Reusable mounted main hoisting device

A technology of main hoisting device and hoisting equipment, which is applied in the direction of transportation, packaging, and load hanging components, etc. It can solve the problems of affecting the appearance, affecting the subsequent installation of the device to be installed, and high quality requirements for welding materials, so as to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

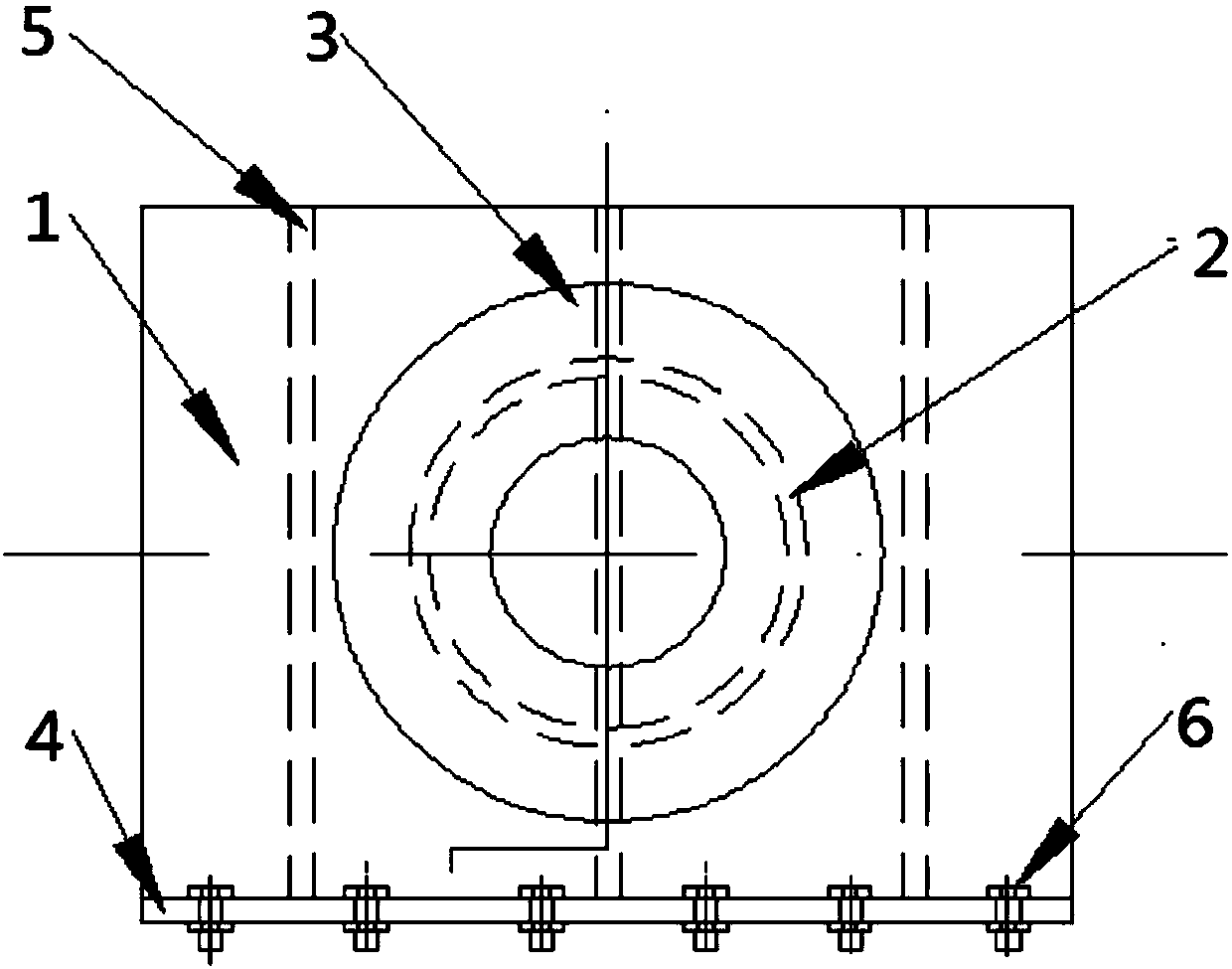

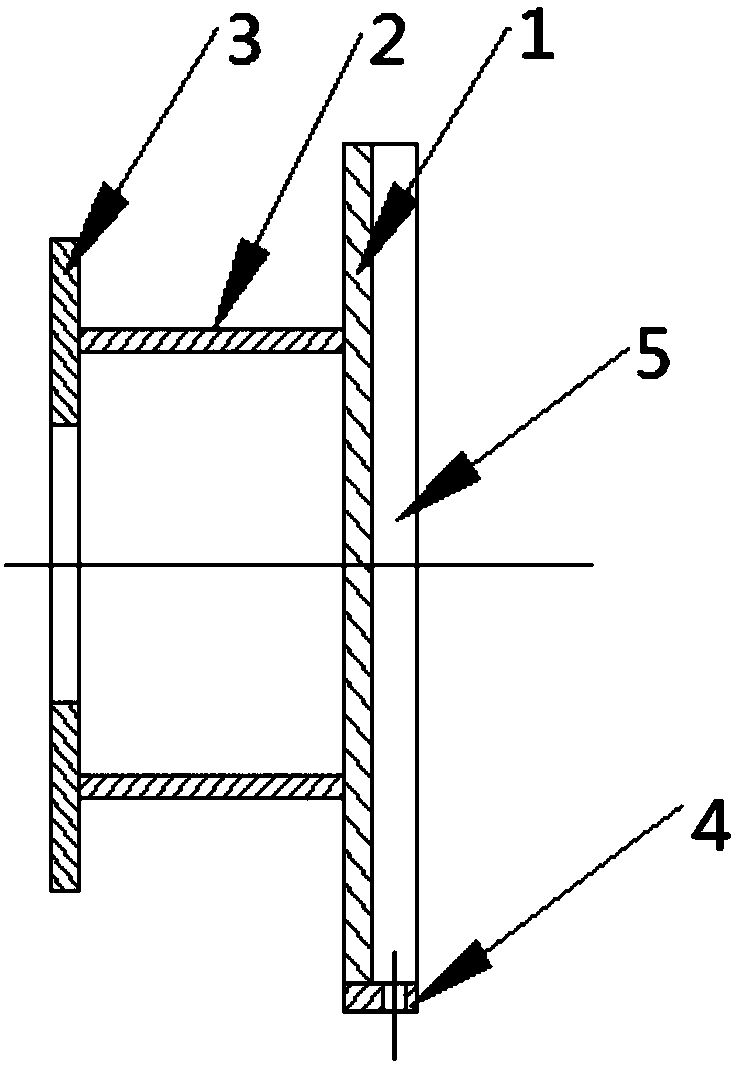

