Vertical rod fixing piece and scaffold

A technology of fixing parts and poles is applied in the accessories of scaffolding, scaffolding supported by house structure, buildings, etc. It can solve the problems of poor structural mechanical properties, easy damage and deformation, and high labor costs, and achieve structural strength and safety improvement. resistance, avoid the effect of unloading failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

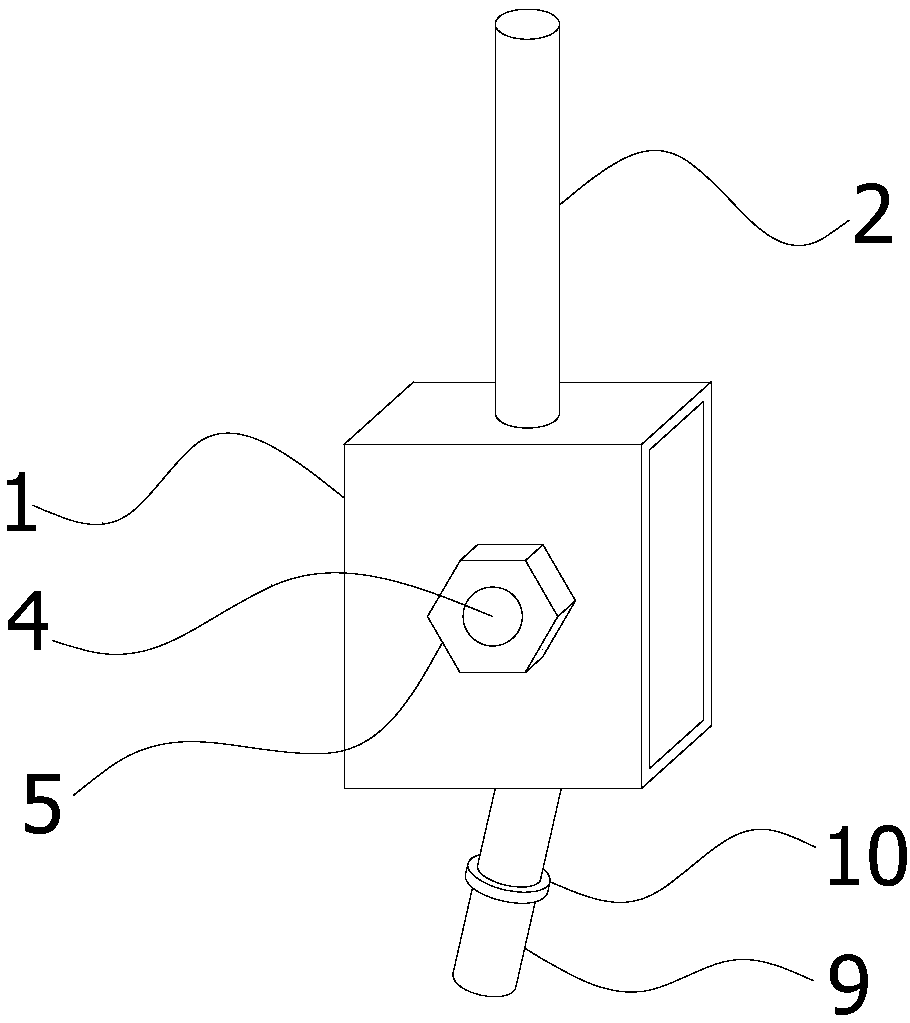

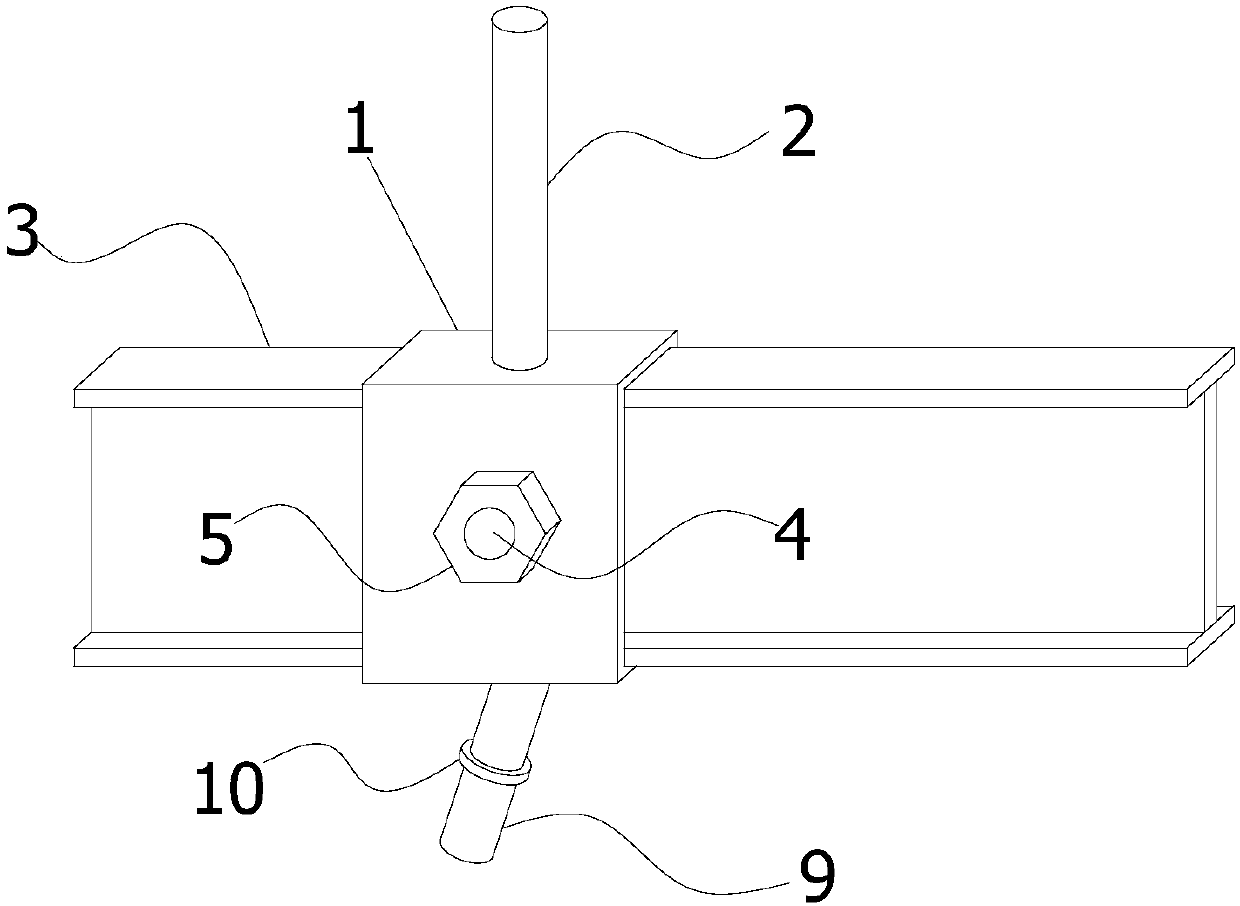

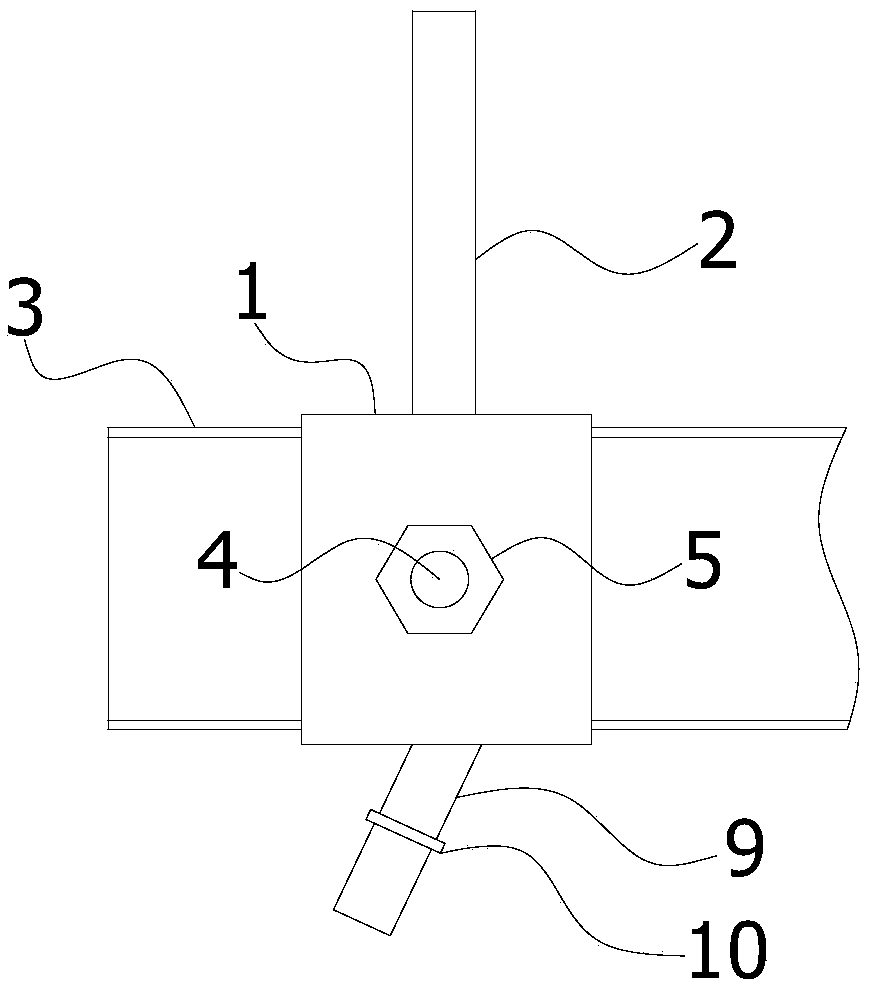

[0044] This embodiment provides a pole fixture, wherein: figure 1 An axonometric view of the pole fixture provided by the embodiment of the present invention; figure 2 An axonometric view of the vertical pole fixing piece provided for the embodiment of the present invention after the I-beam cantilever 3 is sleeved; image 3 The front view of the pole fixing piece provided for the embodiment of the present invention after the I-beam cantilever 3 is sleeved; Figure 4 It is a left side view of the pole fixing piece provided in Embodiment 1 of the present invention after being fitted with the I-beam cantilever 3 . Such as