Patents

Literature

183results about How to "Reduced risk of damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

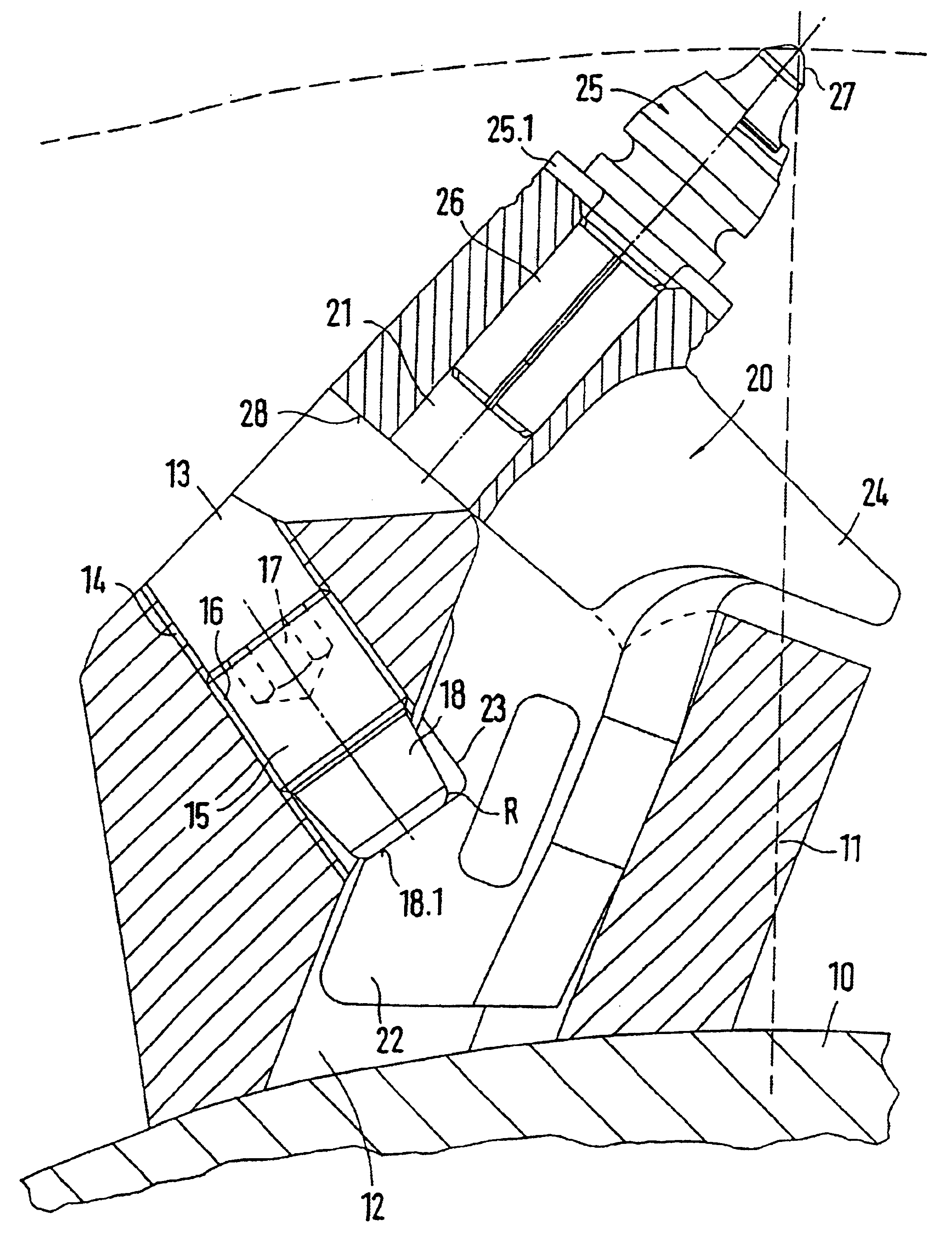

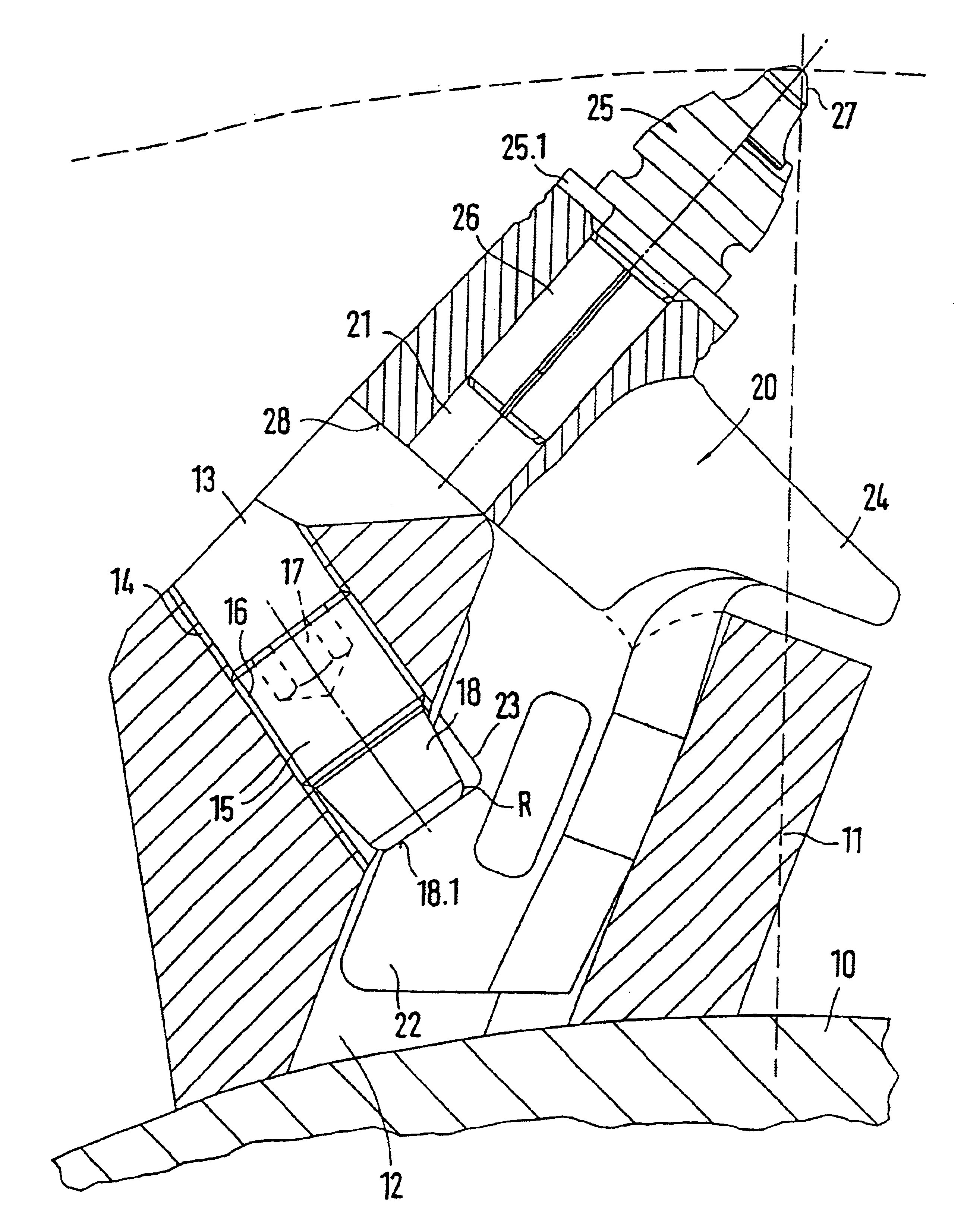

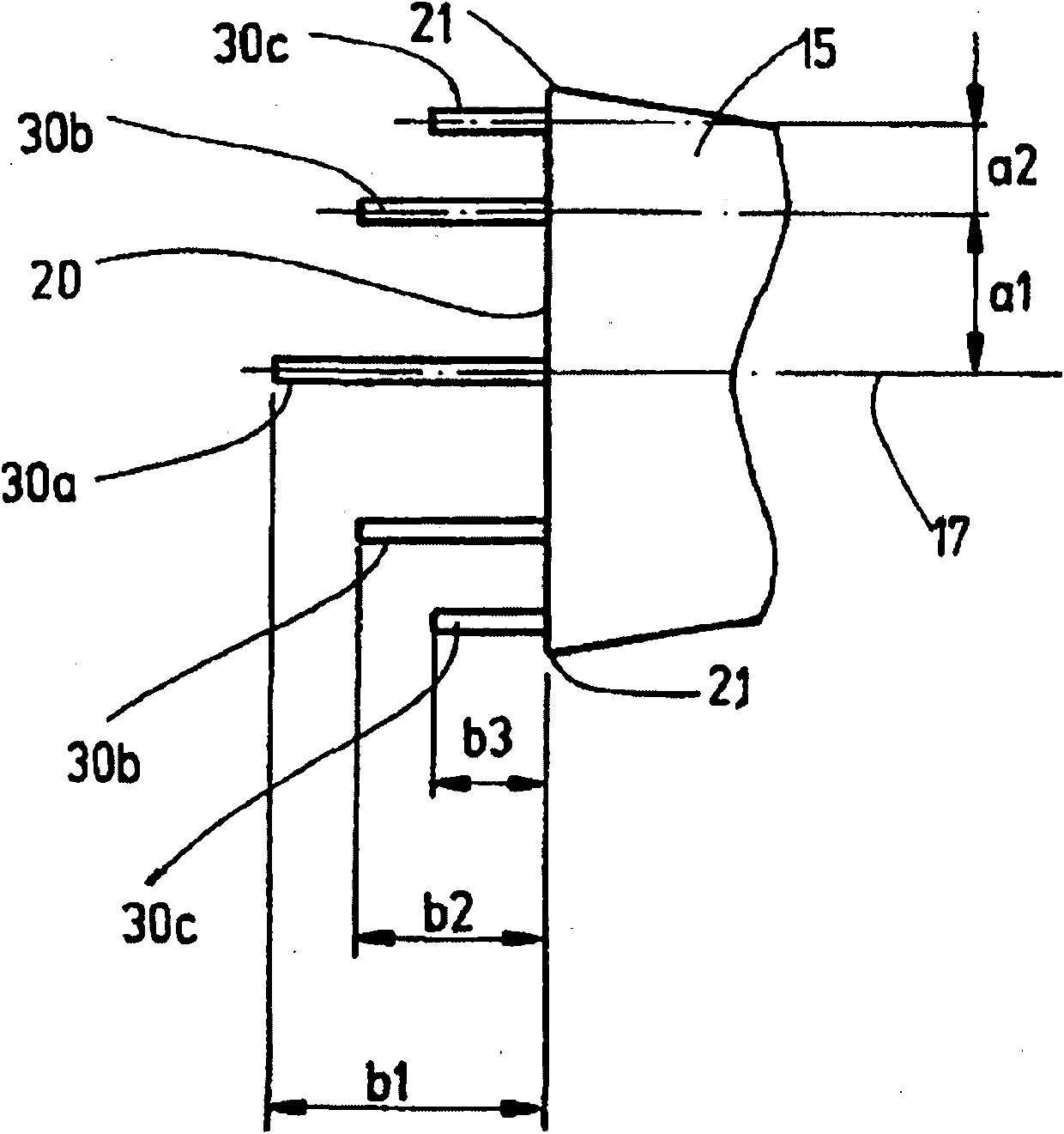

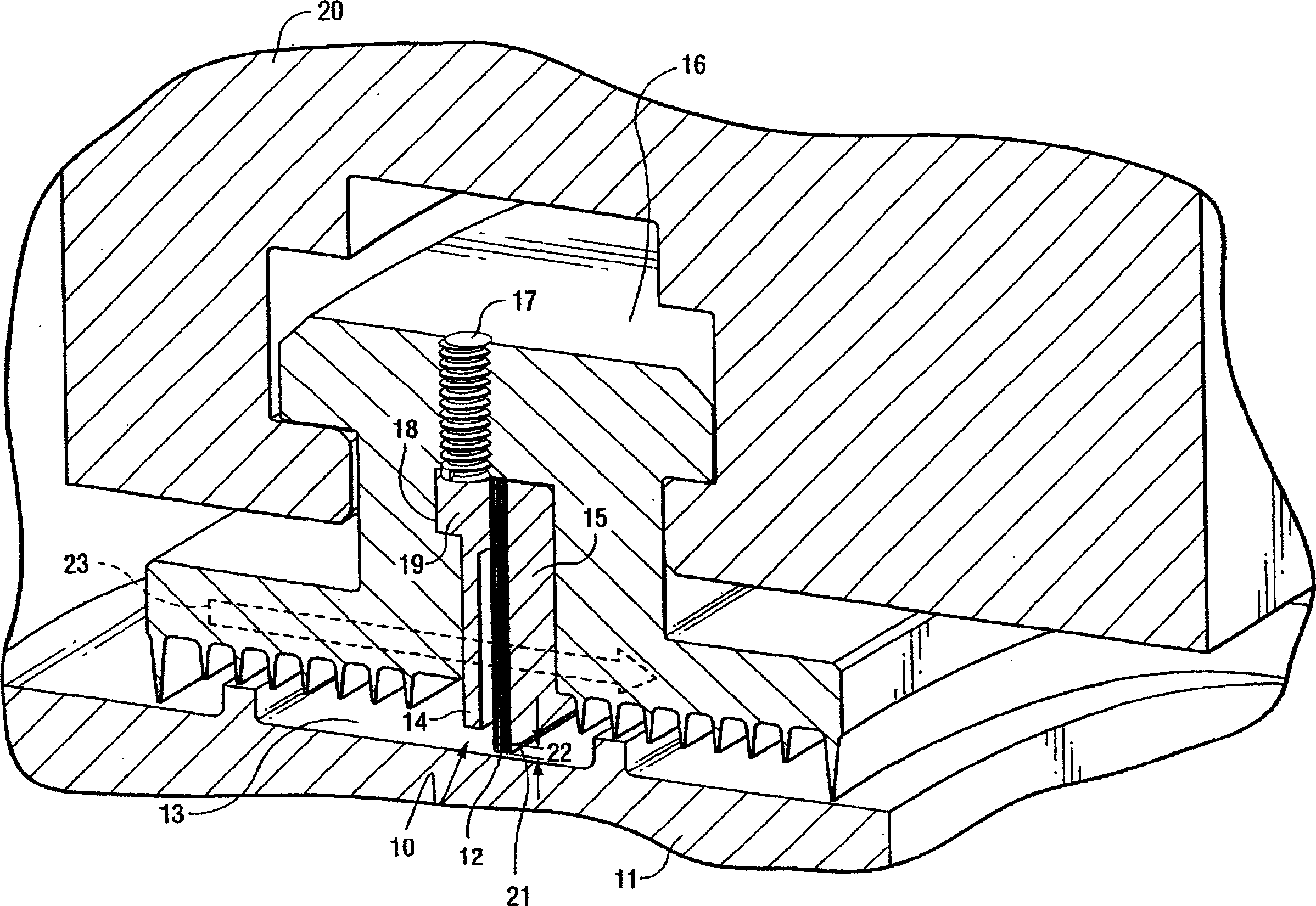

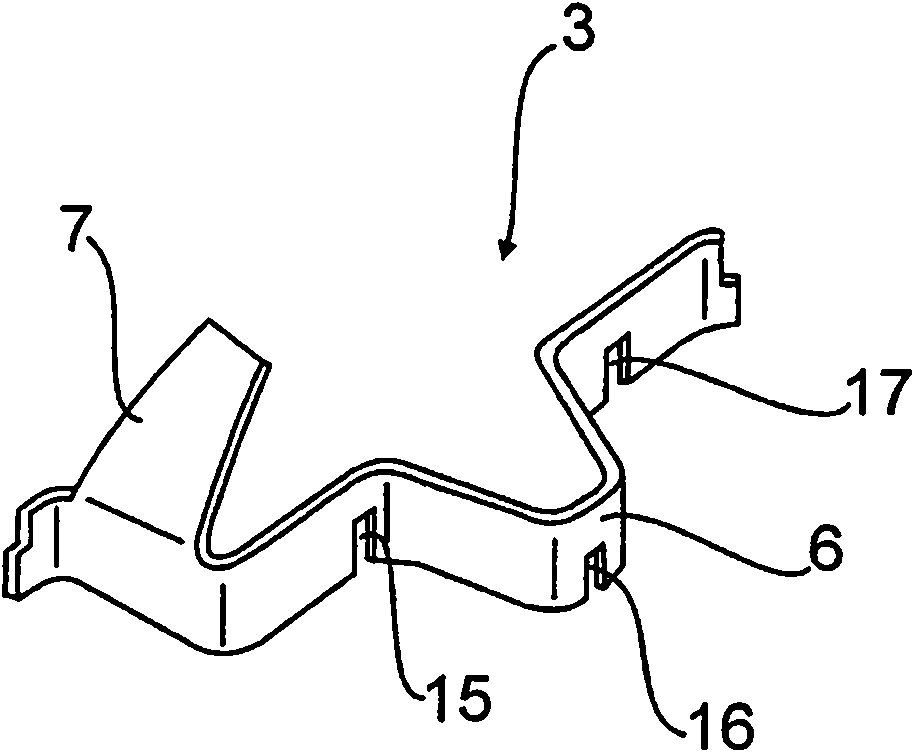

Chisel holder changing system with chisel holder receivers

A chisel holder changing system having a base element with a chisel holder receiver, into which a chisel holder equipped with a chisel can be inserted, wherein the chisel holder is inserted with a holder shaft into the chisel holder receivers and is maintained therein with the aid of bracing screws. Bracing screws can be screwed into a threaded receiver of the base element and during this are supported under tension in a bracing receiver of the holder shaft of the chisel holder. If in a chisel holder changing system in accordance with this invention the surfaces of the outer screw thread of the bracing screw and / or of the inner screw thread of the threaded receivers of the chisel holder receivers have a metallic layer of zinc and aluminum lamellas and a mineral chromium oxide bonding agent, which is burned in after the application, the screw connections are improved so that larger prestressing forces / tightening torques can be transmitted without damage to the screw connections.

Owner:WIRTGEN GMBH

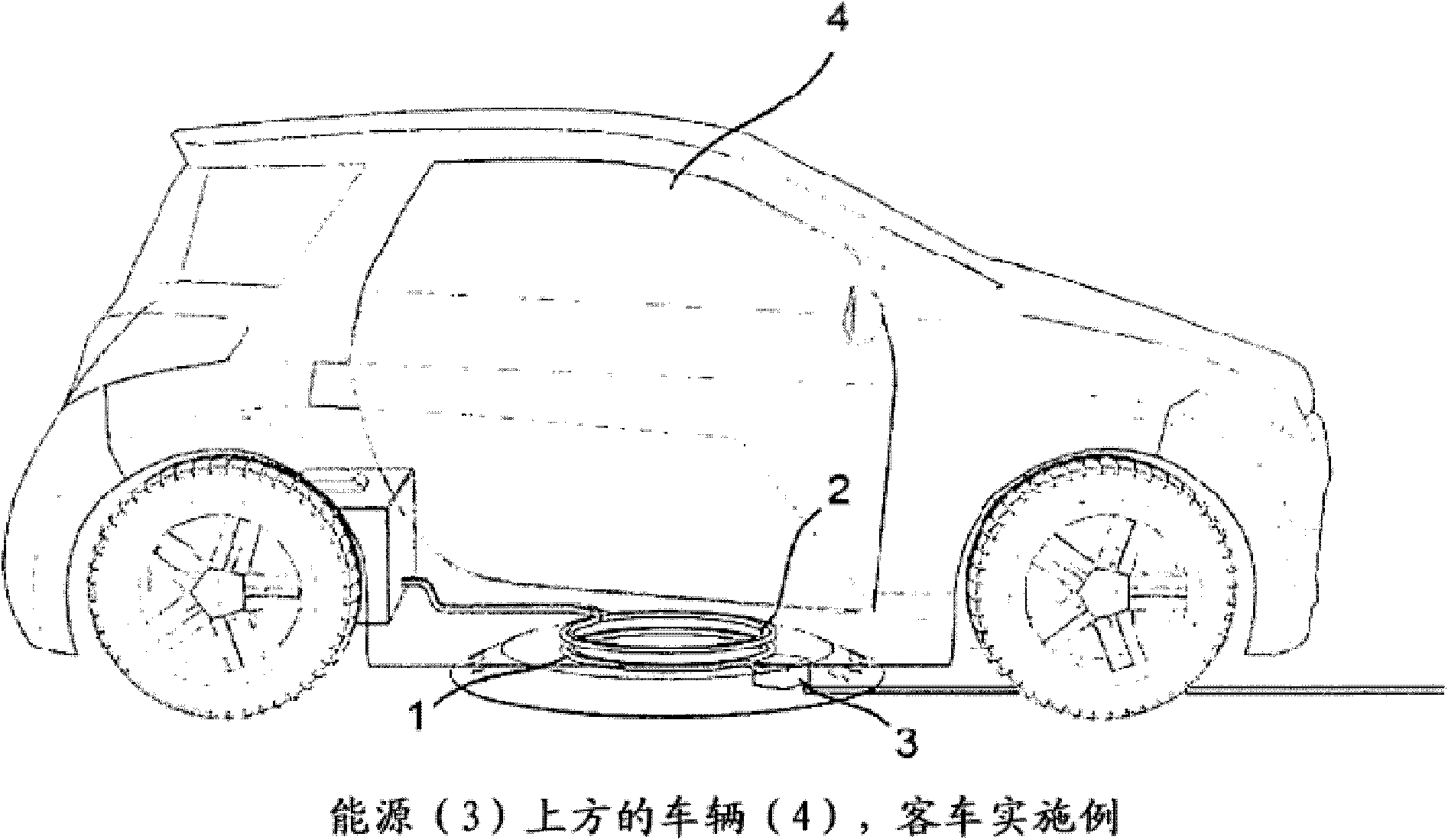

System for inductively charging vehicles, comprising an electronic positioning aid

InactiveCN102741083AImprove convenienceFrequent connectionCharging stationsOperating modesElectricityDriver/operator

The present invention relates to a system that ensures a self-guiding, electronic positioning of a secondary coil at a vehicle side, without the aid of indicators or kinematic or mechanical aids, in relation to a primary coil that is fixed at a a ground side, in order to guarantee a transfer of energy with over 90% efficiency without the disadvantages of moving, frictional and elastic components in terms of energy consumption, functional safety and wear. To achieve this aim, the coil housing at the ground side fulfils the role of an electronics housing, reflective element and cooling element thanks to the choice of material used, the surface and the inner supports and can thus be retrofitted, as a single installation at the ground side in the form of an operation-ready complete package, to any flat base with an electric connection. The vehicle can be used both for transporting passengers and loads and can be steered by a vehicle driver or can be operated without a driver, for example for cleaning areas, for natural protection or for intralogistics.

