Patents

Literature

41results about How to "Avoid direct soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric core connecting sheet, battery and assembling method

ActiveCN109659481ARealize the flow in advanceRealize flow collectionPrimary cell manufactureFinal product manufactureElectrical and Electronics engineeringElectrode

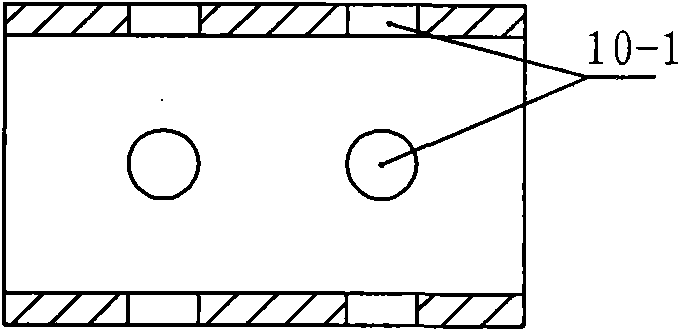

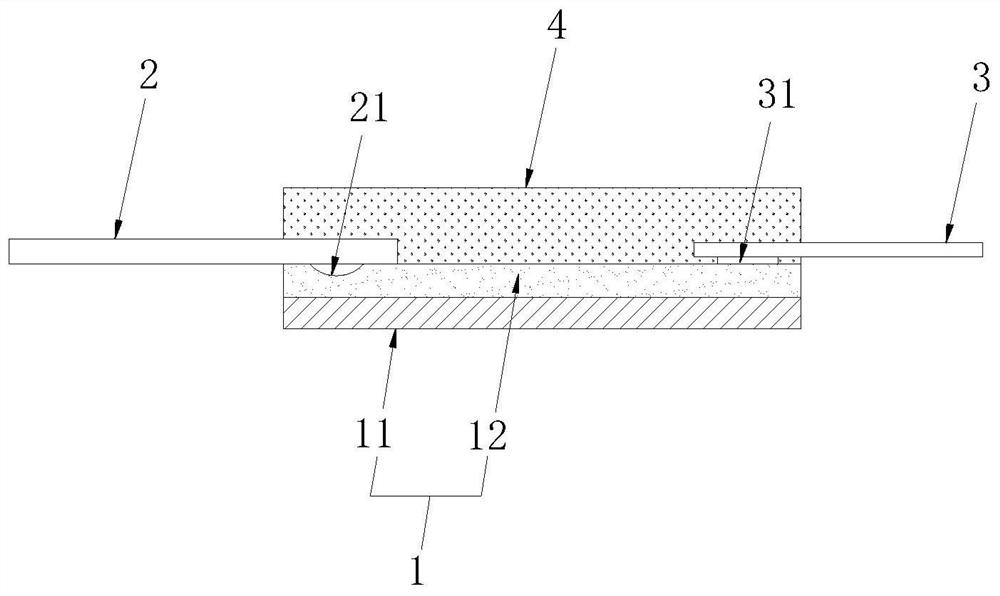

The invention discloses an electric core connecting sheet, a battery and an assembling method. The electric core connecting sheet comprises a body, an electric core connecting portion and a solderingconnecting portion. The electric core connecting portion is disposed on one side of the body and electrically connected with the tab of the electric core. The soldering connecting portion is disposedon the other side of the body, electrically connected to the pole of the battery, and bendable relative to the body. By providing the electric core connecting portion on the electric core connecting sheet, the tabs of the electric core can be soldered and fixed to the electric core connection portion, thereby realizing the early current collection of the positive and negative electrodes of the electric core, preventing the positive and negative of all the electric cores from being directly welded on the poles of the battery, and at the same time, ensuring the overcurrent capability of each connection position during the current collecting process of the battery. In addition, the welding connection portion on the electric core connecting sheet is connected with the pole of the battery, thereby finally realizing the current collection of the positive and negative electrodes of the plurality of electric cores, avoiding the welding difficulty caused by the excessive number of the tabs welded on the pole and improving the welding quality.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

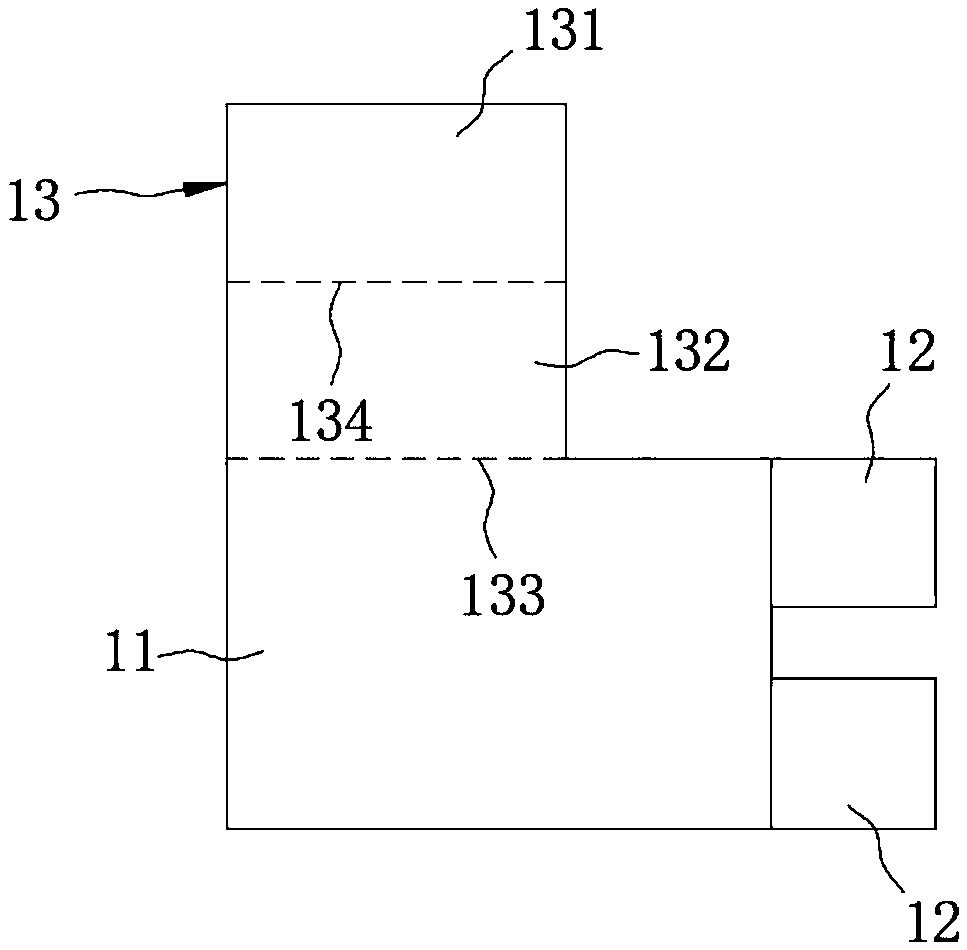

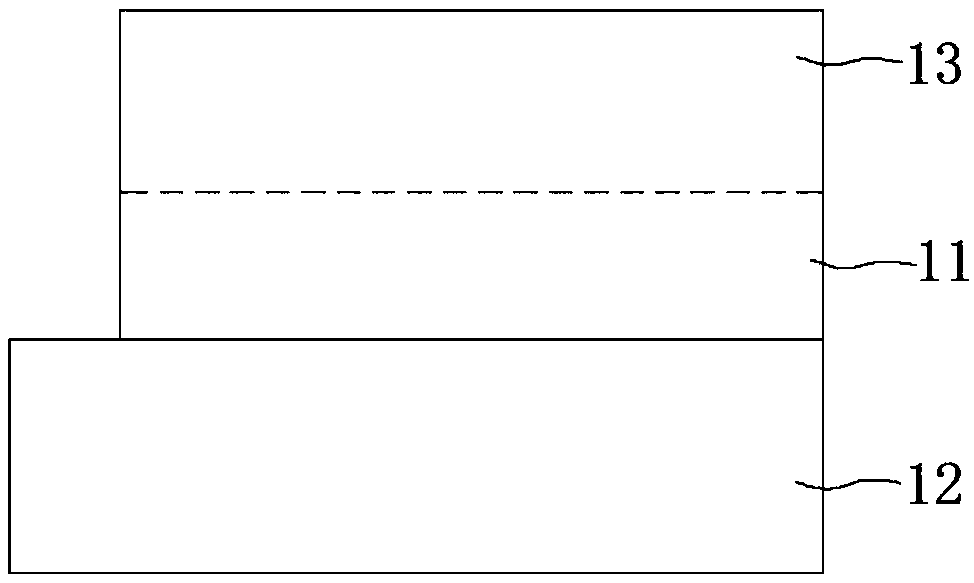

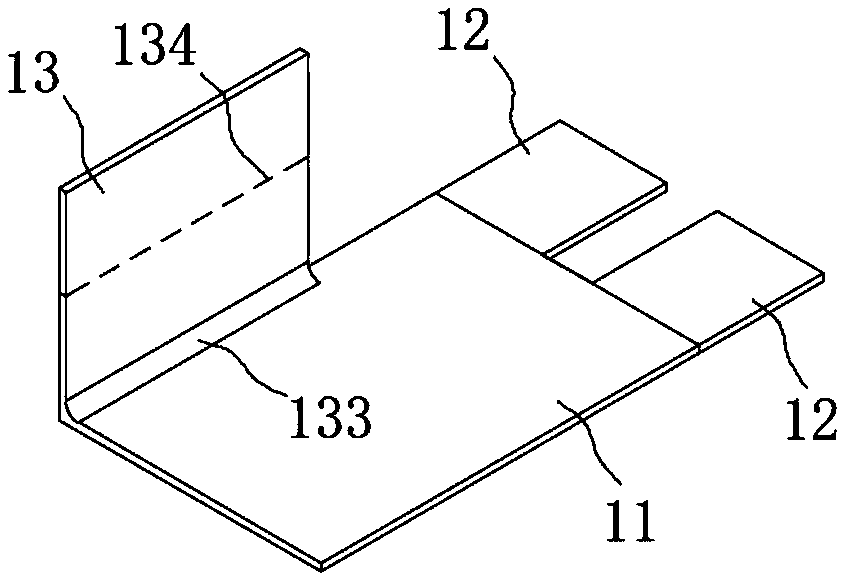

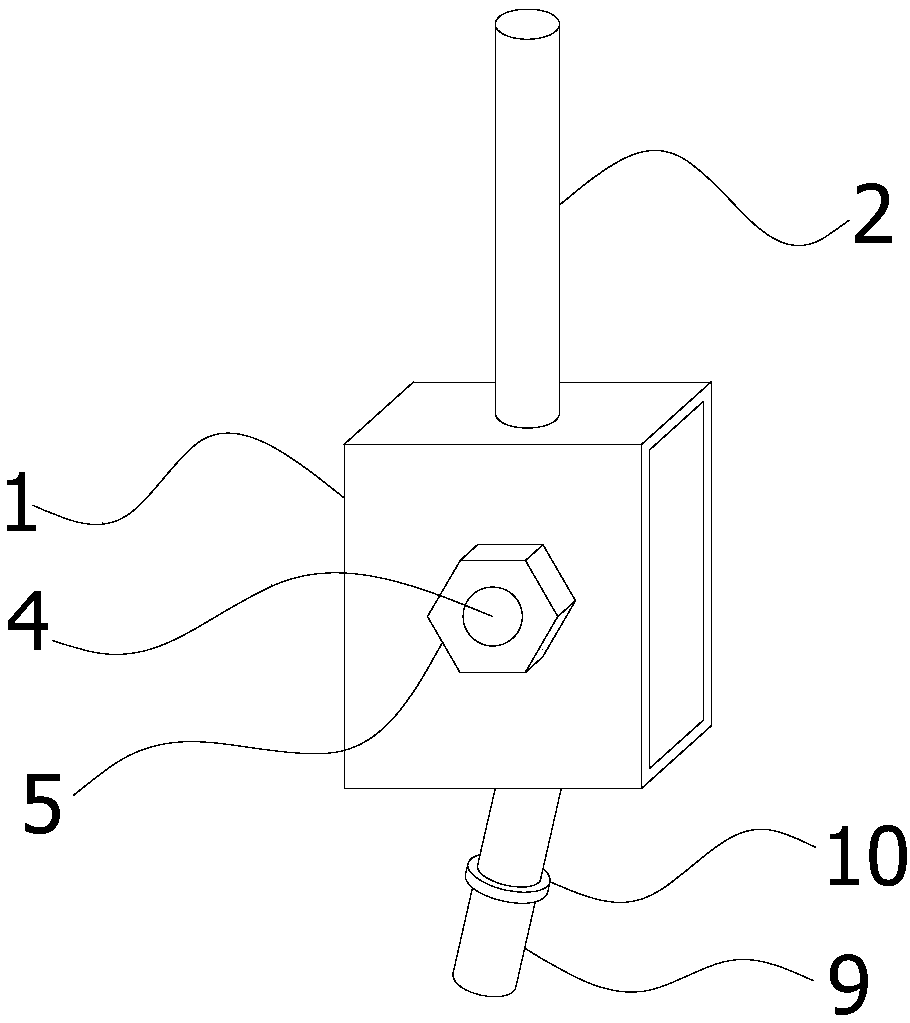

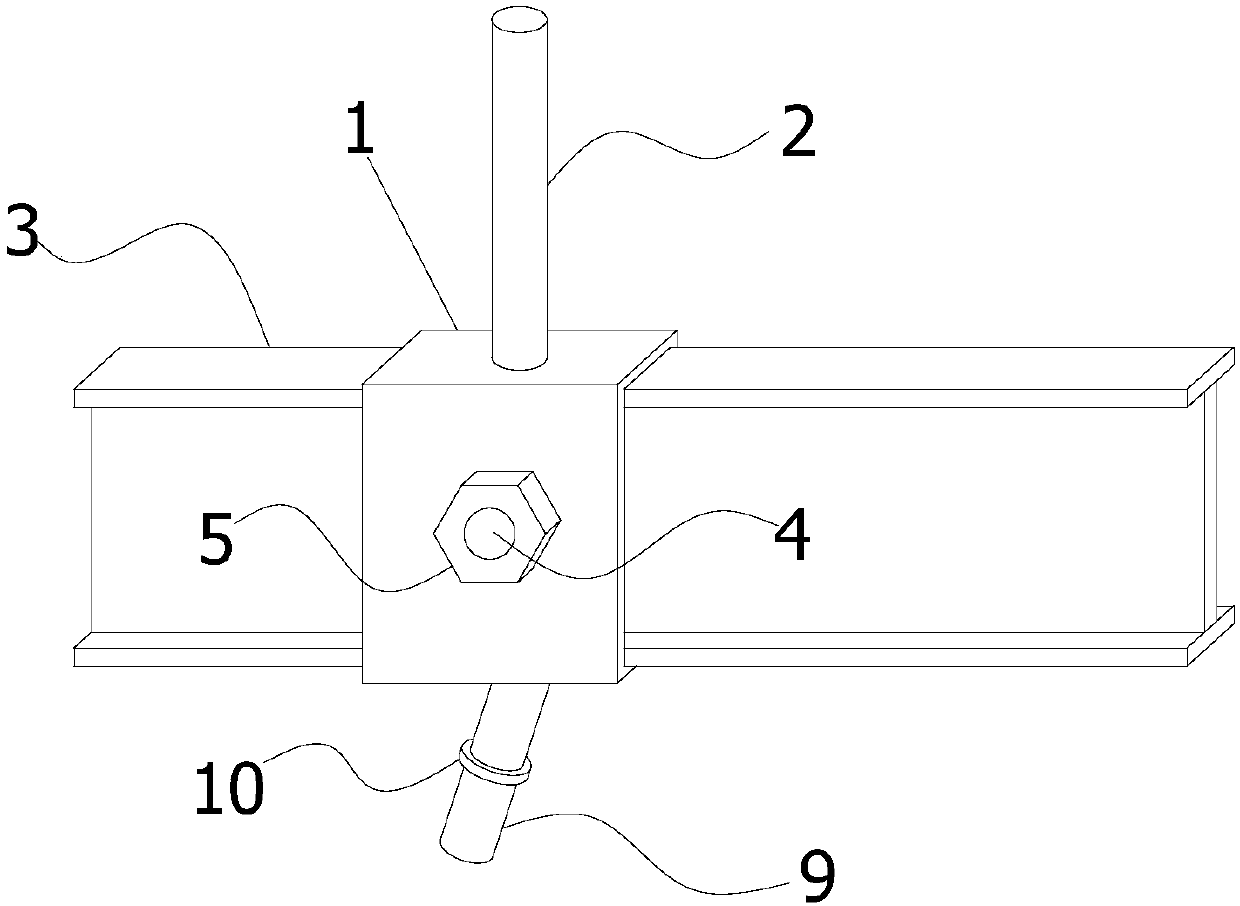

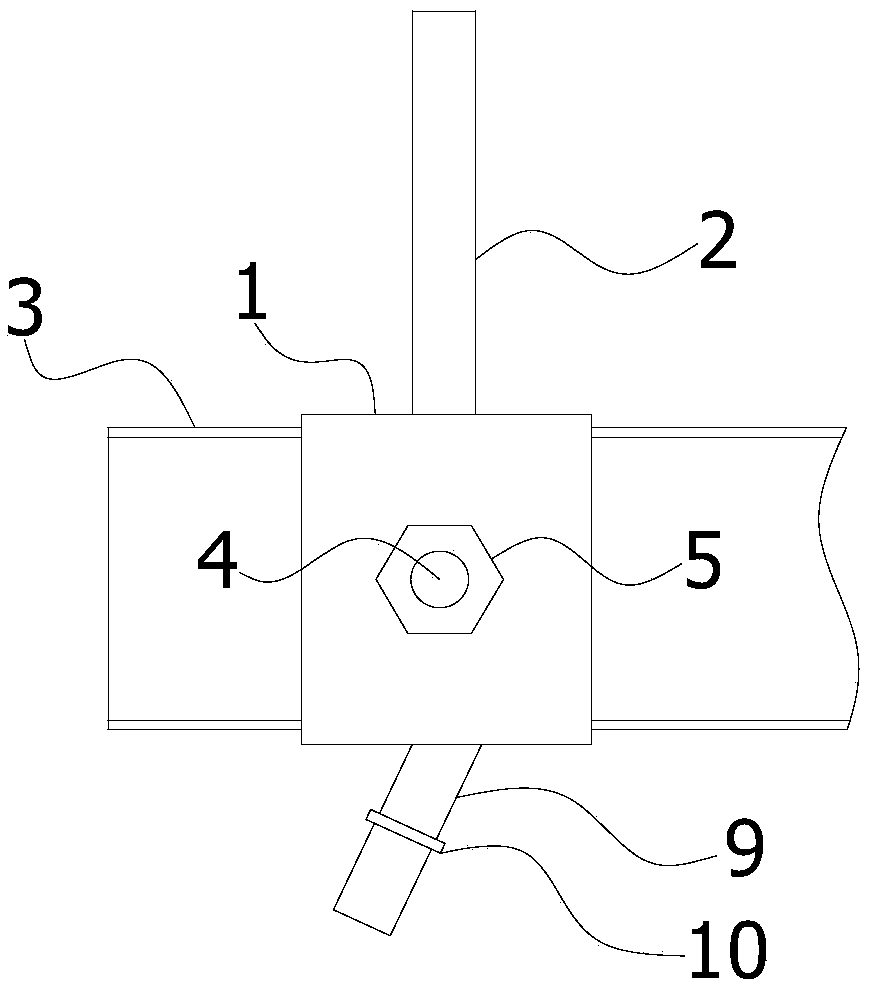

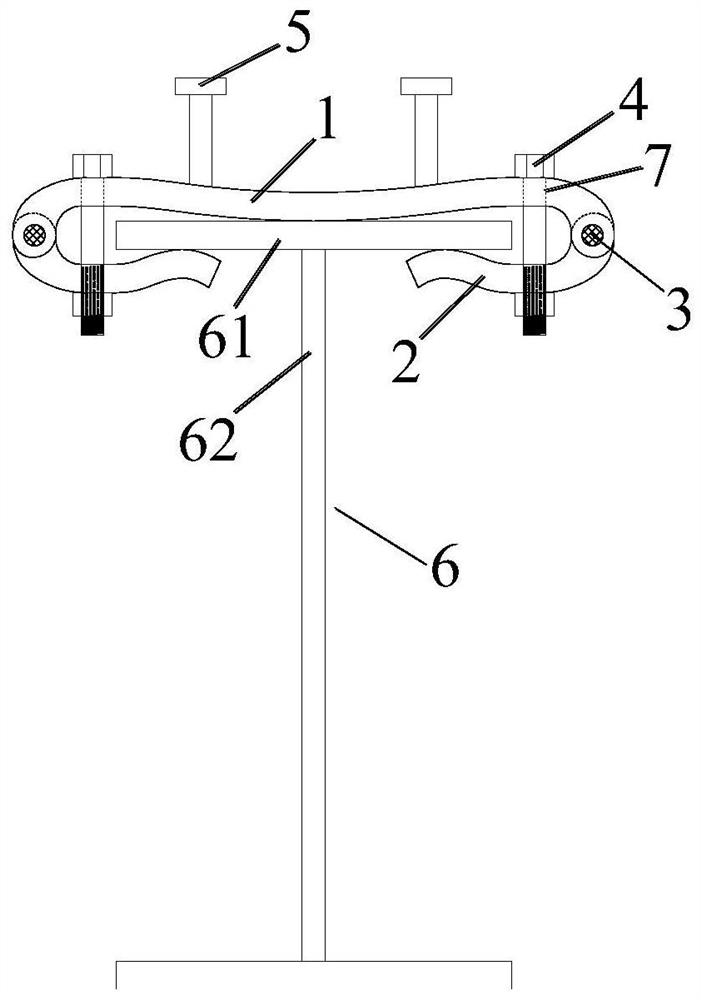

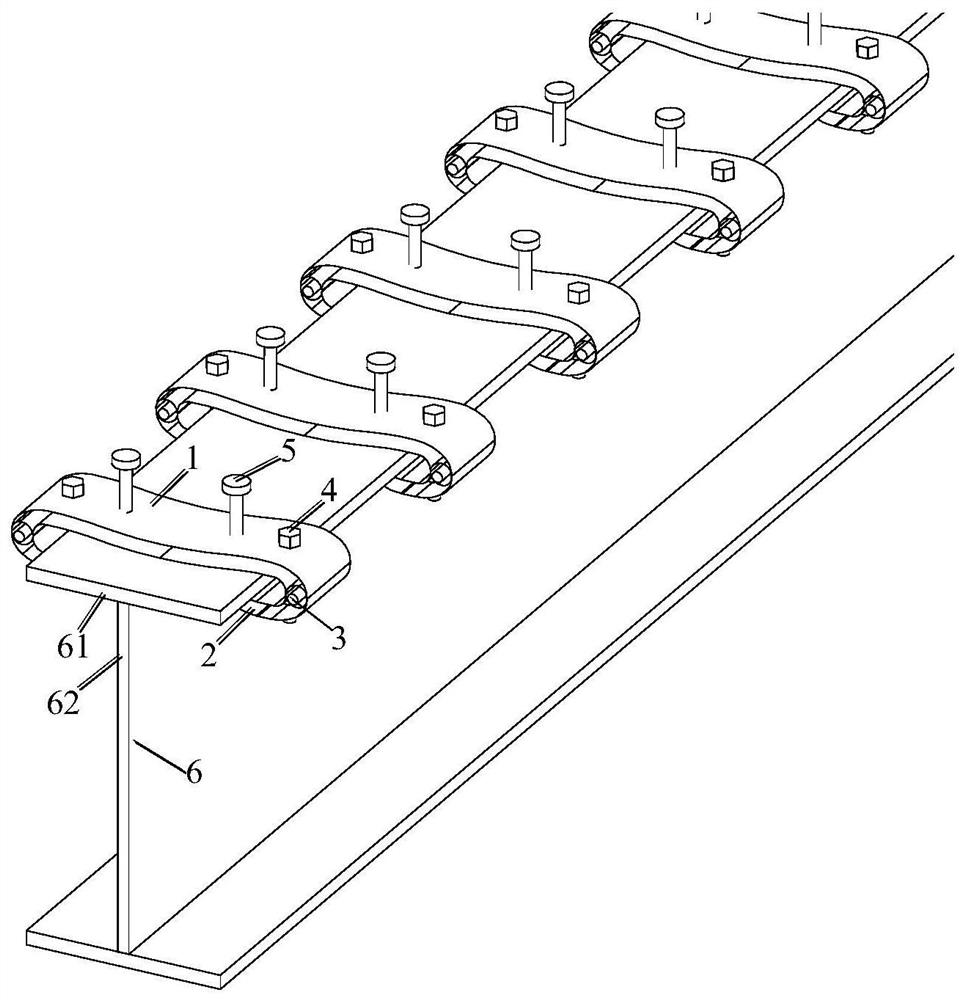

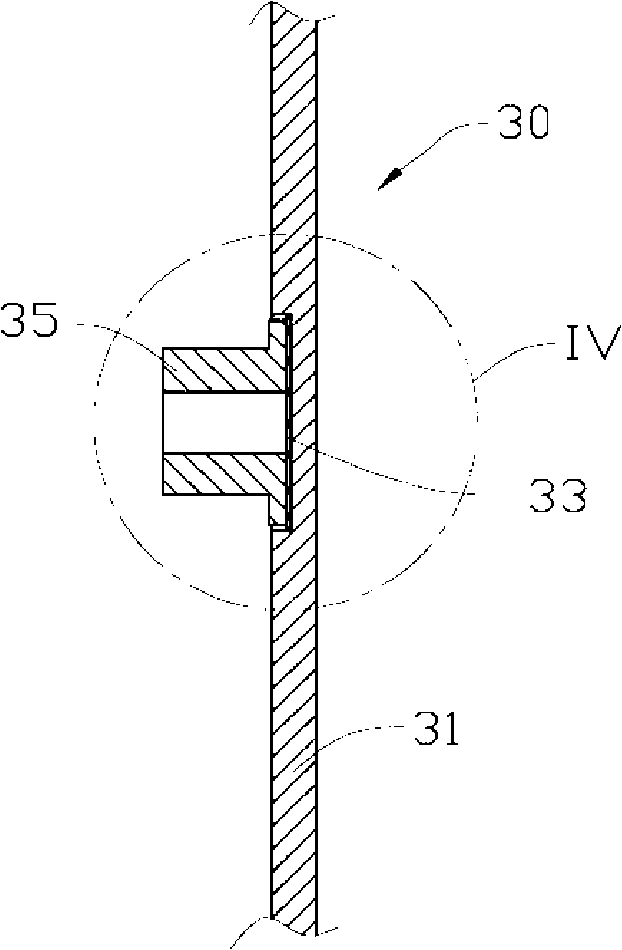

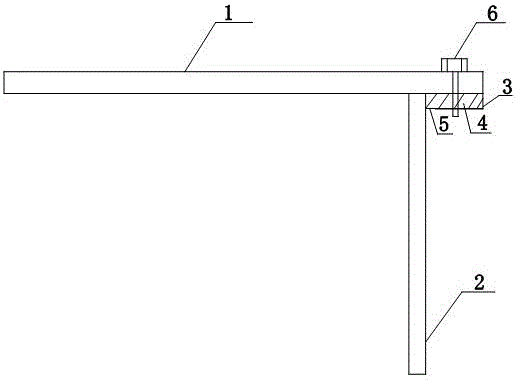

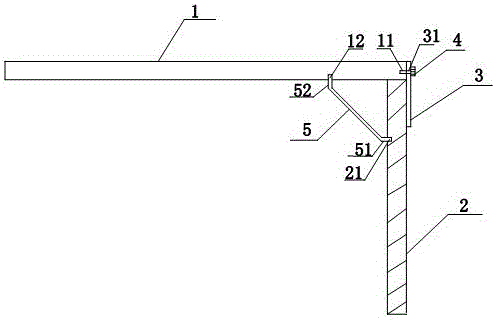

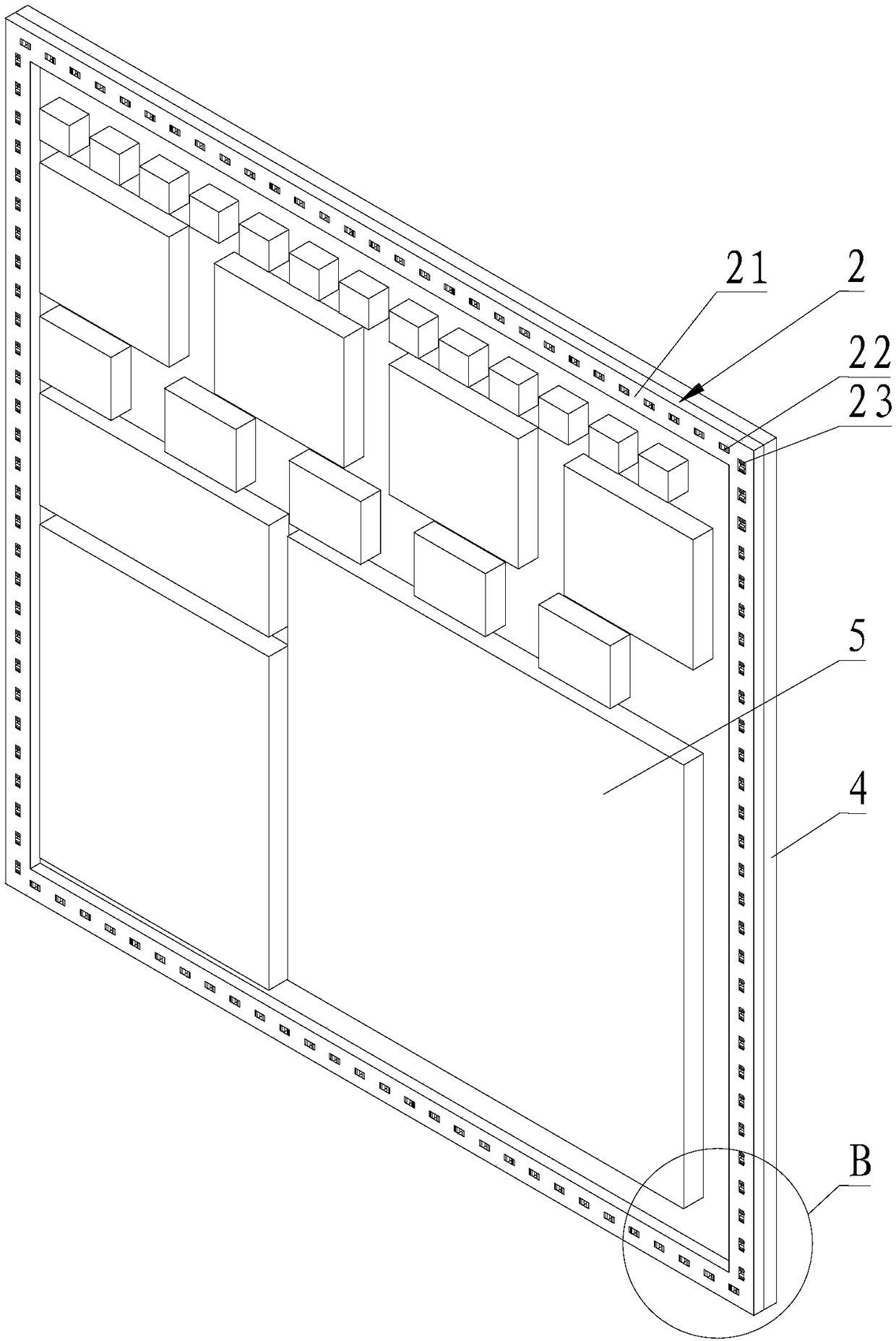

Vertical rod fixing piece and scaffold

PendingCN107558720AAvoid direct solderingReduced risk of damageScaffold accessoriesBuilding support scaffoldsStress concentrationCantilever

