A kind of continuous casting billet burr release agent and burr removal method

A technology of release agent and billet, applied in the field of steel cutting, which can solve the problems of damage, shortening the working cycle of the roll, and scratching the surface of the roll.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare the burr release agent according to the formula of the present invention, adopt NaOH solution and SiO 2 According to silicon atom and OH -1 The molar ratio of ions is 1.5 to prepare an aqueous solution, and the pH value of the aqueous solution is 10.5; when in use, add TiO to the aqueous solution 2 Mix evenly after powder, TiO 2 The particle size of the powder is 20 μm, TiO 2 The mass of the powder accounts for 60% of the total mass of the two; the mixed burr release agent is a suspension in which fixed particles are evenly dispersed.

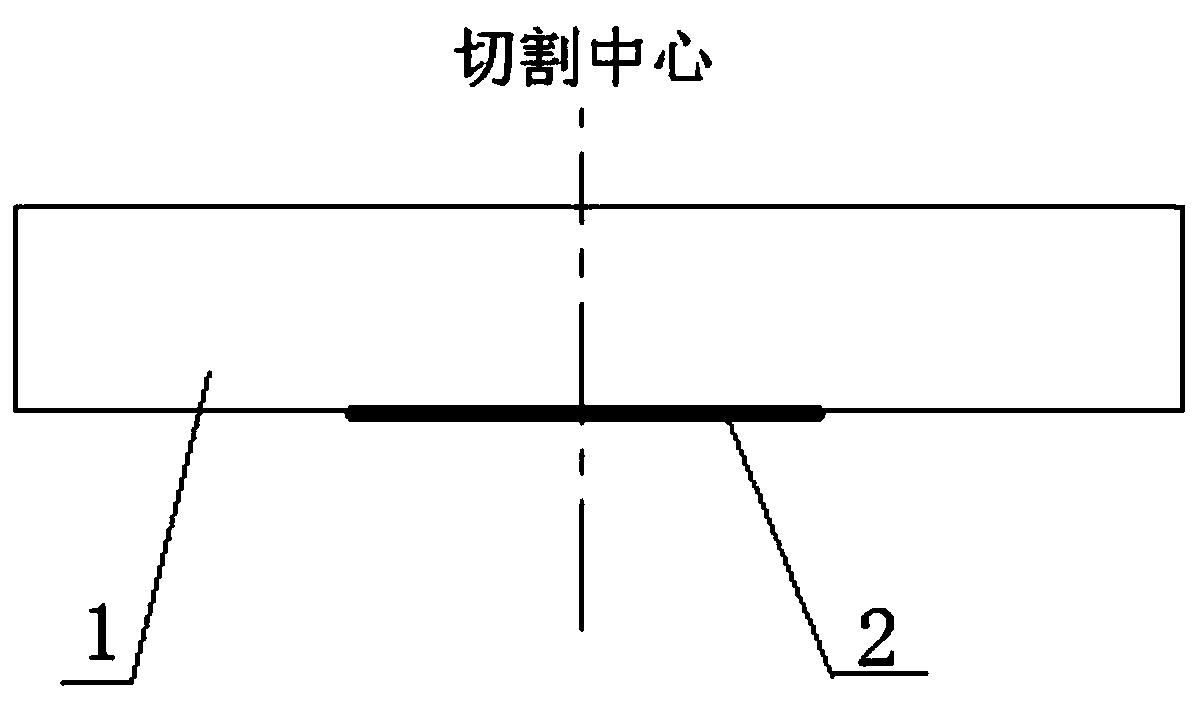

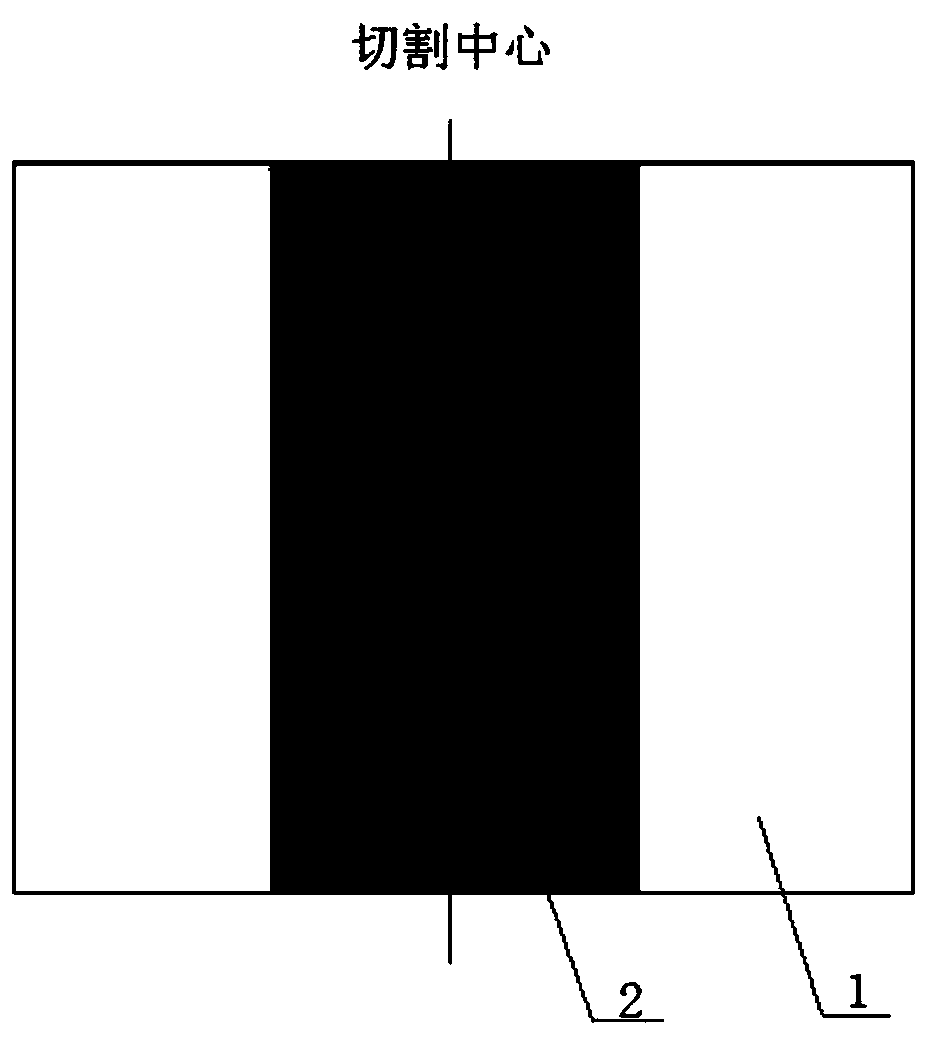

[0043] With the cutting line on the lower surface of the continuous casting billet to be cut as the center, spray a burr release agent coating with a width of 80mm, and spray along the cutting direction of the continuous casting billet. The thickness of the burr release agent coating is 0.2mm.

[0044] Due to the blocking effect of the burr release agent, the burr generated during the cutting process of the continuous casting ...

Embodiment 2

[0046] Prepare the burr release agent according to the formula of the present invention, adopt NaOH solution and SiO 2 According to silicon atom and OH -1 The molar ratio of ions is 1.75 to prepare an aqueous solution, and the pH value of the aqueous solution is 10.75; when in use, add TiO to the aqueous solution 2 Mix evenly after powder, TiO 2 The particle size of the powder is 30 μm, TiO 2 The mass of the powder accounts for 70% of the total mass of the two; the mixed burr release agent is a suspension in which fixed particles are uniformly dispersed.

[0047] With the cutting line on the lower surface of the continuous casting billet to be cut as the center, spray a burr release agent coating with a width of 160mm, and spray along the continuous casting billet cutting direction, and the thickness of the burr release agent coating is 1.0mm.

[0048] Due to the blocking effect of the burr release agent, the burr generated during the cutting process of the continuous casting...

Embodiment 3

[0050] Prepare the burr release agent according to the formula of the present invention, adopt NaOH solution and SiO 2 According to silicon atom and OH -1 The molar ratio of ions is 2 to prepare an aqueous solution, and the pH value of the aqueous solution is 11; when in use, add TiO to the aqueous solution 2 Mix evenly after powder, TiO 2 The particle size of the powder is 40 μm, TiO 2 The mass of the powder accounts for 70% of the total mass of the two; the mixed burr release agent is a suspension in which fixed particles are uniformly dispersed.

[0051] With the cutting line on the lower surface of the continuous casting billet to be cut as the center, spray a burr release agent coating with a width of 200mm, and spray along the continuous casting billet cutting direction, and the thickness of the burr release agent coating is 1.0mm.

[0052] Due to the blocking effect of the burr release agent, the burr generated during the cutting process of the continuous casting bil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com