Connector used for stack PCB

A connector, stacking technology, applied in the direction of connection, two-part connection device, and components of the connection device, can solve the problems of poor PCB communication, high welding process requirements, large host space, etc., to avoid direct welding, reduce Maintenance difficulty and the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

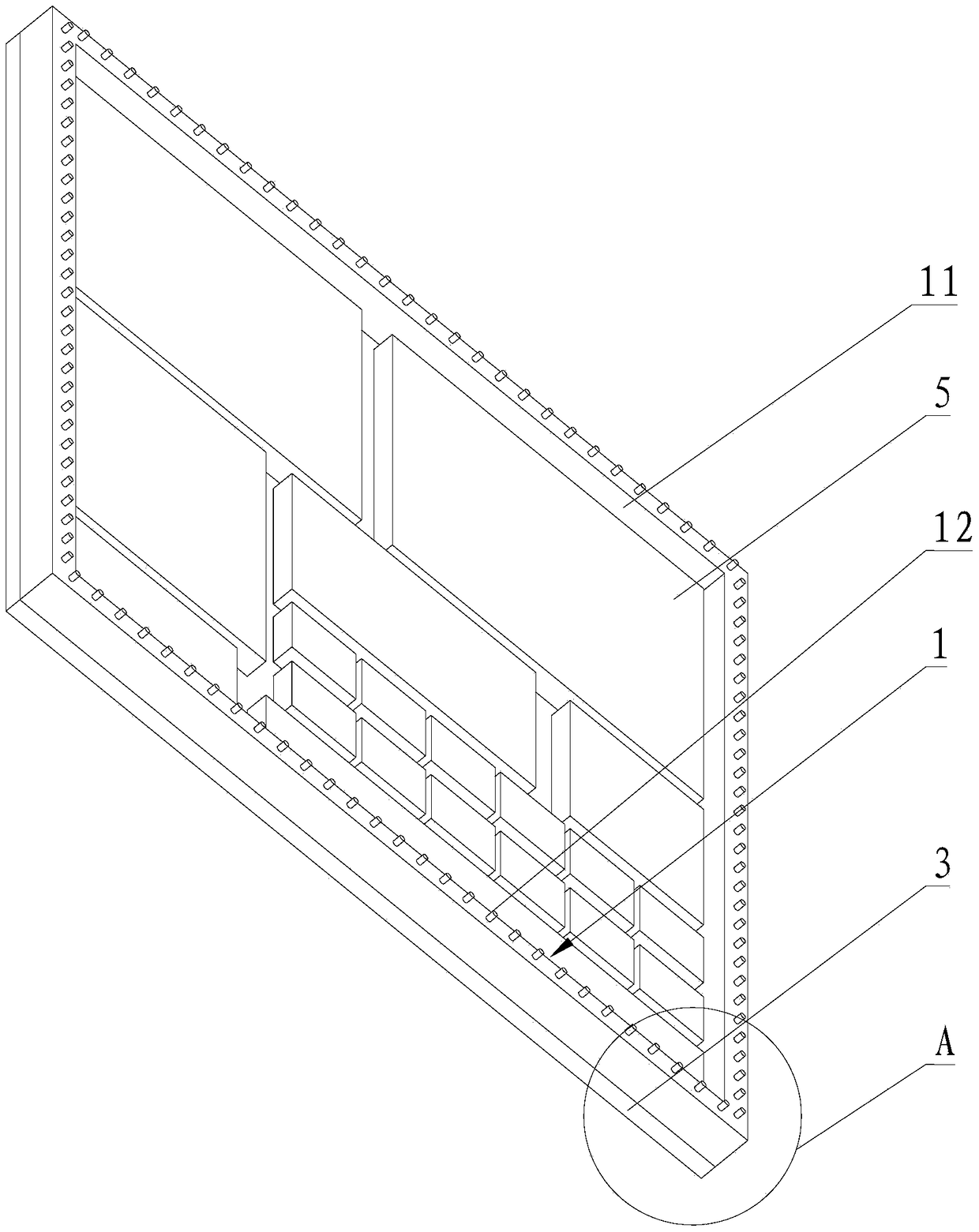

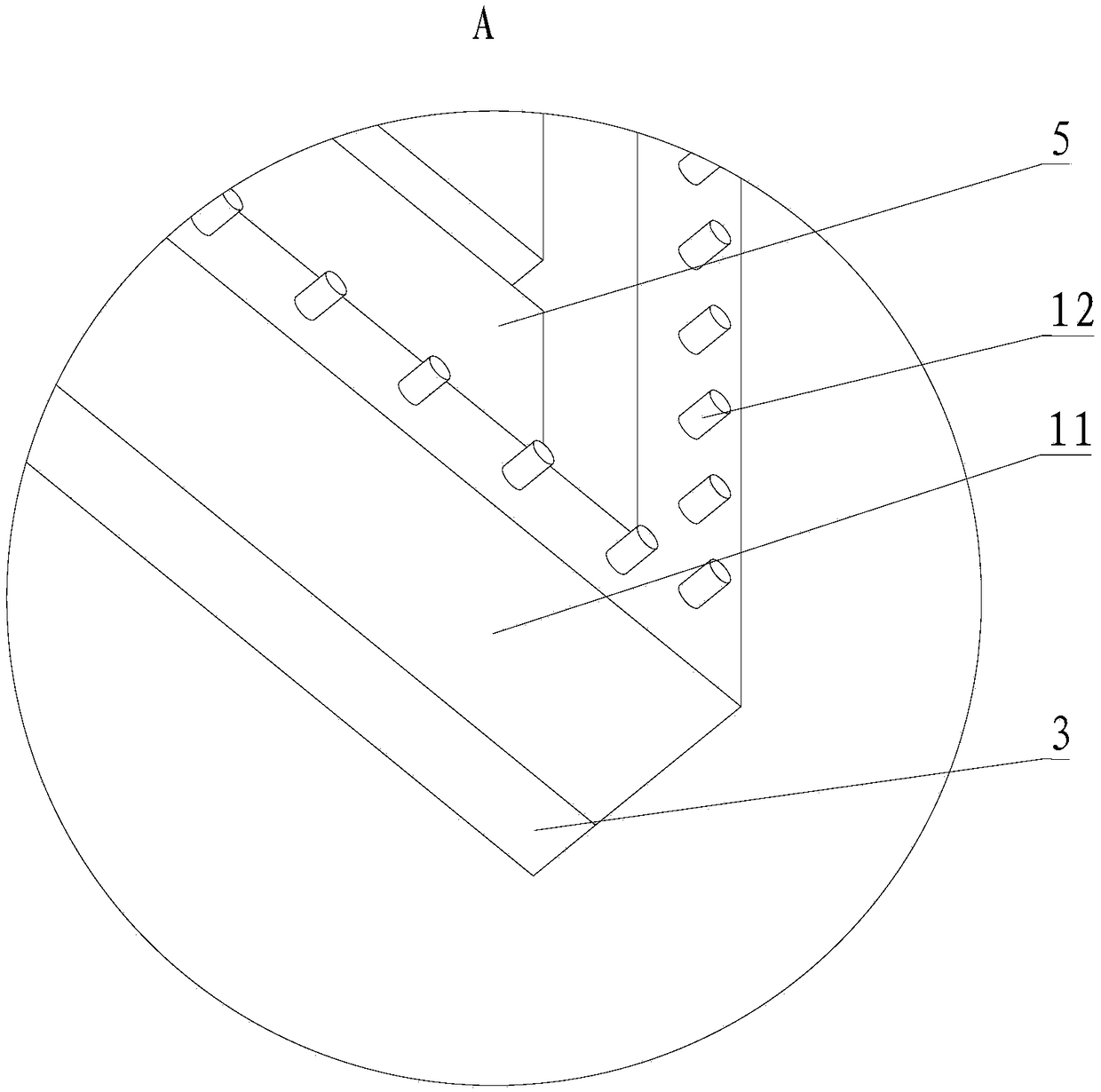

[0038] Please refer to Figure 1-5 , Embodiment 1 of the present invention is:

