Patents

Literature

63results about How to "Reduce construction hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for monitoring oil-gas pipeline in mining subsidence area and system constructing method

InactiveCN102345793AReveal Security WarningReveal collapse featuresPipeline systemsUsing optical meansRelative displacementGas pipeline

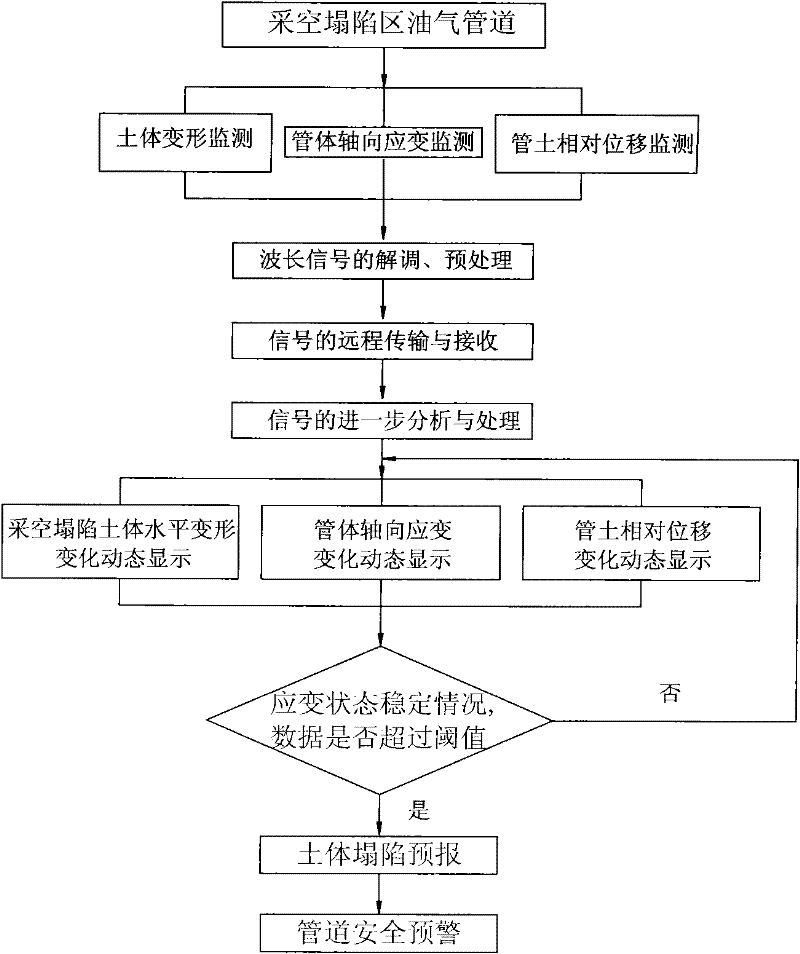

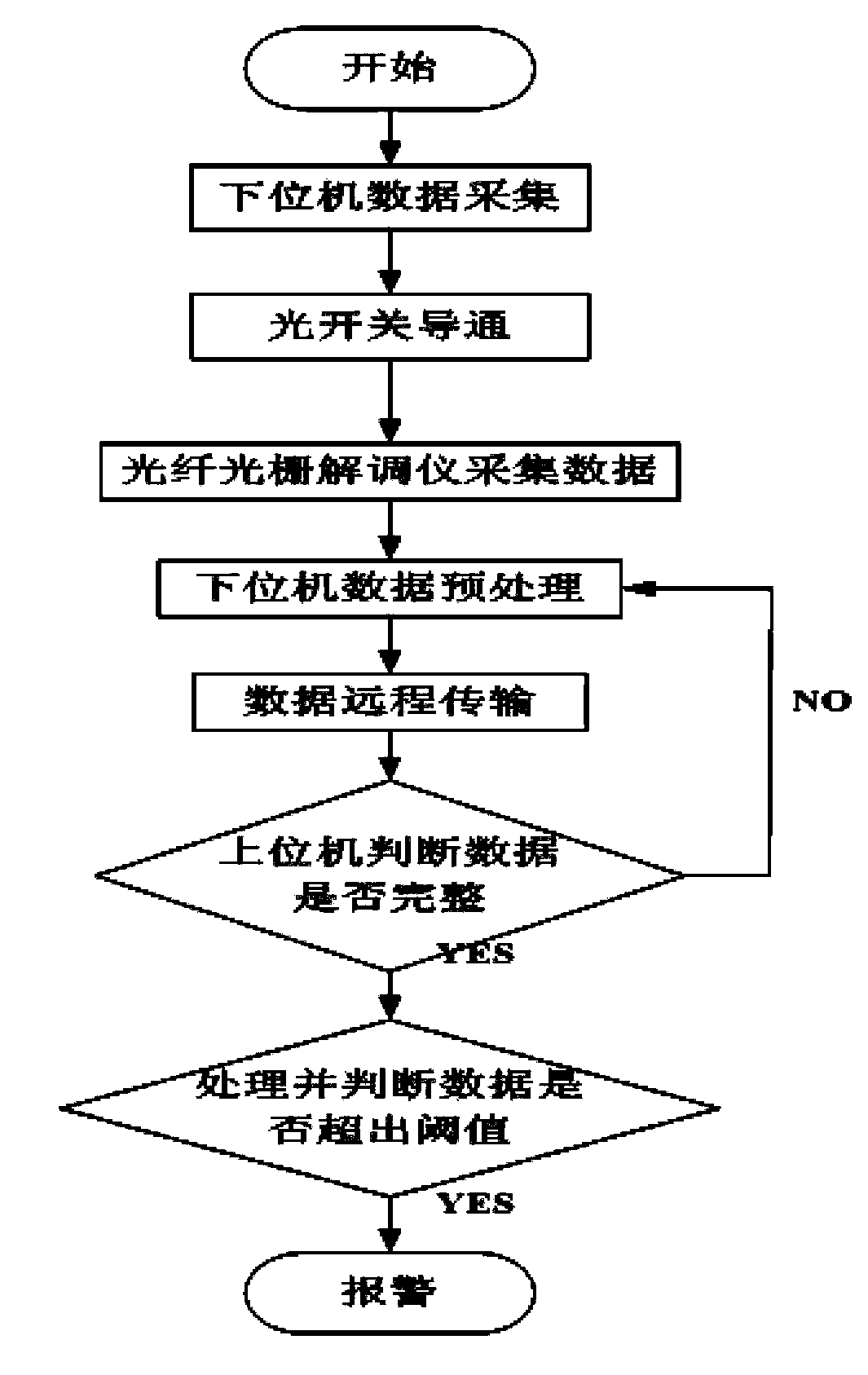

The invention discloses a method and a system for monitoring an oil-gas pipeline in a mining subsidence area and a system constructing method. The method comprises the following steps of: monitoring axial strain of a pipe body with a fiber grating strain sensor, monitoring pipe-soil relative replacement with a fiber grating displacement sensor, and monitoring horizontal deformation of a soil body with a fiber grating sensor; demodulating and preprocessing signals acquired by the sensors, and transmitting the signals to a remote monitoring center; further analyzing and processing data in the monitoring center, and computing horizontal deformation change of a soil body on the top of the pipe in the mining subsidence area, axial strain change of the pipe body and pipe-soil relative displacement change; judging the state stabilities of the pipe body strain change and the soil body strain change, and judging whether the data surpass threshold values; when three parameter values are smaller than respective threshold values, judging that the pipeline is in a safe state; and when the axial strain of the pipe body reaches 70 percent of a pipe body limit strain value, or a pipe-soil relative displacement value reaches a threshold value and keeps constant, or a horizontal deformation curve of the soil body changes suddenly, performing pipeline safety joint early-warning.

Owner:PETROCHINA CO LTD

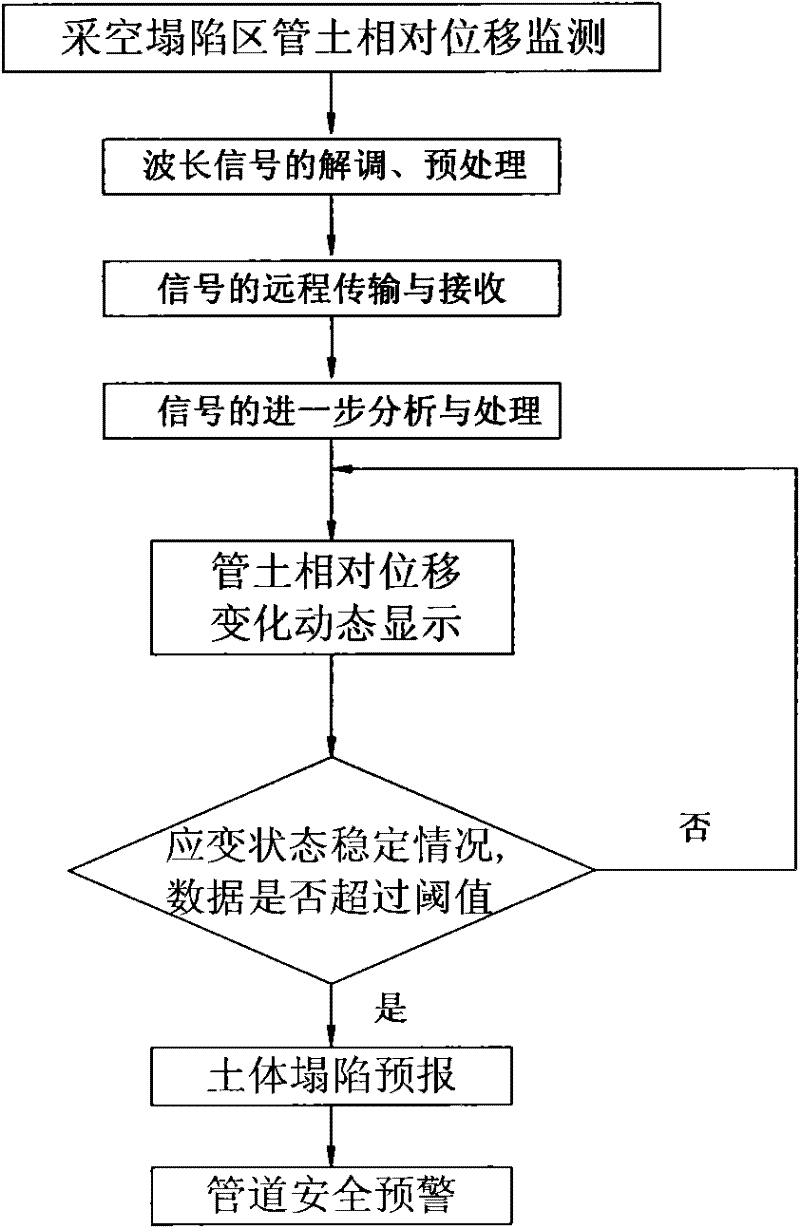

Method for monitoring oil-gas pipeline in mining subsidence area

ActiveCN102345796AReveal Security WarningReveal collapse featuresPipeline systemsUsing optical meansRelative displacementGrating

The invention discloses a method for monitoring an oil-gas pipeline in a mining subsidence area based on a fiber grating sensing technology. The method comprises the following steps of: monitoring pipe body axial strain with a fiber grating strain sensor, monitoring pipe-soil relative replacement with a fiber grating displacement sensor, and monitoring soil body horizontal deformation with a fiber grating sensing network; demodulating and preprocessing signals acquired by the sensors, and transmitting the signals to a remote monitoring center; further analyzing and processing data in the monitoring center, and computing mining subsidence soil body horizontal deformation change, pipe body axial strain change and pipe-soil relative displacement change; judging the state stabilities of the pipe body strain change and the soil body strain change, and judging whether the data surpass threshold values; when three parameter values are smaller than respective threshold values, judging that the pipeline is in a safe state; and when the pipe body axial strain reaches 70 percent of a pipe body limit strain value, or a pipe-soil relative displacement value reaches a threshold value and keeps constant, or a soil body horizontal deformation curve changes suddenly, performing pipeline safety joint early-warning.

