Seven-electrode conductivity sensor

A conductivity sensor and seven-electrode technology, applied in the direction of fluid resistance measurement, etc., can solve the problems of difficult correction of measurement error measurement results, lower insulation, inconsistent thermal expansion coefficients, etc., achieve good promotion and application prospects, improve sealing performance, and field Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

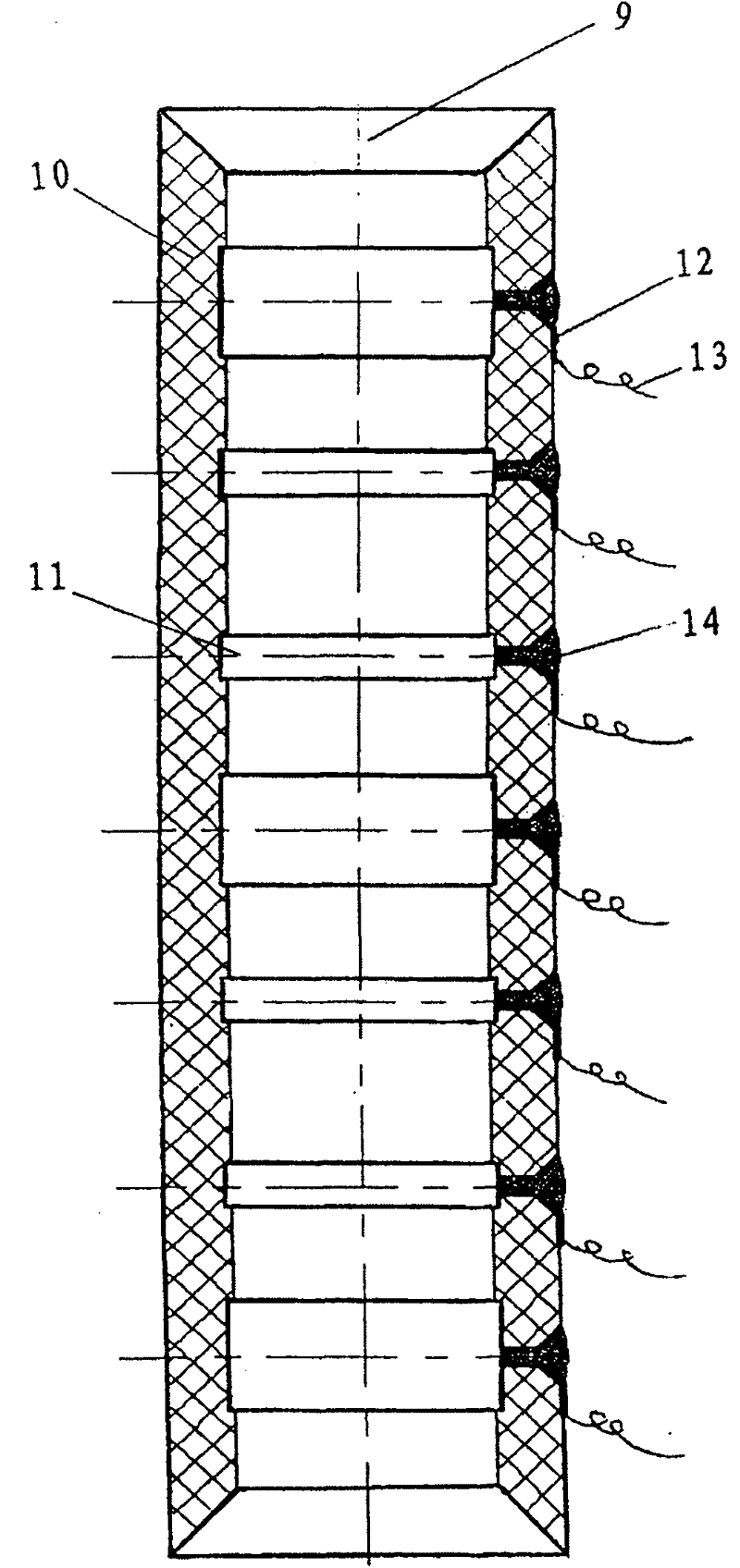

[0038] The present invention will be further described now in conjunction with accompanying drawing. image 3 The basic structure of the conductance cell guide tube of the seven-electrode conductivity sensor of the present invention is shown.

[0039] Such as image 3 As shown, in the small cylinder of the conductivity cell 9 of the seven-electrode conductivity sensor involved in the present invention, there is a quartz crystal guide tube 10 made of precision machining and integral lathing, and the upper water inlet and the lower water outlet of the guide tube 10 are in the shape of horns respectively. mouth shape. The inner wall of the draft tube 10 has seven platinum-coated ring electrodes 11 arranged up and down. The rings of the seven platinum-coated ring electrodes 11 are arranged in parallel up and down and perpendicular to the inner wall of the draft tube 10 . The seven platinum-coated ring electrodes 11 are divided into current electrodes, voltage electrodes and gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com