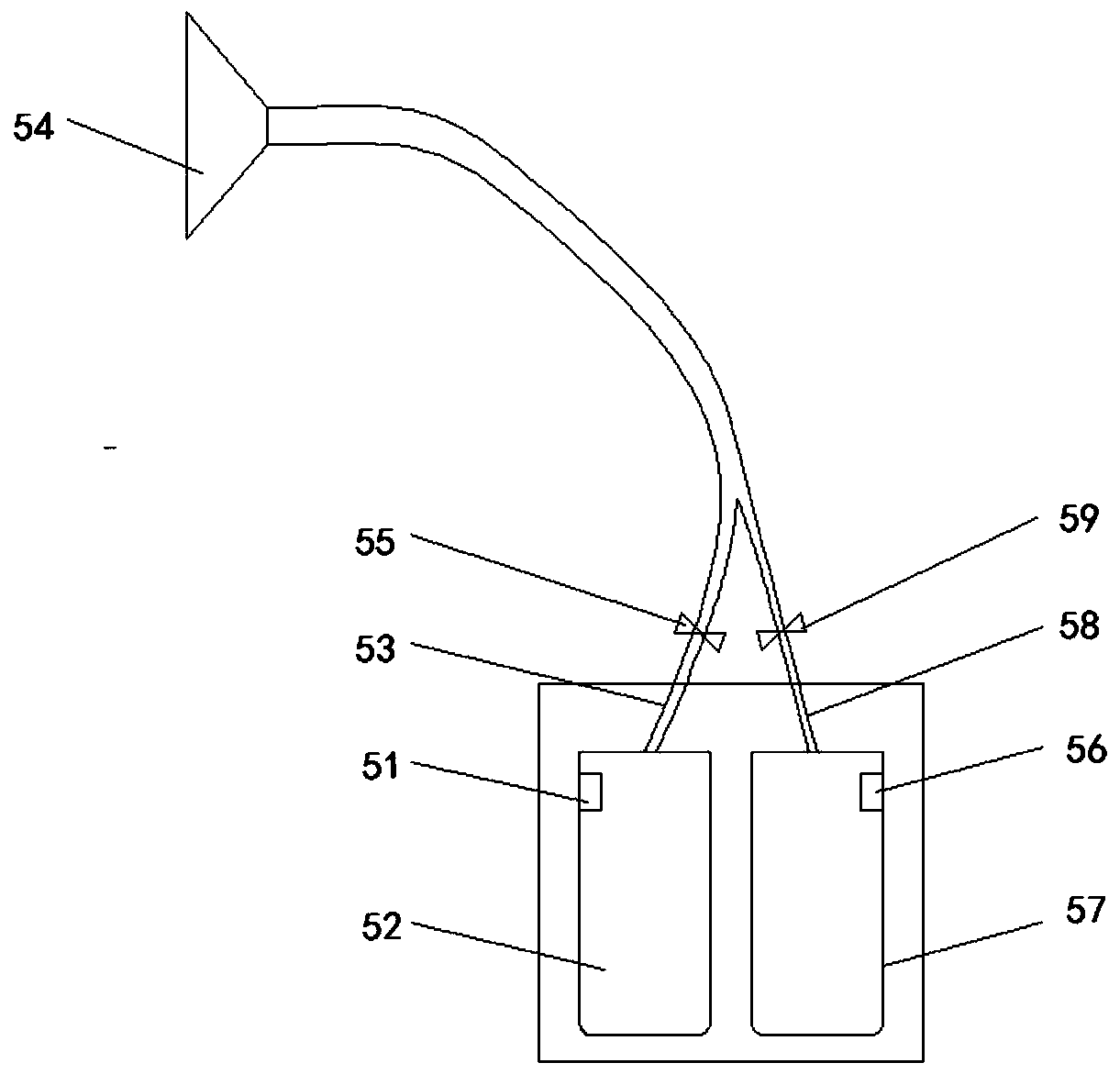

Air conditioning system and coolant recycling method thereof

ActiveCN104061659AAvoid emissionsAvoid economic lossMechanical apparatusSpace heating and ventilation safety systemsRecovery methodAir conditioning

The invention discloses an air conditioning system coolant recycling method. A compressor air exhausting opening of an air conditioning system is in serial connection with a one-way valve. When coolants leak or an air conditioner needs to be maintained, the air conditioning system coolant recycling method comprises the steps of sealing a coolant outlet pipeline of a condenser, detecting return air pressure of a compressor inlet in the air conditioning system, controlling a compressor to be stopped when the return air pressure reaches first preset cut-out pressure and sealing a coolant inlet pipeline of the condenser. The recycling method can recycle coolants of the system in time when the coolants leak or the air conditioner needs to be maintained and prevents the coolants from being discharged into external environment. Thus, the natural environment can be effectively protected, meanwhile health hazards of the coolants to maintaining workers are effectively eliminated, and economical loss caused by coolant waste is avoided. The invention further discloses an air conditioning system where the recycling method is applied.

Owner:SHENZHEN MCQUAY AIR CONDITIONING

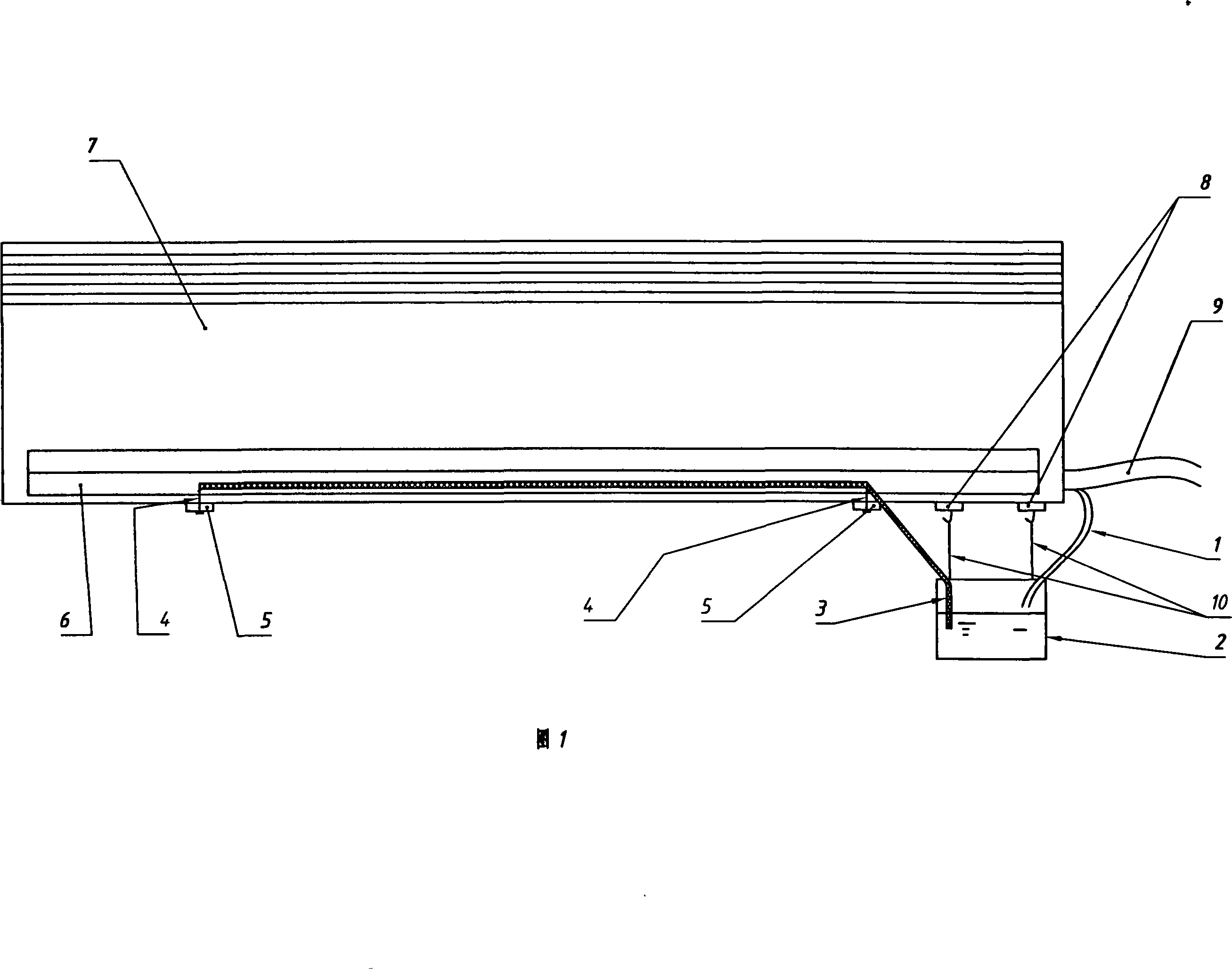

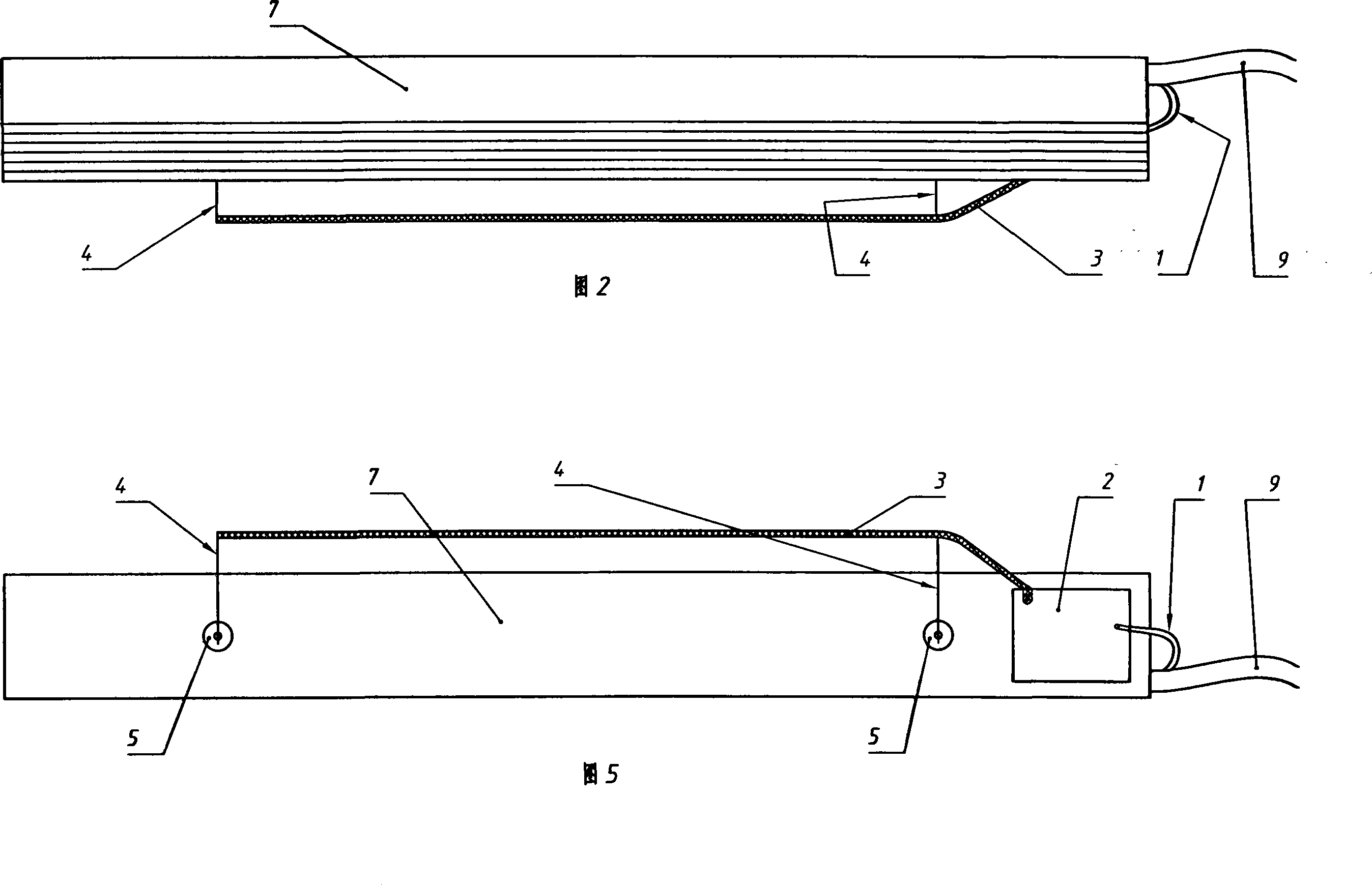

Split type domestic air-conditioning humidifying device

InactiveCN101216196AEasy to cleanLow costCondensate preventionLighting and heating apparatusAbsorbent materialAir conditioning

A humidifying device used with a split-type home air conditioner comprises a water-absorbing strip made of water-absorbent materials and a water tank arranged below the indoor unit of the air conditioner. The water outlet of the condensed water discharge pipe of the indoor unit of the air conditioner is arranged inside the water tank to introduce the condensed water into the water tank. The water-absorbing strip is arranged in front of and in parallel to the air outlet of the indoor unit of the air conditioner, and one end of the water-absorbing strip is immersed in water inside the water tank. All parts of the inventive device are arranged or installed outside the existing indoor unit of the air conditioner. The invention has the advantages of simple structure, low costs for design, fabrication and assembly, no problem of re-condensation of condensed water inside the air conditioner, good humidifying effect, easy cleaning of water tank, and no potential sanitary problem of bacterial proliferation.