Owner:PIPECHINA SOUTH CHINA CO

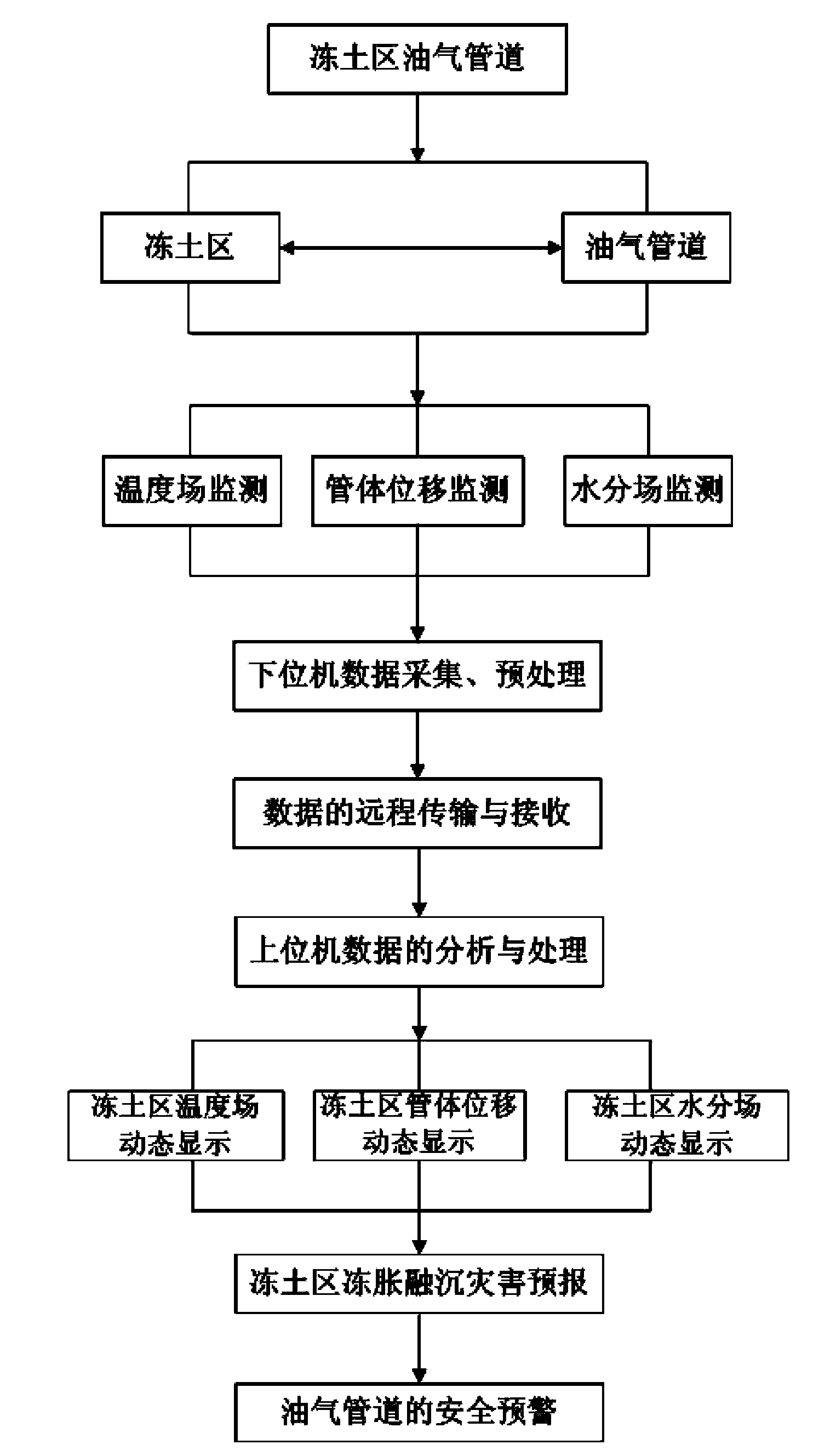

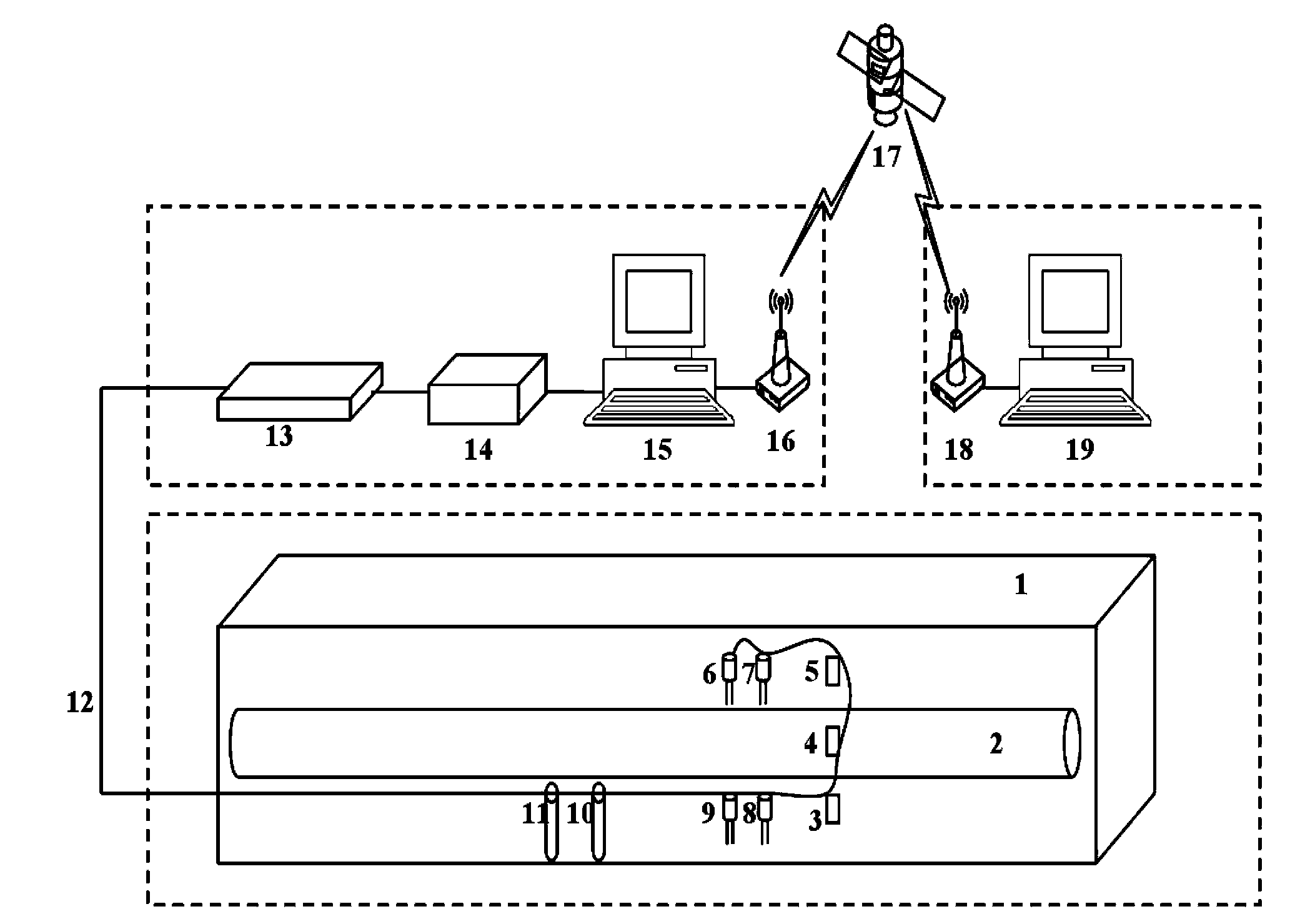

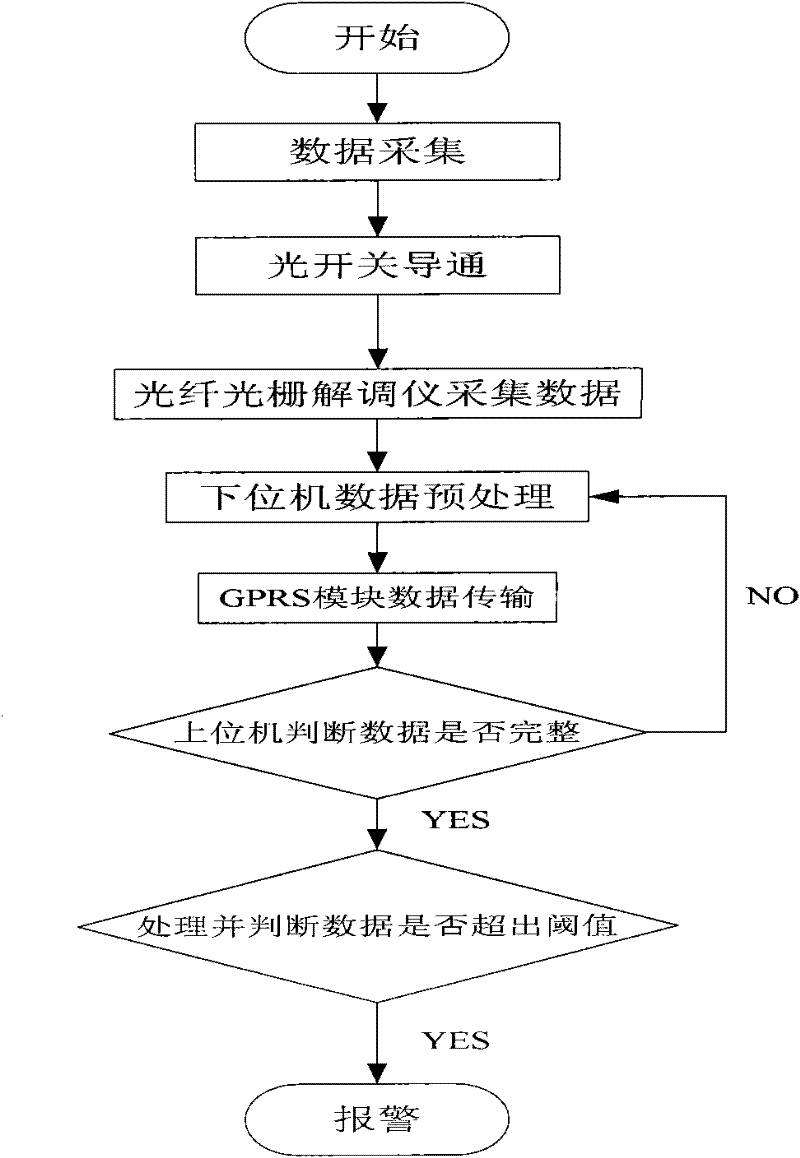

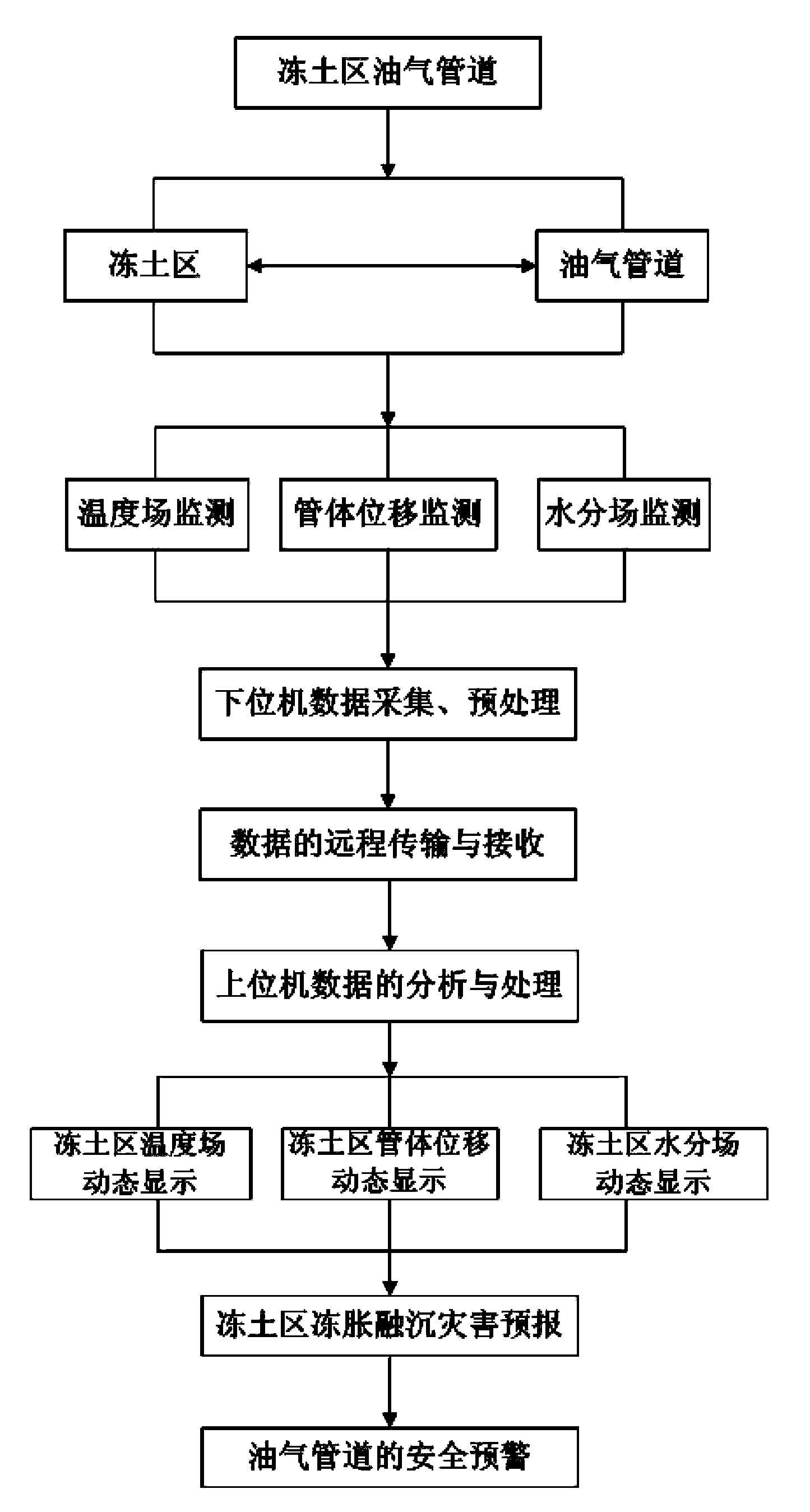

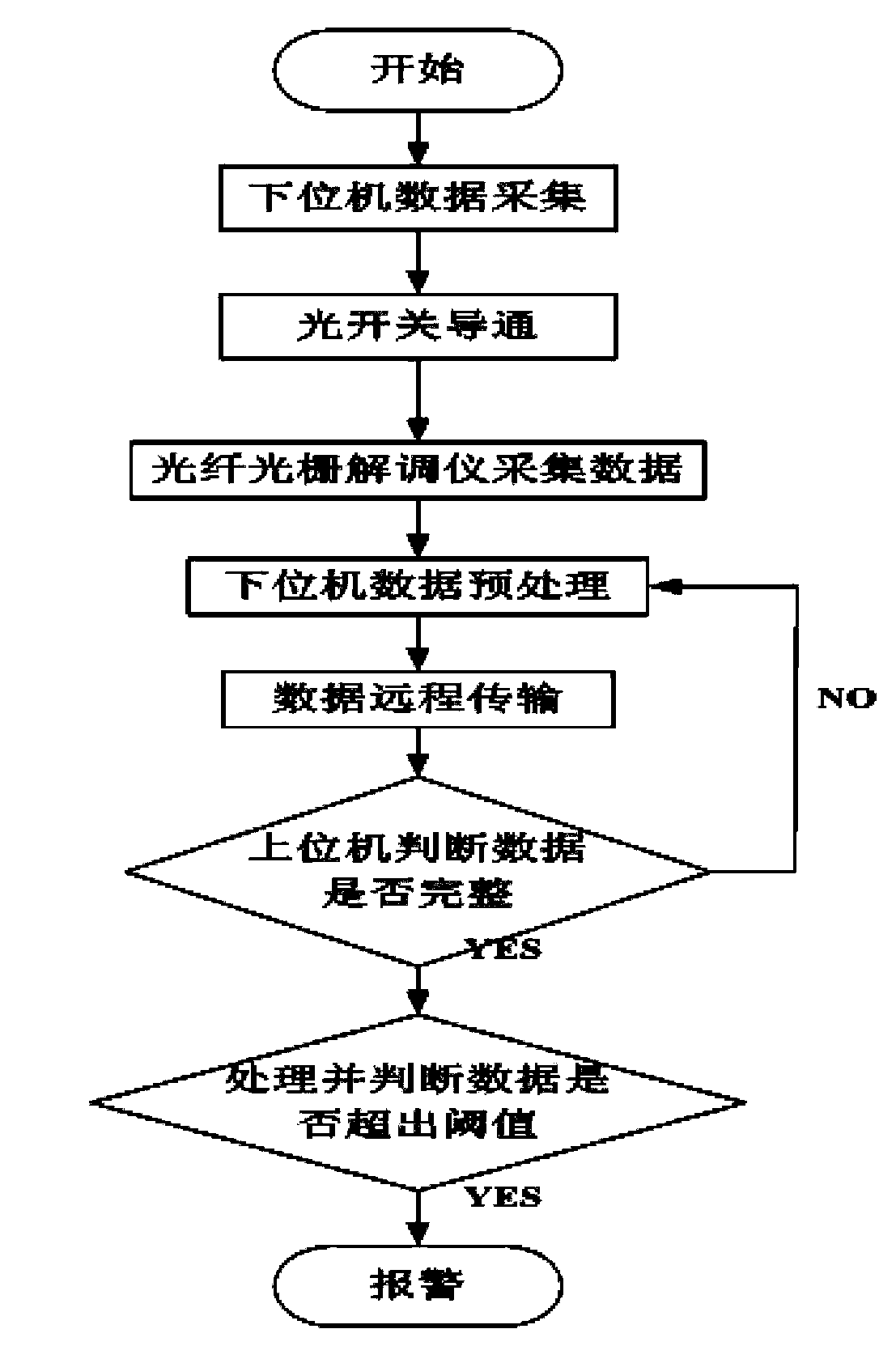

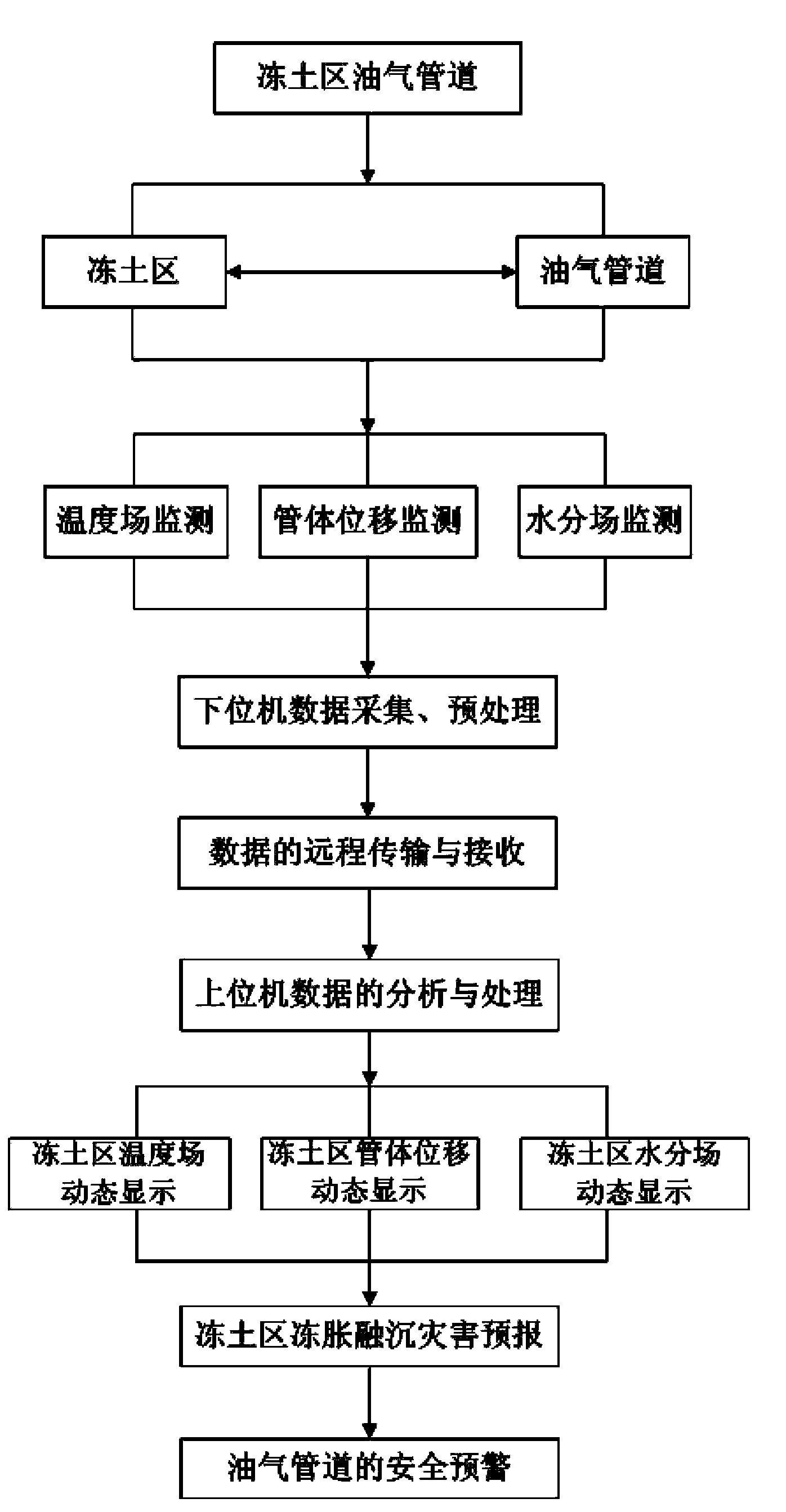

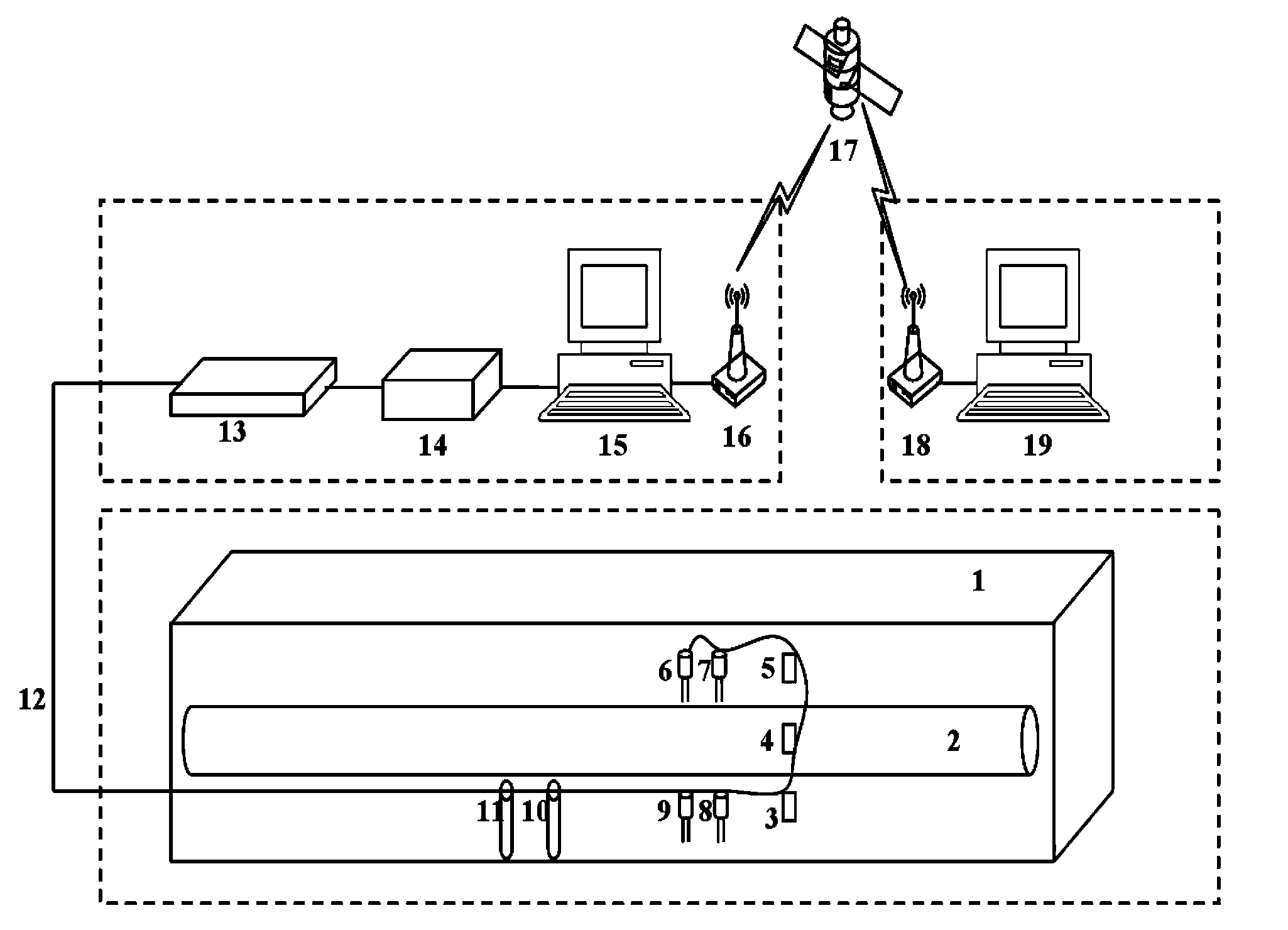

