N08825 composite steel plate for high-corrosion-resistance container and preparation method of N08825 composite steel plate

A composite steel plate with high corrosion resistance technology, applied in chemical instruments and methods, household containers, applications, etc., can solve problems such as difficulty in ensuring 100% bonding of plate surfaces, personal safety protection pollution, poor stability of composite performance, etc., to achieve guaranteed Corrosion resistance, extended service life, and good performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

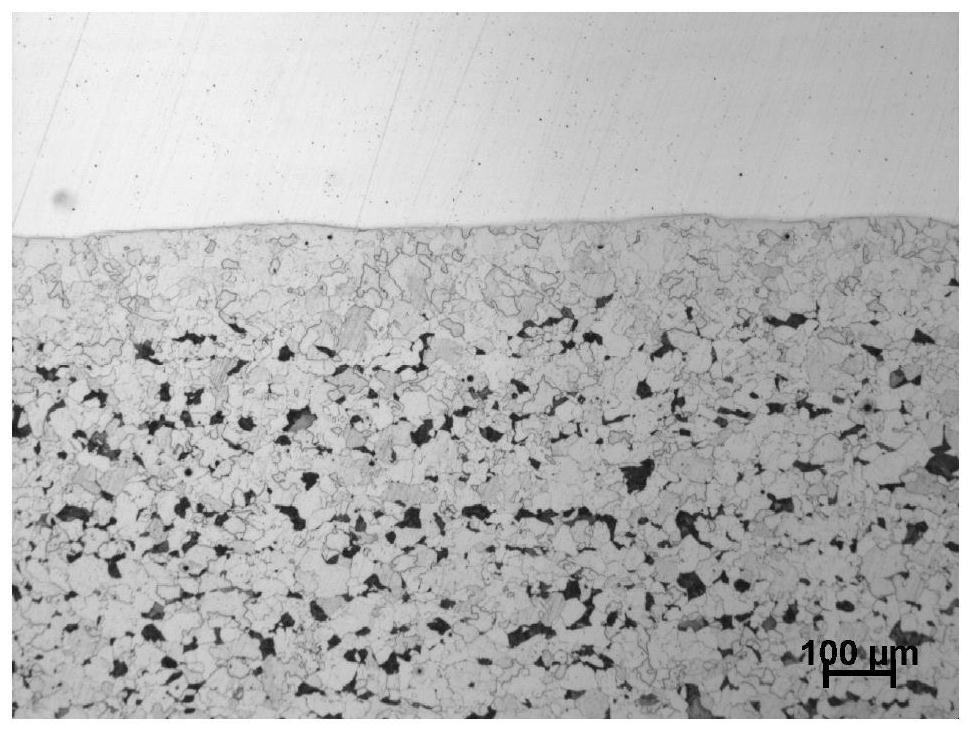

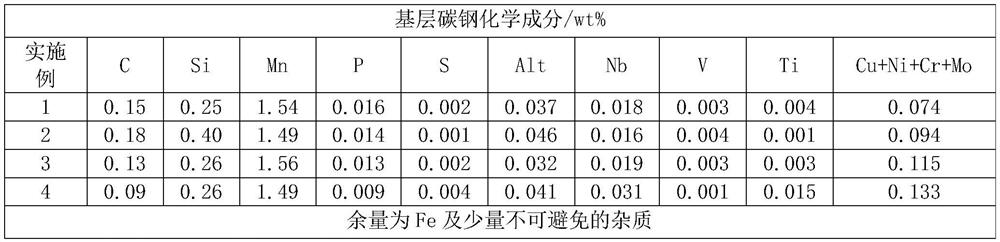

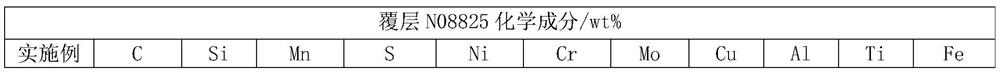

[0030] An N08825 clad steel plate for high corrosion-resistant containers and its preparation method provided in the following examples are composed of a cladding layer and a base layer, and the two are in a state of metallurgical bonding.

[0031] The preparation method specifically comprises the following steps:

[0032] S1. Billet processing: According to the material and specifications of the finished composite steel plate, prepare a pair of base and cladding blanks. Oil stains and iron oxide scale on the surface;

[0033] S1, release agent brushing: apply release agent evenly on the non-bonding surfaces of the two cladding blanks respectively, and then dry them, the drying temperature range is 300-800 °C;

[0034] S3. Blank assembly welding: Stack the blanks in the order of base-coating-coating-base-base according to the symmetrical billet assembly, and use seals to fix the upper and lower bases by spot welding. The height of the seals is between the thickness of the mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com