Owner:CHONGQING UNIV

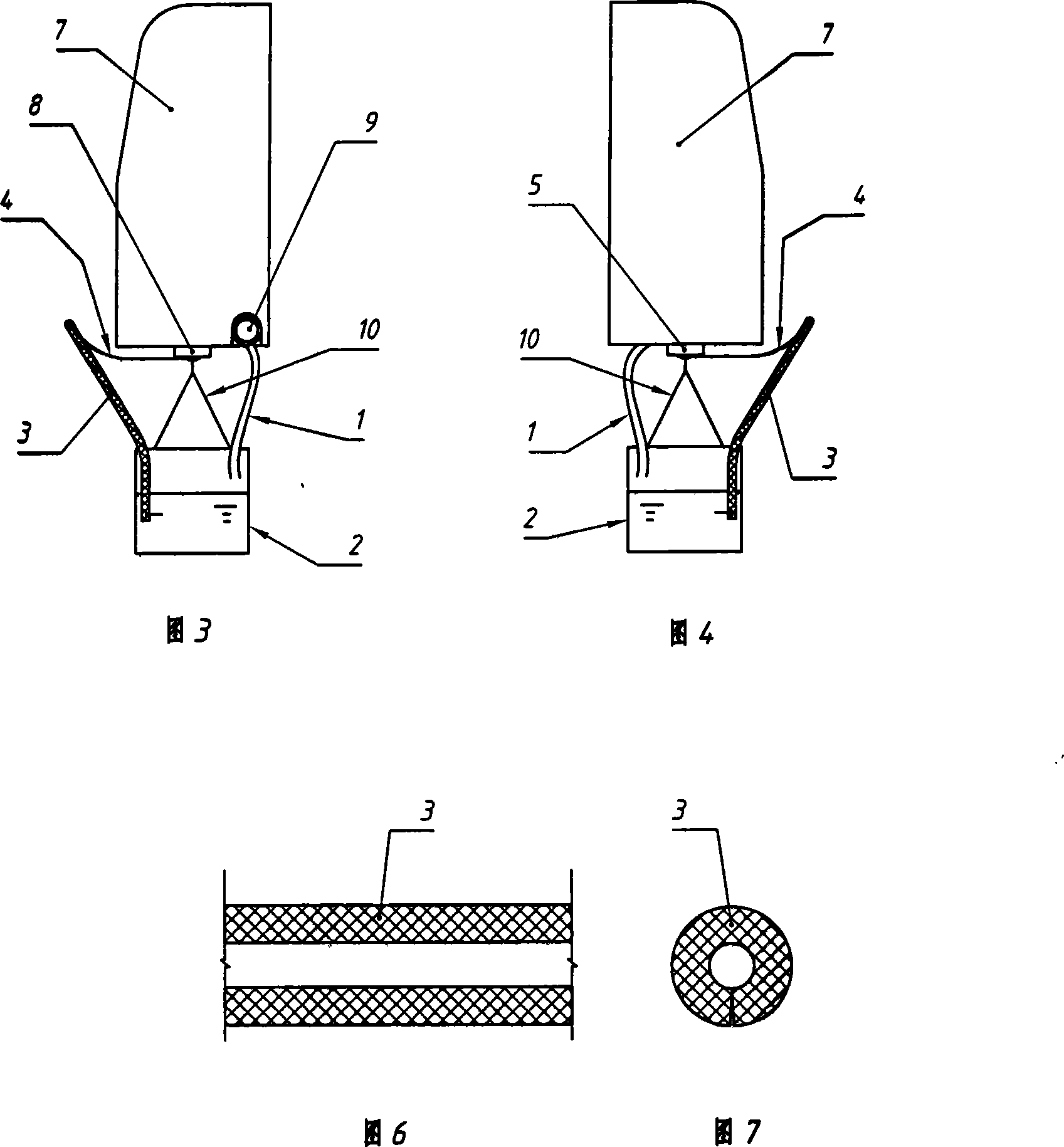

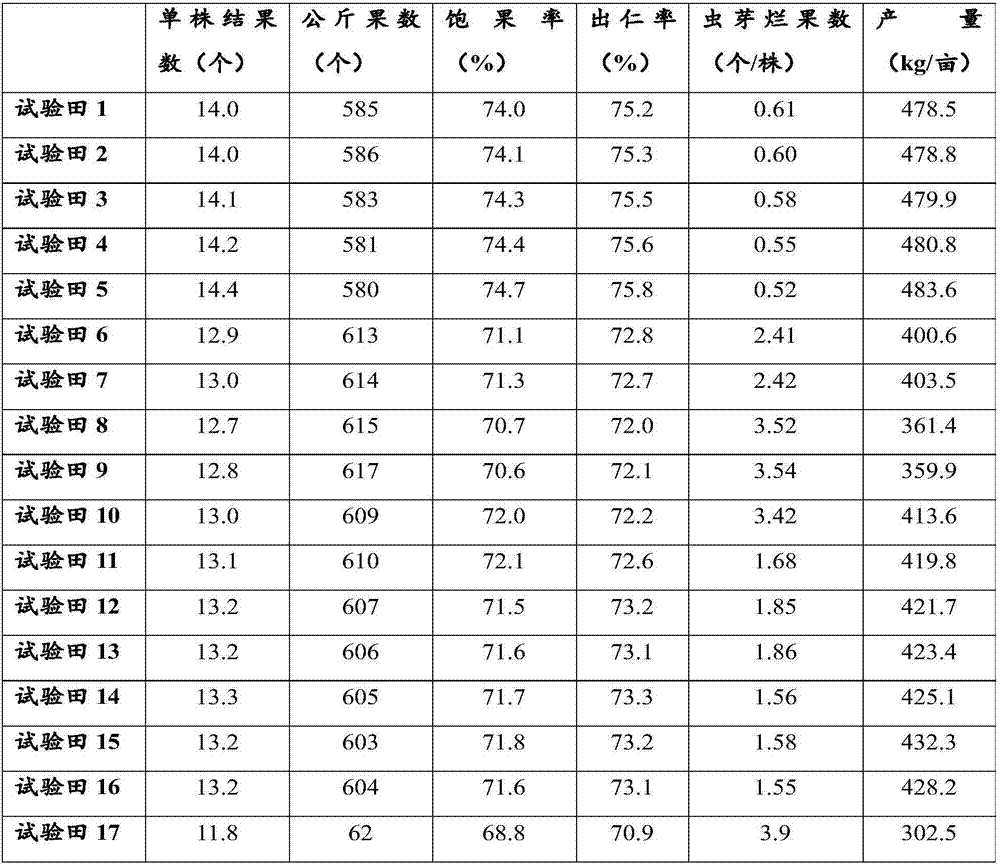

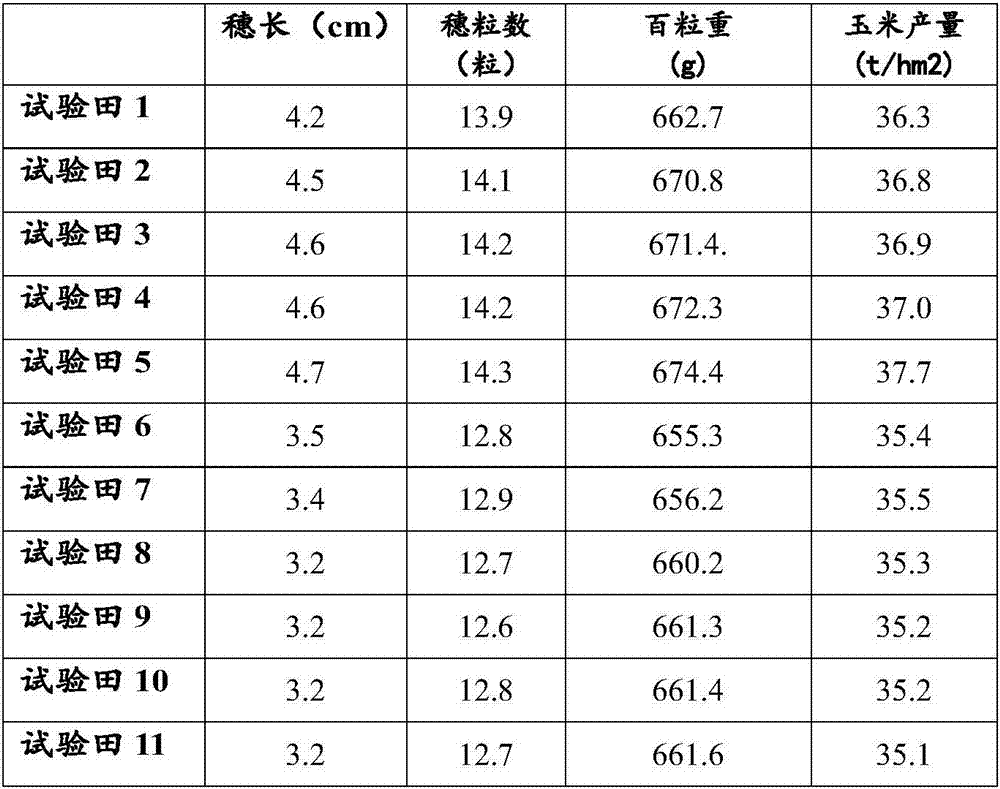

Method for high-temperature efficient aerobic composting of rural organic wastes

InactiveCN109503219AEfficient use ofReduce releaseBatteries circuit arrangementsClimate change adaptationLitterMicrobial agent

The invention relates to the technical field of rural waste treatment and specifically relates to a method for high-temperature efficient aerobic composting of rural organic wastes. The method comprises the following steps: treating rural kitchen wastes in the manner of sorting, oil-water separation and breaking; uniformly mixing the treated rural kitchen wastes with broken animal dung and strawsat a certain ratio, thereby forming a composting material; adding a defined amount of No.1 microbial agent, uniformly mixing and then increasing temperature, controlling temperature and aerating; adding a defined amount of No.2 microbial agent, uniformly mixing and then increasing temperature, controlling temperature and aerating, thereby forming an organic fertilizer. According to the invention,a high-quality fertilizer can be acquired by harmlessly and stably recycling the rural organic wastes within a short period of time. The technology is simple and can be easily popularized.

Owner:SUN YAT SEN UNIV

Urea-formaldehyde adhesive with low free formaldehyde and expanding characteristic and its preparation method

InactiveCN1640906AGood storage performanceImprove efficiencyAldehyde/ketone condensation polymer adhesivesChemistryWeather resistance

The urea formaldehyde resin prepared through one sectioned process with formaldehyde and urea as main material and in the presence of Lewis acid or alkali has free formaldehyde content of about 0.1 % and less than 0.5 %. During the preparation, organic amine assistant is added, and this makes the adhesive possess obvious expansion performance during formation and be suitable for use in producing various kinds of board. The products with the adhesive have low formaldehyde release amount, excellent mechanism performance, excellent weather resistance, etc. The liquid resin may be spray dried to prepare urea formaldehyde adhesive powder capable of maintaining reaction activity for long time. The adhesive of the present invention has no need of adding formaldehyde trapping agent.