The invention provides a vertical rod fixing piece comprising a fixing sleeve, a fixing rod and a fastening assembly. An inner cavity of the fixing sleeve can be connected with the outer contour of anI-shaped steel cantilever beam in attached and sleeving modes. The fastening assembly is arranged on the fixing sleeve and used for firmly mounting the fixing sleeve on the exterior of the I-shaped steel cantilever beam. The fixing rod is welded to the fixing sleeve and used for inserting and fixing a vertical rod of a scaffold. According to the vertical rod fixing piece, by using the fixing sleeve with the welded fixing rod, the situation that the fixing rod is directly welded to the I-shaped steel cantilever beam is avoided, and the damage hidden danger of the I-shaped steel cantilever beamand the fixing rod in construction operation due to stress concentration is reduced; during mounting and demounting, an I-shaped steel cantilever beam without a welded fixing rod can penetrate through a shear wall independently, the aerial operation procedures are simplified, and the construction risks are reduced; and meanwhile, the collision deformation risk of scaffold parts in the process that the scaffold parts are stored and transported to other sites is also avoided. On the basis of the vertical rod fixing piece, the invention further provides the scaffold.

Owner:CCCC FOURTH HIGHWAY ENG

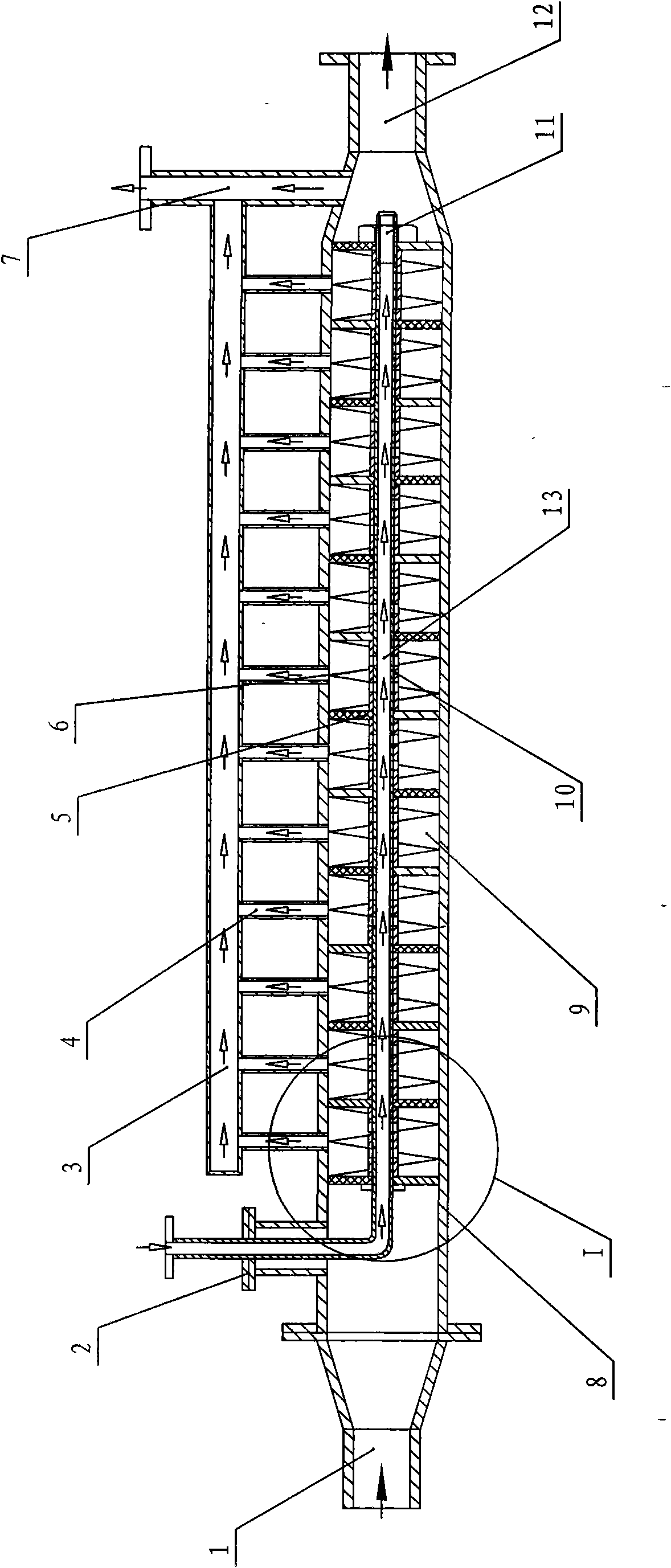

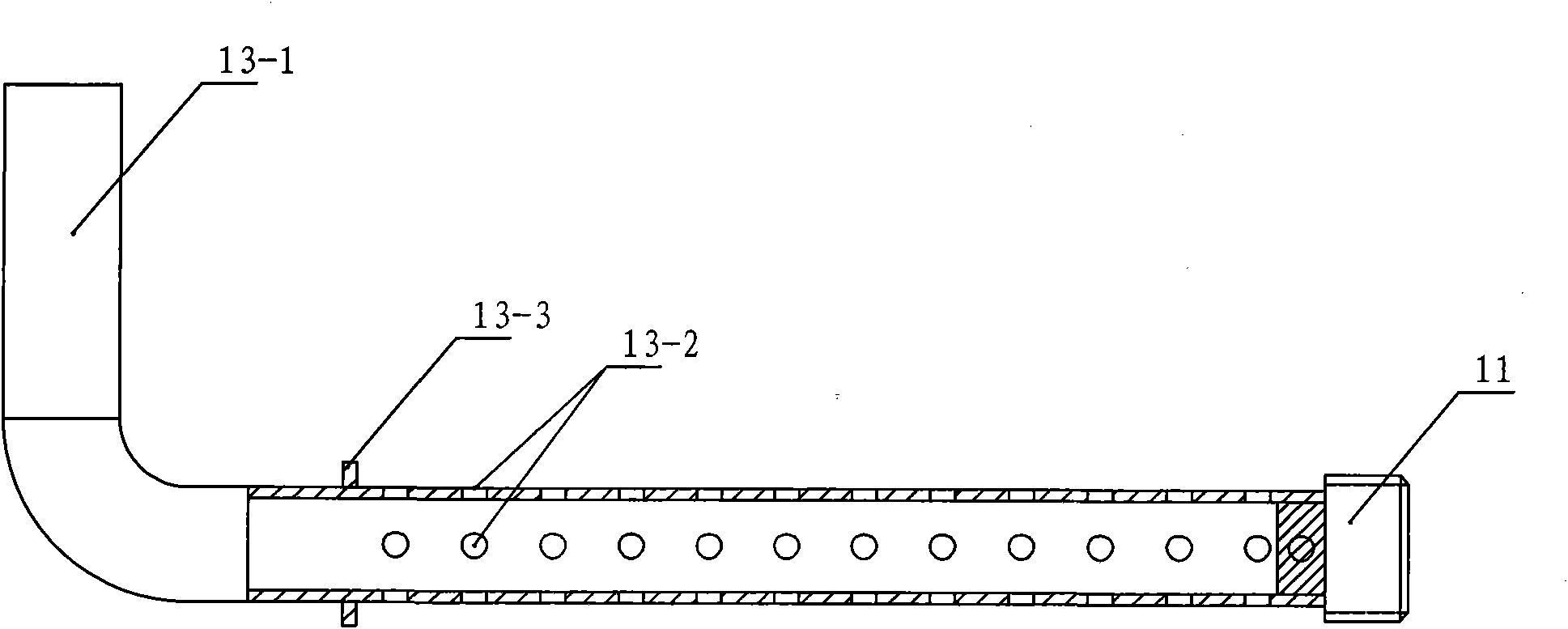

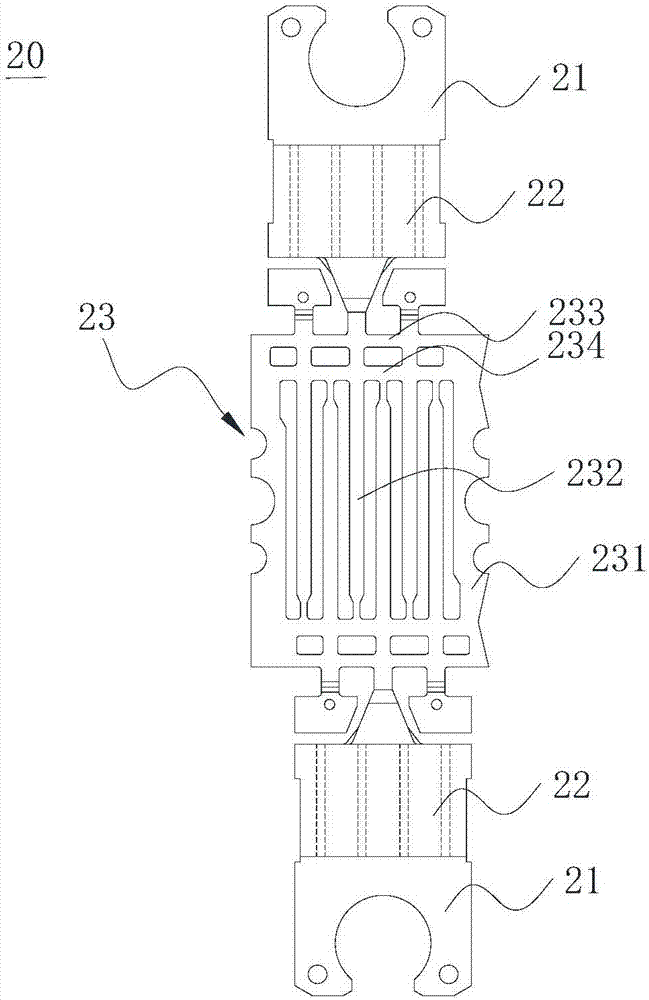

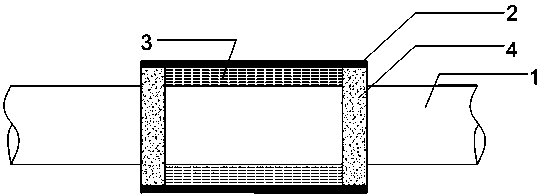

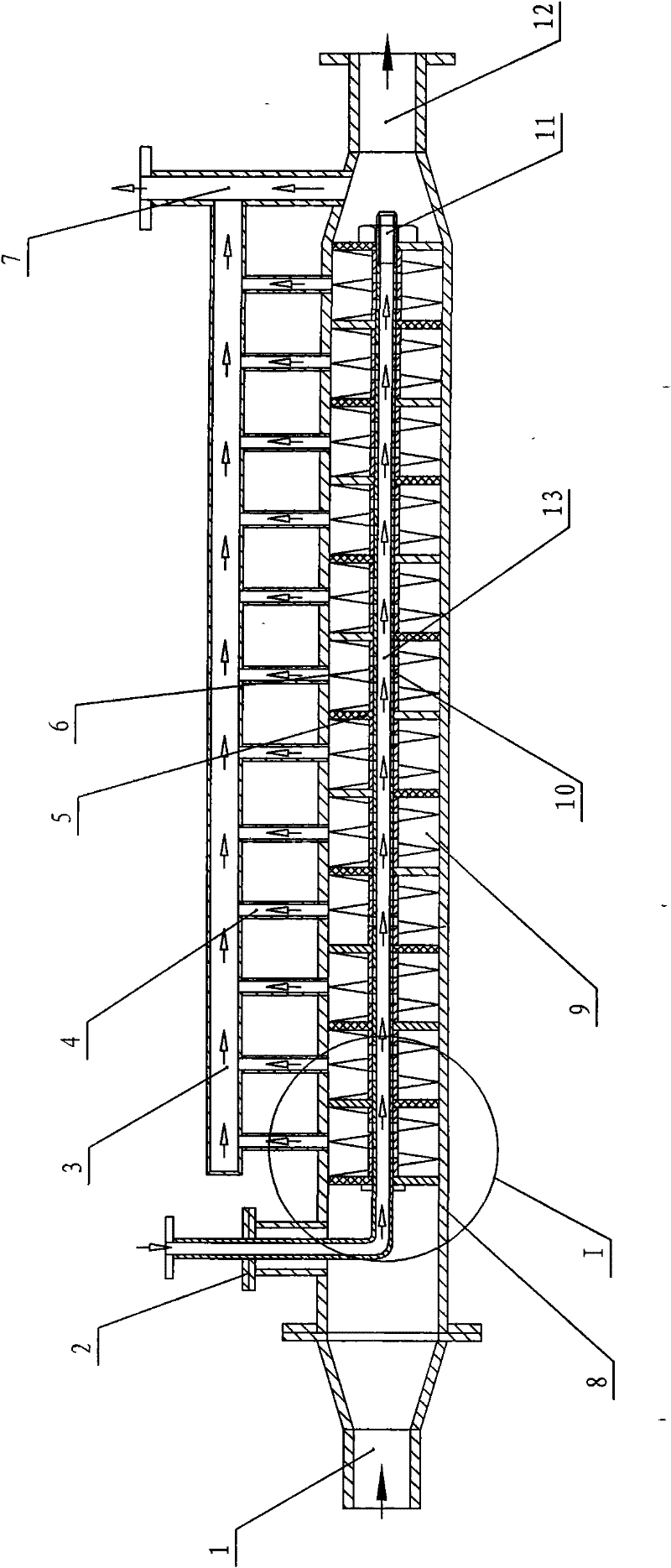

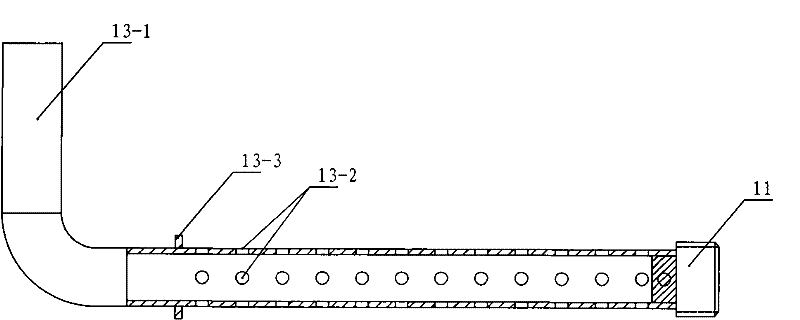

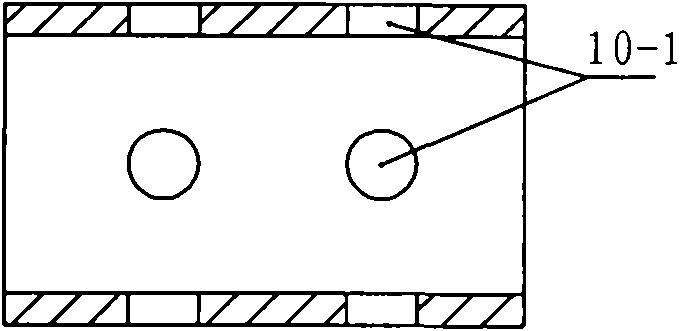

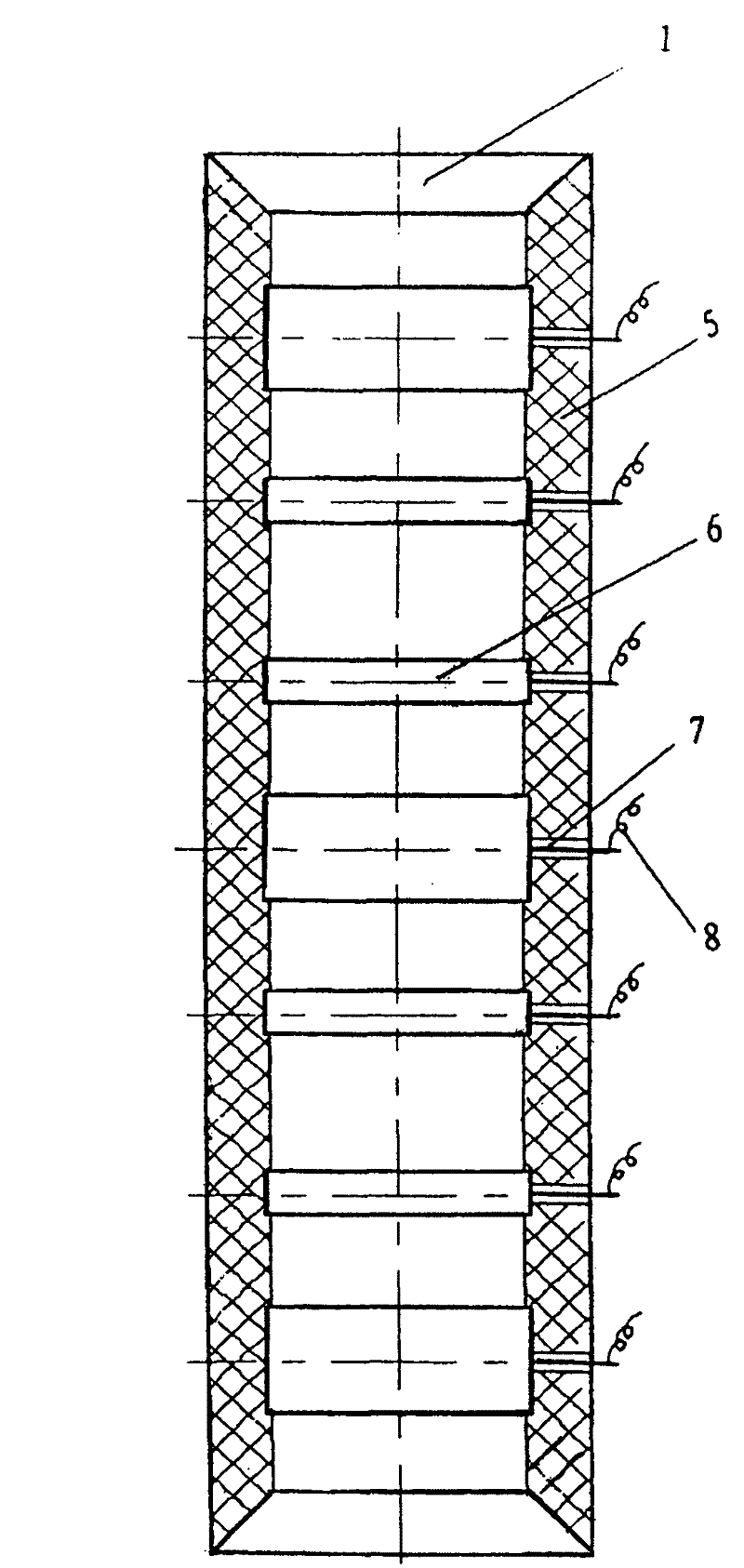

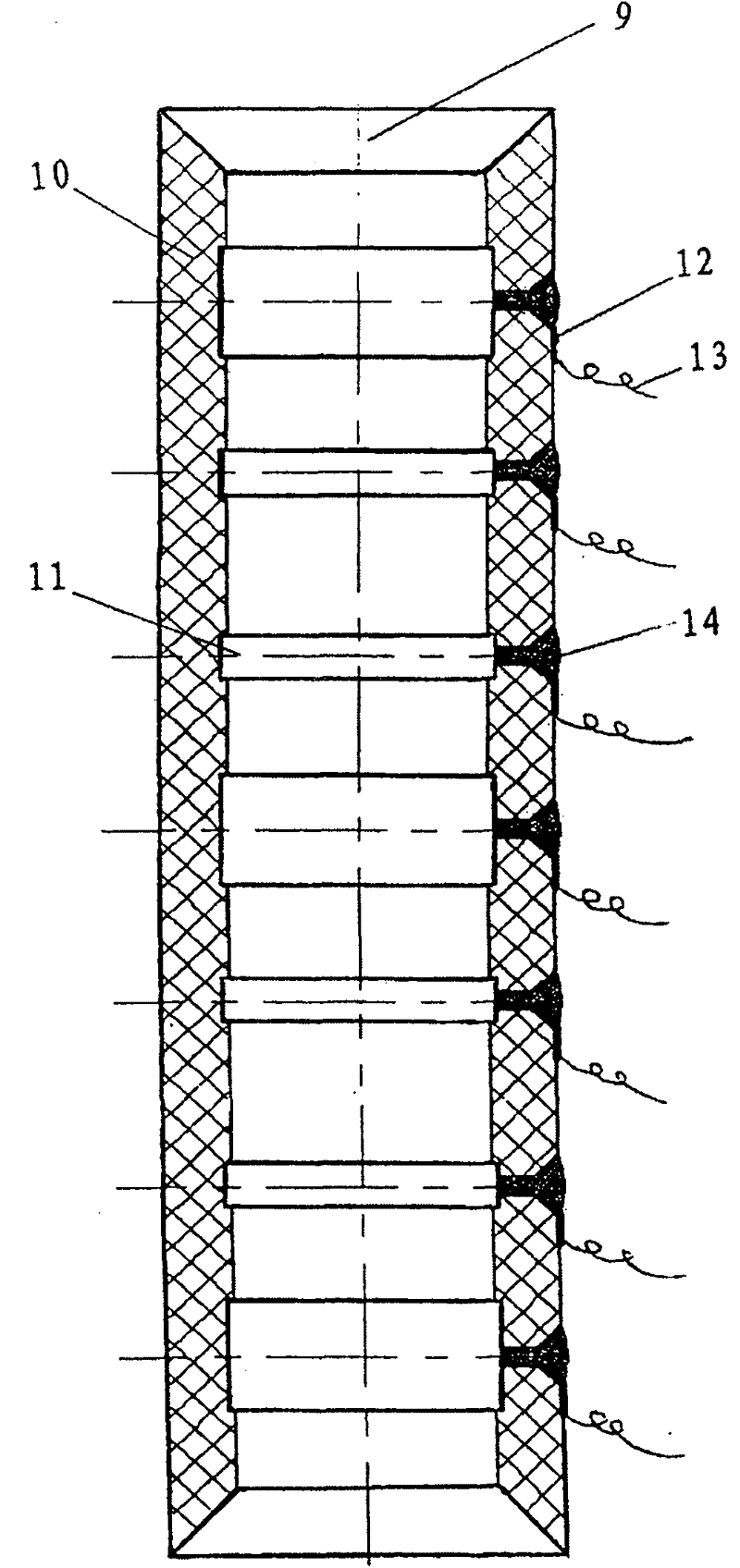

Extraction multi-chamber mixer used in antibiotic production

ActiveCN101890253AImprove split blendingIncrease turbulence velocityFlow mixersLiquid solutions solvent extractionEngineeringMixing chamber

The invention relates to an extraction multi-chamber mixer used in antibiotic production. The mixer of the invention comprises a cylindrical shell, wherein the two ends of the cylindrical shell are provided with a charge tube and a discharge tube; a certain number of dummy plates are arranged in the shell to divide the interior of the shell into multiple mixing chambers; half of the dummy plates are entities, and the other half of the dummy plates are sieve plates distributed with through holes; the adjacent mixing chambers are communicated through the sieve plates; a central tube is arranged at the middle part of the dummy plates in a penetrating mode, and the length of the central tube is matched with that of the cylindrical shell; one end of the central tube, which is close to the discharge tube, is enclosed; the other end of the central tube, which is close to the charge tube, penetrates out from the cylindrical shell through a bent tube; all the parts of the central tube, which are in the mixing chambers, are provided with air hole; and the upper part of each mixing chamber is provided with an exhaust tube. The mixer has high mixing efficiency and can fully mix materials and improve extracting speed and effect.