Owner:CONDUCTIX WAMPFLER

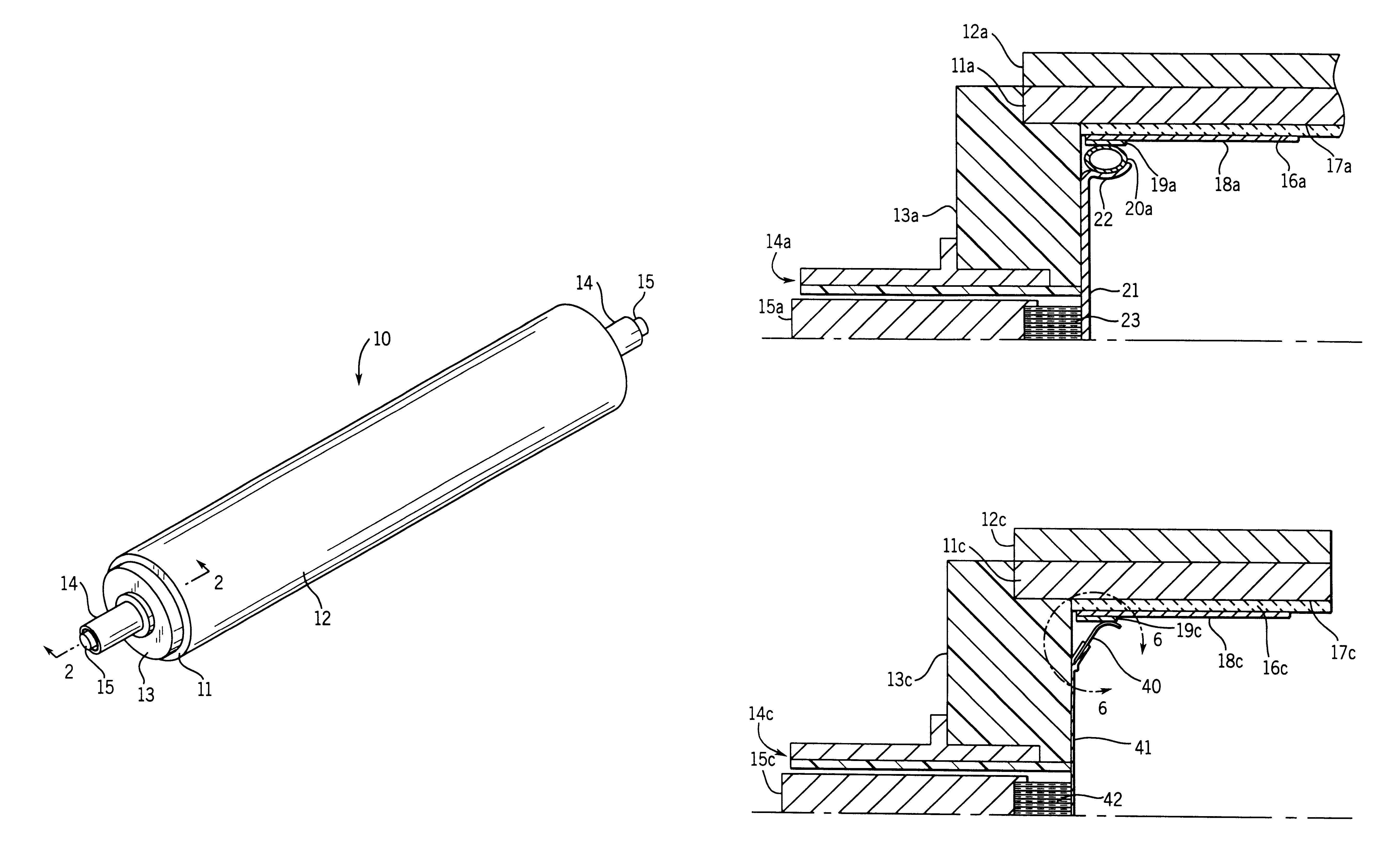

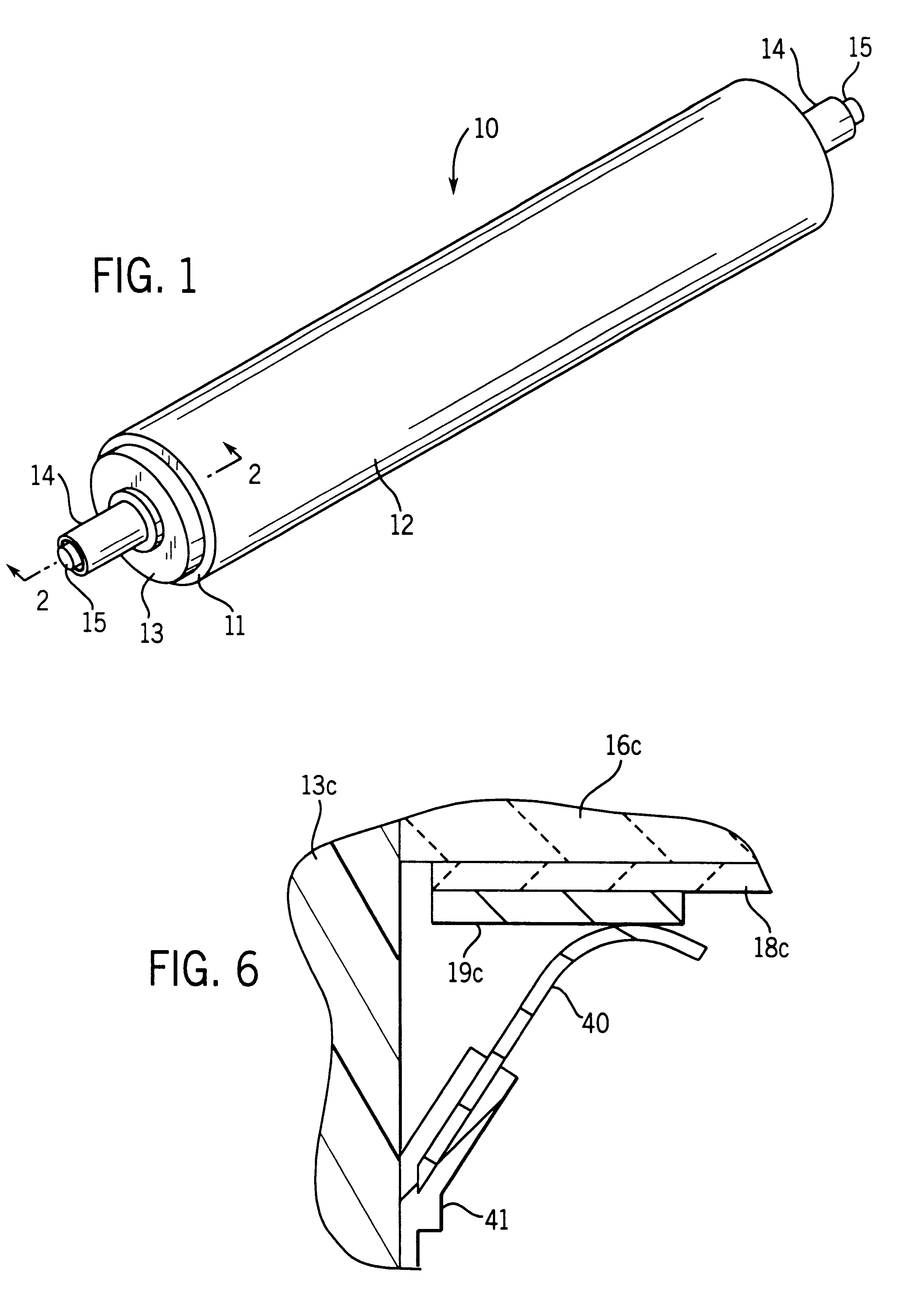

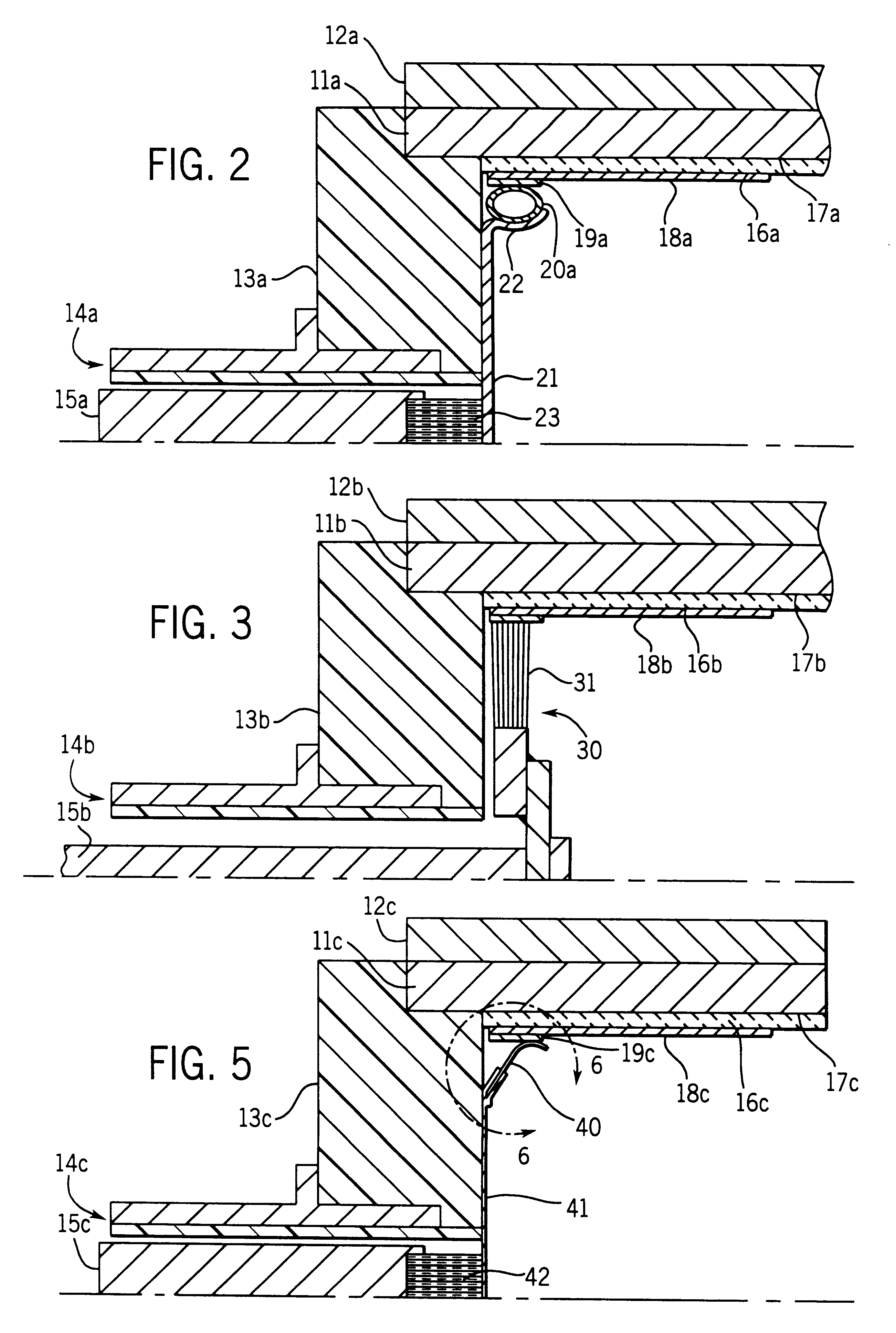

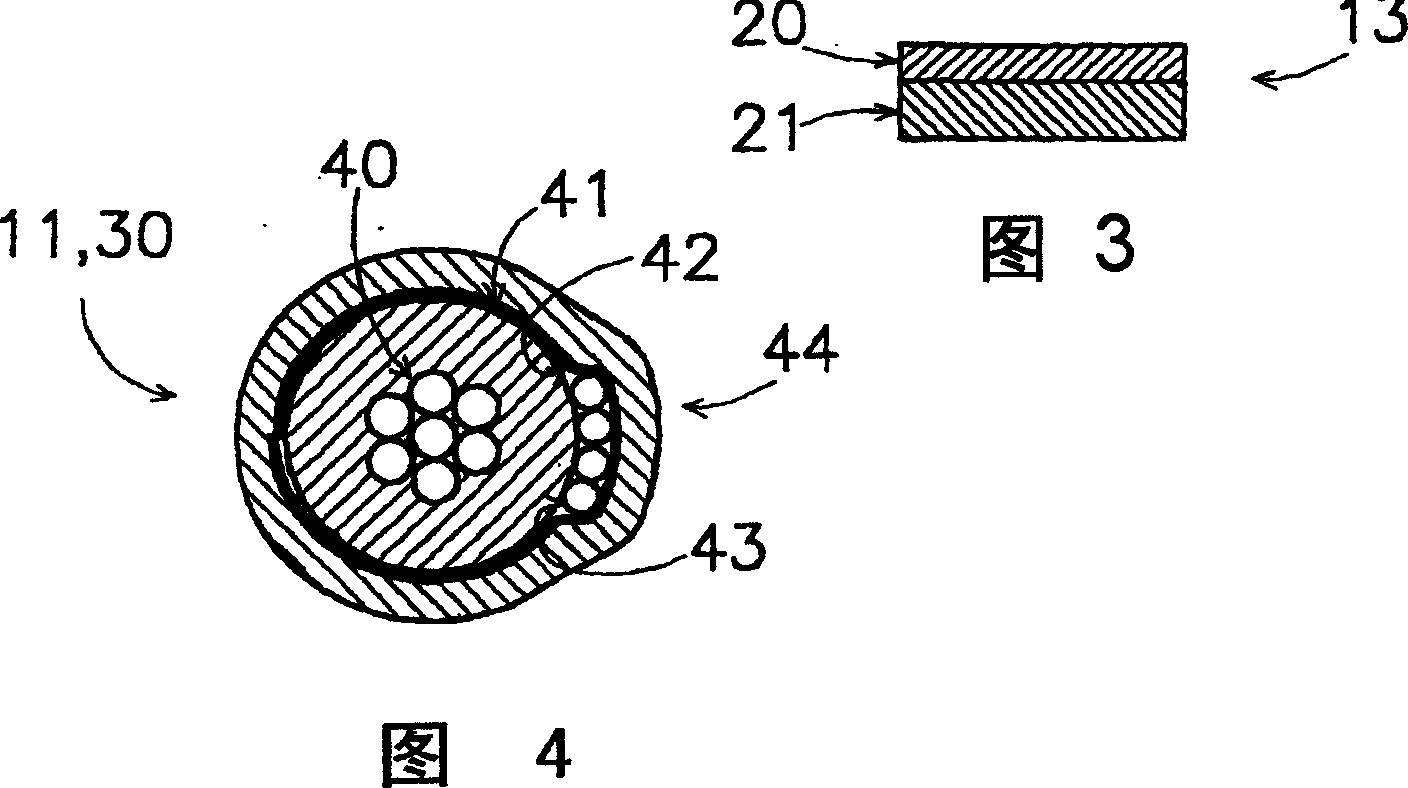

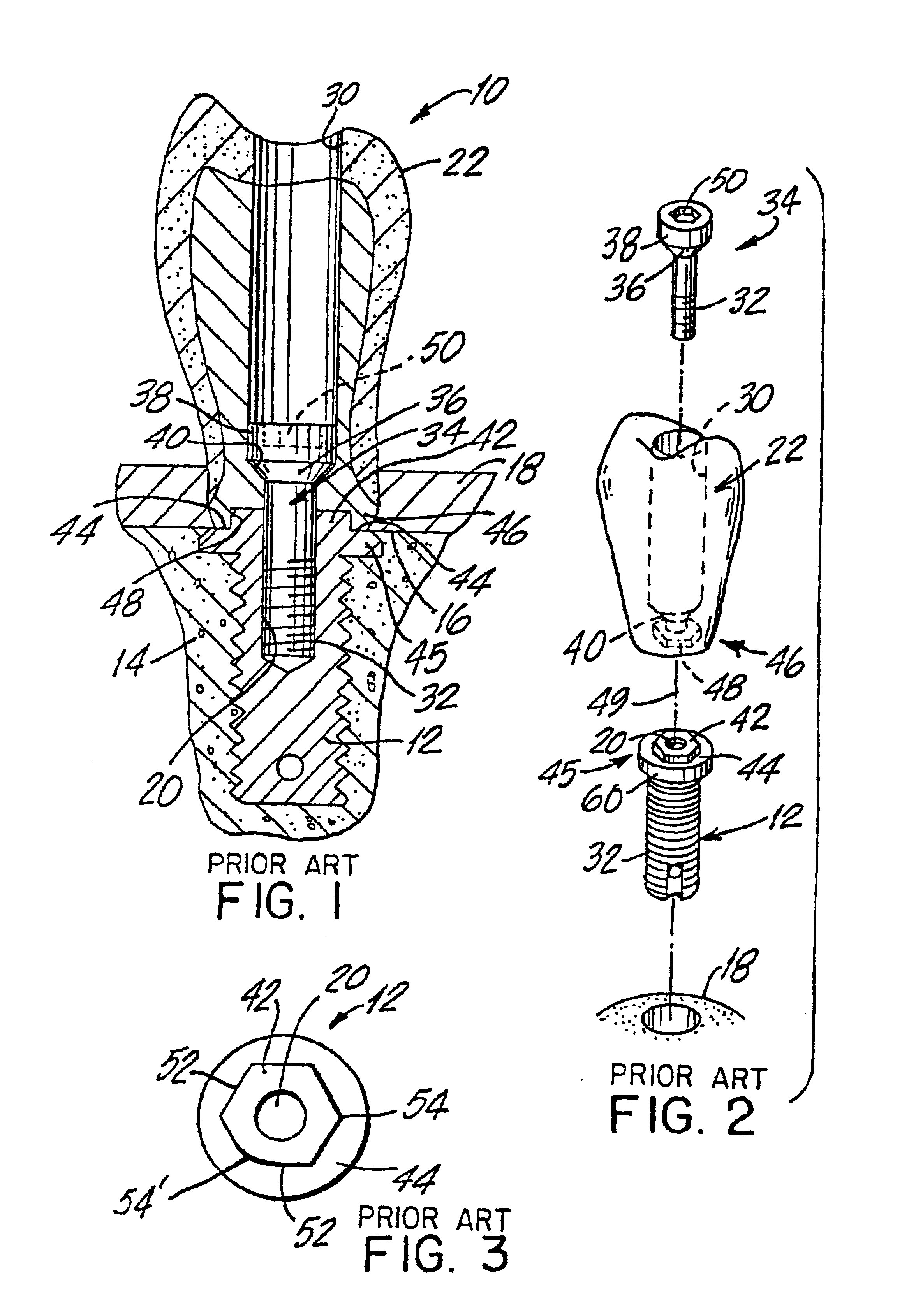

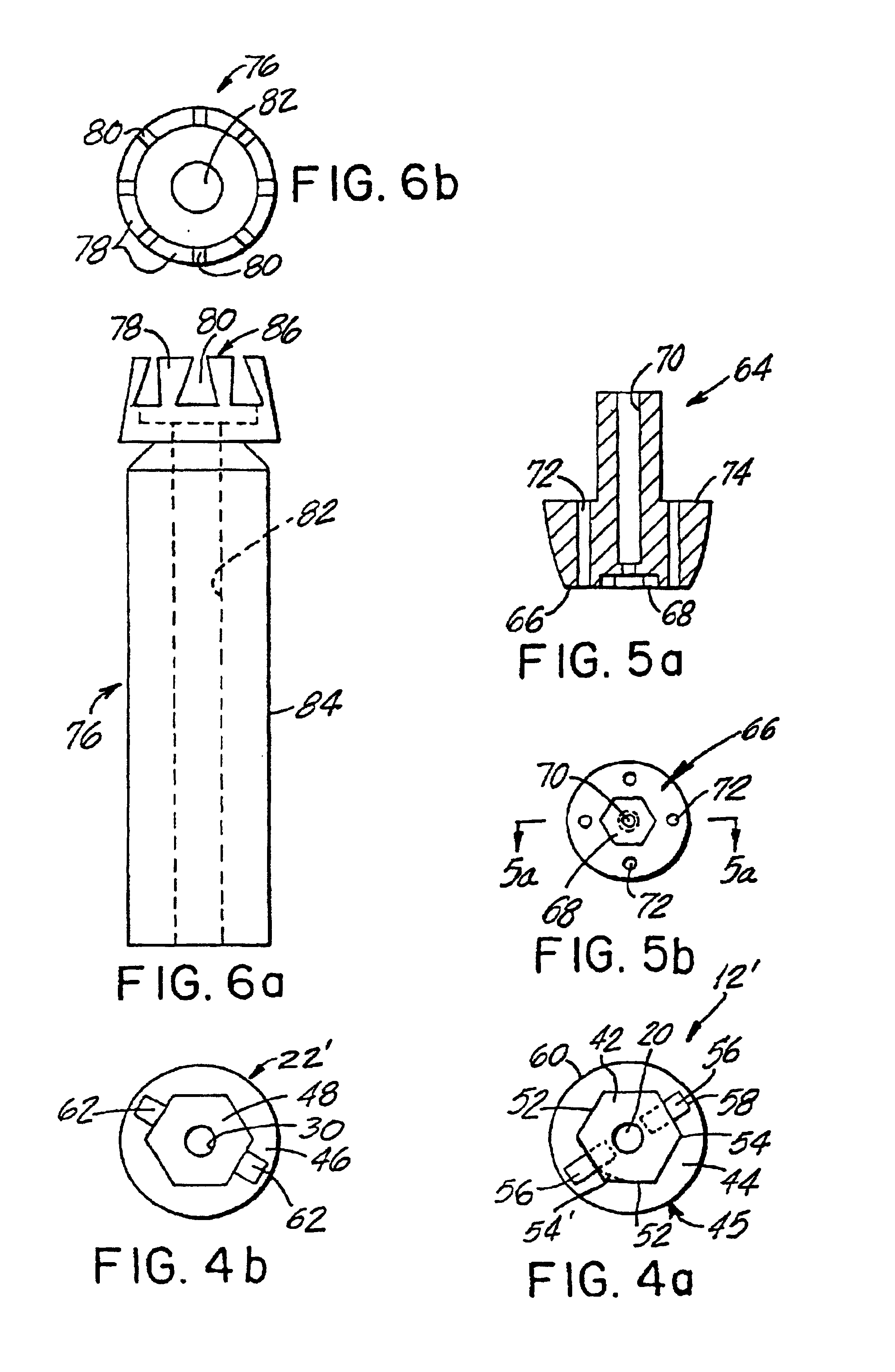

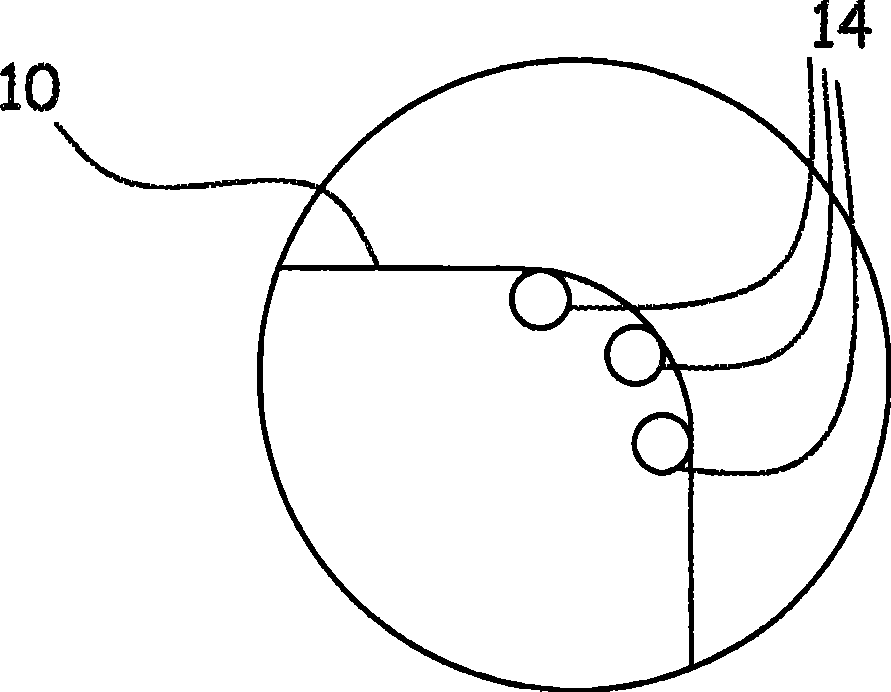

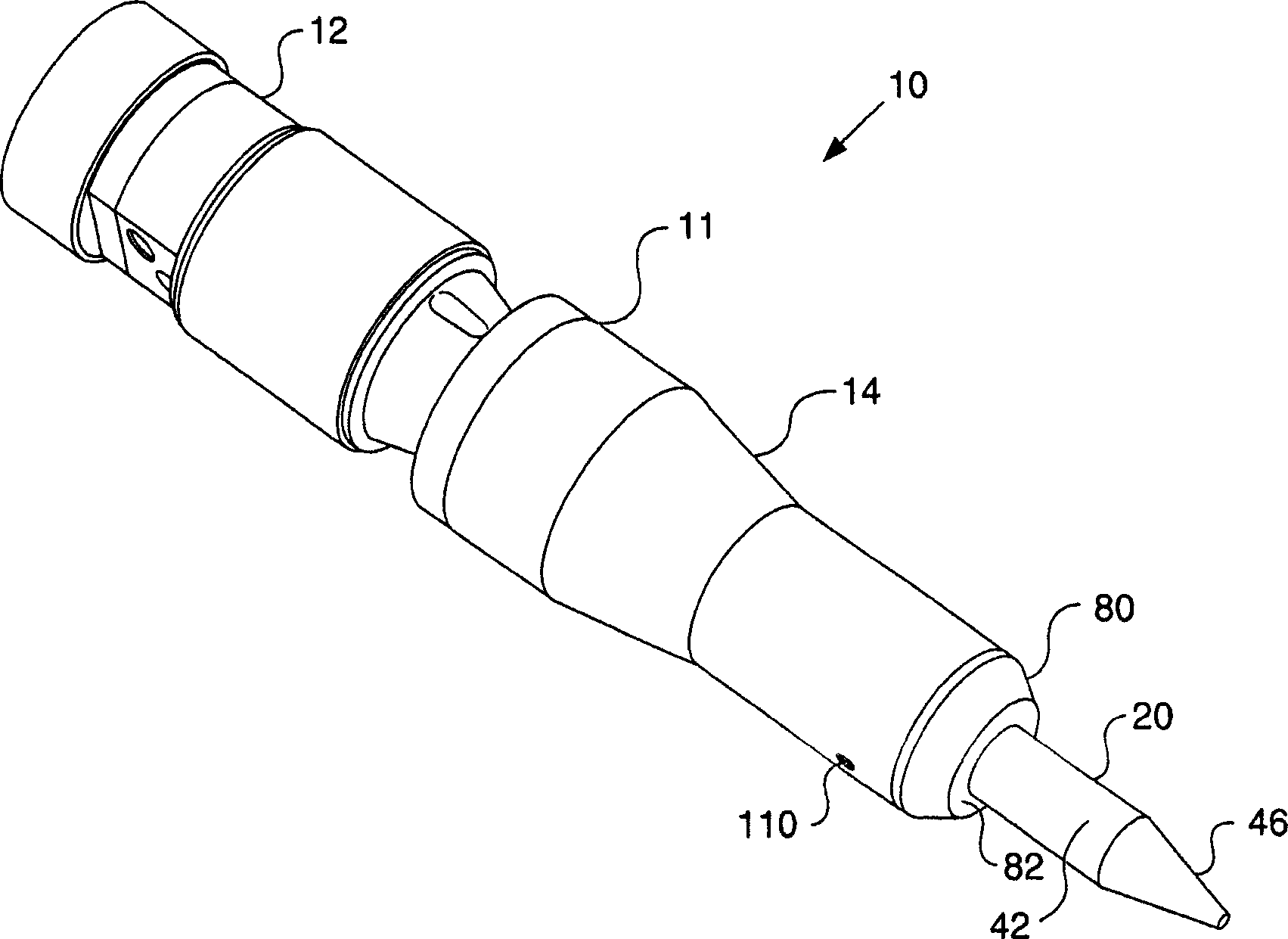

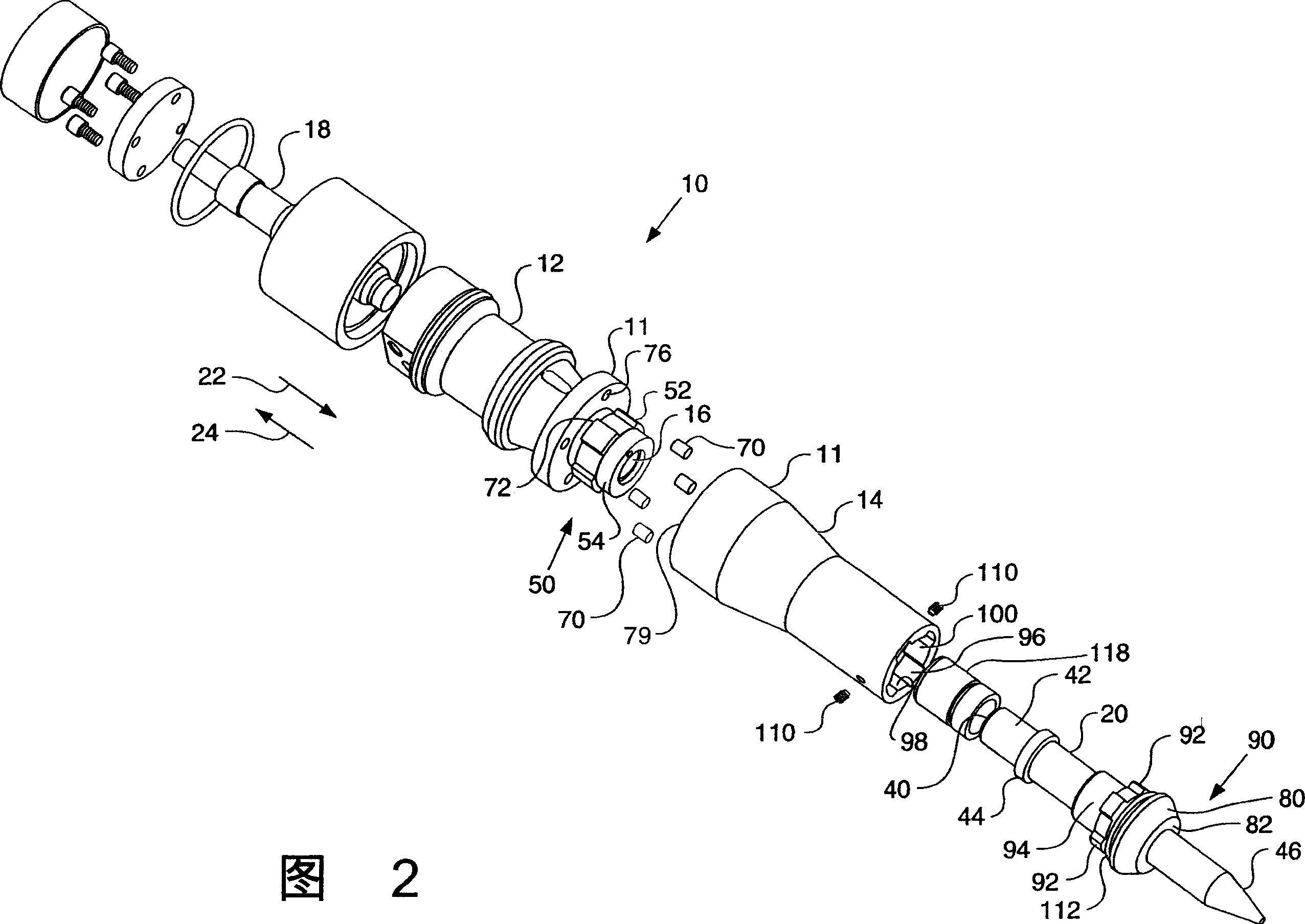

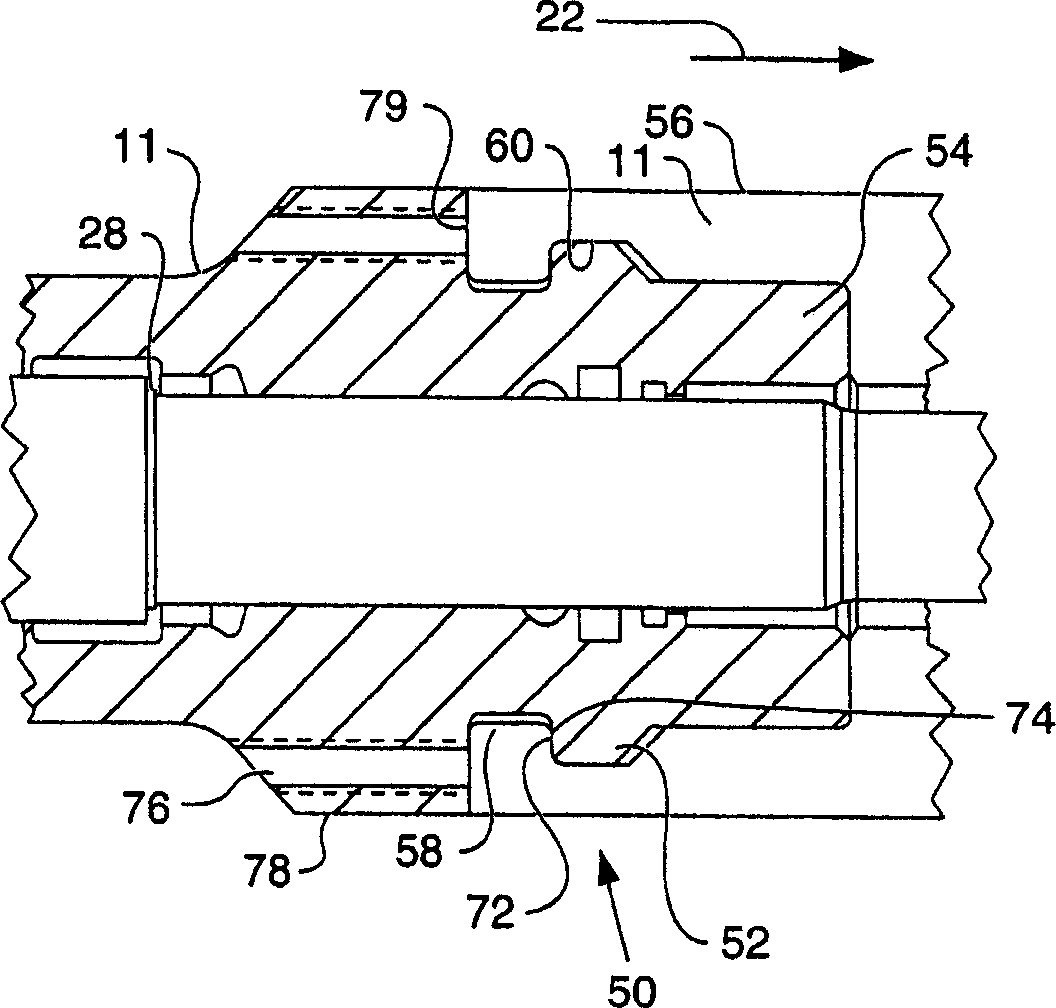

Ceramic heater/fuser roller with internal heater

InactiveUS6285006B1Easy and more straightforward to bondReduced risk of damageOhmic-resistance heating detailsRollsElectricityThree-phase

A thermal conduction roller (10) has a tubular roller core (11) with an inside surface; and an electrical insulator coat (16) primarily of zirconia on the inside surface, a heater coat (18) of titania or a titania blend is disposed over the insulator coat (16), and at least two electrical contact assemblies that are disposed inside the roller and electrically connect to the heater coat (18) as the roller (10) is being rotated. One embodiment utilizes an electrical insulator coat (16) in a range of thickness from about ten mils to about twenty mils. A thinner coat may not have sufficient dielectric strength, while a thicker coat decreases thermal conduction. A release material (12) is applied to the outside of the roller (10). Various contact structures according to the present invention are also described in detail, including one especially adapted to connect to a three-phase power supply.

Owner:AMERICAN ROLLER

Method for Producing a Glass Pane

InactiveUS20090241317A1Reduced risk of damageWide applicationPackagingGlass severing apparatusThermal energyEngineering

A method is described for producing a glass pane having at least one edge section delimiting the glass pane, for whose production the glass pane has been severed along the edge section with the aid of a severing procedure comprising a thermal energy introduction.The invention of the glass pane is enclosed at least sectionally and preferably along the entire edge section by a sheath immediately after production of the at least one edge section using a severing procedure comprising a thermal energy introduction.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