Owner:倪卓

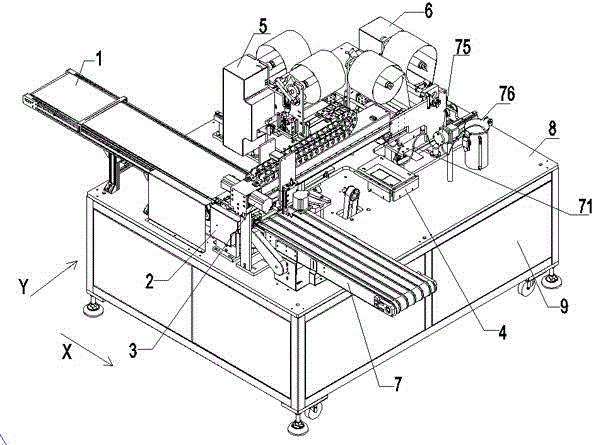

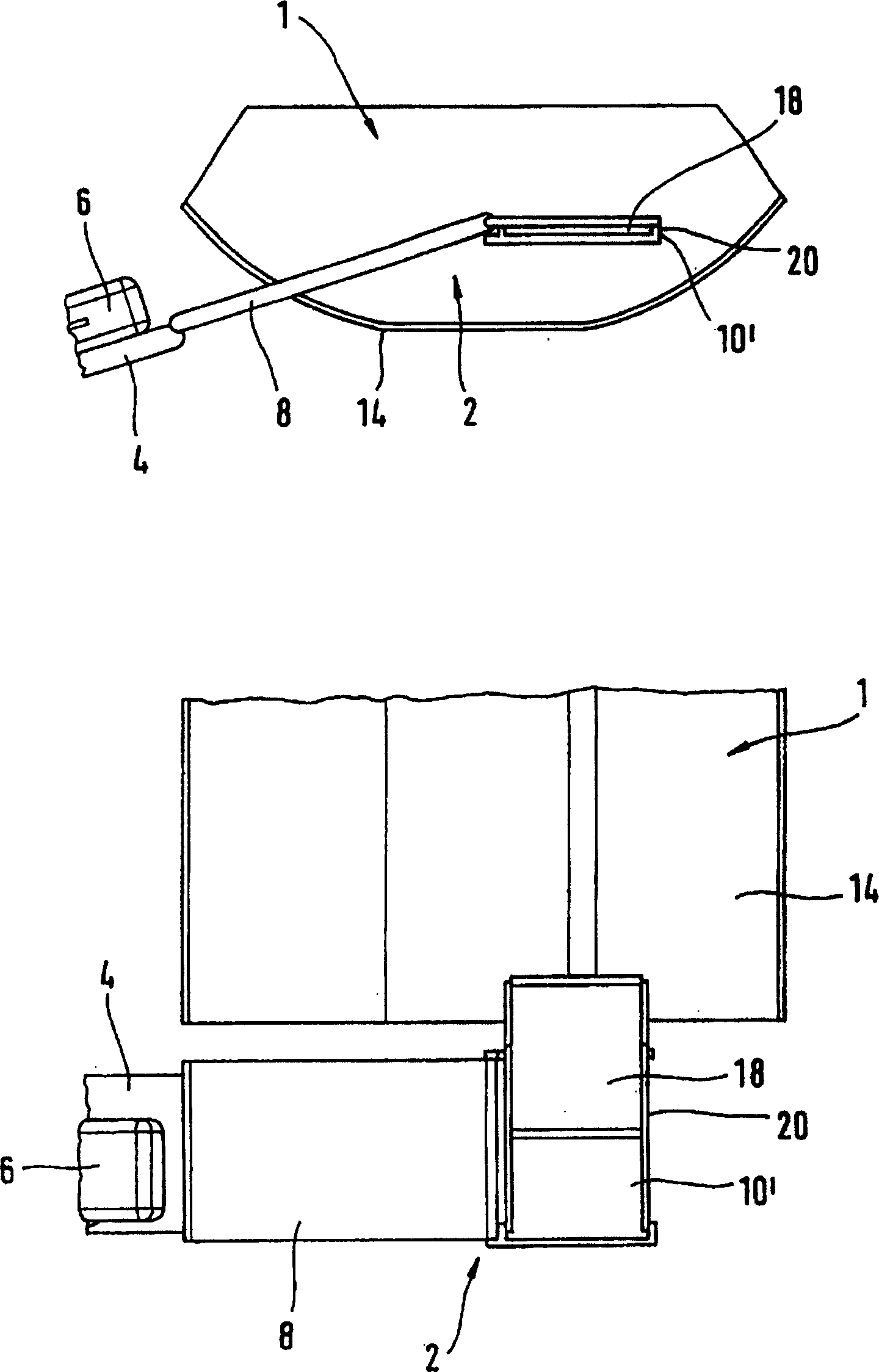

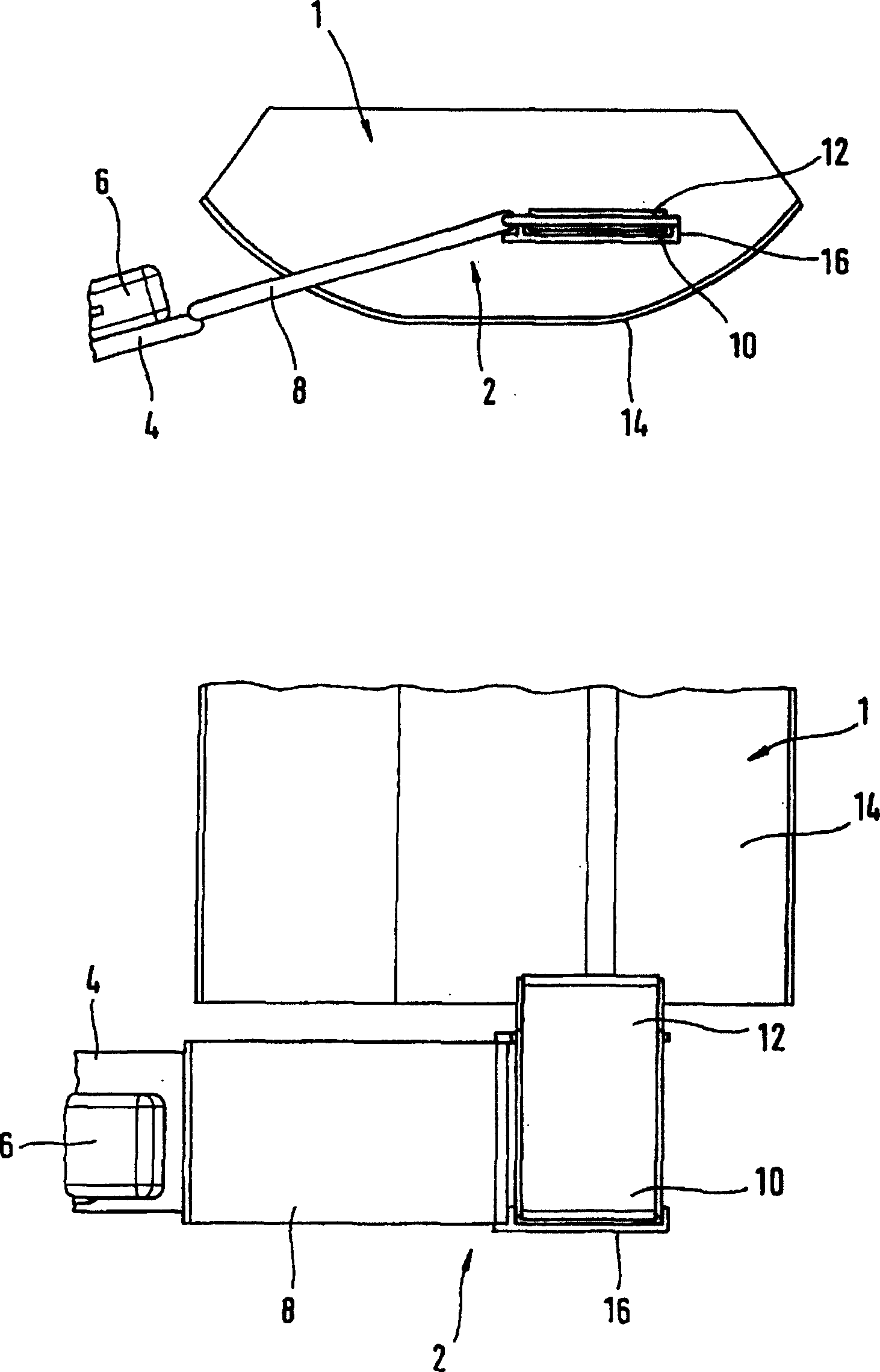

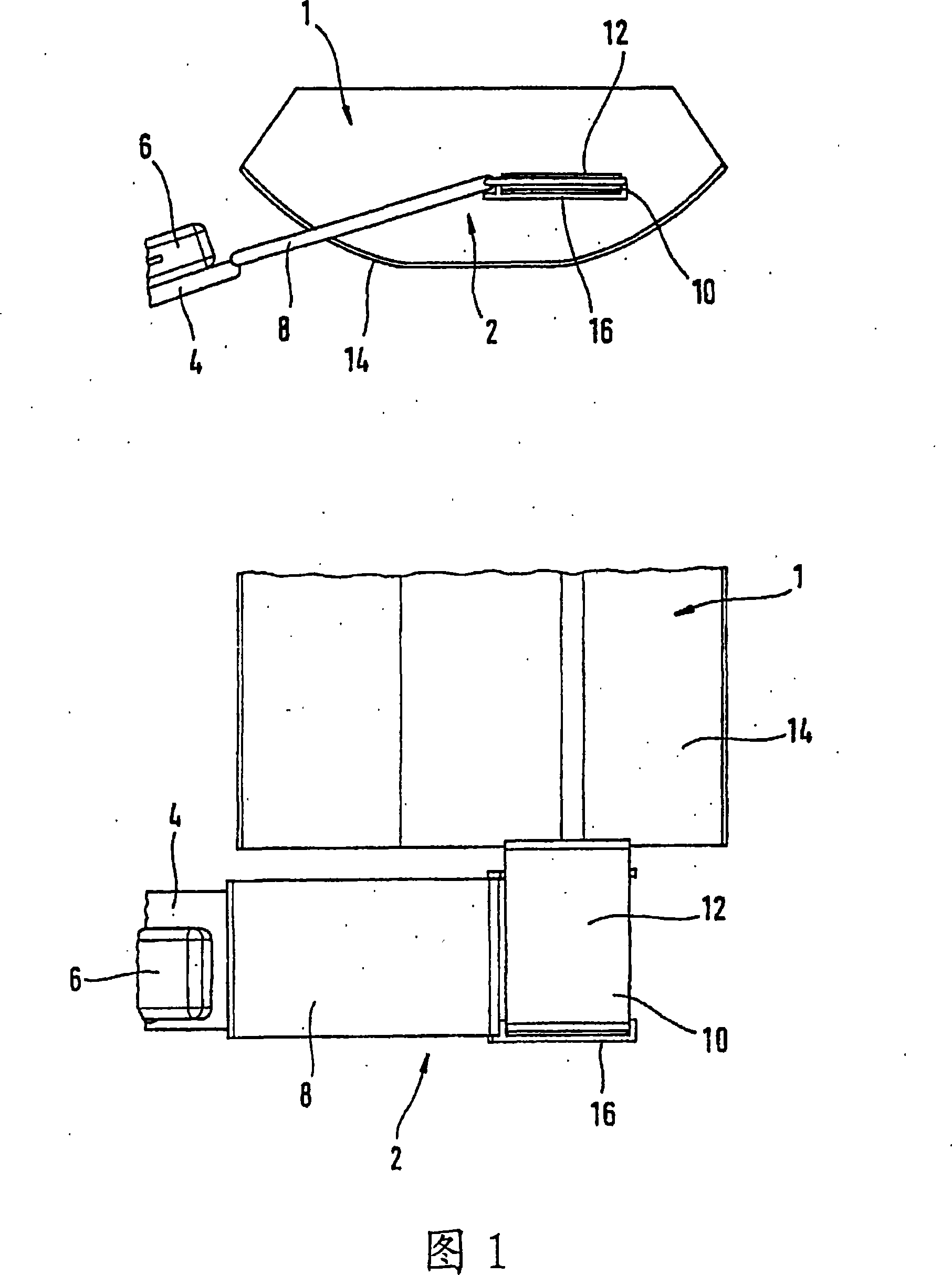

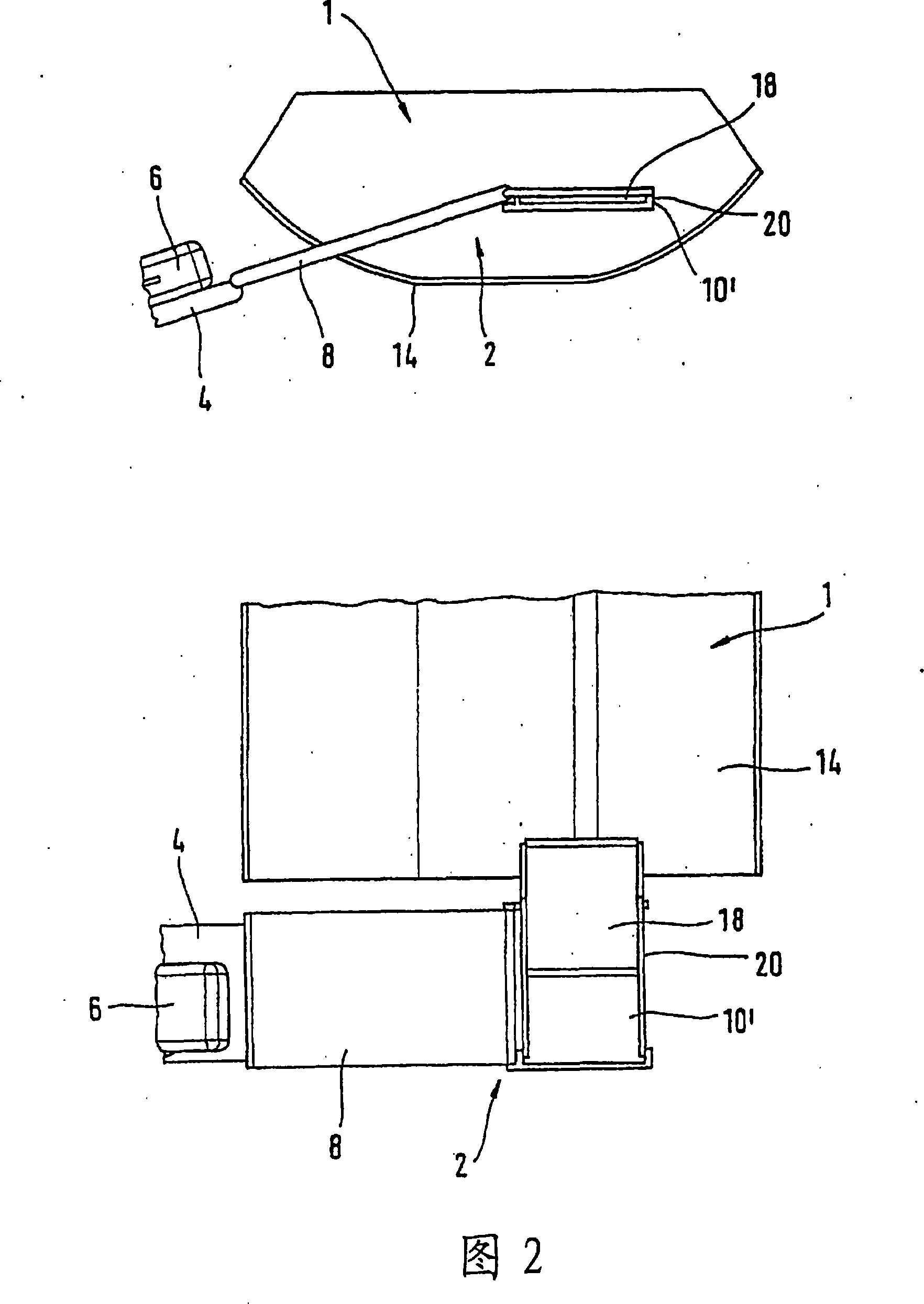

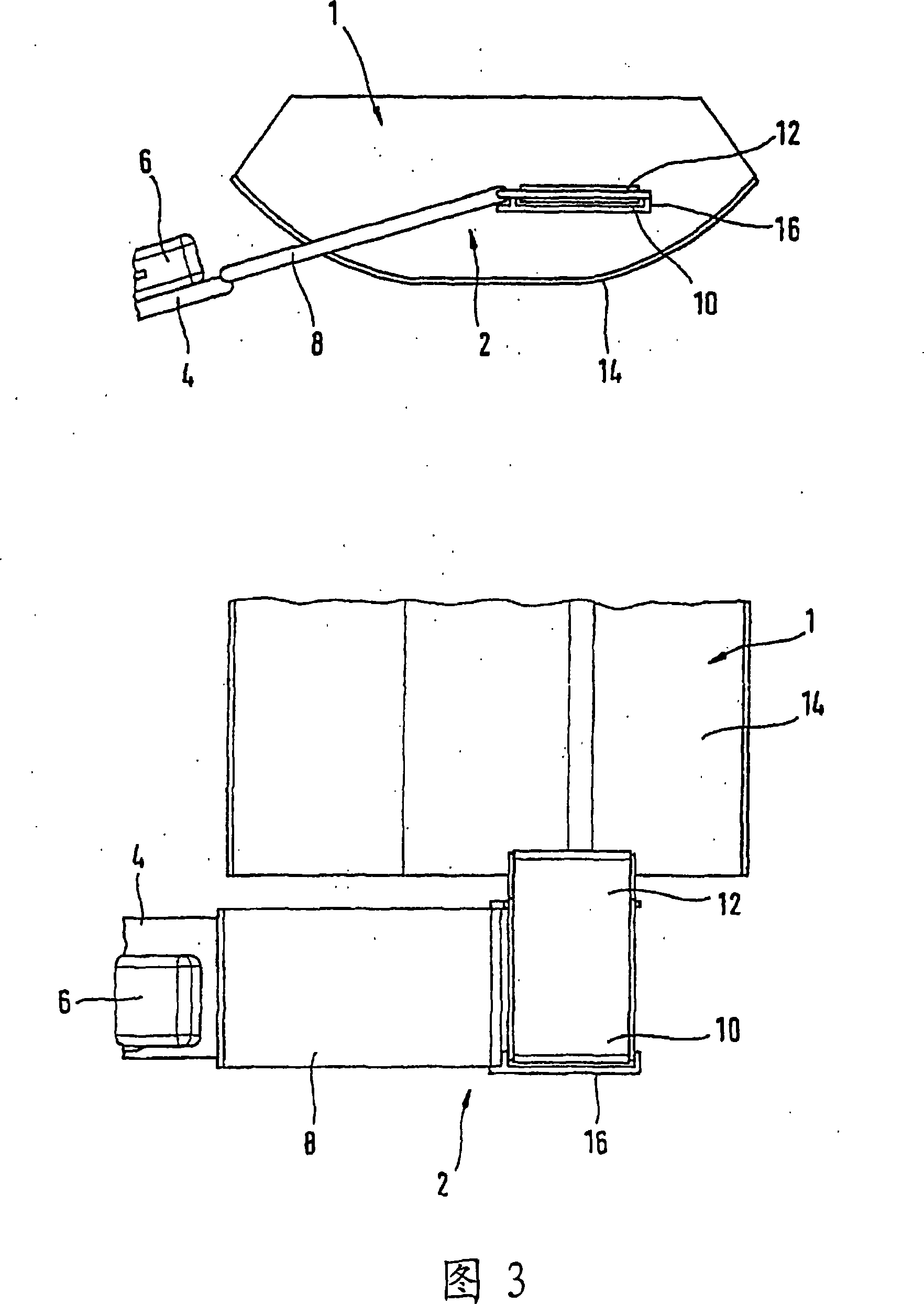

System for loading and unloading unit loads into a cargo hold, in particular of an aircraft, and intermediate transport device or corresponding transport unit

InactiveCN1652972AEliminate the use of manualReduce labor costsFreight handling installationsWeight reductionAirplaneFuselage

The invention relates to a conveying system loading or unloading loose goods (6) in the cargo compartment (1) of an aircraft, comprising an internal end form which the loose goods (6) are sent in the cargo compartment during the loading process and are sent out of the cargo compartment during the unloading process and the loose goods (6) conveyed between the aircraft parking area and the opening of the cargo compartment. The preferred loose goods in the system are baggage. In the conveying system, goods can be conveyed into the fuselage in the axial direction lateral to the vertical direction of the aircraft or in the vertical direction and piled up in the cargo compartment (1); during the unloading process, the loose goods (6) sent back to the opening of the cargo compartment can be sent out in the axial direction lateral to the vertical direction of the aircraft through the opening of the cargo compartment. Meanwhile, the conveying system provides the intermediate conveyor apparatus used for the system; furthermore, the conveying system provides the replacement form of the intermediate conveyor apparatus and the conveyor element.