Figure 1~4 As shown, the pole fixing piece includes a fixing sleeve 1, a fixing rod 2 and a fastening assembly. Specifically, the inner cavity of the fixing sleeve 1 can be fit and socketed with the outer contour of the I-shaped steel cantilever 3, and the fastening assembly is arranged on the fixing sleeve 1 for firmly installing the fixing sleeve 1 on the...

Embodiment 2

[0050] This embodiment provides a pole fixture, wherein: Figure 5 It is a left side view of the pole fixing piece provided in Embodiment 2 of the present invention after being fitted with the I-beam cantilever 3 . Such as Figure 1~3 , 5, the pole fixing piece includes a fixing sleeve 1, a fixing rod 2 and a fastening assembly. Specifically, the inner cavity of the fixing sleeve 1 can be fit and socketed with the outer contour of the I-shaped steel cantilever 3, and the fastening assembly is arranged on the fixing sleeve 1 for firmly installing the fixing sleeve 1 on the I-shaped beam. The exterior of the steel cantilever 3. Wherein, the fixed rod 2 is welded on the fixed sleeve 1 for inserting and fixing the vertical rod of the scaffold.

[0051] Further, the fastening assembly includes bolts 4, nuts 5 and through holes 6, wherein the through holes 6 are arranged on the two side walls of the fixing sleeve 1, and the bolts 4 pass through the through holes 6 of one side wal...

Embodiment 3

[0055] This embodiment provides a pole fixture, wherein: Figure 6 It is a left view of the pole fixing piece provided in Embodiment 3 of the present invention after being fitted with the I-beam cantilever 3 . Such as Figure 1~3 , 6, the pole fixing piece includes a fixing sleeve 1, a fixing rod 2 and a fastening assembly. Specifically, the inner cavity of the fixing sleeve 1 can be fit and socketed with the outer contour of the I-shaped steel cantilever 3, and the fastening assembly is arranged on the fixing sleeve 1 to securely install the fixing sleeve 1 on the I-shaped beam. The exterior of the steel cantilever 3. Wherein, the fixed rod 2 is welded on the fixed sleeve 1 for inserting and fixing the vertical rod of the scaffold.

[0056] Further, the fastening assembly includes bolts 4 and screw holes 8 . Wherein, the screw hole 8 is provided on the side wall of the fixing sleeve 1 , and the bolt 4 passes through the screw hole 8 and contacts the I-beam beam 3 , so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com