Owner:濮阳泓天威药业有限公司

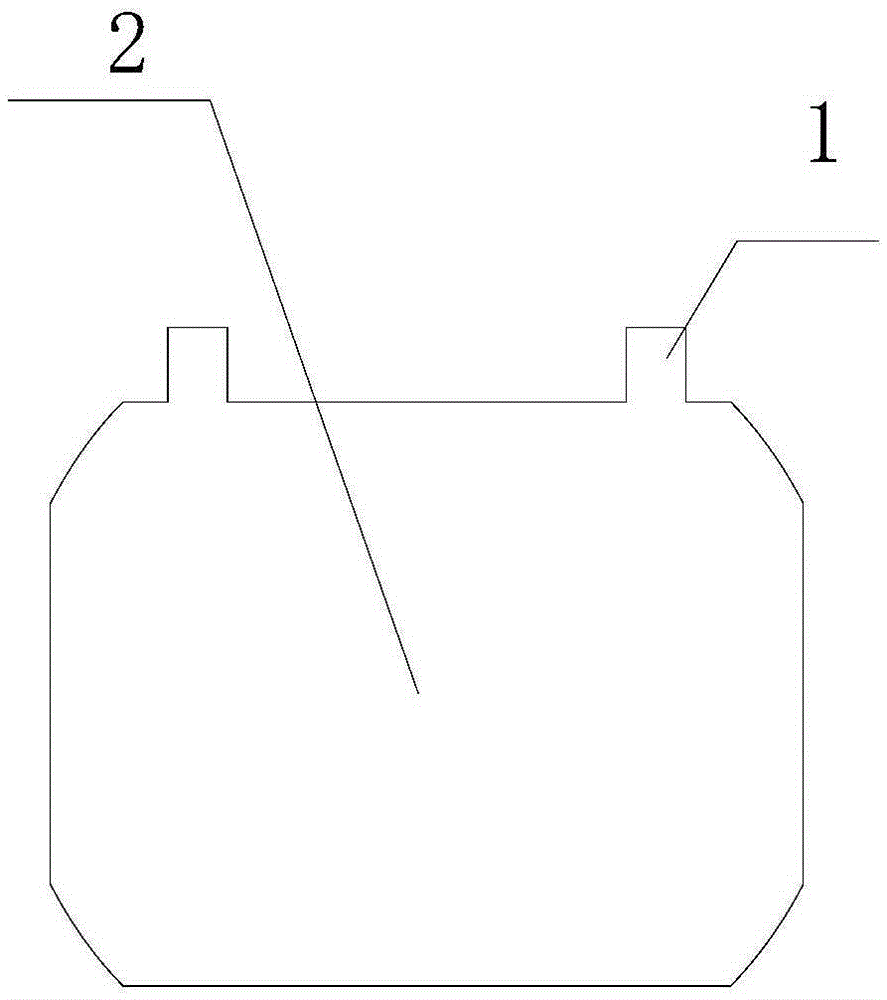

Preparation method for high-porosity silver electrode

ActiveCN105428632AAvoid direct solderingAvoid forceCell electrodesCell component detailsPorositySilver electrode

The invention discloses a preparation method for a high-porosity silver electrode. The preparation method comprises the steps of 1, taking silver acetate powder as a raw material for manufacturing the high-porosity blank silver electrode, taking a silver net as an electrode skeleton, filling the silver acetate powder into a hopper of a roller press and putting the silver net on a reel of the roller press, adjusting the thickness range of the prepared silver electrode to be 0.45-0.55mm and cutting into required dimensions; stamping and molding the cut electrode by a die; sintering the cut silver electrode at the temperature of 300 DEG C plus or minus 20 DEG C for 20 min; and obtaining the high-porosity blank silver electrode; 2, cutting the blank silver electrode into long-strip-type silver foil strips with length of 200mm and width of 20mm, punching a circular hole in one end of each silver foil strip by a drilling machine to be used as a connecting hole, and preparing a silver guide lug; 3, welding the silver guide lug on the sintered high-porosity blank silver electrode by a spot welding machine; and 4, battery formation: connecting the high-porosity blank silver electrode welded with the silver guide lug with a stainless steel auxiliary pole plate through the guide lug for assembling into the formed battery.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

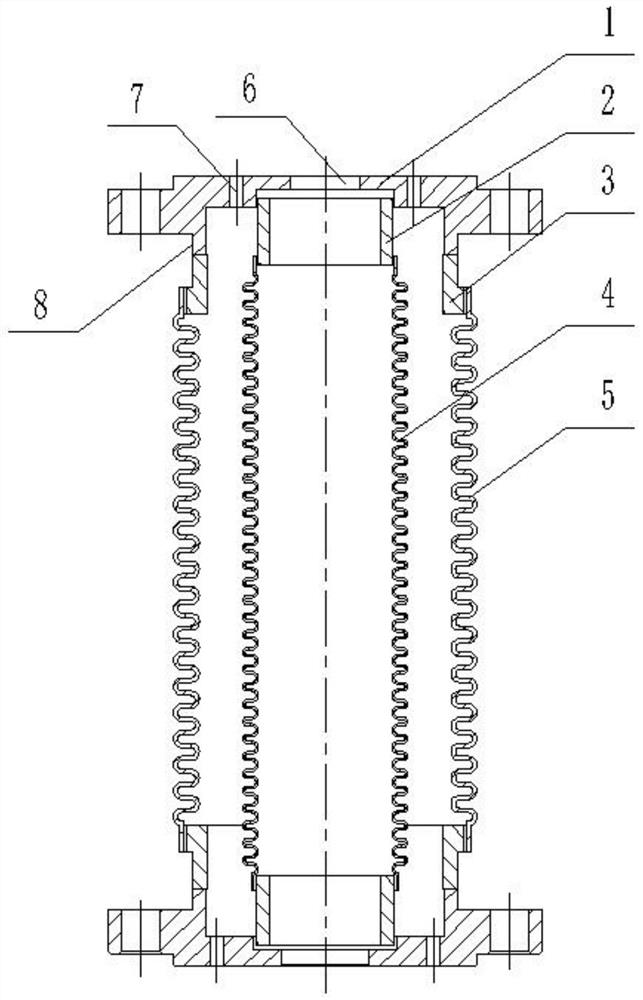

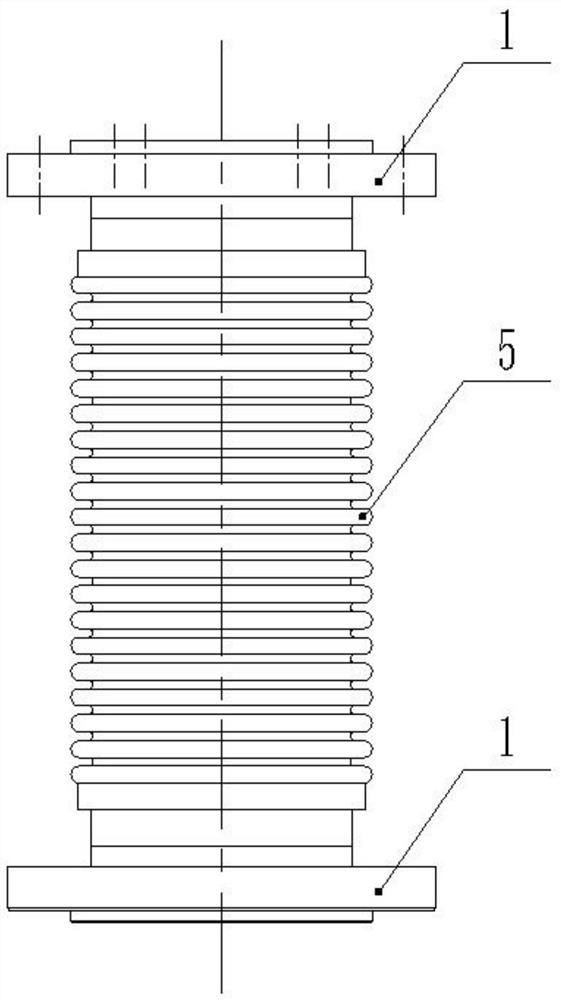

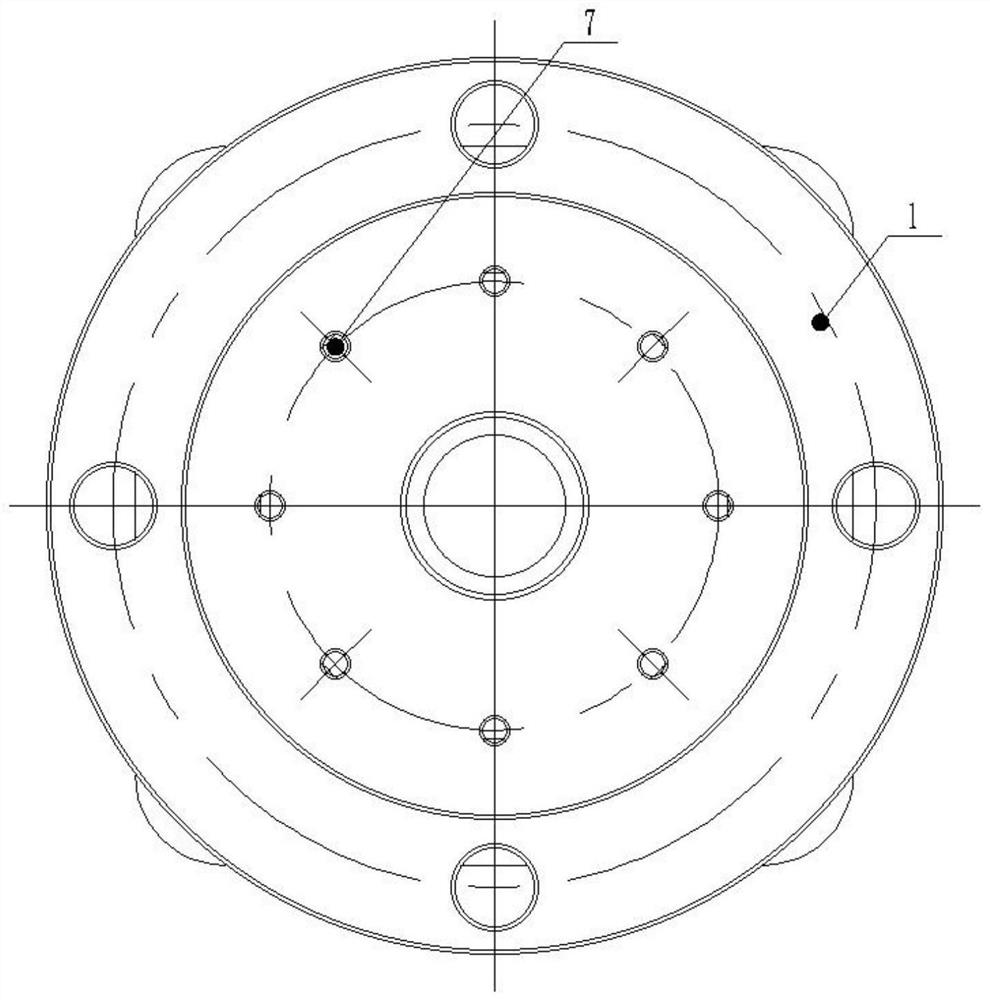

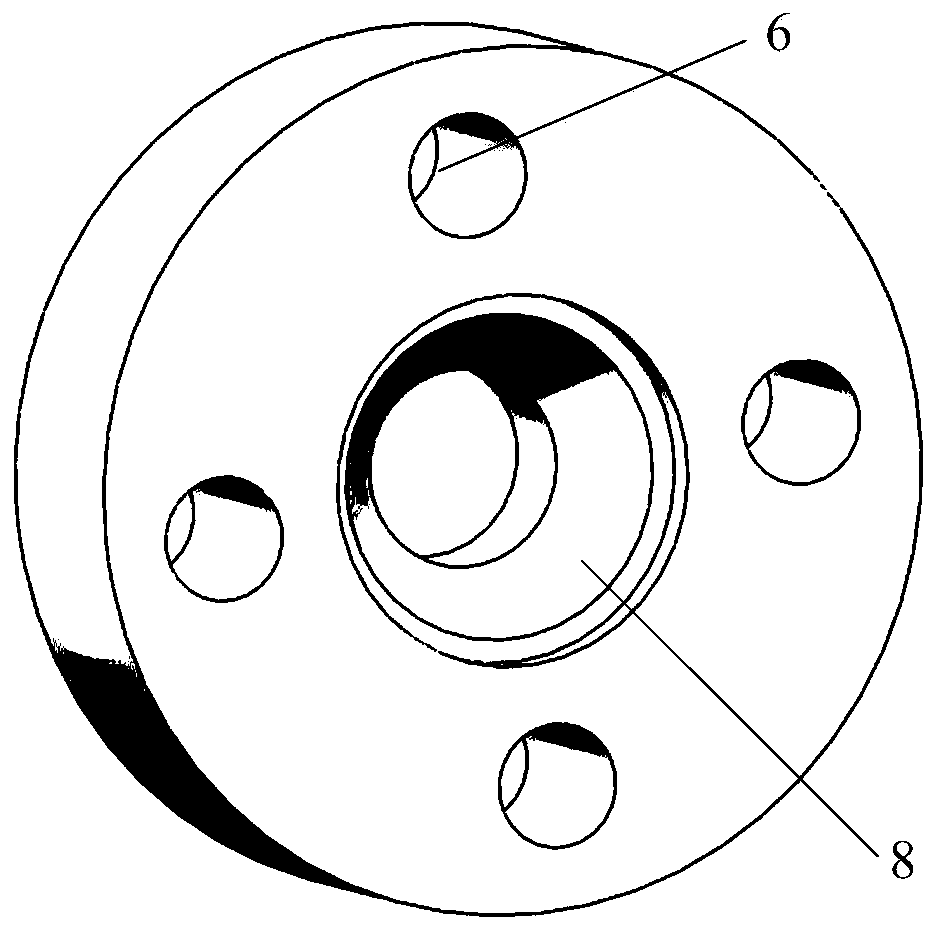

Engine natural gas supply double-wall corrugated pipe

InactiveCN113389660AAvoid direct solderingReduce concentrationInternal combustion piston enginesFuel supply apparatusThermodynamicsWeld seam

The invention belongs to the technical field of engine manufacturing, and particularly relates to an engine natural gas supply double-wall corrugated pipe. The engine natural gas supply double-wall corrugated pipe comprises an inner corrugated pipe body and an outer corrugated pipe body arranged on the outer side of the inner corrugated pipe body and wrapping the inner corrugated pipe body, a flange is arranged at the end of the inner corrugated pipe body and the end of the outer corrugated pipe body, a first sleeve pipe is arranged on the inner corrugated pipe body, the other end of the first sleeve pipe is fixed to the flange, a second sleeve pipe is arranged on the outer corrugated pipe body, the other end of the second sleeve pipe is fixed to the flange, and multiple ventilation holes are formed in the flange. One ends of the sleeve pipes are connected with the flange, the other ends of the sleeve pipes are connected with the corrugated pipe, in this way, effective welding can be achieved, and the problems of vibration and loosening of a welding seam can be solved; and in addition, the multiple holes are formed in the flange, the concentration of natural gas which may leaks in a ventilation pipe is reduced through forced ventilation, centralized fuel gas monitoring is carried out, and safety of a fuel gas supply system is improved.

Owner:淄柴机器有限公司 +1

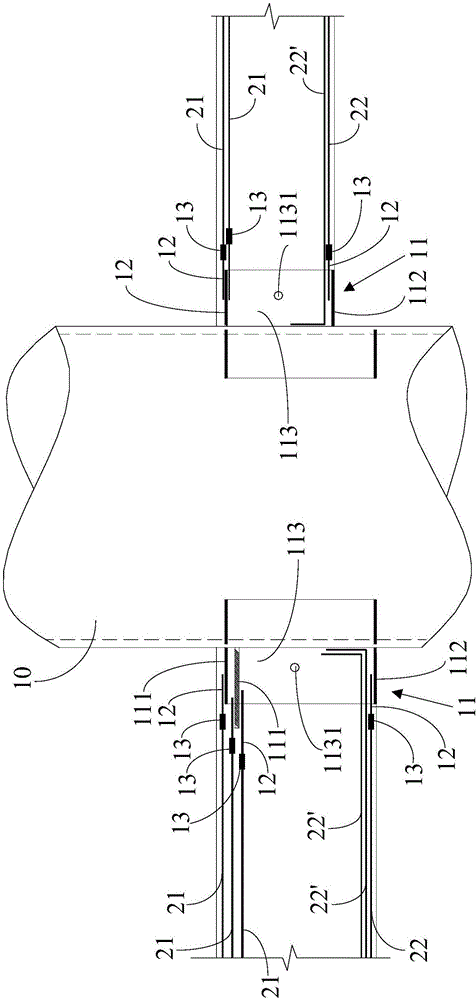

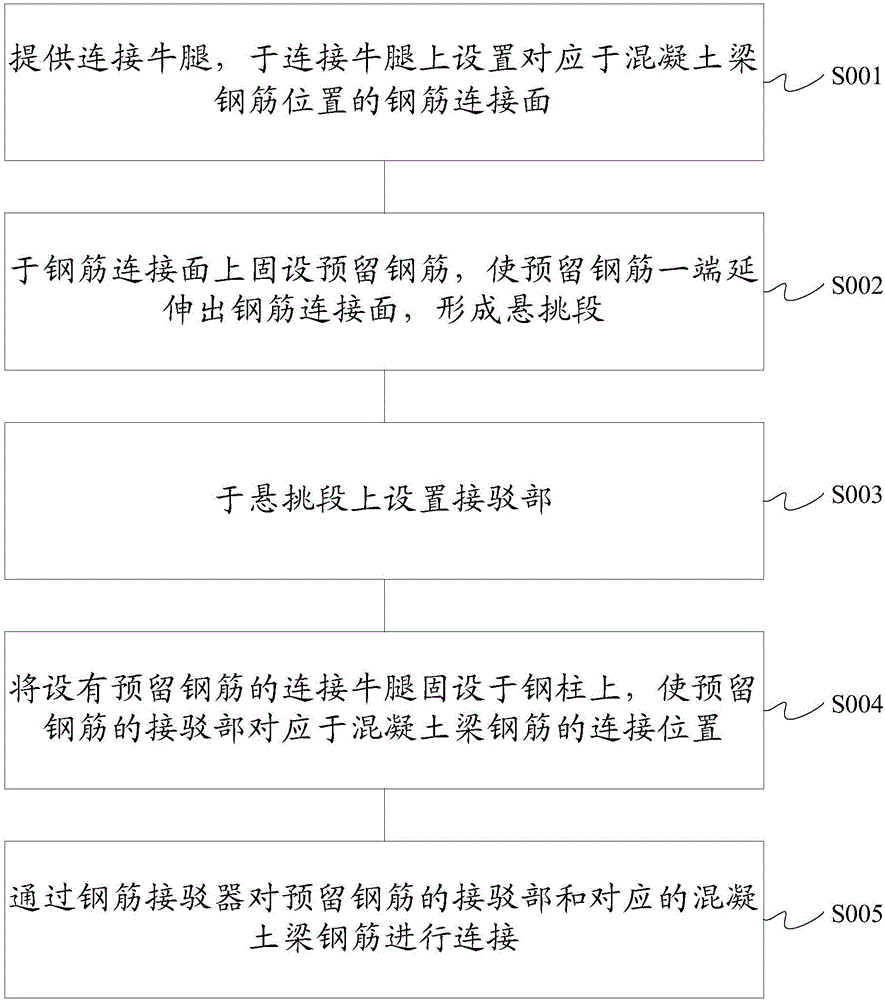

Connecting structure and connecting method for steel pillar and concrete beam steel bar

InactiveCN106223492AReduce welding workloadFast constructionBuilding constructionsSteel columnsSteel bar

The invention discloses a connecting structure and connecting method for a steel pillar and a concrete beam steel bar. The connecting structure comprises a connecting cow leg, a reserved steel bar and a steel bar connector used to connect a connection part and the concrete beam steel bar, wherein the connecting cow leg is fixed on the steel pillar; a steel bar connecting face corresponding to the concrete beam steel bar is disposed on the connecting cow leg; and the reserved steel bar is fixed on the steel bar connecting face and extends to one side of the concrete beam steel bar to form an overhanging section, and the connection part is disposed on the overhanging section. According to the invention, the reserved steel bar is disposed on the connecting cow leg during manufacture of the connecting cow leg, and then the connecting cow leg is welded to the steel pillar; and then, during connection of the concrete beam steel bar, the steel bar connector is installed on the connection part of an end part of the researched steel bar, and the steel bar connector is then used for connection of the concrete beam steel bar. In this way, direct welding of a threaded sleeve on the cow leg is avoided; and the problem that the steel bar cannot be screwed in due to threaded sleeve deformation caused by welding heat can be effectively solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

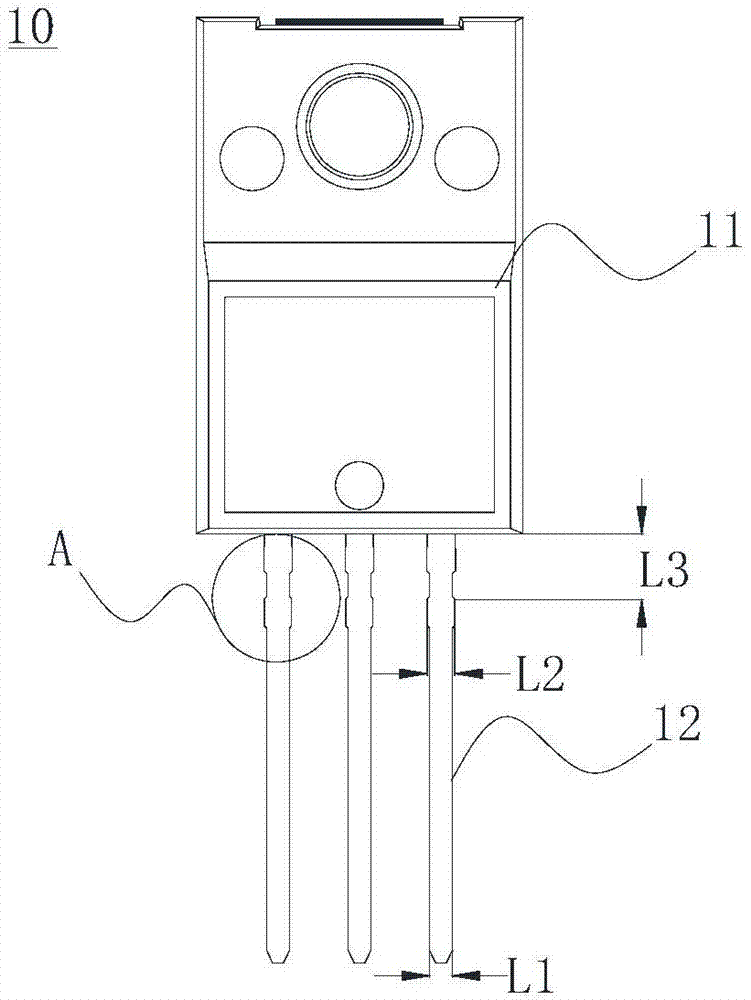

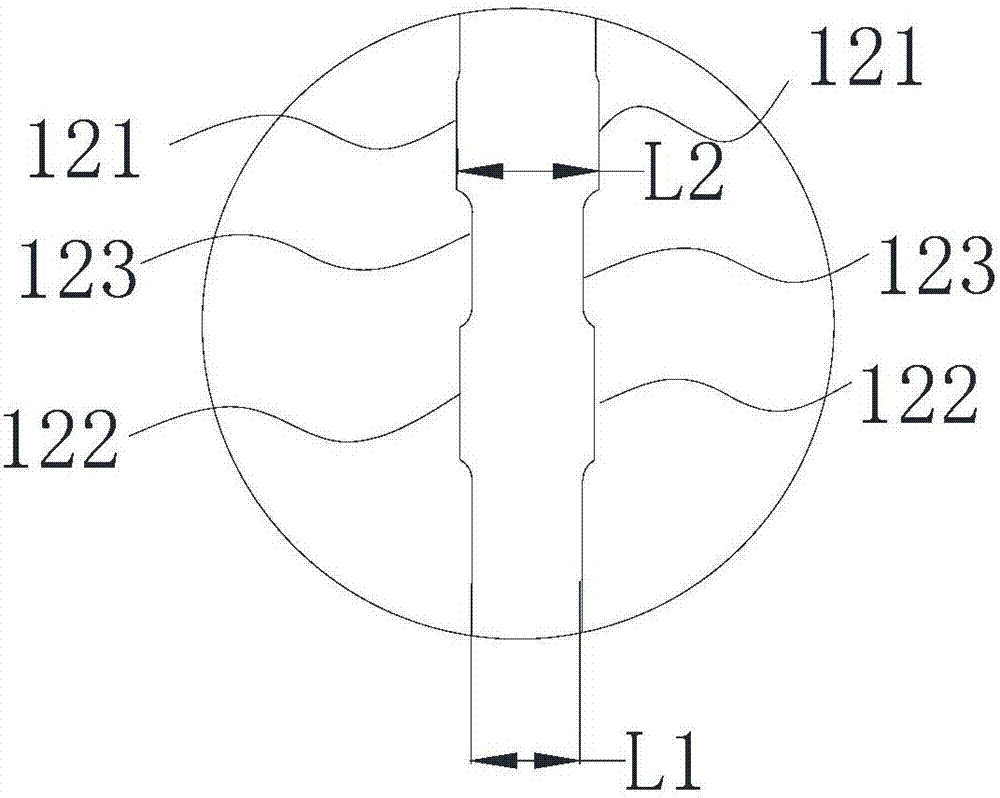

Semiconductor packaging device, semiconductor lead frame and rib-cutting method thereof

PendingCN107275308AImprove welding strengthImprove welding effectSemiconductor/solid-state device detailsSolid-state devicesWave structureDevice material

The invention discloses a semiconductor packaging device, a semiconductor lead frame and a rib-cutting method thereof. The semiconductor packaging device comprises a packaging housing; a semiconductor device encapsulated in the packaging housing; and pins to be electrically connected with the semiconductor device and exposed out of the packaging housing. The two side, adjacent to the packaging housing, of each pin have square-wave structures each formed by two protrusions and a groove. The protrusions and the grooves are arranged successively and alternately along the length direction of the pin. When the pins and a PCB are soldered, soldering tin gathers in the grooves. The semiconductor lead frame and the rib-cutting method thereof are used for manufacturing the semiconductor packaging device. The semiconductor packaging device, the lead frame and the rib-cutting method thereof can improve the soldering performance and reliability of the pin and the PCB.

