Downhole electronic pressure bomb

A pressure gauge and electronic technology, applied in wellbore/well components, measurement, earthwork drilling and production, etc., can solve the problems of inconvenient maintenance and achieve the effects of convenient maintenance, reducing waste of resources, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The invention provides a downhole electronic pressure gauge;

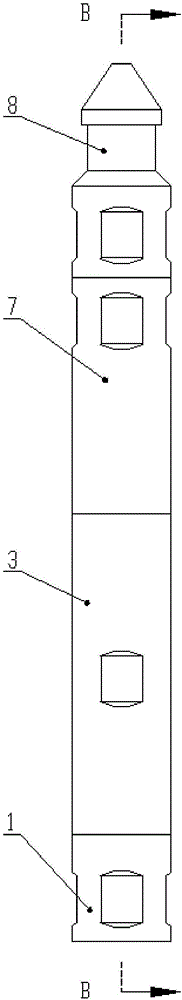

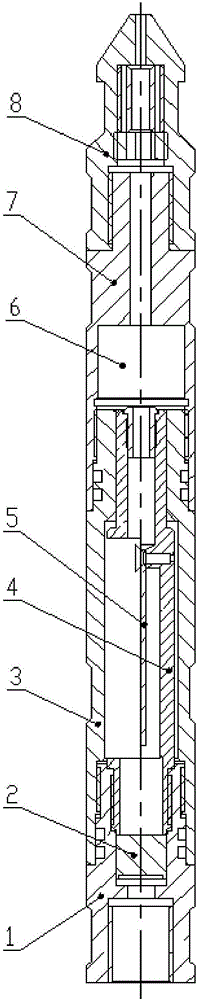

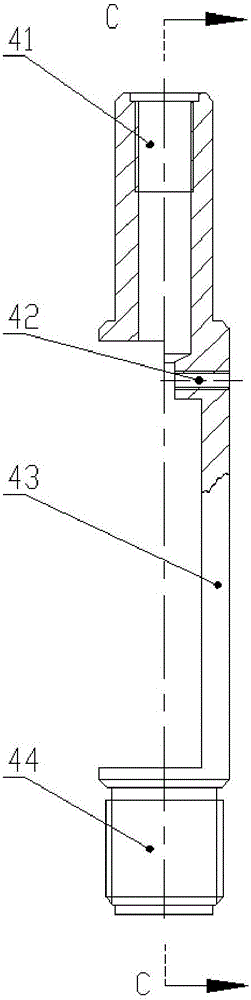

[0027] Such as figure 1 and figure 2 As shown, the downhole electronic pressure gauge in this embodiment includes an upper joint 7, one end of the upper joint 7 is threadedly connected to a terminal 8, the other end of the upper joint 7 is connected to an intermediate joint 3, and the end of the intermediate joint 3 is connected to There is a lower connector 1, a battery 6 is installed inside the upper connector 7, a sensor 2 is arranged inside the lower connector 1, a bracket 4 is arranged inside the middle connector 3, and the bracket 4 is detachably connected with the battery 6 and the sensor 2 respectively , A circuit board 5 is also mounted on the bracket 4 .

[0028] The electronic pressure gauge detachably connects the bracket with the battery and the sensor respectively, and installs the circuit board on the bracket at the same time, thereby avoiding the direct welding connection of the circuit bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com