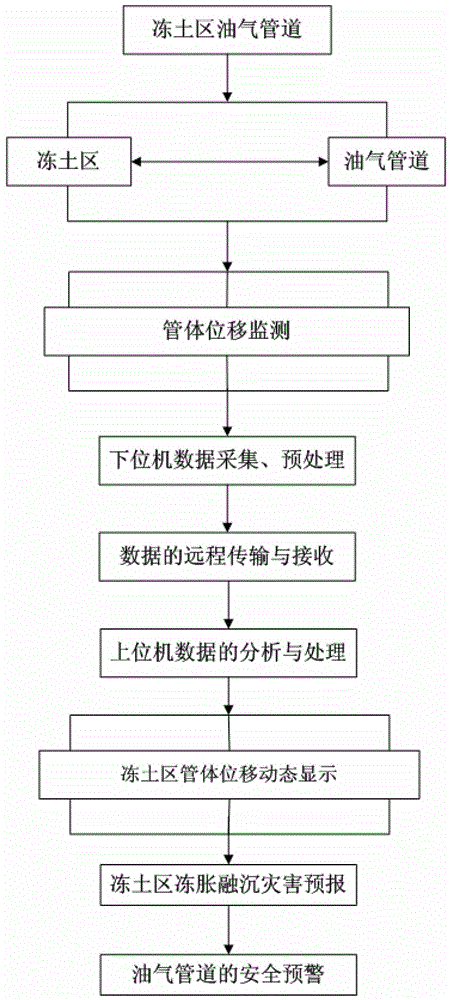

Freeze soil area oil and gas pipeline monitoring method and system

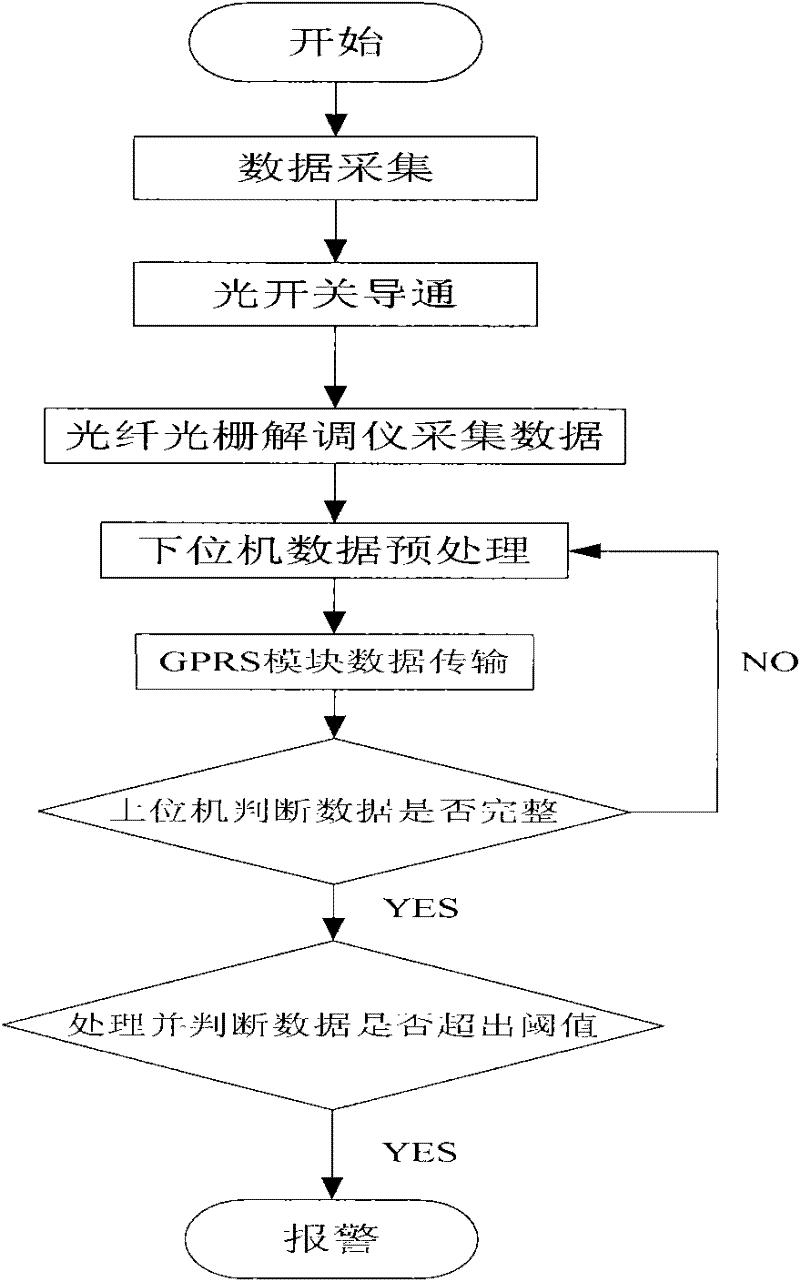

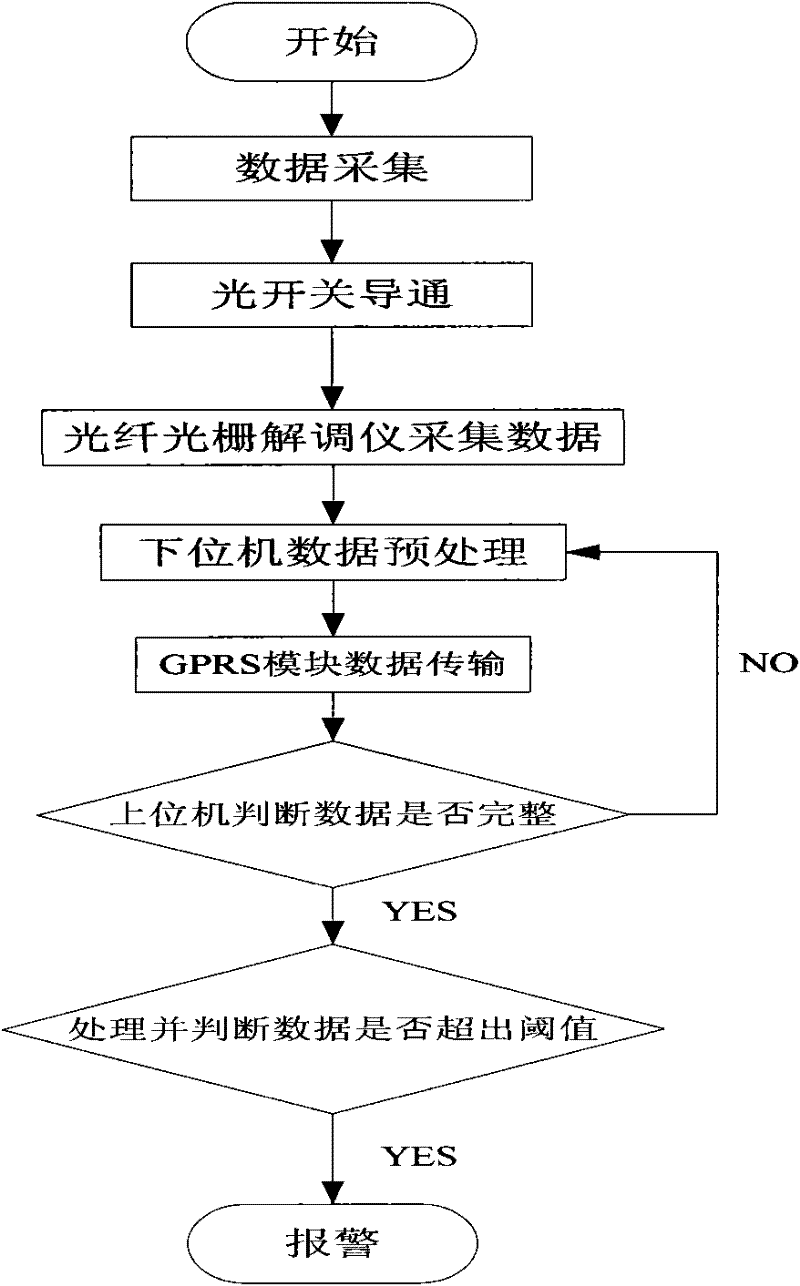

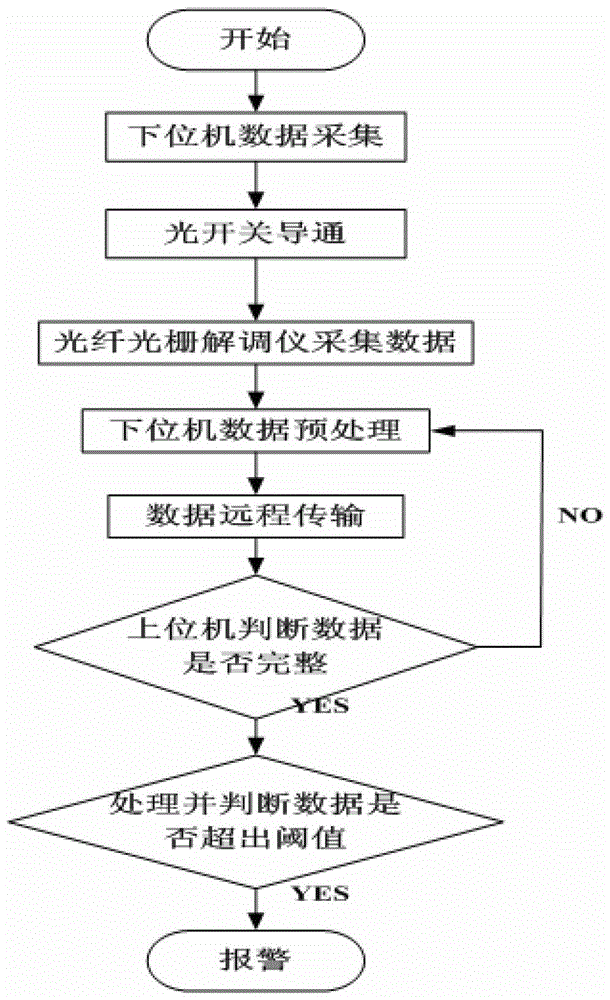

ActiveCN103383241AAvoid displacementLow running costForce measurementMaterial analysis by optical meansFiberPhotoswitch