Owner:SHENZHEN STS MICROELECTRONICS CO LTD

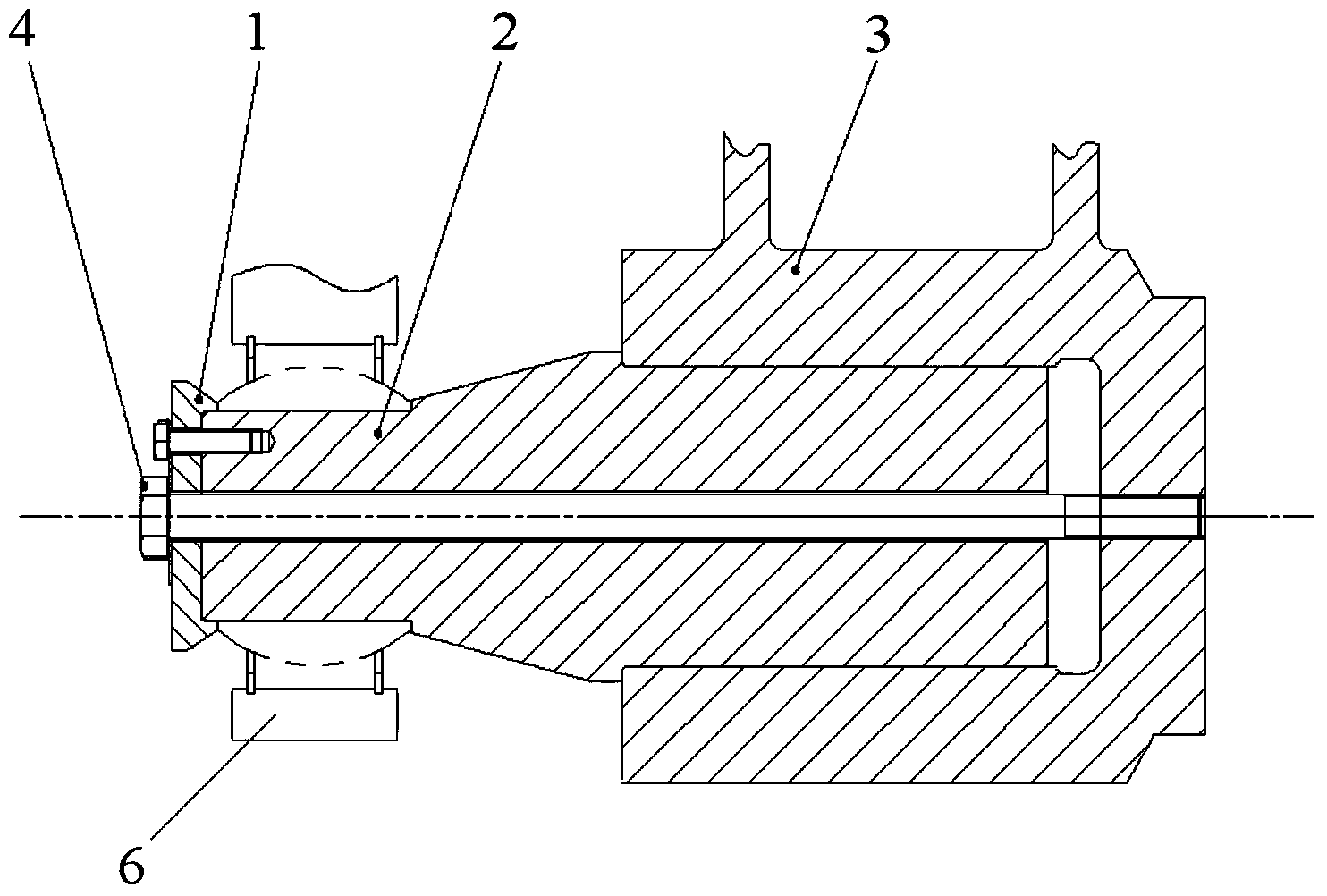

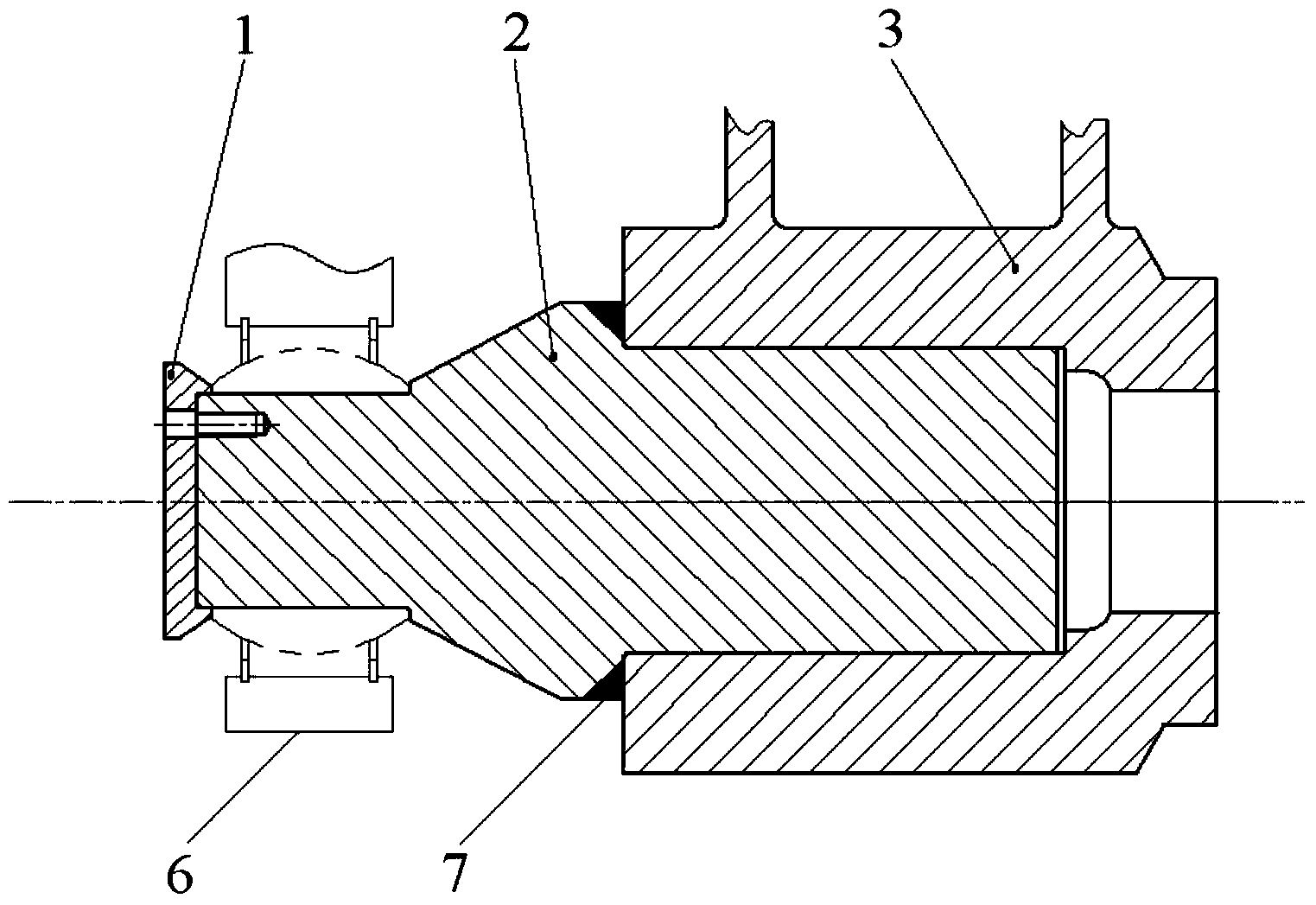

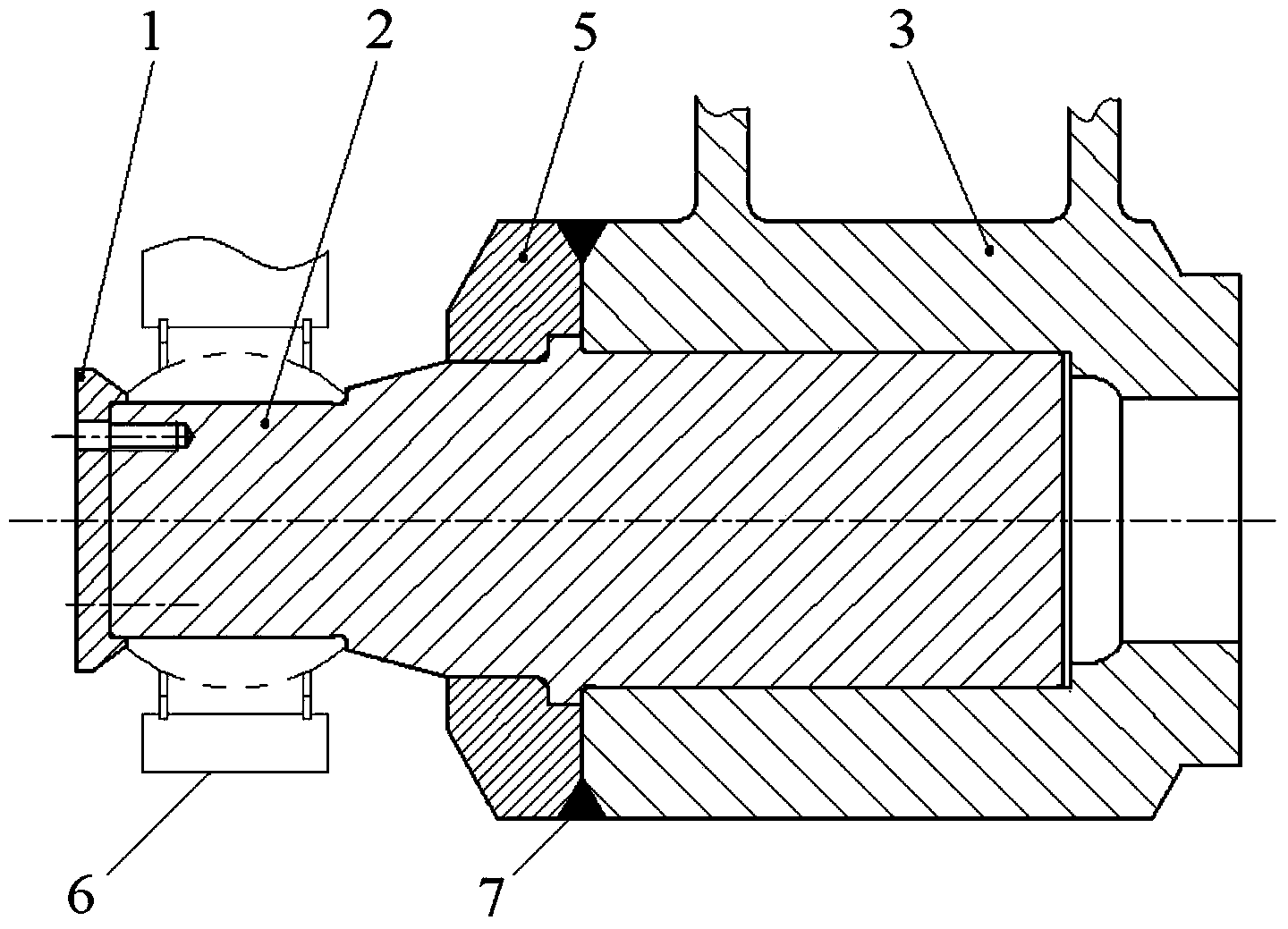

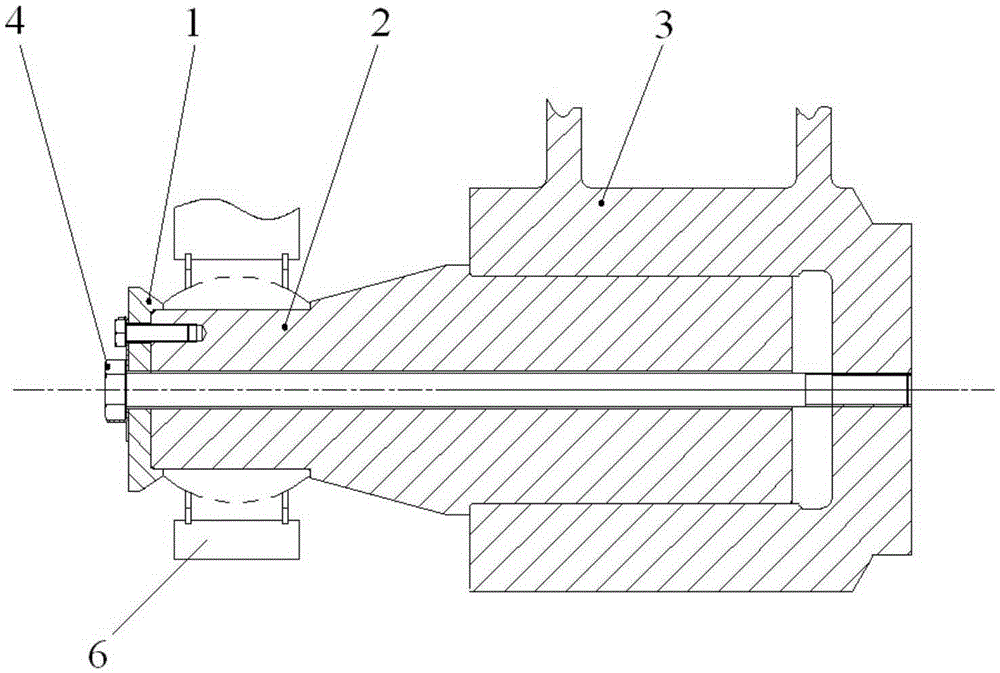

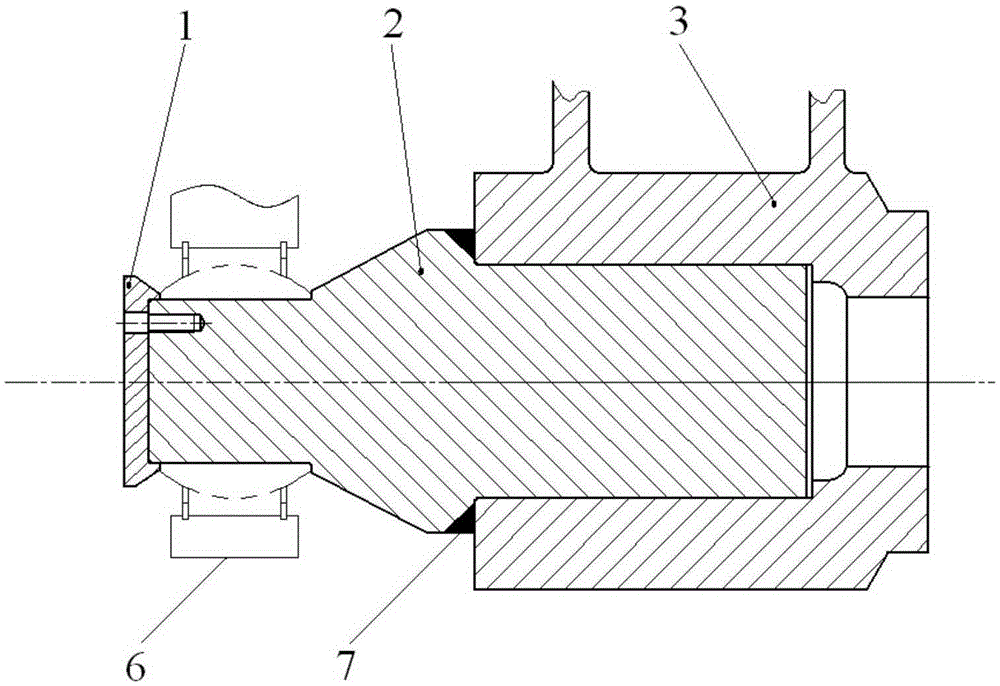

Lifting cylinder shaft assembly of mining dump truck

ActiveCN103661063ASand cleaning is easyEasy dischargeVehicle with tipping movementTruckMechanical engineering

The invention provides a lifting cylinder shaft assembly of a mining dump truck. The lifting cylinder shaft assembly of the mining dump truck comprises a lifting cylinder support, a lifting cylinder shaft, an end cover and a gland, wherein the lifting cylinder support is provided with a shaft hole, the lifting cylinder shaft is provided with a shaft shoulder, a shaft section, at one side of the shaft shoulder, of the lifting cylinder shaft is installed in the shaft hole of the lifting cylinder support, the end cover is arranged at the end of the shaft section, at the other side of the shaft shoulder, of the lifting cylinder shaft, and the gland is axially arranged on the shaft shoulder in a pressing mode and fixed to the lifting cylinder support. The lifting cylinder shaft assembly of the mining dump truck is simple in structure and easy to machine, and the lifting cylinder shaft is high in strength, not damaged easily, stable and reliable in axial fixation, high in size accuracy and installation accuracy, and easy to detach and replace.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

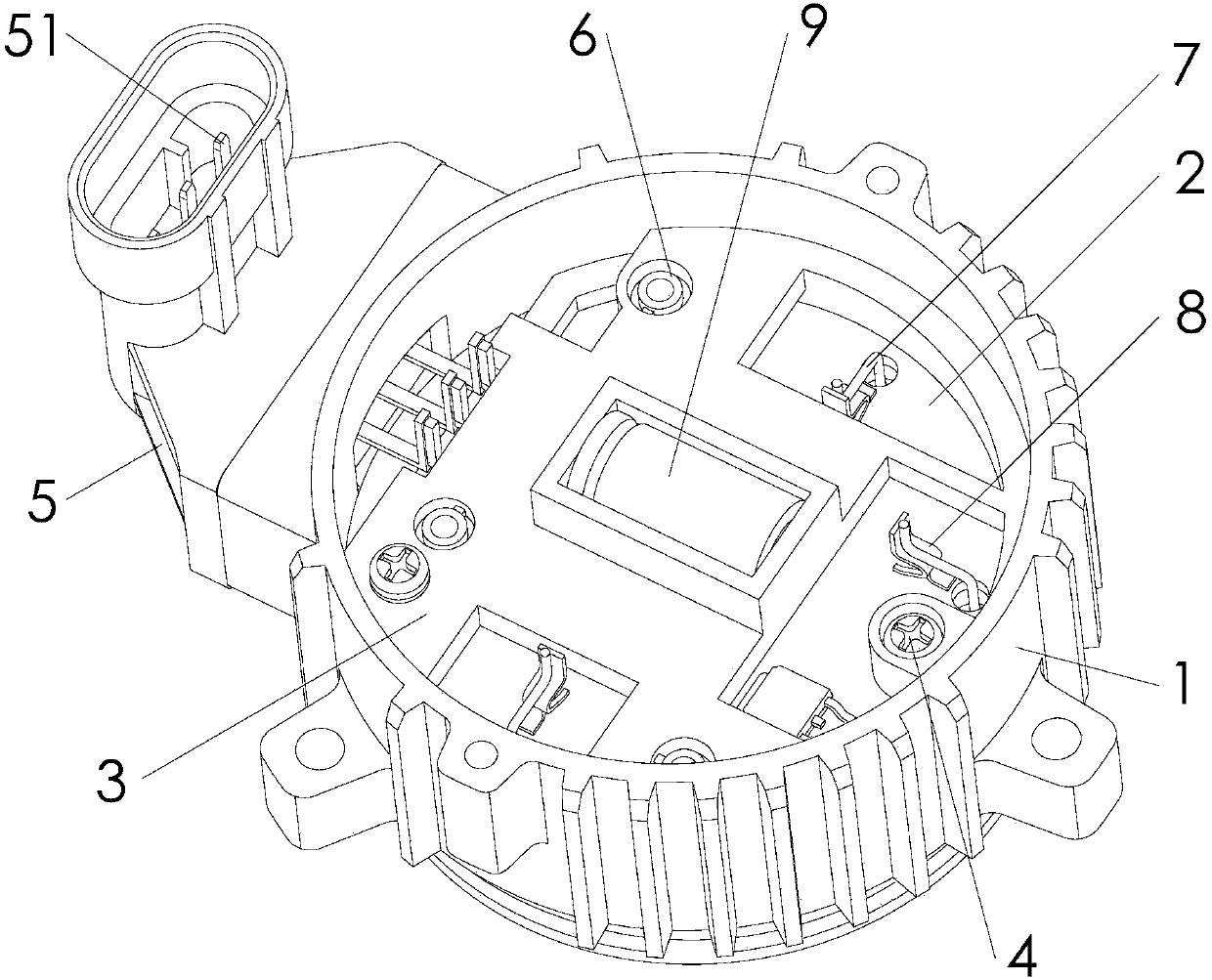

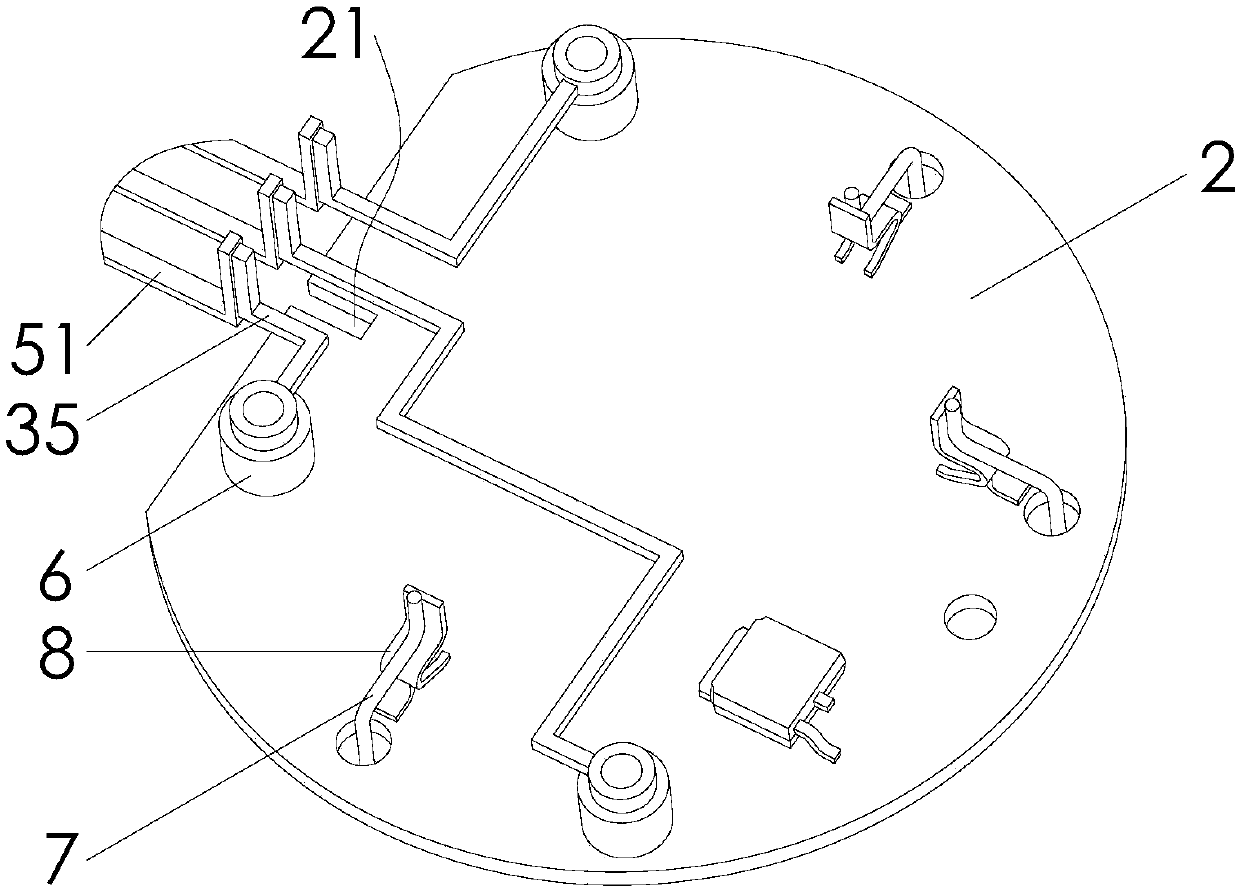

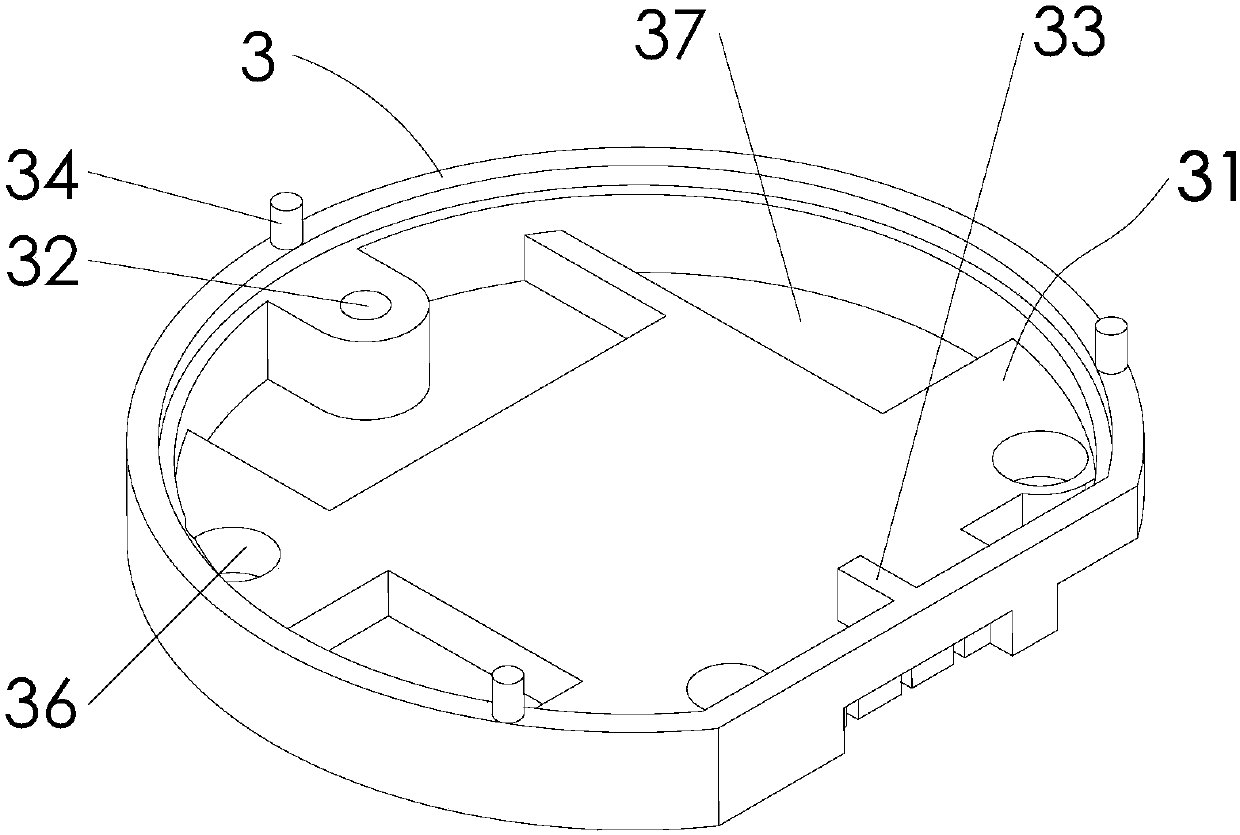

Automotive electronic water pump

ActiveCN108331765ASimple structureNot easy to loosePump componentsPump installationsImpellerEngineering

The invention discloses an automobile electronic water pump, and belongs to the technical field of water pumps. The water pump comprises a pump shell, and a motor, an impeller and a control panel arearranged in the pump shell; the motor comprises an output shaft, a rotor assembly and a stator assembly, and the impeller is fixedly arranged on the output shaft; and the water pump further comprisesa fixing assembly, and the control panel is arranged in the pump shell through the fixing assembly. According to the automobile electronic water pump, the structure of an existing electronic water pump is improved, the fixing assembly is additionally arranged on the basis of the existing electronic water pump, the control panel is fixed in the pump shell through the fixing assembly, the heat dissipation and fixing effects are good, and the control panel is not prone to looseness and displacement under a vibration working condition; and in addition, the control panel is fixed through the fixingassembly, is not directly connected with the framework of the stator assembly of the motor, and is far away from the main heating source of the motor so that the working temperature of the control panel can be effectively reduced, the service life of each power component on the control panel can be prolonged, and the service life of the whole automobile electronic water pump can be further prolonged.

