Engine natural gas supply double-wall corrugated pipe

A technology of double-wall bellows and natural gas, which is applied to combustion engines, engine components, machines/engines, etc., and can solve problems such as poor sealing and easy loosening of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

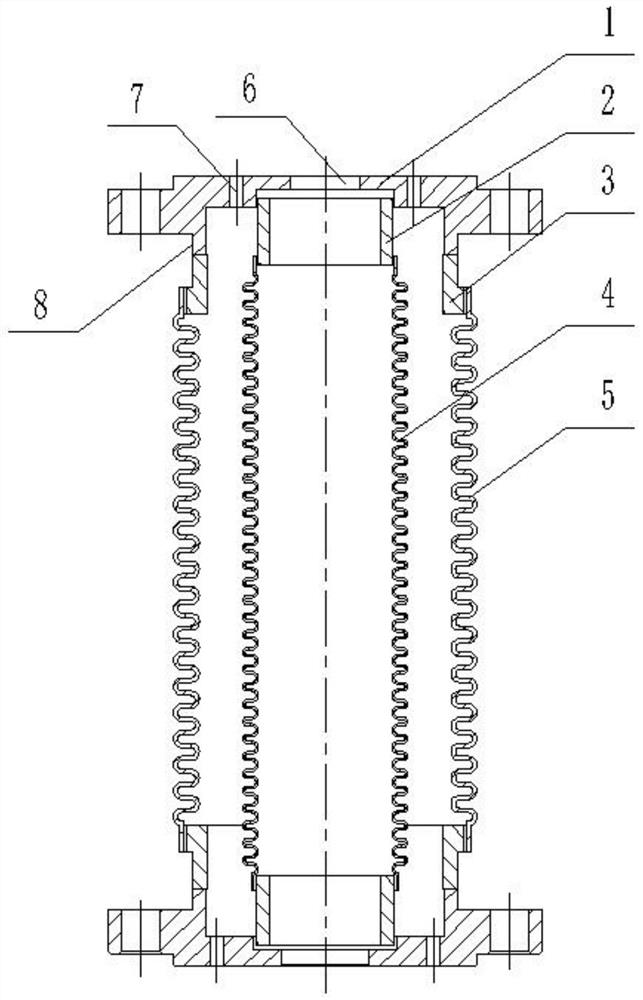

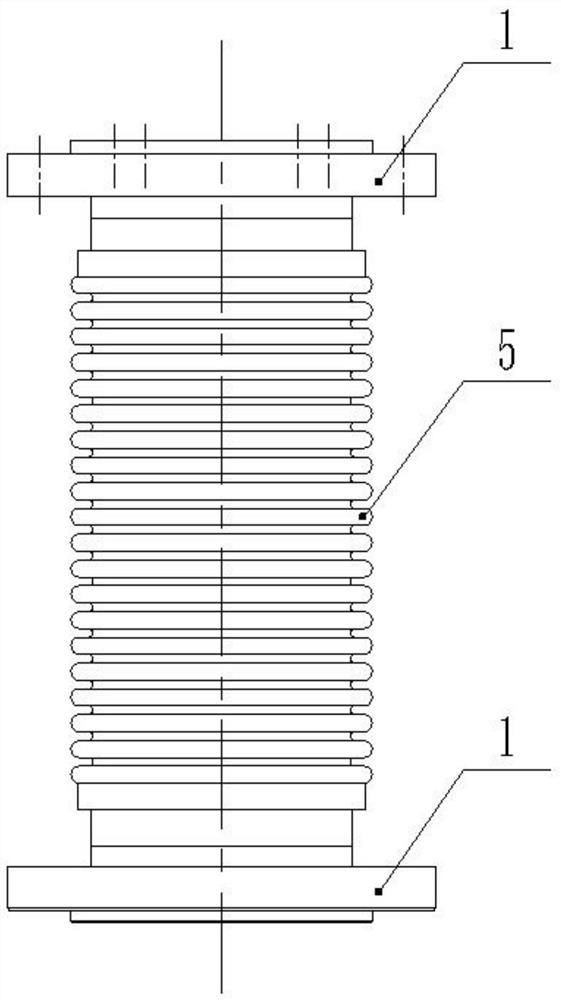

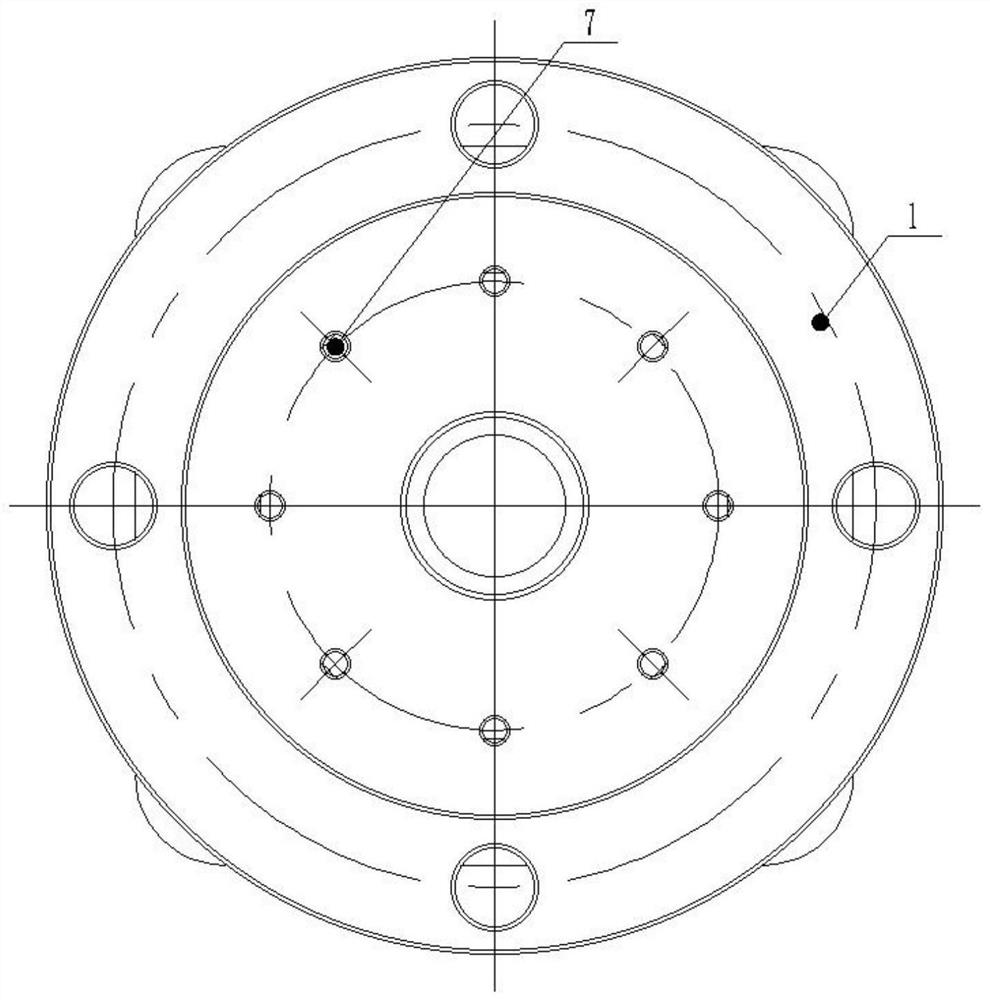

[0031] This application relates to a double-wall bellows for engine natural gas supply. As a specific implementation of the double-wall bellows, this example includes the specific structure of the double-wall bellows, the corresponding materials used and the corresponding national standards. The double-wall bellows include inner bellows 4 and the outer bellows 5 on the outside of the inner bellows 4, the outer bellows 5 wraps the inner bellows 4, the length of the inner bellows 4 is greater than the length of the outer bellows 5, and the inner bellows 4, the outer bellows 5 A cavity is formed between them, and the cavity is used as a ventilation cavity. The inner bellows 4 is a steel braided tube made of 304 stainless steel. As an embodiment, the diameter of the inner bellows 4 is DN25, and the outer bellows 5 is 3.4 stainless steel. The steel braided pipe is made of material, and the diameter of the outer bellows 5 is DN50. The steel braided pipe and bellows are made according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com