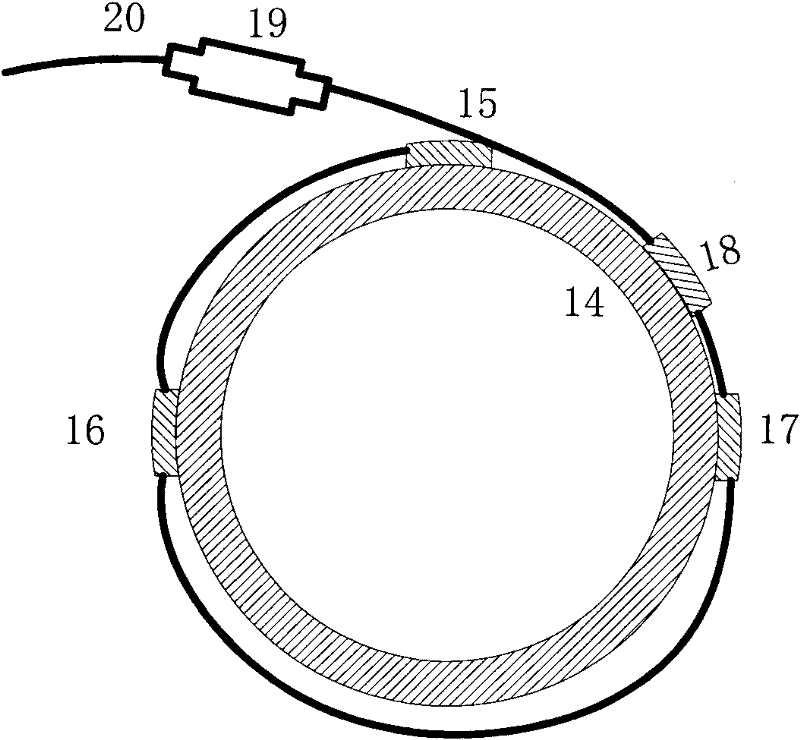

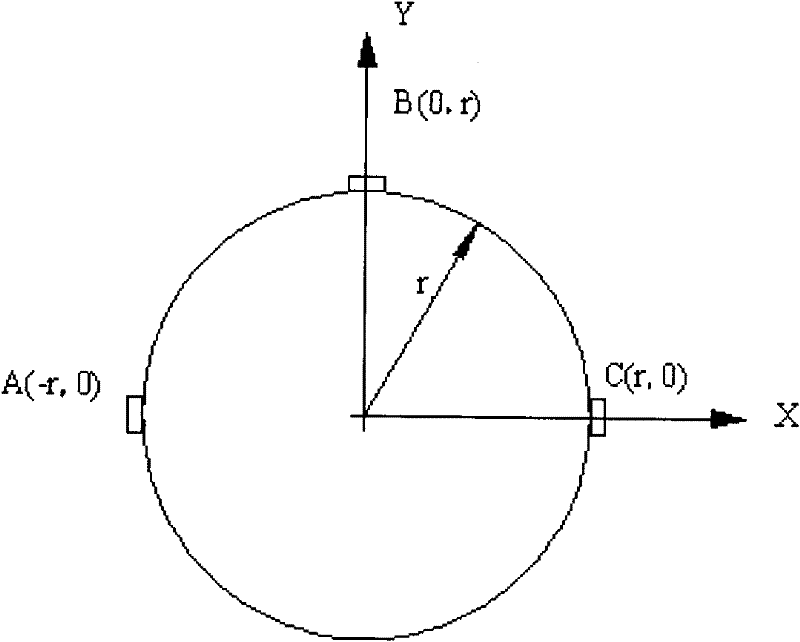

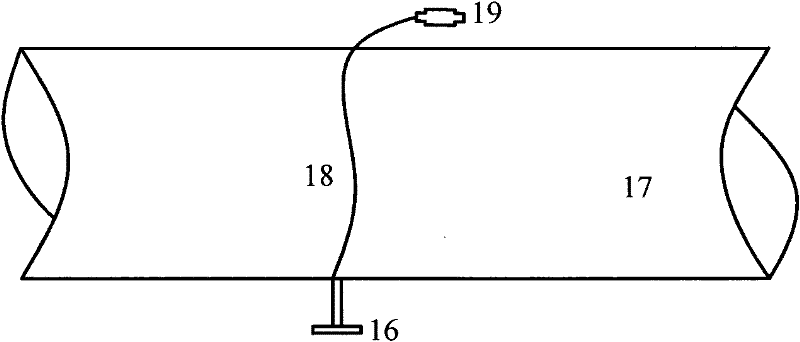

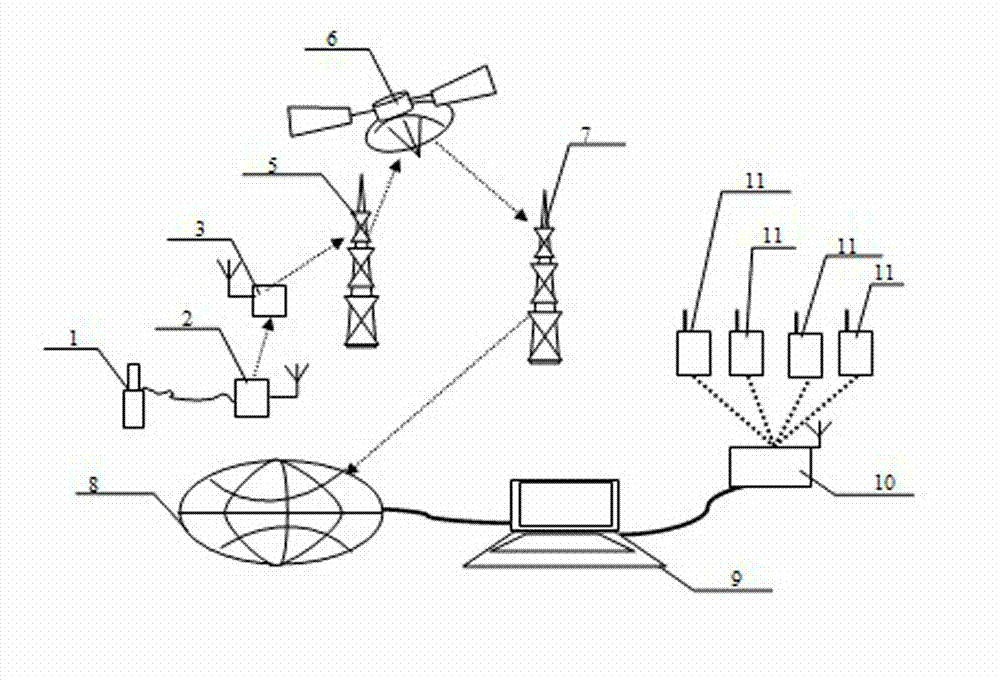

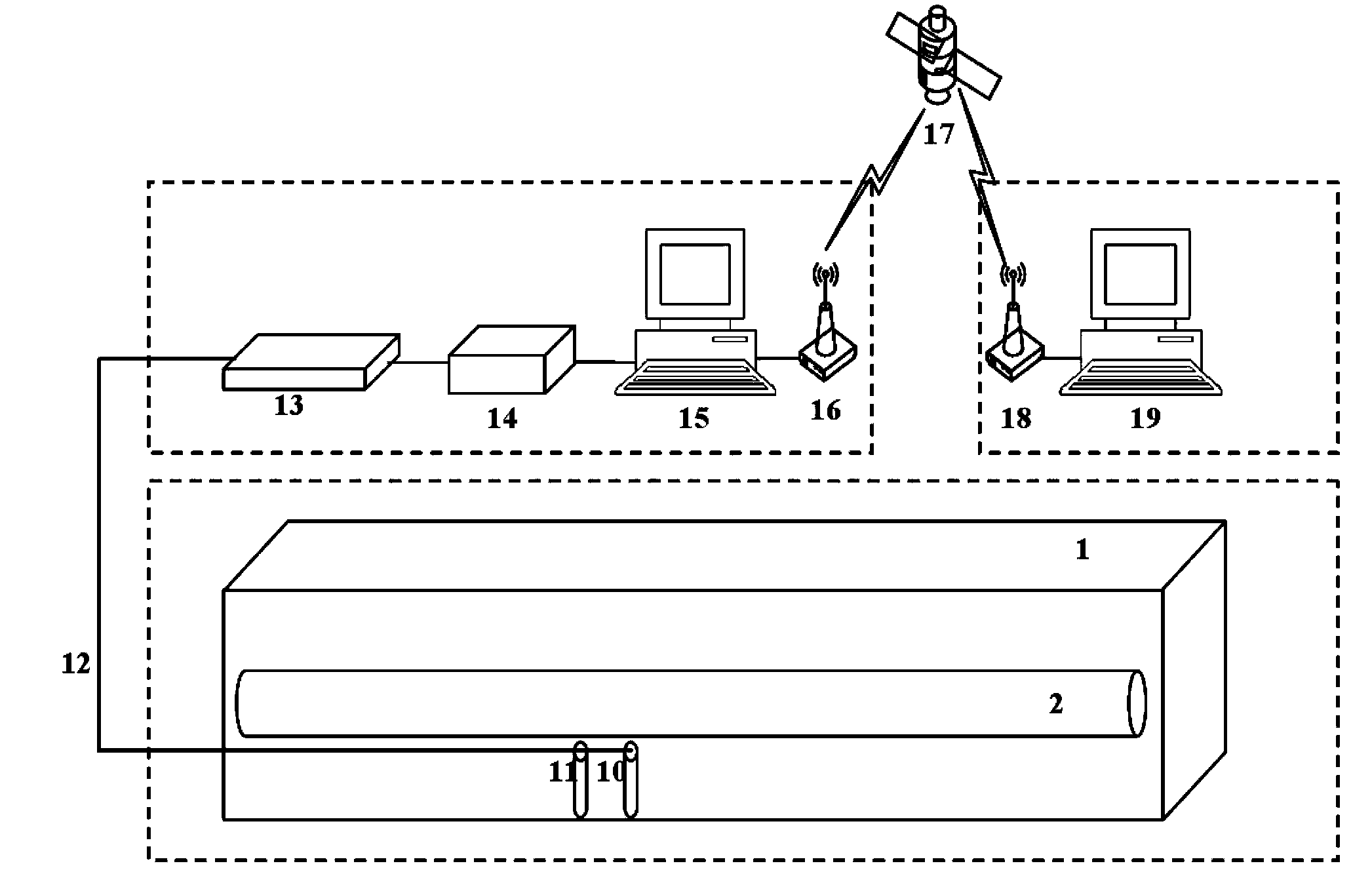

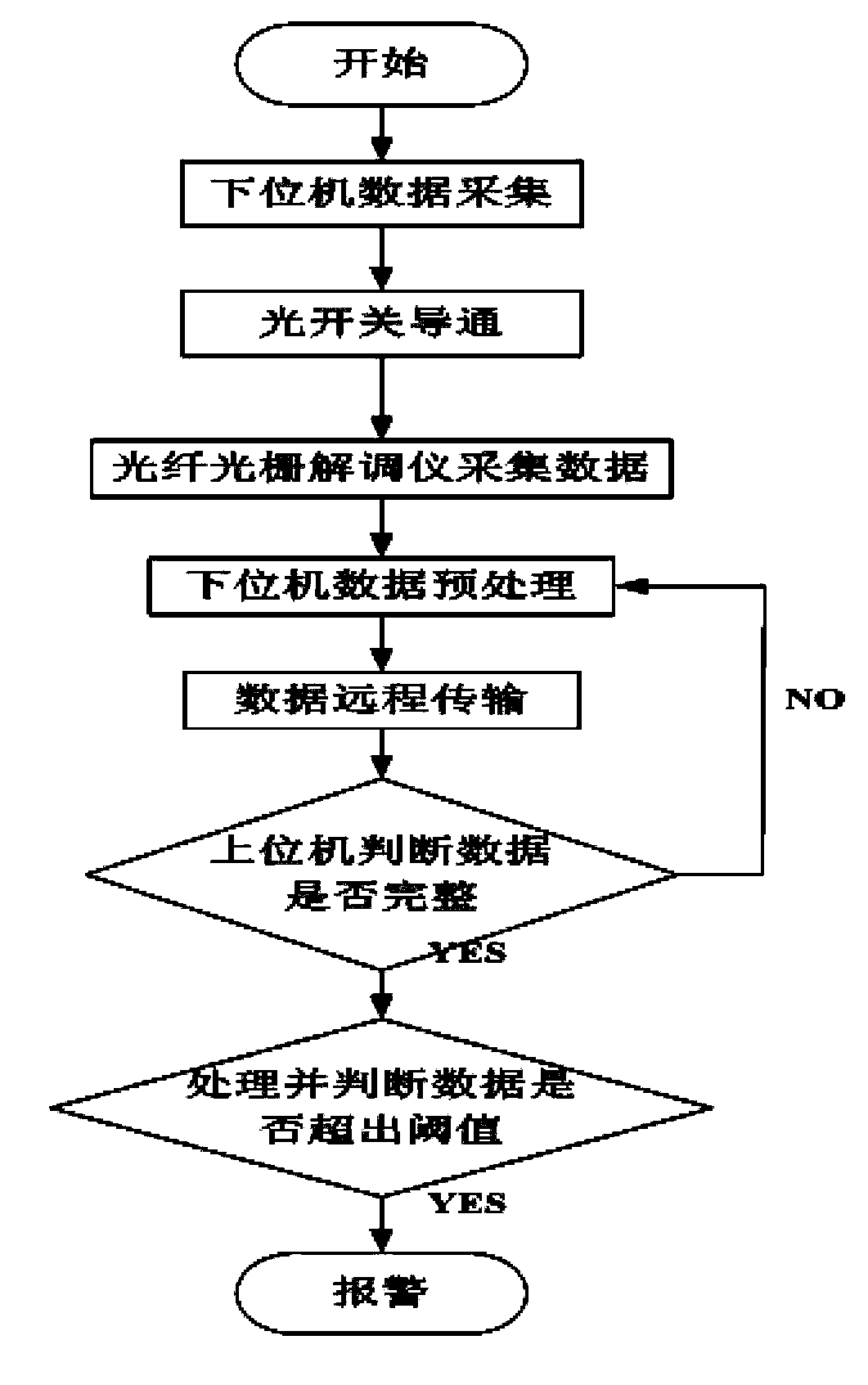

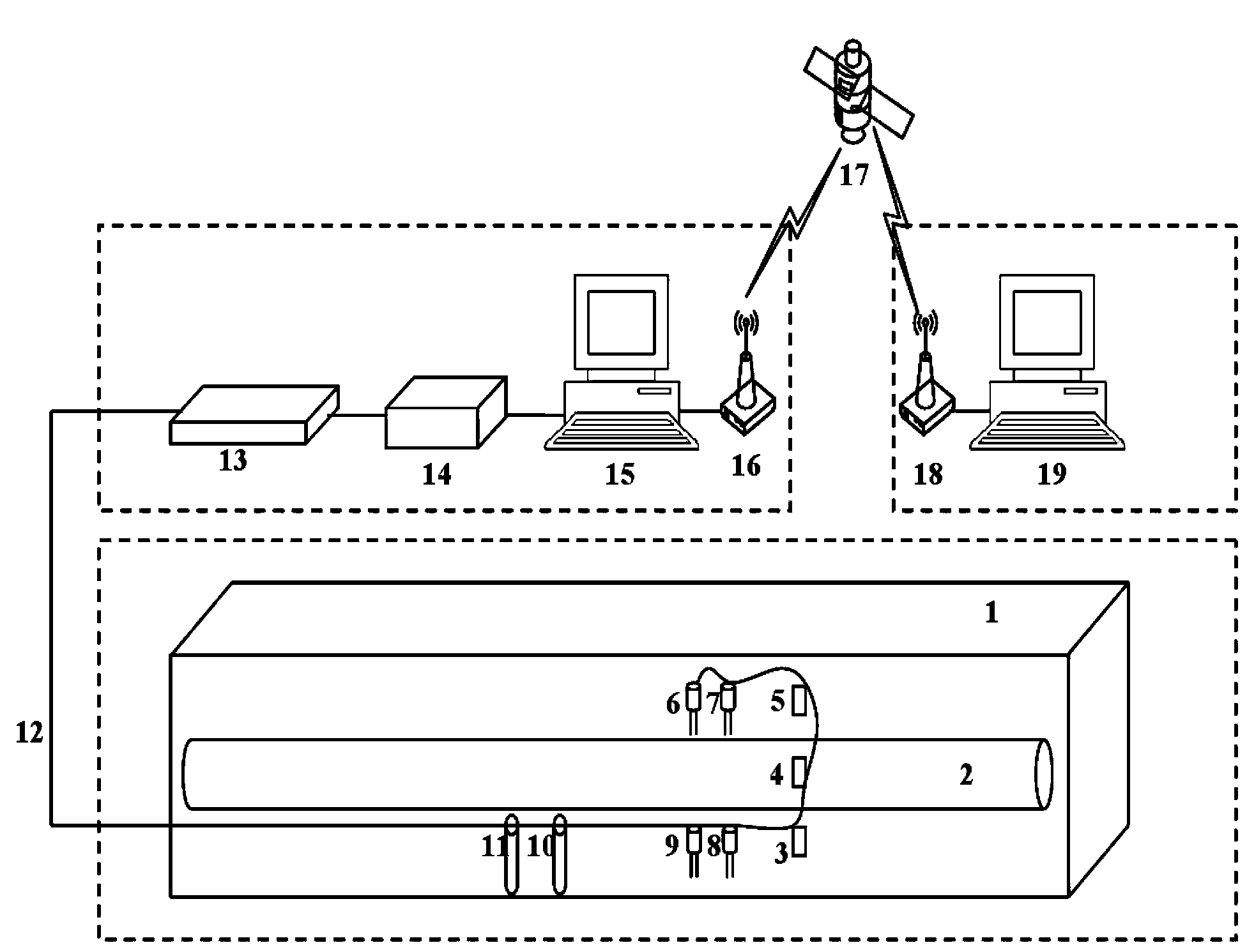

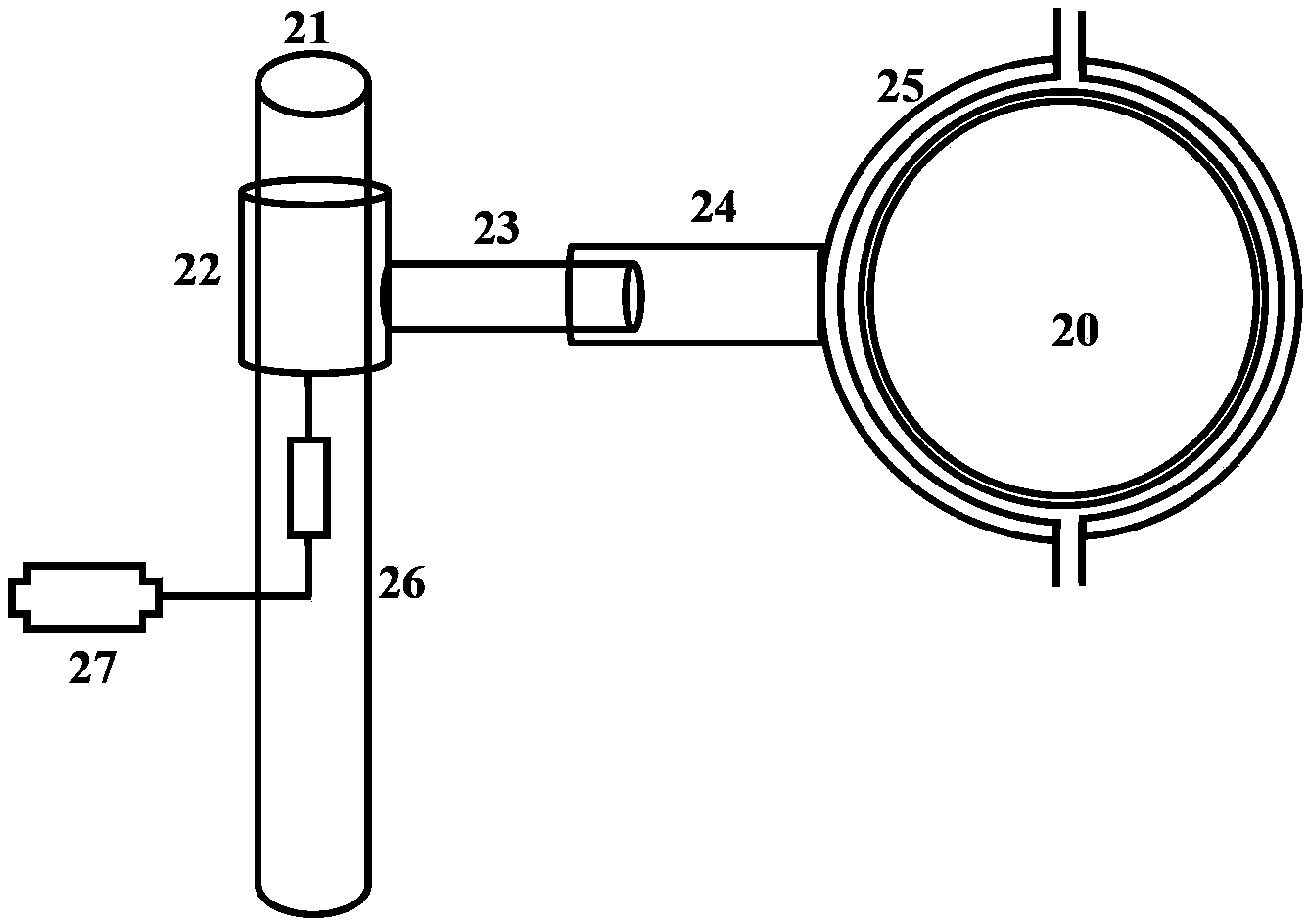

The invention discloses a freeze soil area oil and gas pipeline monitoring method and system. The freeze soil area oil and gas pipeline monitoring method includes the steps of conducting monitoring on the temperatures and the moisture around pipelines and the displacement of a tube bodies through temperature sensor sets, moisture sensor sets and fiber bragg grating displacement sensor sets respectively, sending signals obtained through monitoring to a photoswitch (13) through optical cables (12), sending the signals to a lower computer (15) after the signals are demodulated by an interrogator (14), enabling the lower computer (15) to call self-programmed programs, control the photoswitch (13) and the interrogator (14), collect data and preprocess the data, transmitting the preprocessed data to a low-orbit satellite (17) through a satellite communication module (16), receiving the data through the low-orbit satellite (17) and forwarding the data to a satellite communication module (18), transmitting the received data to an upper computer (19) through the satellite communication module (18), analyzing and processing the data through the upper computer (19), and judging the safety condition of the pipelines to conduct damage forecasting. The freeze soil area oil and gas pipeline monitoring method and system are high in precision, high in stability and low in cost.

