Static mixer for an exhaust gas system of an internal combustion engine-driven vehicle, in particular motor vehicle

A static mixer and engine-driven technology, which is applied to fluid mixers, engine components, machines/engines, etc., can solve problems such as damage and cracks in the supporting grid area, achieve simple structure and manufacturing technology, and avoid damage to the mixer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

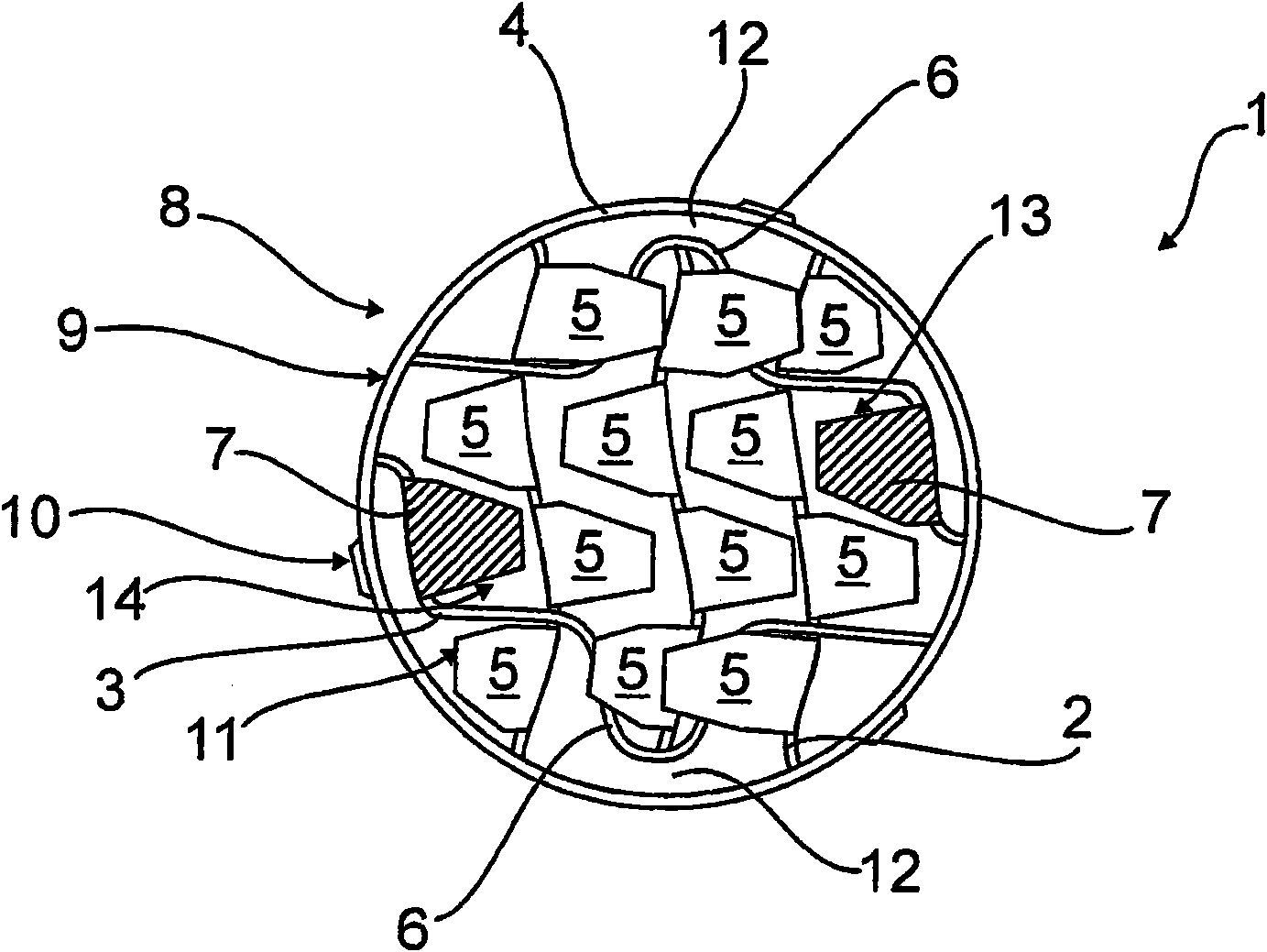

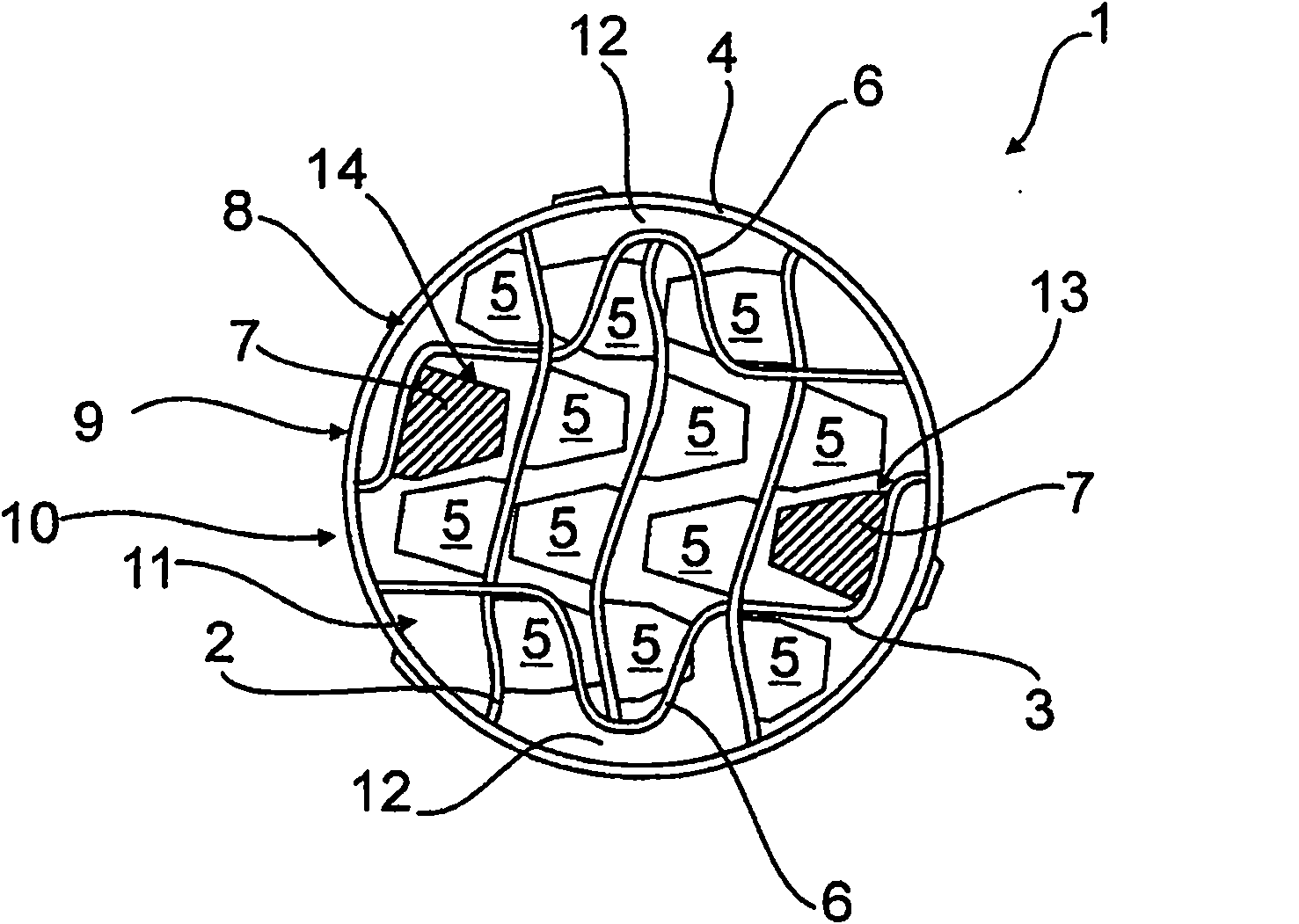

[0026] in figure 1 Schematically shows a top view of the static mixer 1 according to the present invention, as in particular in combination with image 3 with Figure 4 It can be seen that the static mixer 1 is composed of three retaining slats 2 designed as the same fittings