Owner:TELAIR INTERNATIONAL GMBH

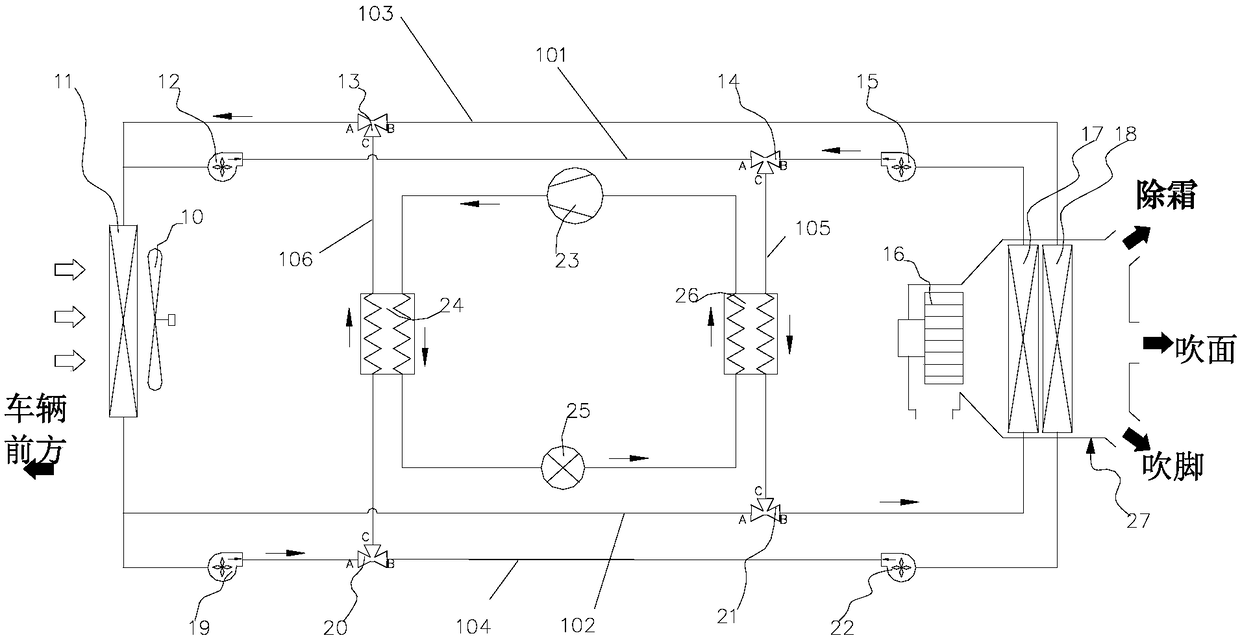

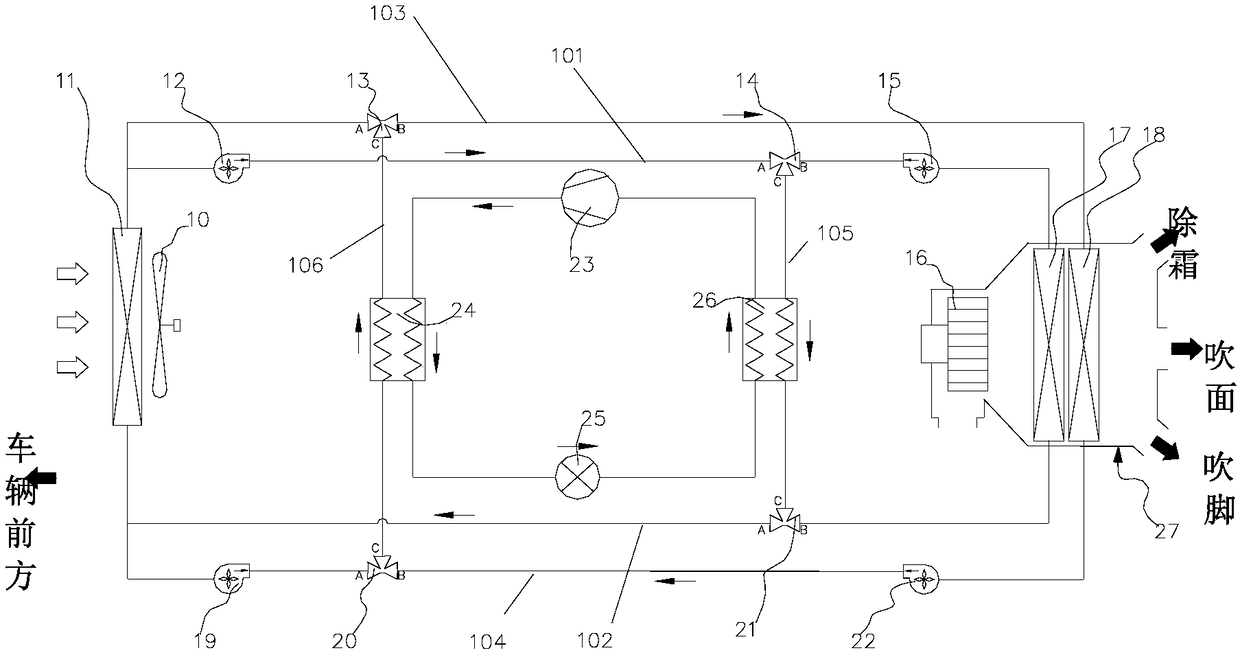

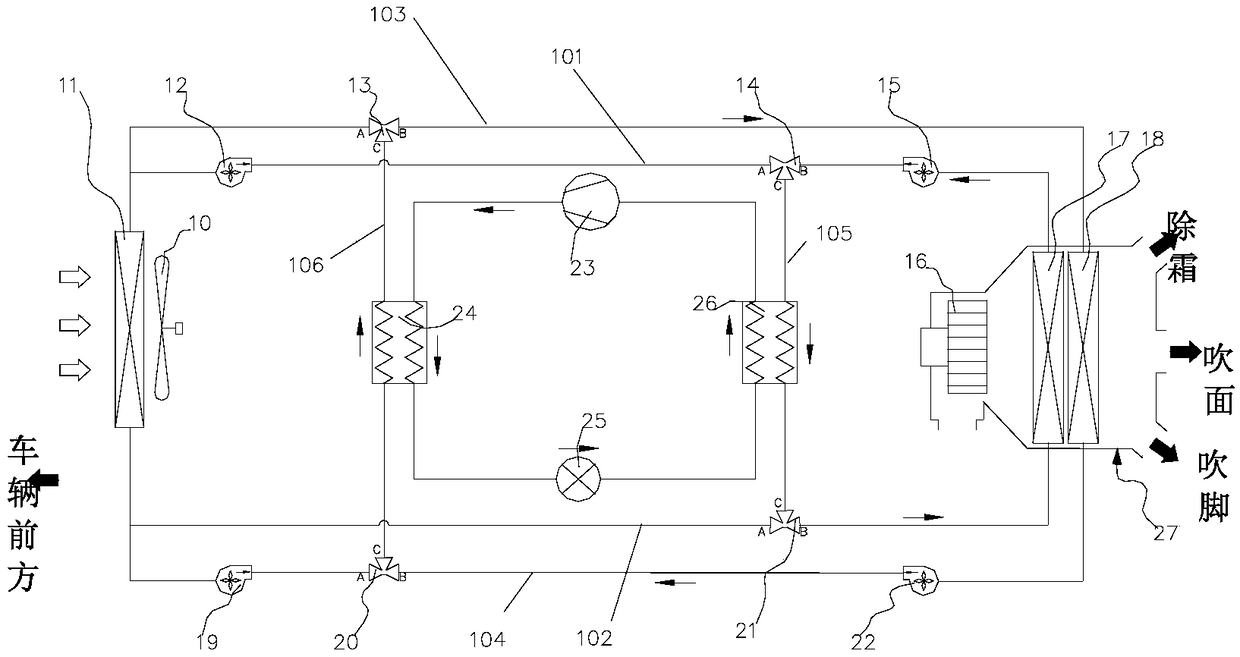

Heat pump air conditioner and control method thereof

ActiveCN109383228AAvoid LeakageEliminate health hazardsAir-treating devicesVehicle heating/cooling devicesEngineeringWater circulation

The invention provides a heat pump air conditioner and a control method thereof. The heat pump air conditioner comprises a refrigerant circulation loop and an indoor heat exchanger (27); the refrigerant circulation loop consists of a compressor (23), an intermediate condenser (24), an intermediate evaporator (26) and a throttling device (25); the indoor heat exchanger (27) capable of achieving refrigeration or heating in a room can exchange heat with the intermediate evaporator (26) or the intermediate condenser (24) through a water circulation loop in which water flows. The heat pump air conditioner can effectively prevent refrigerant leakage caused by the connection of a refrigerant pipeline into the room and effectively avoid harm caused to people in vehicles or indoors, and the use safety and reliability of the heat pump air conditioner are improved. As the water circulation loop is adopted for heat exchange with air, valve parts, including electromagnetic valves, reversing valvesand the like which are resistant to high pressure, high temperature and corrosion are effectively reduced, the development cost is greatly reduced, the fault probability is effectively decreased, andrunning is safer and more reliable.

Owner:GREE ELECTRIC APPLIANCES INC

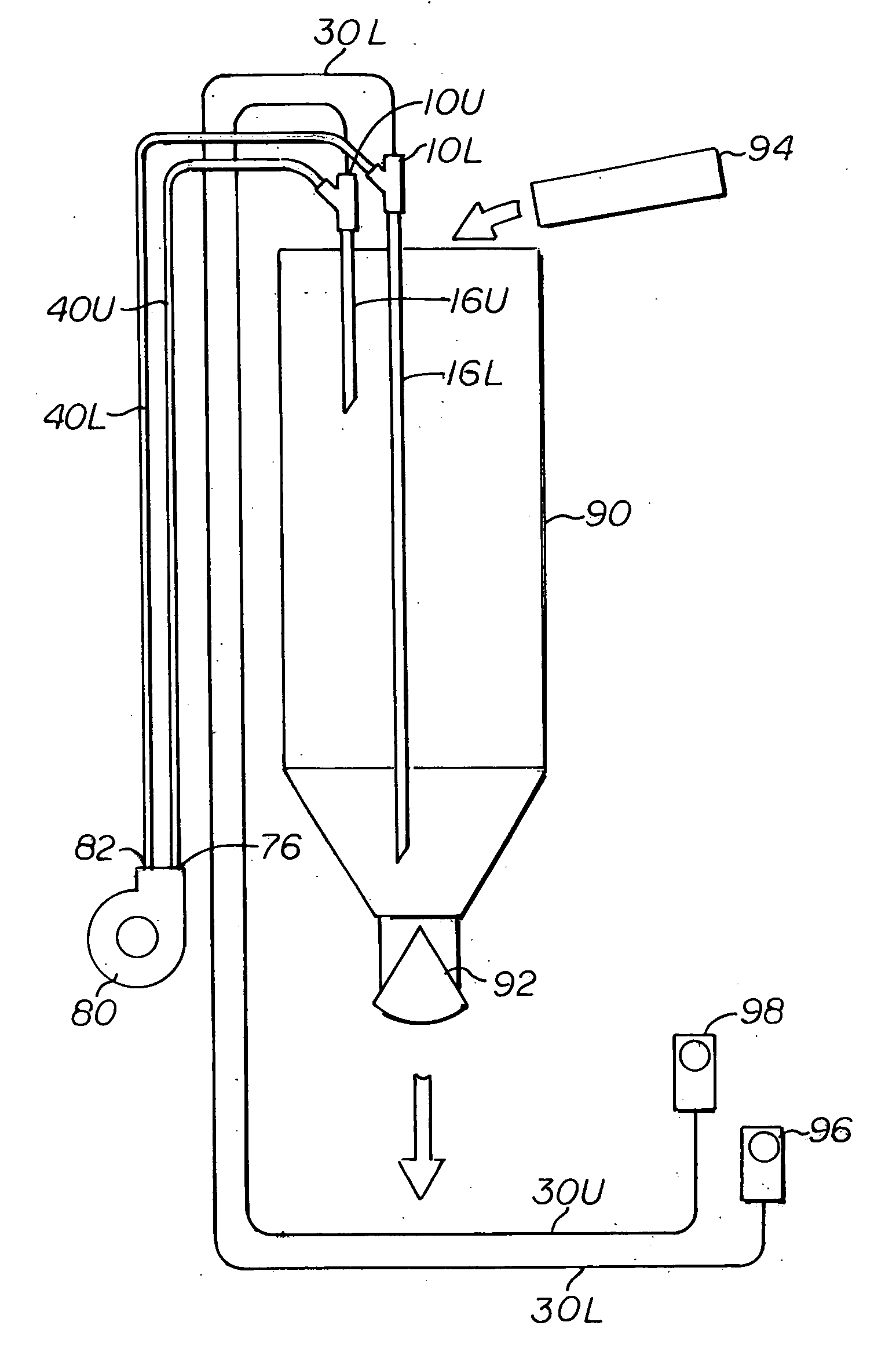

Bin level indicator

InactiveUS20070039384A1Reduce labor costsEliminate health hazardsLiquid fillingMachines/enginesEngineeringPressure increase

A sensor involving a housing having a lower orifice to which a primary hose is connected. A secondary hose inside the primary hose is slightly shorter than the primary hose, with these hoses being placed inside a bin for determining fill level. One of two upper orifices in the housing is connected to a supply of air under pressure, with this air normally caused to flow outwardly from one of the hoses. Upon the degree of the fill of the bin being such that the material approaches the remote end of one of the hoses, the air normally flowing from the one hose is caused to be deflected into the remote end of the other of the hoses, causing a pressure increase. This pressure increase is directed through the other upper orifice, for being sensed at remotely located pressure sensing equipment.

Owner:SMITH DANIEL R

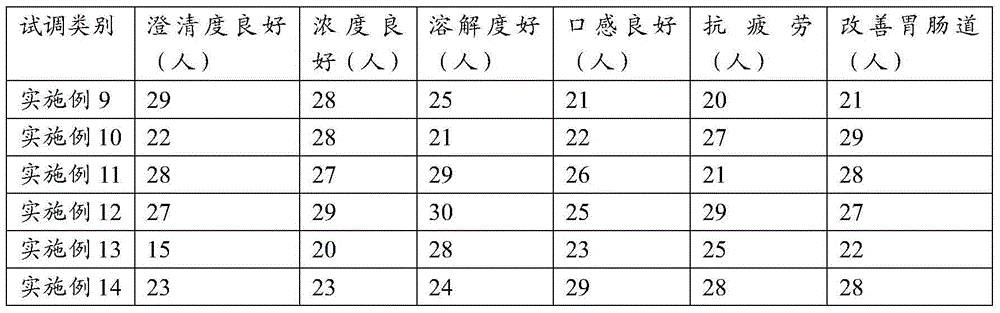

Maca coffee and preparation method thereof

The invention discloses a Maca coffee which comprises the following components in parts by weight: 1-15 parts of Maca extract, 5-50 parts of coffee, 5-30 parts of fructo oligosaccharides, 5-30 parts of polydextrose, 10-60 parts of erythritol and 0-5 parts of sucralose. The Maca coffee can be prepared into Maca coffee solid drinks, Maca coffee tea or Maca coffee candy through a preparation method of the Maca coffee; by combining Maca and coffee, the mouth feel of the Maca can be greatly improved, the effect of relieving physical fatigue can be prolonged; in addition, based on conventional solid drinks, the effects of improving the intestinal flora and promoting the absorption of mineral elements are achieved, more importantly, the range of crowds is enlarged, more choices are provided for the crowds suffering from obesity, high blood pressure, high blood lipid and high blood sugar, and the health hidden danger of a consumer is eliminated.