Owner:PIPECHINA SOUTH CHINA CO

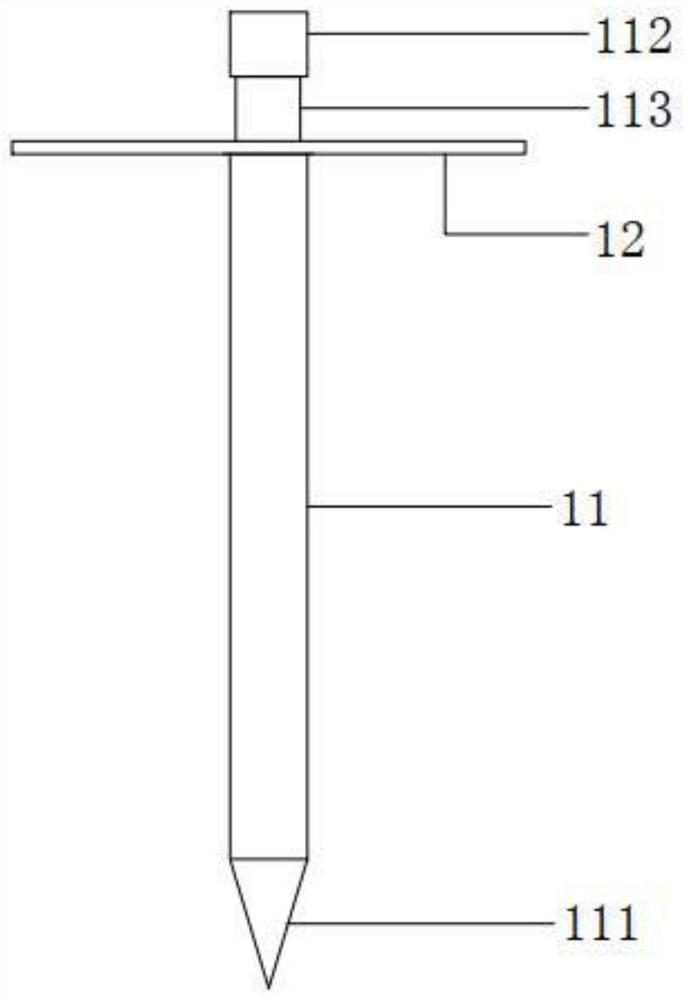

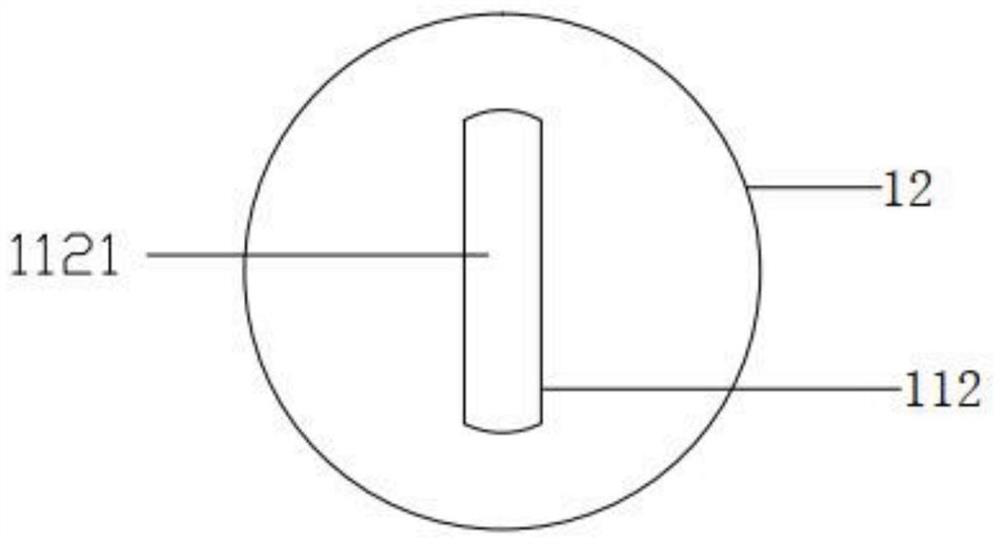

Method and system for monitoring pipe-soil relative displacement of oil-gas pipeline in mining subsidence area

ActiveCN102345795ARealize real-time automatic collectionRealize remote transmissionPipeline systemsUsing optical meansRelative displacementLength wave

Owner:PIPECHINA SOUTH CHINA CO

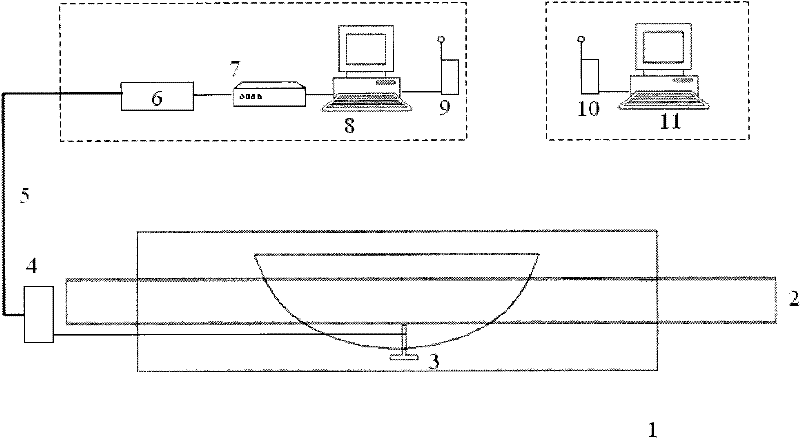

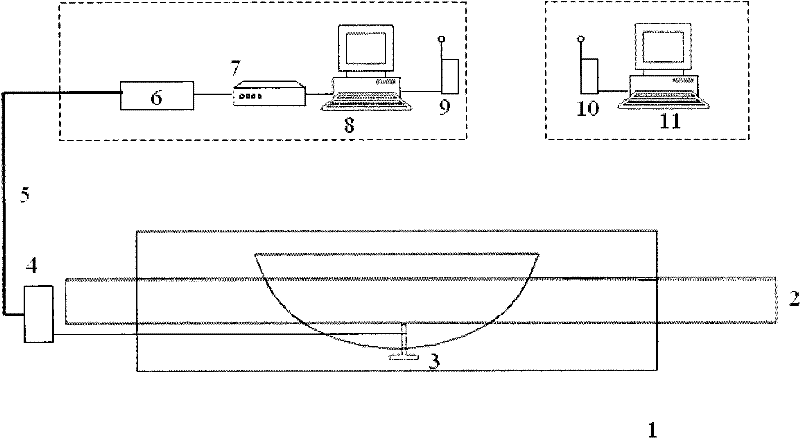

System for monitoring oil-gas pipeline in mining subsidence area and constructing method thereof

ActiveCN102345794ASimple networkingEasy to realize remote automatic real-time online monitoringPipeline systemsUsing optical meansRelative displacementStrain sensor

