Impeller of a pump unit and corresponding pump unit

A technology of a pump device and an impeller is applied to the impeller of a sewage pump device, and the field of the pump device with the impeller can solve the problems of reducing the efficiency of the pump device and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

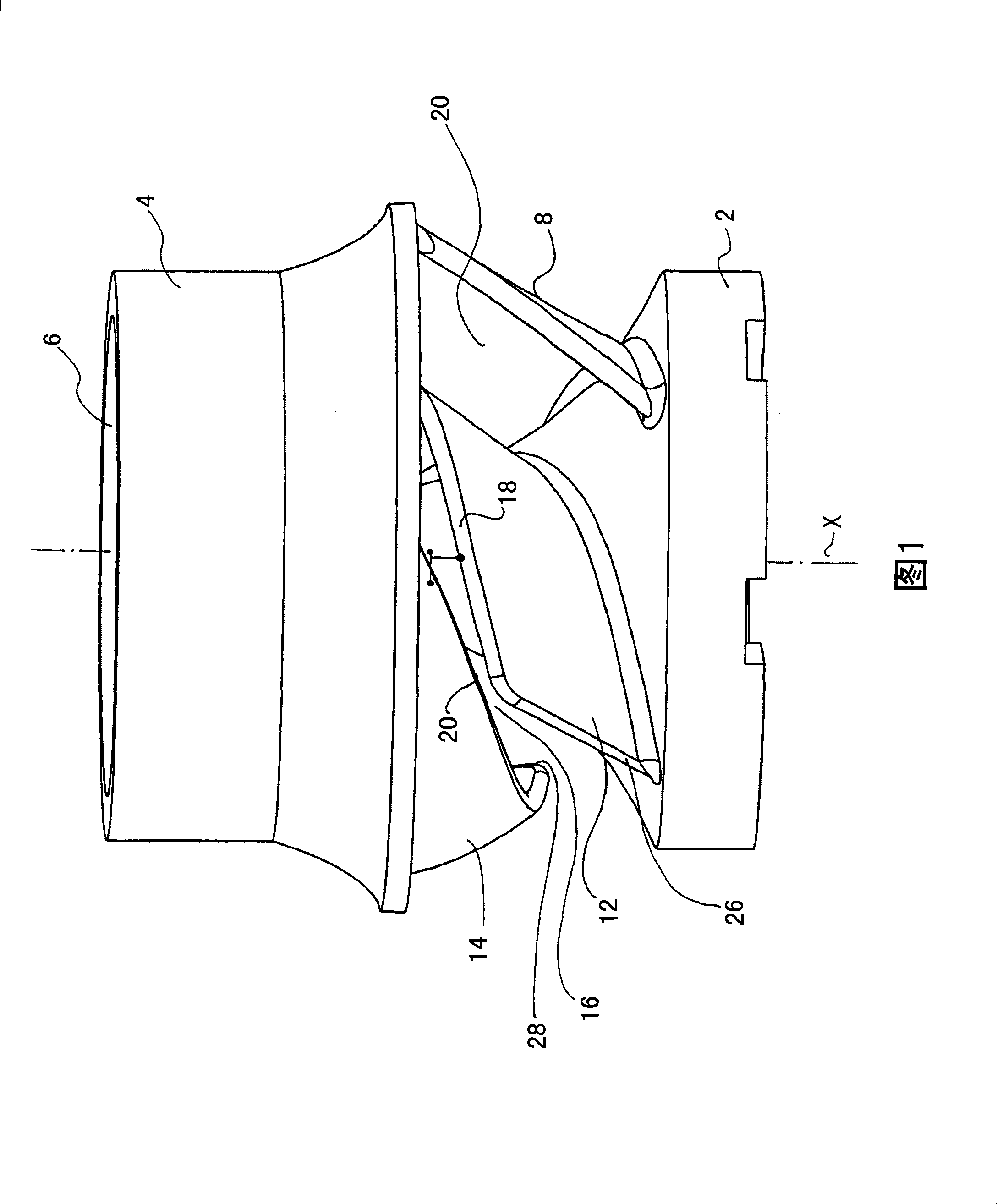

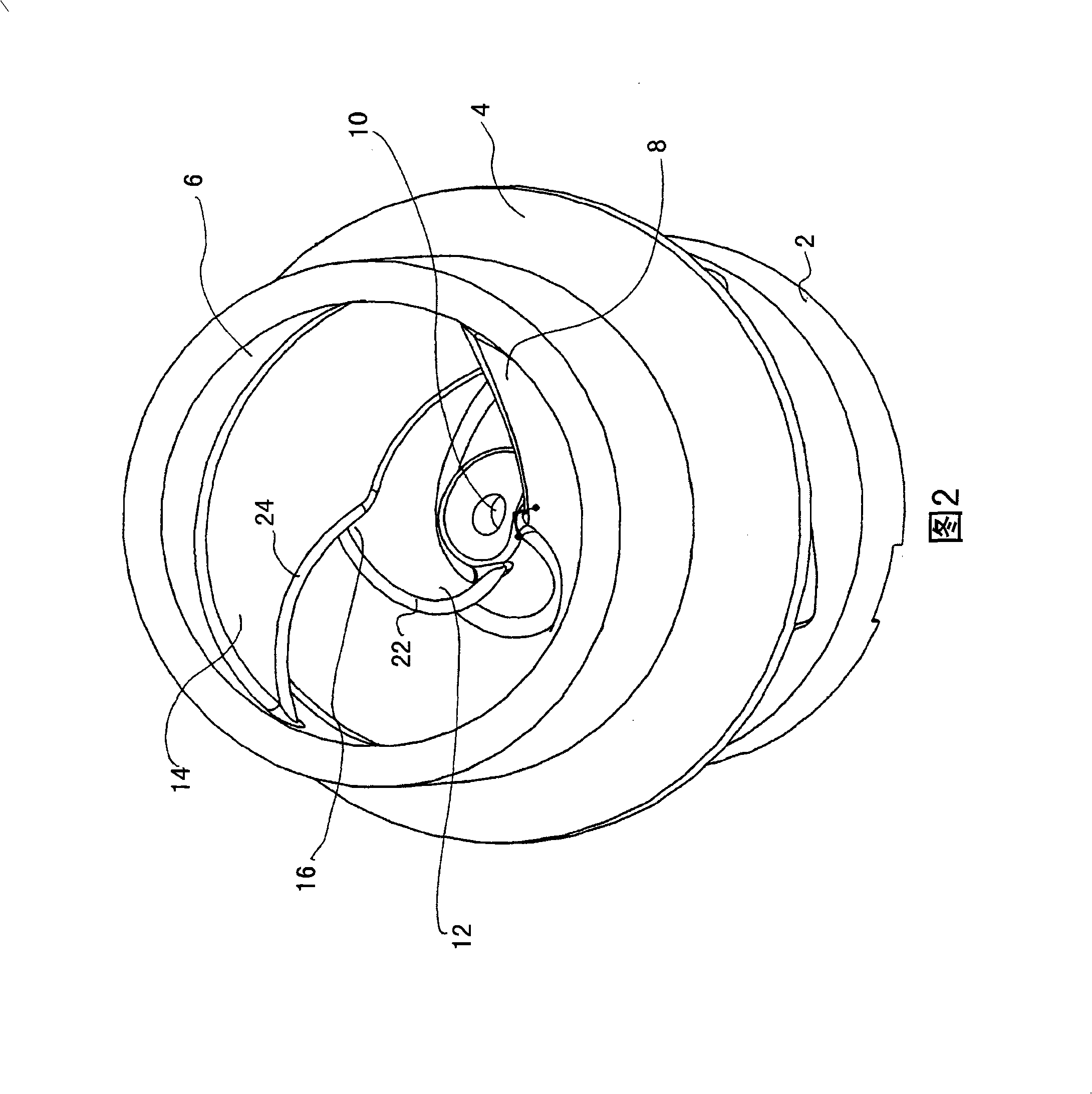

[0025] The impeller has two end caps 2 and 4 , wherein the end cap 4 has a central inlet 6 . When the impeller rotates about the axis of rotation X, the fluid to be conveyed is sucked in through the inlet 6 .

[0026] Between the two end caps 2 and 4 there is provided a continuous first vane 8 which firmly connects the end caps 2 and 4 to each other, thereby keeping the end caps 2 and 4 in a certain direction along the longitudinal axis X. spacing. In addition, the blades 8 also serve to rotate the end cap 4 together with the end cap 2 around the longitudinal axis X. The drive shaft of the impeller acts on the central hole 10 in the end cover 2 so that the drive torque is transmitted to the end cover 2 and from the end cover 2 to the end cover 4 via the blades 8 .

[0027] Instead of having continuous blades 8 , the impeller can also have blades of split construction, which consist of two blade parts 12 and 14 . The blade part 12 is firmly connected to the end cover 2 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com