System for loading and unloading unit loads into a cargo hold, in particular of an aircraft, and intermediate transport device or corresponding transport unit

A conveyor and conveying device technology, applied in the direction of equipment for loading and unloading goods, loading/unloading, equipment for transporting goods, etc., can solve problems such as high cost and shorten the life of aircraft, so as to reduce work costs and save labor. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

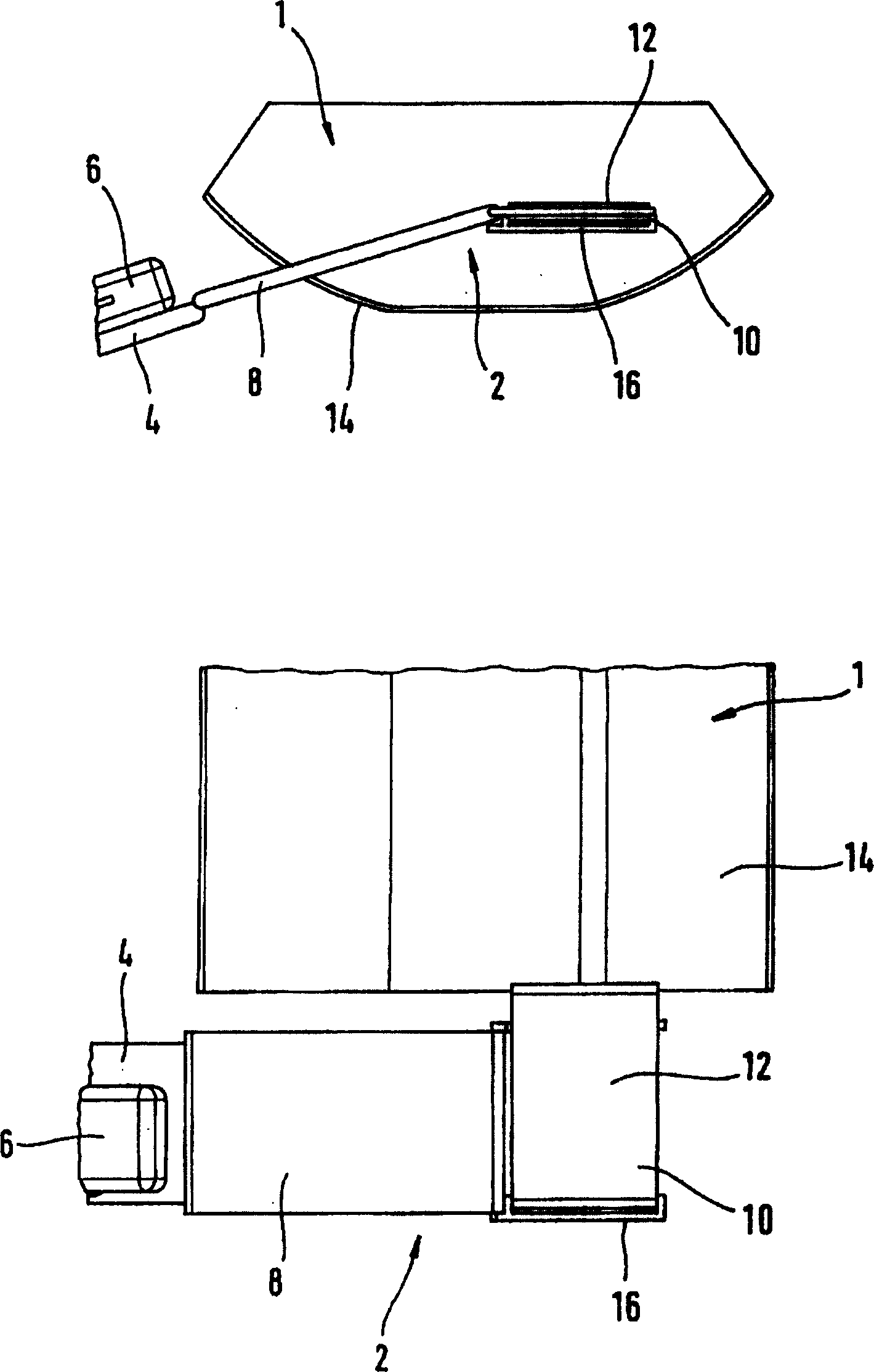

