Abradable and/or abrasive coating and brush seal configuration

A brush-type sealing and coating technology, which is applied in engine sealing, coating, metal material coating process, etc., can solve problems such as rotor damage, achieve enhanced temperature and pressure performance, reduce bristle bending stress, and compress drop and temperature performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

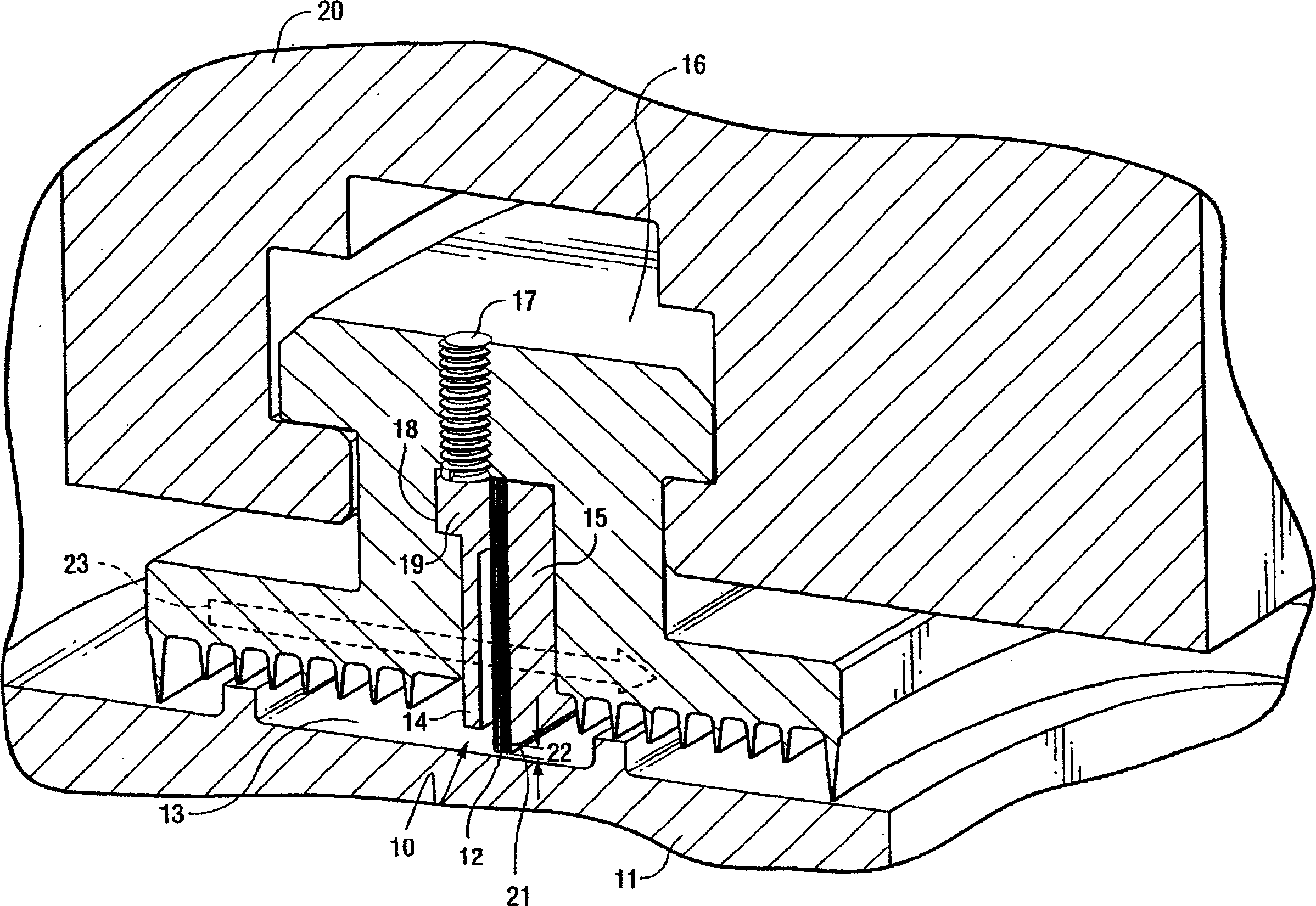

[0007] figure 1 Is a cross-sectional perspective view showing the brush holder assembly 10 engaged with a rotor 11 of a turbine (not shown). The brush holder assembly 10 includes a plurality of wire bristles 12 engaging a surface 13 of a rotor 11 . The bristles 12 are located between a front plate 14 and a back plate 15 which provides support for the bristles 12 . The tops of the bristles 12, front plate 14 and back plate 15 including the brush holder assembly 10 are welded together. They are mounted in the sealing ring 16 and are held in the sealing ring 16 by a set screw 17 which pushes the shoulder 18 of the front plate 14 against a notch in the sealing ring 16 designed to accommodate the shoulder 18 19 in. The seal ring 16 is in turn supported by a seal holder 20 mounted in the turbine.

[0008] The brush holder assembly 10 is urged against the surface 13 of the rotor 11 by a spring assembly (not shown), which spring assembly exerts a defined force on the assembly 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com