Owner:IDEALITY TECH GRP

Soft capsule of active rhizoma gastrodiae, and its prepn. method

InactiveCN1868526APromote absorptionImprove bioavailabilityNervous disorderCapsule deliveryGastrodiaMedicine

An active gastrodia soft capsule with both medical and health-care functions is composed of a core prepared from superfine active gastrodia powder extracted from gastrodia tuber, special plant oil rich in lenolenic acid (20% or more), and suspending agent, and a shell prepared from gelatin, water, glycerine and polyethanediol. Its preparing process is also disclosed.

Owner:云南龙威生物产业有限公司

Chicken manure organic fertilizer and preparation method thereof

InactiveCN107266183AIncrease productionAvoid erosionBio-organic fraction processingExcrement fertilisersMicrobial agentMushroom

The invention provides a chicken manure organic fertilizer and a preparation method thereof, and relates to the technical field of fertilizers. The chicken manure organic fertilizer is mainly prepared from, by mass, 30-40 parts of chicken manure, 10-20 parts of wheat bran, 10-20 parts of zeolite powder, 10-20 parts of needle mushroom residues, 5-10 parts of tobacco powder, 5-10 parts of sugar cane pomace, 1-5 parts of silkworm excrement and 1-5 parts of a composite microbial agent, the composite microbial agent is a mixture containing Aspergillus oryzae, Bacillus subtilis, yeast, actinomycetes, ammonifying bacteria and photosynthetic bacteria according to a mass ratio of (1-3):(1-3):(1-3):(1-3 ):(1-3):(1-3). The chicken manure organic fertilizer alleviates the technical problem of crop insect diseases brought by the direct application of existing chicken manure to the field, reaches the harmlessness of parasites, eggs and pathogens existing in the chicken manure, increases the crop yield, can kill and repel pests, makes crops green and safe, and eliminates people's hidden health troubles.

Owner:CHONGQING CITY WANYUAN EGGS FOOD

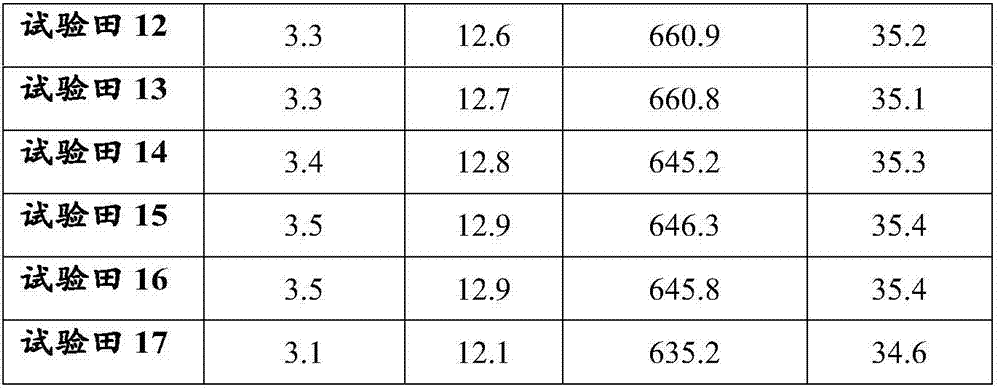

Comprehensive recovering method for tailings containing precious metal

ActiveCN105132694AEffective recyclingThe process is clean and environmentally friendlyProcess efficiency improvementBrown iron oxideLead smelting

The invention discloses a comprehensive recovering method for tailings containing precious metal. The comprehensive recovering method specifically includes the following steps that the tailings are led into oxygen to be subjected to oxidizing roasting; oxidation leaching is conducted on zinc calcine through sulfuric acid, most of iron is removed, a leaching agent is evaporated and crystallized, and industrial iron sulfate is obtained; after chloridizing leaching is conducted on leaching slag through sulfuric acid and sodium chloride, the leaching slag serves as lead-rich slag to be sent to a lead smelting enterprise; replacement is conducted on the leaching agent through iron powder, and crude gold and silver mixtures are obtained and sent to a precious metal deep processing system; and PH of replacement fluid is adjusted through ammonium water or sodium hydroxide, iron is deposited, obtained ferric hydroxide is roasted to obtain iron oxide red, and the iron oxide red serves as the raw material of the coating industry. According to the technology method, the influences on the environment due to long-term stacking of the kind of slag are eliminated, the process is clean and environmentally friendly, and secondary pollution is avoided.

Owner:甘肃高能中色环保科技有限公司

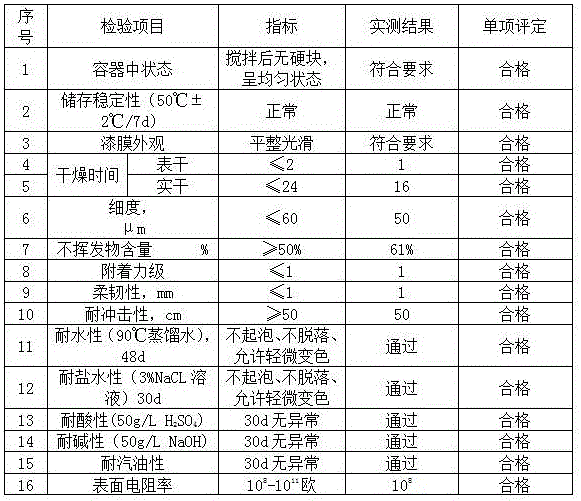

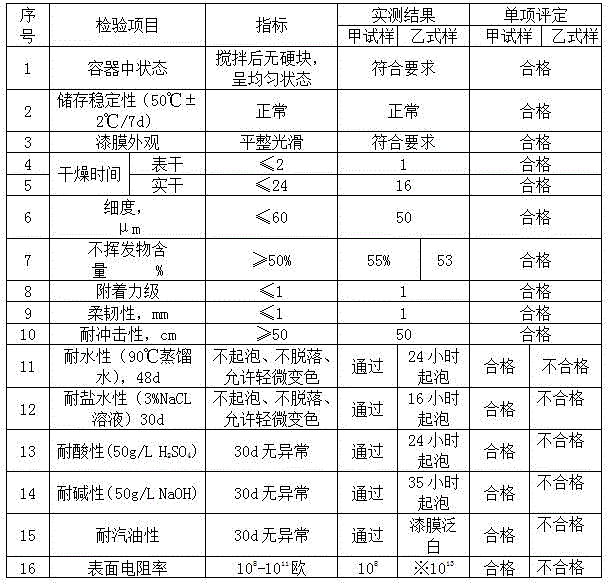

Anti-corrosion waterborne epoxy static electricity conducting paint and preparation method and application thereof

ActiveCN106634410AEliminate health hazardsNo health effectsAnti-corrosive paintsSpecial surfacesEpoxySodium Bentonite

The invention discloses waterborne epoxy static electricity conducting anti-corrosion paint, which is prepared from the following method including the steps that 1, water and waterborne dispersing agents are pre-mixed; then, the mixture is added into epoxy resin emulsion to be uniformly stirred; talcum powder, precipitated barium sulphate, titanium dioxide and bentonite are added step by step; high-speed uniform scattering is performed, then, the materials are ground until the fineness is smaller than 50 micrometers; then, the rest waterborne epoxy resin emulsion and the conducting powder are added; the mixture is uniformly stirred; wetting agents are added; the mixture is uniformly stirred; defoaming agents, flatting agents and flash-rust inhibitors are added step by step; diluted waterborne thixotropic agents are added; the materials are uniformly stirred; water is added for regulating the viscosity; an ingredient A is obtained; 2, water and ethyl alcohol are used for proportionally diluting waterborne epoxy curing agents to obtain an ingredient B; 3, the ingredient A and the ingredient B are respectively packaged according to the construction mixture ratio for simultaneously forming the waterborne epoxy static electricity conducting anti-corrosion paint. The paint can be used for the inner wall coating of steel crude oil storage tanks or petrochemical engineering steel intermediate product storage tanks and finished product oil steel storage tanks; obtained coatings have good protection functions of water resistance, oil resistance, chemical medium resistance, salt fog resistance, temperature resistance and the like.

Owner:湖北铁神新材料有限公司

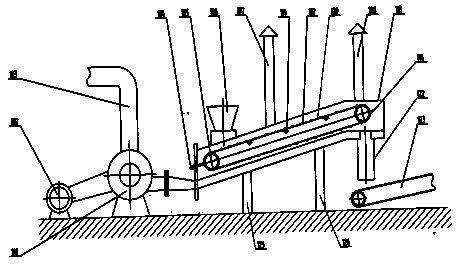

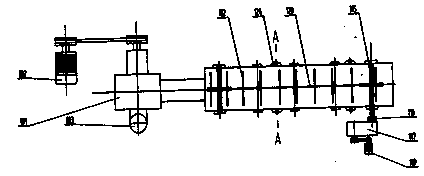

Preparing method of iron powder for powder metallurgy

InactiveCN103447539AHeating and drying fully and evenlyFaster heating and dryingTunnel kilnCardboard

The invention provides a preparing system of iron powder for powder metallurgy. The preparing system comprises a chain-type dual-chamber raw material drying device, structure of an upper drying chamber and a lower drying chamber is adopted, and gas with waste heat discharged from a tunnel kiln is utilized to heat and dry. A raw-material iron powder loading device adopts a paper-board round sleeve unit, so that the surface of obtained primarily reduced iron is smooth and easy to clean. According to the tunnel kiln used for reduced iron powder, a kiln top water tank covering the entire kiln top is mounted on the top of the kiln wall in a third temperature zone, hot water in the kiln top water tank is leaded into a heat supply system and a hot water supply system through hot water discharging pipes, and energy is saved greatly. According to a reduced iron cleaning device, the problem of long-time manual cleaning in the industry is solved, and health hazards of cleaning workers due to dust are eliminated. The iron powder produced by a method for powder metallurgy is high in purity, medium in Poisson ratio, and high in compression, strength and formability, and can be used for producing porous, semi-dense or fully dense material and products.

Owner:JILIN HUAXING POWDER METALLURGY TECH

Environmentally compatible processes compositions and materials treated thereby

InactiveUS20050284822A1Increase productionEliminate health hazardsBiocidePeroxide active ingredientsCell culture mediaCopper

Owner:PIMI AGRO CLEANTECH

Environmentally compatible processes compositions and materials treated thereby

InactiveUS6946155B2Increase productionEliminate health hazardsBiocideInorganic active ingredientsVegetable matterAgricultural science

Environmentally friendly processes for prevention of qualitative deterioration and quantitative loss of plant matter and foodstuffs, during all stages of storage and handling, including pre- and post-harvest, pre- and post-planting, distribution and marketing involves the use of H2O2 compositions including Ag and at least one of Cu and Zn ions. The processes can also be used to prevent sprouting and rooting, and to promote fecundity of certain plant matter, and can also be used to eliminate or reduce quantities of harmful organisms and substances from soil, other growth media and substrates, equipment, materials water, workspaces and surfaces.

Owner:PIMI AGRO CLEANTECH

Low formaldehyde melamine adhesive with expanding characteristic and preparation method

The melamine resin prepared with formaldehyde and melamine as main material and in the presence of Lewis acid or alkali has free formaldehyde content of about 0.1 %. The adhesive possesses excellent expansion performance during formation and is suitable for use in producing various kinds of board. The products with the adhesive have low formaldehyde release amount, excellent mechanism performance, excellent weather resistance, etc. The liquid resin may be spray dried to prepare melamine adhesive powder capable of maintaining reaction activity for long time. The adhesive of the present invention has no need of adding formaldehyde trapping agent.