in the first retaining slat group and two retaining slats 3 designed as the same fittings in the second retaining slat group , The retaining strip is fixed in the mixer ring 4 of the static mixer in a manner described in detail below.

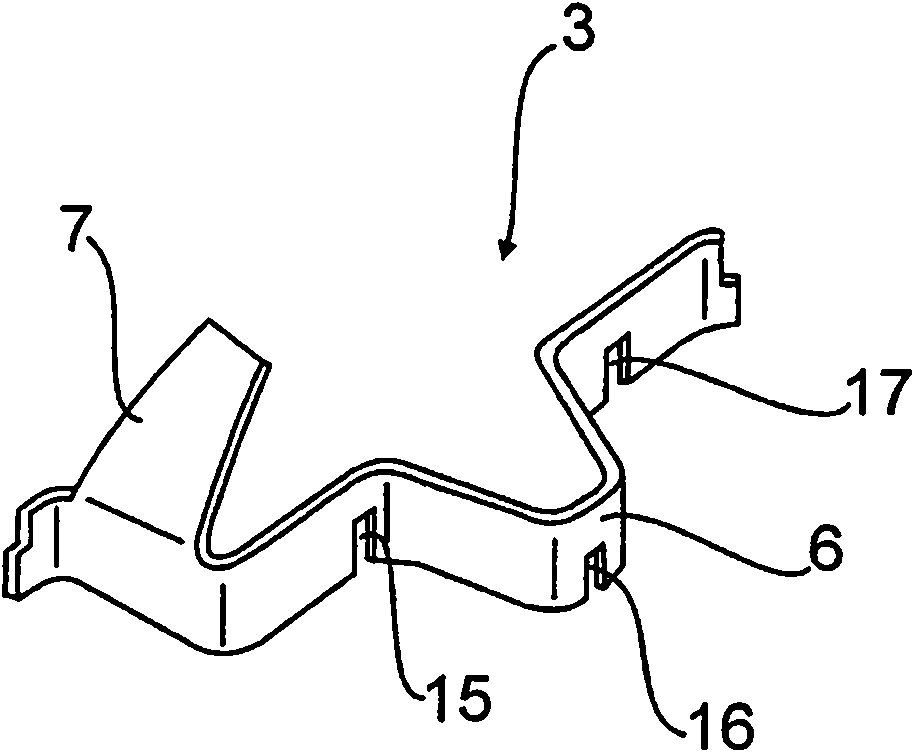

[0027] Such as Figure 4 As shown, the holding slats 2 respectively have a substantially S-shaped curved portion, wherein when viewed in the longitudinal direction of the holding slats, a plurality of single-leaf plate-shaped guide vanes 5 spaced apart from each other are provided. The guide vanes 5 are from the same side of the holding slat 2 and then in the installed state-such as figure 1 Shown—extend from the same side of the mixer plane, in which, viewed along the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com