Owner:DUNAN ENVIRONMENT TECH

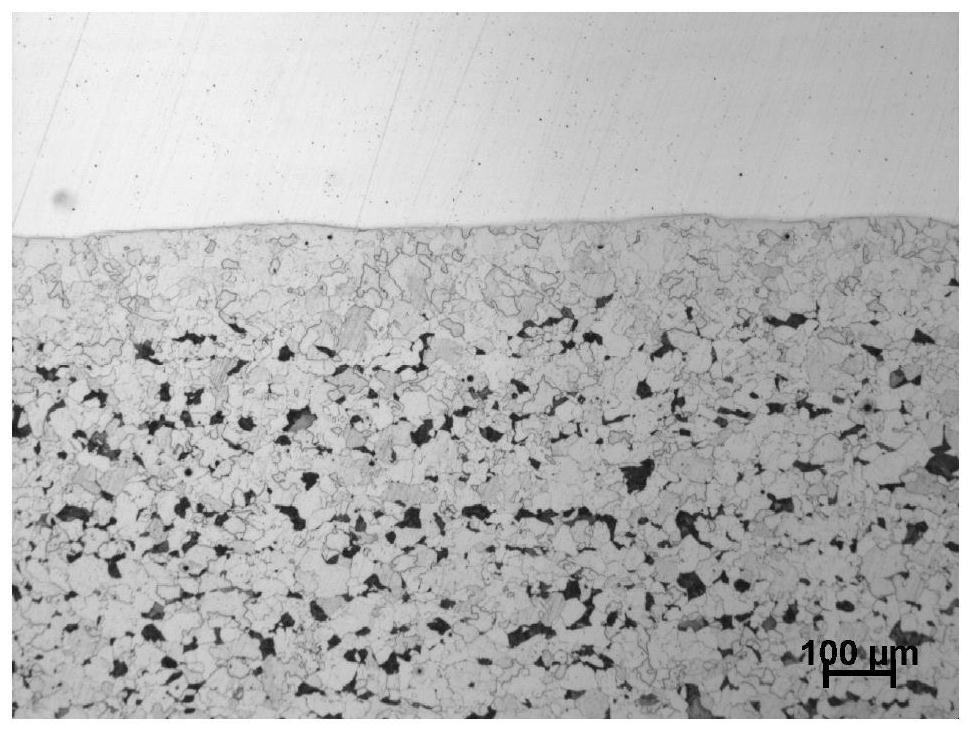

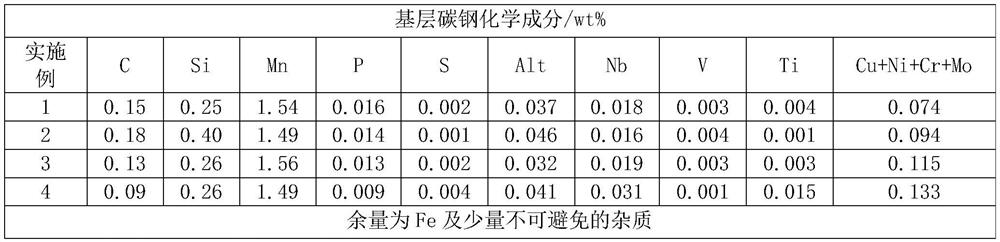

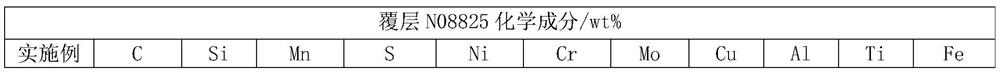

N08825 composite steel plate for high-corrosion-resistance container and preparation method of N08825 composite steel plate

InactiveCN112721349AImprove mechanical propertiesImprove corrosion resistanceLamination ancillary operationsLaminationChemical compositionImpurity

The invention discloses an N08825 composite steel plate for a high-corrosion-resistance container, and relates to the technical field of steel production, and the N08825 composite steel plate comprises a base layer and a coating which are in a metallurgical bonding state, the base layer comprises the following chemical components in percentage by mass: C<=0.20%, Si<=0.55%, Mn: 0.5%-1.7%, Cu<=0.30%, Ni<=0.30%, Cr<=0.30%, Mo<=0.08%, Nb<=0.050%, V<=0.050%, Ti<=0.030%, Alt>=0.020%, P<=0.025%, S<=0.010%, Cu+Ni+Cr+Mo<=0.70%, and the balance of Fe and other unavoidable impurities. The coating is N08825 and comprises the following chemical components in percentage by mass: Ni: 38.0%-46.0%, Cr: 19.5%-23.5%, Fe>=22.0%, Mn<=1.00%, C<=0.05%, Cu: 1.5%-3.0%, Si<=0.5%, S<=0.030%, Al<=0.2%, Ti: 0.6%-1.2%, and Mo: 2.5%-3.5%.

Owner:NANJING IRON & STEEL CO LTD

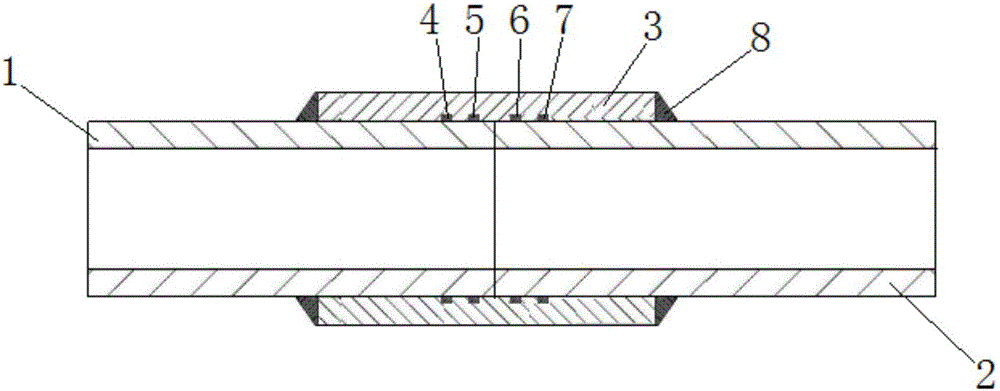

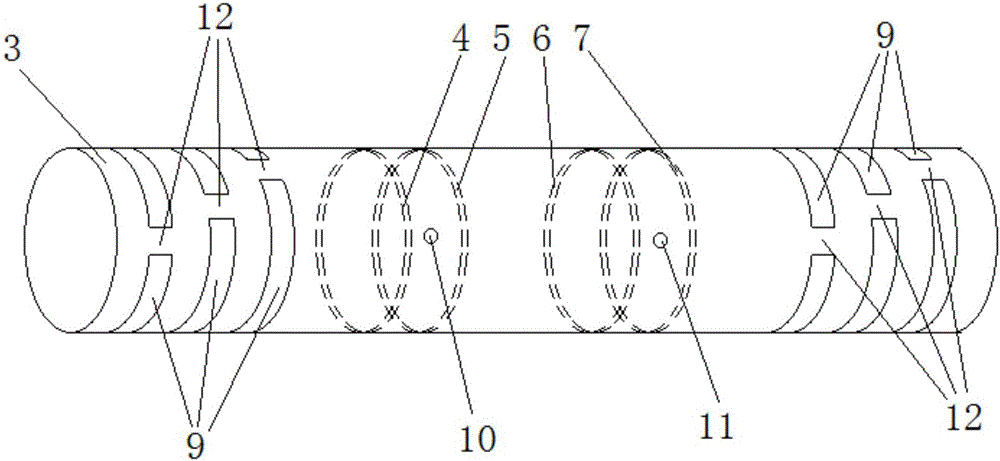

Pipeline welding structure for pull pipe construction method

InactiveCN105952992AGuaranteed welding fastnessAvoid the problem of unstable weldingPipe couplingsCouplingsArchitectural engineeringPipe welding

The invention discloses a pipeline welding structure for a pull pipe construction method. The pipeline welding structure comprises an outer sleeve at a pipeline joint, more than one welding slot is arranged at each of two ends of the outer sleeve, the welding slots do not run through the pipe wall of the outer sleeve; at two sides of the outer sleeve and in the welding slots, the outer sleeve is welded with a pipeline in the outer sleeve; on the inner wall of the outer sleeve, a first welding rod, a second welding rod, a third welding rod and a fourth welding rod are arranged in the middle of the outer sleeve; the pipeline joint is located between the second welding rod and the third welding rod; and the first welding rod, the second welding rod, the third welding rod and the fourth welding rod are connected between the outer sleeve and the pipeline in a sealed way by adopting a hot melting manner. The pipeline welding structure is simple in structure, and the arrangement of the outer sleeve structure ensures the firmness and tightness of welding of two pipelines in long-distance traction and drawing.