Owner:倪卓

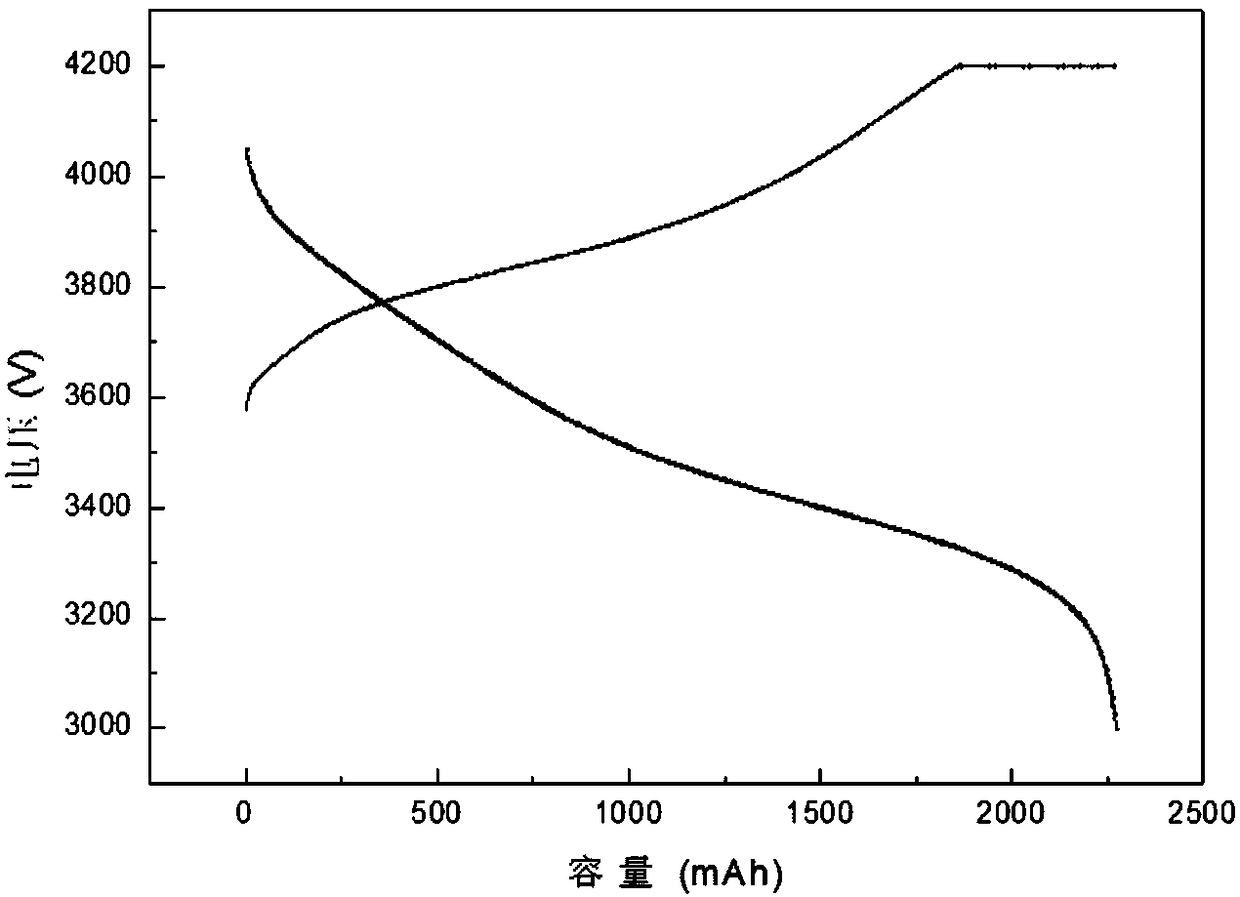

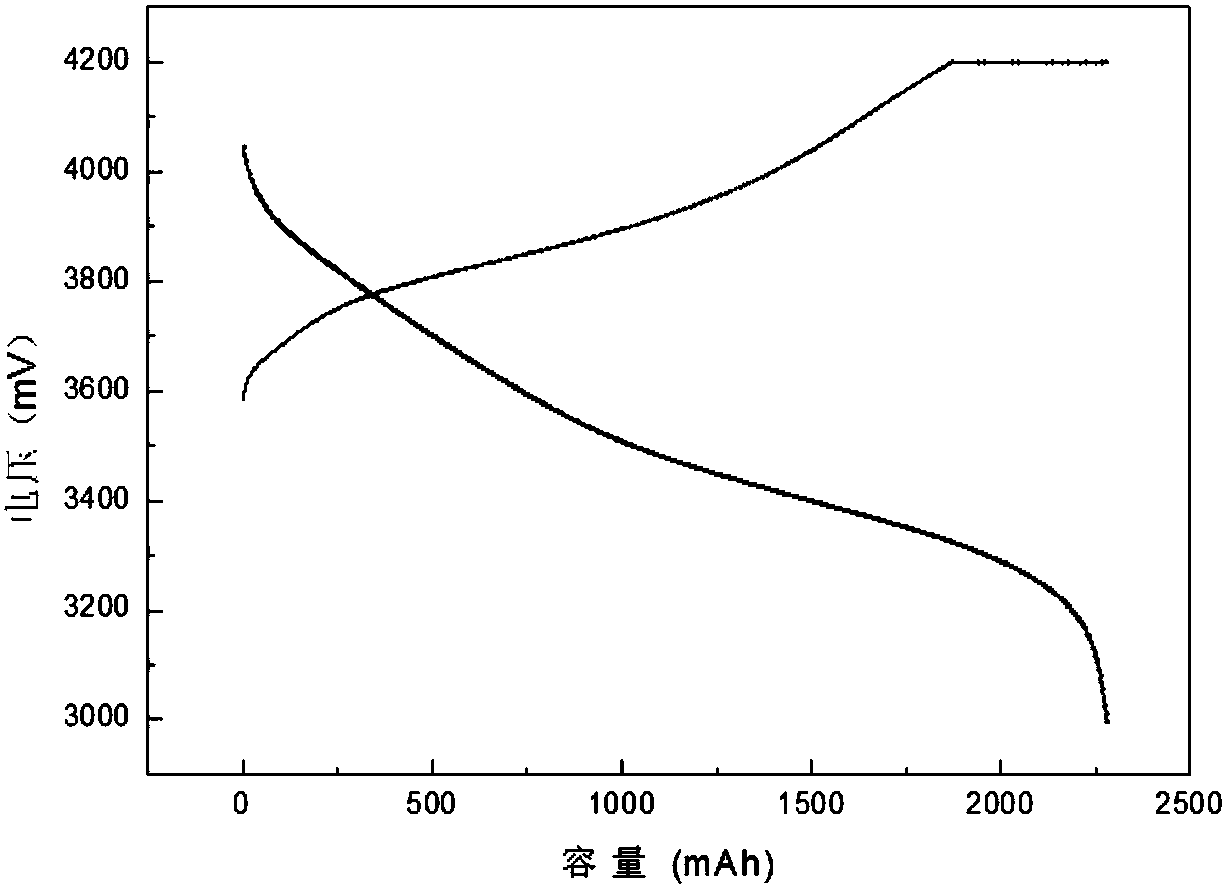

Lithium ion battery anode material, lithium ion battery anode piece as well as preparation method thereof and lithium ion battery

InactiveCN108155386AReduce processing costsReduce pollutionSecondary cellsNon-aqueous electrolyte accumulator electrodesAluminium-ion batterySlurry

The invention provides a lithium ion battery anode material, a lithium ion battery anode piece as well as a preparation method thereof and a lithium ion battery, which relates to the technical field of electrode material preparation methods. The lithium ion battery anode material comprises an anode active substance, a conducting agent and a binder, wherein the binder at least comprises a polyacrylamide binder; and the technical problem of the traditional lithium ion battery anode piece that in the process of slurry preparation, the use of the N-methyl pyrrolidone as a solvent pollutes the peripheral environment and harms the body health of working personnel, and the production cost can be increased can be solved, and the technical effects that the environmental pollution in the slurry preparation process can be reduced, the health potential hazard of a human body can be eliminated, the energy can be saved, and the processing cost of the lithium ion battery can be decreased can be achieved by adopting the binder at least comprising the polyacrylamide binder to substitute polyvinylidene chloride and using the water as the solvent in the slurry preparation process.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