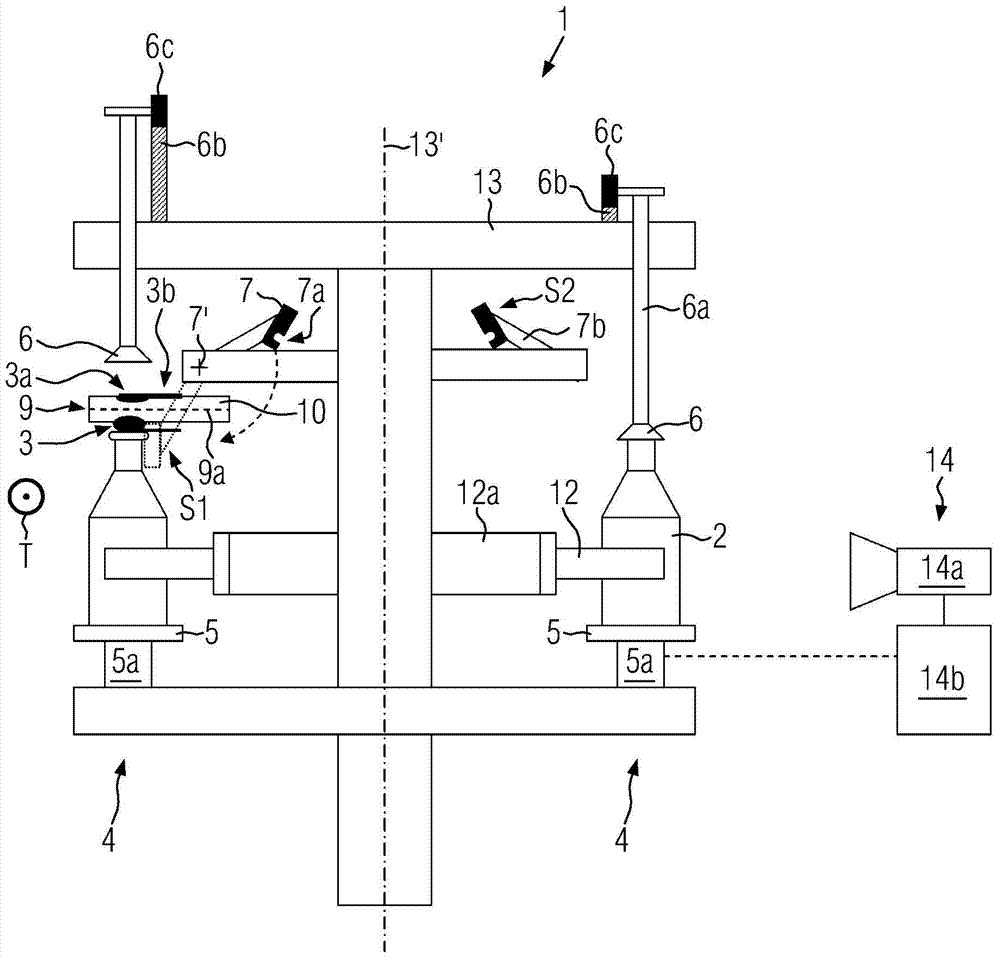

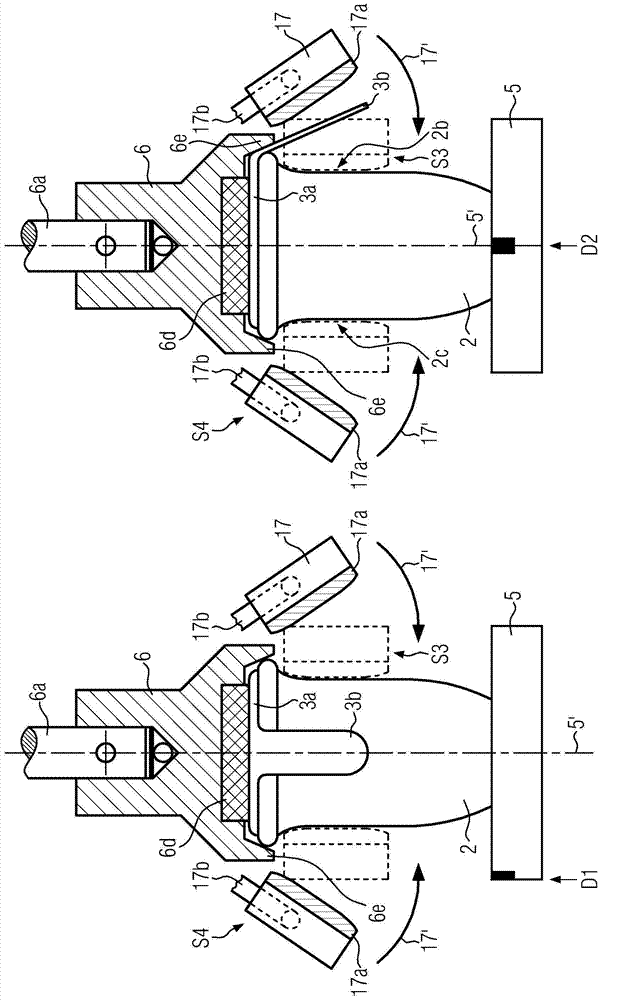

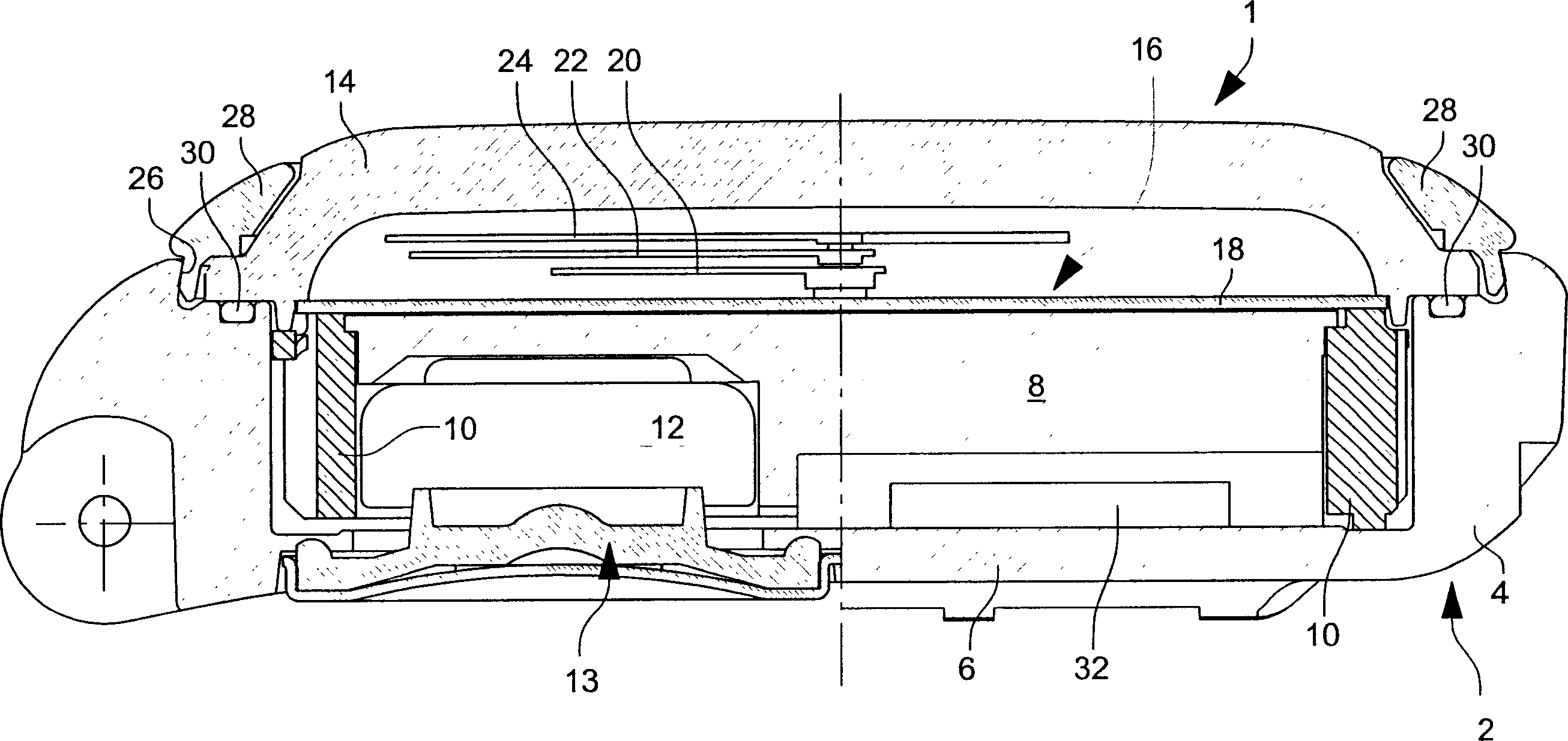

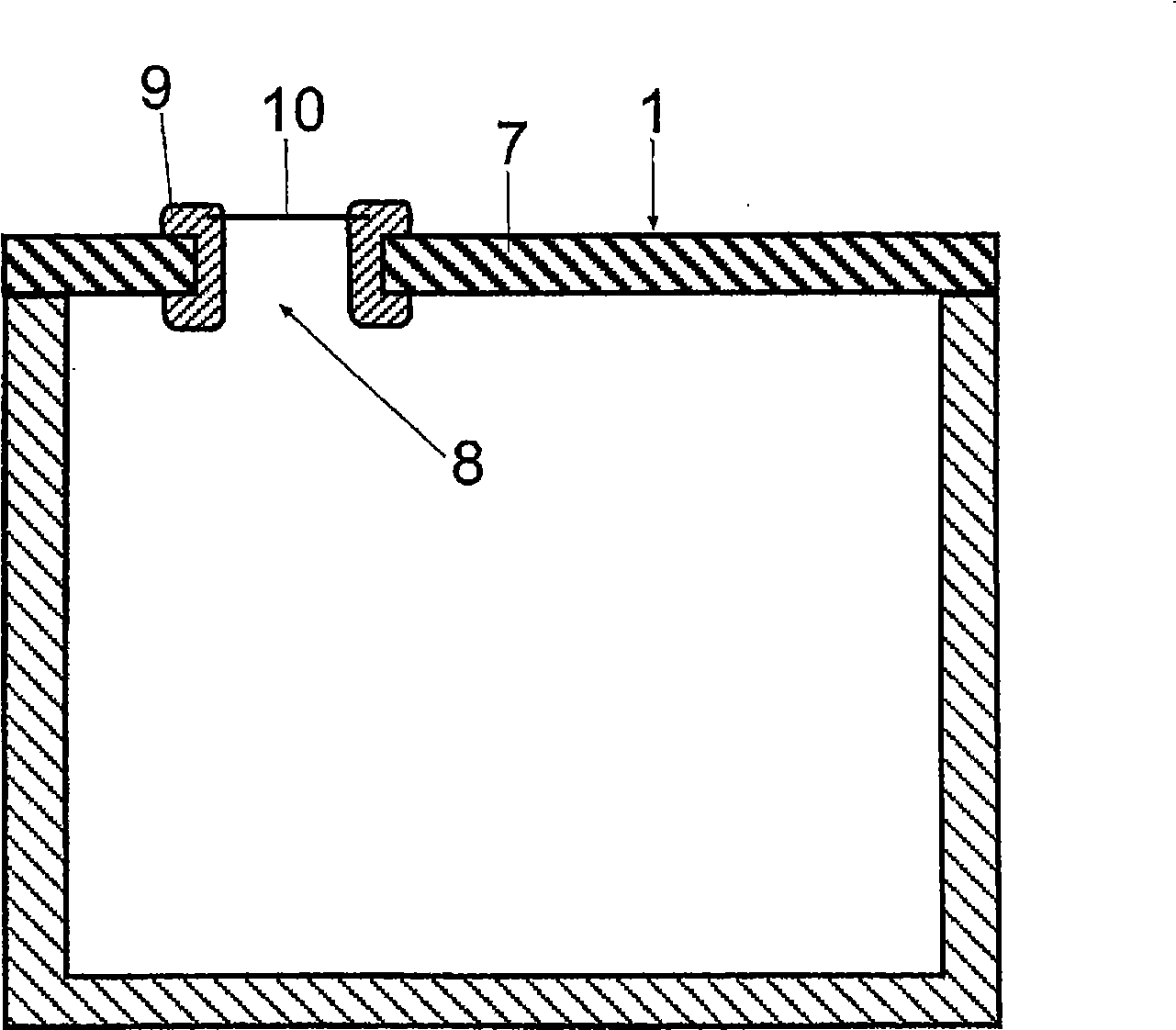

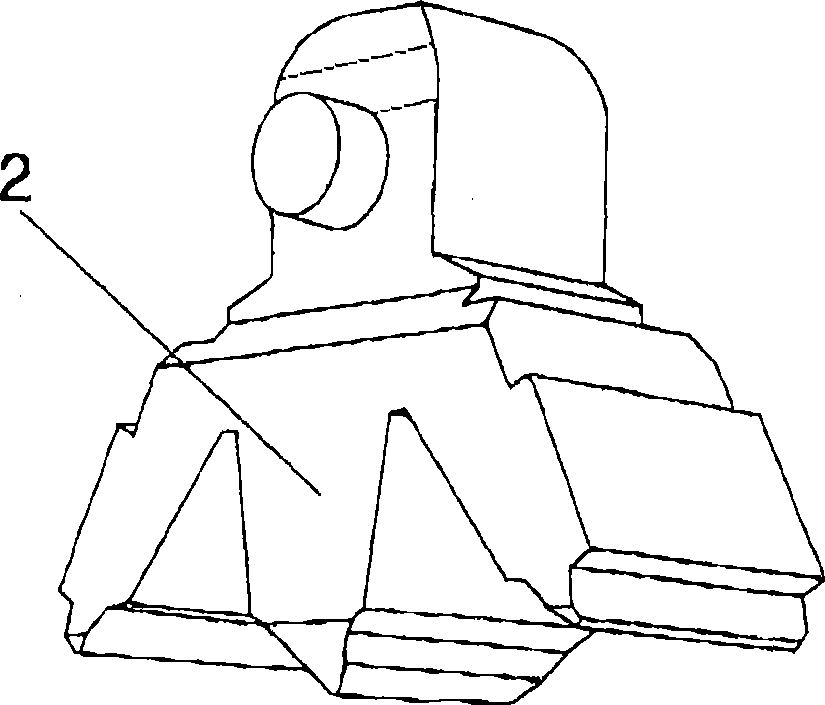

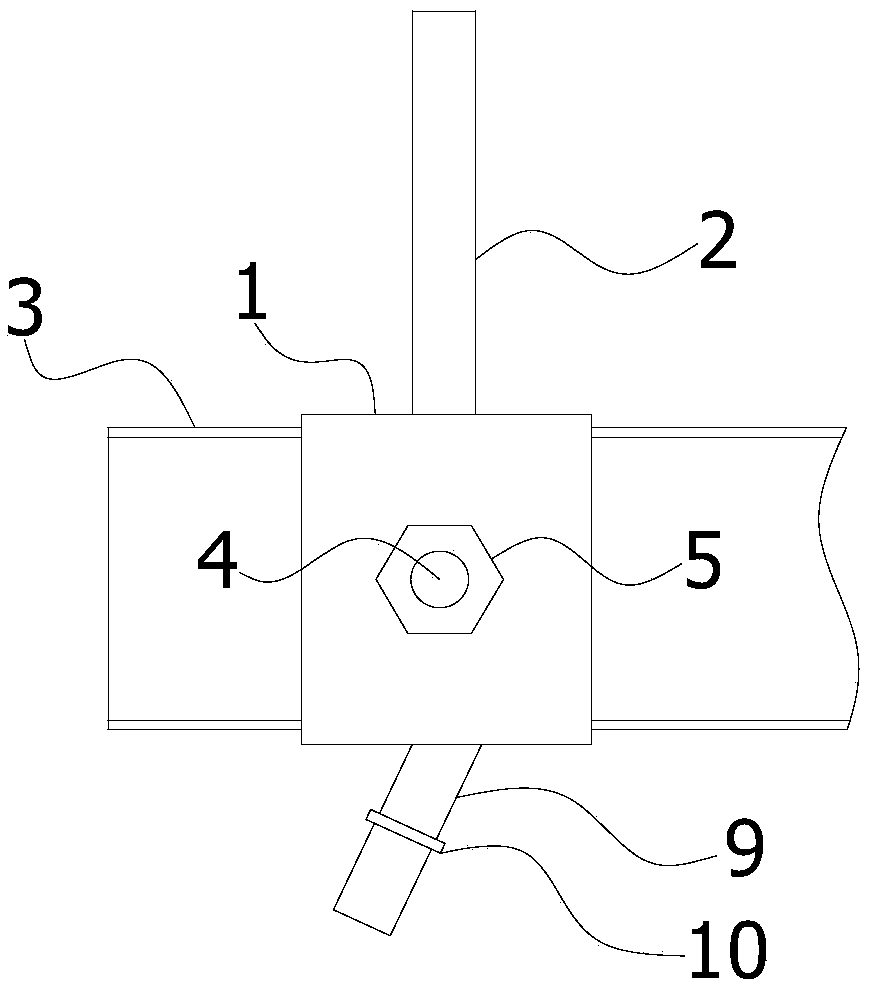

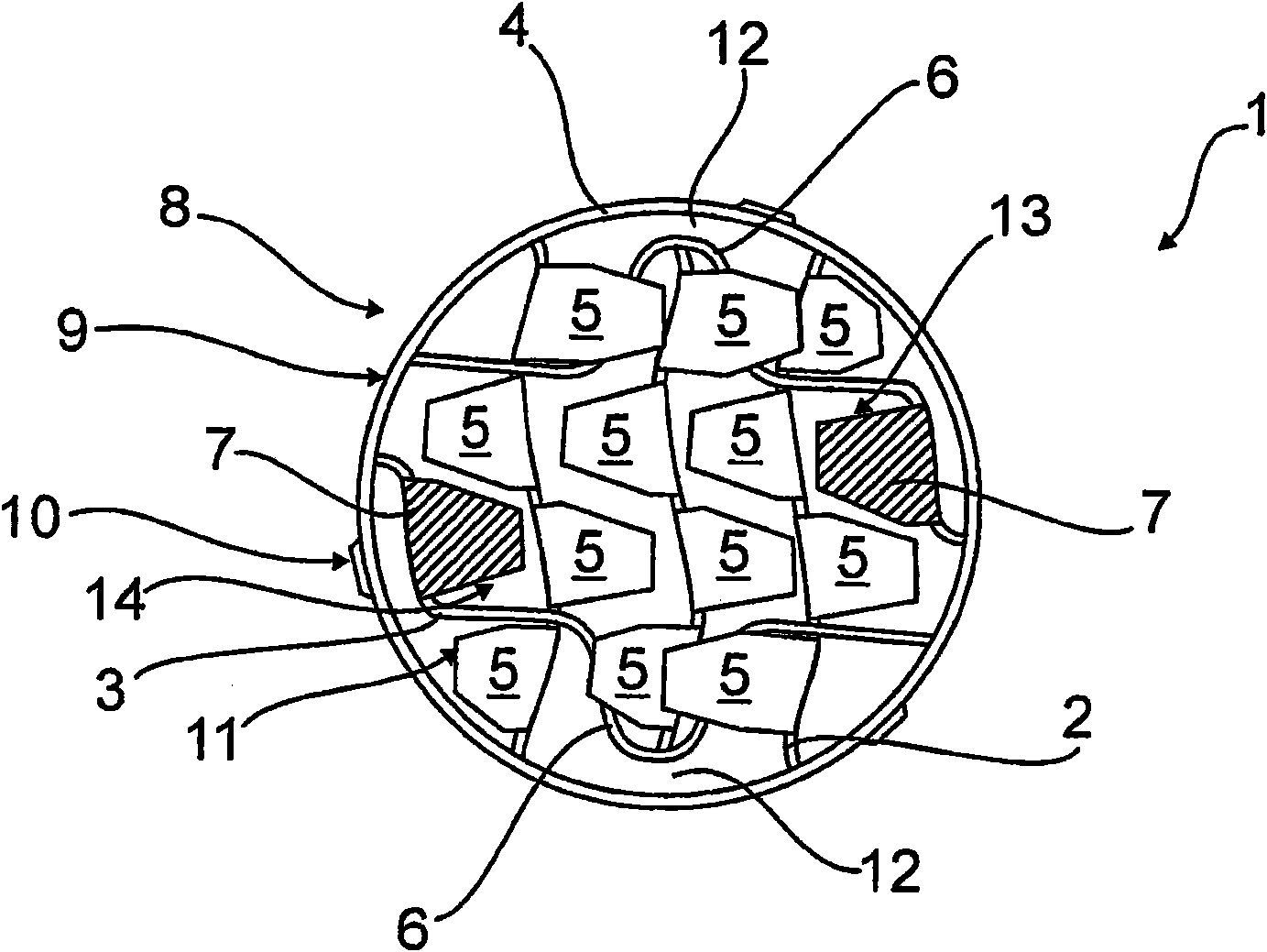

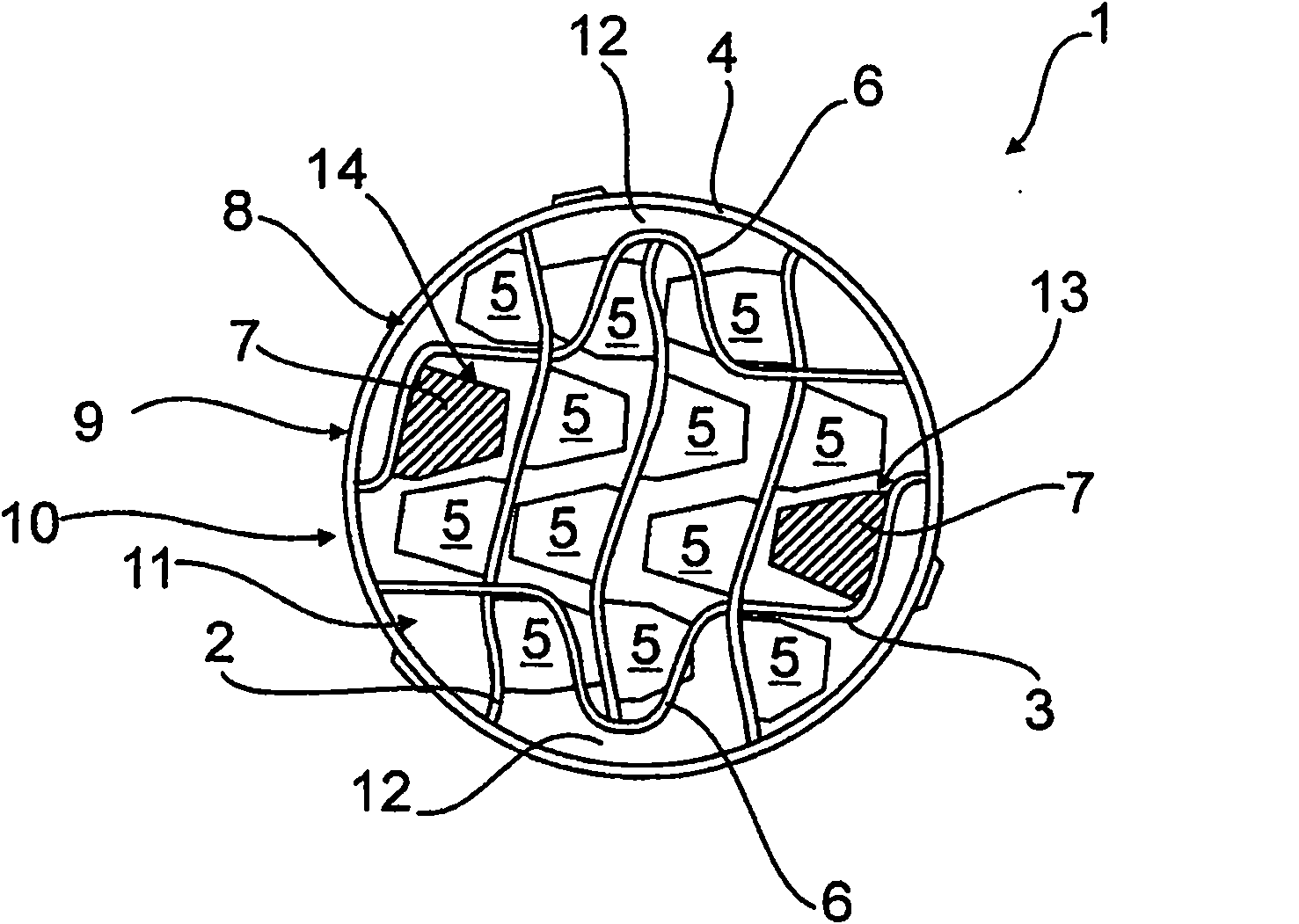

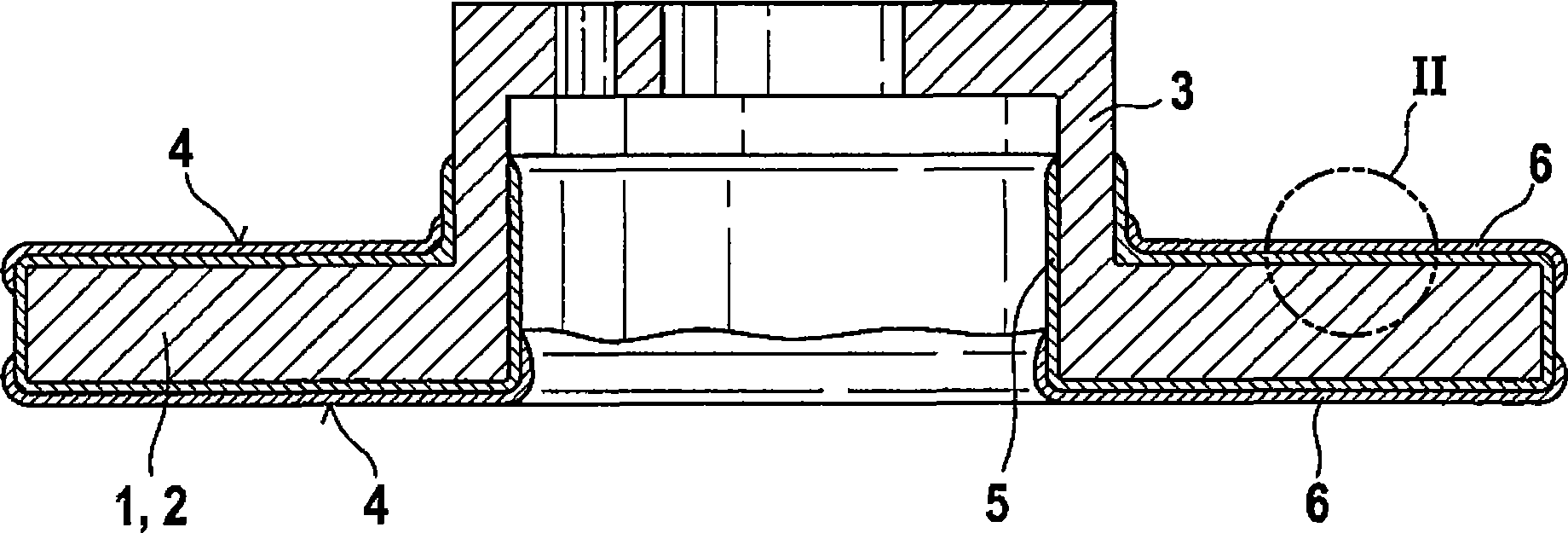

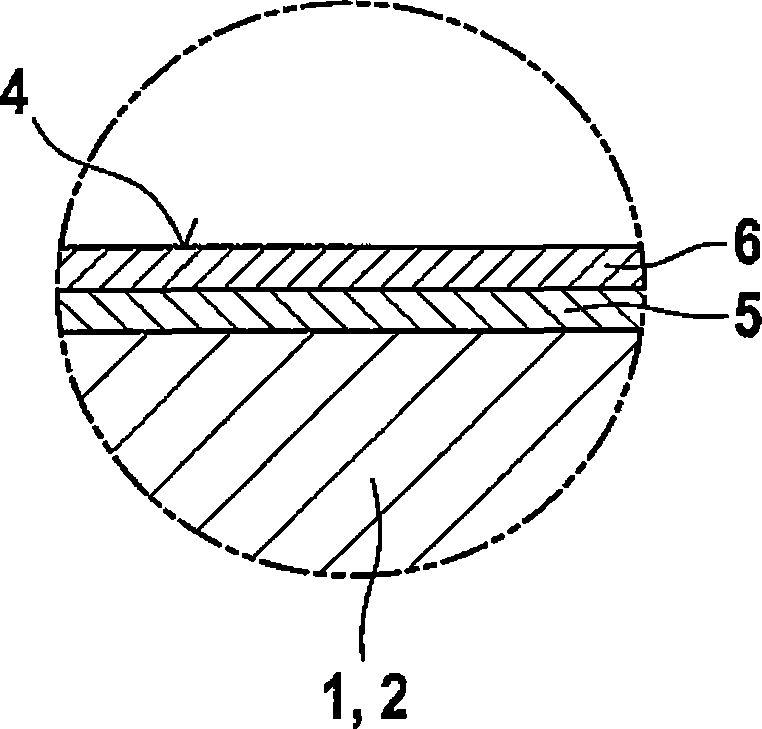

Gripper, in particular a bernoulli gripper

InactiveCN101687322AGuaranteed bufferReduced risk of damageGripping headsSemiconductor/solid-state device manufacturingDevice formRobotic arm

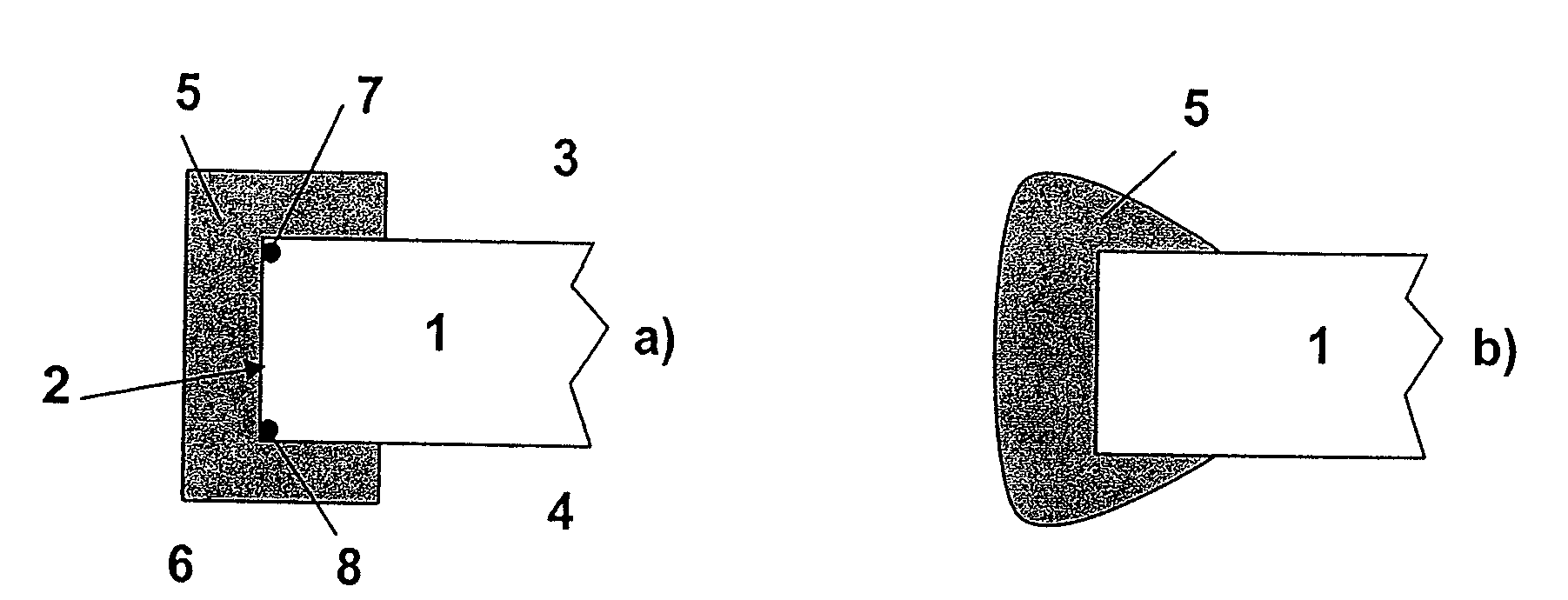

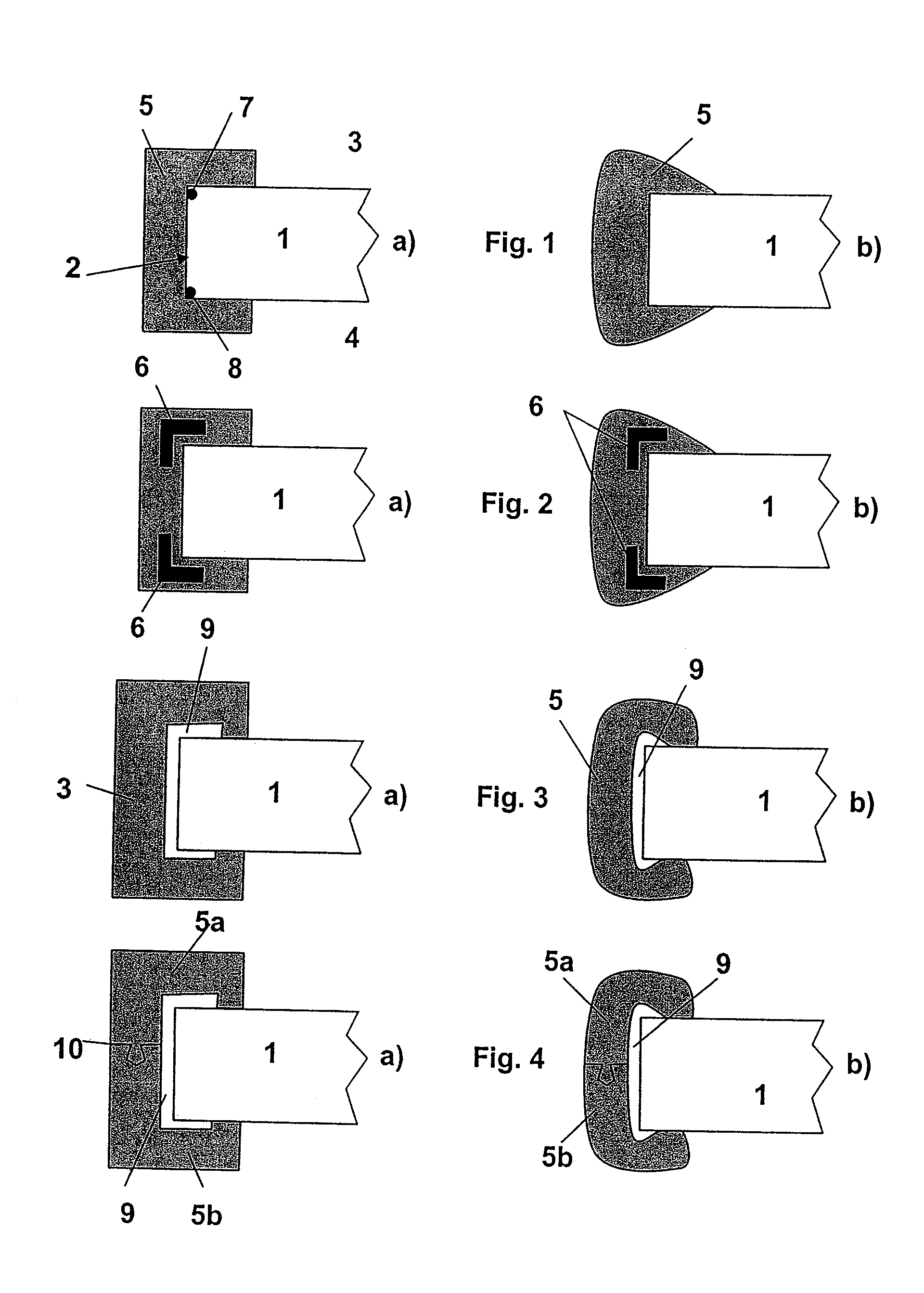

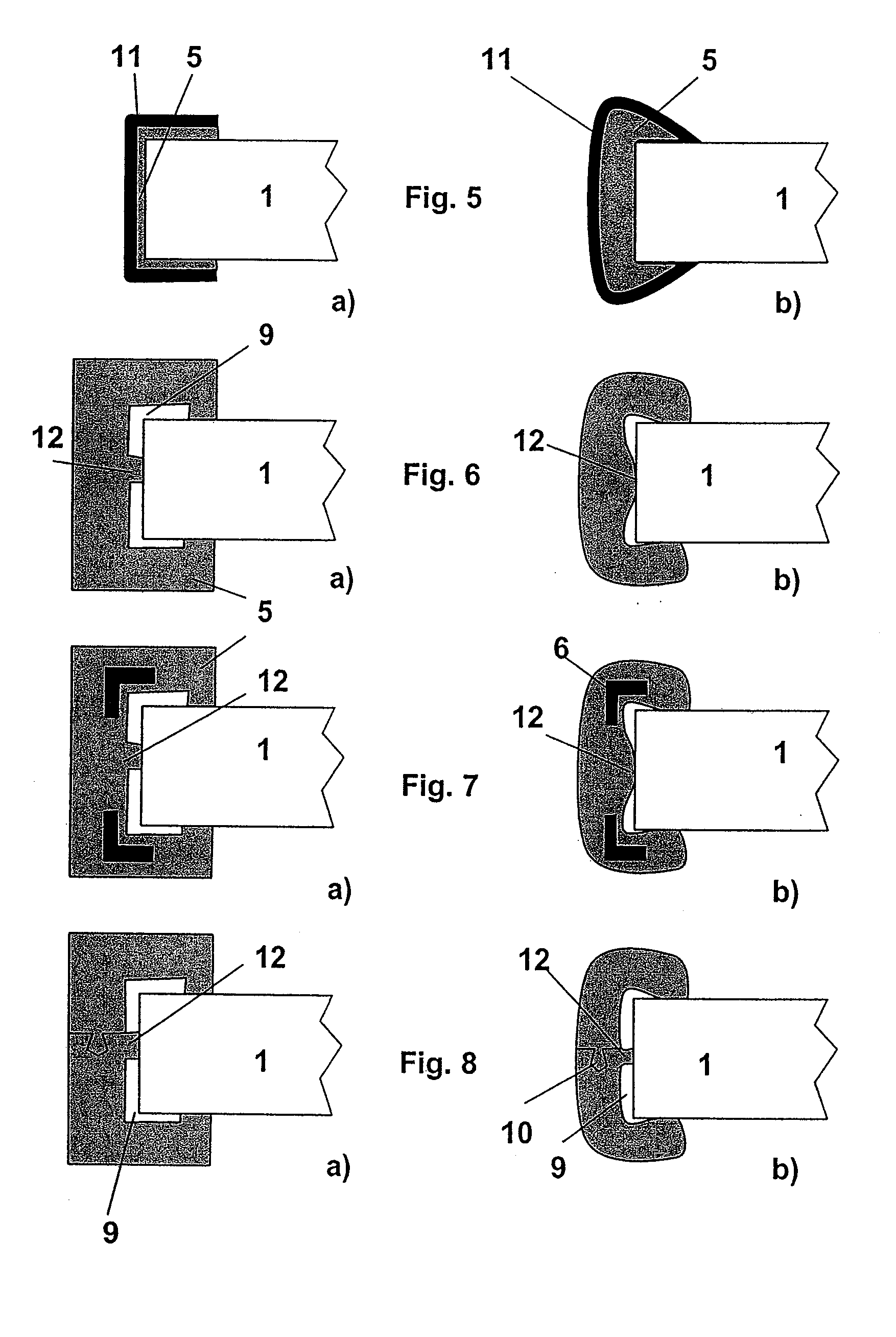

The invention relates to a gripper (1), in particular a Bernoulli gripper for holding two-dimensional components such as silicon-based wafers (2) with a low degree of loading, having a clamping ring (4) connected to a controllable robot arm (3), having a baffle plate (6) which is connected to the clamping ring (4) by means of a funnel-shaped component (5) and has a gripping face (7) which communicates with a flow system (8) which passes through the funnel-shaped component (5) and the baffle plate (6) and by means of which, after an excess pressure has been applied to the Bernoulli gripper (1),a negative pressure is to be produced on the gripping face (7) of the baffle plate (6) in order to attach by suction the wafer (2) to be gripped, having a rubberized bearing surface (9) of a bearingring (10) which is integrated in the gripping face (7) and provides a slip-resistant movement of the wafer (2) attached to the gripping face (7) by suction, and having a sensor (11) for detecting thewafer (2) attached to the gripping face (7) by suction. In order to permit an extremely shock-resistant attachment of the wafer to be gripped on the gripping face of the gripper, the invention provides a damping device (12) which is circumferentially adapted to the gripper (1), the contour of which device, as viewed in the plan view of the gripper (1), protrudes circumferentially above the contourof the latter, and which device forms such a damping resistance for the wafer (2) to be gripped during its suction-induced approach towards the gripping face (7) that the wafer (2) comes to bear in ashock-free manner against the rubberized bearing surface (9) of the bearing ring (10).