Owner:江苏中达建设工程有限公司

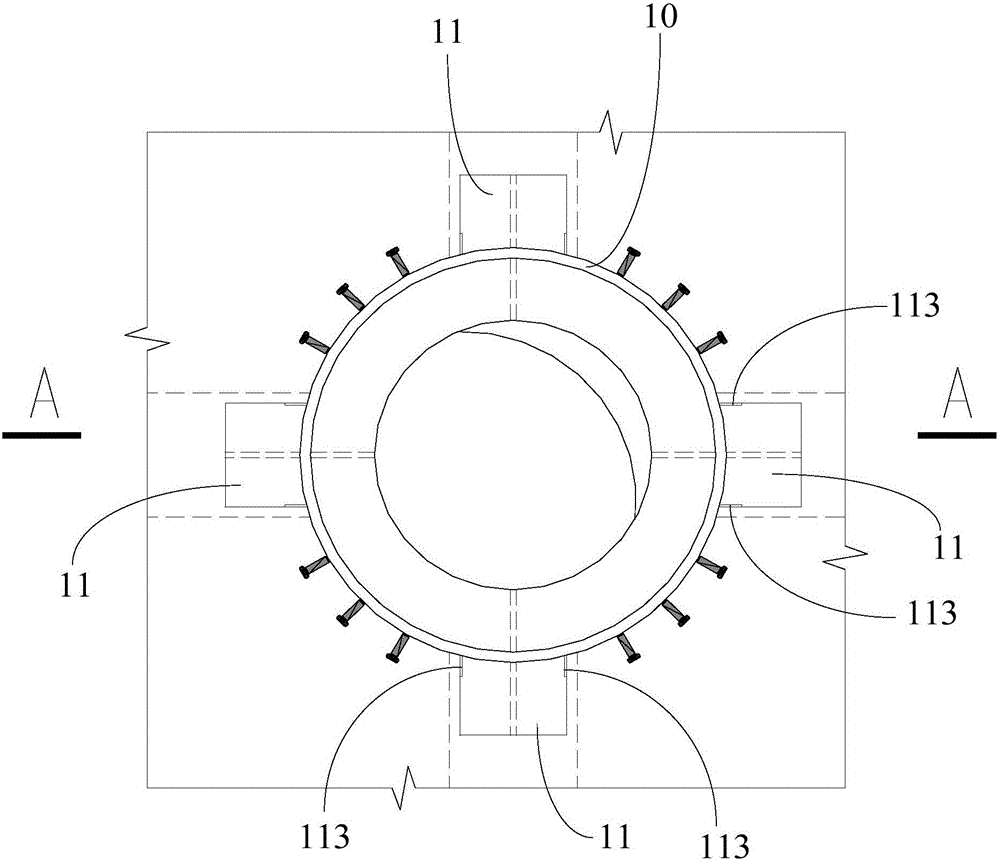

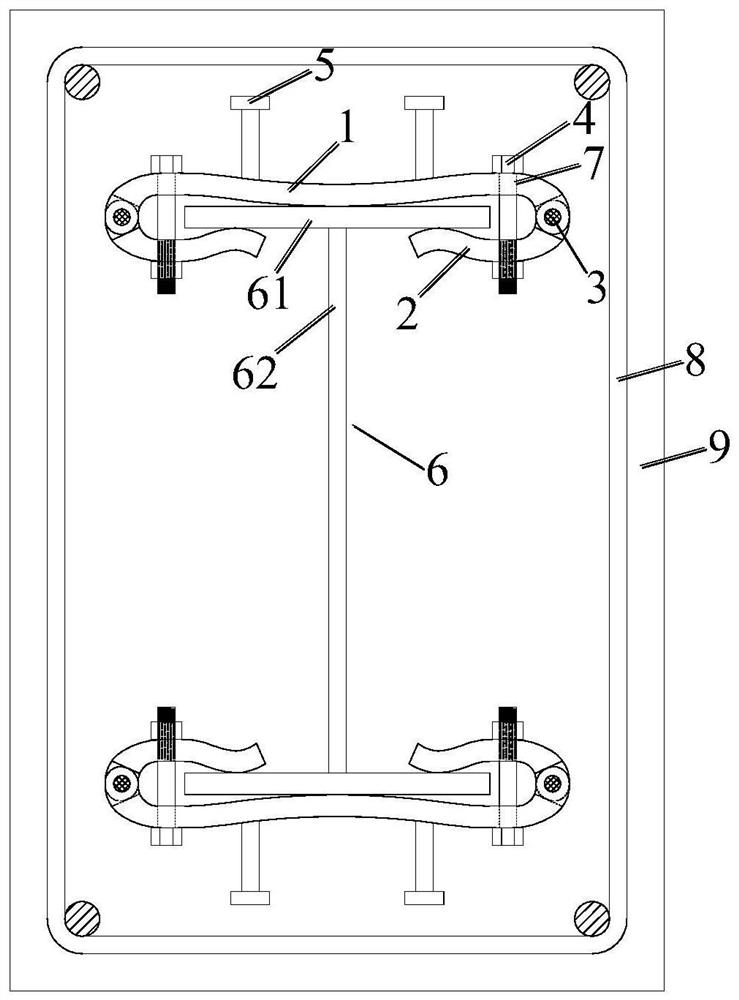

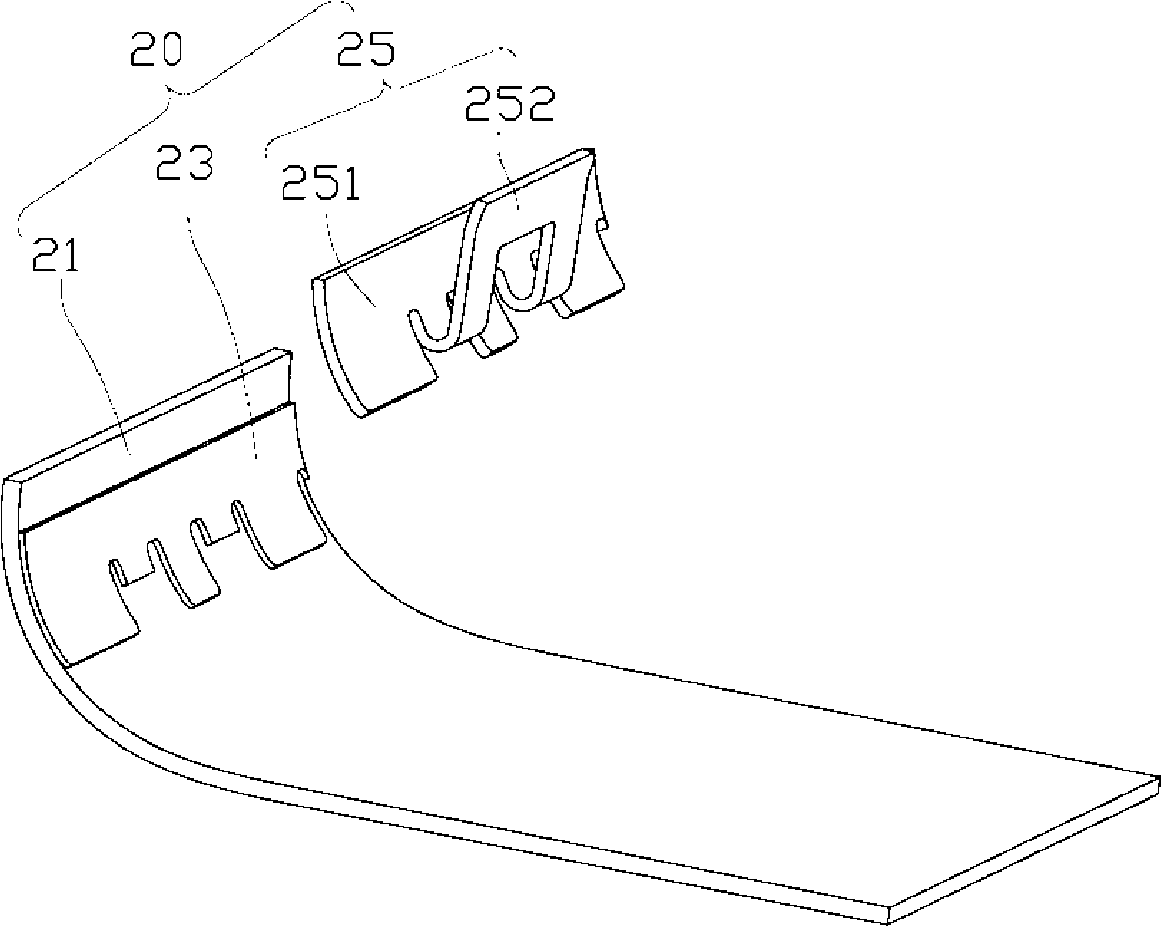

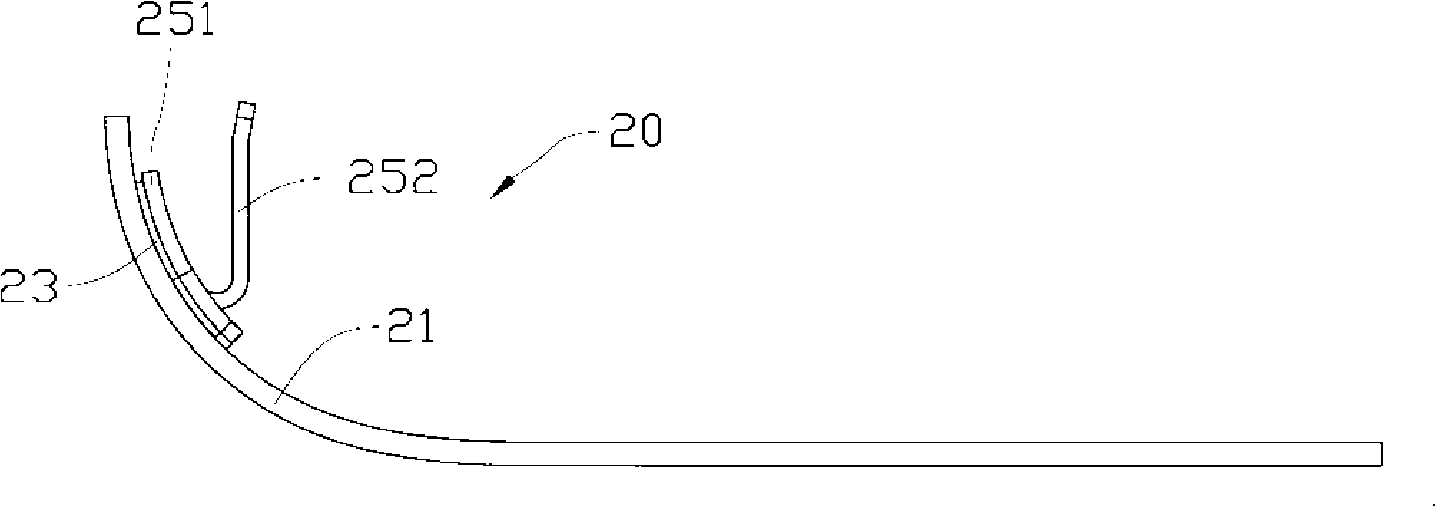

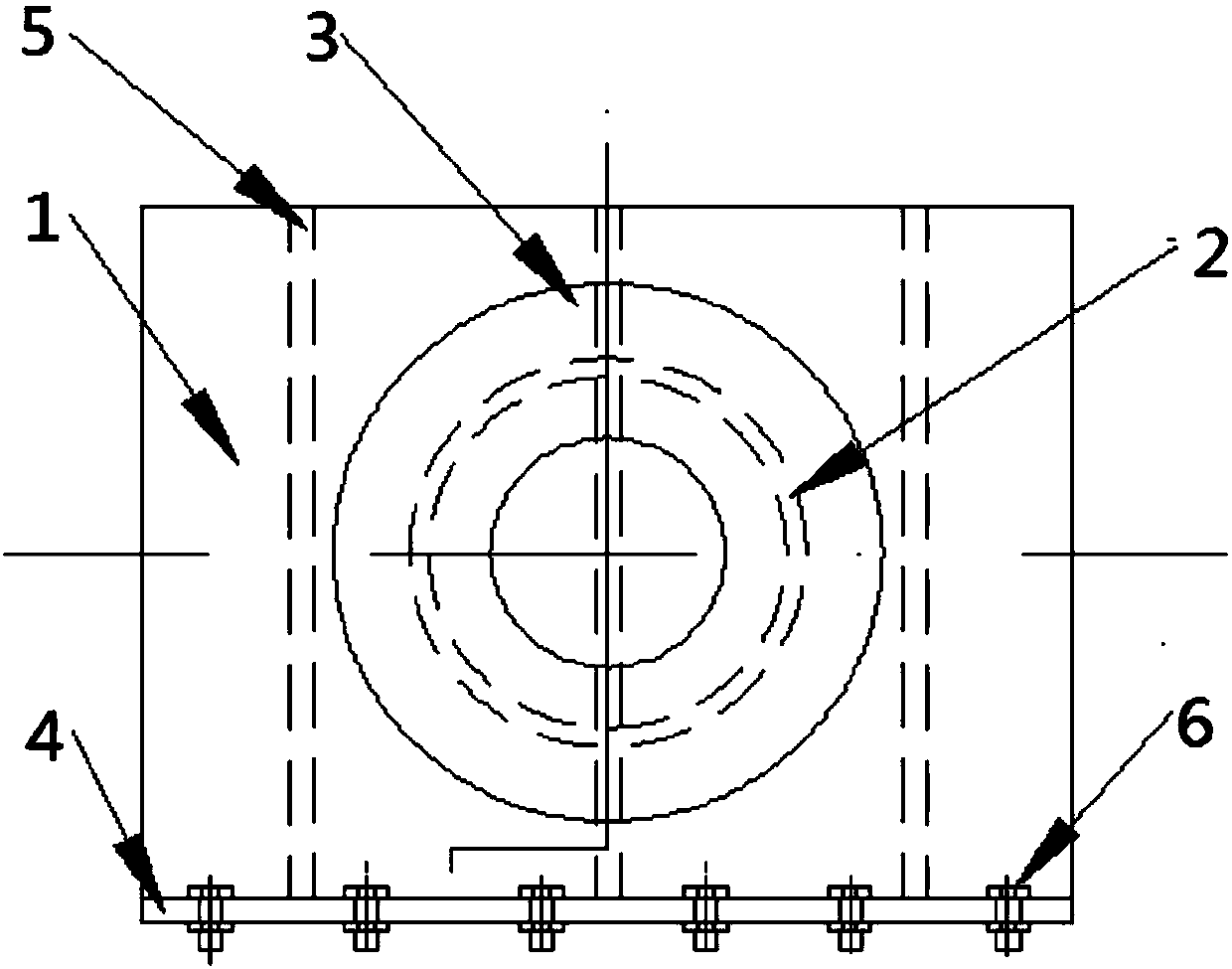

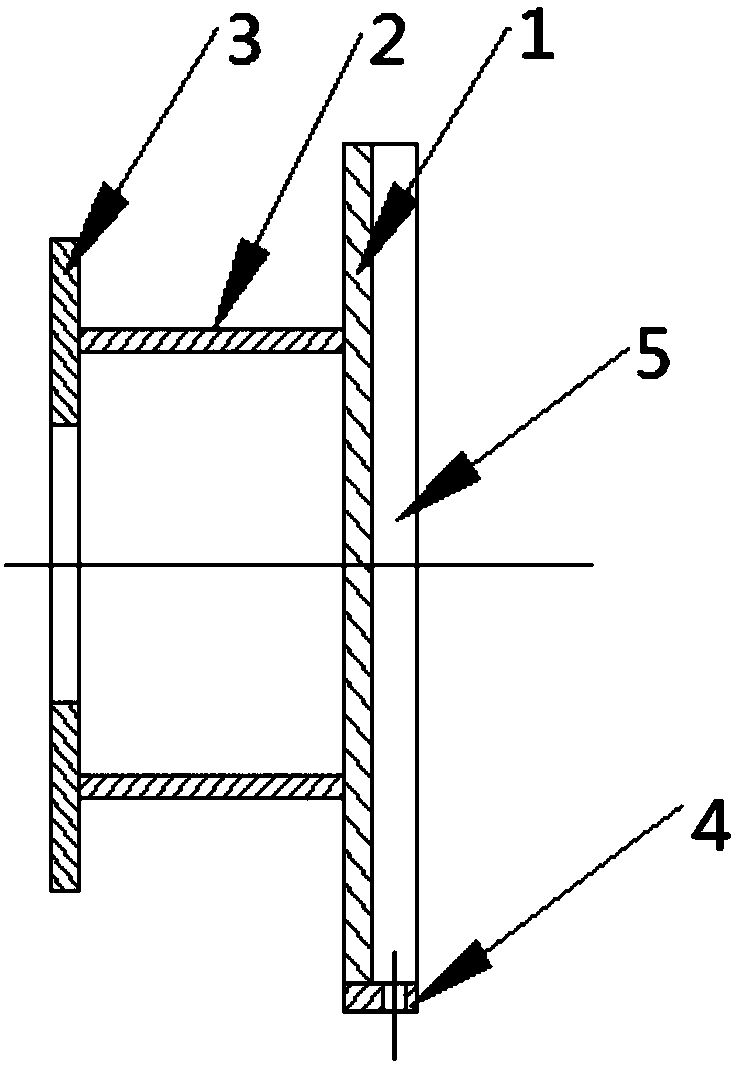

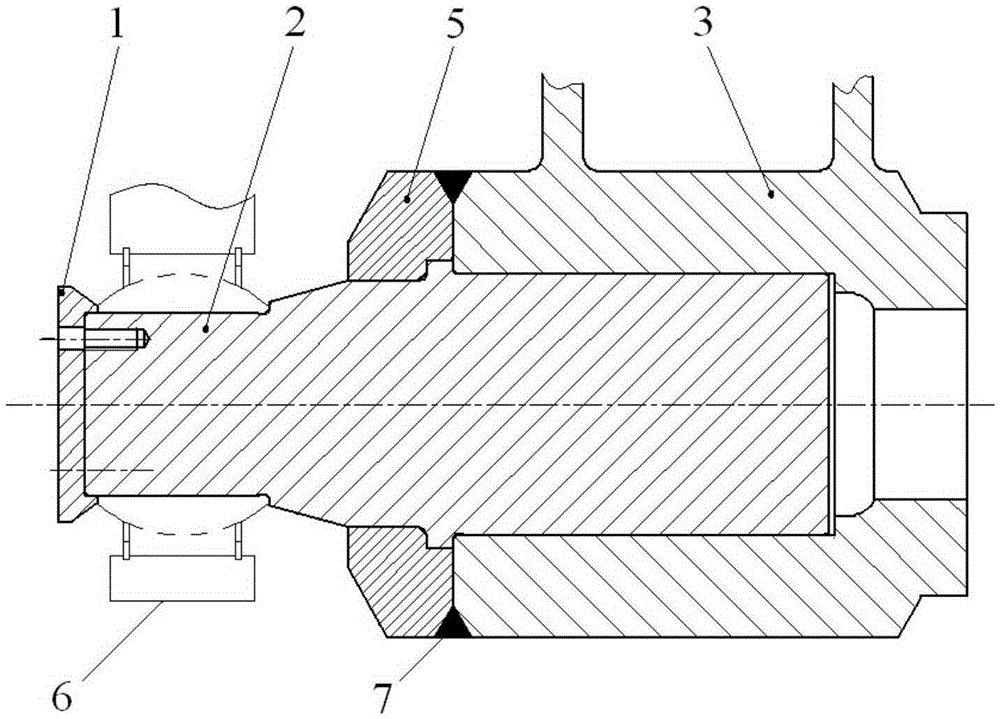

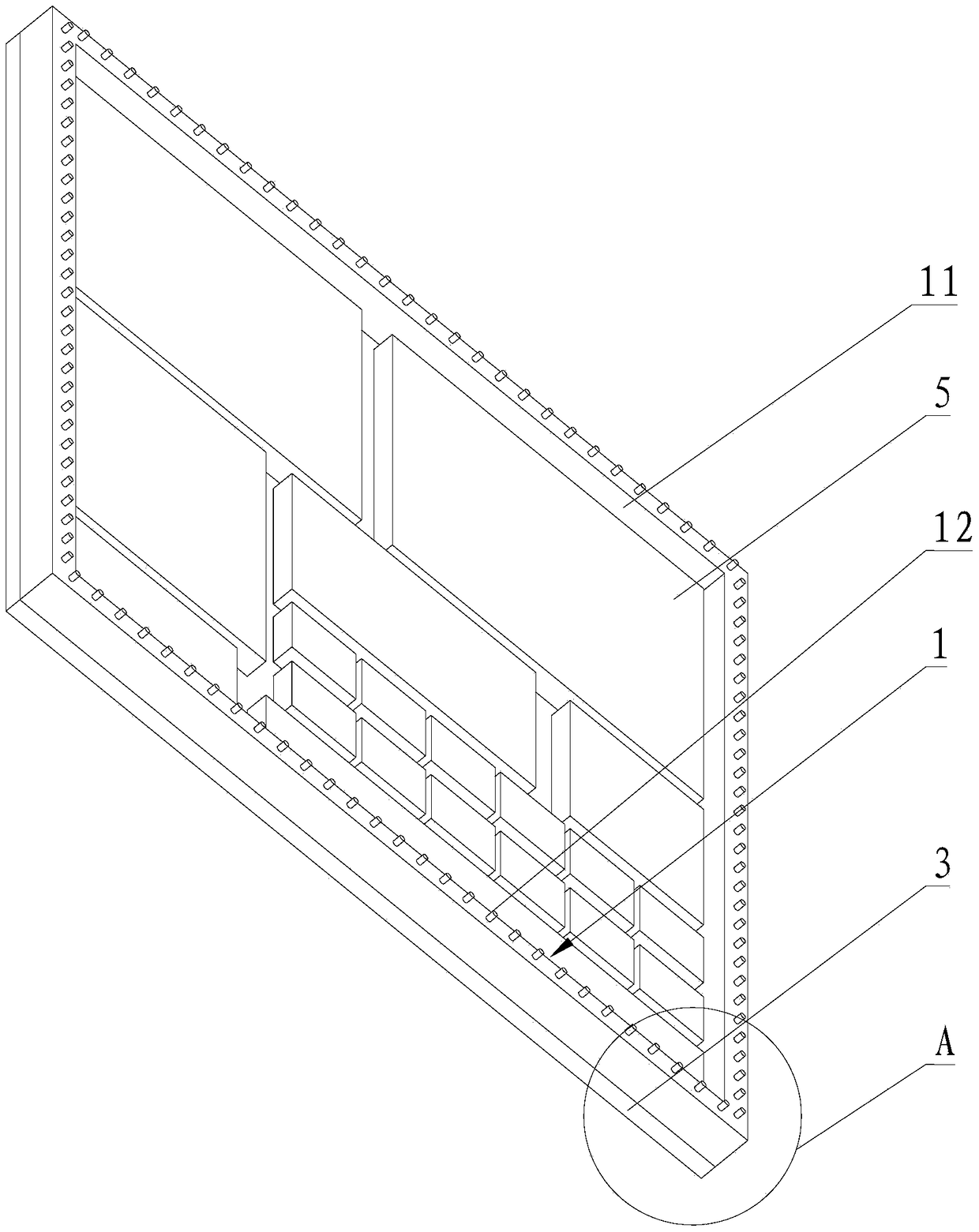

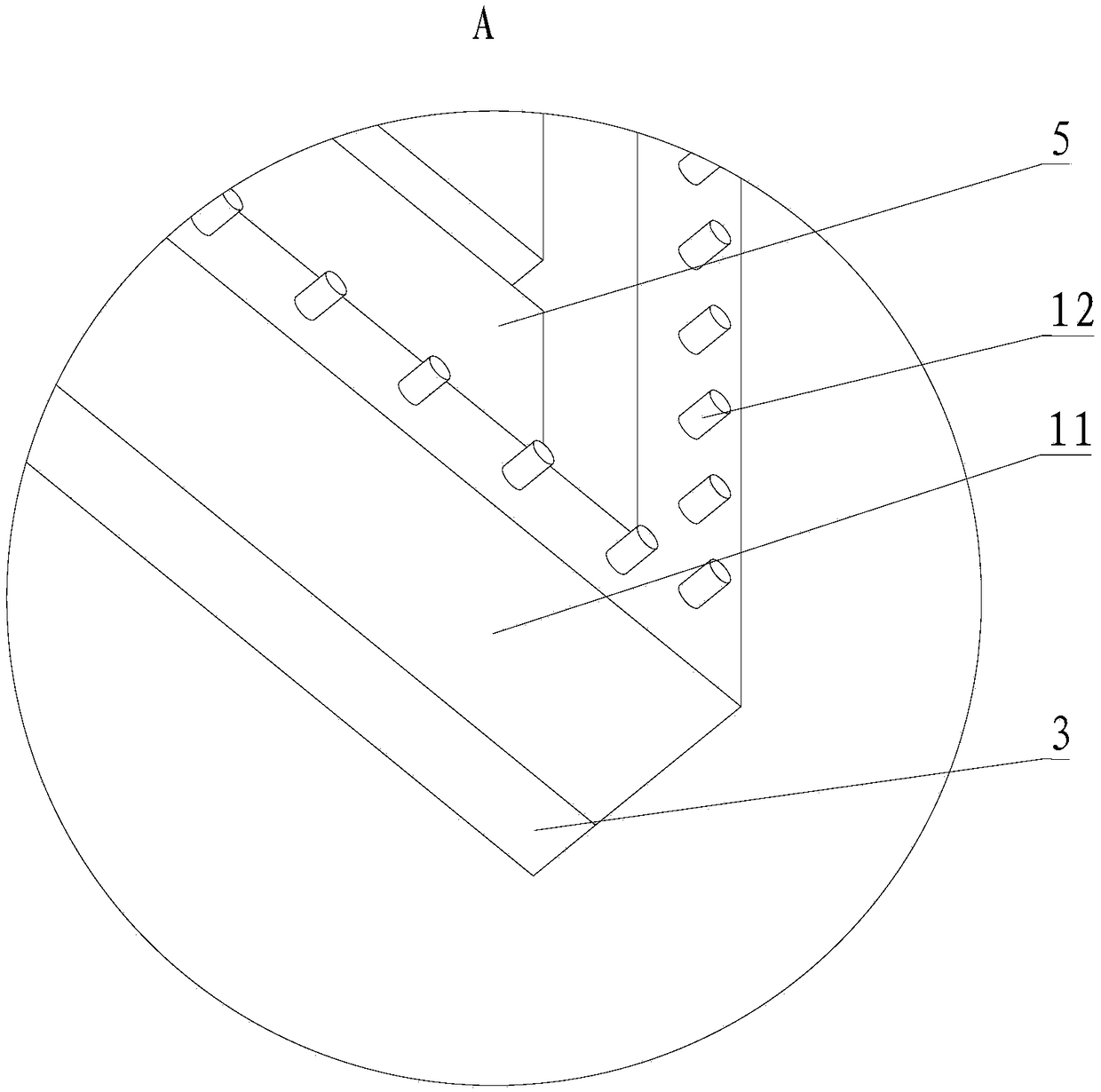

Steel-concrete composite structure shear connector, construction method and shear composite structure

ActiveCN112411877AGuarantee welding qualityGuarantee processing qualityLoad-supporting elementsBridge structural detailsStress concentrationBolt connection

The invention relates to a steel-concrete composite structure shear connector. The shear connector comprises an upper clamping plate, lower clamping plates, hinge pins, high-strength bolts, studs andan H-shaped steel beam, wherein the two sides of the upper clamping plate are hinged to the two lower clamping plates respectively, the lower clamping plates are in a curved surface shape and clamp flanges of the H-shaped steel beam in a surrounding mode after rotating inwards around hinge points, the corresponding portions, located on the outer sides of the flanges, of the upper clamping plate and the lower clamping plates are connected and fastened through the high-strength bolts, so that the flanges are clamped by the upper clamping plate and the lower clamping plates and at least one anti-shearing stud is welded and fixed above the upper clamping plate. According to the shear connector, the anti-shearing and anti-pulling functions of the shear connector are achieved, meanwhile, a connecting piece is prevented from being directly welded to the surface of the steel beam, stress concentration is prevented, the fatigue life of the structure is prolonged, industrialized manufacturing can be achieved, welding and machining quality is guaranteed, and on-site installation is simple and convenient.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

Electronic product with metal connecting structure and method for producing the same

InactiveCN101316487ANo deformationGood lookingCasings/cabinets/drawers detailsElectrically conductive adhesive connectionsHot-melt adhesiveMetal

The invention discloses an electronic product provided with a metal connecting structure. The electronic product comprises a metal shell and at least one metal part which is fixed at the inner side of the metal shell by hot melt adhesive layer. In addition, the invention also discloses a method for preparing the electronic product provided with the metal connecting structure. The electronic product has the advantages of simple preparation and elegant appearance.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

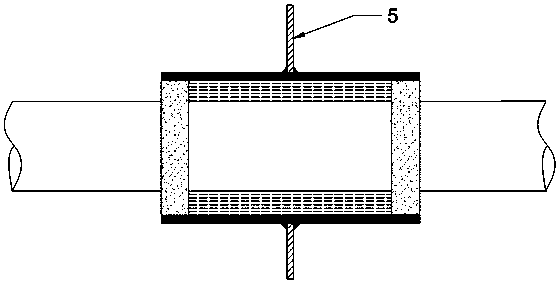

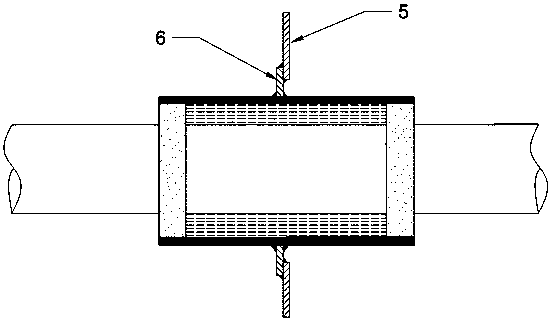

Titanium alloy tube cabin passing method for ship

The invention discloses a titanium alloy tube cabin passing method for a ship. The method is used for a steel bulkhead or a deck with the water-tight and fire-proof requirements on the ship through the titanium alloy tube, wherein the cabin passing method is based on the following titanium alloy tube device; the following titanium alloy tube device comprises a titanium alloy tube, a steel outer frame body which is arranged on the titanium alloy tube in a sleeving manner, a fireproof packing which is filled between the steel outer frame and an interlayer formed by the titanium alloy tube and fireproof plugs are filled at the two ends of the interlayer; and the cabin passing method comprises the following steps that 1, a cabin penetrating position of the titanium alloy tube is determined according to a tube system installation diagram; 2, a cabin penetrating hole with a preset diameter is formed in the position, on the cabin wall or the deck, of the cabin penetrating hole; and 3, the steel outer frame body is fixed in the cabin penetrating hole. The titanium alloy tube cabin passing method has the beneficial effects that the situation that the titanium alloy tube is difficult to weldto steel so as to cause a real-ship application disorder is solved, so that the fireproof, smoke-proof and watertight separation of the two ends of a cabin penetrating part is realized.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

A kind of cell connecting piece, battery and assembly method

ActiveCN109659481BRealize the flow in advanceRealize flow collectionPrimary cell manufactureFinal product manufactureElectrical batteryElectrical connection

The invention discloses a cell connection sheet, a battery and an assembly method. The cell connection sheet includes a body, a cell connection part and a welding connection part. The cell connection part is arranged on one side of the body and is electrically connected to the tab of the cell. The welding connection part is arranged on the other side of the body, electrically connected with the pole of the battery, and the welding connection part can be bent relative to the body. By setting the battery connection part on the battery connection piece, the tabs of the battery can be welded and fixed on the battery connection part one by one, so as to realize the pre-collection of the positive and negative poles of the battery and avoid the positive and negative of all the batteries. The poles are directly welded on the pole of the battery, and at the same time, it can ensure the overcurrent capacity of each connection position during the current collection process of the battery. In addition, the welding connection part on the cell connection piece is connected to the pole of the battery, and finally realizes the current collection of the positive and negative electrodes of multiple cells, which can avoid the welding difficulty caused by the excessive number of tabs welded on the pole. Thereby improving welding quality.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

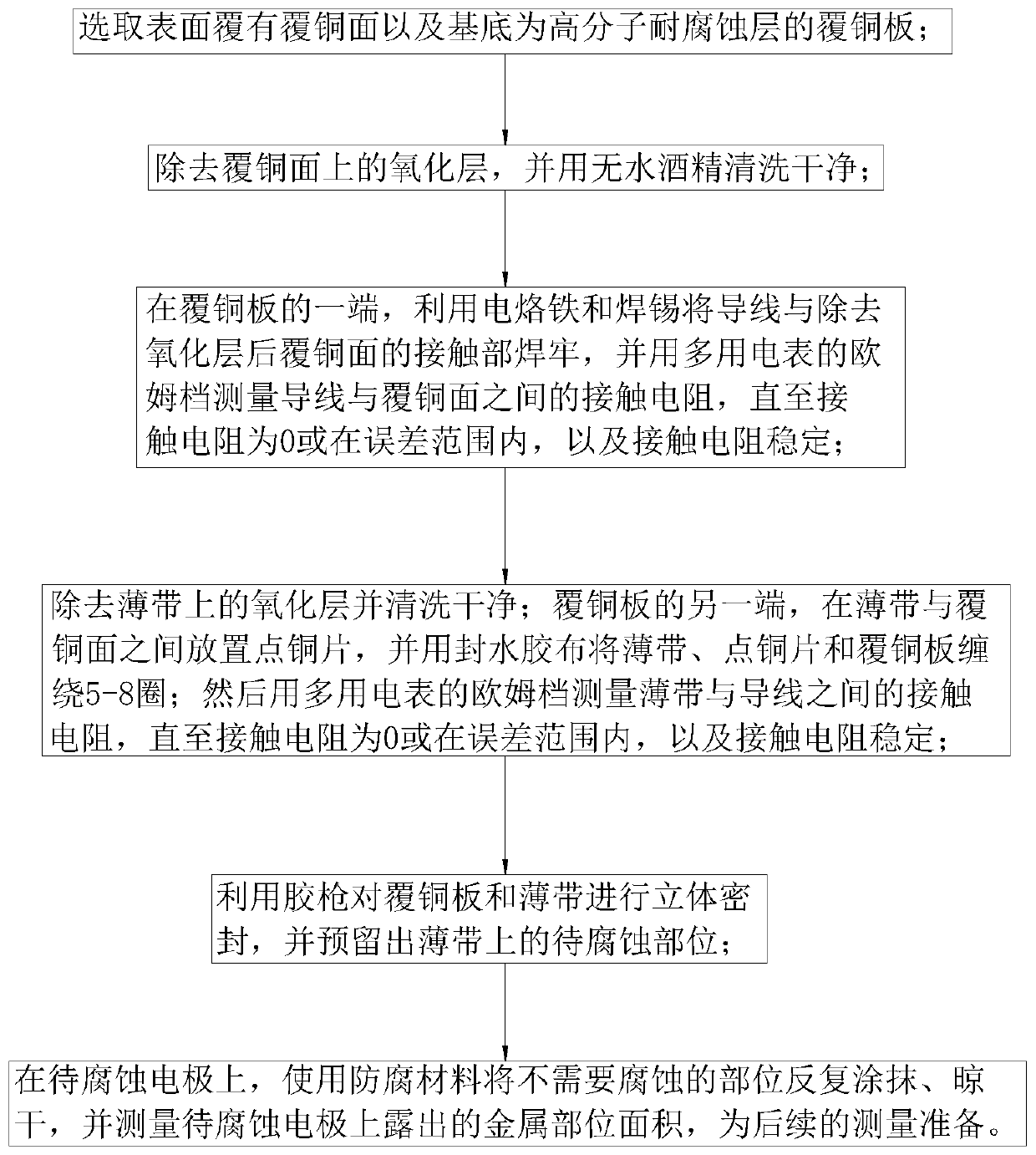

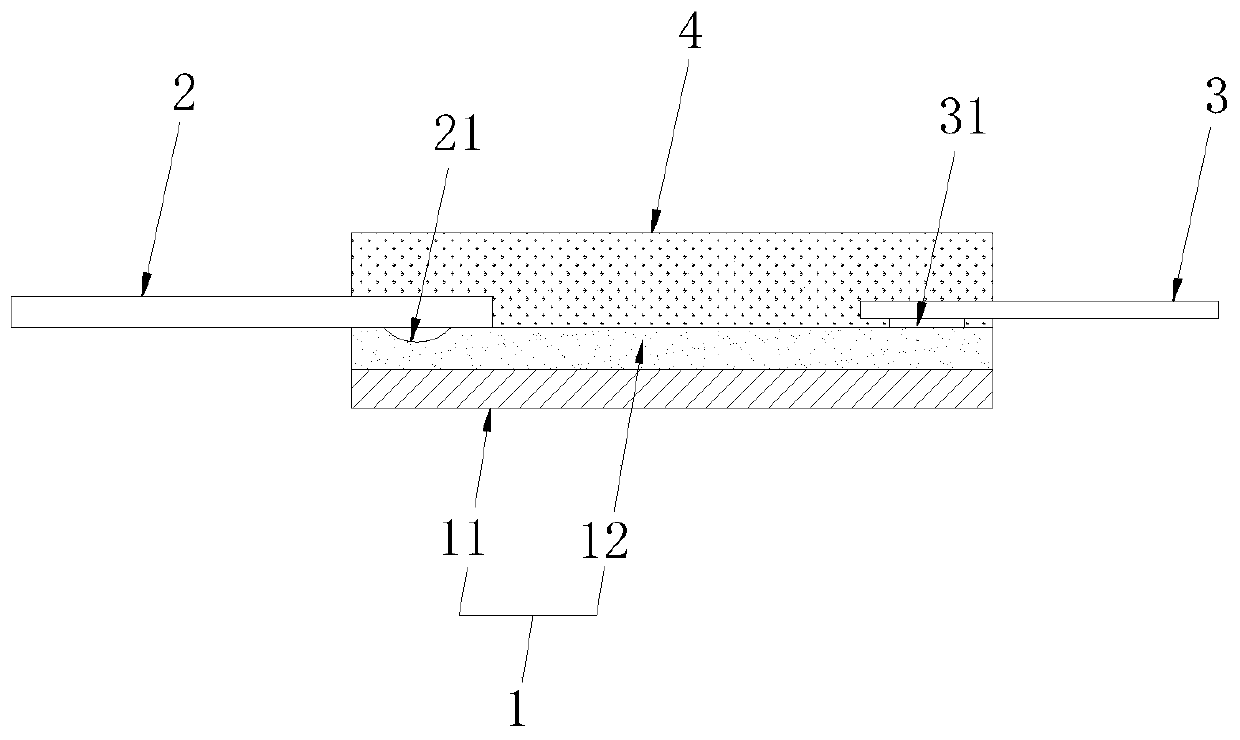

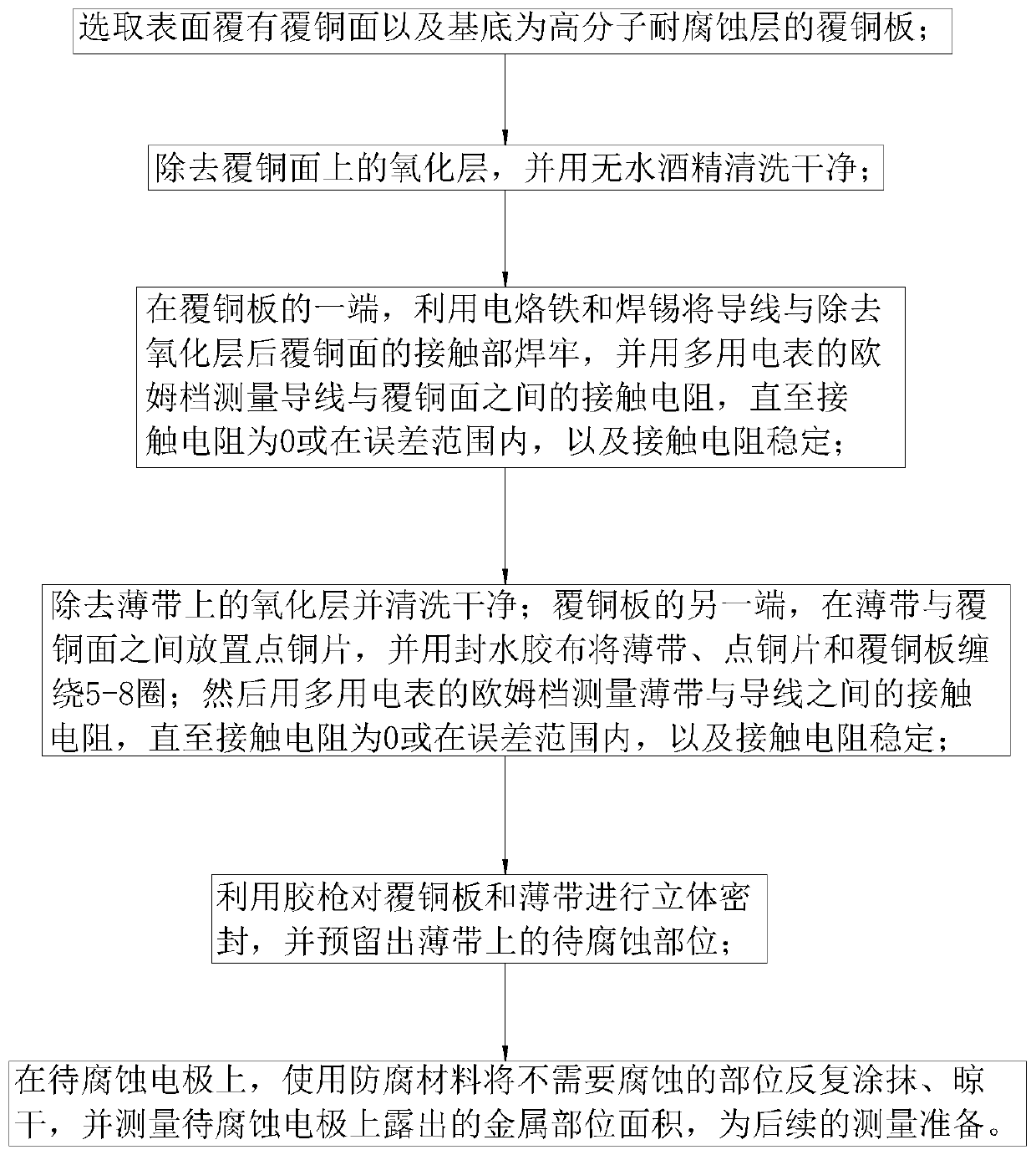

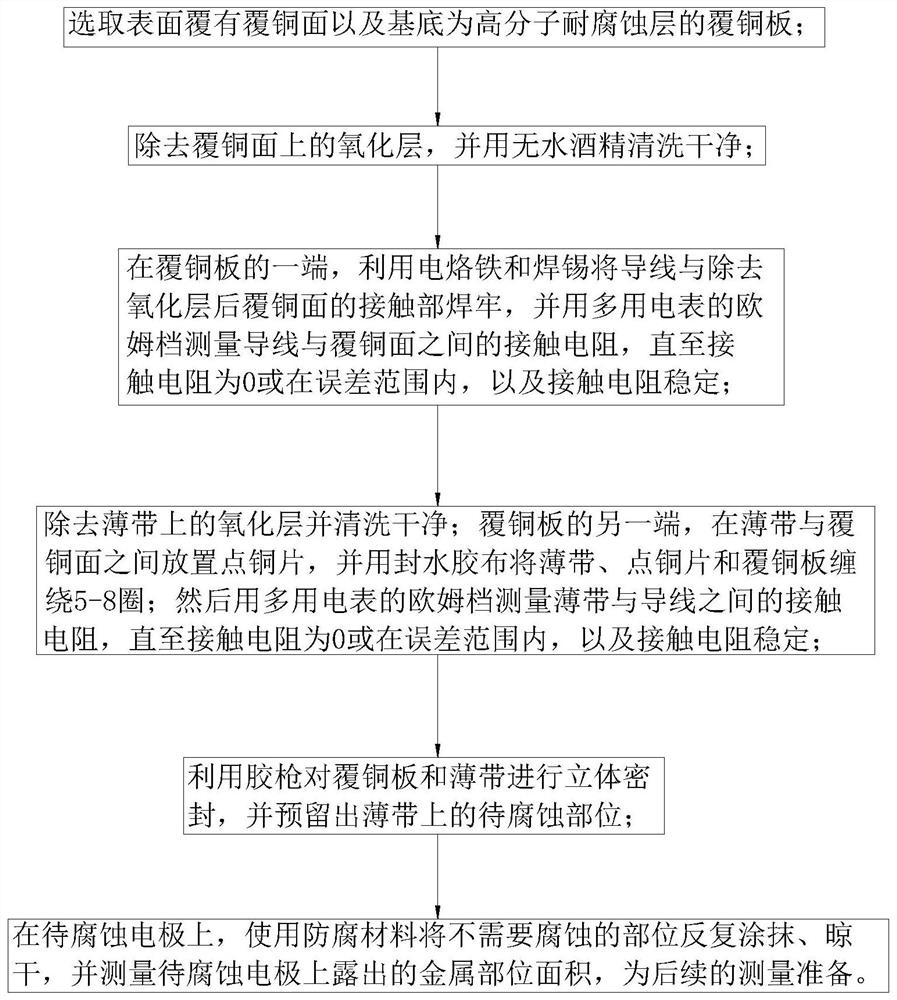

Manufacturing method of amorphous metal thin-strip corrosion electrode

ActiveCN110006813ALow input costAvoid direct solderingWeather/light/corrosion resistanceElectricityOxide

The invention discloses a manufacturing method of an amorphous metal thin strip corrosion electrode, relates to the technical field of electrode corrosion, and solves the problems that in the existingelectrode corrosion, the stability of electric signal transmission is poor, a thin strip body is easy to damage, and an electric signal is easy to interfere by the outside. The technical solution isthat: selecting a copper-clad surface; removing the oxide layer on the copper-clad surface; firmly welding the wire and the contact part of the copper-clad surface; removing the oxide layer on the thin strip body, placing a point copper sheet between the thin strip body and the copper-clad surface, and winding the point copper sheet with a water-sealing adhesive tape; performing three-dimensionalsealing on the copper-clad plate and the thin strip body by using a glue gun, and reserving a to-be-corroded part; repeatedly smearing and air drying parts which do not need to be corroded by the anti-corrosion material, so that the effects of ensuring effective transmission of electric signals in electrode corrosion, ensuring the integrity of the thin strip body, preventing the thin strip body from shaking in corrosive liquid and reducing external interference on the electric signals are achieved. According to the patent, the invention is supported by the scientific and technical funds in Guizhou province.

Owner:合肥名龙电子科技有限公司

Extraction multi-chamber mixer used in antibiotic production

ActiveCN101890253BImprove split blendingIncrease turbulence velocityFlow mixersLiquid solutions solvent extractionEngineeringMixing chamber

The invention relates to an extraction multi-chamber mixer used in antibiotic production. The mixer of the invention comprises a cylindrical shell, wherein the two ends of the cylindrical shell are provided with a charge tube and a discharge tube; a certain number of dummy plates are arranged in the shell to divide the interior of the shell into multiple mixing chambers; half of the dummy plates are entities, and the other half of the dummy plates are sieve plates distributed with through holes; the adjacent mixing chambers are communicated through the sieve plates; a central tube is arrangedat the middle part of the dummy plates in a penetrating mode, and the length of the central tube is matched with that of the cylindrical shell; one end of the central tube, which is close to the discharge tube, is enclosed; the other end of the central tube, which is close to the charge tube, penetrates out from the cylindrical shell through a bent tube; all the parts of the central tube, which are in the mixing chambers, are provided with air hole; and the upper part of each mixing chamber is provided with an exhaust tube. The mixer has high mixing efficiency and can fully mix materials and improve extracting speed and effect.