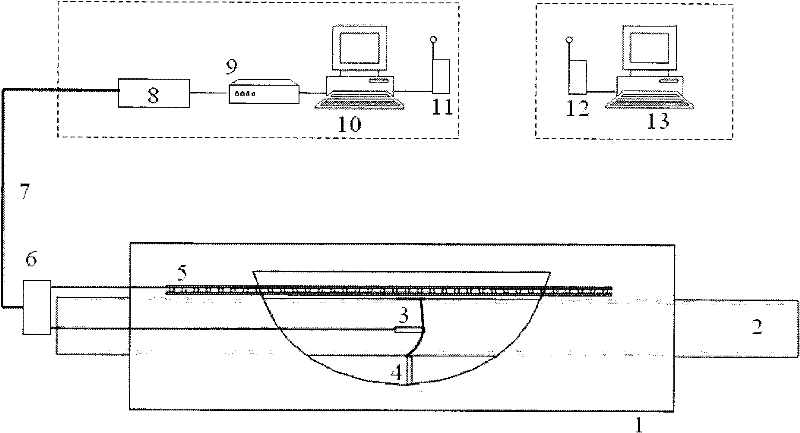

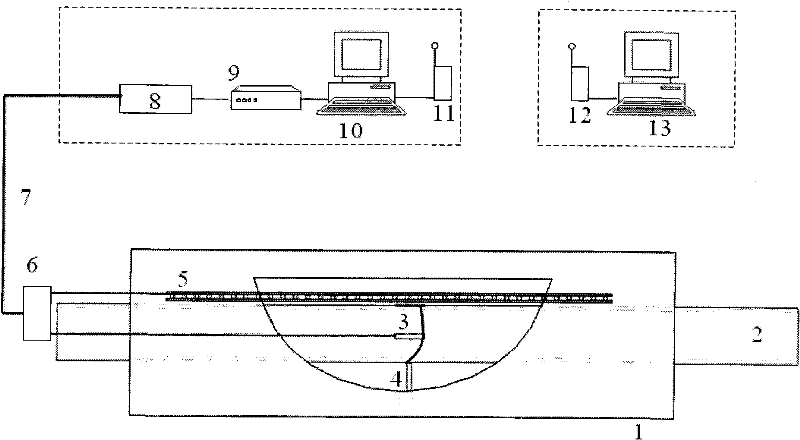

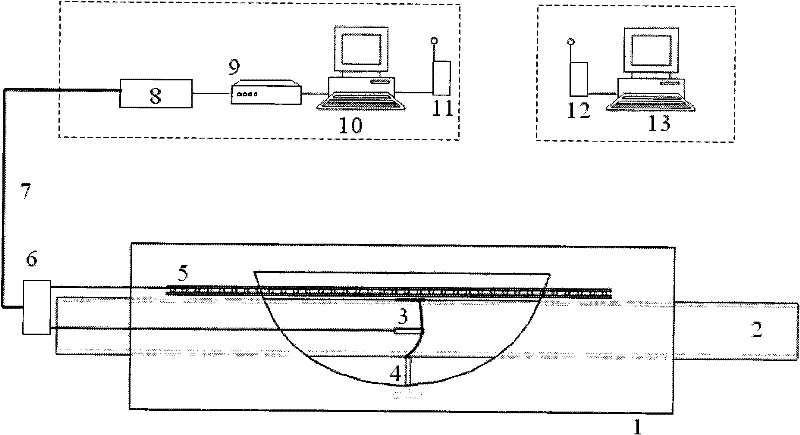

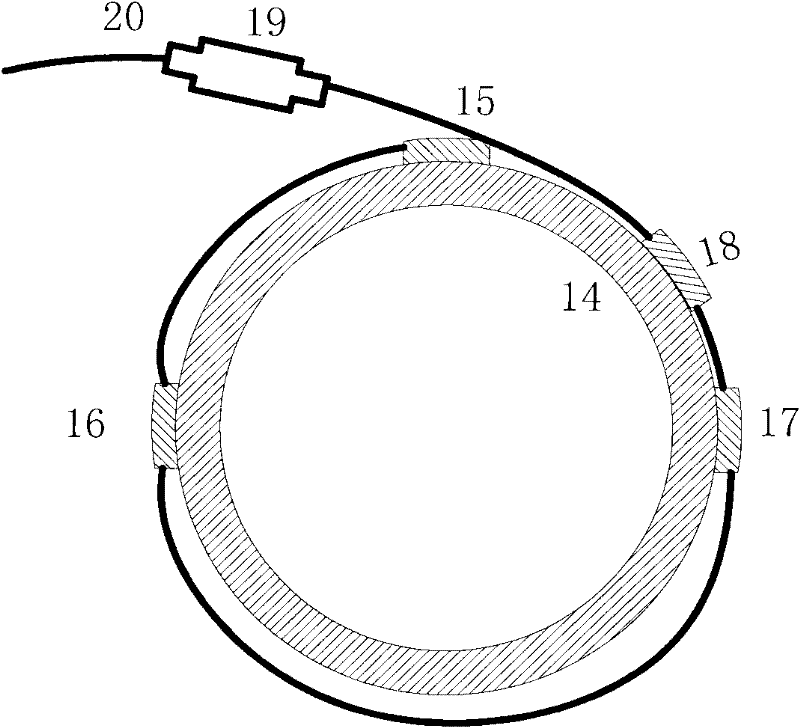

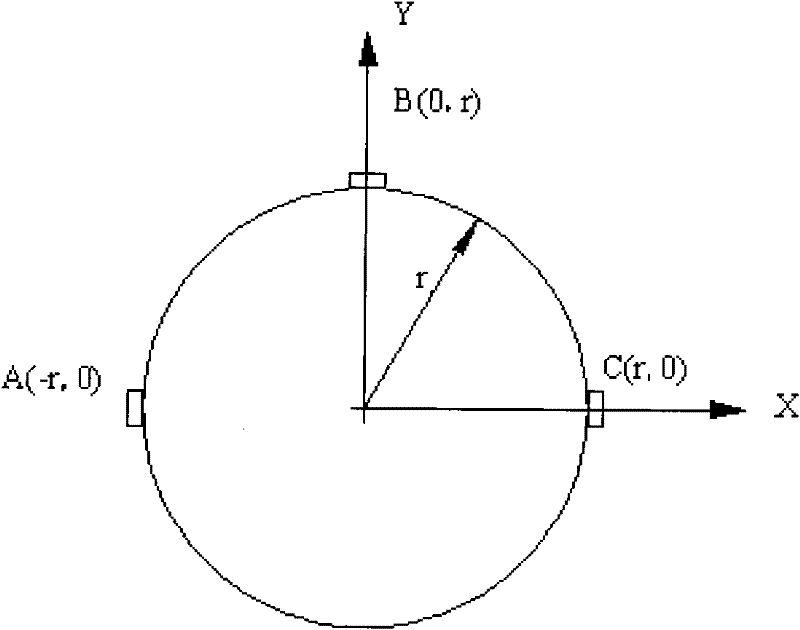

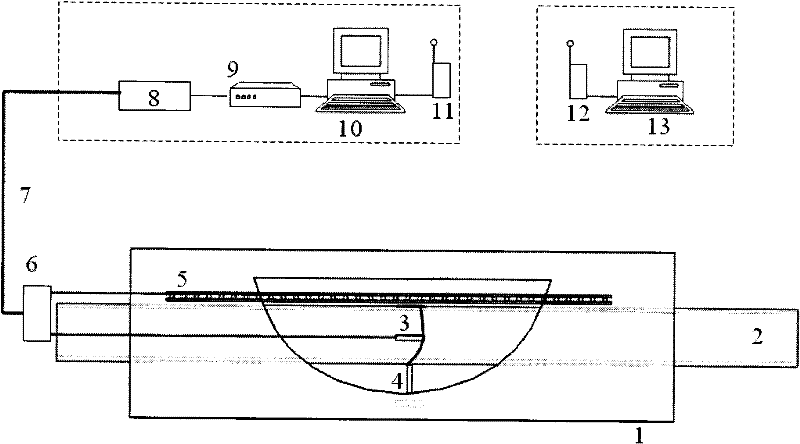

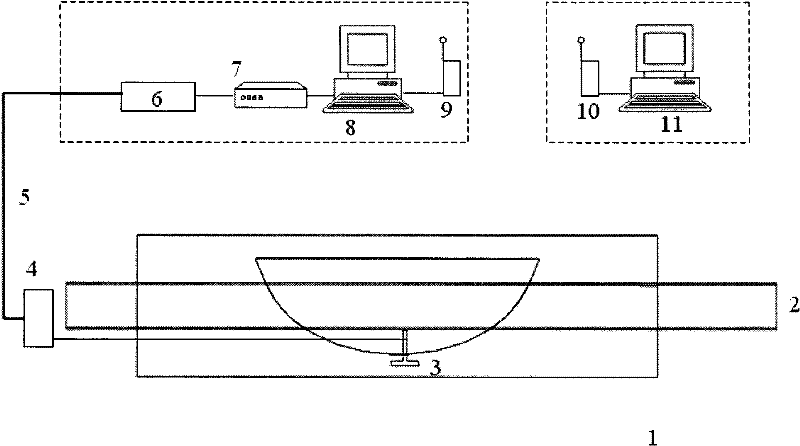

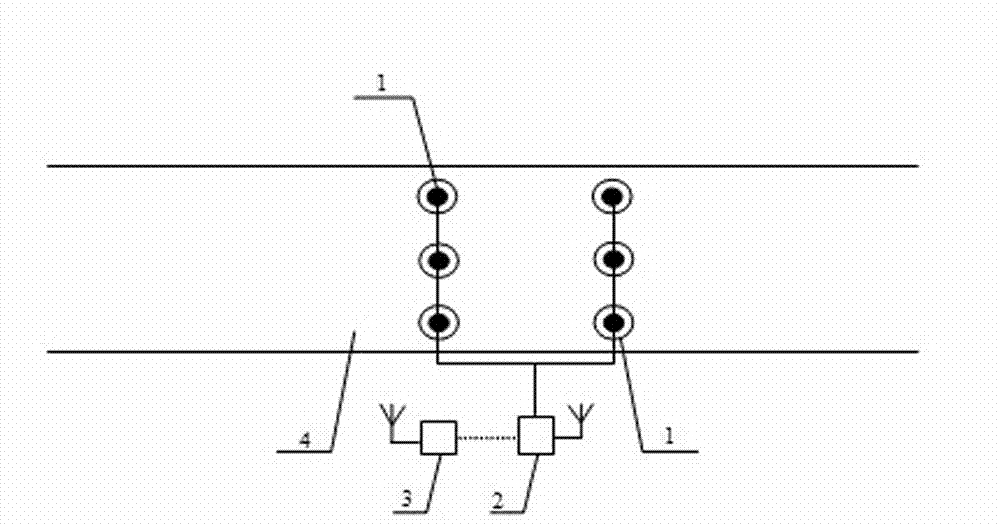

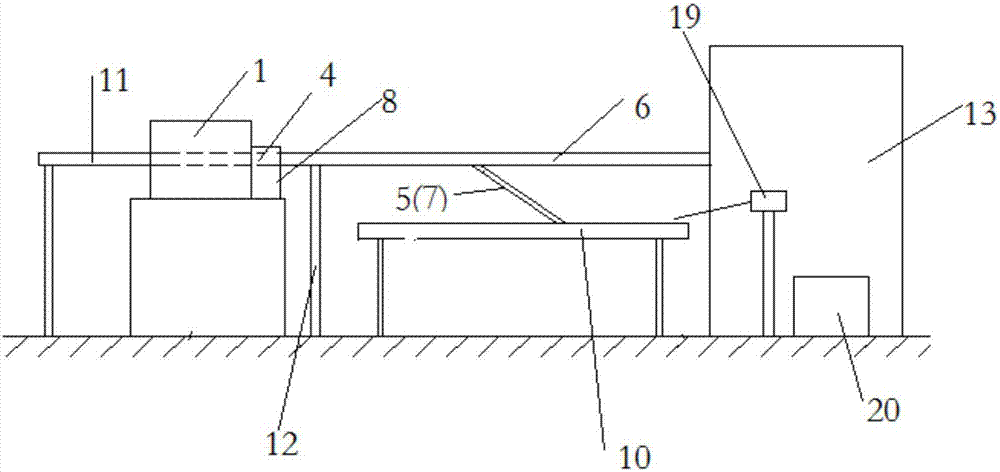

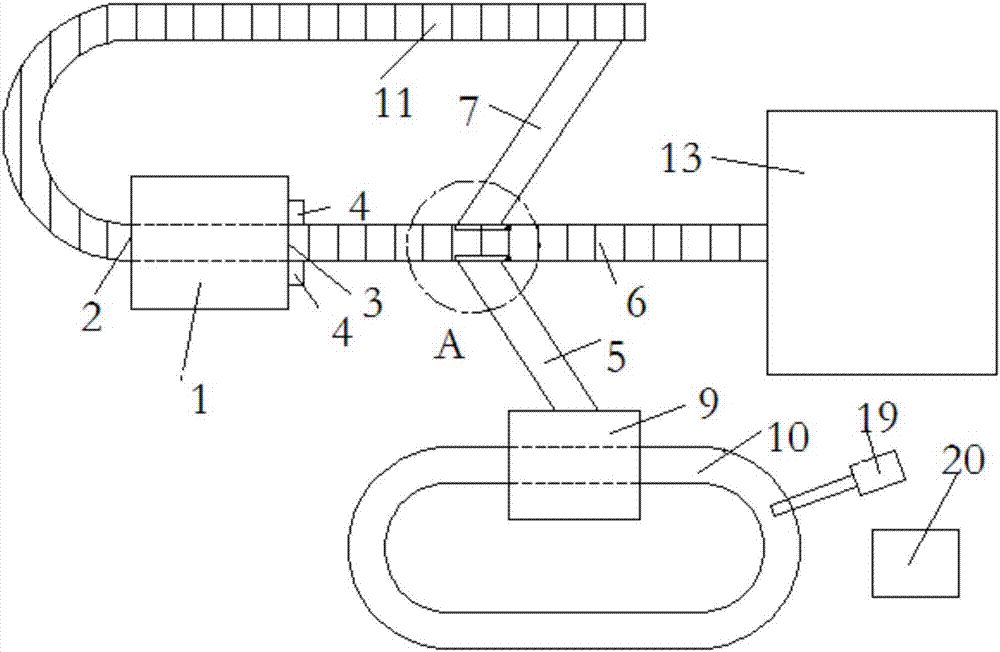

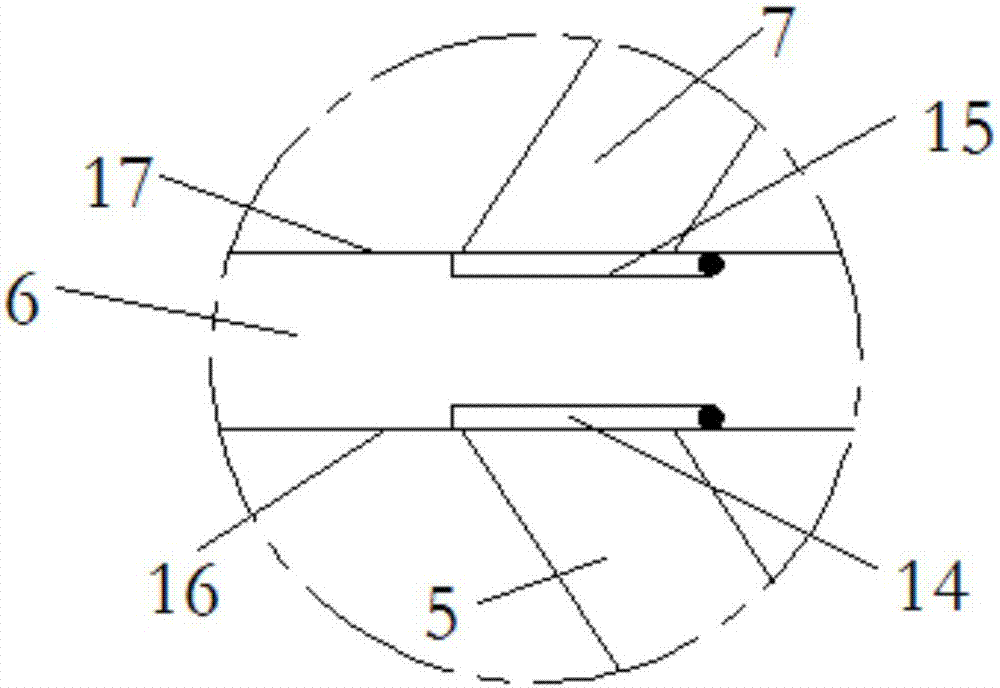

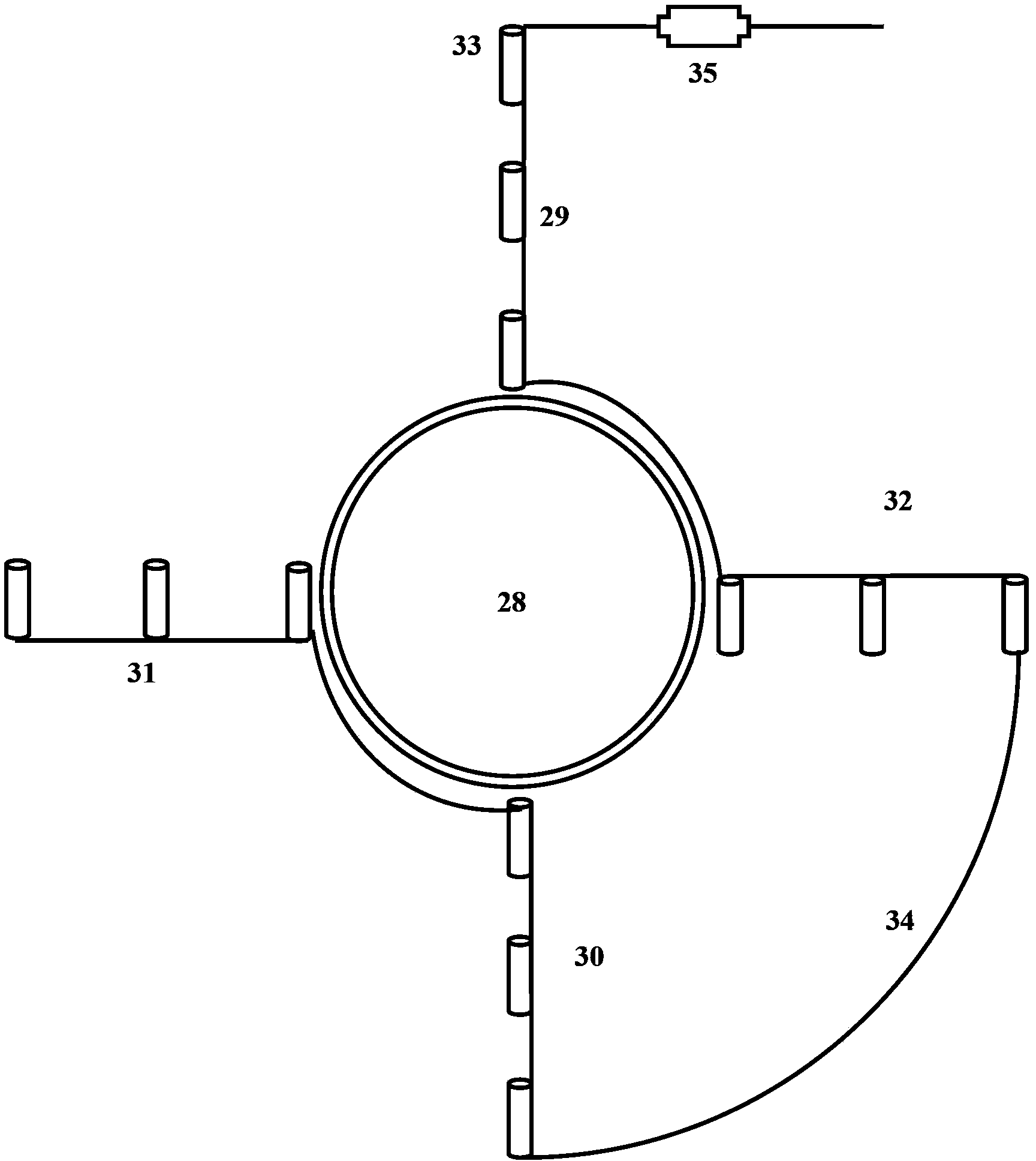

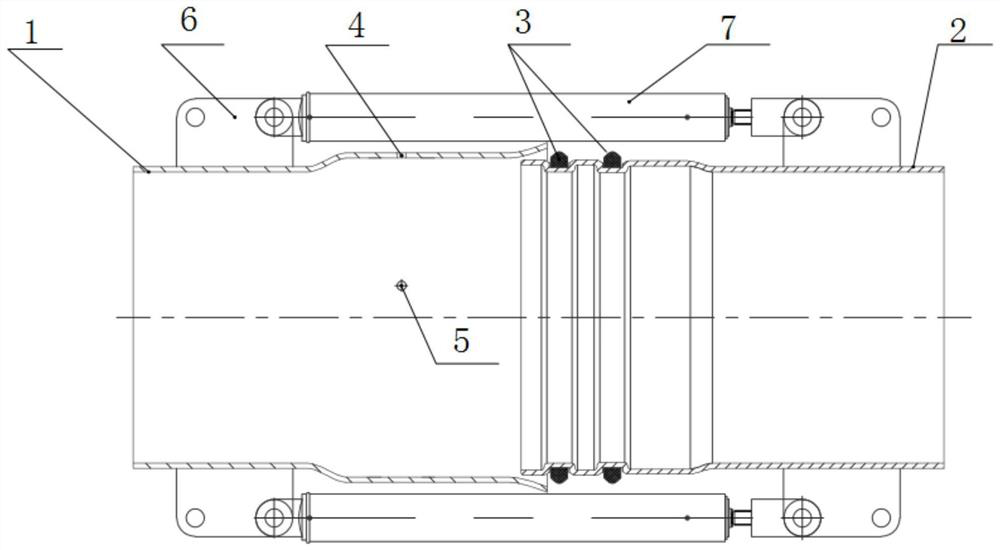

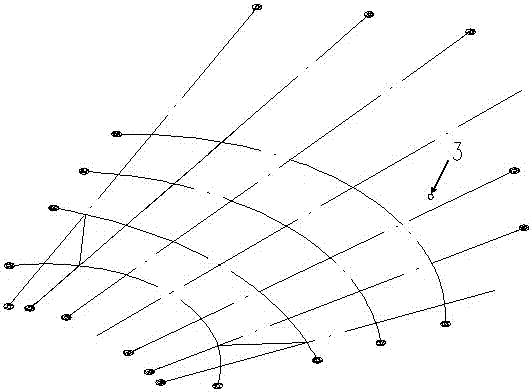

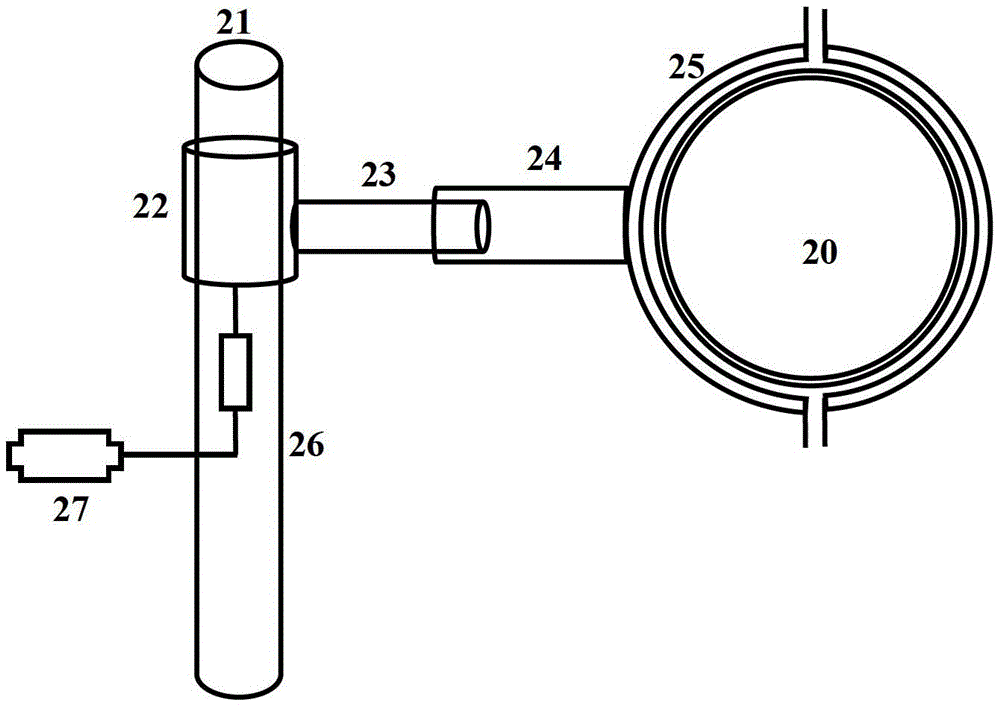

The invention discloses a system for monitoring an oil-gas pipeline in a mining subsidence area and a constructing method thereof. The system comprises a pipe body strain monitoring device, a pipe-soil relative displacement monitoring device and a mining subsidence area horizontal deformation monitoring device; a fiber grating strain sensor a (3) and a pipe-soil relative displacement sensor a (4)are arranged on the monitoring section of an oil-gas pipeline a (2) of a mining subsidence area (1); sensors on every section are connected in series by fusing, and are connected with an optical cable a (7) through a fiber junction box a (6); a fiber grating sensing network a (5) is arranged on the top of the pipeline a (2), and is connected with the optical cable a (7) through the fiber junctionbox a (6); the optical cable a (7) is connected with an optical switch (8); the optical switch (8) is connected with a fiber grating demodulator (9); the demodulator (9) is connected with a lower computer (10); the output of the lower computer (10) is connected with a wireless communication module a (11); and the output of a wireless communication module b (12) is connected with an upper computer(13).

Owner:PIPECHINA SOUTH CHINA CO

System for monitoring oil-gas pipeline in mining subsidence area

ActiveCN102345797AAvoid damageEnsure safetyMining devicesPipeline systemsGratingDeformation monitoring

The invention discloses a system for monitoring an oil-gas pipeline in a mining subsidence area based on a fiber grating sensing technology. The system comprises a pipe body strain monitoring device, a pipe-soil relative displacement monitoring device and a mining subsidence area horizontal deformation monitoring device; a fiber grating strain sensor a (3) and a pipe-soil relative displacement sensor a (4) are arranged on the monitoring section of an oil-gas pipeline a (2) of a mining subsidence area (1); sensors on every section are connected in series by fusing, and are connected with an optical cable a (7) through a fiber junction box a (6); the optical cable a (7) is connected with an optical switch (8); the optical switch (8) is connected with a fiber grating demodulator (9); the demodulator (9) is connected with a lower computer (10); data preprocessed with the lower computer (10) are transmitted through a wireless communication module a (11), received by a wireless communication module b (12) and transmitted to an upper computer (13); and a fiber grating sensing network a (5) is used for monitoring soil body horizontal displacement in real time and transmitting data to the upper computer (13).

