Radspanner

A wheel tensioner and tensioner technology, applied in the direction of overhead lines, can solve problems such as braking and unevenness, and achieve the effects of high mechanical stability and cheap manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

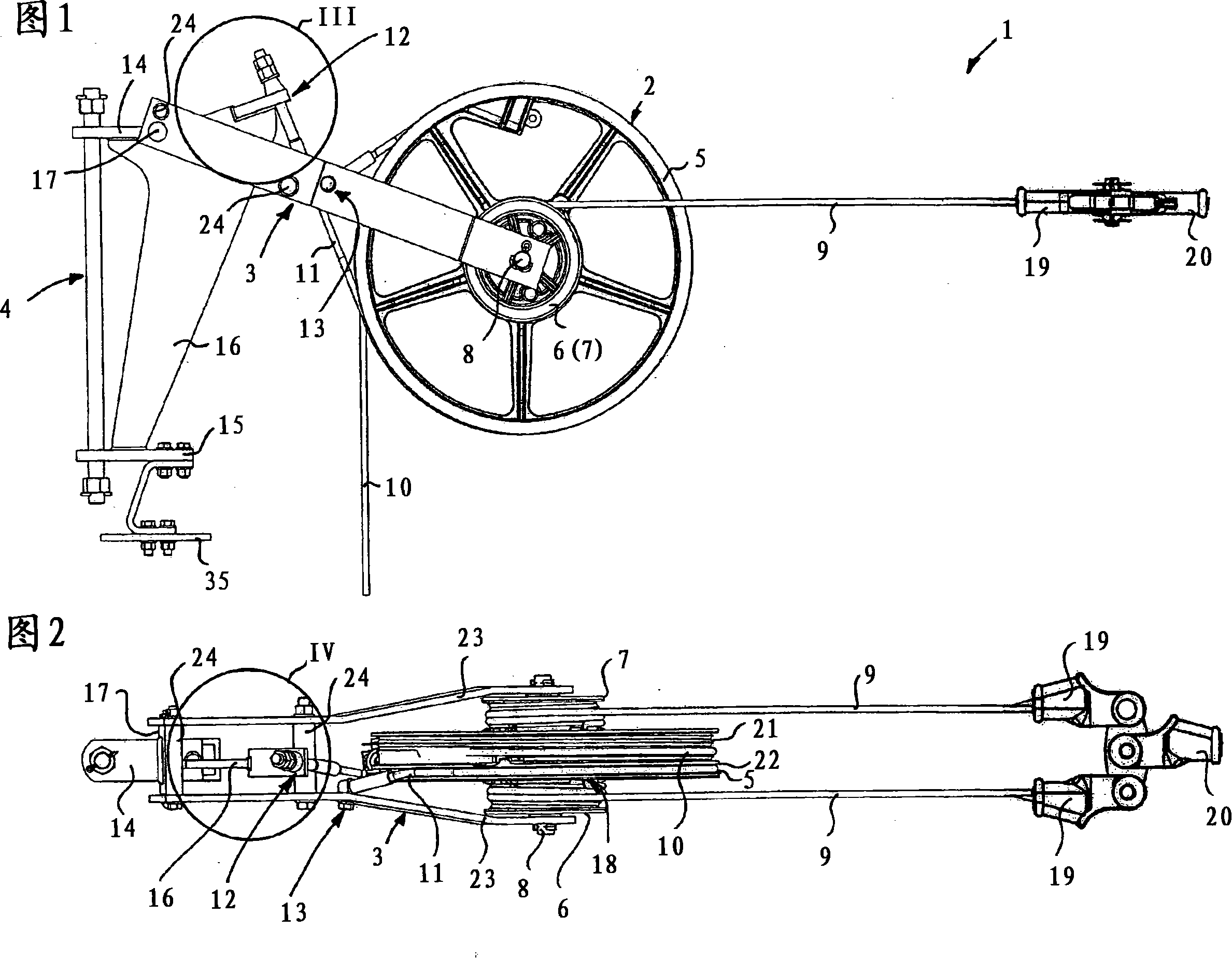

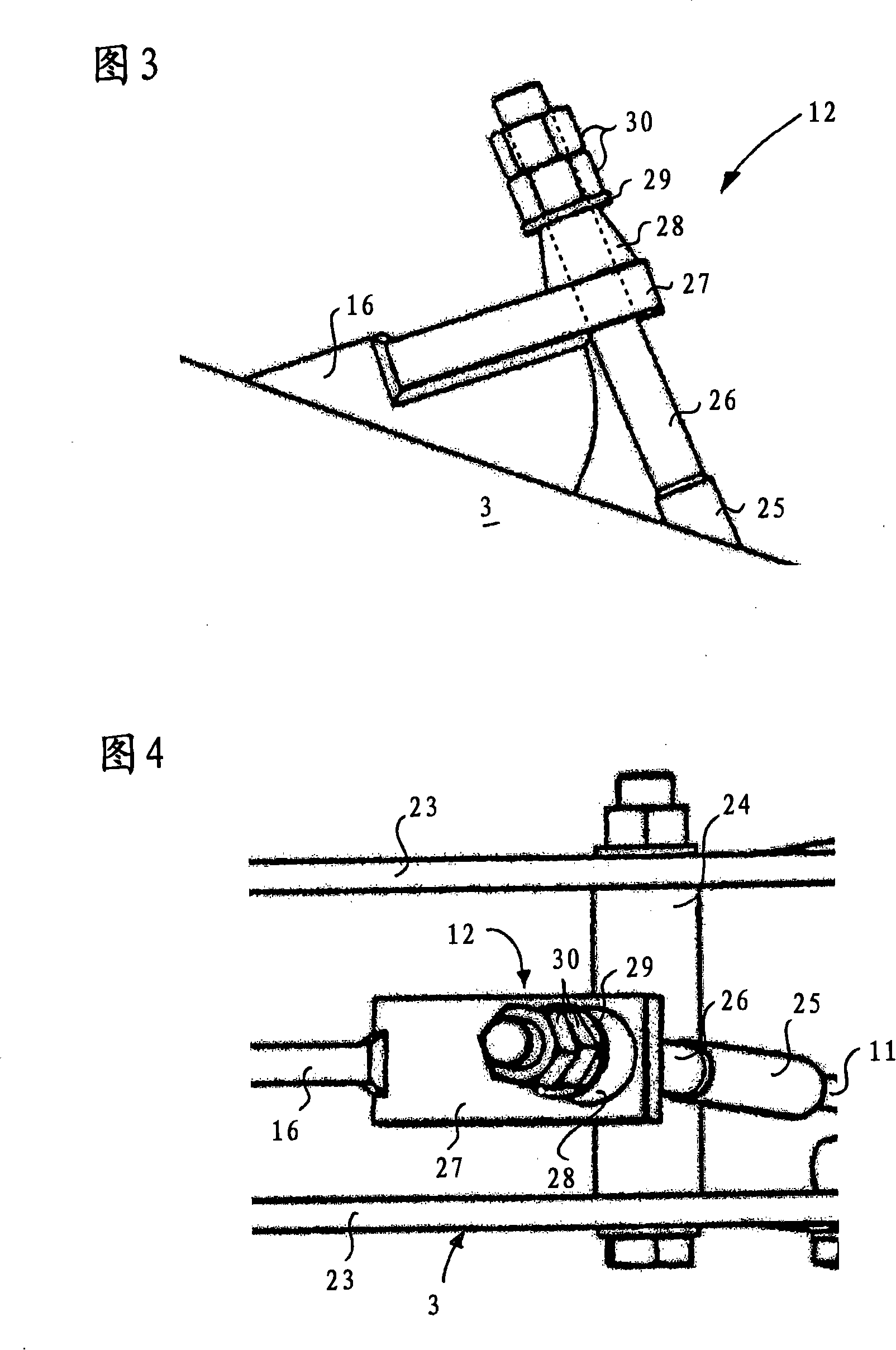

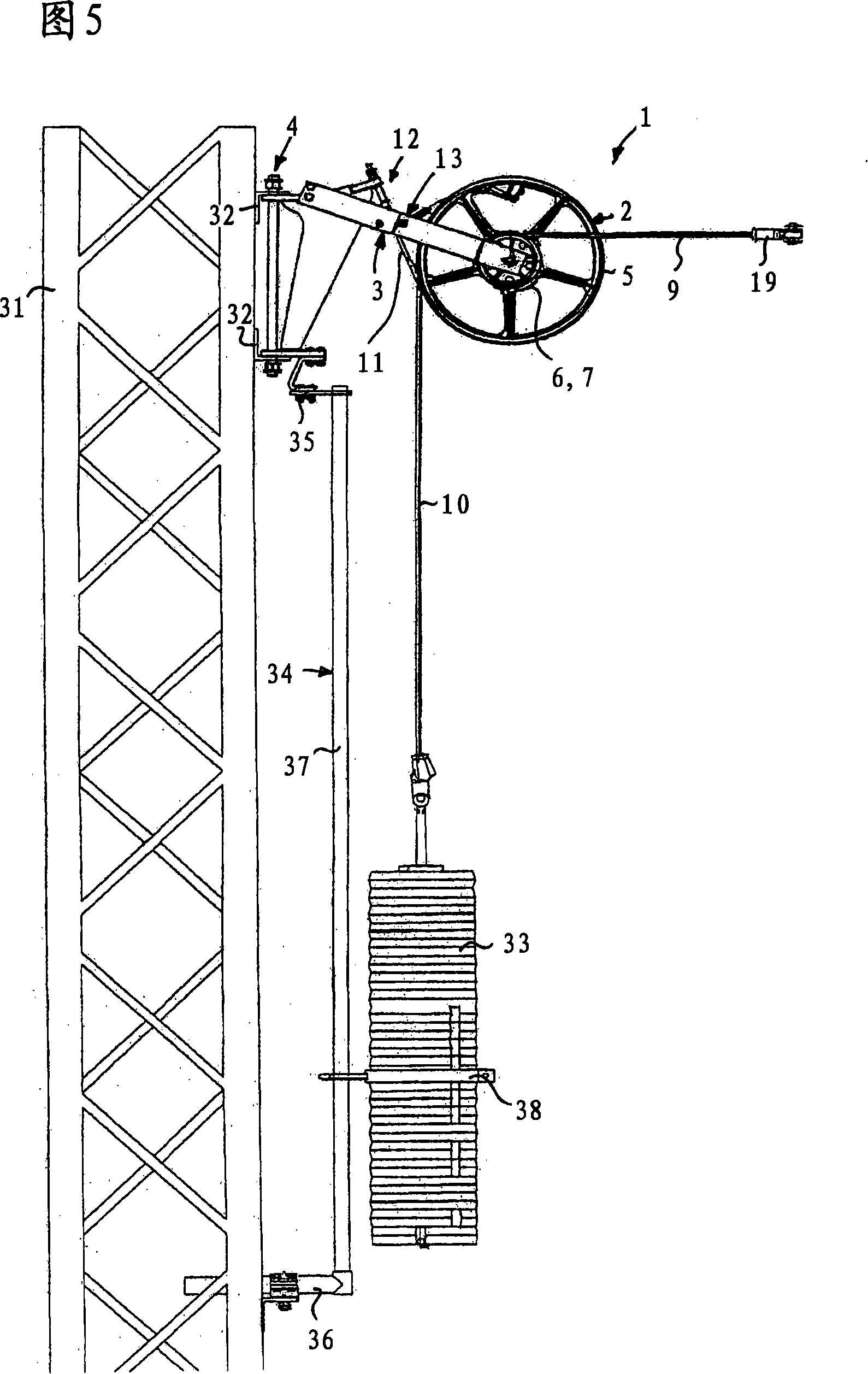

[0044] Figure 1 shows a side view of the wheel tensioner of the present invention in operation. The wheel tensioner 1 basically comprises a tensioning wheel 2 which is connected via a pivot arm 3 to a fastening device 4 . A tensioning wheel 2 in the form of a spoked wheel has a larger roller 5 and smaller rollers 6, 7 (see FIG. 2 ) arranged on either side of said larger roller, resulting in a symmetrical configuration of the tensioning wheel 2 . The rollers 5 , 6 , 7 are mounted rotatably on a common hub 8 held by the pivot arm 3 .

[0045] A tensioning rope 9 is wound on the two tensioning drums 6 , 7 . The larger brake drum 5 carries the weight rope 10 for the subsequent tensioning weight 33 shown in FIG. 5 . The weight rope 10 is wound multiple times around the brake drum to increase the applied gravitational force. The brake drum 5 also carries a brake cable 11 , which is fastened at an upper fastening point 12 to the fastening device 4 and at its lower fastening point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com