Boiler tube bank suspension device

A suspension device and boiler tube technology, applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve problems such as increased costs, difficulties, and large stress, and achieve cost savings for enterprises, easy suspension, and support Effect of reduced space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

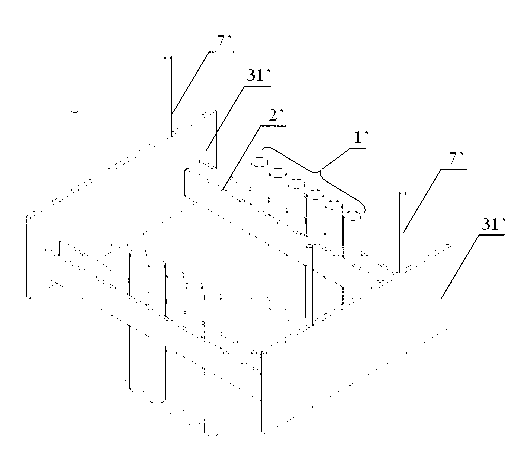

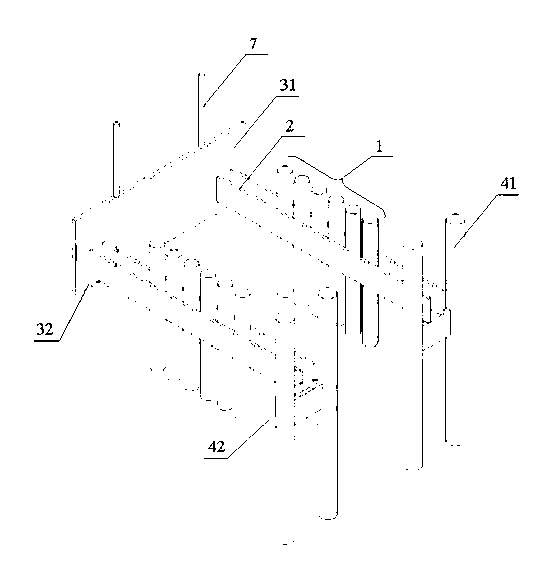

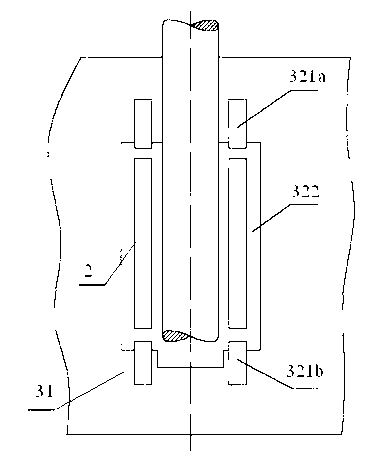

[0032] The following combination Figure 2~Figure 6 The invention is further elaborated, and a preferred embodiment of the invention is described in detail.

[0033] Such as figure 2 As shown, a boiler tube row suspension device includes a tube row 1, a pair of clamping steel plates 2, an end plate suspension device 3, a suspension tube support 4 and a boom 7, and the end plate suspension device 3 includes end The plate 31 and the end plate support 32 vertically arranged on the end plate 31; the suspension tube suspension device 4 includes a suspension tube 41 and a suspension tube support 42 arranged between the suspension tubes 41; the clamping steel plate 2 One end is set on the end plate suspension device 3, the other end is set on the suspension tube suspension device 4, and both ends of the clamping steel plate 2 can also be set on the suspension tube suspension device 4, in this embodiment One end of the clamping steel plate 2 is set on the end plate suspension devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com