Owner:JONAS & REDMANN AUTOMATIONSTECHNIK GMBH

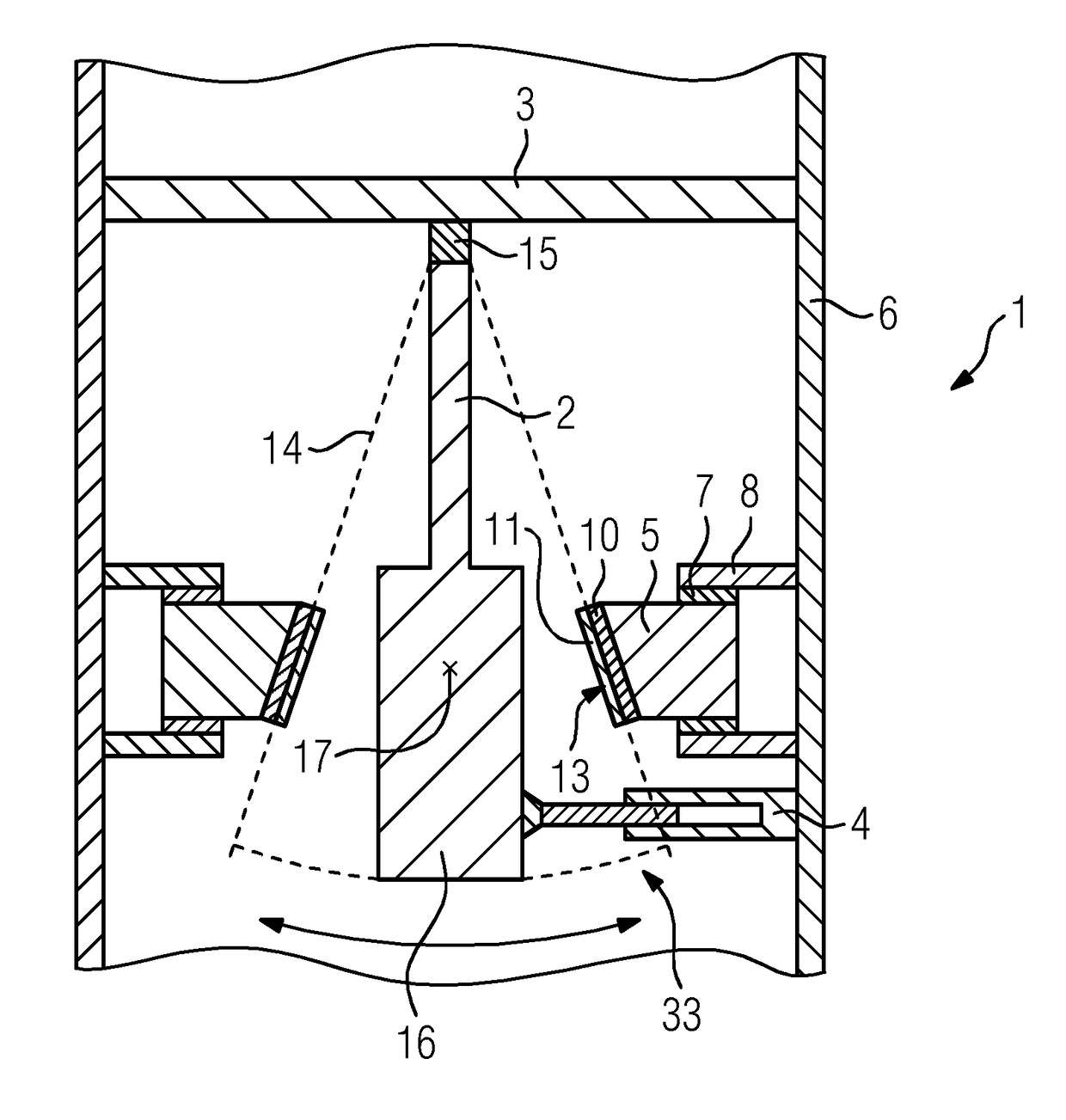

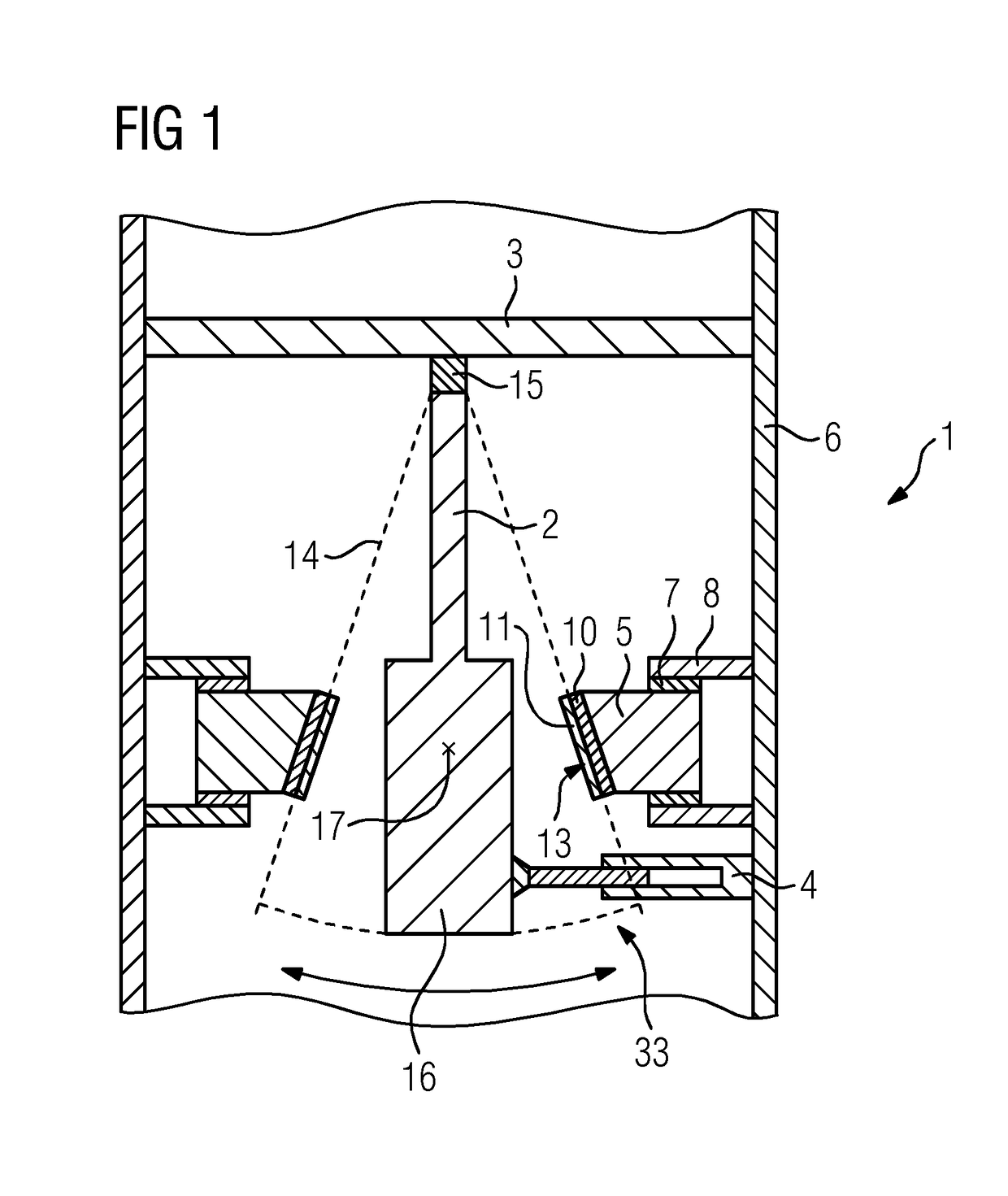

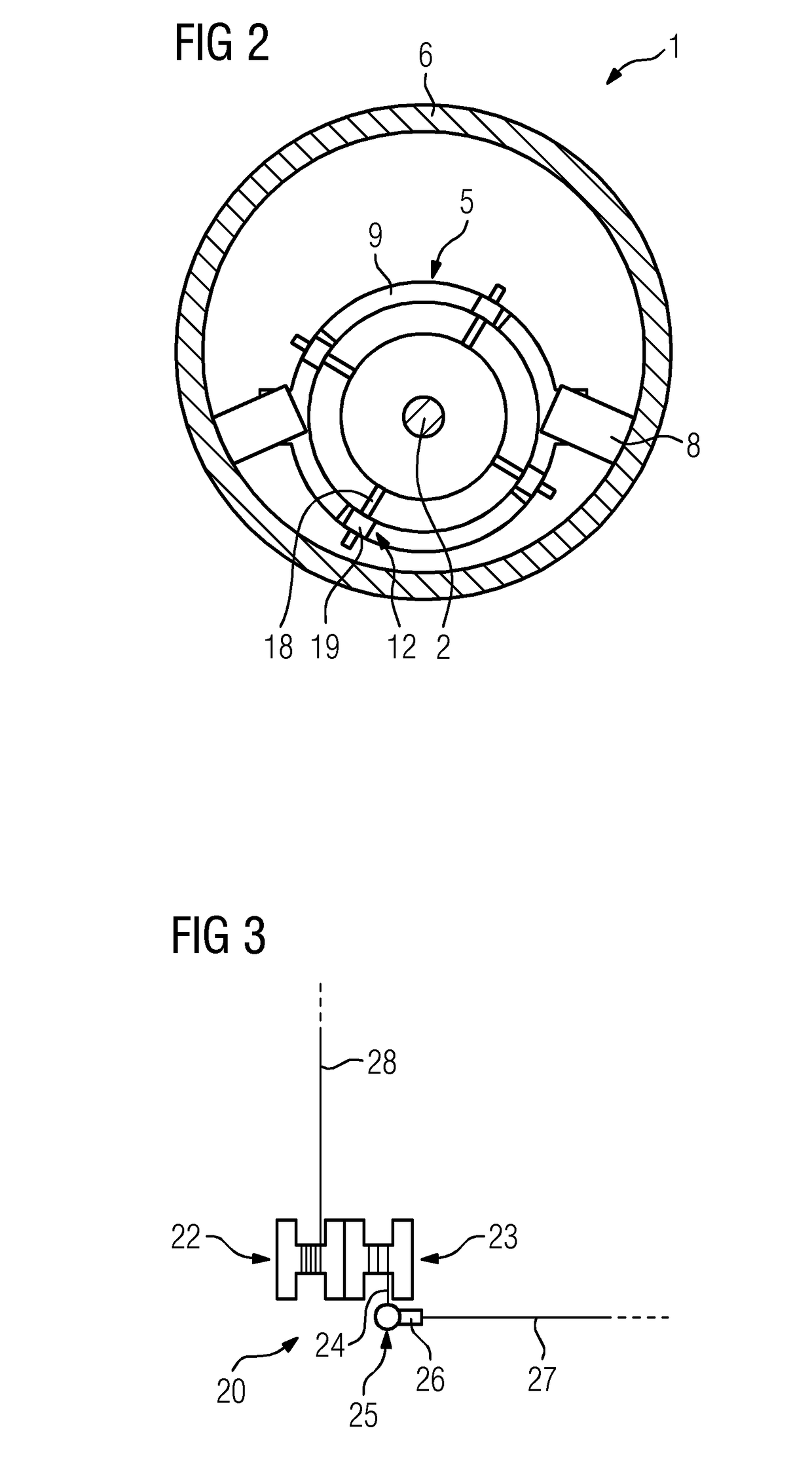

Brush apparatus for an electric machine and electric machine

ActiveCN102460909AIncrease temperatureReduce external temperatureVehicle connectorsPower operated startersBusbarElectric machine

The invention relates to an electric machine (1), especially a starter for an internal combustion engine, comprising a commutator (4) and a brush apparatus (2), brushes (3) being arranged on the commutator (4) in such a manner that at least one pair of brushes can rotate off-set from each other, every brush (3) being held in a brush holder (5), every brush holder (5) being fastened to an axial face on a brush plate (6), every brush (3) being alternately switchable in series either with a negative pole or a positive pole by a current conducting device (18, 19) to give a pair of brushes, and the brush plate (6) with connecting leads (24, 25, 26) leading to brushes (3) on the negative pole side and a busbar (10) with connecting leads (21, 22, 23) leading to brushes (3) on the positive pole side forming a respective current conducting device (18, 19). In order to protect the brush apparatus (2) from thermal overloads in an easy manner, at least one current conducting device (18, 19) is designed to have a unit for reducing heat dissipation.

Owner:SEG AUTOMOTIVE GERMANY GMBH

Oscillation absorber for a structure

ActiveUS20180017125A1Reduce frictionIncrease frictionEngine fuctionsWind motor supports/mountsPower stationEngineering

Provided is an oscillation absorber for a structure, particularly a wind power plant, with a pendulum that is attachable to a component of the structure and a damper for dampening the motion of the pendulum, in which the pendulum passes through a containment ring that limits the deflection of the pendulum, wherein the containment ring is attachable to at least one wall of the structure.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

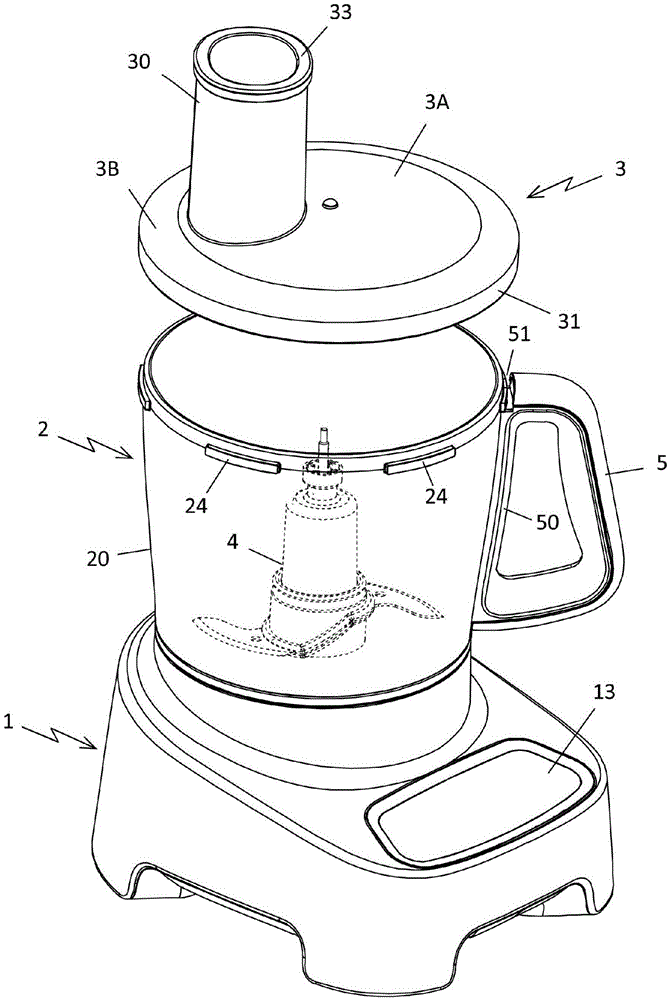

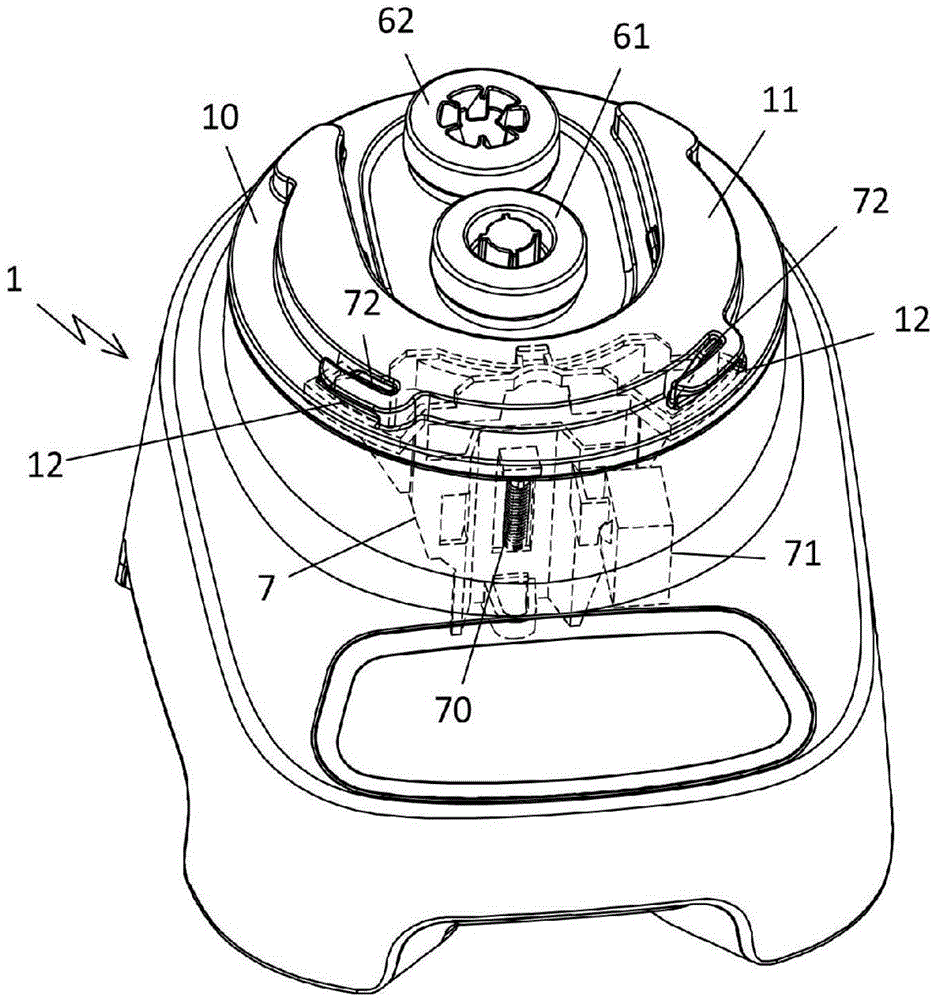

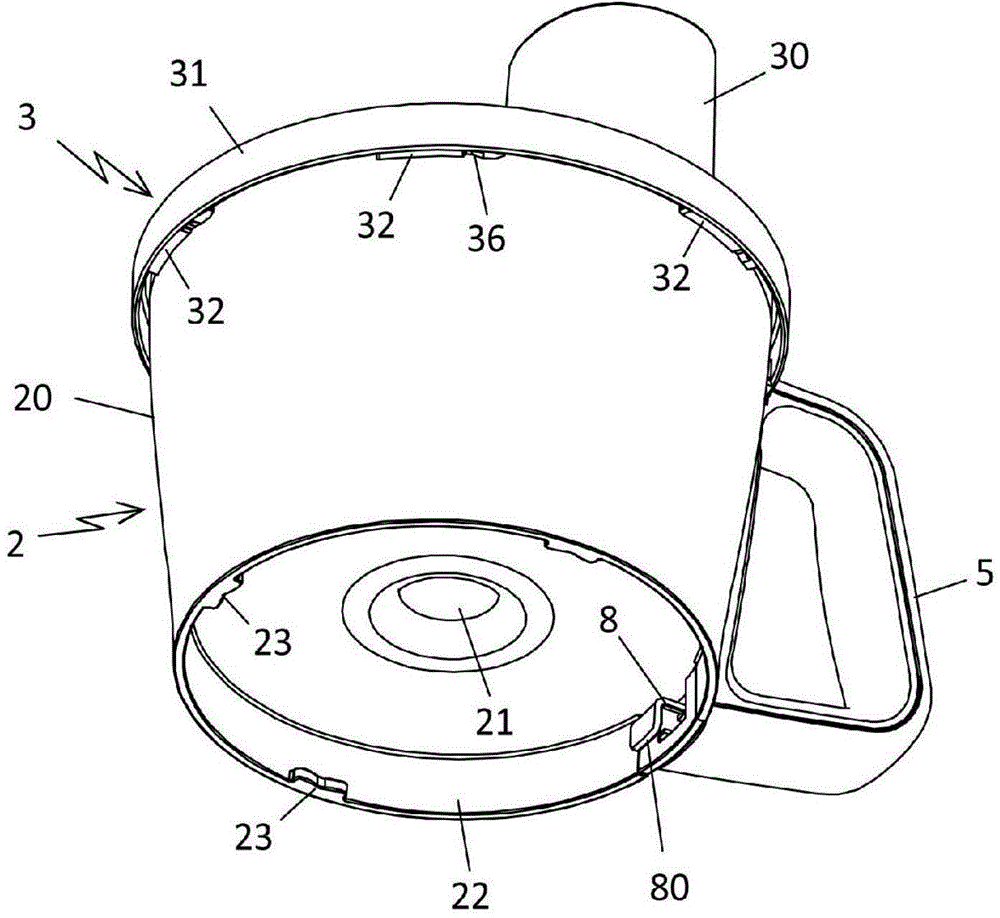

Household electrical appliance for food preparation comprising a container closed by a removable cover engaging with a safety device

The invention relates to a household electrical appliance for preparing food comprising a container (2) receiving a working tool (4) driven to rotate by a motor (6) and a lid (3) which detachably closes the container (2), the container (2) having a sensor element (8) cooperating with a safety device to prevent the motor (6) from operating when the lid (3) is not locked on the container (2), said sensor element (8) being movable between a rest position towards which it is brought by biasing means (81) and an operative position towards which it is moved by an actuating member (32) of the lid (3) when the latter is locked on the container (2), characterized in that the lid (3) comprises a skirt (31) extending over the entire peripheral circumference of the lid (3), the skirt (31) having an inner wall coming opposite an outer wall of the container (2) when the cover closes the container, and in that said actuating member (32) projects from the internal wall of the skirt (31) cover (3).

Owner:SEB SA

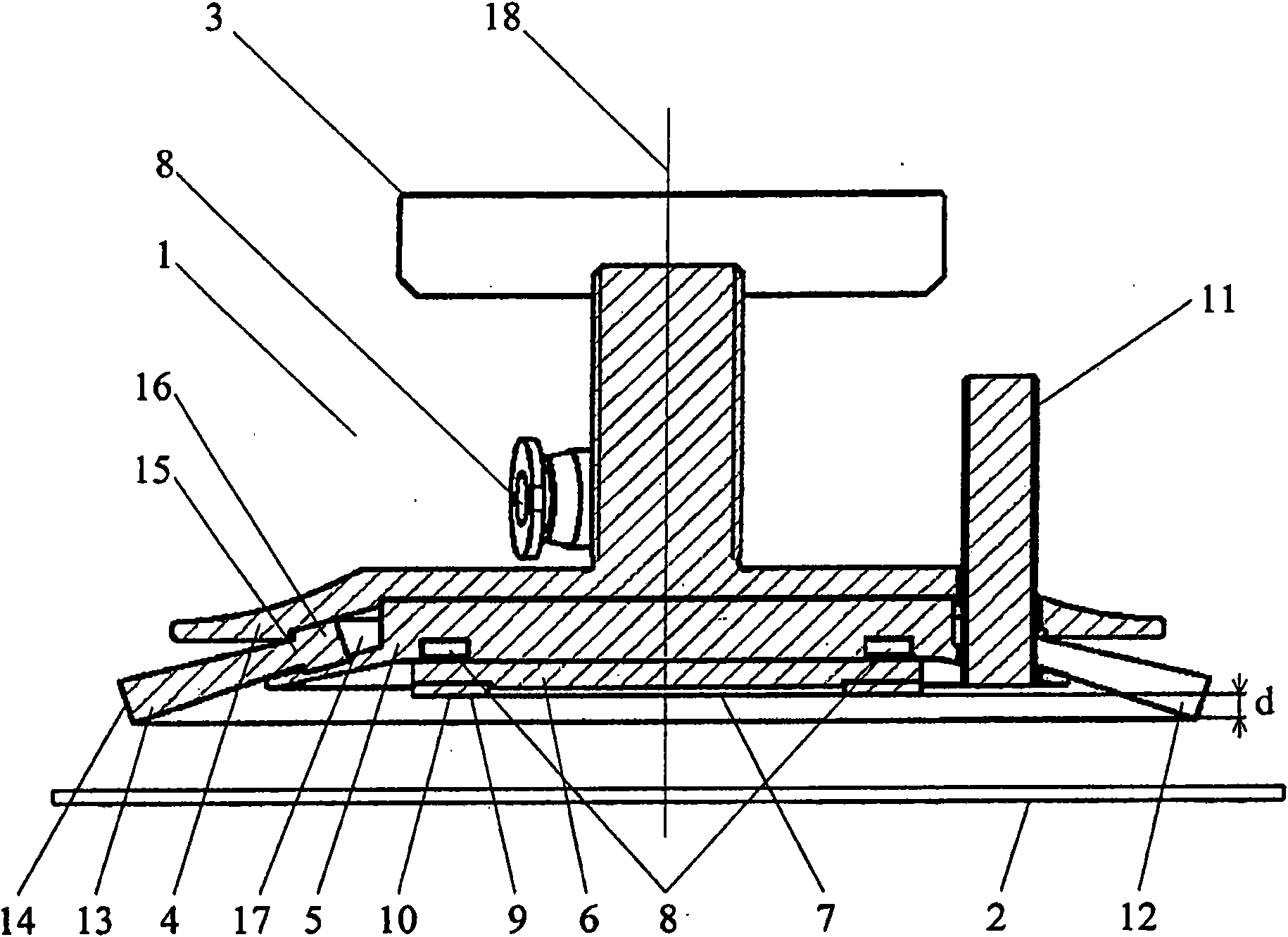

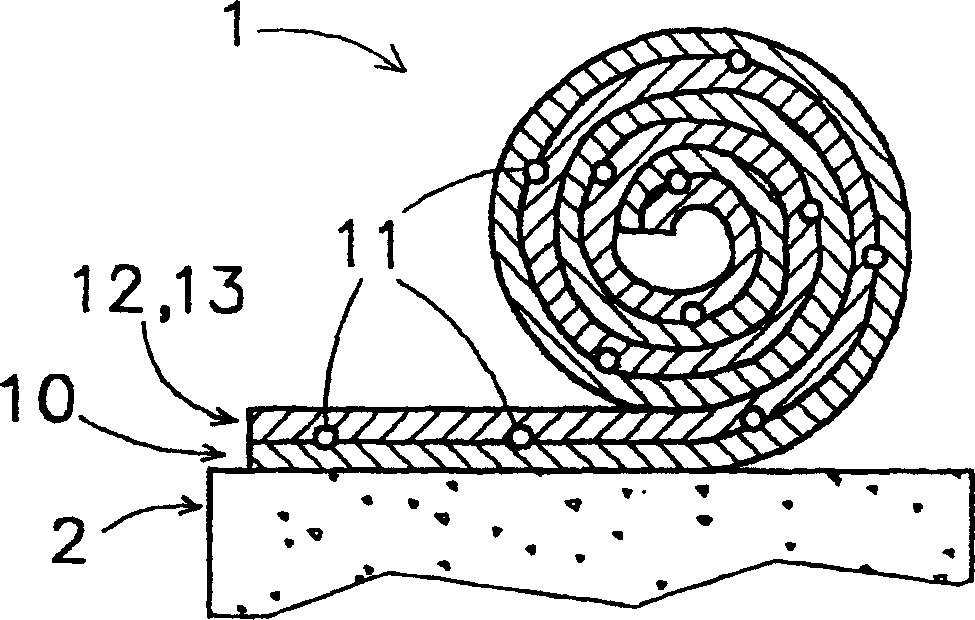

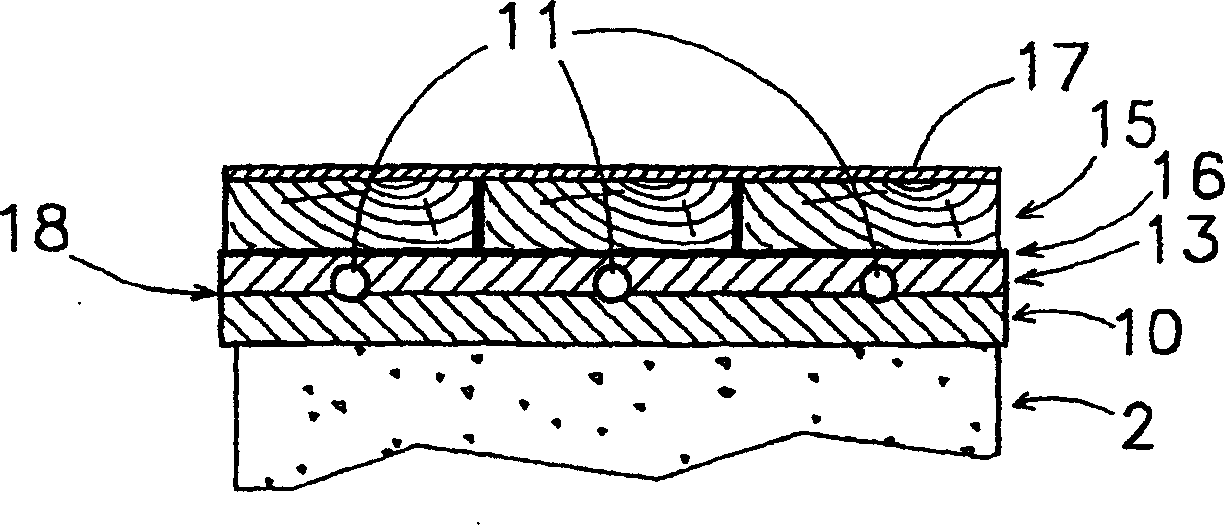

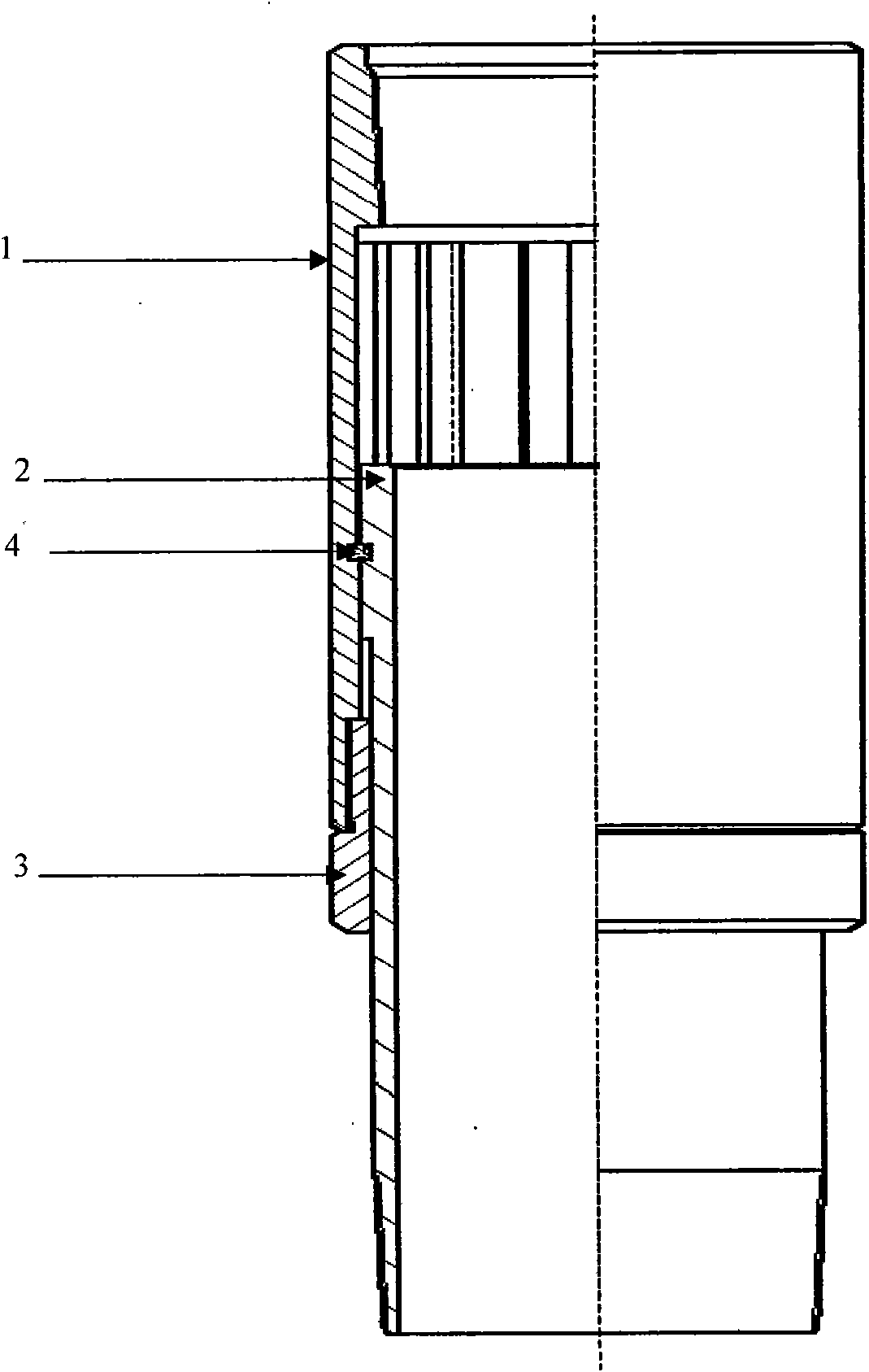

Roll-up heating for a floor, or wall

ActiveCN1749651AReduced risk of damageLighting and heating apparatusElectric heating systemEngineeringFloor covering

The roll-up heating (1) for a floor, or wall, comprises an insulating layer (10), a heating element (11) and a cladding (12). The insulating layer (10) is intended for laying on a floor (2) and the heating element (11) extends between the cladding (12) and the insulating layer (10). The cladding (12) is intended to support a floor covering (15) and comprises a force distribution layer (13) for transmitting a force which is exerted on the cladding (12) in a distributed manner to the insulating layer (10). In as far as (a part of) the heating element (11) is at the location or in the vicinity of the exerted force, the load which will be exerted on it will be lower than the original load, due to the force being transmitted in a distributed manner. This lowers the risk of the heating element (11) being damaged.