Owner:PIPECHINA SOUTH CHINA CO

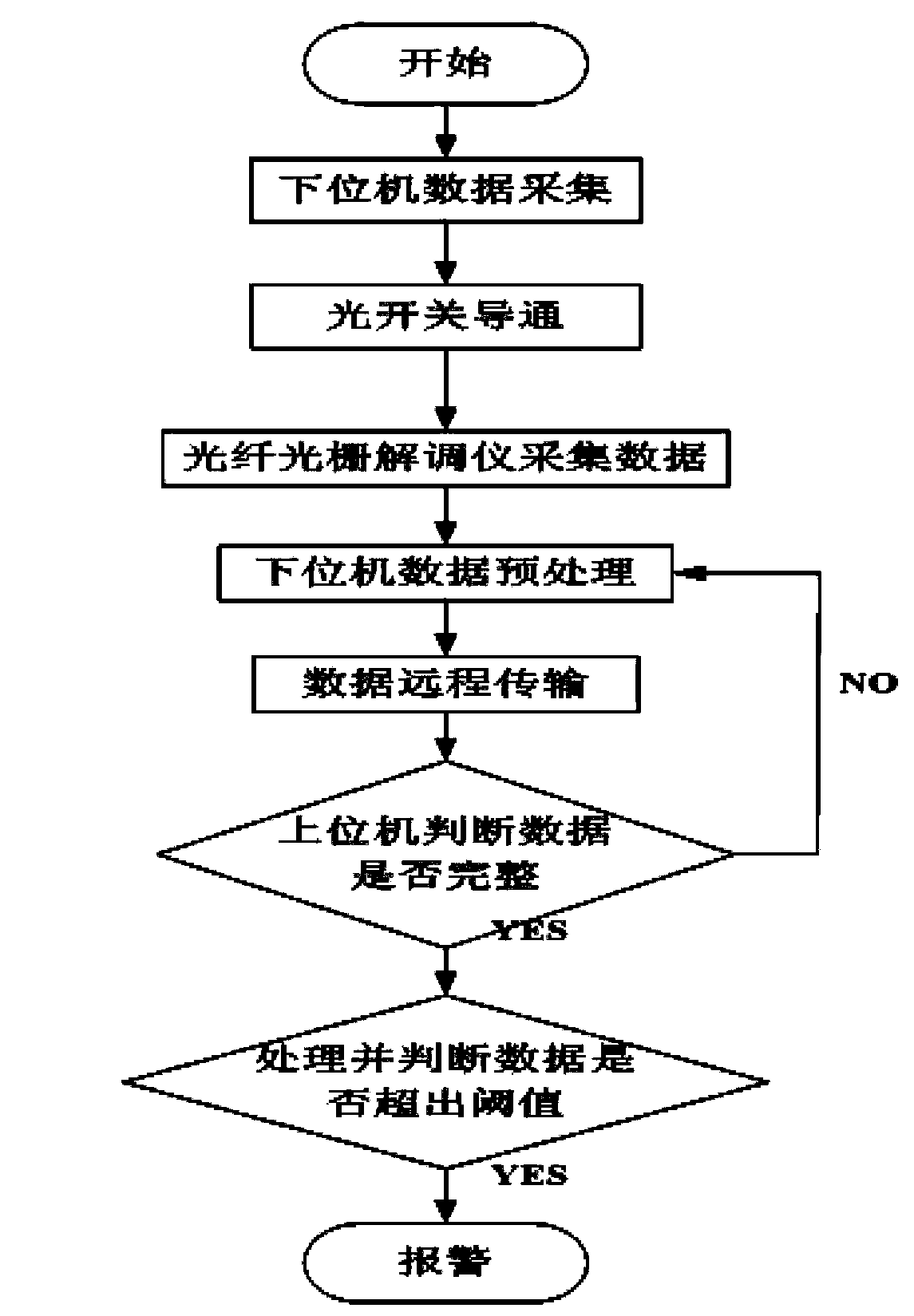

System for monitoring pipe-soil relative displacement of oil-gas pipeline in mining subsidence area

InactiveCN102345798ALow running costGuaranteed operational safetyMining devicesPipeline systemsRelative displacementGrating

The invention discloses a system for monitoring pipe-soil relative displacement of an oil-gas pipeline in a mining subsidence area based on a fiber grating sensing technology. A pipe-soil relative displacement sensor a (3) is arranged on the monitoring section of an oil-gas pipeline a (2) of a mining subsidence area (1), and is connected with an optical cable a (5) which is led to a monitoring station through a fiber junction box (4); in the monitoring station, the optical cable a (5) is connected with an optical switch (6); the optical switch (8) is connected with a fiber grating demodulator (7); the demodulator (7) is connected with a lower computer (8); and data preprocessed with the lower computer (8) are transmitted through a wireless communication module a (9), received by a wireless communication module b (10) and transmitted to an upper computer (11). The system has high space resolution and low cost, and is safe and effective.

Owner:PETROCHINA CO LTD

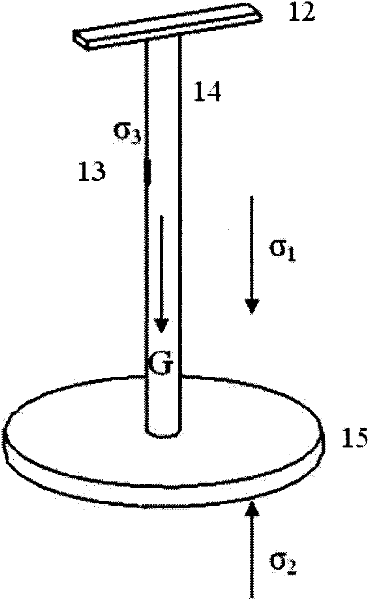

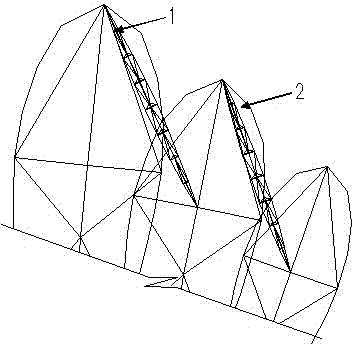

Remote intelligent detection method and facility for subgrade settlement

ActiveCN102853813AImprove construction qualityReduce construction hazardsTransmission systemsHeight/levelling measurementData transmissionMonitoring data

In the invention, a subgrade settlement numerical model is established based on subgrade design parameters, construction filling record data and FLAC<3D> technology; subgrade settlement real-time monitoring data are acquired by using a single-point settlement meter to realize real-time continuous monitoring of the stability of subgrade settlement, the real-time monitoring data are transmitted to a user computer, the subgrade settlement numerical model carries out comparative analysis on an actually measured subgrade settlement deformation value and a subgrade settlement threshold obtained through numerical analysis and analyzes and evaluates the stability of the subgrade settlement, and results are displayed by using a 3D visualization safety pre-warning platform; all the pre-warning information are sent to the phones of management staff through a short message module connected with the computer in a manner of short messages, and all the monitoring data automatically generate database files in a computer terminal to complete remote intelligent detection and analysis of the subgrade settlement. With the invention, relevant construction personnel on a railway and a highway can take preventive measures in time based on detection data information so as to improve the quality of subgrade construction and reduce hidden construction dangers.

Owner:CHINA RAILWAY 21TH BUREAU GROUP

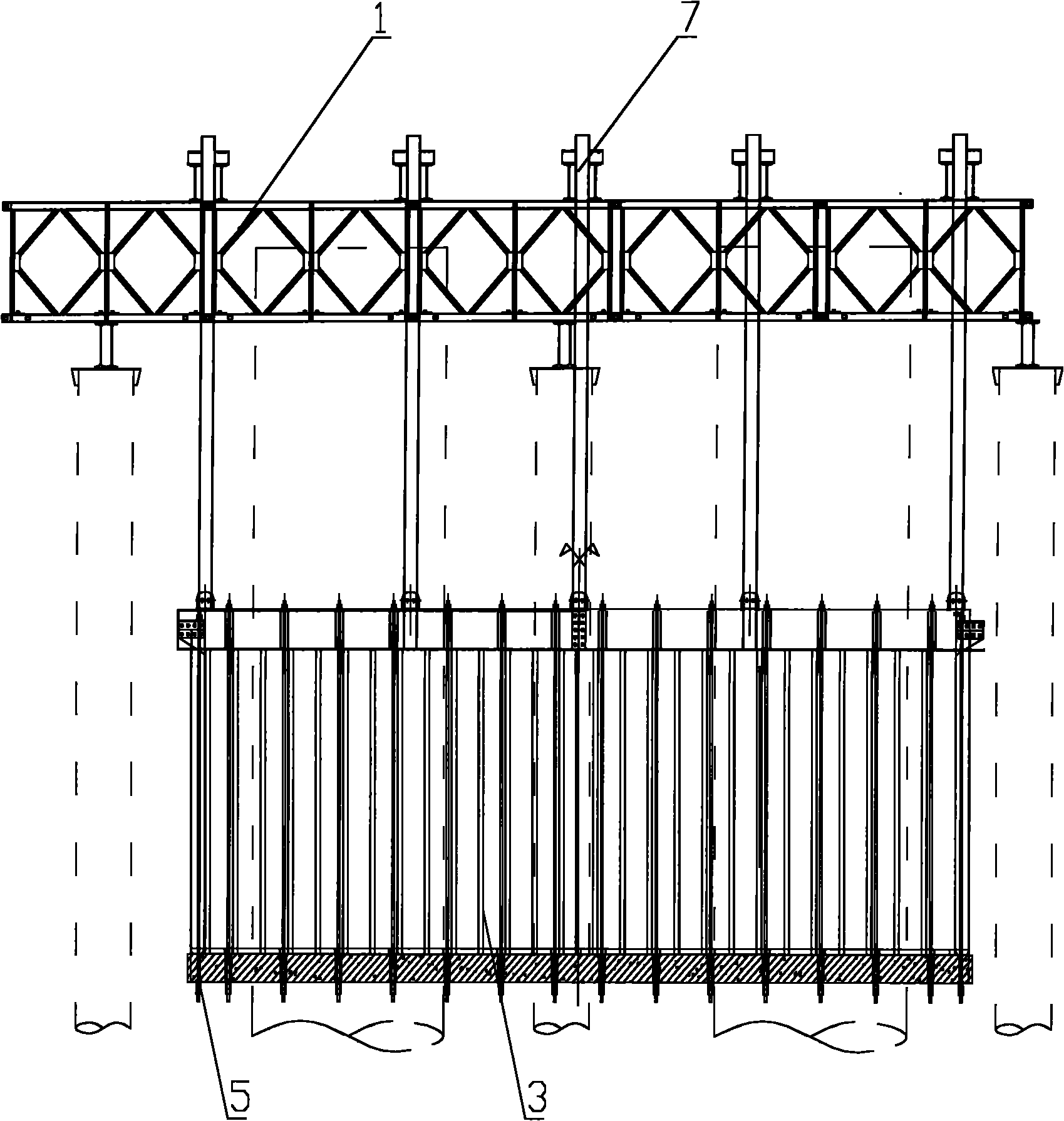

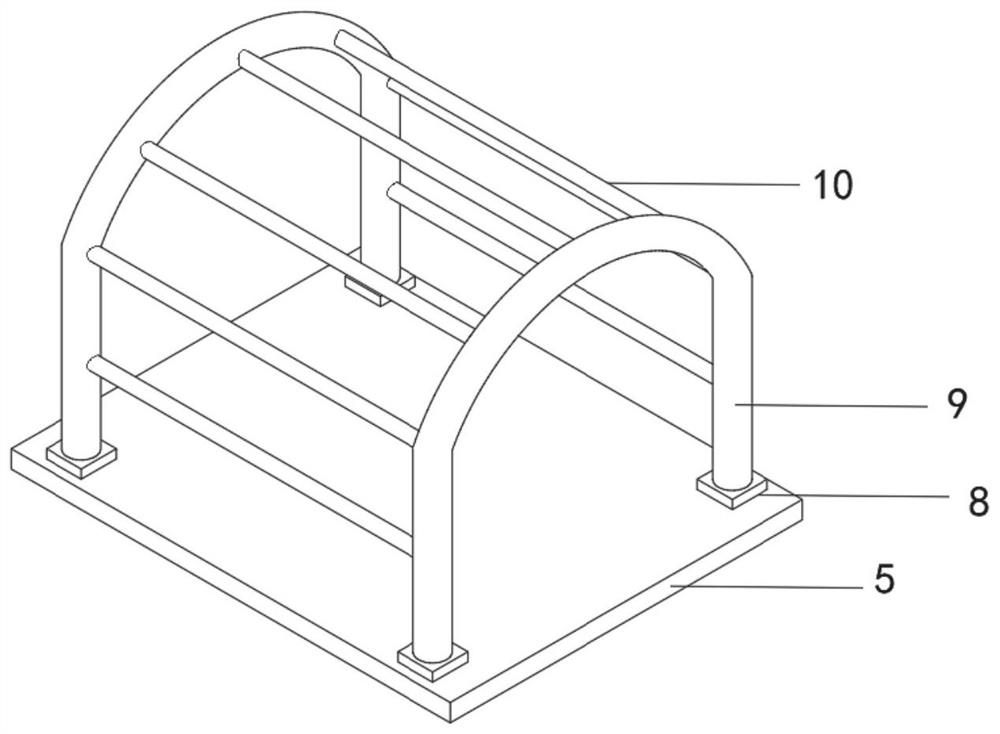

Device used for replacing wide and thick plate rolling mill hydraulic AGC cylinder and using method thereof

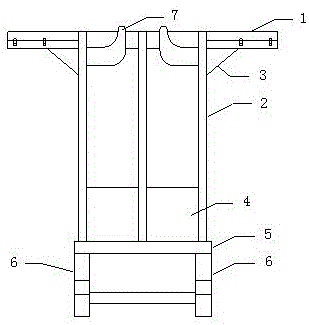

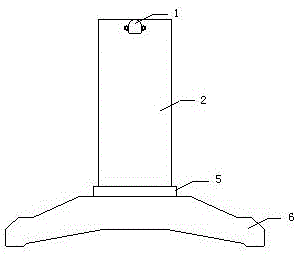

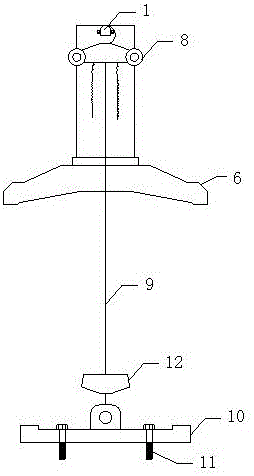

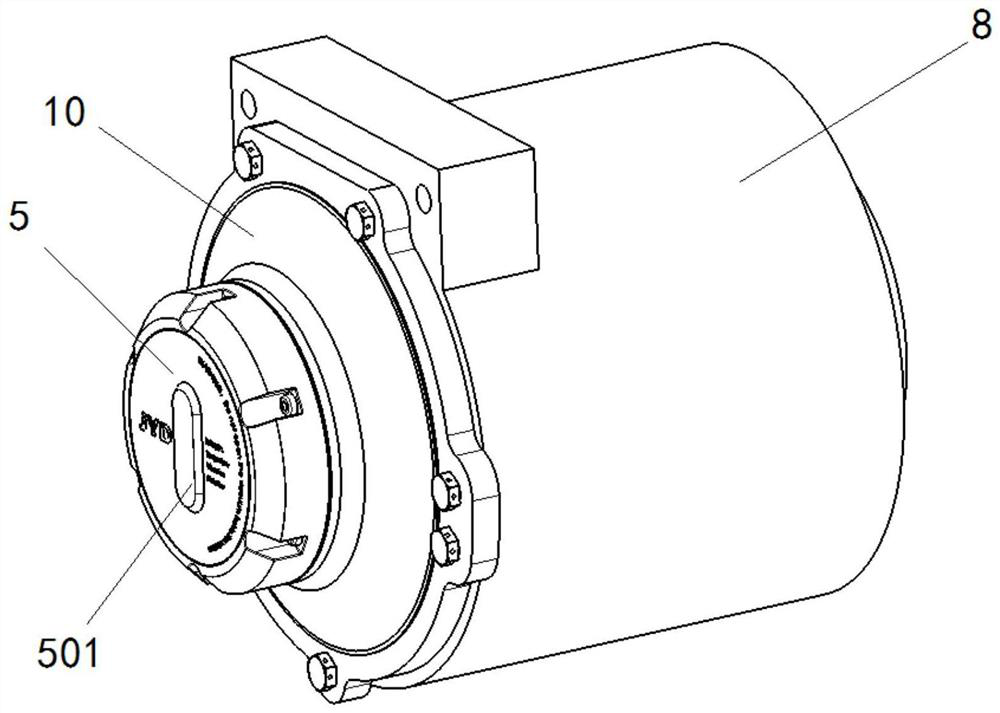

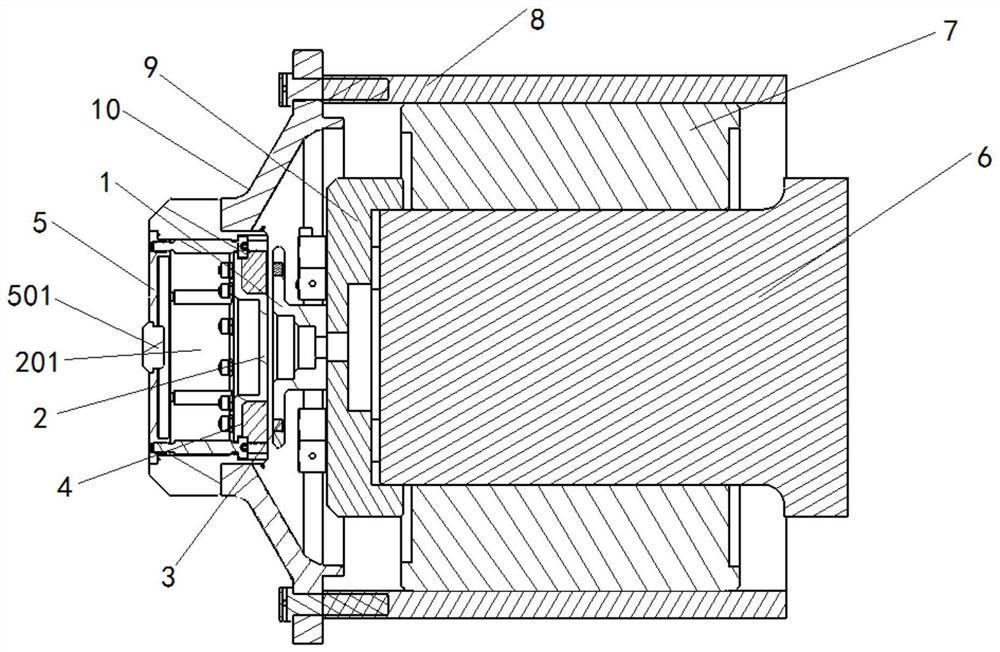

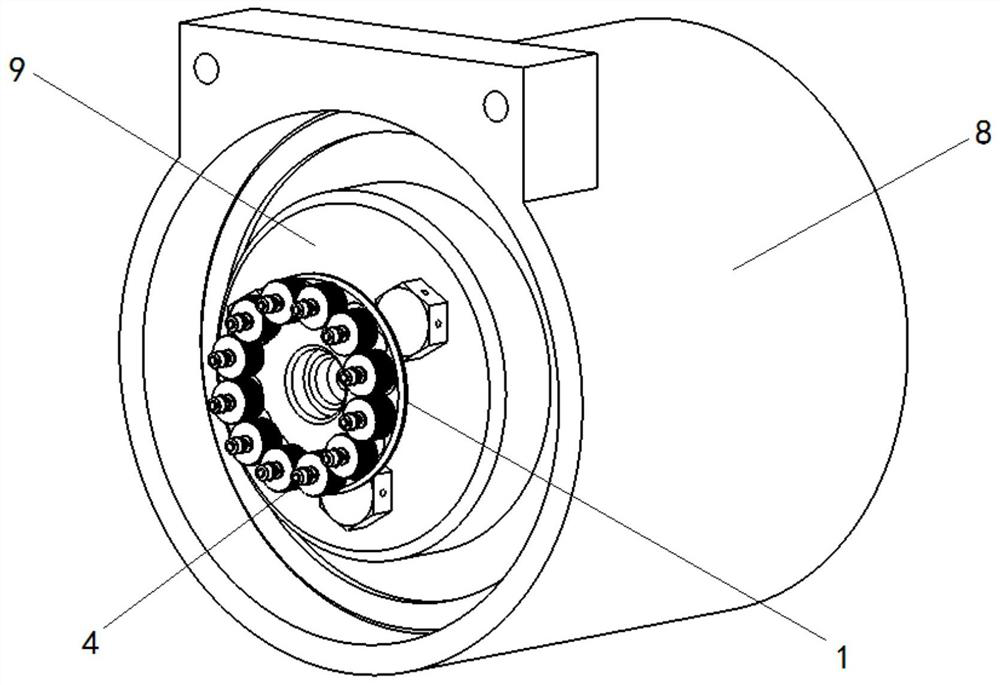

InactiveCN106216408ASimple structureEasy to manufactureMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderThick plate

