Shock absorber for the holding assembly of a reciprocating tool

A technology of assembly and shock absorber, applied in the field of shock absorbers, which can solve the problems of high instantaneous stress and large impact load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

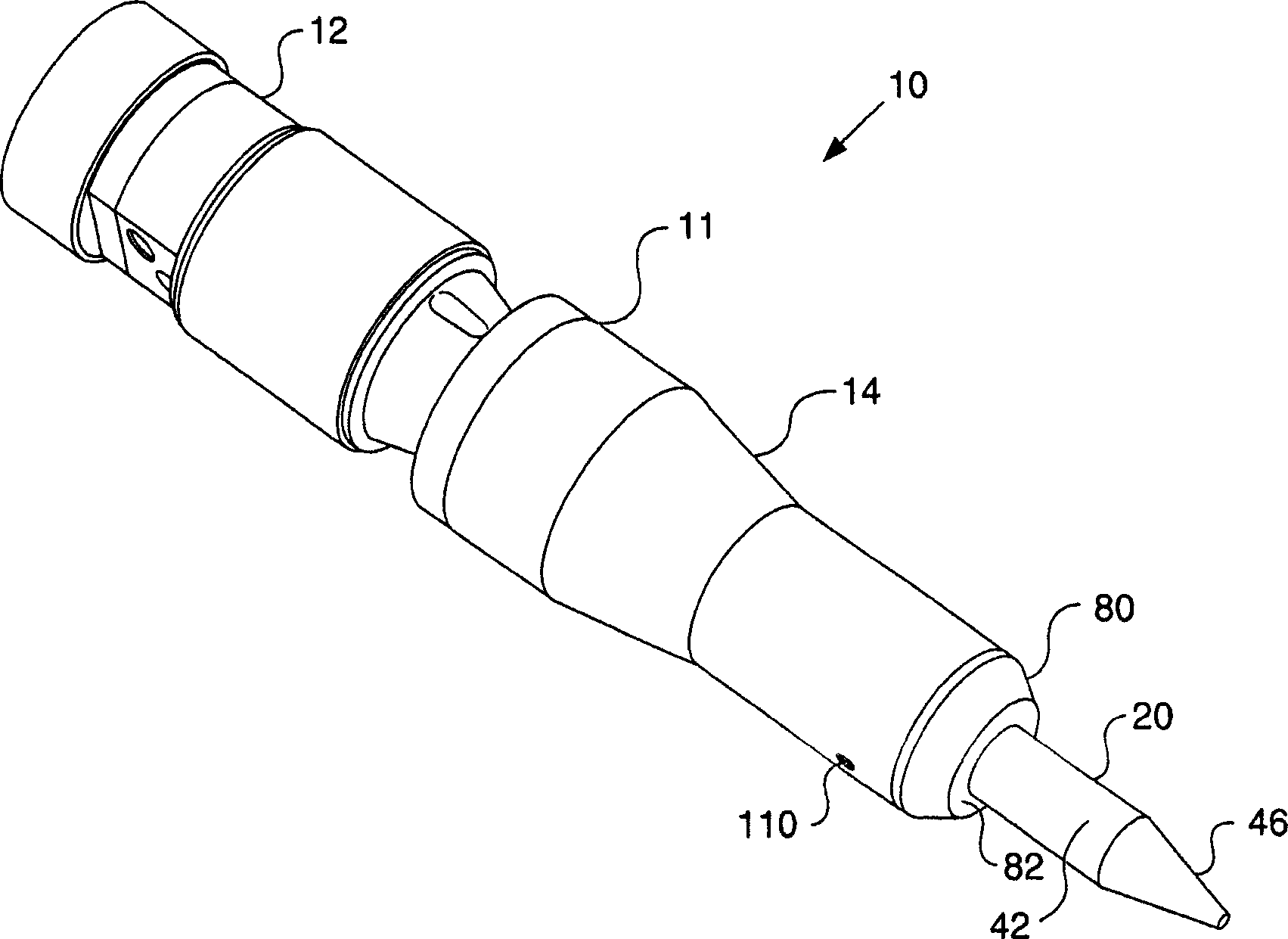

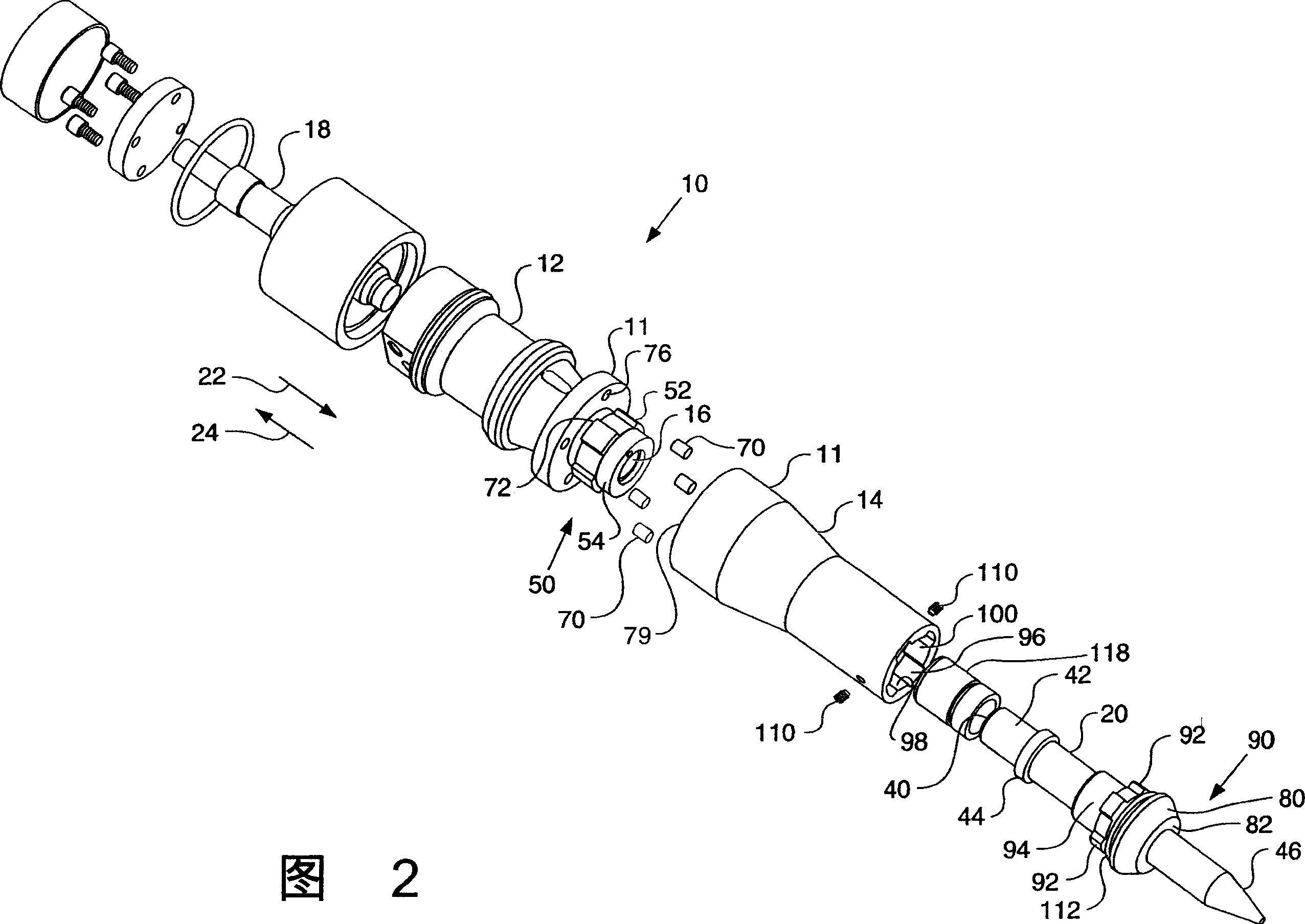

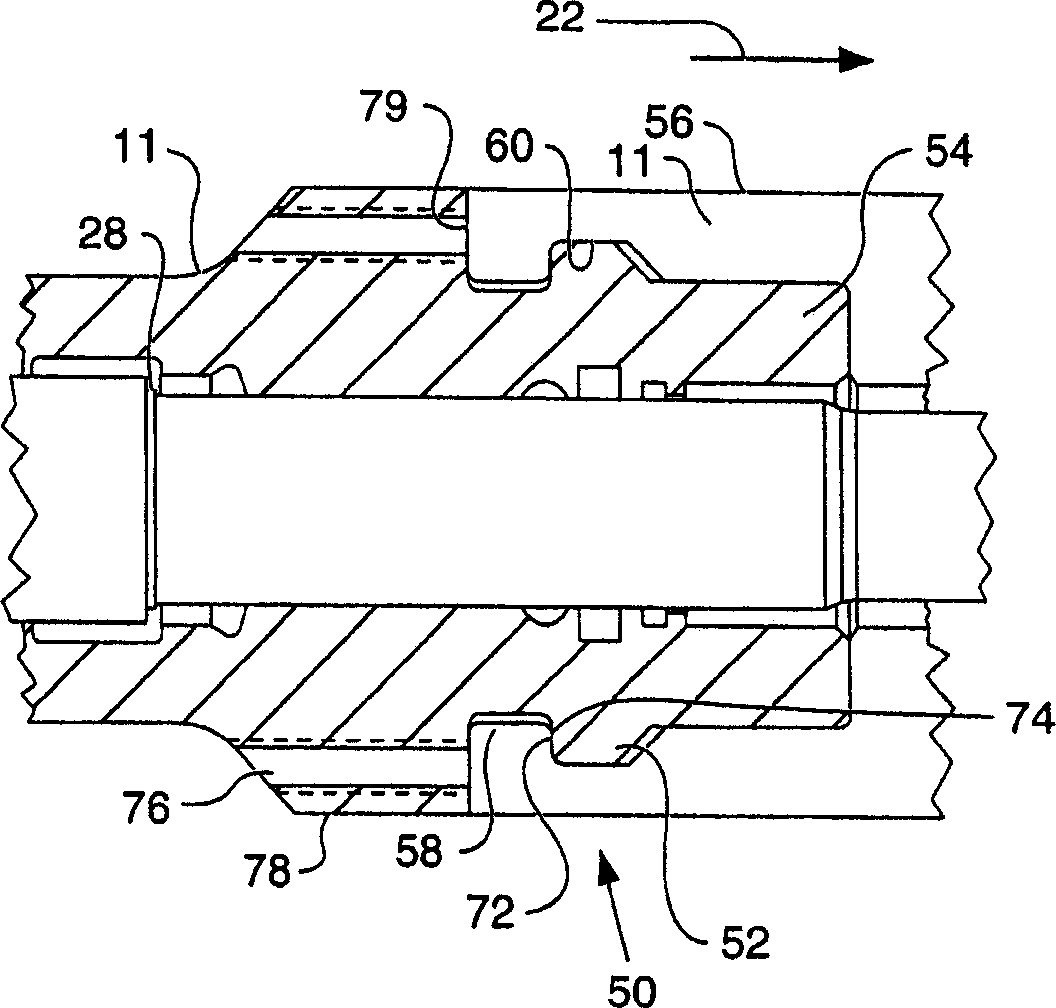

[0017] see Figure 1 to Figure 3 , which shows a tool assembly 10, in particular a hydraulic hammer tool assembly, which is connectable to a backhoe or excavator (not shown). The tool assembly 10 includes a housing 11 , a chamber 16 formed in the housing 11 , a piston 18 and a working tool 20 . The housing 11 is a two-piece housing comprising an upper housing member 12 and a lower housing member 14, which usually form an upper and a lower chamber respectively, and these two chambers together form a chamber 16, the lower housing member The housing member is often referred to as the front end shield. Piston 18 is operably received within chamber 16 such that piston 18 is translatable in the general directions of arrows 22 and 24 . Specifically, during a working stroke, the piston 18 moves in the general direction of the arrow 22 , thereby impacting the working tool 20 . Conversely, on the return stroke, the piston 18 moves in the general direction of arrow 24 .

[0018] A hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com