Owner:DANFOSS AS

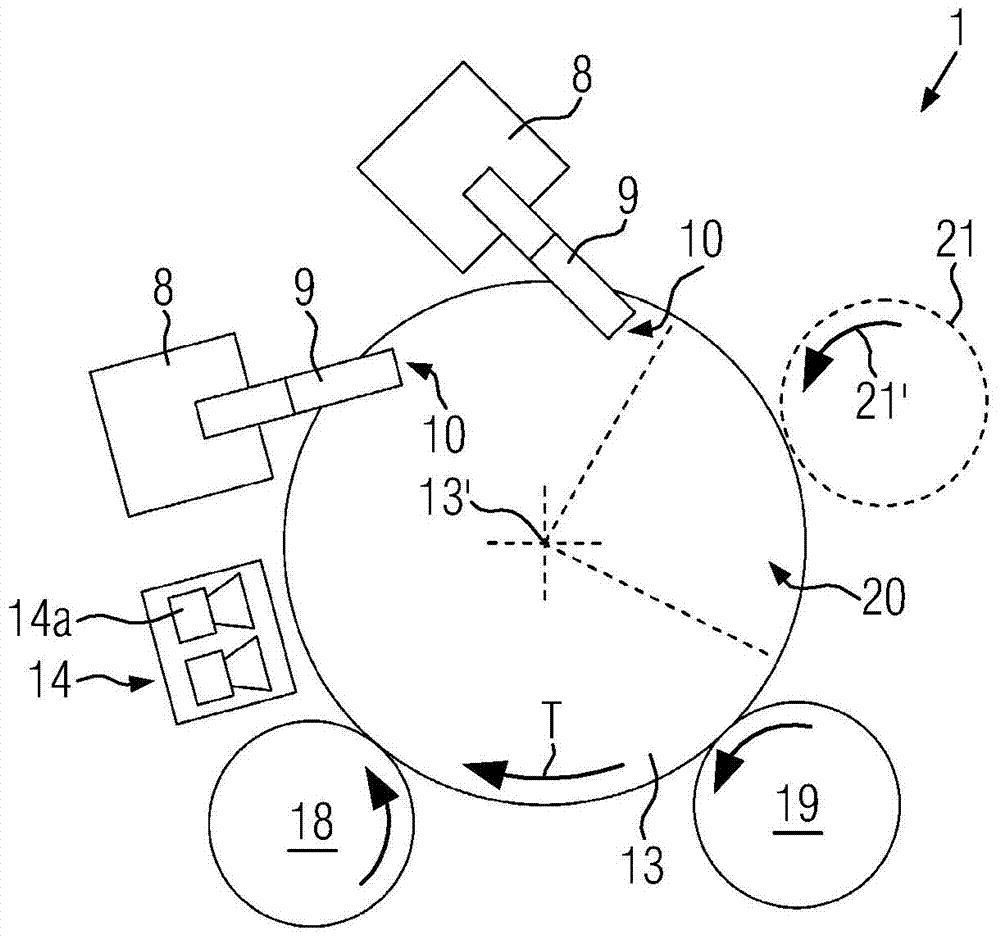

Device and method for providing containers with adhesive labels

InactiveCN103803137AIncrease productivityFacilitated releaseLabelling short rigid containersLabelling machinesRotating discEngineering

The invention discloses a device and a method for providing containers with adhesive labels. By using the device, the labels can be extended from the container to the side wall area of the container. The device comprises a circulating positioning unit used for clamping and adjusting a rotating disc and a centring cover of the container; at least one stationary fixed label supplier used for supplying and attaching the first segment of the labels to the upper side of the container; a pressing device used for pressing the second segment of the label to the side wall area waiting to be attached; an elevating device used for lifting the adjusted container controllably before the container arriving at the label supplier. By clamping the container between the rotating disc and the centring cover, and holding the adjusted container, the labels can be supplied from the upper side, and can be applied from top to bottom.

Owner:KRONES AG

Sleeve compensator special for thermal production well

ActiveCN101655004ASignificant progressRemarkable effectDrilling rodsPipeline expansion-compensationLocking mechanismPetroleum engineering

The invention discloses a sleeve compensator special for a thermal production well in petroleum industry. The sleeve compensator is connected in the tubular column of the sleeve of a thick oil thermalproduction well so as to provide effective compensation for the extension of the tubular column of the sleeve of the thermal production well which is caused by steam injection technology or the contraction of the tubular column which is caused by carbon dioxide injection and other measures and prevent the deformation damage of the sleeve caused by the extension or contraction. The sleeve compensator comprises an outer barrel and a central tube, the outer barrel is connected with a boot cap, the central tube is connected with the outer barrel through splines, a locking mechanism is arranged between the outer barrel and the central tube. The sleeve compensator of the invention has stable operation, simple structure, short tool length, low cost and long compensation distance, is applicable to the design of various thermal production well completion technologies, can be placed to any desired place and can not be affected by inclination. The sleeve compensator can ensure that when performing the steam injection of thick oil thermal production well, the completion string can be intact and not be damaged owning to the temperature change; no successive activity is needed to do after the construction and the inner drift diameter of the well is kept the same after well completion, thus providing good conditions for successive activity and construction.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

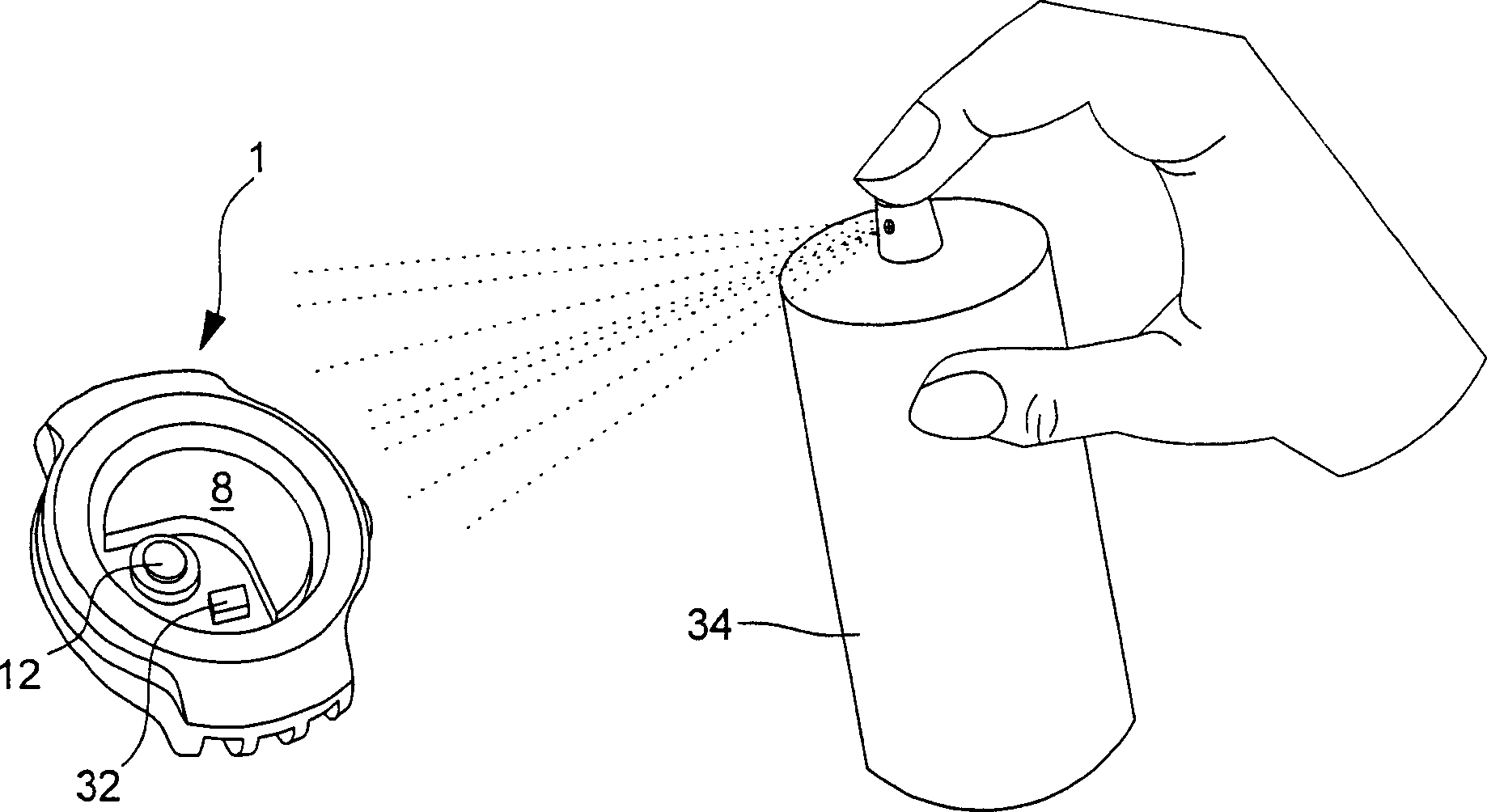

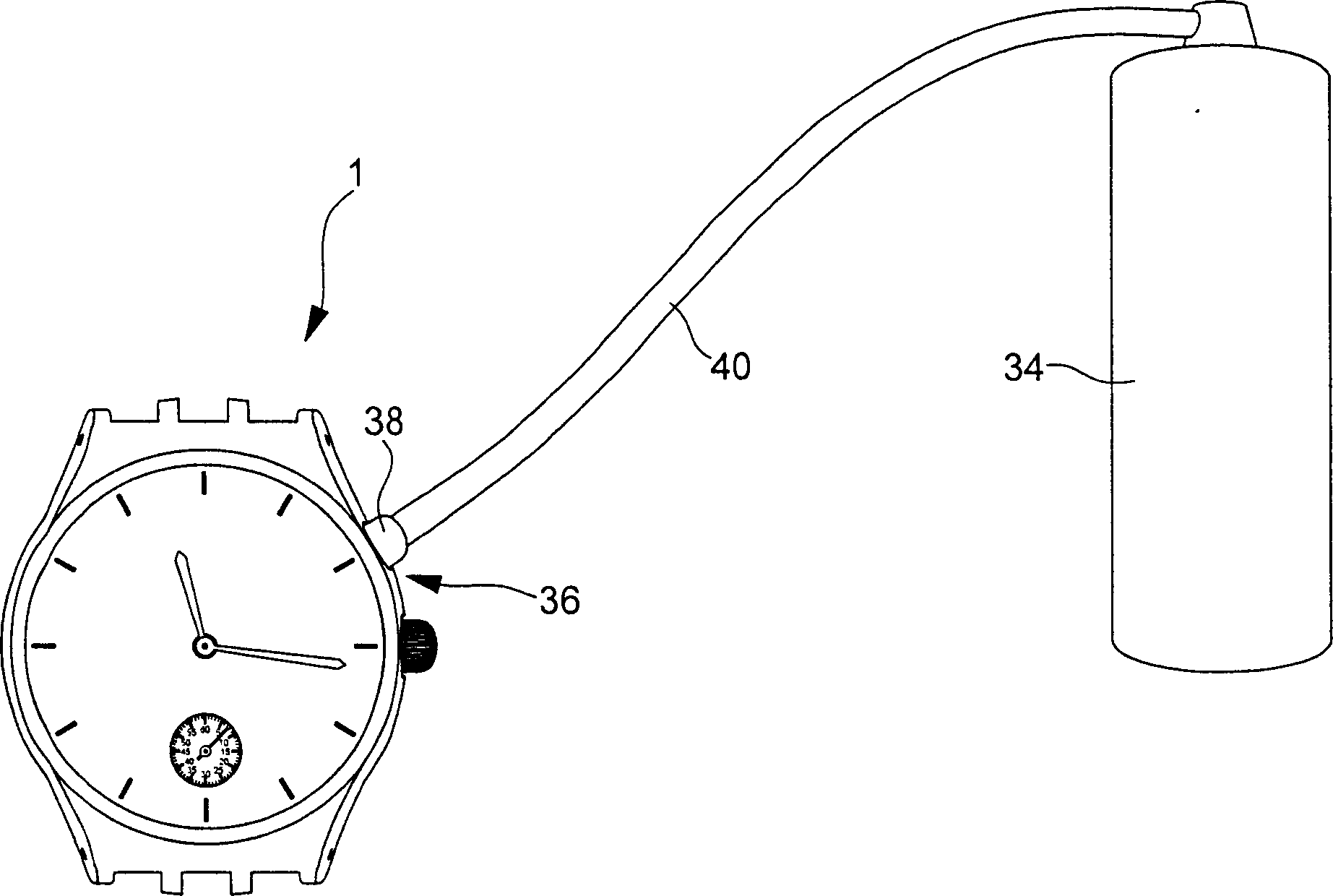

Device and method for testing the leak-tightness of a timepiece case

InactiveCN1675598AReduced risk of damageSave spaceDetection of fluid at leakage pointElectric windingEngineeringVisual perception

The invention relates to a device for testing the leak-tightness of a case (2) belonging to an electronic timepiece (1) comprising a time base (42) which is used to produce a standard frequency signal and a central processing unit (44) which is used to determine the time from said standard signal. The invention is characterised in that it comprises an electronic sensor (32) which can measure fluctuations in the concentration of an atmospheric gas confined in the case (2). According to the invention, the results of the measurement taken by the electronic sensor (32) are processed by the central processing unit (44) which, if necessary, emits an audible or visible alarm in response to the measurement signal.

Owner:ASULAB SA

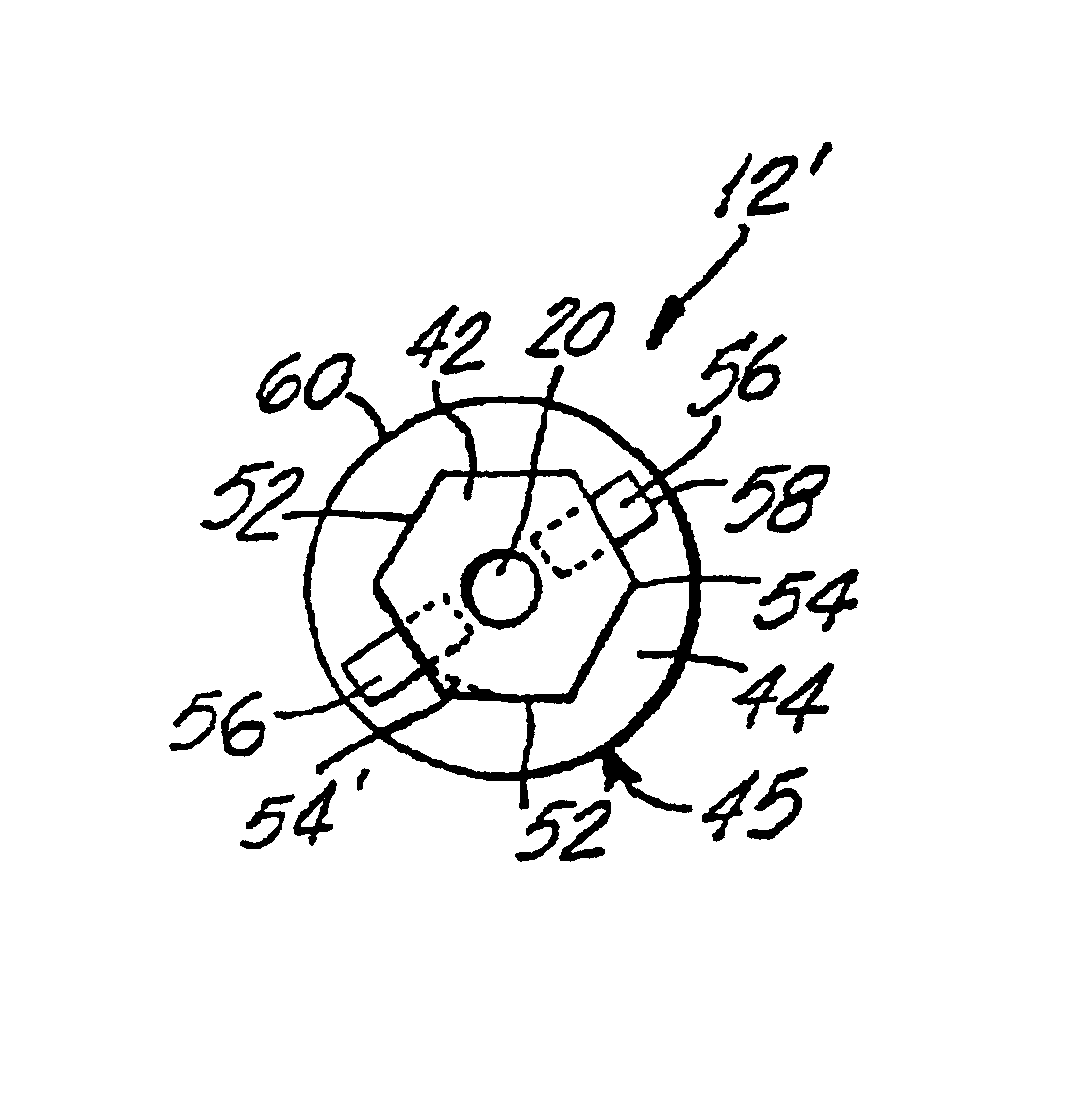

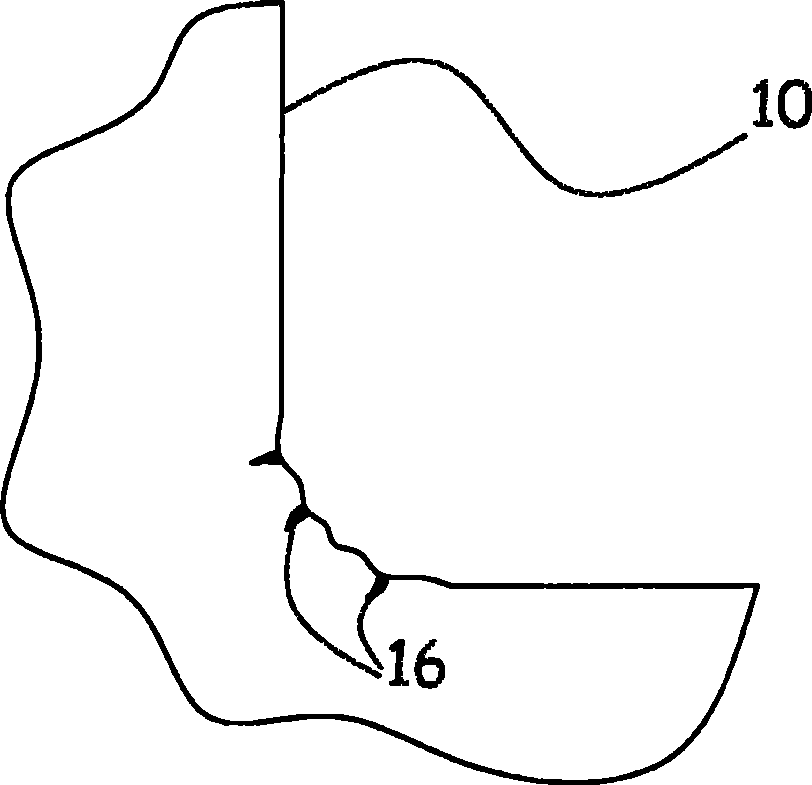

Dental implants and methods for extending service life

InactiveUSRE38945E1Extended service lifePrevent rotationDental implantsFastening prosthesisJaw boneOsseointegration

An implant has a proximal protrusion that is distinctly non-round even in a worn state, e.g. square in cross section, and may include radial slots for use in threading the implant into the jaw bone. No forces need be applied directly to the protrusion's external surfaces when inserting the slotted implant for subsequent osseointegration.

Owner:FRIED PAULA S +1

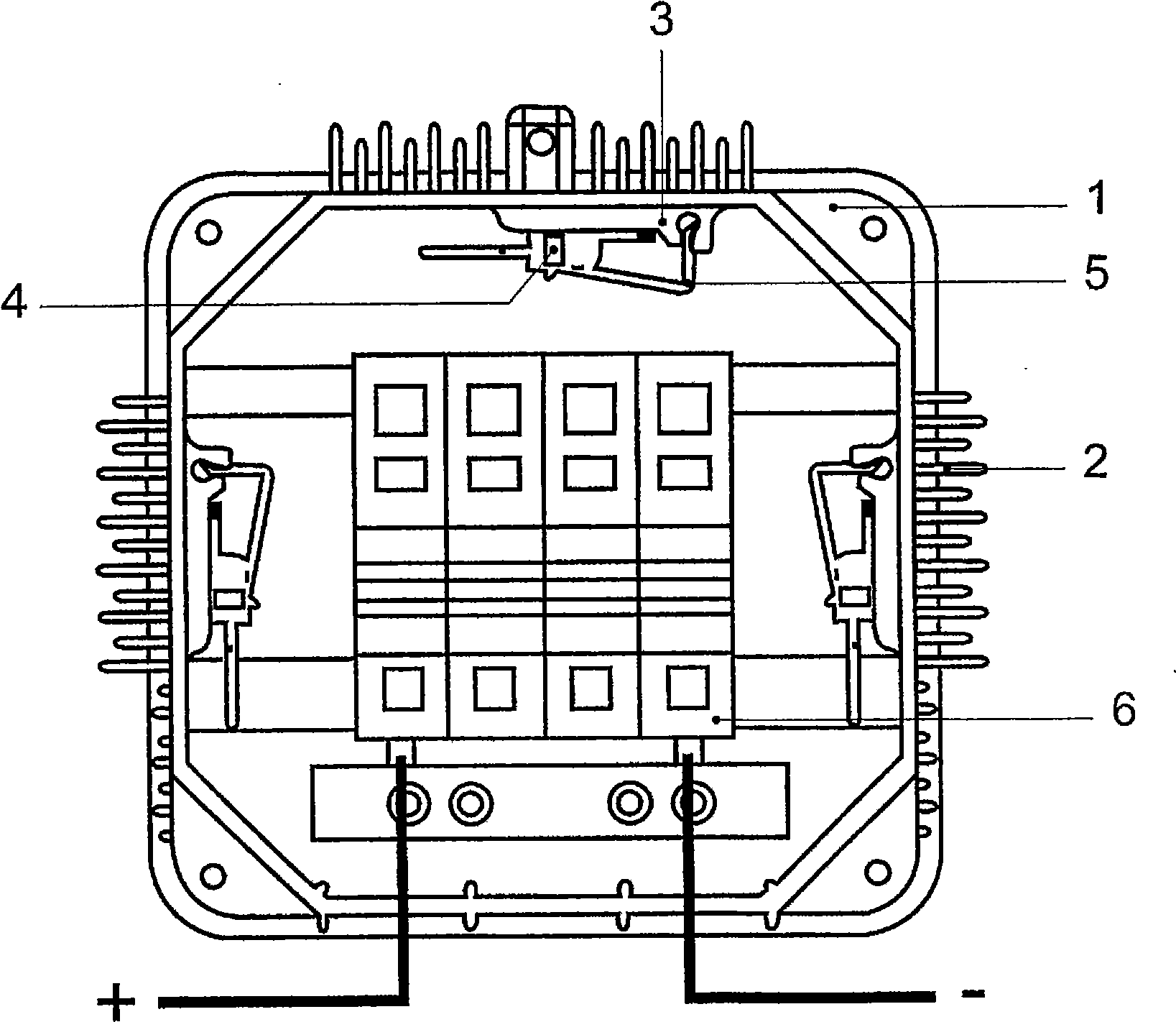

Junction box to protect individual solar panels from overheating

InactiveCN101501867AAvoid damageReduced risk of damageElectrically conductive connectionsPhotovoltaicsMOSFETEngineering

The invention relates to a junction box for solar panels, with which the heat produced in the protecting diodes, MOSFETs, or other suitable power semiconductors of a solar panel is safely carried off. The electronic components are pressed against the housing (1) or into recesses (3) in the connection box that match the geometry of the components, by means of pressure elements, wherein there is electrical insulation, preferably a thermally conductive silicone rubber, between the housing (1) and the components.

Owner:FPE FISCHER GMBH

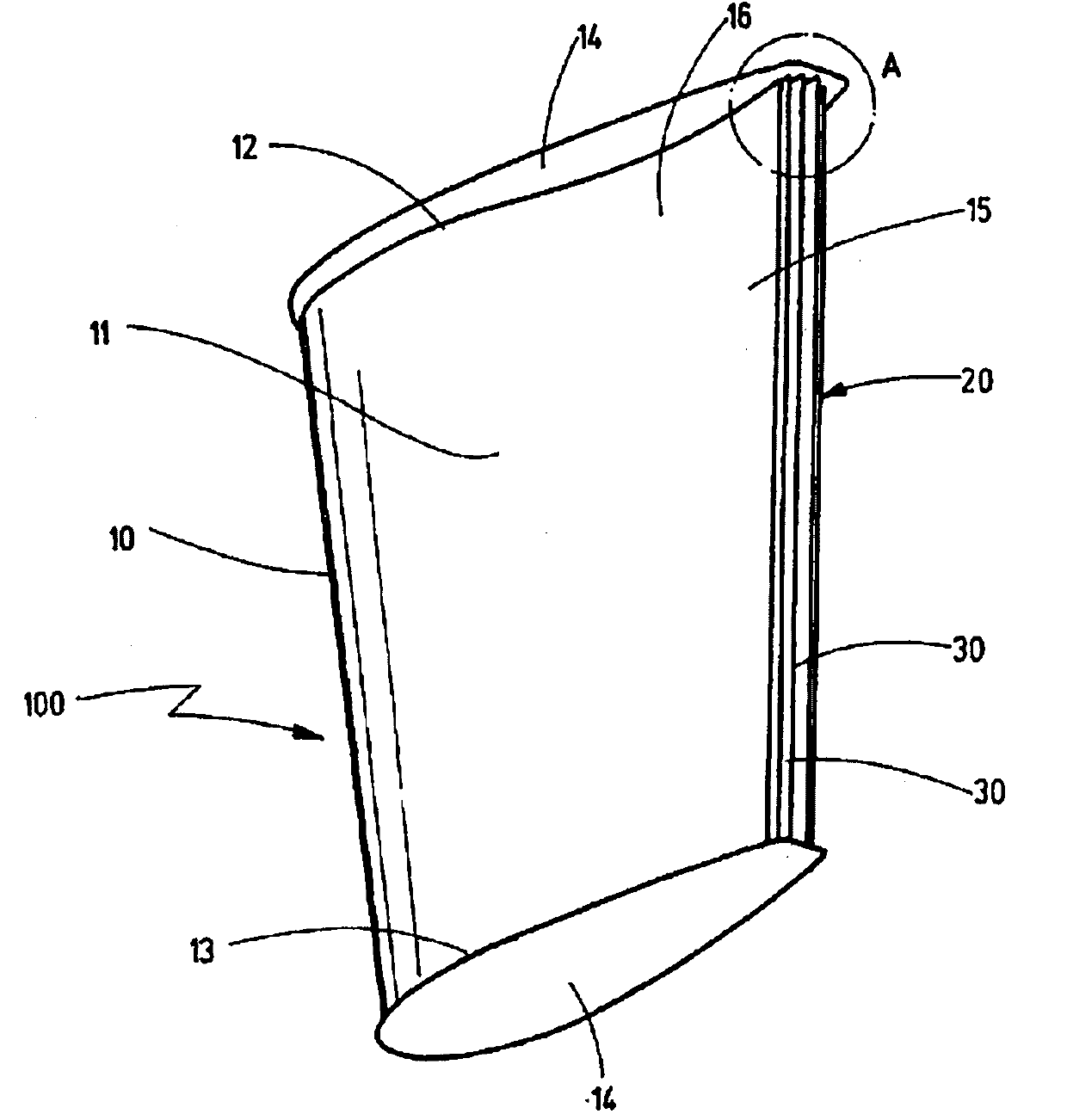

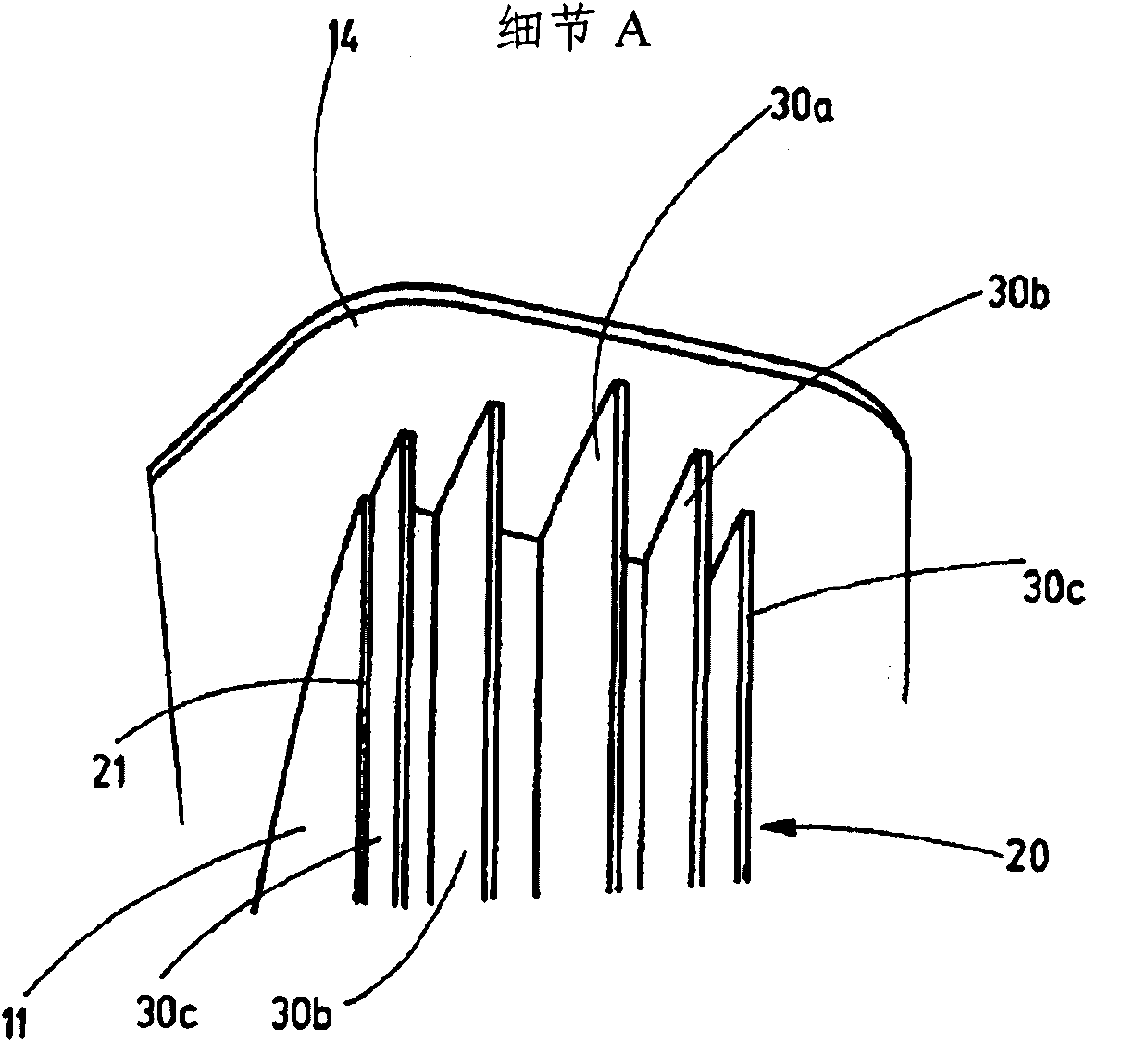

Hydrofoil for water-borne vessels

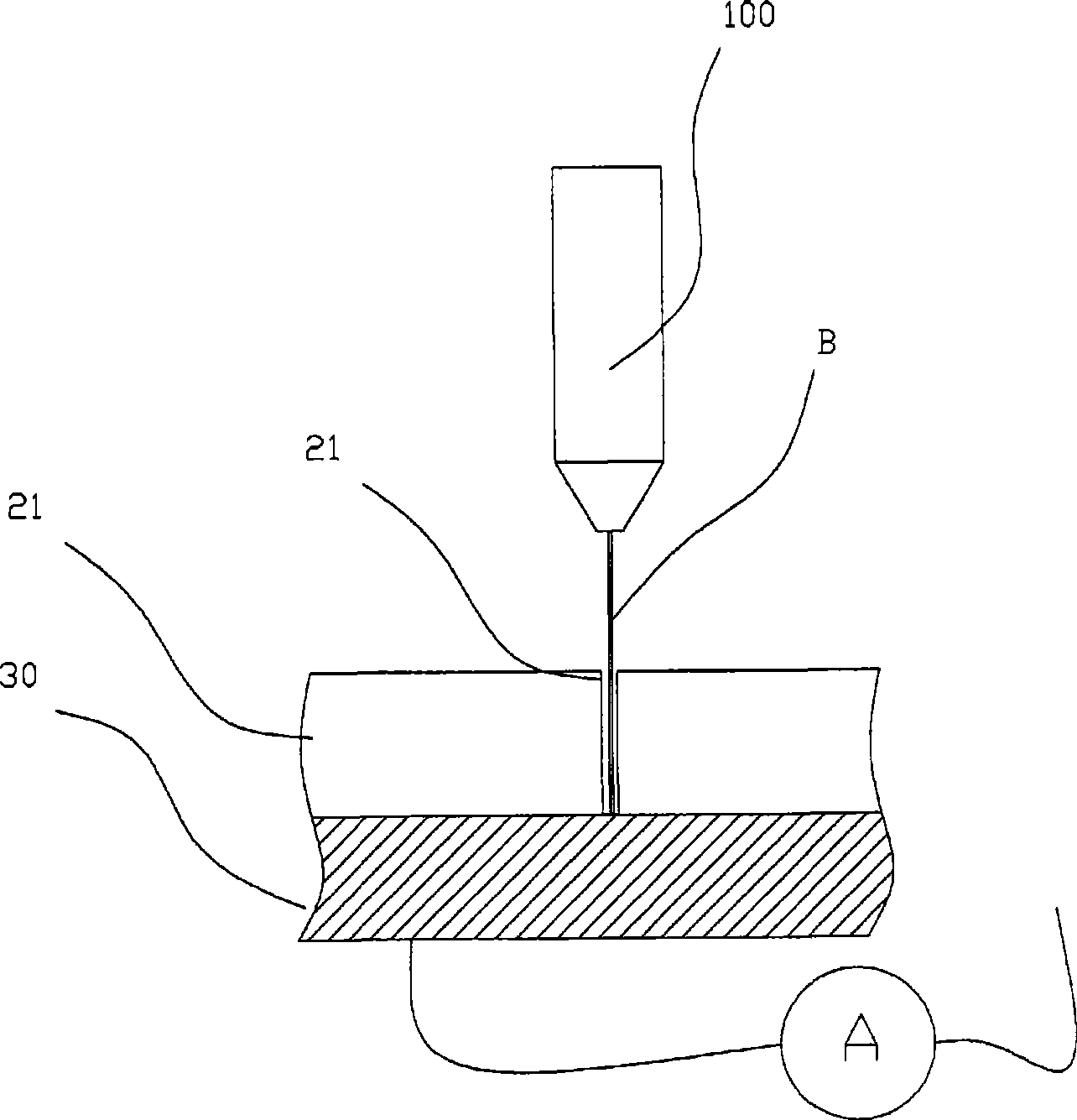

InactiveCN101992852AReduced risk of damageIncrease resistanceSteering ruddersVessel movement reduction by foilsEngineeringTrailing edge

Provided is a hydrofoil (100), in particular a rudder, for water- borne vessels, in particular ships, with a trailing edge (20), in which the negative effects of vortex formation in the direction of flow behind the hydrofoil, and / or of Karman vortex streets, are reduced, a projecting body (30) is arranged at the trailing edge (20) for the purpose of reducing vortex formation.

