Hole inspection apparatus and hole inspection method using the same

一种检查装置、检查方法的技术,应用在孔检查装置和使用该孔检查装置的孔检查领域,能够解决花费时间等问题,达到减小试样损害的危险的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

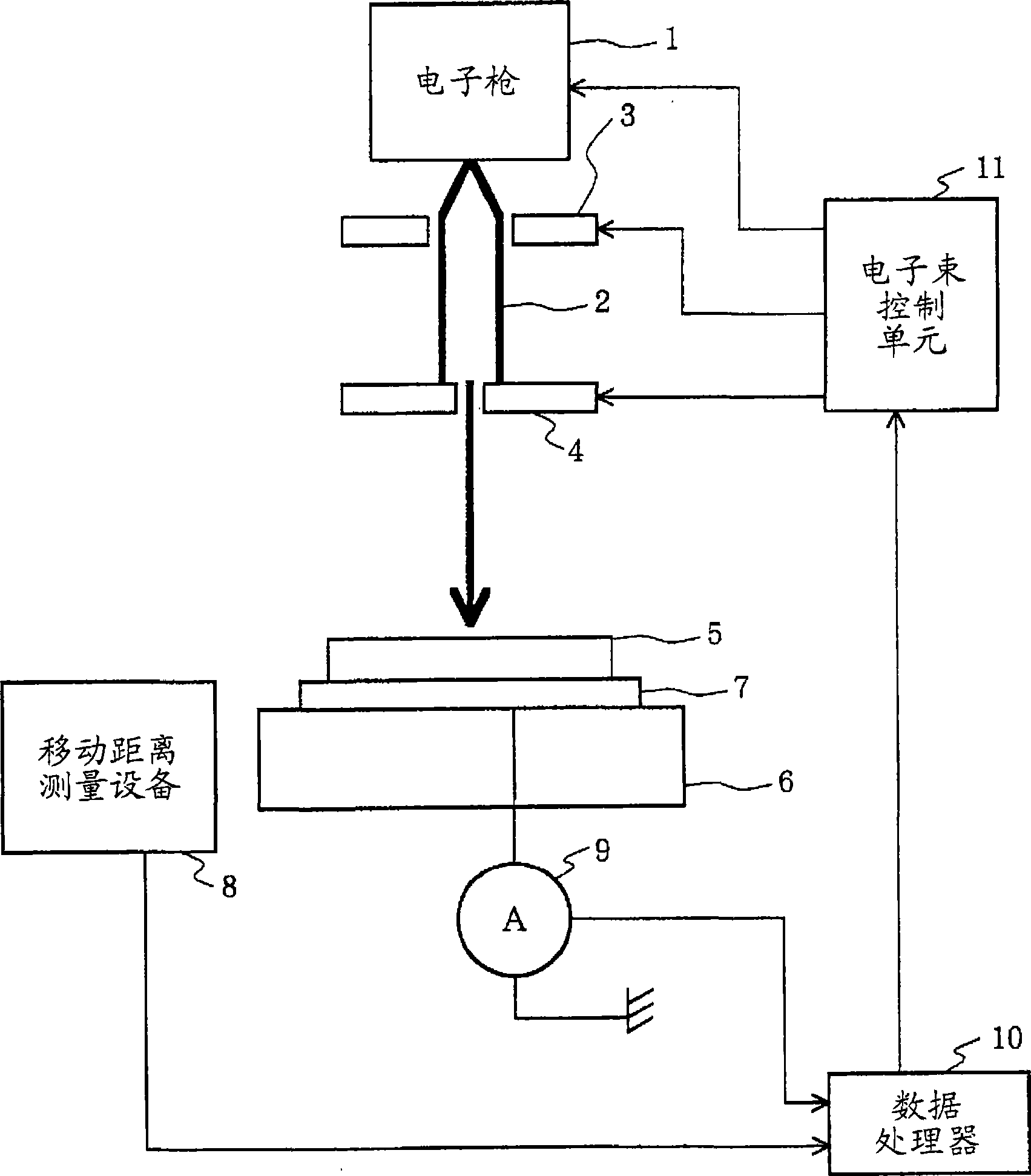

Method used

Image

Examples

Embodiment Construction

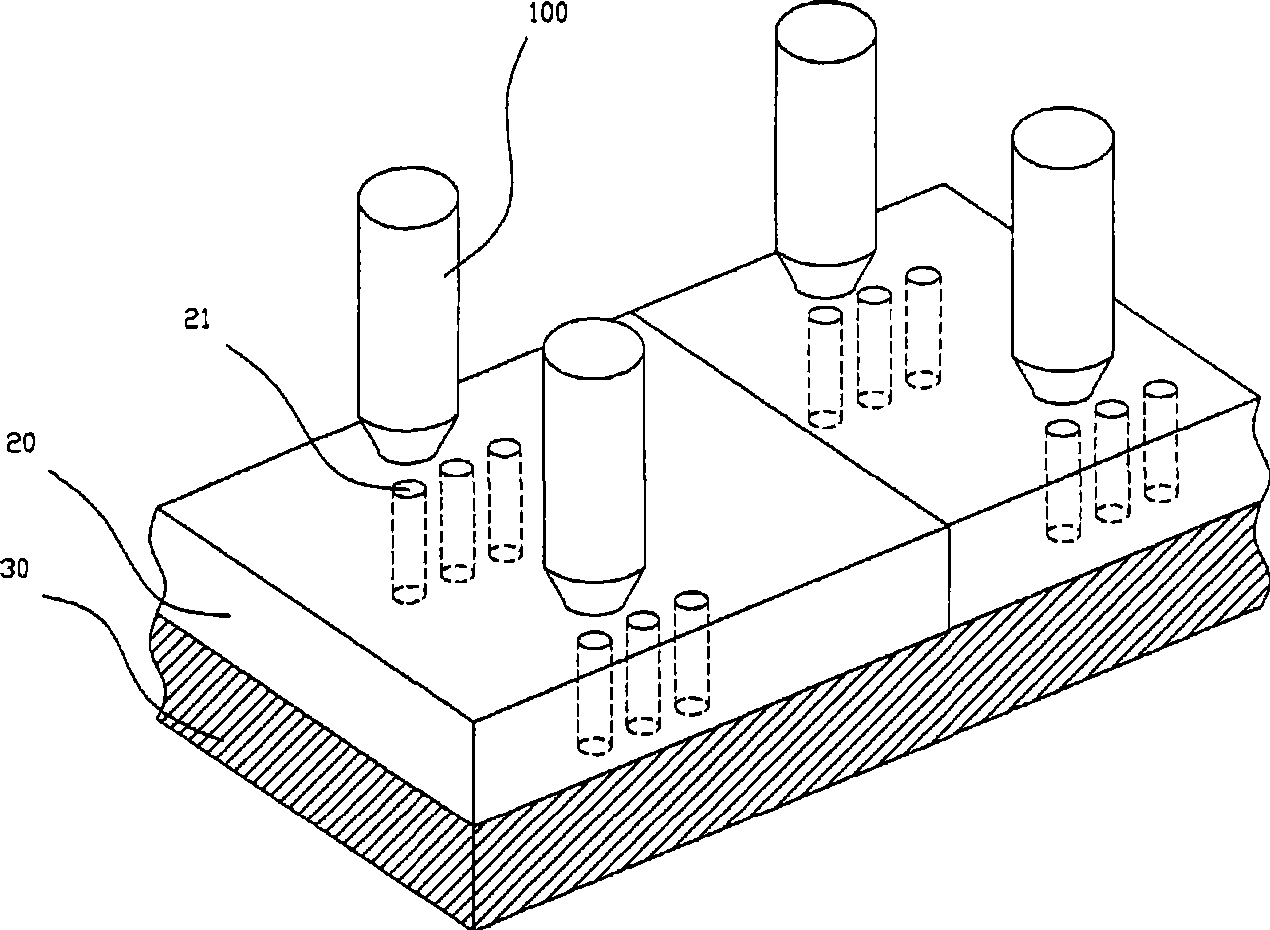

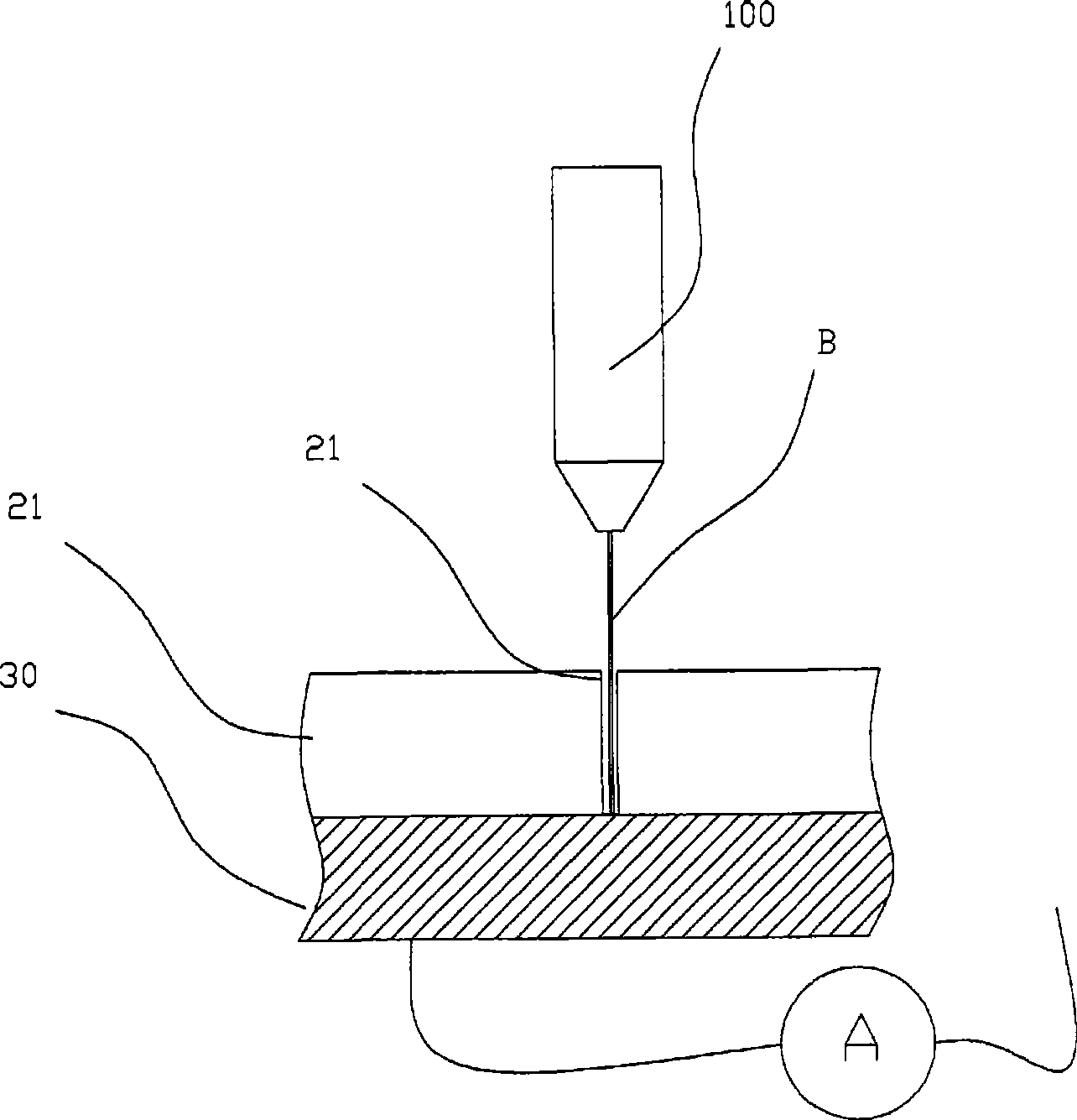

[0030] figure 2 A perspective view of the hole inspection device according to the present invention is schematically shown.

[0031] exist figure 2 In this example, four electron columns 100 were used as the electron beam irradiating means. For each description, each electron column 100 is described as radiating electron beams onto three holes 21 . The hole 21 is formed in the insulating layer 20 . The conductive layer 30 is located under the insulating layer 20 . In this case, three holes 21 to be inspected by the respective electron columns 100 are formed in the insulating layer 20 . Although the number of holes 21 and the size and shape of each hole have been set for the reason of describing the inspection device according to the present invention, the number of holes 21 and the size and shape of each hole may be determined differently.

[0032] Such as figure 2 As shown, the insulating layer 20 is divided into two regions, and the conductive layer 30 under the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com