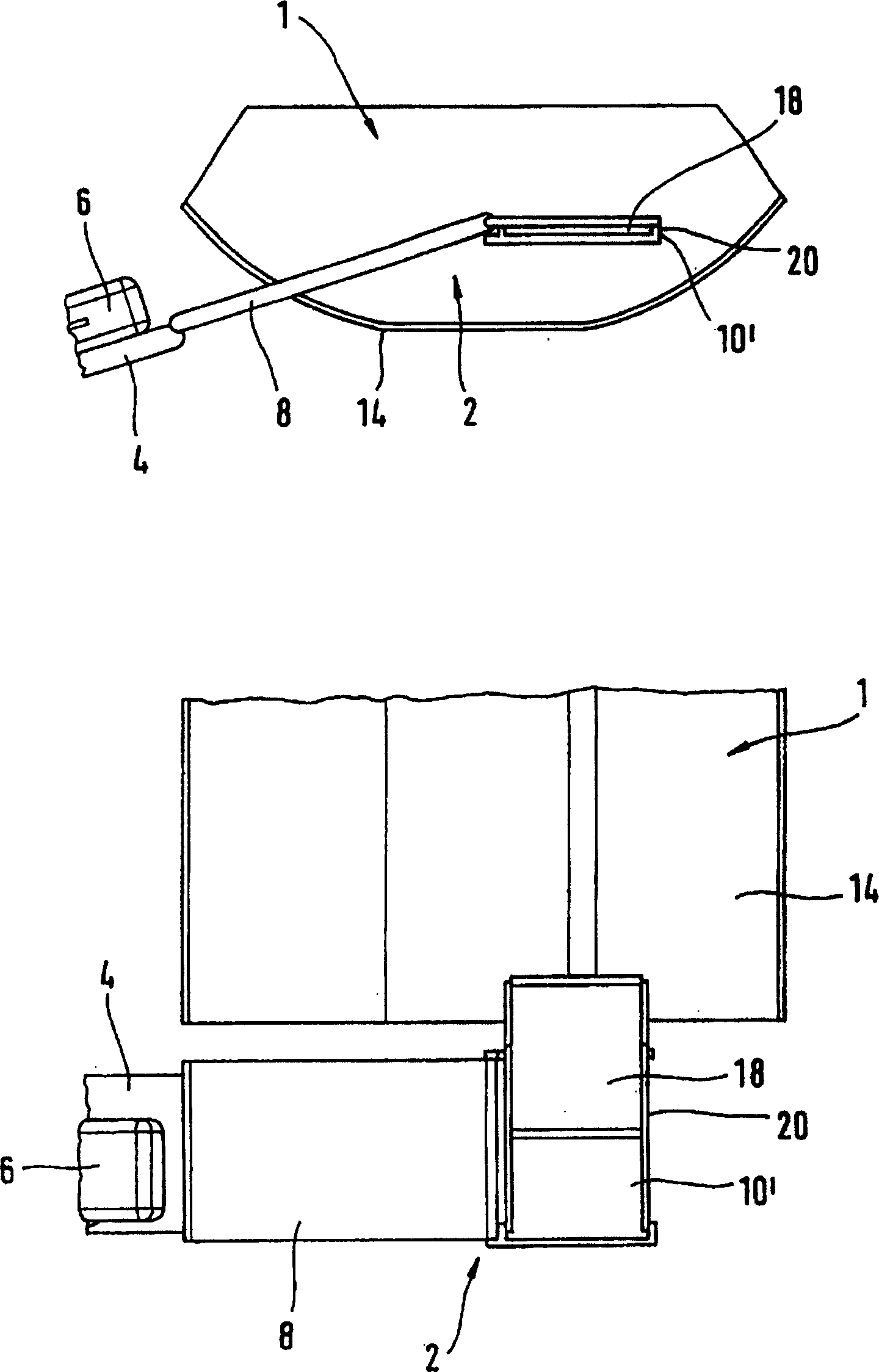

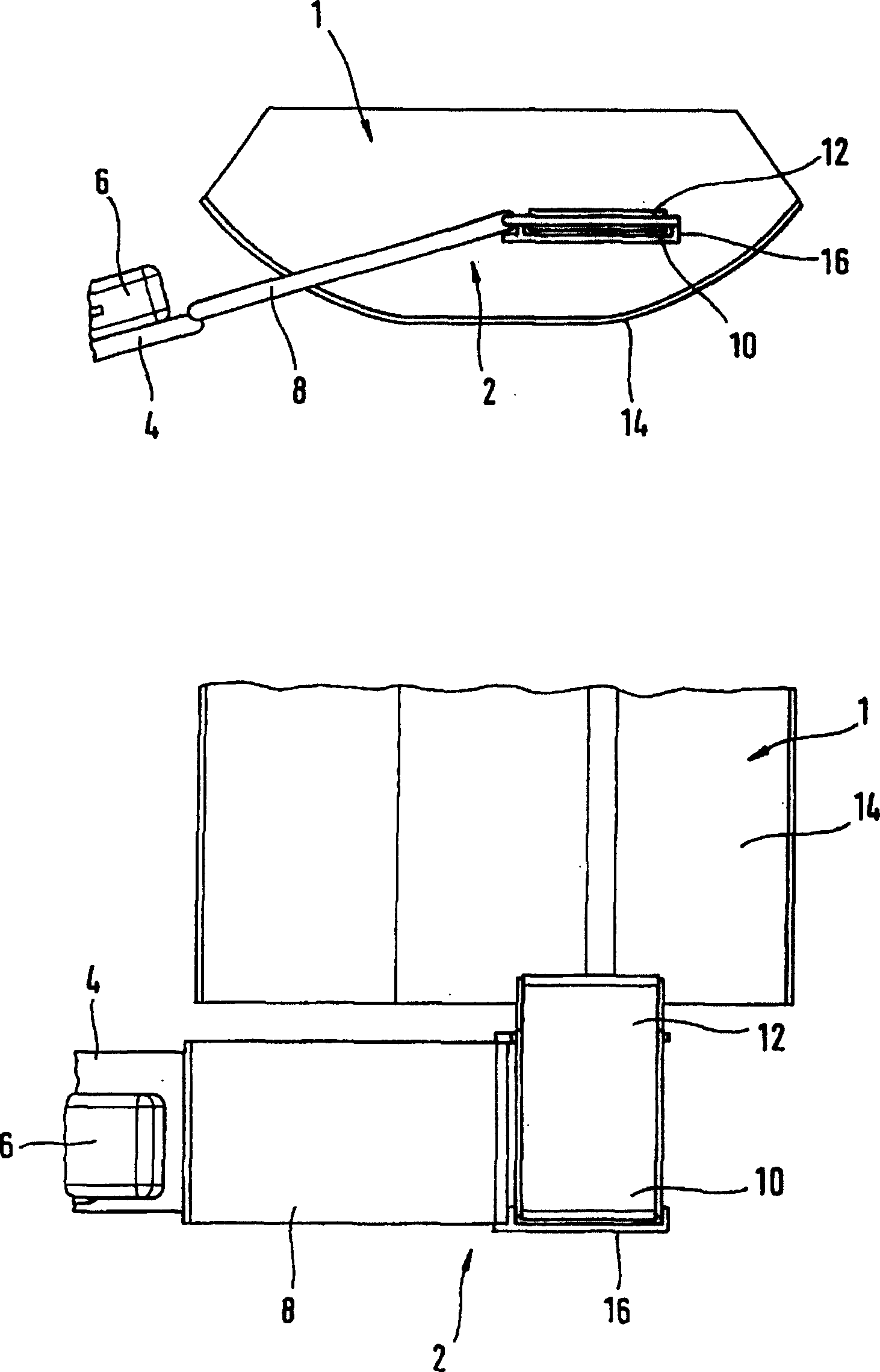

[0116] figure 1 A schematically simplified sectional view and a schematically simplified top view of a cargo compartment 1 of an aircraft (not shown) in which a first embodiment of an intermediate conveyor device 2 according to the invention is arranged, during loading is shown. The intermediate conveyor device 2 is connected to an apron conveyor mechanism 4, which is only partially shown in section, which conveys loose goods 6, which are partly shown in sectional view. According to the above description, the apron conveyor mechanism is capable of operating on the apron.

[0117] exist figure 1 Among them, the intermediate conveyor device 2 includes: a first conveyor mechanism 8, which enters the cargo hold 1 from the apron conveyor mechanism 4 through the cargo hold opening, and here, the first conveyor mechanism 8 Examples are in the form of a conveyor belt; and a second conveyor mechanism 10 . This second conveyor mechanism 10 comprises a conveyor part 12, which is, for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com