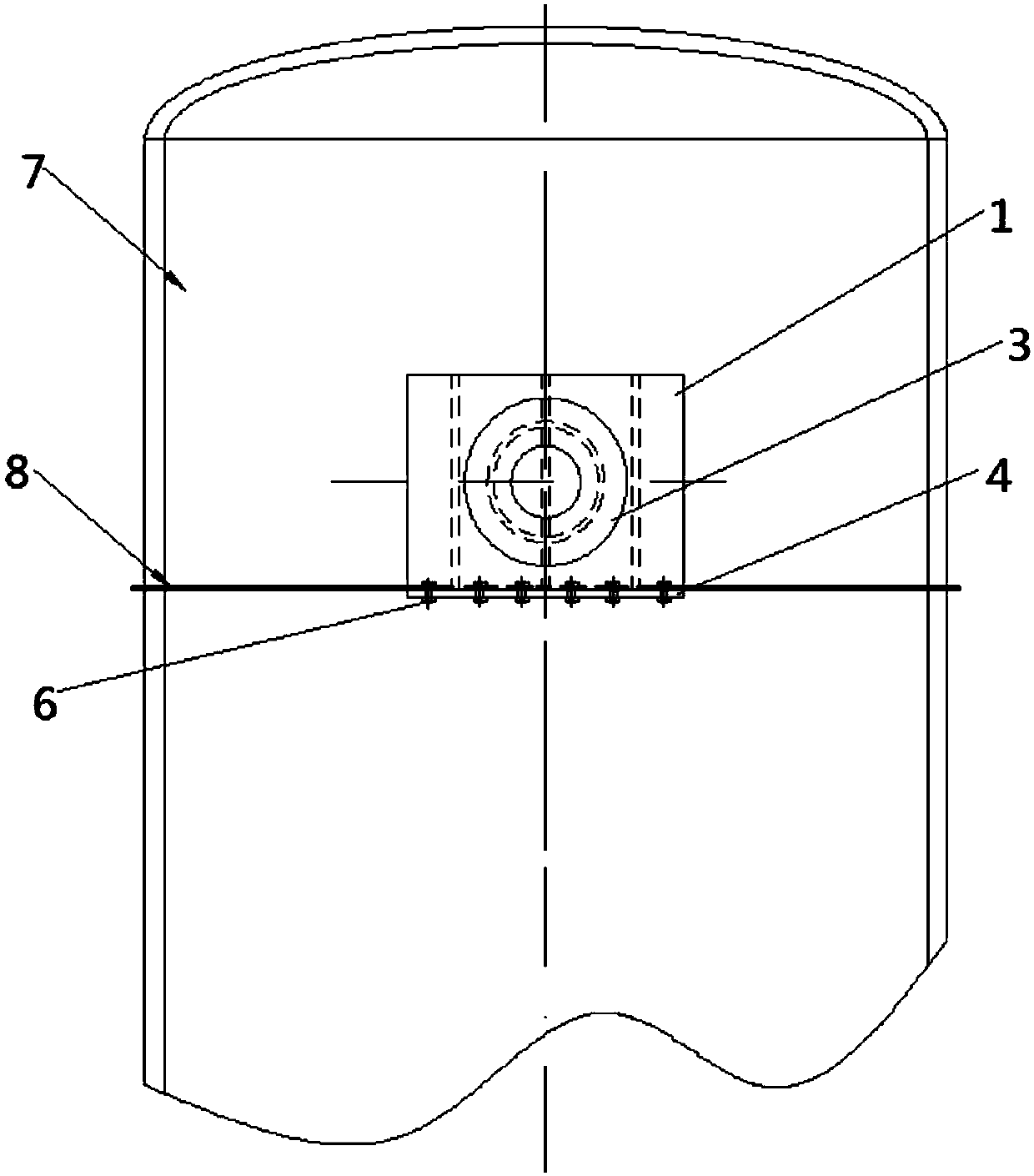

[0054] figure 1 A front view of a reusable mounted main hanger according to an exemplary embodiment of the present invention is shown. figure 2 A side view of a reusable mounted main hanger according to an exemplary embodiment of the present invention is shown.

[0055] like Figure 1-Figure 2 As shown, a reusable installation type main suspension device of the present embodiment includes:

[0056] The lifting lug main board 1, the lifting lug main board 1 is arc-shaped, matching the outer wall of the lifting device 7;

[0057] The lifting lug tube shaft 2, the lifting lug tube shaft 2 is arranged in front of the lifting lug main board 1;

[0058] The lifting lug baffle 3, the lifting lug baffle 3 is arranged in front of the lifting lug tube shaft 2;

[0059] The connecting plate 4 is arranged under the main plate 1 of the lifting lug, and the connecting plate 4 is provided with a connecting hole.

[0060] Among them, the installed main hoisting device also includes:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com