Owner:BECKER MARINE SYST

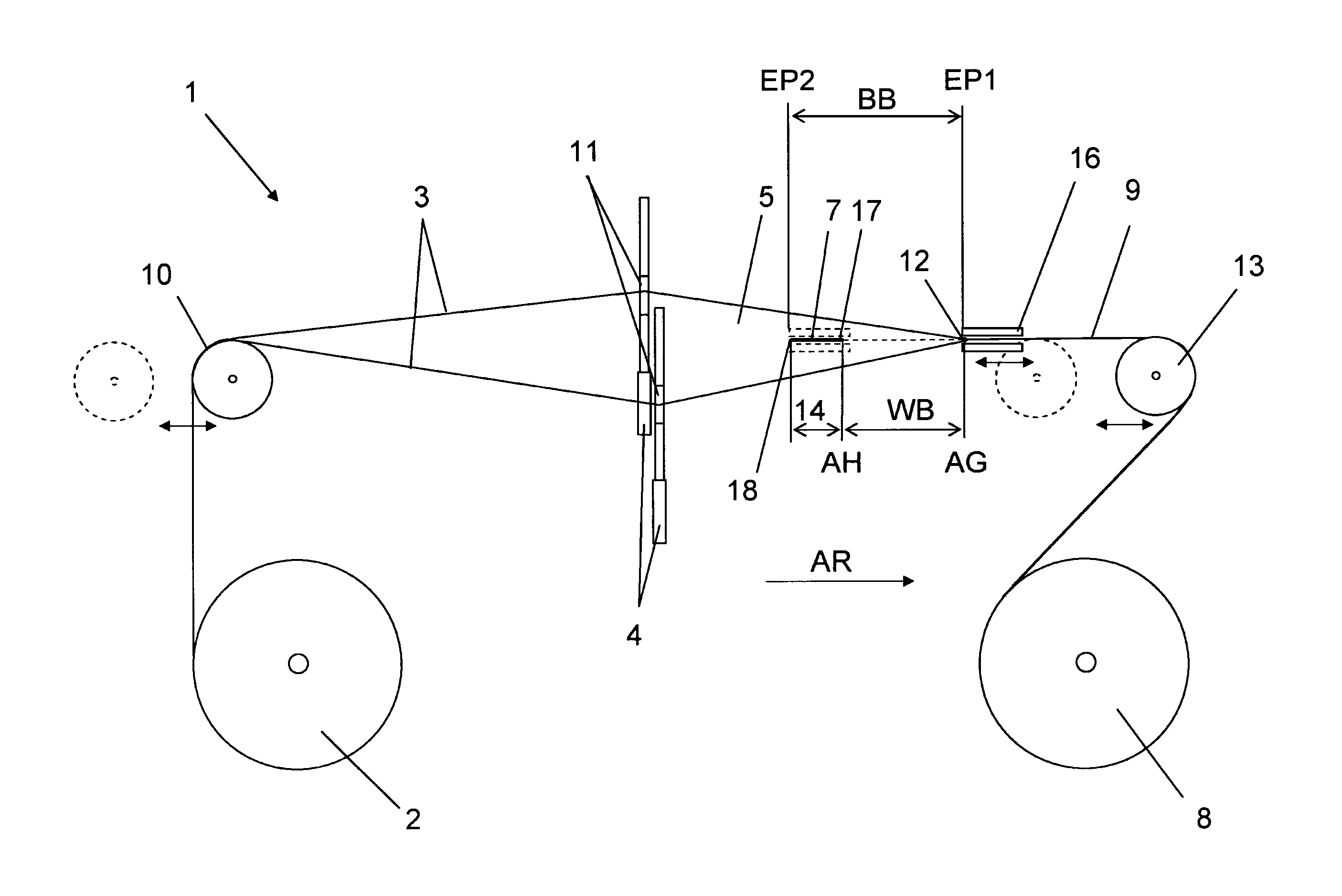

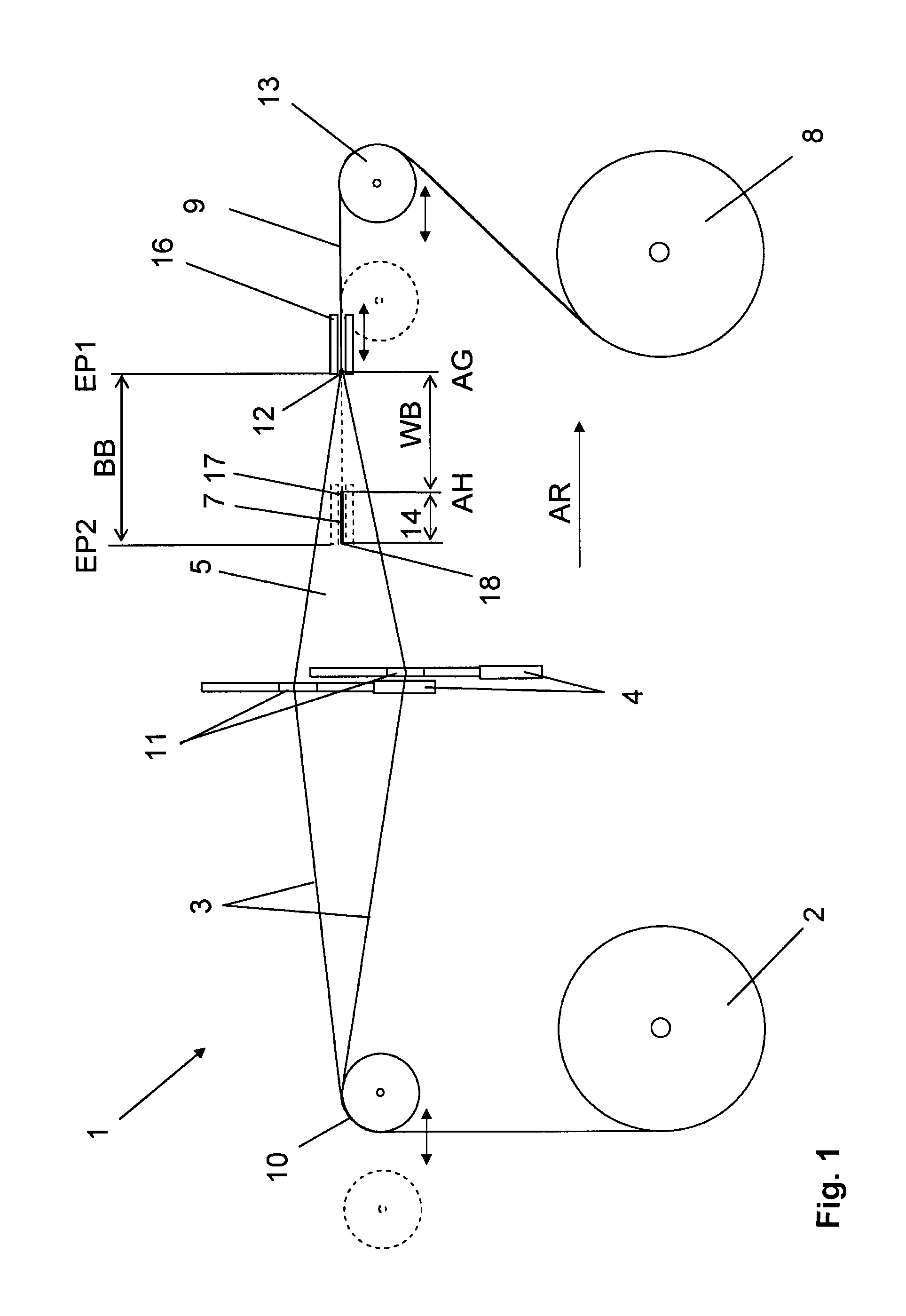

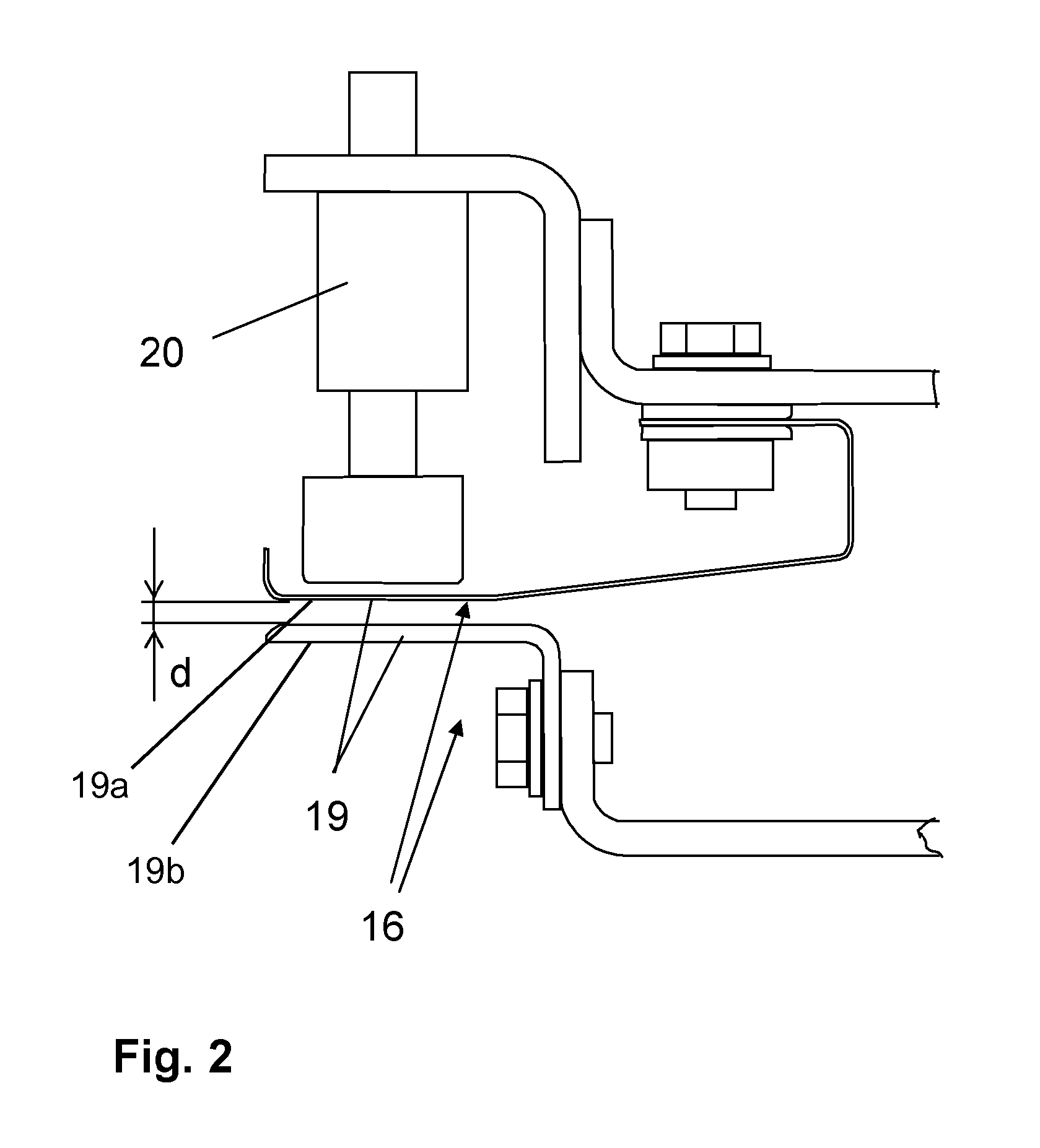

Weaving machine having movable shed opening limiter device

InactiveUS8939179B2Avoid collisionReduced risk of damageLoomsAuxillary apparatusWoven fabricInsertion device

A weaving machine for producing a woven fabric has a shedding device to form a loom shed of warp material, a weft insertion device for inserting a preferably tape-shaped or band-shaped weft material into the loom shed, a drawing-off device for drawing off the finished fabric in a drawing-off direction, fabric movement device for moving the fabric back and forth in the warp direction to bring the last inserted weft material into contact with the binding point or fabric edge. A shed limiter device limits the opening of the loom shed from above and below the warp, and is movable back and forth in the warp direction. The shed limiter device only loosely bounds the fabric and essentially without actively clamping or pinching or contacting the fabric and / or the last inserted weft material, at least while moving in the direction opposite the drawing-off direction.

Owner:LINDAUER DORNIER GMBH

Method of repairing a damaged area of an aircraft fuselage

ActiveCN101472798AExtended operating hoursExtended service lifeAircraft maintainanceEngineeringFuselage

The object of the invention is method of cutting out a damaged area from an aircraft fuselage, in particular in order to repair said damaged area, consisting in making at least one cut-out in the fuselage (20) in order to delimit a cut-out area (24) encompassing the damaged area and comprising at least one rounded section, characterized in that it consists in making an opening (34) near said rounded section of the cut-out area (24) with a tool the diameter of which corresponds to that of the desired rounded section.

Owner:AIRBUS OPERATIONS (SAS)

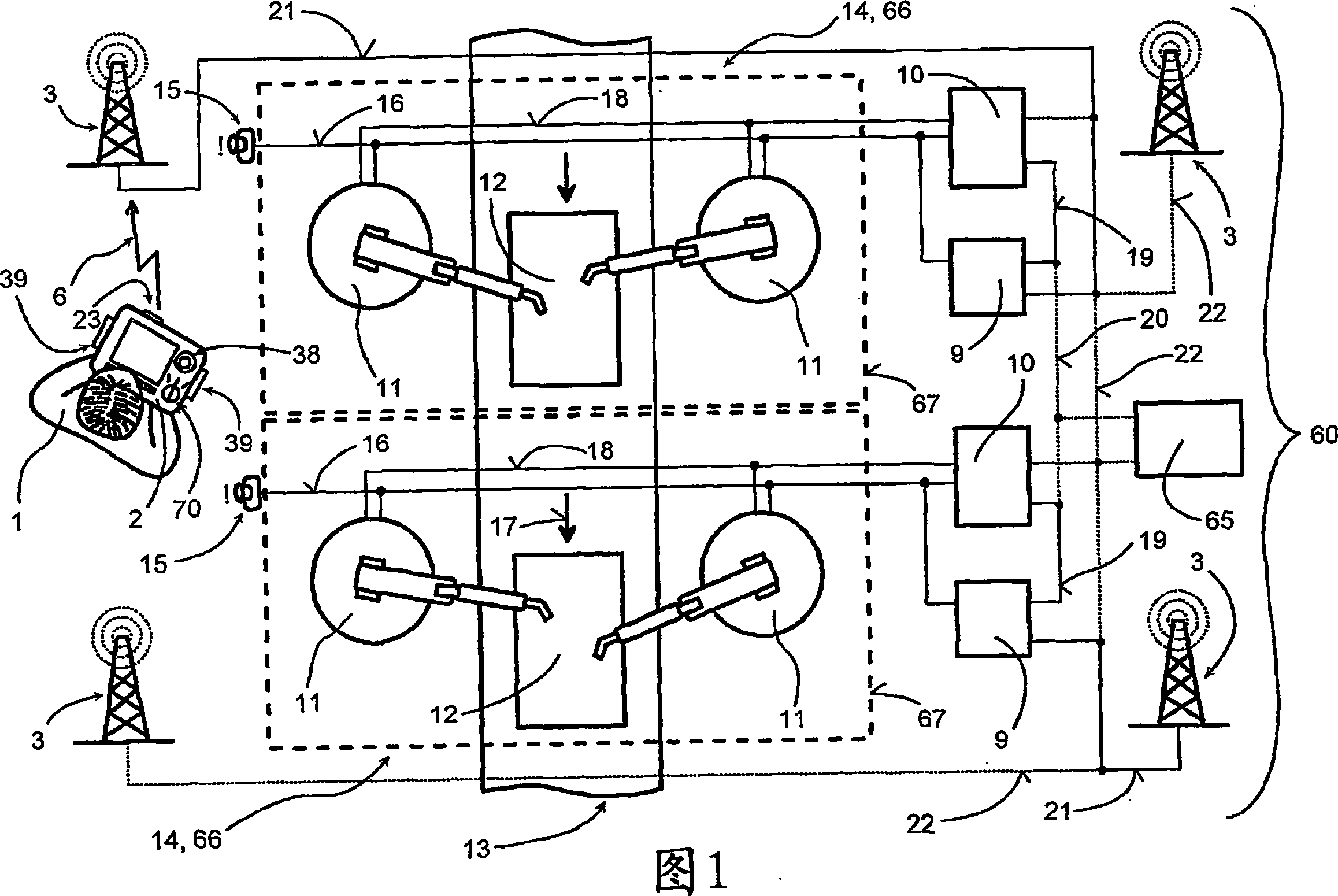

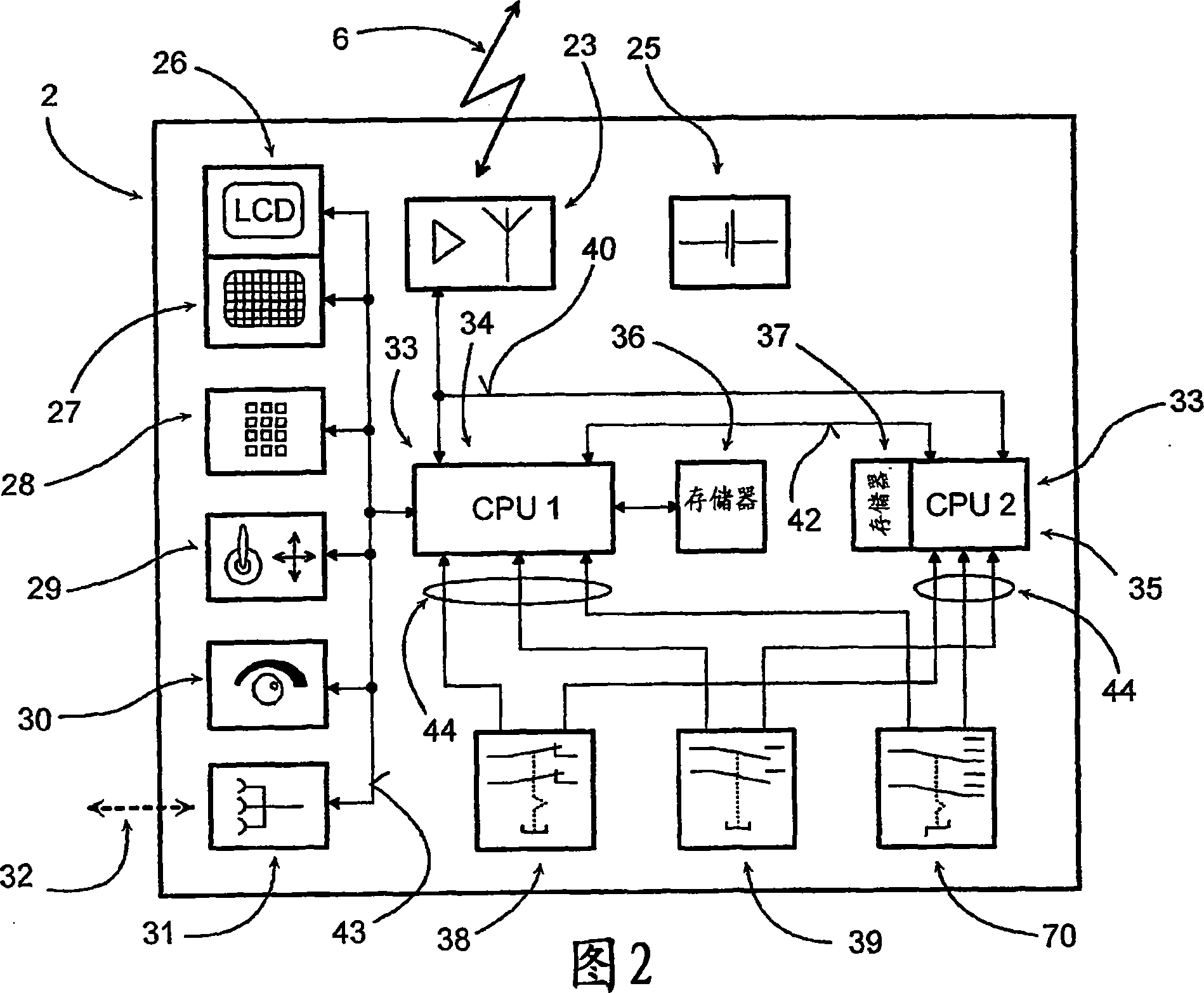

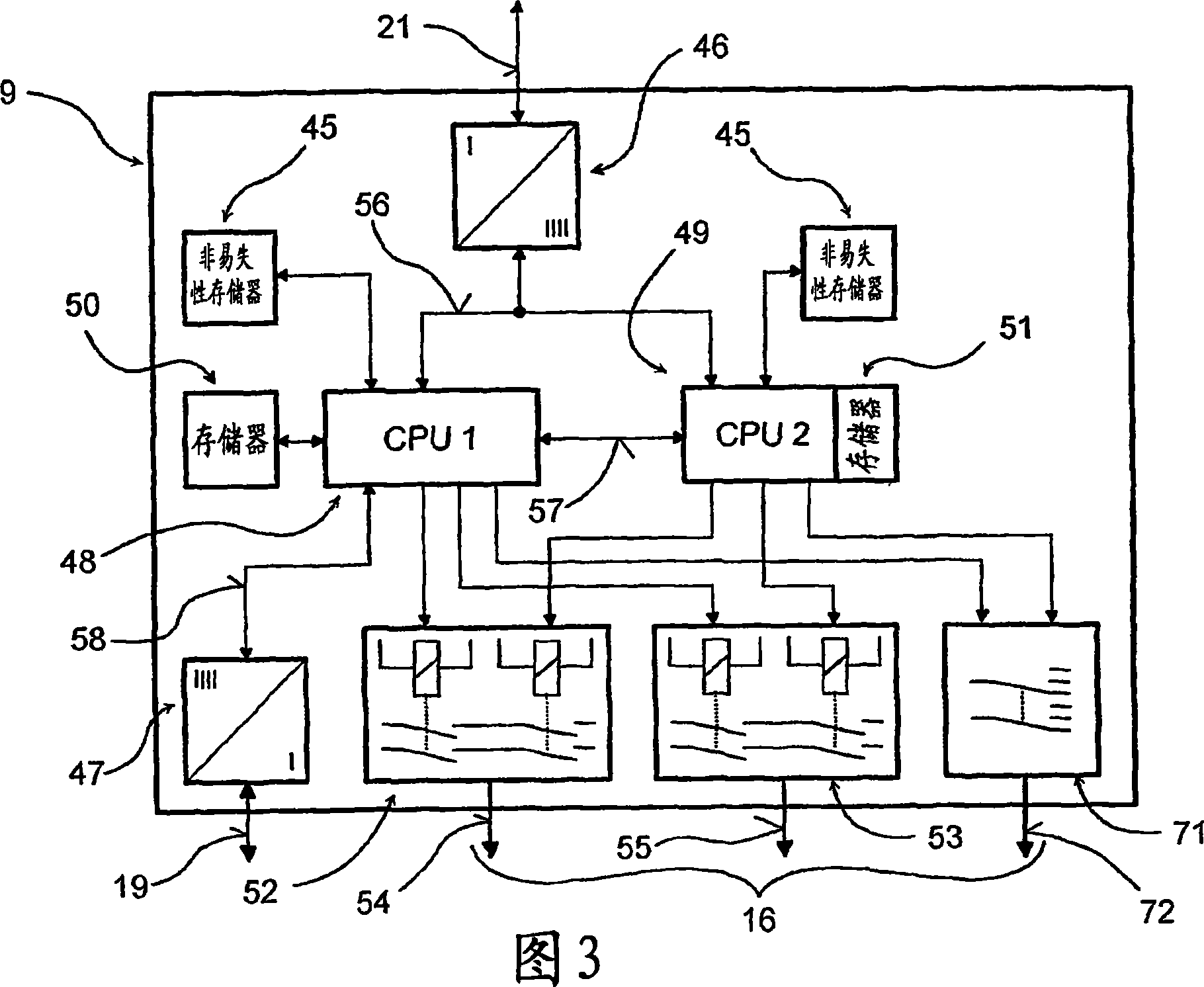

Method for establishing, disconnecting and operating a temporary active connection between a mobile operating device and a controllable unit and appropriately configured data-transmission remote termi

ActiveCN101253455AFavorable Design PossibilitiesSave independent power supplyProgramme controlProgramme-controlled manipulatorControl theoryData transmission

The present invention relates to methods and suitable devices for the safe establishment and disconnection of a temporary data or signal active connection between a mobile operating device (2), which comprises at least one specially configured safety switching device (38) opposite a safety circuit (16), and the functional controller (10) of a controllable unit. Said methods and devices ensure that the safety switching element (38) can be coupled to and disconnected from the safety circuit (16) during the establishment and disconnection of the temporary active connection and that no operator can unintentionally modify the signal condition of the safety device and the operating state of the controllable unit. In addition, the present invention relates to a method for operating a temporary data or signal active connection between a mobile operating device (2) and a controllable unit, with a secure interconnected data-transmission remote terminal (9).

Owner:KEBA GMBH & CO

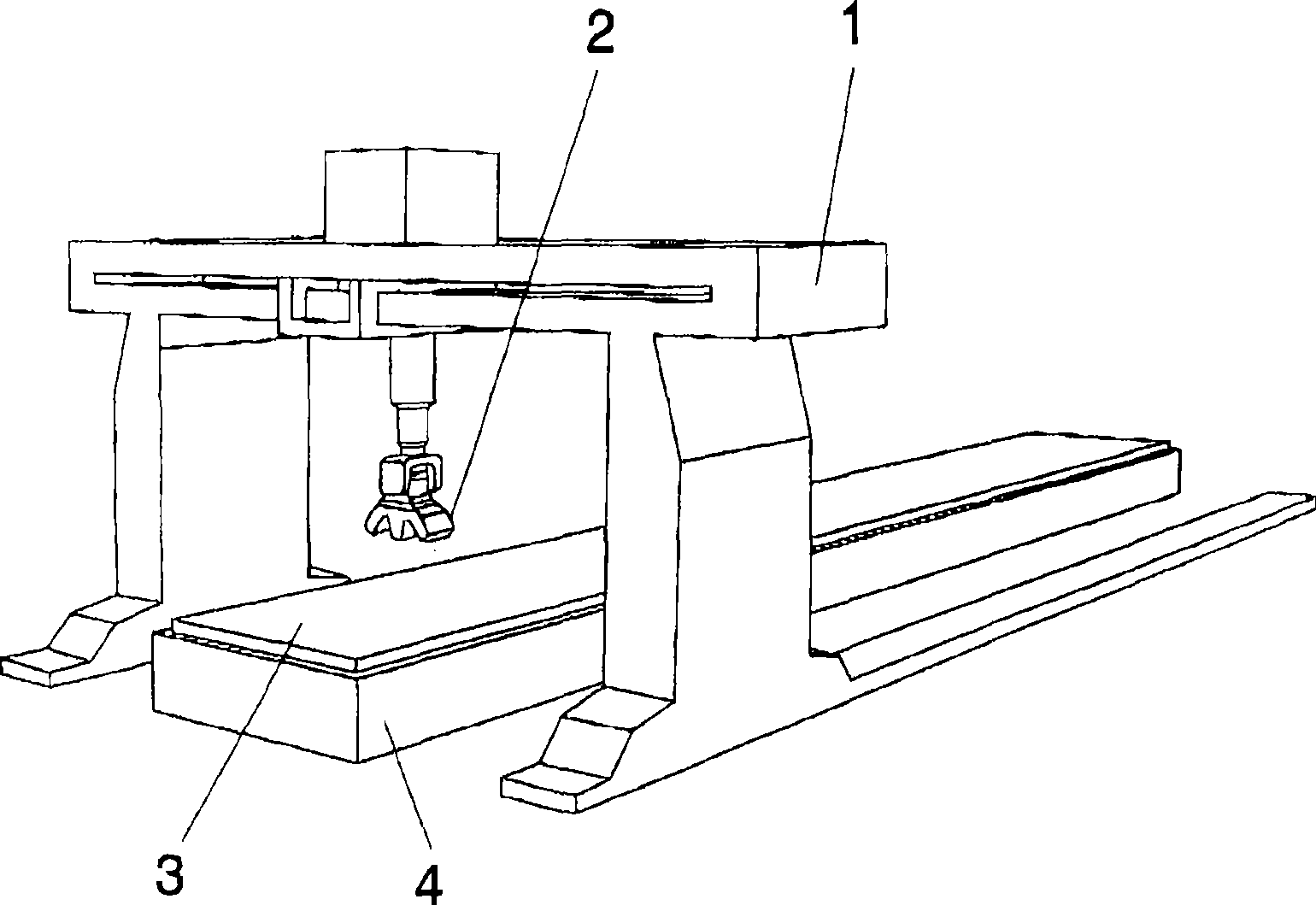

Procedure for the preparation and cleaning of tools used for manufacturing composite material components, and the corresponding device

ActiveCN101462108AImprove securityImprove hygienePretreated surfacesCoatingsThird phaseBiomedical engineering

A procedure for the preparation and cleaning of tools used for manufacturing composite material components includes: a first phase of blowing and sucking a surface resin layer from the tool; a second phase of cleaning all surfaces and notches by laser and suction where the tool (3) on a positioner (4) is held under a laser head; a third phase of applying a releasing agent on the tool (3) by spray, and a fourth phase for drying off this releasing agent by means of the aforementioned laser head (2) through different settings.