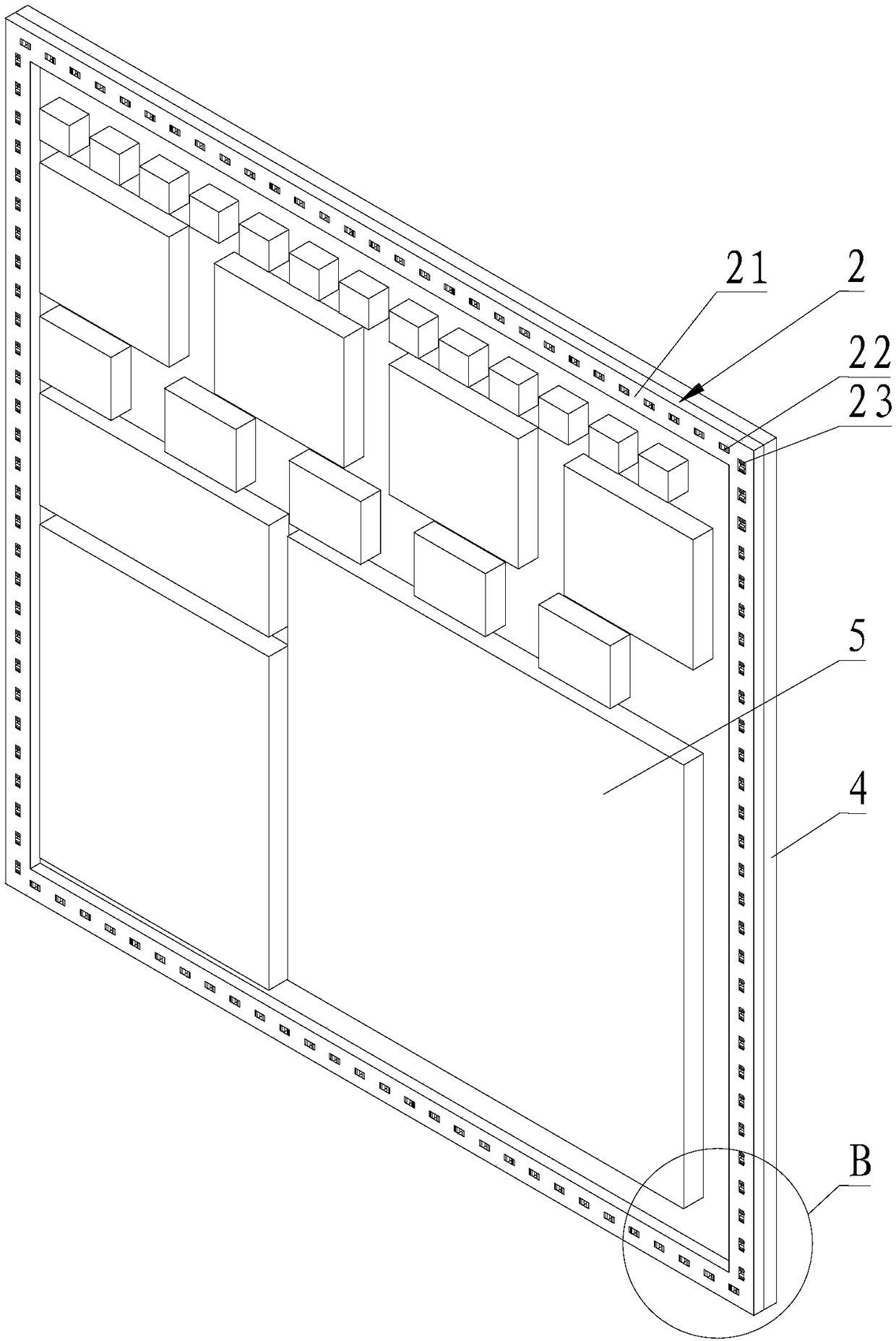

[0039] A connector for a stacked PCB, comprising a connector male 1 and a connector female 2, the side of the connector male 1 away from the connector female 2 is set as a male soldering surface, the connector The side of the female head 2 away from the connector male head 1 is set as the female head welding surface;

[0040] The connector male 1 includes a male housing 11, and a conductive insert 12 is arranged inside the male housing 11; one end of the conductive insert 12 extends away from the male housing 11 and extends out of the male housing 11 Outside; the other end of the conductive insert 12 is flush with the soldering surface of the male head, the conductive insert 12 is a "T"-shaped structure, and the end of the conductive insert 12 of the "T"-shaped structure with a smaller radius extends to the connection outside of male header 1.

[0041] The connector female head 2 includes a fem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com