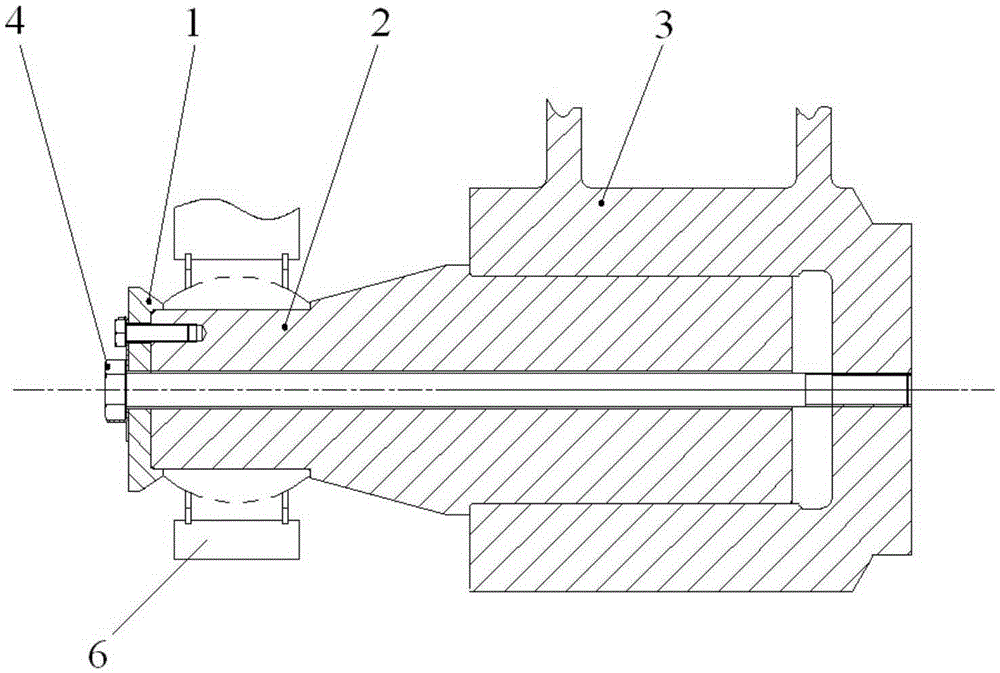

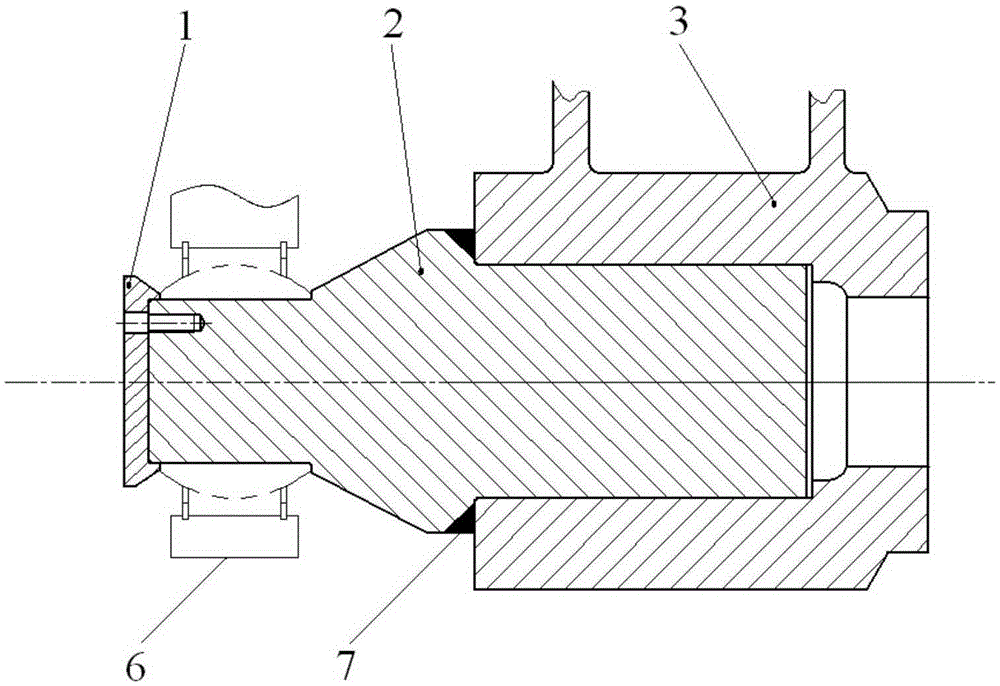

A mining dump truck lift cylinder shaft assembly

A technology for mining dump trucks and lifting cylinders, which is applied in the direction of tilted load-carrying vehicles, etc., can solve the problems of reducing the strength of the lifting cylinder shaft 2, complicated welding process, welding stress deformation, etc., so as to reduce welding risk and avoid direct welding. Welding, the effect of eliminating stretching deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

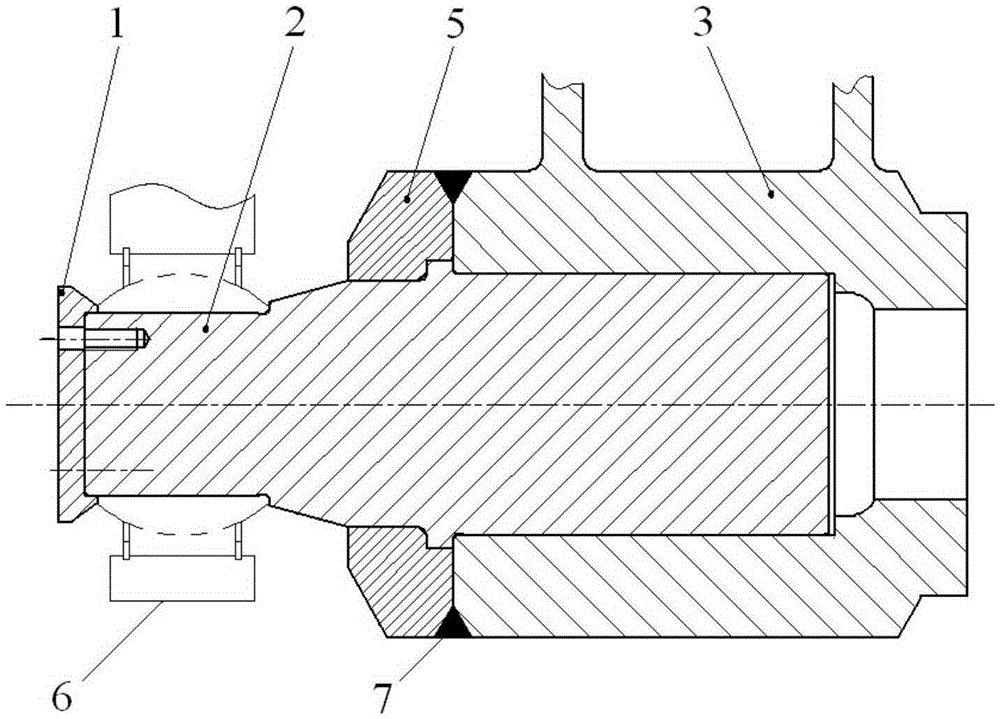

[0032] like image 3 As shown, the mine dump truck lift cylinder shaft assembly provided in this embodiment includes an end cover 1 , a lift cylinder shaft 2 , a lift cylinder support 3 and a gland 5 .

[0033] The lift cylinder support 3 in this embodiment has a shaft hole for fixing the lift cylinder shaft 2 . In this embodiment, the lifting cylinder support 3 is cast with medium carbon alloy steel, which is an integral casting structure, and its shaft hole is a through hole, so as to facilitate the sand cleaning of the casting structure and the discharge of chips during the subsequent machining process .

[0034] The middle part of the lift cylinder shaft 2 of this embodiment is provided with a shoulder ( image 3 shown at a), the shaft section of the lift cylinder on the shoulder side is installed in the shaft hole of the lift cylinder support 3, the lift cylinder shaft 2 and the lift cylinder support 3 The connection surface is a cylindrical surface; moreover, the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com