Owner:AIRBUS OPERATIONS SL

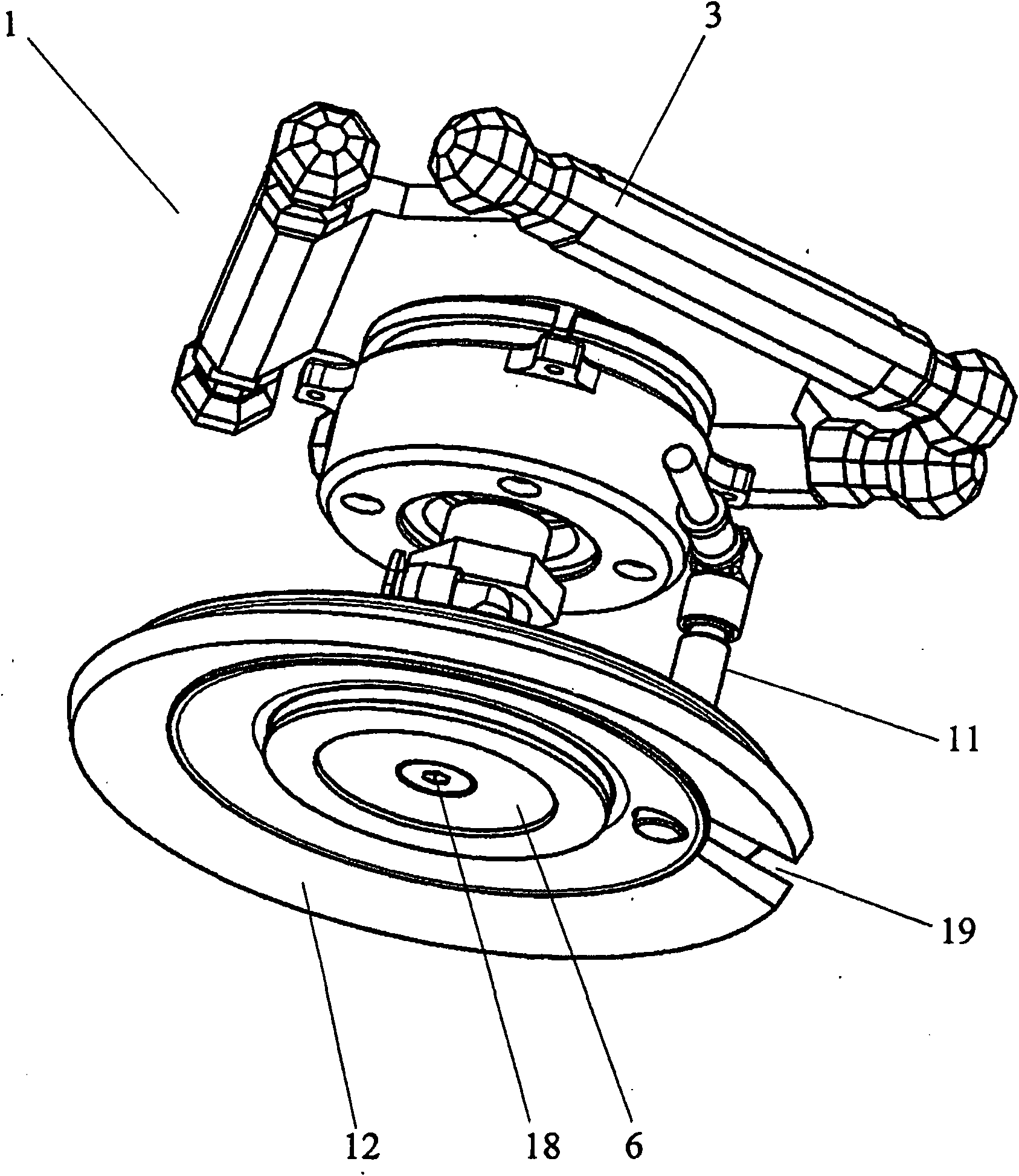

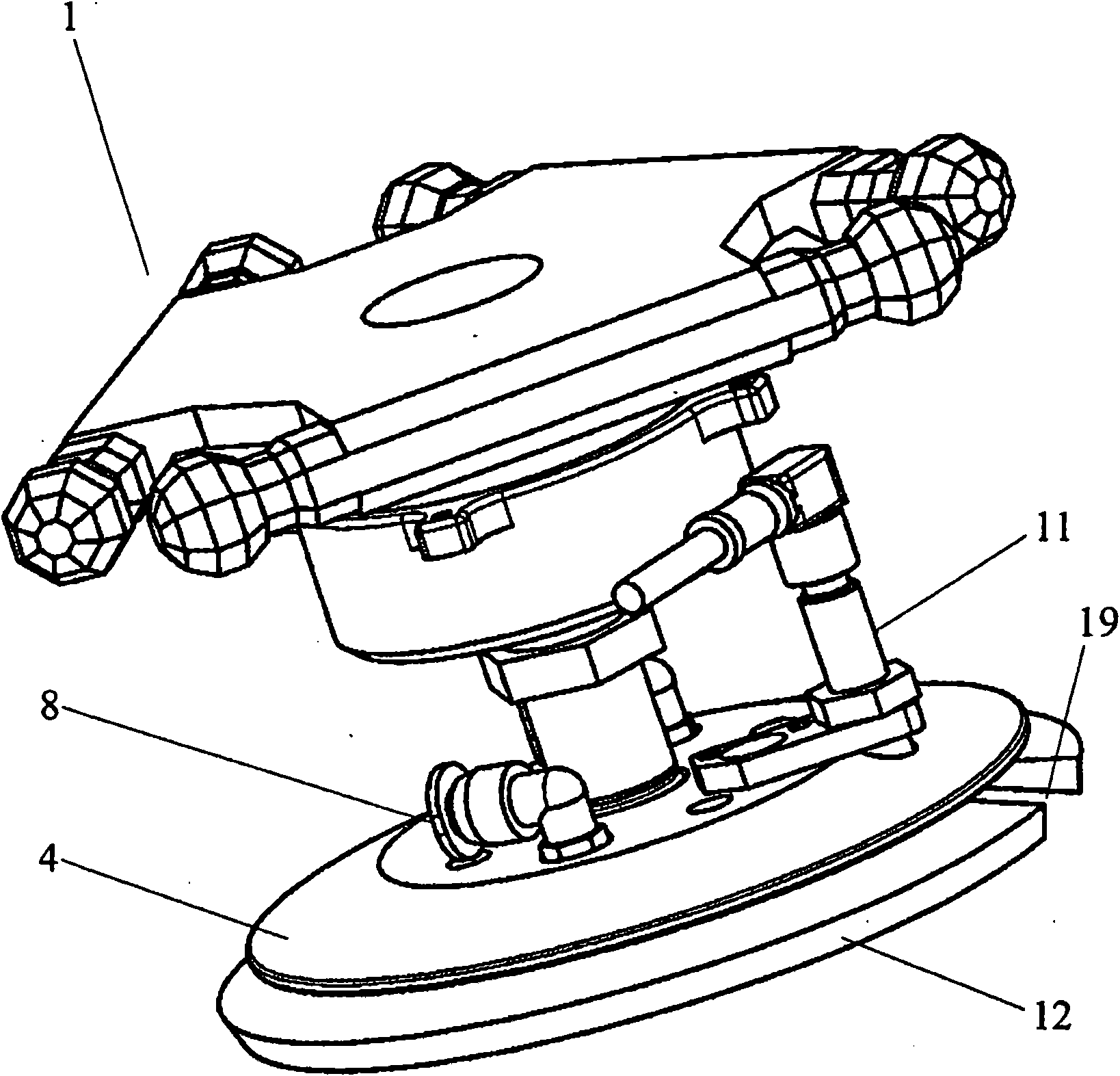

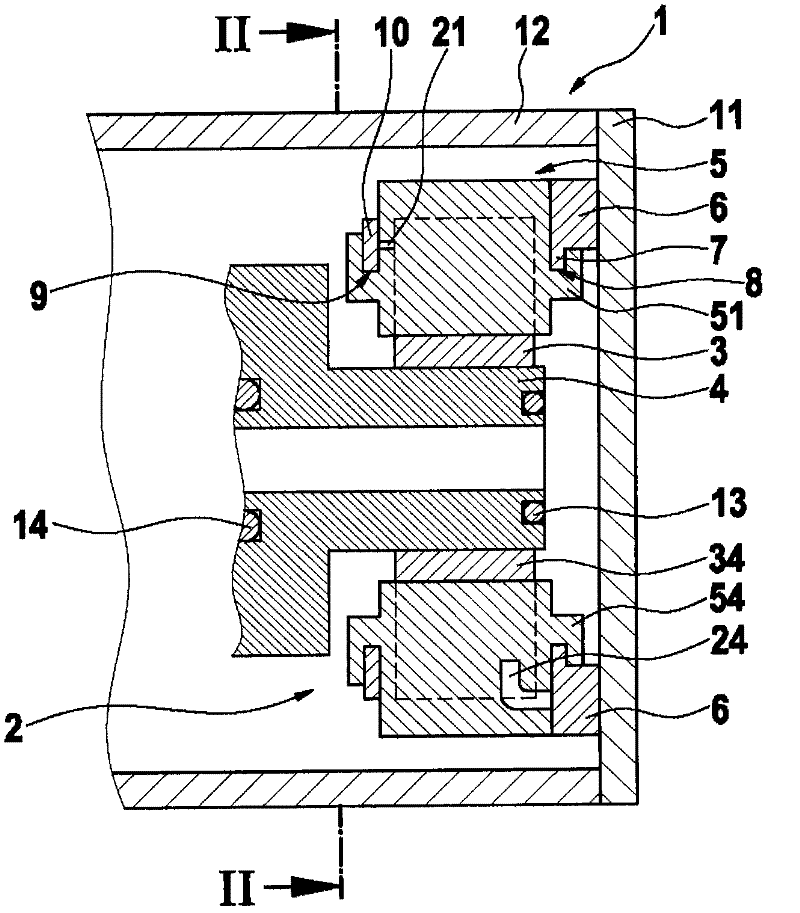

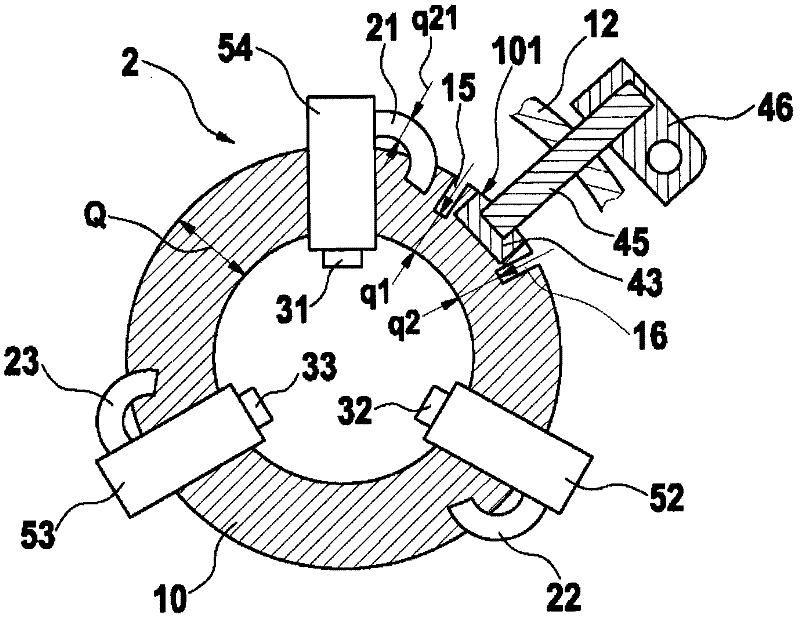

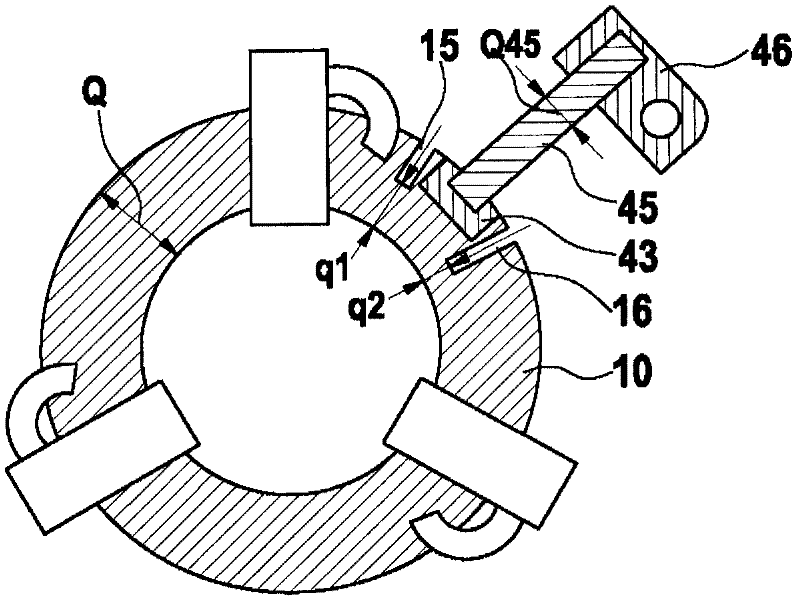

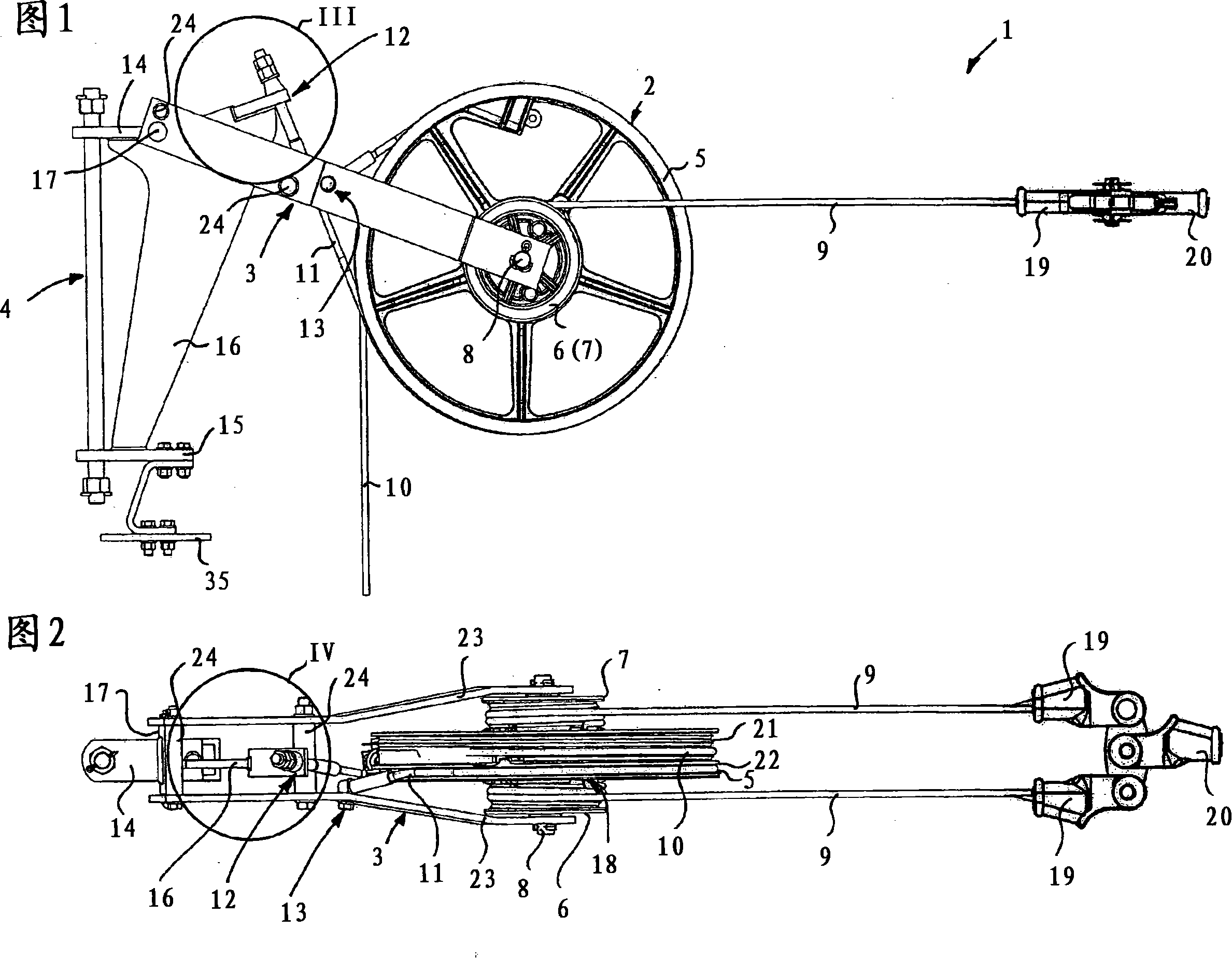

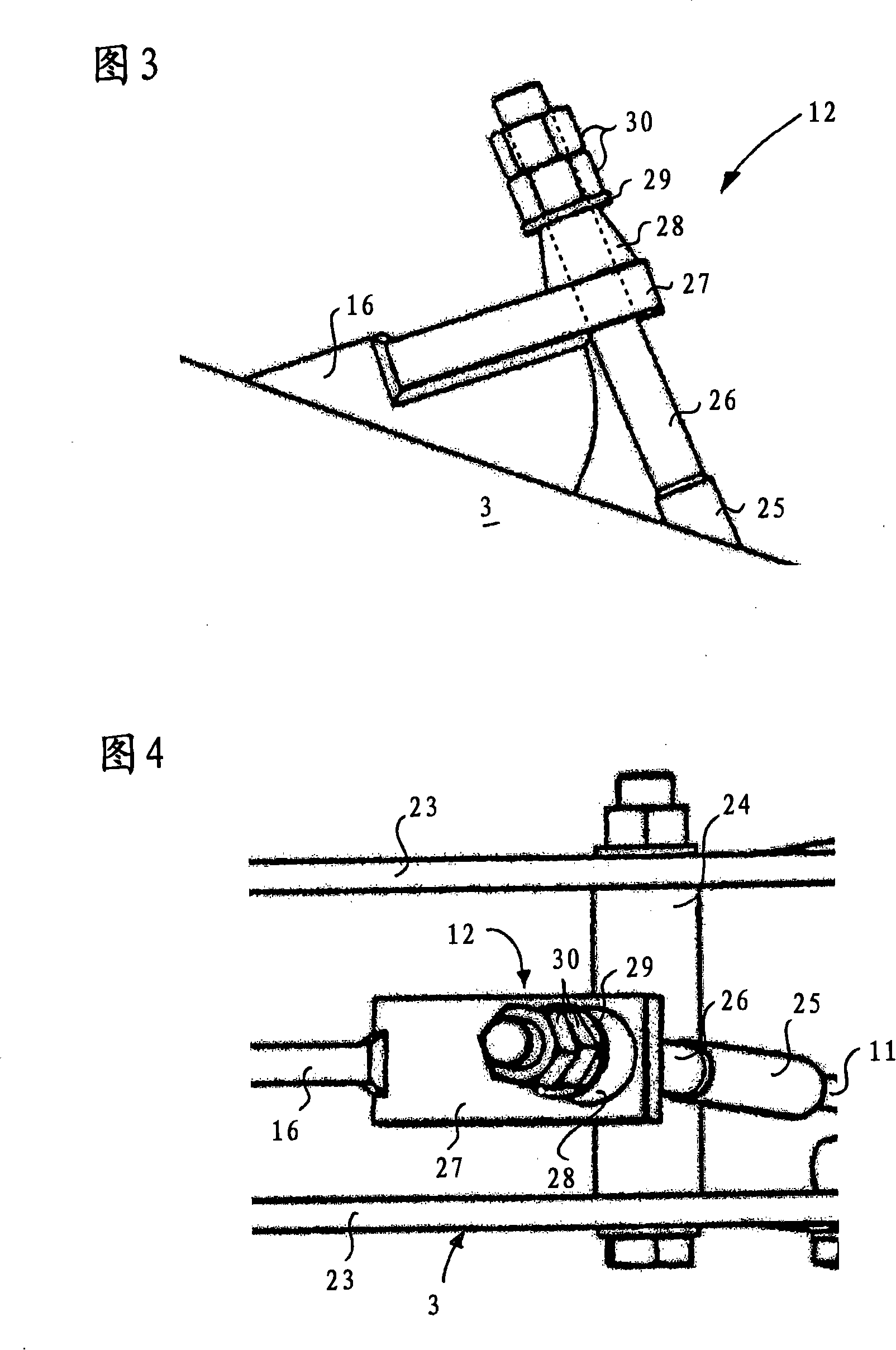

Radspanner

ActiveCN101104386AReduce manufacturing costImprove mechanical stabilityTrolley linesRotational axisBrake

The present invention relates to a wheel tensioner (1) for sliding contact line or bearing rope of a trackless device. The wheel is arranged with a stop with an arrester and a holding device used when the sliding contact line or the bearing rope ruptures. Thus, the wheel tensioner comprises a tensioner pulley (2) which is fixed on the trackless bracket or a wall by means of a fixed device (4) and can swing relative to the trackless bracket or the wall vertically; the tensioner pulley is arranged with a braking roller (5) for installing braking belt or braking rope (11). The braking rope is fixed on the fixed device (4) at the upper fixing point (12). The wheel tensioner also comprises a swing arm (3) which supports the tensioner pulley (2) and is supported on the fixed device (4) by means of the swing of a rotary bearing (17). The braking rope (11) is fixed on the swing arm (3) at the lower fixing point (13).

Owner:理查德伯格电子装置有限及两合公司

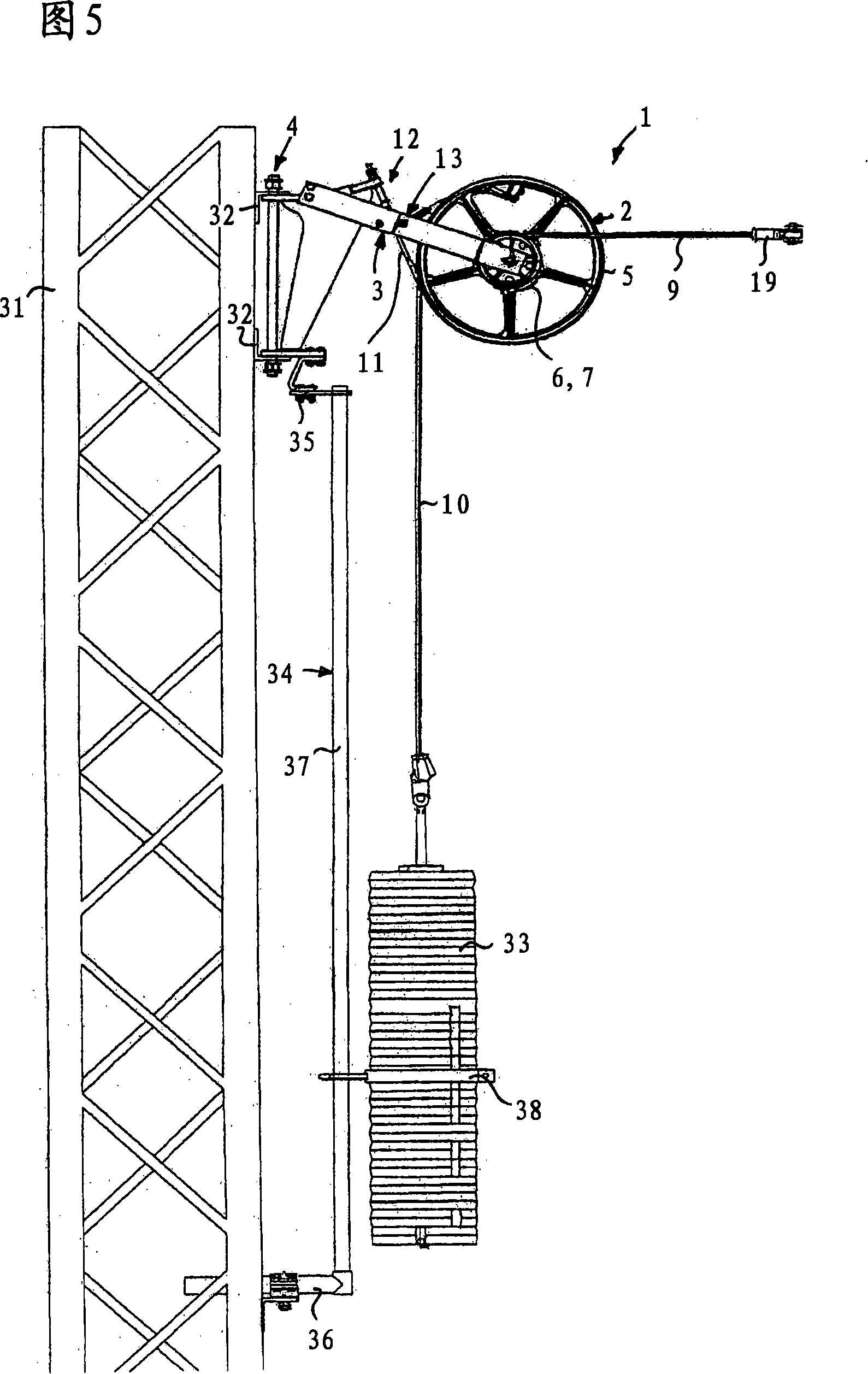

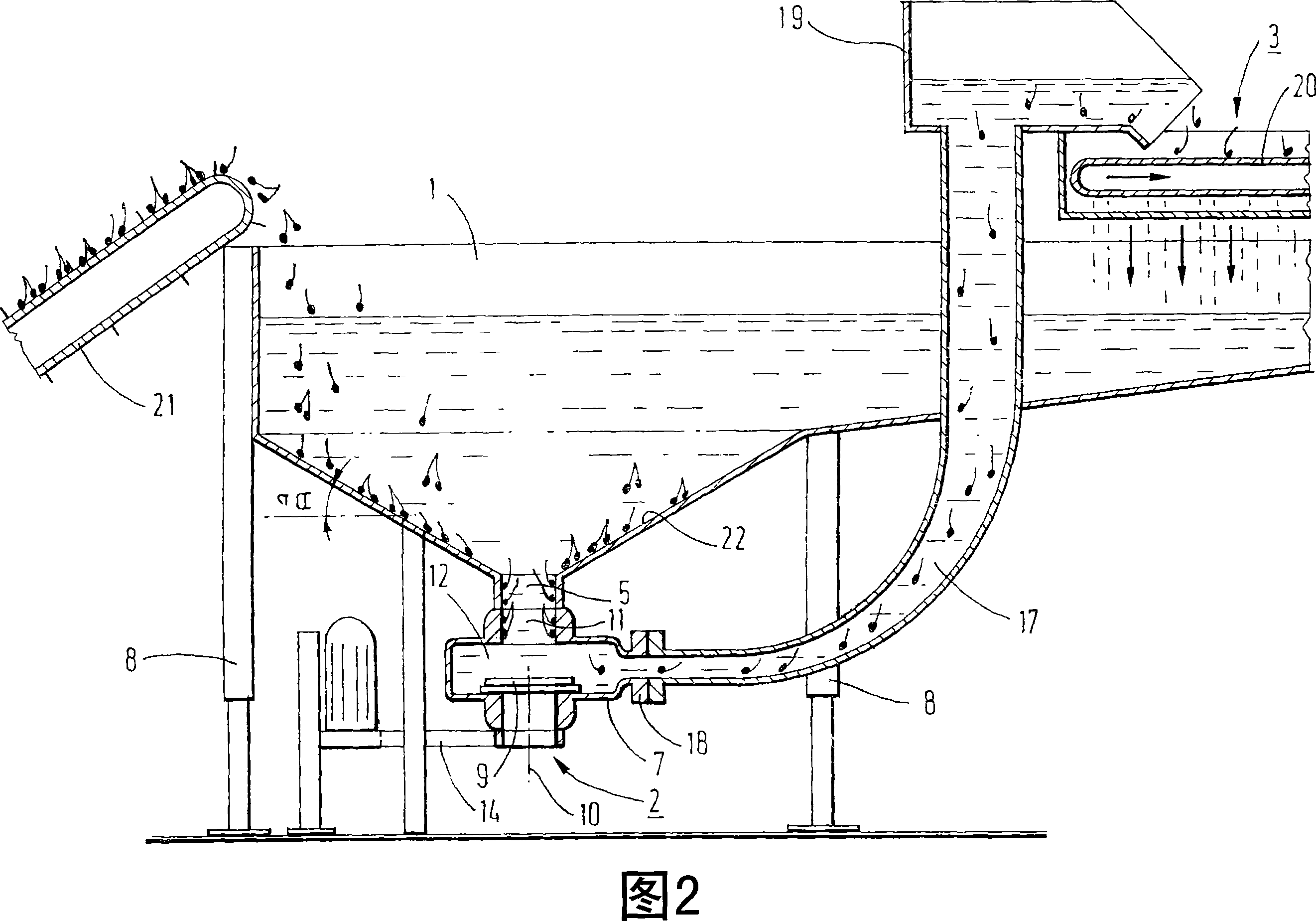

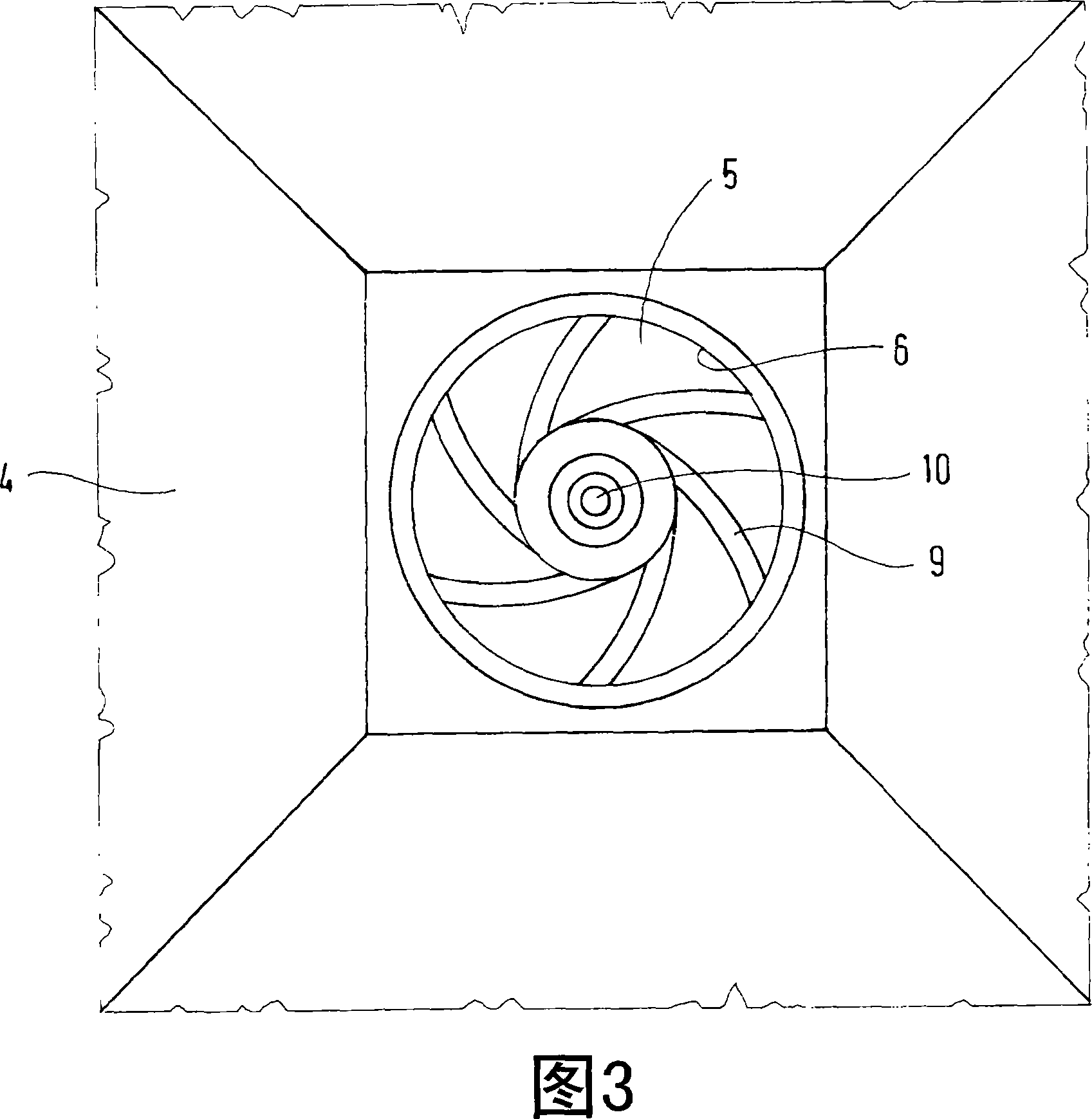

Device for separating the stalks of fruit, grouped together in clusters, from one another

Device for separating the stalks of fruit such as cherries, grouped together in clusters, from one another at their joining point, includes at least one hydraulic circuit including a tank ( 1 ) receiving the fruit to be treated; a centrifugal pump ( 2 ) connected to the tank for sucking up the liquid and the fruit therefrom; and at least one filtration device ( 3 ) receiving the liquid and the fruit discharged by the pump and capable of separating the fruit from the liquid. The tank has a base ( 4 ) which converges downwards as far as a lower outlet orifice ( 5 ) of this tank. The pump includes a housing ( 7 ) and at least one pumping wheel ( 9 ) guided in rotation relative to the housing along an at least substantially vertical axis ( 10 ) of rotation, and the pump has an axial suction inlet ( 11 ) connected below the lower outlet orifice.

Owner:水果栽培材料公司

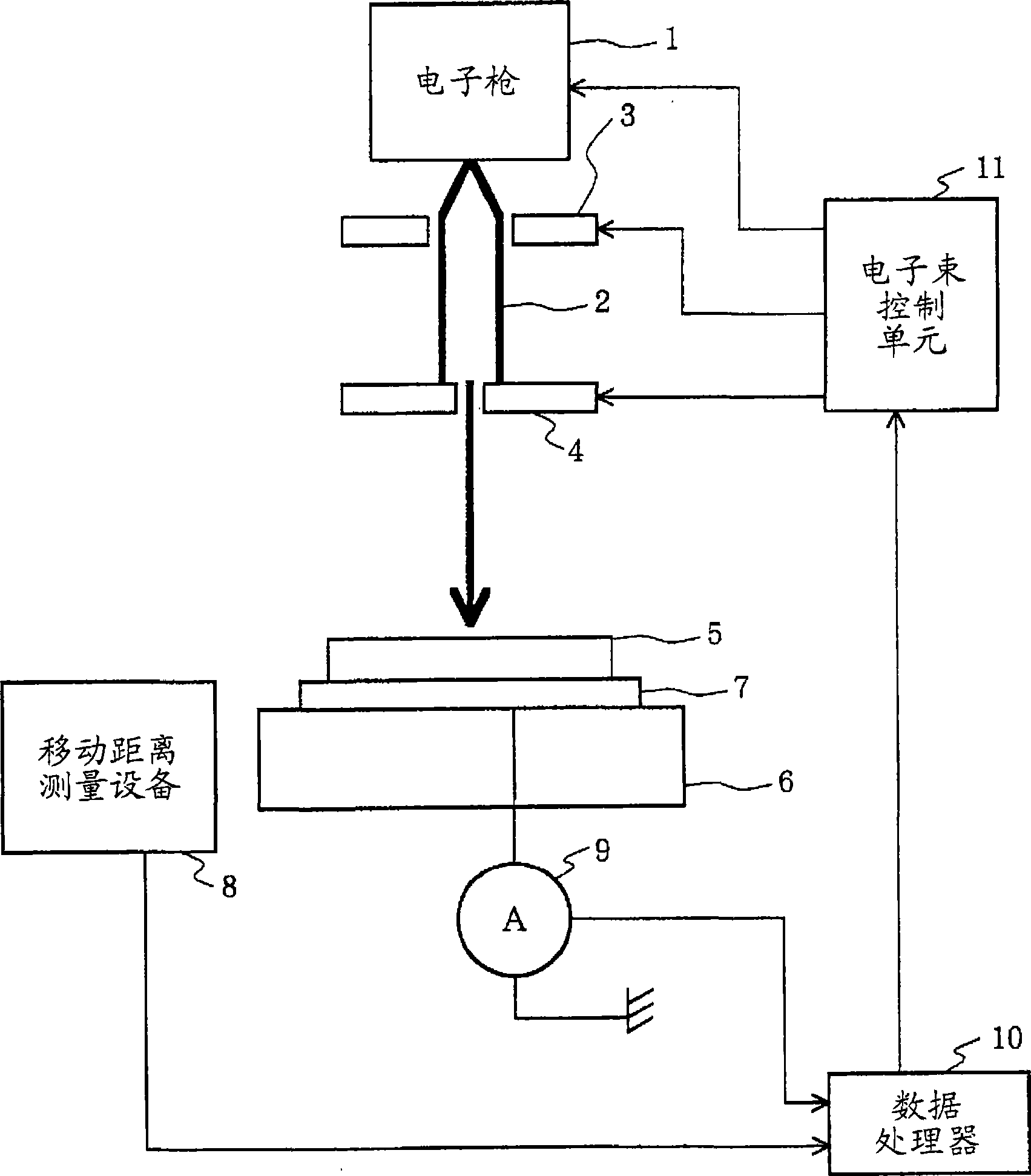

Hole inspection apparatus and hole inspection method using the same

InactiveCN101416295AShorten the timeReduced risk of damageSemiconductor/solid-state device testing/measurementElectric discharge tubesElectronSemiconductor

Disclosed herein is an apparatus and a method for inspecting the via holes of a semiconductor device using electron beams. The apparatus includes electron beam irradiation means, a current measuring means, and a current measuring means and data processing means. The electron beam irradiation means radiate respective electron beams to inspect a plurality of inspection target holes. The current measuring means measures current, which is generated by irradiating the electron beams, radiated from the electron beam irradiation means, through a conductive layer located under the holes, or through the conductive layer and a separate detector. The data processing means processes data acquired through the measurement of the current measuring means.