Owner:濮阳泓天威药业有限公司

Reusable mounted main hoisting device

InactiveCN109552980AVersatilityQuick fire-free removalLoad-engaging elementsMarine engineeringMotherboard

The invention discloses a reusable mounted main hoisting device. The mounted main hoisting device comprises: a lifting lug main plate; a lifting lug pipe shaft, the lifting lug pipe shaft being arranged in front of the lifting lug main plate; a lifting lug baffle, being arranged in front of the lifting lug pipe shaft; a connecting plate, being arranged under the lifting lug main plate, and the connecting plate is provided with a connecting hole. The device has advantages that the reusable mounted main hoisting device prevents direct welding on a device body, and a main lifting lug and an outerreinforcing ring inherent to the device are organically combined by a connecting member. After device hoisting is completed, extension length of the main lifting lug influences subsequent installation of the device, and the connecting member is directly removed, and rapid and non-fire removal of the main lifting lug of the device is realized. A semi-box structure is adopted as a main structural form of the main lifting device, to ensure stability of the main lifting lug structure. The material and dimensions of the main lifting lug are made according to site conditions to make the main hoisting device versatile.

Owner:中石化重型起重运输工程有限责任公司 +1

A kind of preparation method of macroporous silver electrode

ActiveCN105428632BAvoid direct solderingAvoid forceCell electrodesCell component detailsSilver electrodePunching

The invention discloses a preparation method of a large-porosity silver electrode, comprising: step 1, the raw material of the large-porosity blank silver electrode is silver acetate powder, the electrode skeleton is a silver mesh, the silver acetate powder is loaded into the hopper of a roller press, and the silver Load the net into the reel of the roller press, adjust the thickness of the prepared silver electrode to 0.45-0.55mm, and then cut it into the required size; punch the cut electrode into a mold; put the punched silver electrode at 300°C Sinter at ±20°C for 20 minutes; prepare a rough silver electrode with large porosity; step 2, cut a long strip of silver foil with a length of 200 mm and a width of 20 mm, and punch a circular hole at one end of the silver foil with a punching machine as a connection hole, and prepare the silver guide lug; Step 3, weld the silver guide lug on the sintered large-porosity blank silver electrode with a spot welder; Step 4, form a battery: weld the large-porosity blank electrode with the silver guide lug It is connected with the stainless steel auxiliary plate by lugs and assembled into a formation battery.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

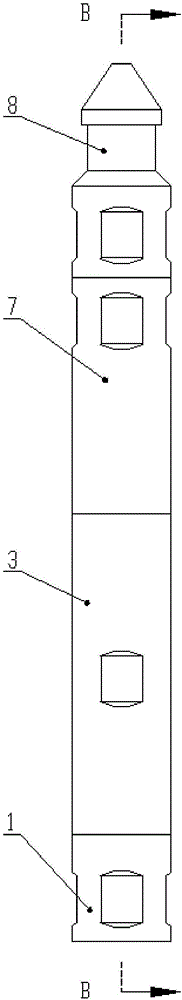

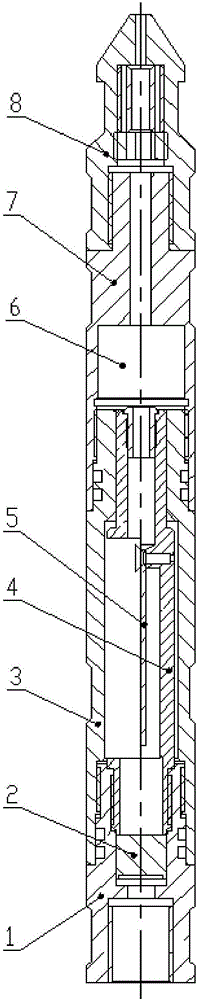

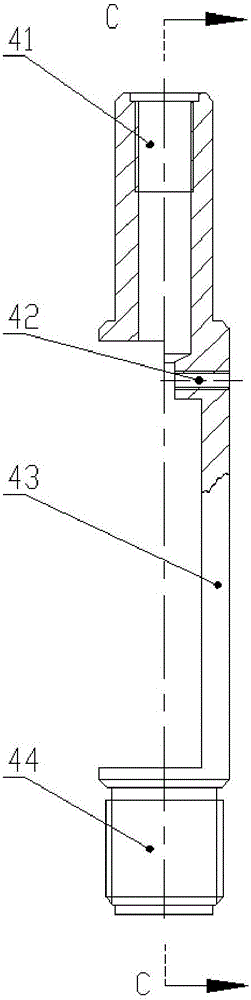

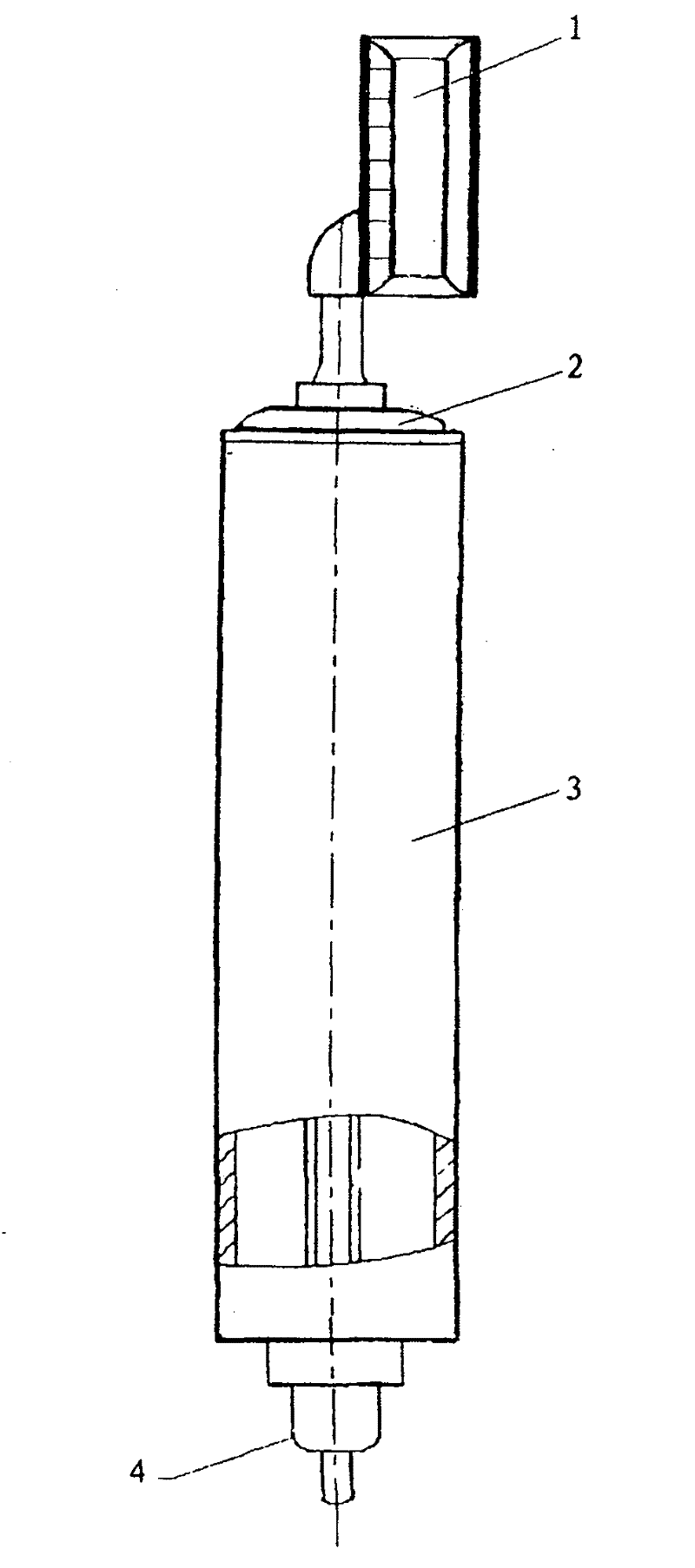

Downhole electronic pressure bomb

PendingCN106703790AEasy maintenanceReduce waste of resourcesSurveyEngineeringElectrical and Electronics engineering

The invention relates to the electronic pressure gauge field, in particular to a downhole electronic pressure bomb. The downhole electronic pressure bomb comprises an upper joint, wherein a connector lug and a middle joint are respectively connected with two ends of the upper joint, a battery is arranged in the upper joint, a lower joint is connected with the end of the middle joint, a sensor is arranged in the lower joint, a support is arranged in the middle joint, the support is respectively connected with the battery and the sensor in detachable mode, and a circuit board is further installed on the support. According to the downhole electronic pressure bomb, the support is respectively connected with the battery and the sensor in detachable mode, and simultaneously the circuit board is installed on the support, and therefore direct welding connection between the circuit board and the sensor is avoided, the design can facilitate maintenance of the downhole electronic pressure bomb, and when the downhole electronic pressure bomb breaks down, the circuit board or the sensor can be separately replaced, integral replacement is not needed, unnecessary resource waste can be reduced in maintenance, and maintenance cost of the product is reduced.

Owner:CHENGDU HAICHUAN HI TECH CO LTD

A method for manufacturing an amorphous metal strip corrosion electrode

ActiveCN110006813BClean upImprove reliabilityWeather/light/corrosion resistanceCopperElectric signal

The invention discloses a manufacturing method of an amorphous metal thin strip corrosion electrode, relates to the technical field of electrode corrosion, and solves the problems of poor stability of electric signal transmission, easy damage of the thin strip body and easy external interference of electric signals in the existing electrode corrosion. The key points of the technical solution are: select the copper clad laminate; remove the oxide layer on the copper clad surface; weld the contact between the wire and the copper clad surface firmly; remove the oxide layer on the thin strip body, Place some copper sheets between the copper surfaces and wrap them with water-sealing tape; use a glue gun to three-dimensionally seal the copper-clad laminate and the thin strip body, and reserve the parts to be corroded; use anti-corrosion materials to repeatedly smear and dry the parts that do not need to be corroded Dry, with the effect of ensuring the effective transmission of electrical signals during electrode corrosion, the integrity of the thin strip, and preventing the thin strip from shaking in the corrosive liquid, reducing the effect of external interference on electrical signals. This patent has been supported by the Science and Technology Fund of Guizhou Province (Qian Ke He J Zi [2014] No. 2122).

Owner:合肥名龙电子科技有限公司

Improved wagon rear carriage side door board

InactiveCN106005054AAvoid WeldingImprove connection strengthLoading-carrying vehicle superstructuresEngineeringTruck

The invention discloses an improved wagon rear carriage side door board. The improved wagon rear carriage side door board comprises a side board; an L-shaped board is arranged at one end of the side board; a groove is formed by the L-shaped board and the side board; an opening of the groove faces towards the other end of the side board; a welding board is clamped and embedded into the groove; the length of the welding board is larger than that of the groove; the end, exceeding out of the groove, of the welding board is used for being welded to a rear board; and a fixing bolt penetrates through the side board, the welding board and the groove to fix the welding board into the groove. As the welding board fixed into the groove and the rear board are welded, direct welding between the side board and the rear board is avoided, and accordingly separation of the side board and the rear board can be achieved easily by taking out the welding board, disassembly is very convenient, and a rear carriage is convenient to move and transport; and under the action of the groove and the fixing bolt, the welding board and the side board have the good connection strength, so that the connection strength of the side board and the rear board is also ensured, and the overall connection strength of the rear carriage is improved.

Owner:南京力源轨道交通装备有限公司

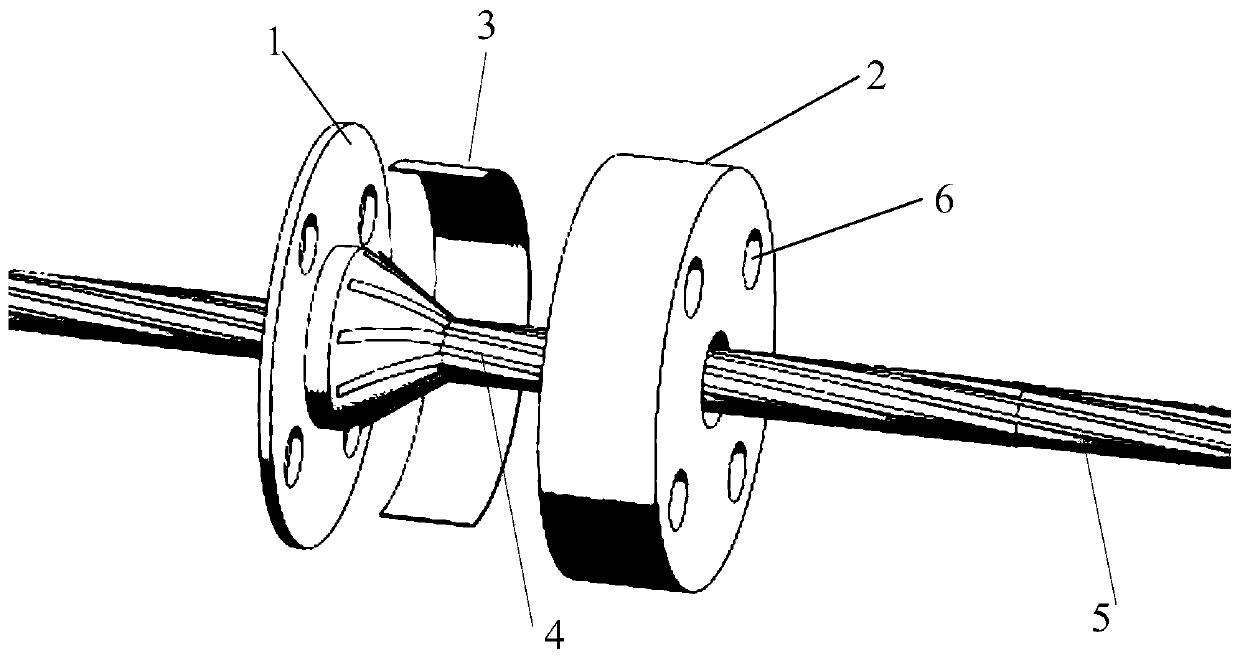

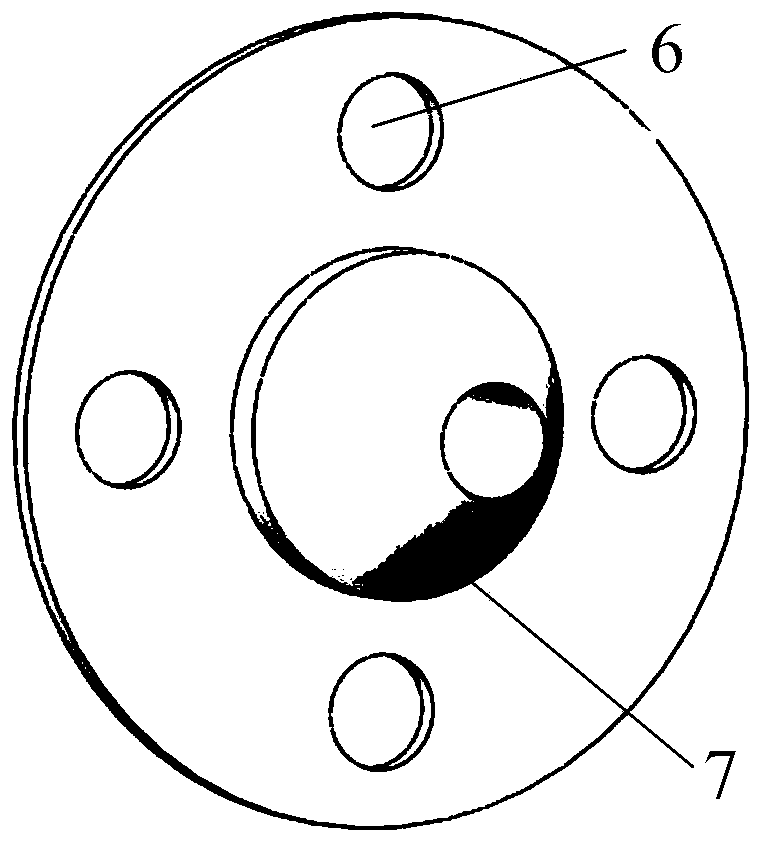

A high-temperature superconducting cable end connection structure and connection method

ActiveCN108063320BAvoid direct solderingSolve the impactLine/current collector detailsClamped/spring connectionsElectrical conductorHigh temperature superconducting

The invention relates to an end connection structure and method for a high-temperature superconducting cable. The structure comprises a first end connection structure and a second end connection structure. In a to-be-connected superconducting strip material layer, each superconducting strip material is connected with one transition copper strip material. The end connection structure passes throughthe high-temperature superconducting cable, and the transition copper strip materials are clamped and fixed through the end connection structure. Finally, a current lead wire is connected to the endconnection structure. The transition copper strip materials prevent the direct welding of a superconducting strip material with the current lead wire, and the contact parts of the transition copper strip materials with the end connection structure are not welded, thereby preventing the end welding process from affecting other superconducting material layers. Each superconducting strip material isindependently welded with the corresponding transition copper strip material, thereby facilitating the control of the welding length. The connection of the end connection structure and the current lead wire is bolt connection, thereby facilitating the assembly, disassembly and transportation. According to the invention, one lead wire can be independently led out of any conductor layer, and a current of each cable layer can be controlled independently.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