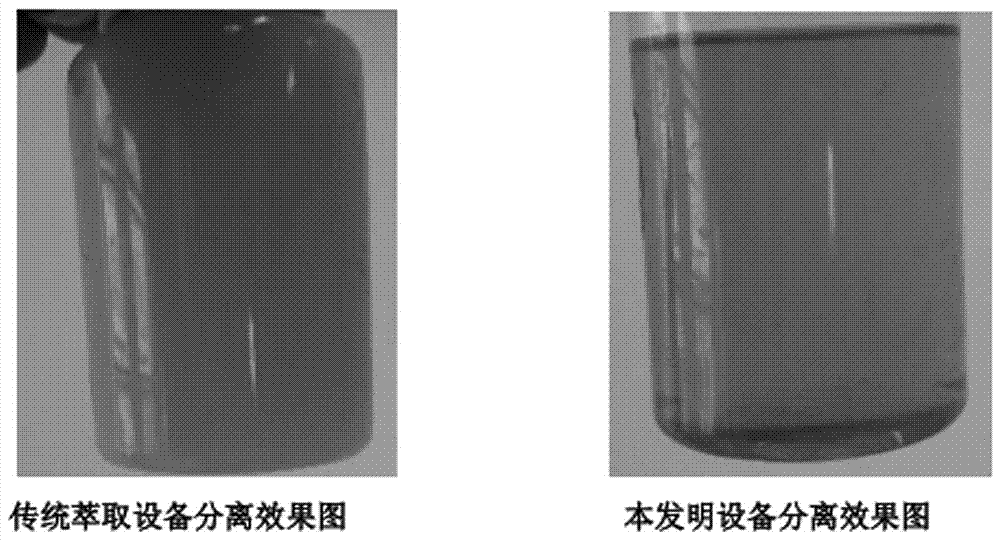

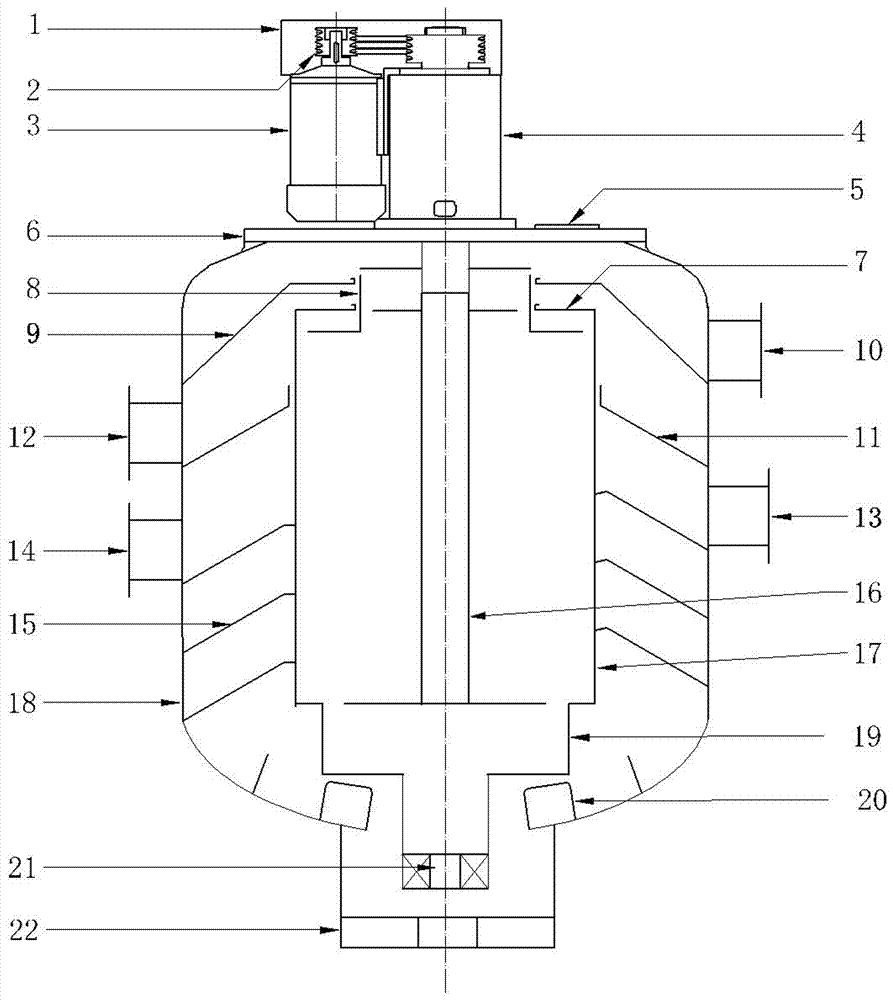

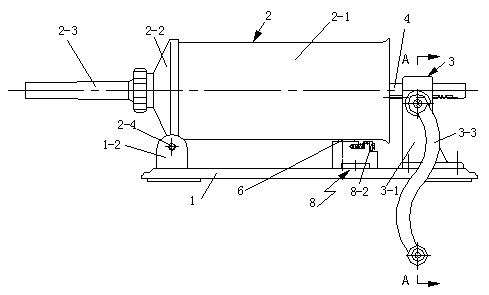

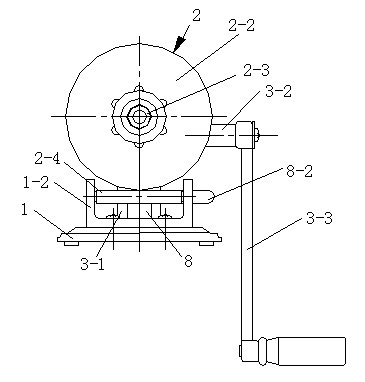

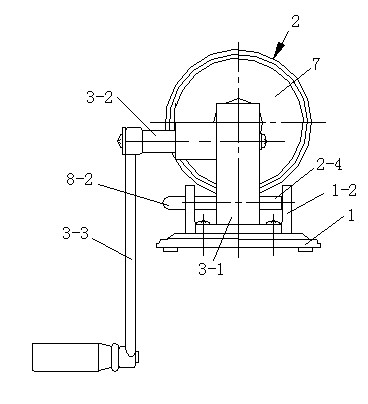

Method for extracting citric acidby employingcentrifugal extractor

ActiveCN107050924AImprove the mixing effectHigh extraction rateCounter-current extractionLiquid solutions solvent extractionEmulsionSmall footprint

The invention discloses a method for extracting citric acidby employinga centrifugal extractor. The centrifugal extractor comprises an extraction section, a washing section and a re-extraction section. After the efficient centrifugal extractor is applied to the extraction method of citric acid, the two-phase separation efficiency is obviously improved, and meanwhile emulsion phenomenon in the traditional technology is obviously improved; in addition, in the technical condition, wastes are hardly produced in the re-extraction section; the equipment is small in floor space, and the stage efficiency is further obviously improved; as the novel and efficient centrifugal extractor adopts totally sealed equipment, the sharp flavor of an extraction agenthardly exists in an operation site, the operating environment is greatly improved, and the health hazard of operating personnel during production is eliminated.

Owner:ZHENGZHOU TIANYI EXTRACTION TECH

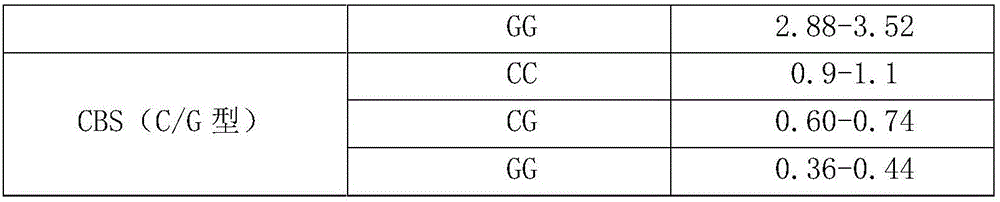

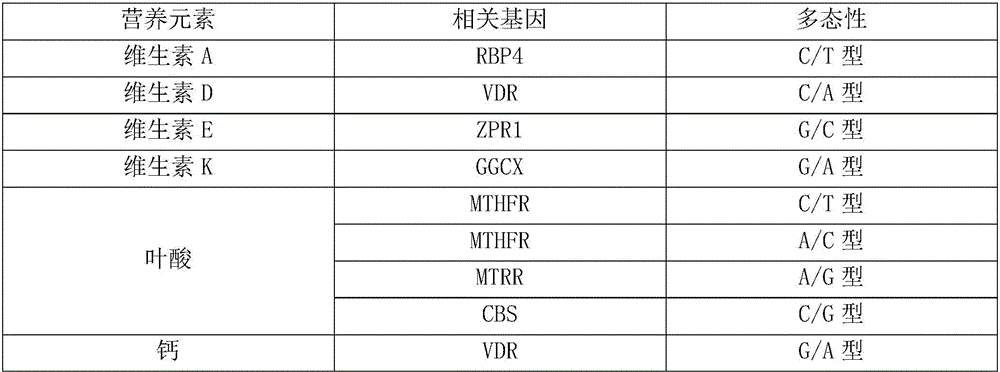

Gene detection method for evaluating intake of nutrient elements

InactiveCN106884042AEliminate health hazardsPrecise and comprehensive nutrition and health guidanceMicrobiological testing/measurementDesalinationDesign software

The invention provides a gene detection method for evaluating intake of nutrient elements. The method is characterized by comprising the steps of 1, designing a polymerase chain reaction (PCR) amplification primer and a single base extension reaction primer according to online primer design software; 2, after diluting a DNA sample to be detected, conducting PCR amplified reaction, shrimp alkaline phosphatase treatment reaction, single base extension reaction of genes to be detected, sample desalination and application of the sample to a chip; 3, analyzing the gene type of the DNA sample to be detected by means of the single nucleotide polymorphism typing detection technique; and 4, obtaining a genetic typing result according to obtained data.

Owner:北京东方亚美基因科技研究院有限公司

Device and method for high polymer material burning harmless treatment

InactiveCN102434888AReduce pollutionAchieve clean emissionsIncinerator apparatusTunnel kilnToxic gas

The invention discloses a device and a method for high polymer material burning harmless treatment. A high temperature pyrolysis tunnel furnace with an insulating layer is arranged between a combustion furnace and a heat exchange device, a smoke inlet of the tunnel furnace is connected with a smoke outlet of the combustion furnace, and a smoke outlet of the tunnel furnace is connected with the heat exchange device. A tunnel in the tunnel furnace is isolated to be an A tunnel cavity, a B tunnel cavity and a C tunnel cavity which are communicated in a head-and-tail mode and in a shape of an S through a front partition wall and a back partition wall. A furnace opening fan, a furnace opening temperature measurement device and an external heating source are respectively arranged at the smoke inlet of the tunnel furnace. An excess air measurement device and a furnace end temperature measurement device are respectively arranged at the smoke outlet of the tunnel furnace. A tunnel temperature measurement device and a tunnel fan are respectively arranged in the middle of the tunnel furnace. Dioxin, cyanide and other toxic gas in the smoke can complete a pintsch process to become nontoxic micromolecule gas, harmless clean discharge of the combustion furnace is achieved, pollution to the neighboring environment is reduced, and safety hidden dangers of people are removed.

Owner:冯之军

Visible light curing nail enamel and preparation method thereof

InactiveCN105012160AEliminate health hazardsCause health damageCosmetic preparationsToilet preparationsSodium bicarbonateUltraviolet lights

The invention belongs to the technical field of material chemistry, and particularly relates to visible light curing nail enamel and a preparation method thereof. The visible light curing nail enamel comprises the components: 2-98wt% of oligomer, 2-98% of reactive diluent, 0.01-10wt% of visible light initiating agent, 0.01-1wt% of brightening agent and 0-10wt% of pigment. The nail enamel can be cured under the irradiation of visible light with wavelength of 380-780nm, and the harm of ultraviolet light to the skin is avoided; the nail enamel can be rapidly dried in a visible light curing nail printer, and can also be slowly cured under the irradiation of sunlight or other common lighting sources. The visible light curing nail enamel is free of toxic organic solvent or film coalescing aid and safe to use, is guaranteed to be bright lastingly and not easy to drop after being dried, is insoluble in daily oil or water solutions, but can be removed by saline solution or sodium bicarbonate water solution without grinding, so that the harm to the nails is avoided, and the condition that the fine particulate matters are inhaled to affect the lung health is also avoided.

Owner:FUDAN UNIV +1

System for loading and unloading unpakced cargo and intermediate transport device or unit

InactiveCN101239657AEliminate the use of manualReduce labor costsWeight reductionFreight handling installationsFuselageAirplane

The invention relates to a system for loading or unloading loose goods (6), preferably luggage, etc., in an aircraft cargo hold (1), comprising, during the loading process, feeding the loose goods (6) into the interior of the cargo hold (1) end, or from there during unloading, and includes the transfer of loose cargo (6) between the ramp level and the hold opening. In the system of the invention, loose cargo (6) can be fed into the fuselage during loading in a direction transverse to the longitudinal axis of the aircraft and in the longitudinal direction of the aircraft and stacked in the hold (1). During unloading, loose cargo (6) sent back into the cargo hold opening of the aircraft can be sent out through the cargo hold opening in a direction transverse to the longitudinal axis of the aircraft. Furthermore, the invention proposes an intermediate conveyor device (2) for the system. Furthermore, the invention also identifies alternatives to the system, intermediate conveyor means and conveyor units.

Owner:TELAIR INTERNATIONAL GMBH

Filling machine

ActiveCN102125077ANot easy to residueSave foodSausage filling/stuffing machinesEngineeringPiston rod

The invention discloses a filling machine used for extruding food stuff, and the filling machine provided by the invention comprises a charging barrel, a piston, a piston rod, a base and a piston rod driving device, wherein the front end of the charging barrel is provided with a taper hopper; the piston is fixedly connected with the piston rod; the piston is in sliding fit with the inner wall of the charging barrel; the piston rod driving device is in transmission connection with the piston rod; the piston is provided with a conical surface; and the conical surface is matched with the inner taper wall surface of the taper hopper. The filling machine can be used for extruding the food stuff in the taper hopper, and the food stuff has less possibility of being left in the taper hopper, so that the food stuff can be saved, the hidden health hazard is eliminated, and the filling machine is convenient to clean.

Owner:CHANGZHOU HANHUA KITCHENWARE

Cotton core and preparing method thereof

InactiveCN104018292AWill not affect healthImprove insulation effectInspecting textilesNon-woven fabricsEngineeringEnvironmentally friendly

The invention relates to a cotton core which comprises a first non-woven fabric layer, a cotton layer and a second non-woven fabric layer. The cotton layer is arranged between the first non-woven fabric layer and the second non-woven fabric layer in a sandwiched mode, and the cotton core has the advantages of being environmentally friendly and long in service life. The preparing method of the cotton core includes the following steps of cotton assorting, cotton supplying, opening, cotton mixing, cotton feeding, carding, net laying, baking and rolling. The preparing method of the cotton core further includes the following step of cloth laying. The cloth laying step is conducted between the net laying step and the baking step or between the baking step and the rolling step. The preparing method of the cotton core is simple in operation, mature in technology, high in production efficiency, low in defective rate and suitable for large-scale application and popularization.

Owner:DONGGUAN SANYAN TEXTILE

Intelligent environmental regulation-based rearing cage

InactiveCN110972967ARealize Odor MonitoringAvoid spreadingLavatory sanitoryAnimal housingAnimal scienceEnvironmental regulation

The invention relates to the technical field of rearing cages, and discloses an intelligent environmental regulation-based rearing cage. The rearing cage comprises a cage, an electronic nose, a controller, an alarm apparatus and an atomizer; the atomizing direction of the atomizer is set towards the inside of the cage; the electronic nose is arranged in the cage; the electronic nose is electrically connected with the controller, and is used for detecting odor information in the cage; the controller is electrically connected with the alarm apparatus and the atomizer; and the controller is usedfor judging whether the odor information contains abnormal odor information or not; and if the odor information contains the abnormal odor information, the alarm apparatus is driven to give an alarm,and the atomizer is controlled to be started to perform atomizing disinfection. The rearing cage can monitor air quality therein and performs disinfection in time to guarantee the health of an animalrearing environment and the health of surrounding human beings.

Owner:YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com