Owner:CEBT

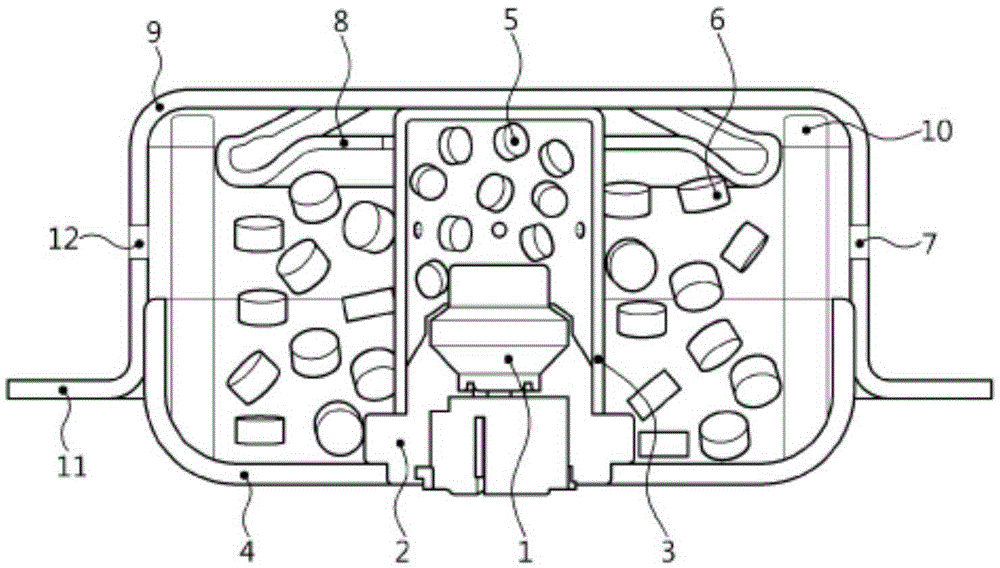

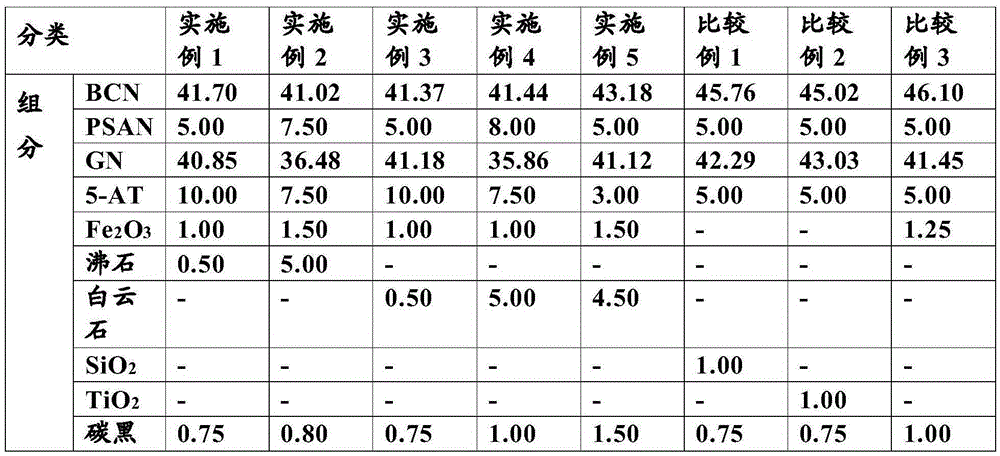

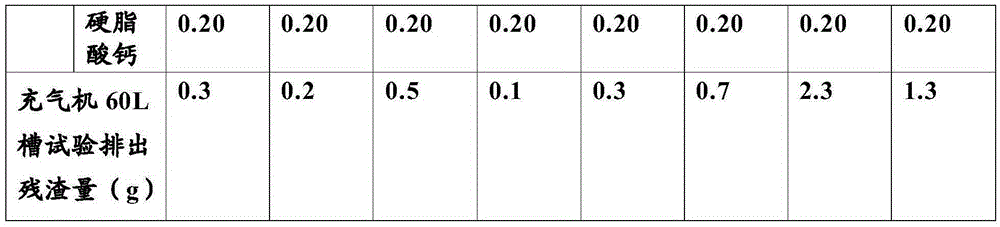

Gas generating agent composition having reduced solid discharge amount of inflator

InactiveCN105358507AThe overall thickness is thinReduce weightNon-explosive fillers/gelling/thickening agentsPedestrian/occupant safety arrangementCombustionSlag

A gas generating agent for an inflator is an explosive composition required for expanding an airbag to protect passengers when a car accident occurs. An electrical signal detected by a sensor due to a car crash may cause the ignition and combustion of an igniter, an ignition charge, and a gas generating agent of the inflator in order. Gases and a high-temperature melting compound generated by the combustion of the gas generating agent are cooled and filtered through a filter to expand the airbag. In order for the high-temperature melting compound to be effectively cooled and filtered through the filter, the high-temperature melting compound must be converted into slag. In the present invention, by converting the high-temperature melting compound into the slag by using zeolite [Na4Al4Si4O25H18] or dolomite [CaMg(CO3)2] as a slag forming agent, and allowing an amount of combustion residuals discharged into the interior of the airbag during the operation of the inflator to be equal to or less than 1g, which is a standard value specified in USCAR-24, damage to the airbag can be prevented and passengers can be effectively protected.

Owner:株式会社三松

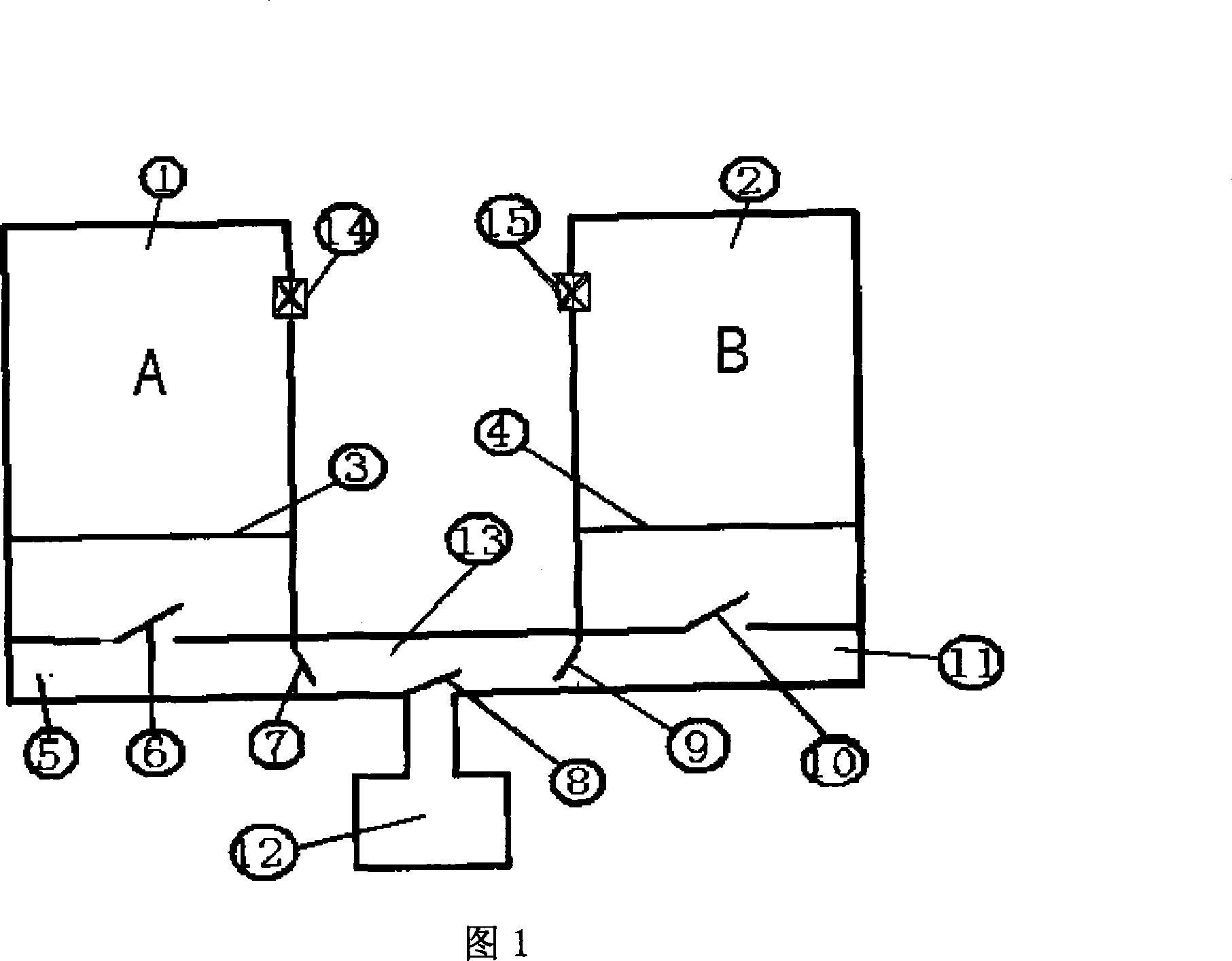

Multiple reaction cavity atom layer deposition device and method

InactiveCN101215692AGood response controlReduce wasteChemical vapor deposition coatingChemistryIntegrated circuit

The invention belongs to a multi reaction chamber atomic layer deposition apparatus and a method, and belongs to the field of manufacturing equipment of semiconductors and processing technology. The atomic layer deposition apparatus comprises an A reaction chamber and a B reaction chamber, which are connected with a group of vacuum pumps through a transition chamber, the A reaction chamber and the B reaction chamber are reacted, the A reaction chamber and the B reaction chamber are respectively communicated with the reaction chambers and the transition chamber through channel valves, the reaction chambers are connected with a storeroom through a vacuum valve and a baffle of the storeroom, and an air inlet valve is arranged on the upper portion of the storeroom. The deposition method is that wafers of an integrated circuit are transferred back and forth between the A reaction chamber and the B reaction chamber through the channel valves, when transfers to the A reaction chamber, A phase reaction is produced, when transfers to the B reaction chamber, B phase reaction is produced, the A and the B phase reactions are conducted alternatively, and nanometer-thin layers or compound structure materials with thickness which is demanded by the integrated circuit are grown on each atomic layer of the surface of the wafers. The reaction chamber is less smirched, the deposition quality is improved, the reactant sources amount is saved, the process cost is reduced, and the environment hazard degree is lowest.

Owner:TSINGHUA UNIV

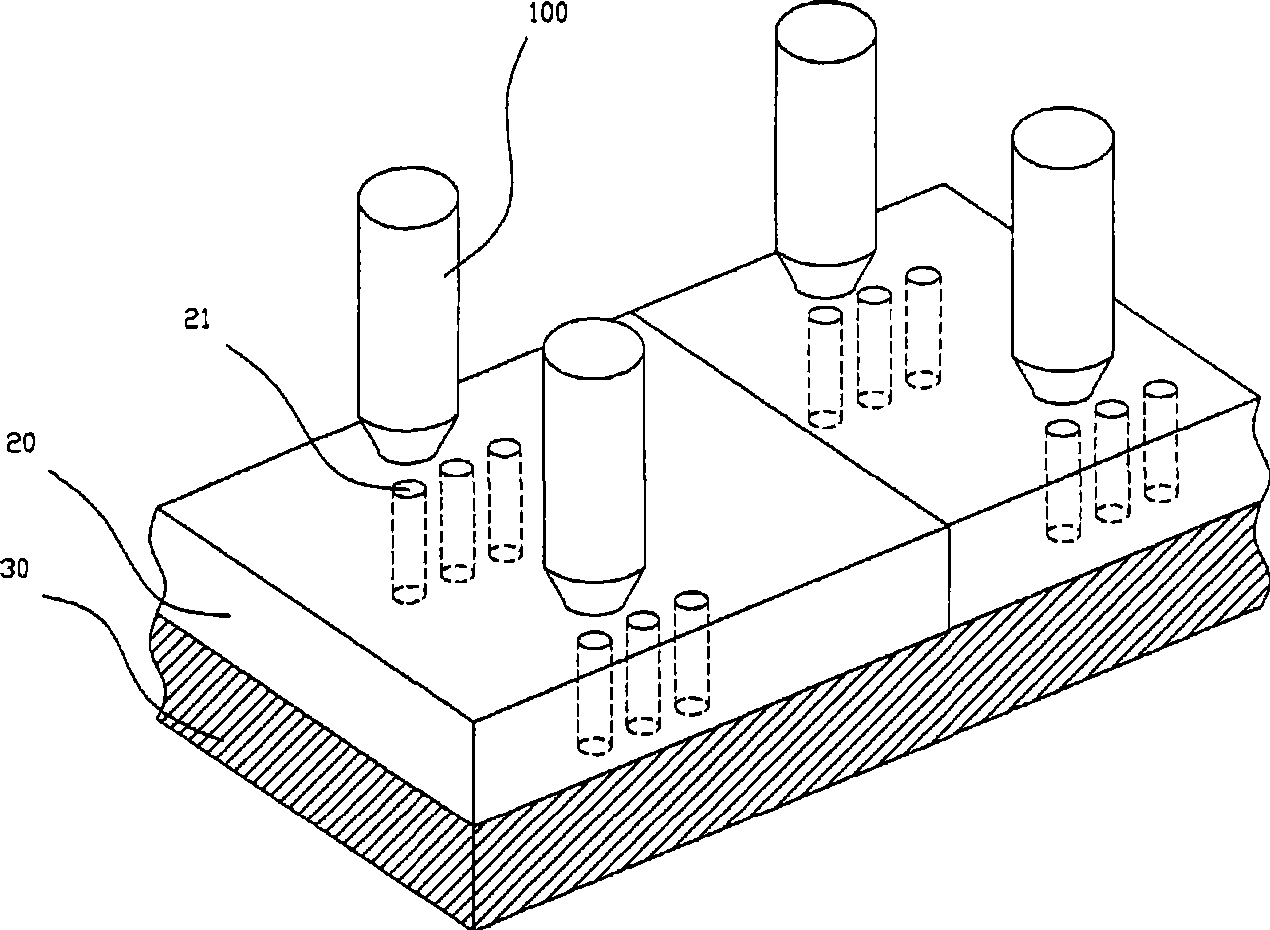

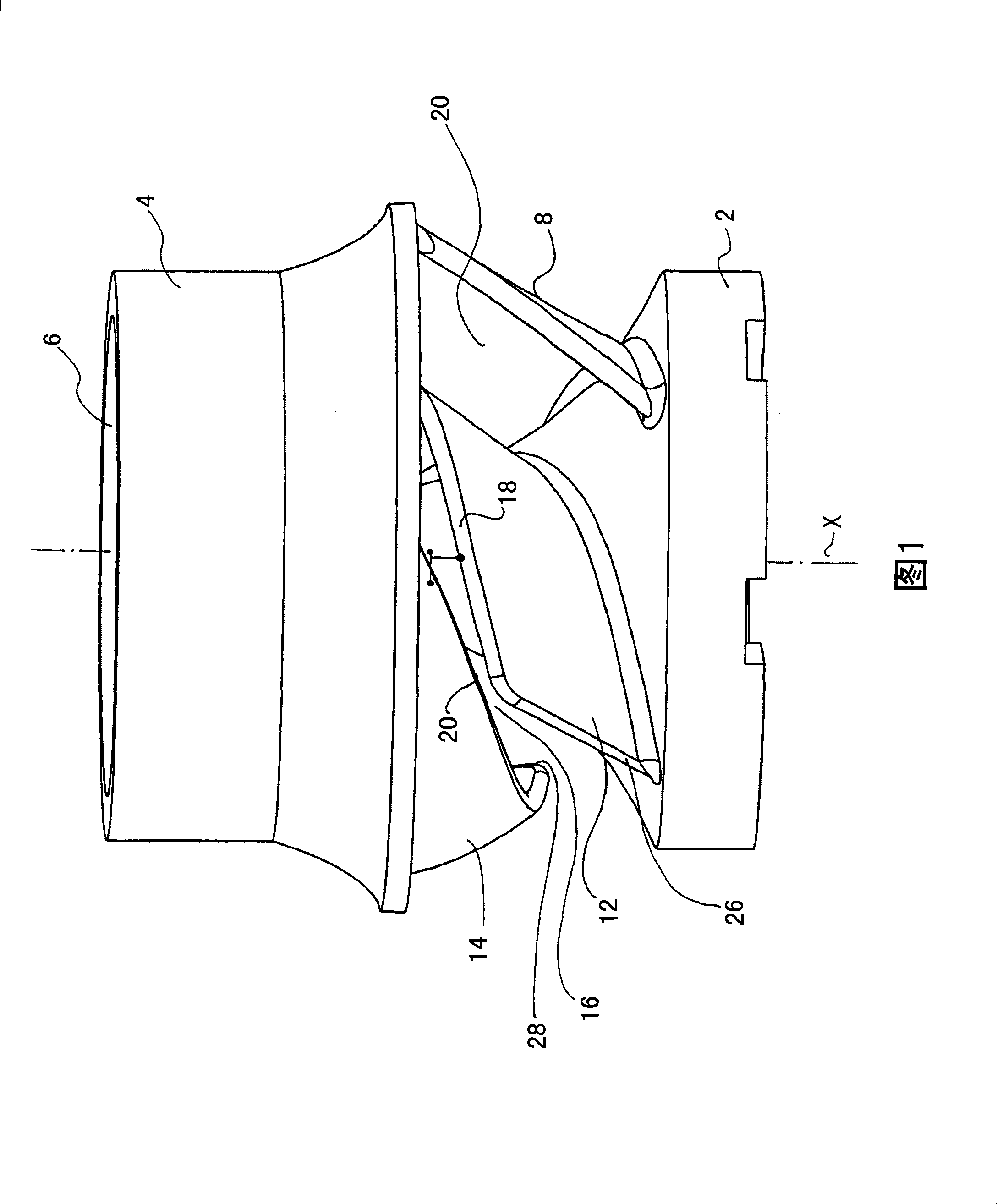

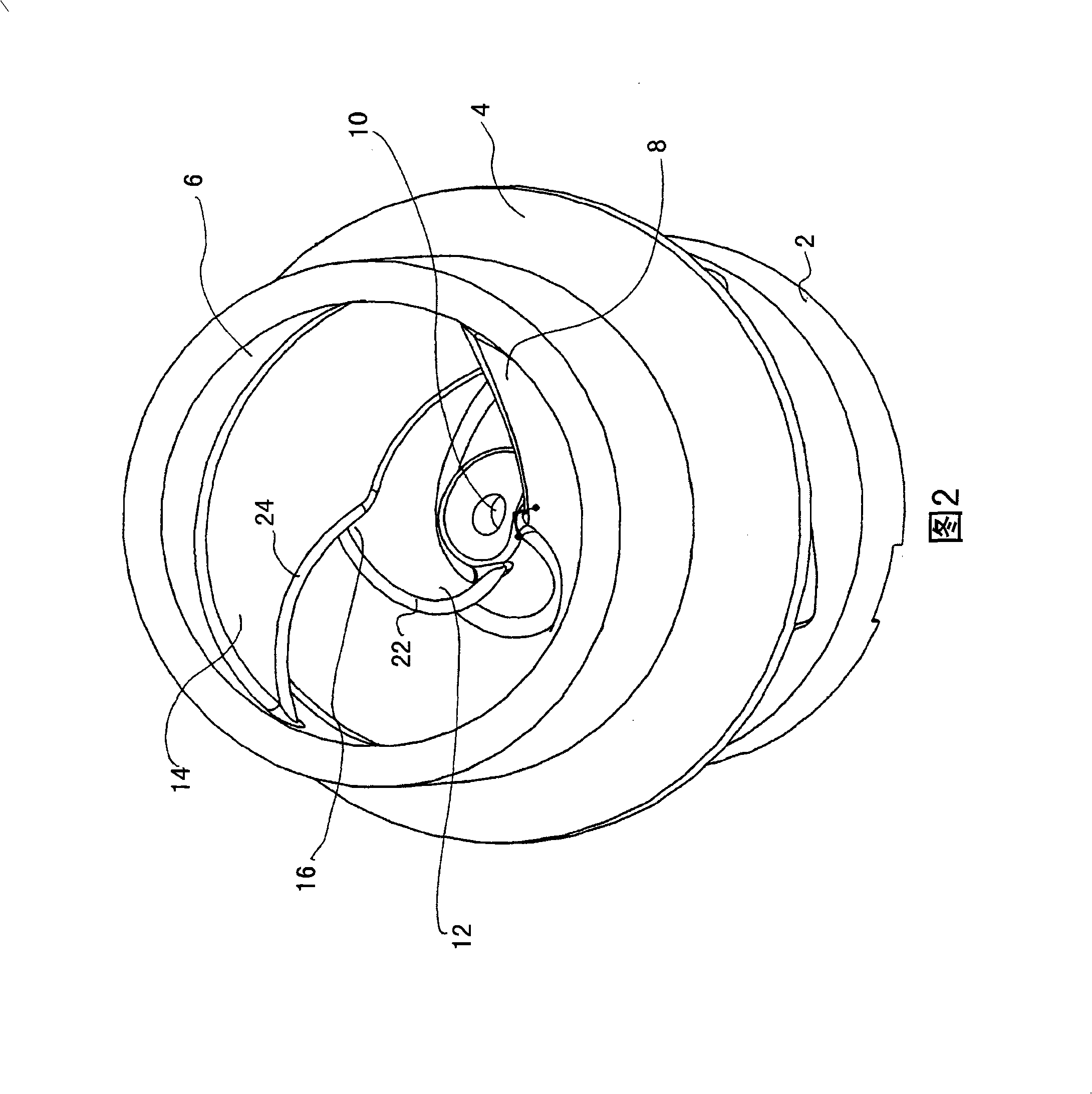

Impeller of a pump unit and corresponding pump unit

InactiveCN101326372AImprove efficiencyReduce adhesionSpecific fluid pumpsPump componentsImpellerSump pump

The invention relates to an impeller for a pump unit, in particular for a waste water pump unit, having two cover plates (2, A) which are spaced apart from one another in the axial direction (X) and are connected to one another by means of at least one connecting element (8), and having at least one blade (12, 14) which is arranged between the two cover plates (2, 4) and extends from an inner diameter of the impeller to an outer diameter of the impeller, wherein the blade (12, 14) has a continuous slot (16) which extends from that edge (22, 24) of the blade (12, 14) which is situated at the inner diameter to that edge (26, 28) of the blade (12, 14) which is situated at the outer diameter, and to a pump unit having an impeller of said type.

Owner:GRUNDFOS MANAGEMENT AS

Abradable and/or abrasive coating and brush seal configuration

InactiveCN1869411AReduced risk of damageNo risk of damageEngine sealsMolten spray coatingBristleEngineering

An abradable coating and / or an abrasive coating applied to the rotor (11) of a steam or gas turbine allows the temperature and pressure drop capabilities of conventional brush seal assemblies to be increased. The pressure drop capability of brush seals is closely related to fence height (22), i.e., the distance between the rotor (11) and the bottom edge of the backing plate (15) supporting the brush seal wire bristles (12). Application of the abradable or abrasive coating allows the fence height to be reduced and the pressure capability of a brush seal assembly increased commensurately because the risk of the backing plate (15) rubbing against the surface (13) of the rotor (11), so as to cause damage to the rotor (11), is reduced. In addition, the backing plate (15) can be made from a higher strength material that can withstand higher temperatures because any contact between the backing plate (15) and the rotor (11) results in no damage to the rotor (11), but rather a gradual reduction of the backing plate (15) as it wears.

Owner:GENERAL ELECTRIC CO

Shock absorber for the holding assembly of a reciprocating tool

InactiveCN1880026AExtend your lifeReduced risk of damagePortable percussive toolsPortable power-driven toolsCantileverShock absorber

A tool assembly, for example a hydraulic or pneumatic hammer assembly, comprises a housing defining a chamber, a reciprocating work tool arranged in the chamber for cyclical movement in a work stroke and a return stroke, and a tool retention member arranged to restrain the work tool at the end of the work stroke. The tool assembly includes a shock absorber arranged to absorb impact from the work tool at the end of a stroke. The shock absorber comprises an annular resilient flange, which may be cantilevered from the tool retention member to absorb impact at the end of the work stroke or may be provided on a bushing arranged to absorb impact at the end of the return stroke. The shock absorbing flange reduces the transmission of shocks into the tool assembly, thereby providing increased life for tool assembly components.

Owner:CATERPILLAR INC

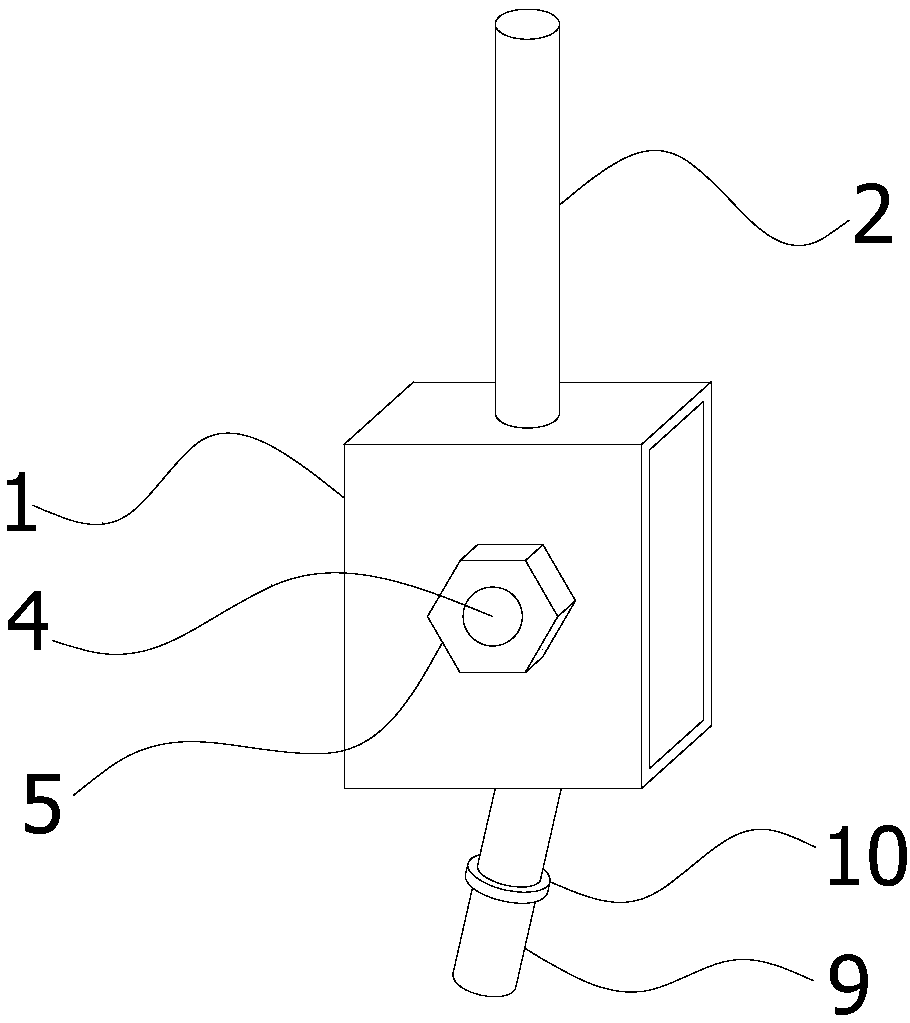

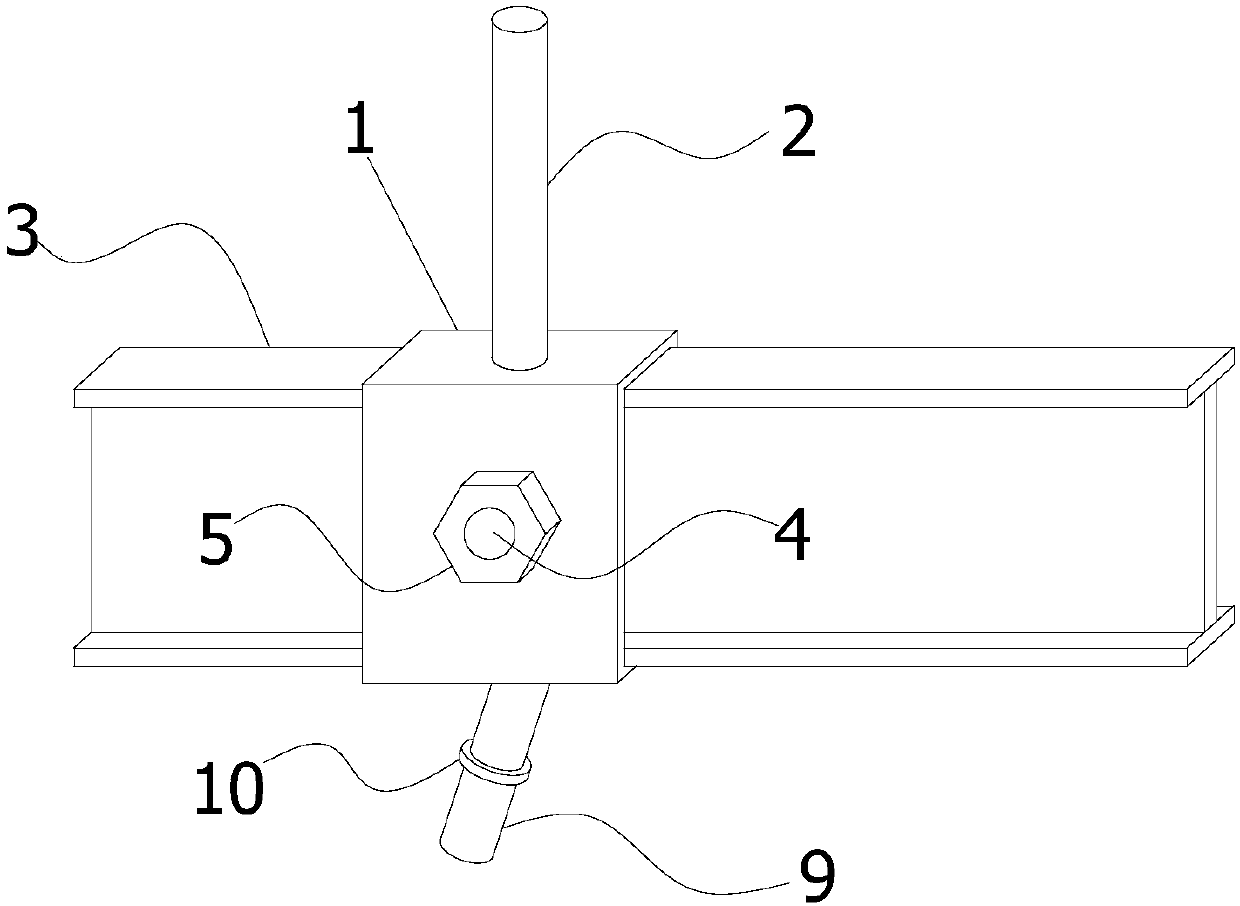

Vertical rod fixing piece and scaffold

PendingCN107558720AAvoid direct solderingReduced risk of damageScaffold accessoriesBuilding support scaffoldsStress concentrationCantilever

The invention provides a vertical rod fixing piece comprising a fixing sleeve, a fixing rod and a fastening assembly. An inner cavity of the fixing sleeve can be connected with the outer contour of anI-shaped steel cantilever beam in attached and sleeving modes. The fastening assembly is arranged on the fixing sleeve and used for firmly mounting the fixing sleeve on the exterior of the I-shaped steel cantilever beam. The fixing rod is welded to the fixing sleeve and used for inserting and fixing a vertical rod of a scaffold. According to the vertical rod fixing piece, by using the fixing sleeve with the welded fixing rod, the situation that the fixing rod is directly welded to the I-shaped steel cantilever beam is avoided, and the damage hidden danger of the I-shaped steel cantilever beamand the fixing rod in construction operation due to stress concentration is reduced; during mounting and demounting, an I-shaped steel cantilever beam without a welded fixing rod can penetrate through a shear wall independently, the aerial operation procedures are simplified, and the construction risks are reduced; and meanwhile, the collision deformation risk of scaffold parts in the process that the scaffold parts are stored and transported to other sites is also avoided. On the basis of the vertical rod fixing piece, the invention further provides the scaffold.

Owner:CCCC FOURTH HIGHWAY ENG

Static mixer for an exhaust gas system of an internal combustion engine-driven vehicle, in particular motor vehicle

ActiveCN101883625AAvoid damageAvoid stressFlow mixersExhaust apparatusExternal combustion engineInternal combustion engine

The invention relates to a static mixer for an exhaust gas system of an internal combustion engine-driven vehicle, comprising a plurality of flow conduction elements that influence the flow of an exhaust gas stream, are inclined at a predefined angle towards the mixer plane and are mounted in the exhaust gas duct by means of at least one mounting strip. According to the invention, the mounting strip or strips (2, 3) is or are designed to be resilient and / or are mounted in a spring-loaded manner in the mixer plane.

Owner:AUDI AG +1

Process for coating a brake disk and brake disk produced by the process

InactiveCN103185087AReduce mechanical stressReduced risk of damageLiquid surface applicatorsMolten spray coatingInter layerMaterials science

A gray cast iron brake disk (1) for a motor vehicle has a wear-reducing surface coating (6) applied thermally, for example, by flame spraying. The brake disk also includes an intermediate layer (5) of, for example, nickel. Due to its resilience, the intermediate layer reduces mechanical stress between the surface coating (6) and the brake disk (1).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com