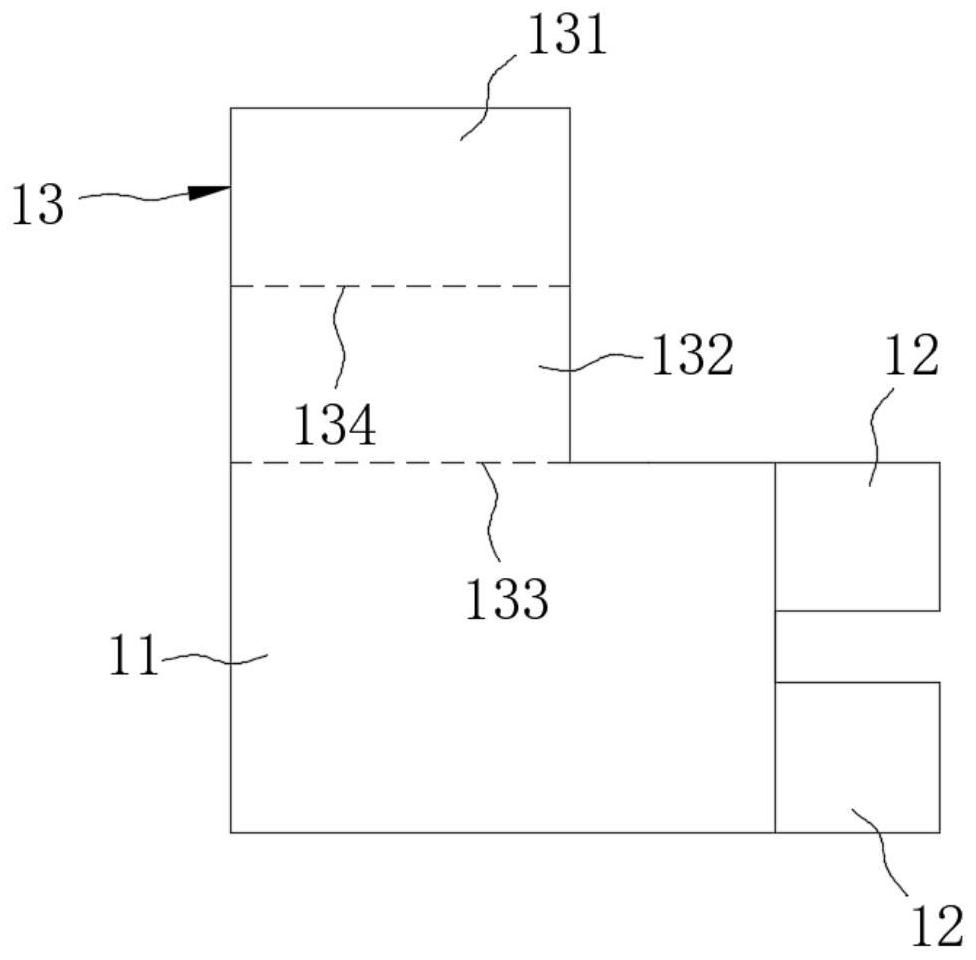

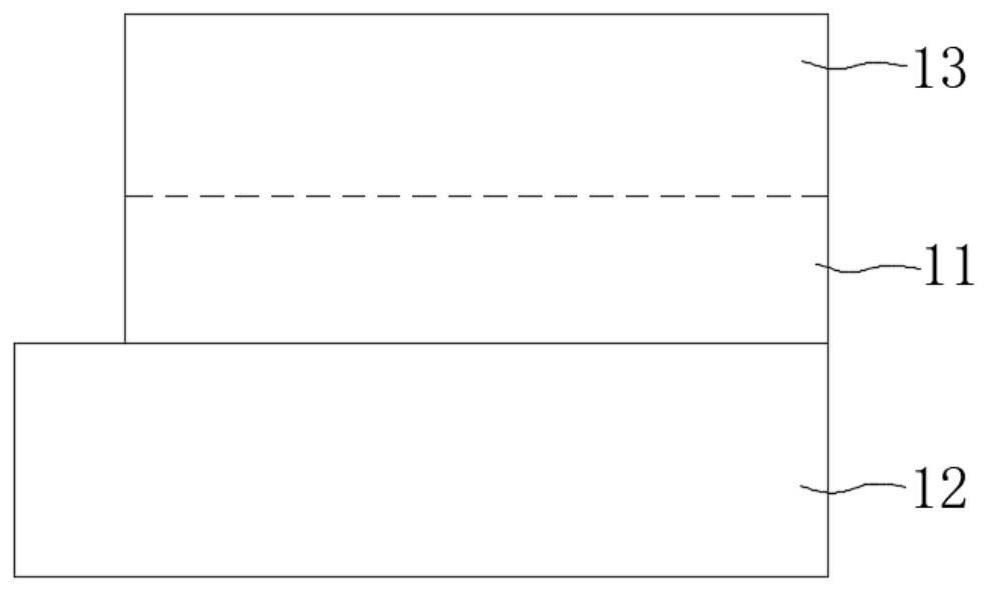

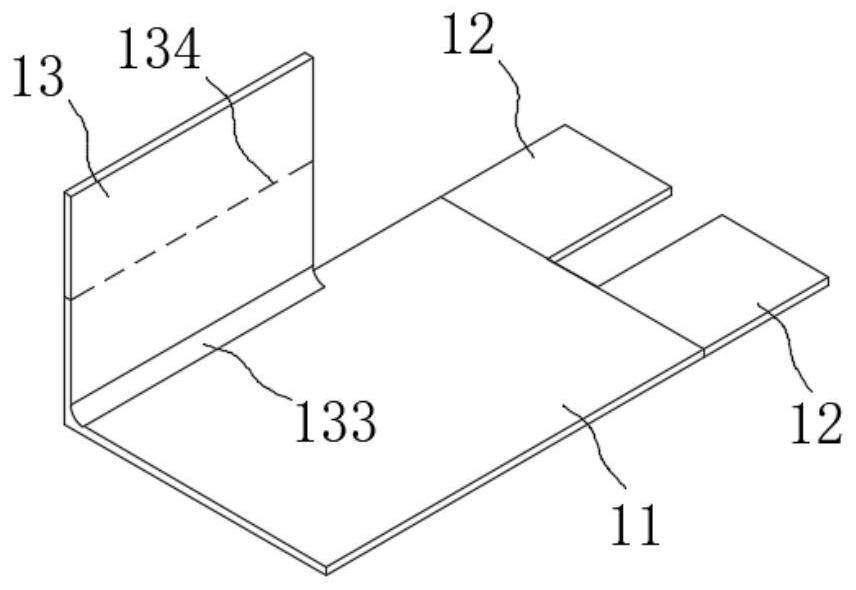

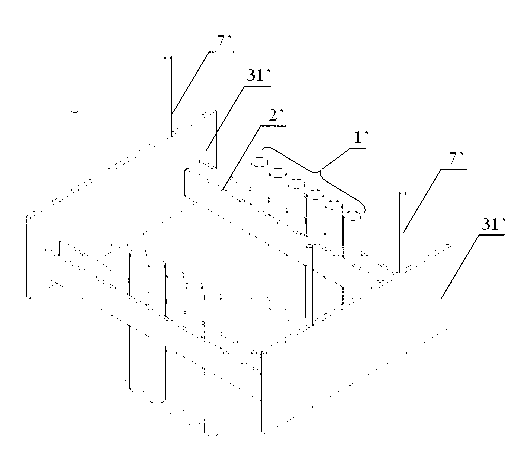

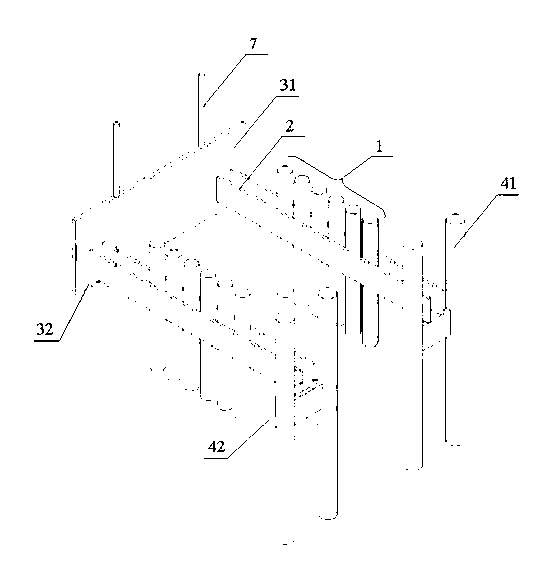

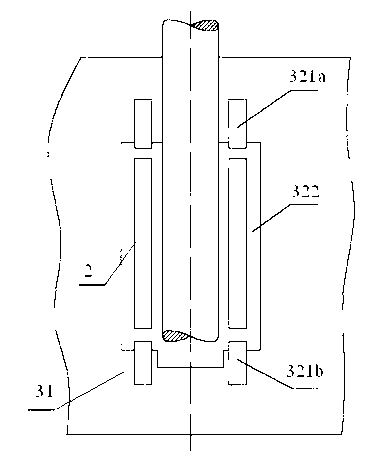

Boiler tube bank suspension device

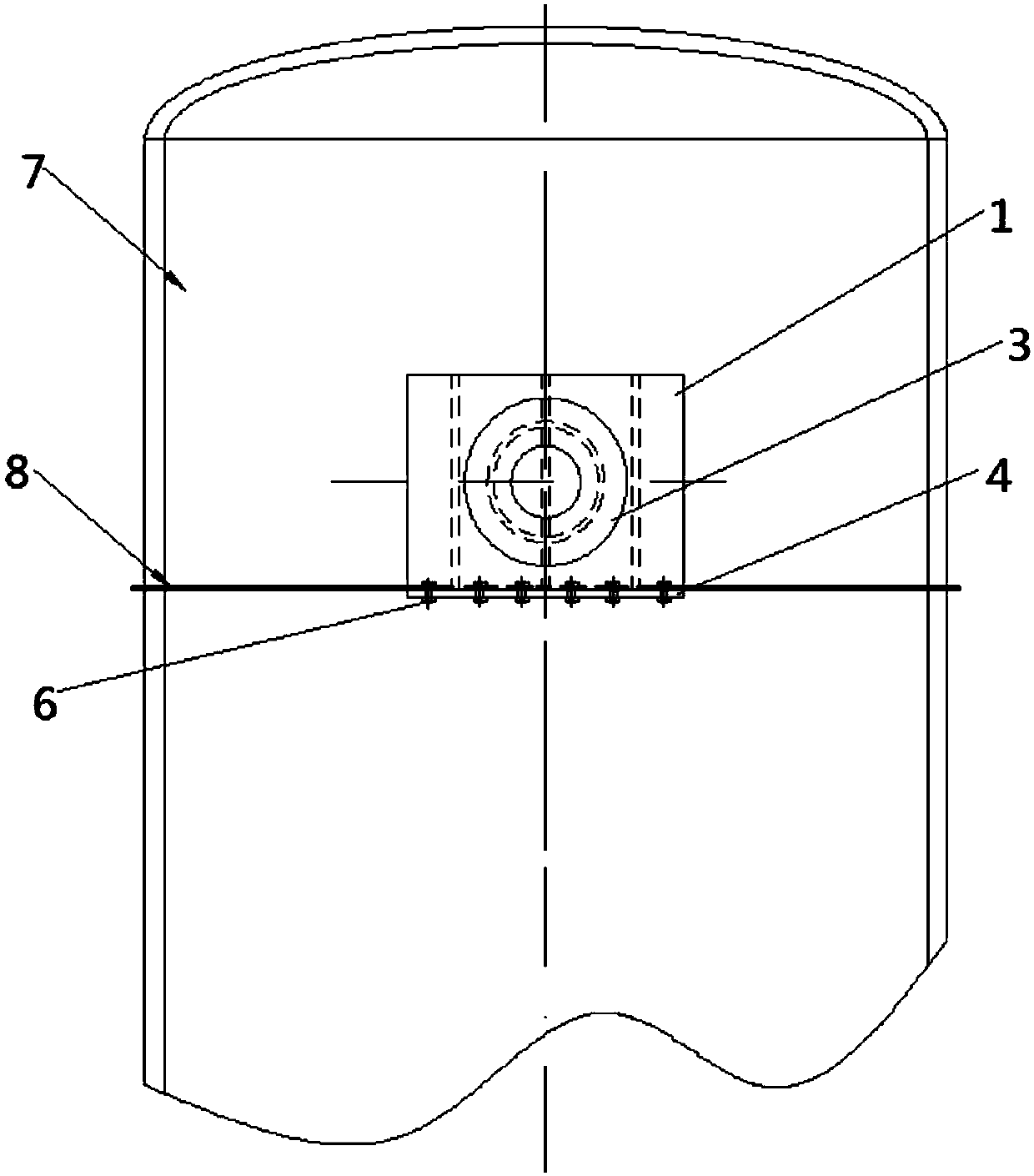

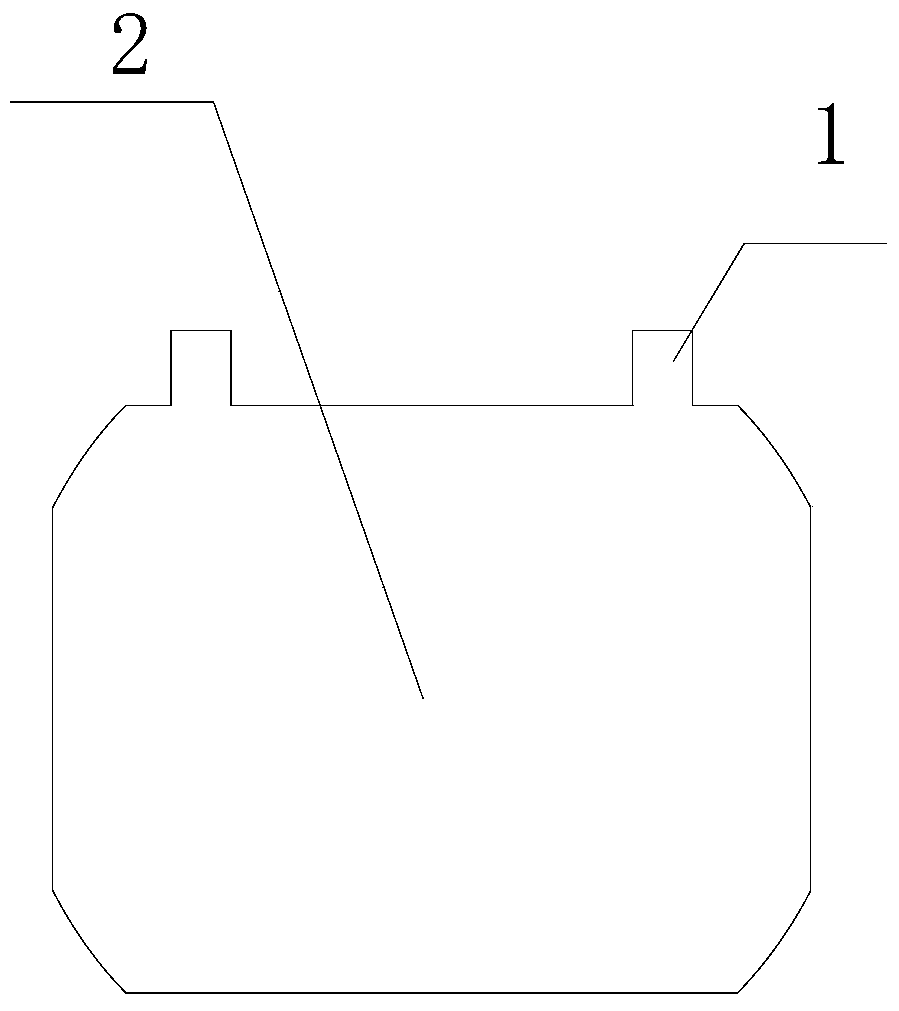

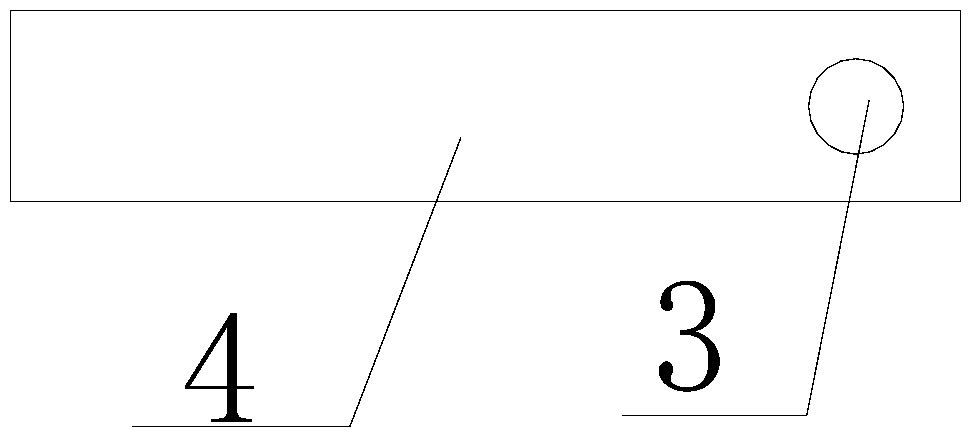

ActiveCN102393008BOptimize layoutSmall footprintFluid heatersHeat exchanger casingsEngineeringPre embedding

A boiler tube bundle suspension device, comprising a tube bundle (1), a pair of clamping steel plates (2), a end plate suspension device (3) and a suspension tube suspension device (4); the tube bundle (1) is connected with the clamping steel plate (2) via a pre-embedded part, the end plate suspension device (3) comprises an end plate (31) and an end plate support part (32) disposed on the end plate (31), and the suspension tube suspension device (4) comprises a suspension tube (41) and a suspension tube support part (42) disposed between the suspension tubes (41); one end of the clamping steel plate (2) is disposed on the end plate suspension device (3) and the other end is disposed on the suspension tube suspension device (4), or the two ends are both disposed on the suspension tube suspension device (4); the end plate support part (32) comprises a holding plate (321) and a support plate (322), the holding plate (321) is disposed on the end plate (31), the clamping steel plate (2) is connected with the support plate (322) and disposed on the clamping plate (321) via the support plate (322). The device can suspend the tube bundle (1) simply and conveniently, and provide a very good condition for the expansion under load of the tube bundle (1), avoiding interference with other parts and, at the same time, saving cost by eliminating spring hangers.

Owner:SHANGHAI BOILER WORKS

Carriage side door board and rear door board connecting combined board

InactiveCN106004376AEasy to disassembleGood connection strengthDoorsEngineeringElectrical and Electronics engineering

The invention discloses a combination panel connecting a side door panel and a rear door panel of a carriage, comprising a side door panel and a rear door panel, one end of the side panel is connected with a welding plate, the length of the welding plate is greater than the width of the side door panel, and the side door panel is A first bolt hole and a second bolt hole are respectively arranged on the end surface in contact with the welding plate and the welding plate, and the first bolt hole and the second bolt hole are matched with the fixing bolts, and the fixing bolts pass through the first Bolt holes and a second bolt hole hold the side door panels and welded panels together. The invention utilizes the connection mode of welding the welding plate fixed on the side door panel and the rear door panel, and the welding plate can be easily taken out from the side door panel, thereby realizing the separation of the side door panel and the rear door panel, and improving the convenience and flexibility of disassembly , Under the action of fixing bolts and reinforcing plates, the side door panel and the rear door panel have realized a three-dimensional connection, and the connection strength has been greatly improved.

Owner:南京力源轨道交通装备有限公司

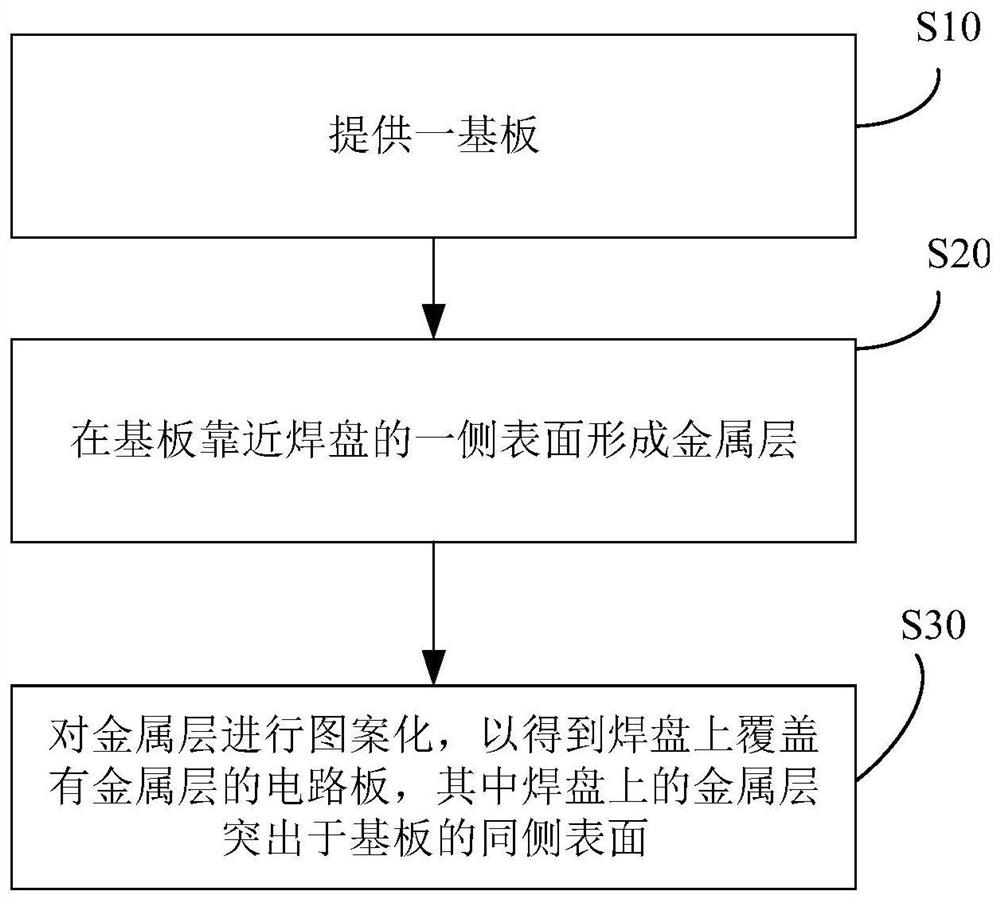

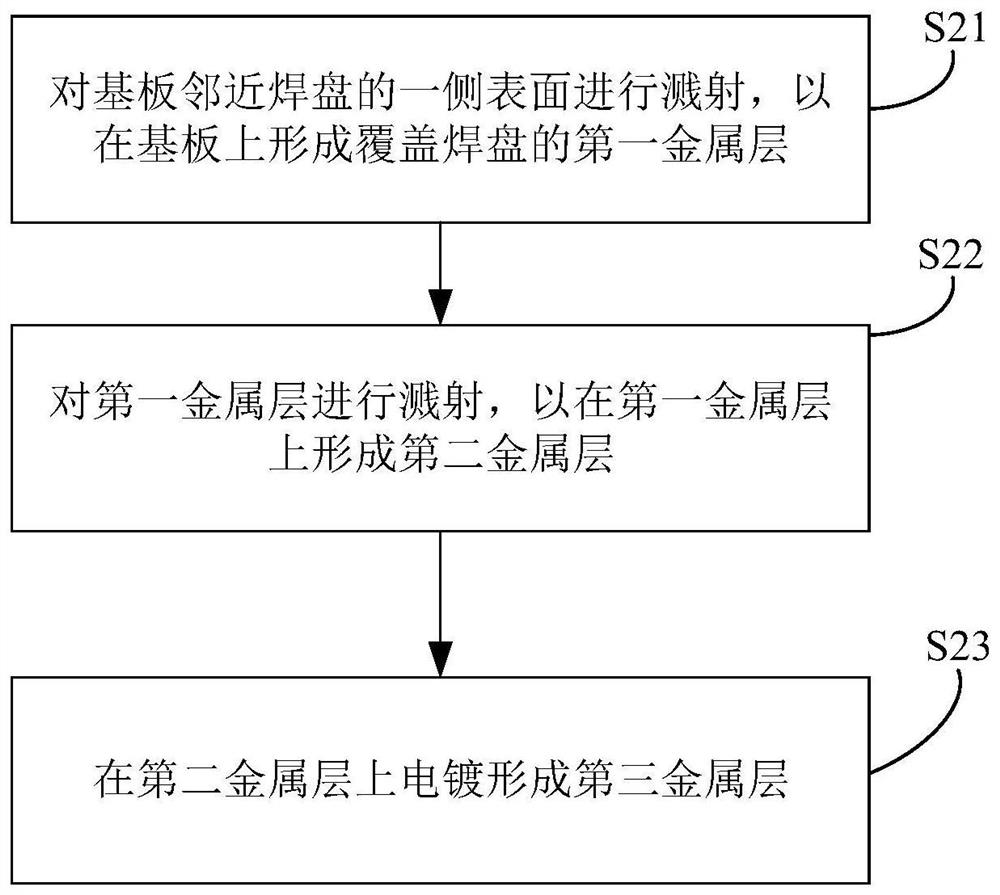

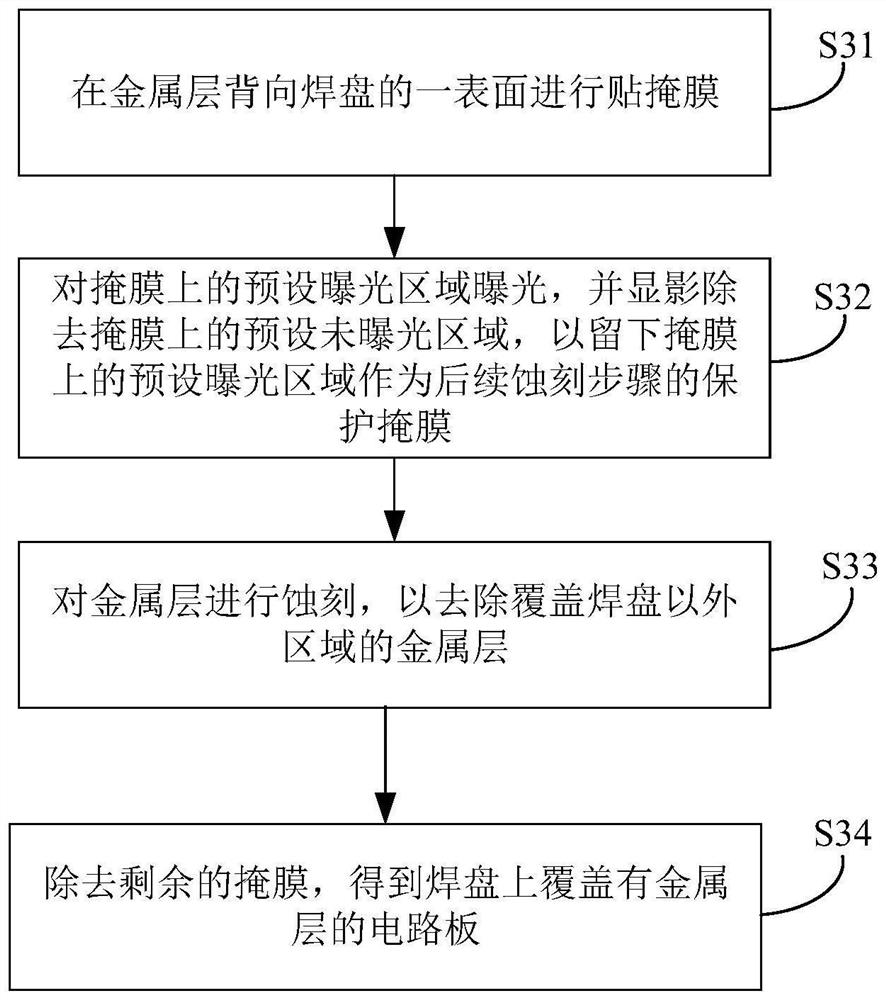

Manufacturing method of embedded circuit board, embedded circuit board and application

PendingCN112203433AMeet thermal requirementsImprove cooling effectTransformers/reacts mounting/support/suspensionSemiconductor/solid-state device detailsEngineeringMechanical engineering

The invention relates to the technical field of circuit boards, and particularly discloses a manufacturing method of an embedded circuit board, the embedded circuit board and application, the method comprises the following steps: providing a substrate, embedding an electronic device in the substrate, arranging a bonding pad on the surface of one side of the electronic device, and flushing the endsurface of the bonding pad with the surface of the same side of the substrate; forming a metal layer on the surface of one side, close to the bonding pad, of the substrate; and patterning the metal layer to obtain the circuit board with the bonding pad covered with the metal layer, the metal layer on the bonding pad protruding out of the surface of the same side of the substrate. By means of the above manner, secondary processing can be conducted on the bonding pads on the substrate according to user requirements, and then the embedded circuit board meeting different product performance requirements of users is manufactured.

Owner:SHENNAN CIRCUITS

Seven-electrode conductivity sensor

InactiveCN101839944BGuaranteed stabilityHigh precisionFluid resistance measurementsCopper conductorHoneycomb

The invention discloses a seven-electrode conductivity sensor with a novel structure. In the invention, seven platinized film ring electrodes are arranged at the inner wall of the honeycomb duct of a conductance cell up and down; a cylindrical bore penetrating through the duct wall of the honeycomb duct is arranged in a ring groove at the inner wall of the honeycomb duct corresponding to each ring electrode, and the cylindrical bore is internally provided with platinized film inner layers; the platinized film inner layer at the inner port of the cylindrical bore is connected with the platinized film ring electrode, and the platinized film inner layer at the outer port of the cylindrical bore forms a thickened platinized film welding ring; the thickened platinized film welding ring is welded with one end of a platinum lead wire at the outside of the honeycomb duct, and the other end of the platinum lead wire is welded with a copper conductor which is connected with a signal conversion circuit in the pressure-proof watertight shell of the sensor; and elastic sealing grease is casted into the cylindrical bore penetrating through the duct wall of the honeycomb duct, thus the platinum lead wire is prevented from being directly welded on the quartz duct wall of the honeycomb duct, the sealing property of the honeycomb duct and the stability of the sensor are improved, and the advantages of high precision, convenient field usage and the like of the sensor are fully expressed.

Owner:STATE OCEAN TECH CENT

A mining dump truck lift cylinder shaft assembly

The invention provides a lifting cylinder shaft assembly of a mining dump truck. The lifting cylinder shaft assembly of the mining dump truck comprises a lifting cylinder support, a lifting cylinder shaft, an end cover and a gland, wherein the lifting cylinder support is provided with a shaft hole, the lifting cylinder shaft is provided with a shaft shoulder, a shaft section, at one side of the shaft shoulder, of the lifting cylinder shaft is installed in the shaft hole of the lifting cylinder support, the end cover is arranged at the end of the shaft section, at the other side of the shaft shoulder, of the lifting cylinder shaft, and the gland is axially arranged on the shaft shoulder in a pressing mode and fixed to the lifting cylinder support. The lifting cylinder shaft assembly of the mining dump truck is simple in structure and easy to machine, and the lifting cylinder shaft is high in strength, not damaged easily, stable and reliable in axial fixation, high in size accuracy and installation accuracy, and easy to detach and replace.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Connector used for stack PCB

PendingCN108777382AEasy to disassembleReduce maintenance difficultyCoupling contact membersCouplings bases/casesElectric signalWelding process

The invention provides a connector used for a stack PCB. The connector comprises a connector male head and a connector female head. The connector male head comprises a male head shell which is internally provided with a conductive plug-in. One end of the conductive plug-in extends towards the direction away from the male head shell and stretches out of the male head shell. The connector female head comprises a female head shell which is provided with jacks. The conductive plug-in is arranged in the jacks so that the connector male head and the connector female head are enabled to be electrically conducted. The connector male head and the connector female head are plugged to form a whole connector. Physical structural connection and electric signal transmission of two PCBs can be realized through the connector. Direct welding of the two PCBs can be avoided so that the requirement of the welding process can be greatly reduced and the possible risk appearing in welding can be reduced. Theconnector male head and the connector female head are conveniently detached so that maintenance in the production process can be facilitated, and the later maintenance difficulty of the client side can also be reduced. Upgrading and updating of the product can be flexibly realized.

Owner:SUNWAY COMM BEIJING

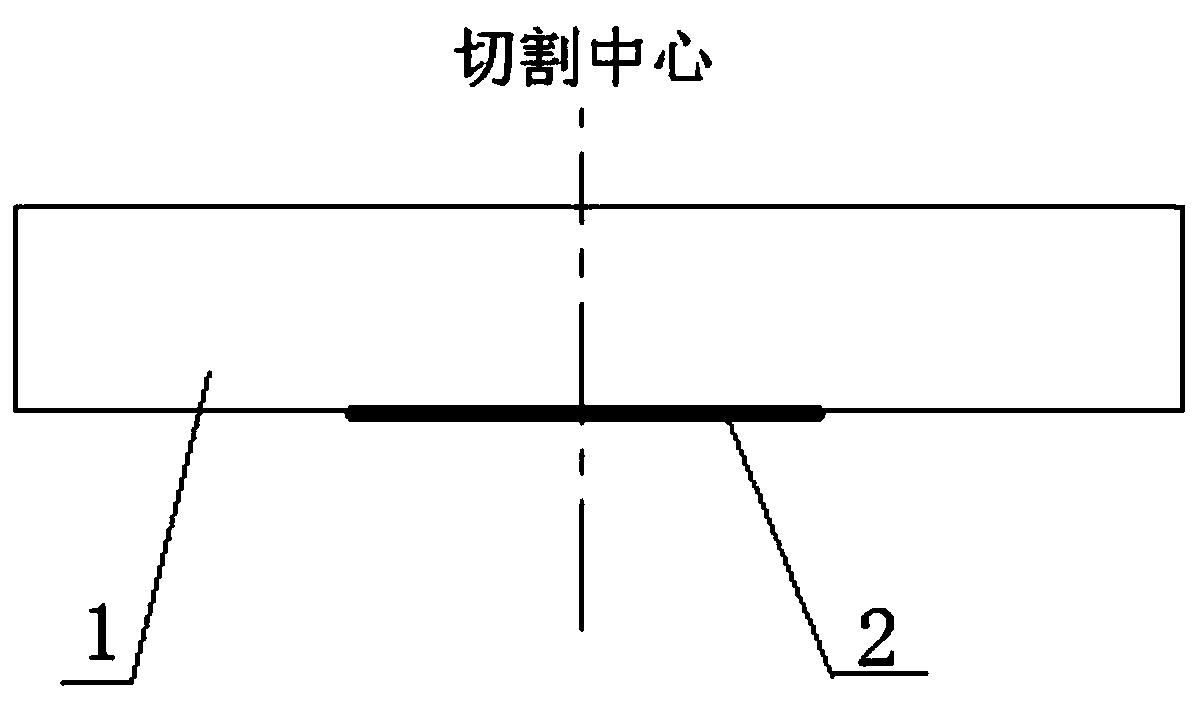

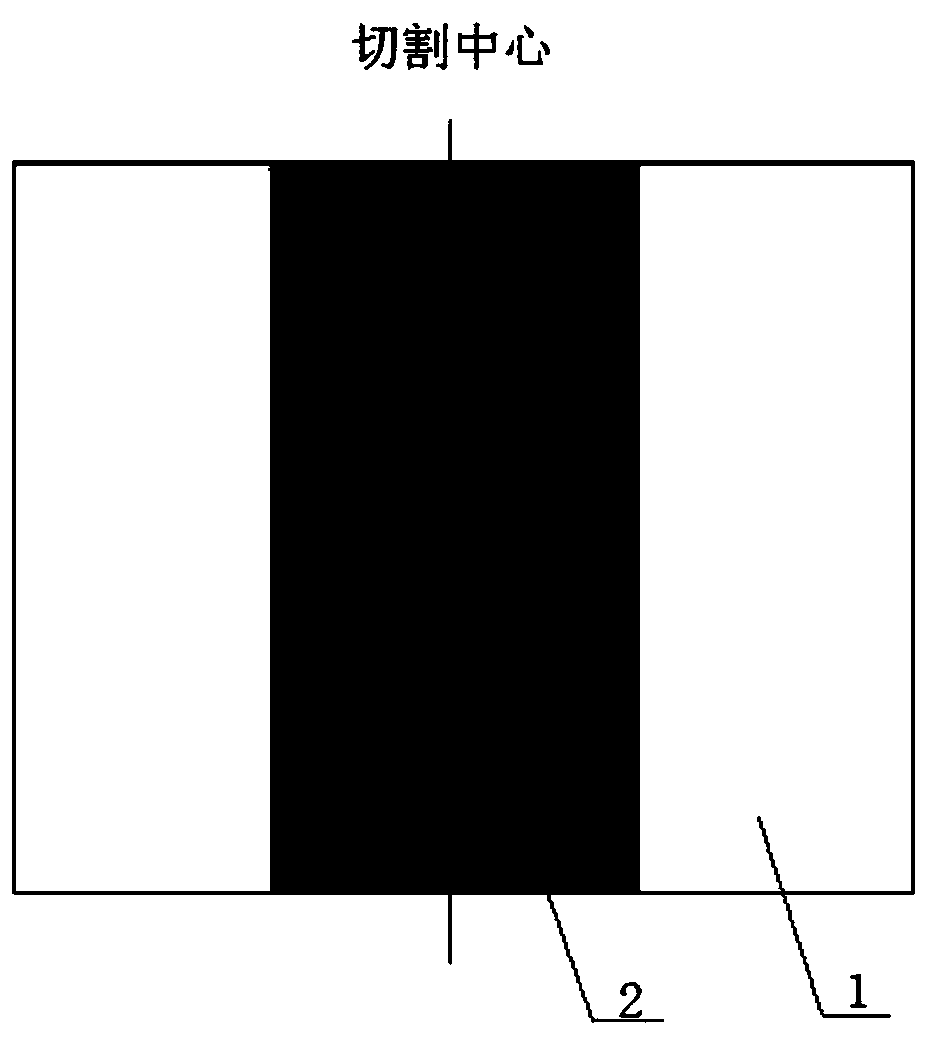

A kind of continuous casting billet burr release agent and burr removal method

The invention relates to a burr isolating agent for a continuously cast steel billet and a burr removal method. Before cutting of the continuously cast steel billet, the burr isolating agent is sprayed onto the lower surface of the continuously cast steel billet along a cutting track, and then the continuously cast steel billet is cut; after burrs generated during cutting detach from a continuouscast steel billet body, under the isolating effect of the burr isolating agent, the burrs directly shed or are bonded to the continuously cast steel billet body through the burr isolating agent instead of being directly in contact with the continuously cast steel billet body and welded to the continuously cast steel billet body; the continuously cast steel billet is conveyed into a heating oven for heating after cutting is finished, and since the burr isolating agent loses effect under high temperature, the bonded burrs automatically shed from the continuously cast steel billet body. The purpose of completely removing the burrs without damaging the continuously cast steel billet body can be achieved.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com