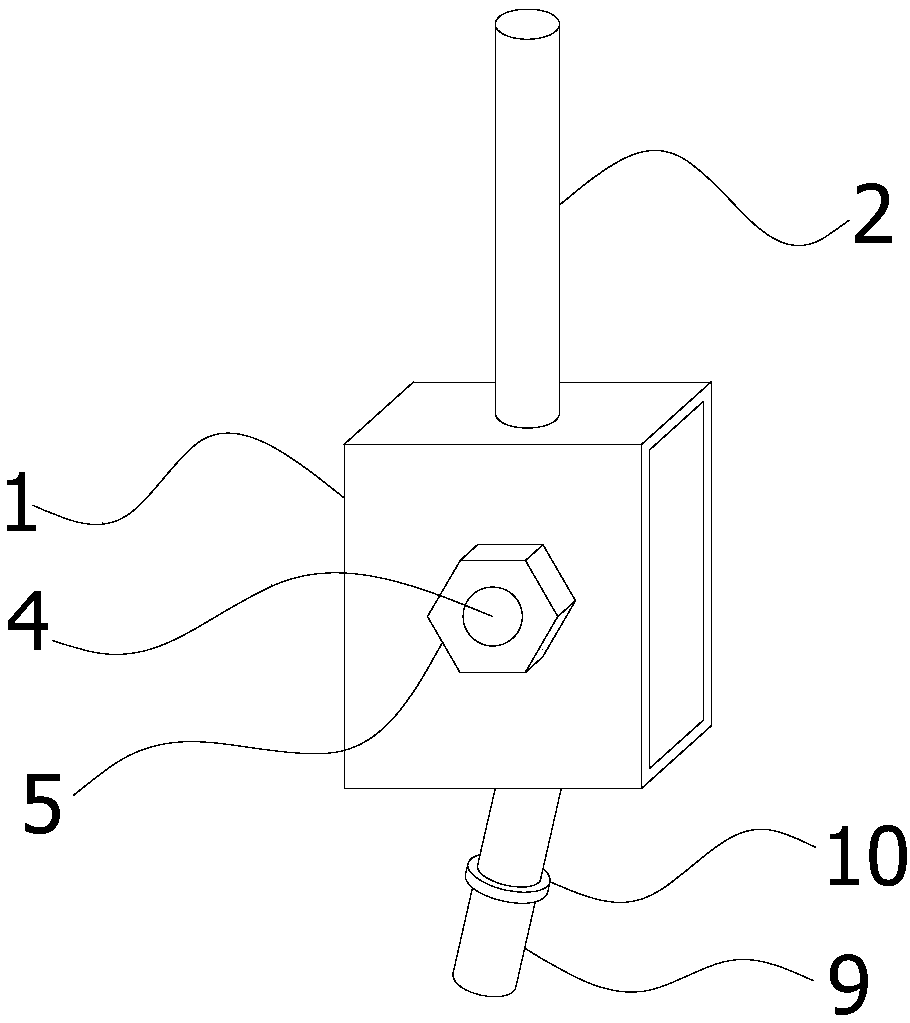

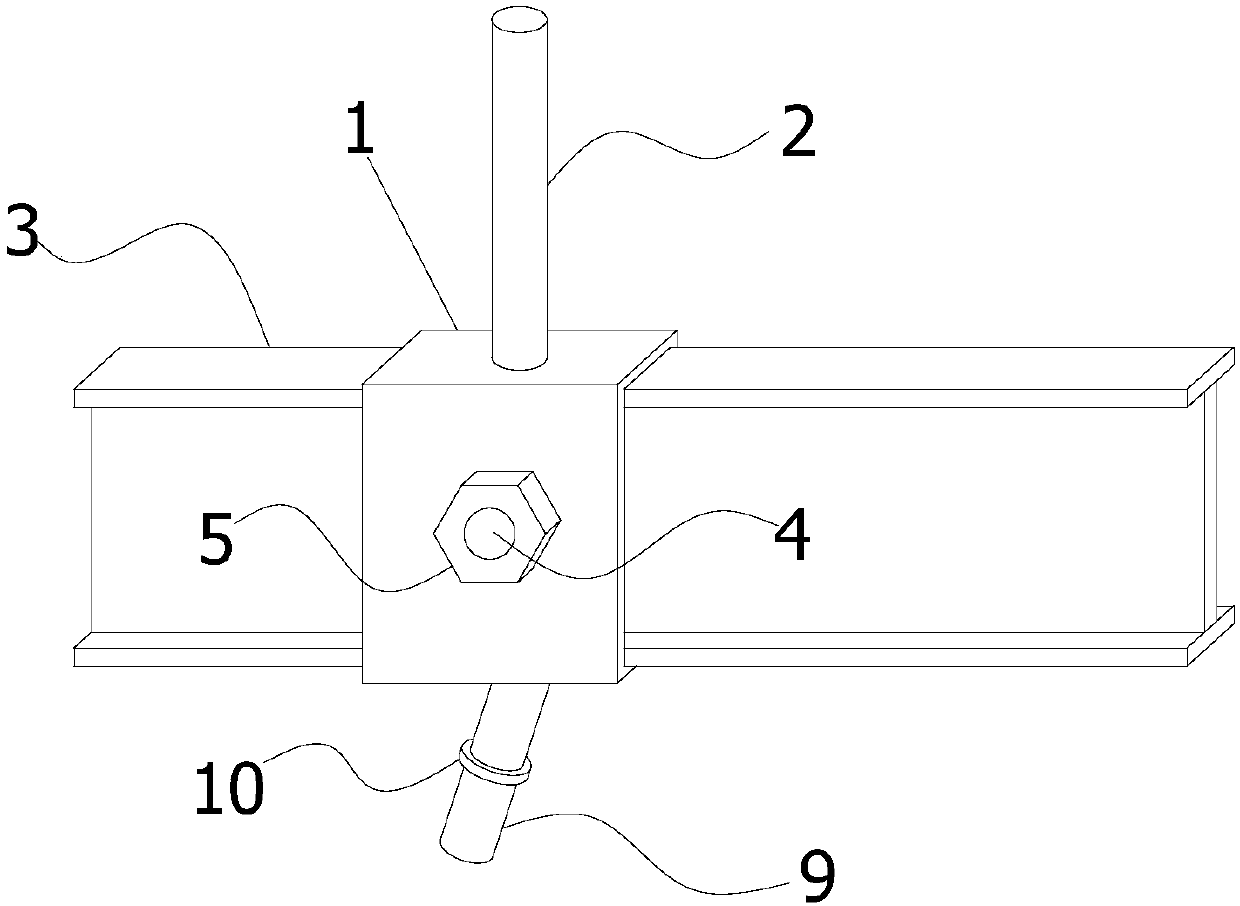

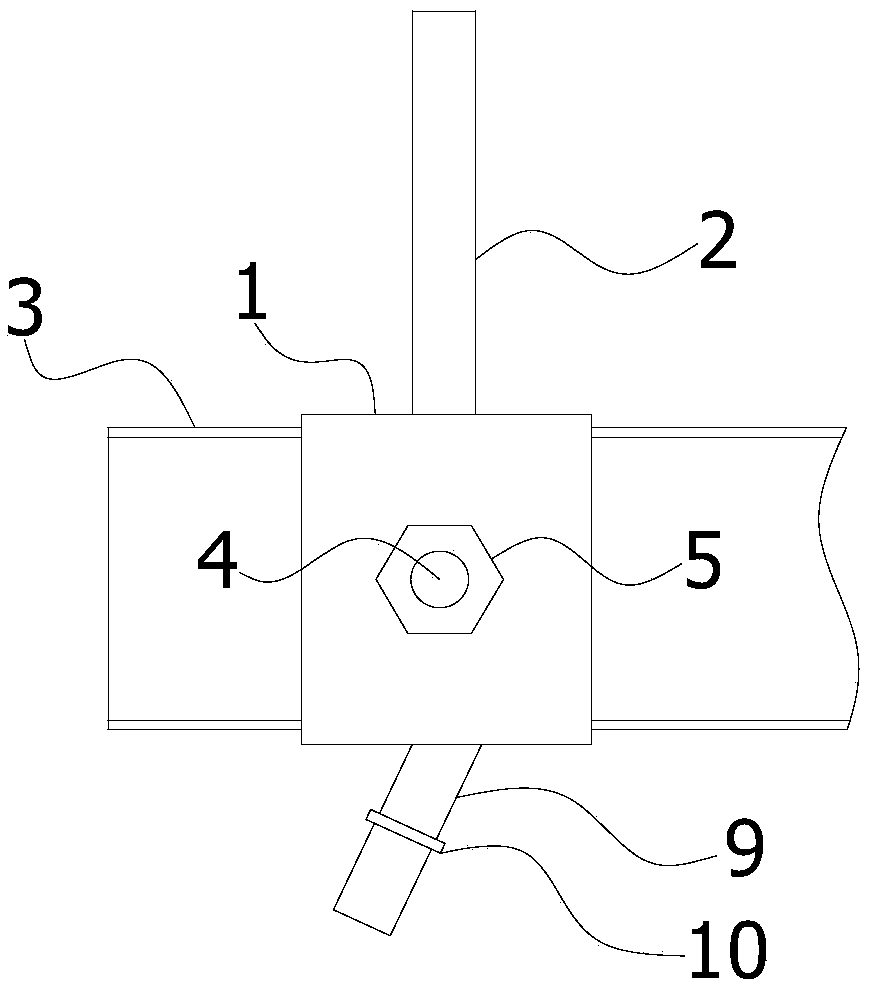

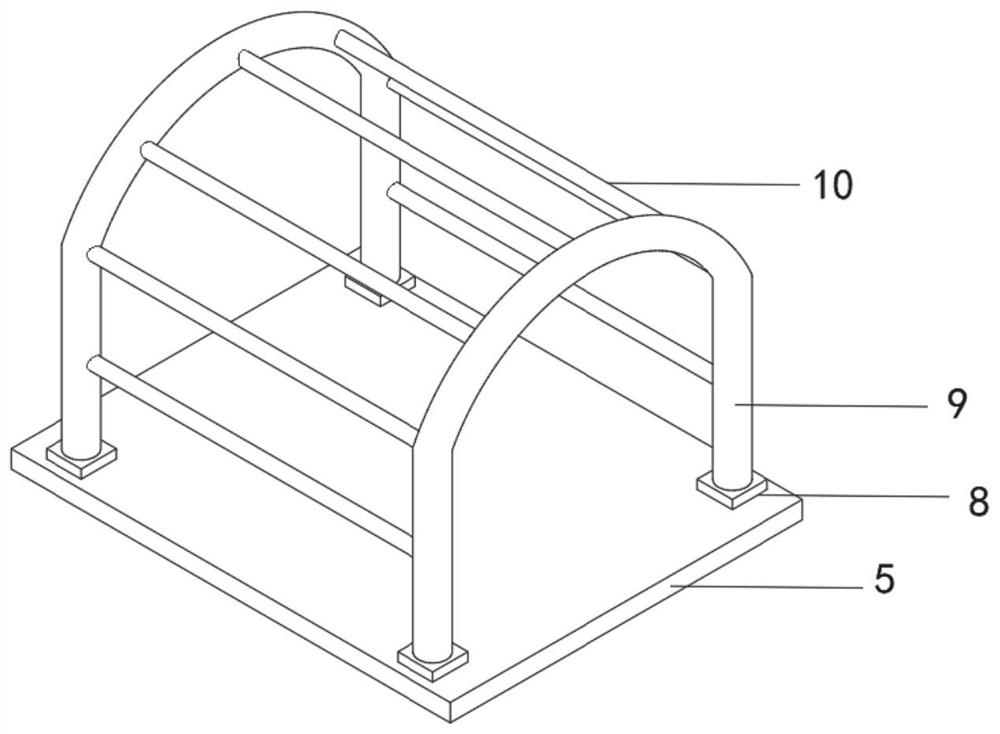

The invention discloses a device used for replacing a wide and thick plate rolling mill hydraulic AGC cylinder. The device comprises a cross beam supporting unit and two electric hoists. The device is characterized in that the cross beam supporting unit comprises a cross beam, supporting plates, a rib plate and a base; the cross beam (1) is a long bar-shaped steel beam with the length being larger than or equal to 2060mm; the two sides of the cross beam are fixedly welded with the tops of the supporting plates (2), and the supporting plates are used for vertically supporting the cross beam; triangular reinforcing ribs (3) of 60mm are arranged at the connecting positions of the cross beam and the supporting plates for reinforcing; the two electric hoists (8) are installed on the cross beam through chain hooks (7) suspended at the two sides of the cross beam; and the electric hoists are connected with a carrying pole (10) through a steel wire rope (9). The device used for replacing the wide and thick plate rolling mill hydraulic AGC cylinder has the advantages that the structure is simple, manufacturing is convenient, safety and reliability are achieved in the replacing construction process of the wide and thick plate rolling mill hydraulic AGC cylinder, construction efficiency is improved, and construction cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

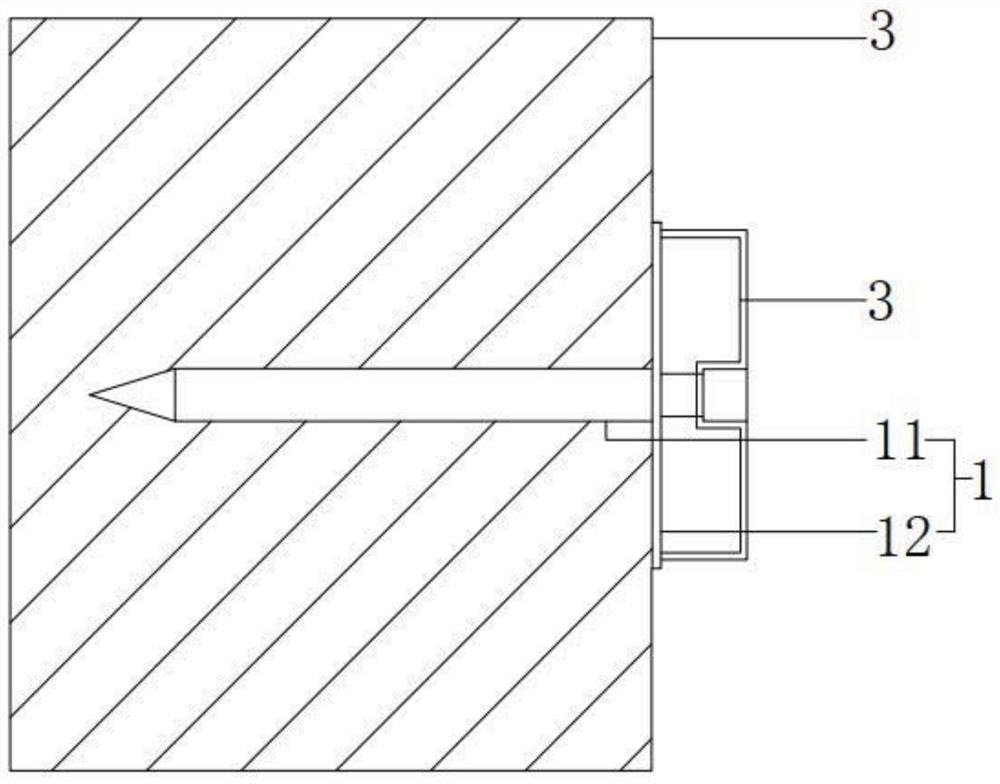

Mounting structure of wall leveling member and mounting method of mounting structure

The invention provides a mounting structure of a wall leveling member. The mounting structure comprises a leveling part, an M type keel, a wall base layer and a veneer, wherein the leveling part comprises a fixed rod and a leveling plate fixedly connected to the fixed rod, a sinking groove is formed in the M type keel, the fixed rod penetrates through the sinking groove and extends to enter the wall base layer, the M type keel is fixedly connected to the wall base layer through the fixed rod, the side, close to the wall base layer, of the M type keel is propped against the leveling plate, andthe veneer is mounted on the M type keel. The invention further provides a mounting method of the mounting structure of the wall leveling member. Compared with the prior art, the problems of low efficiency and big errors of wall leveling can be effectively solved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

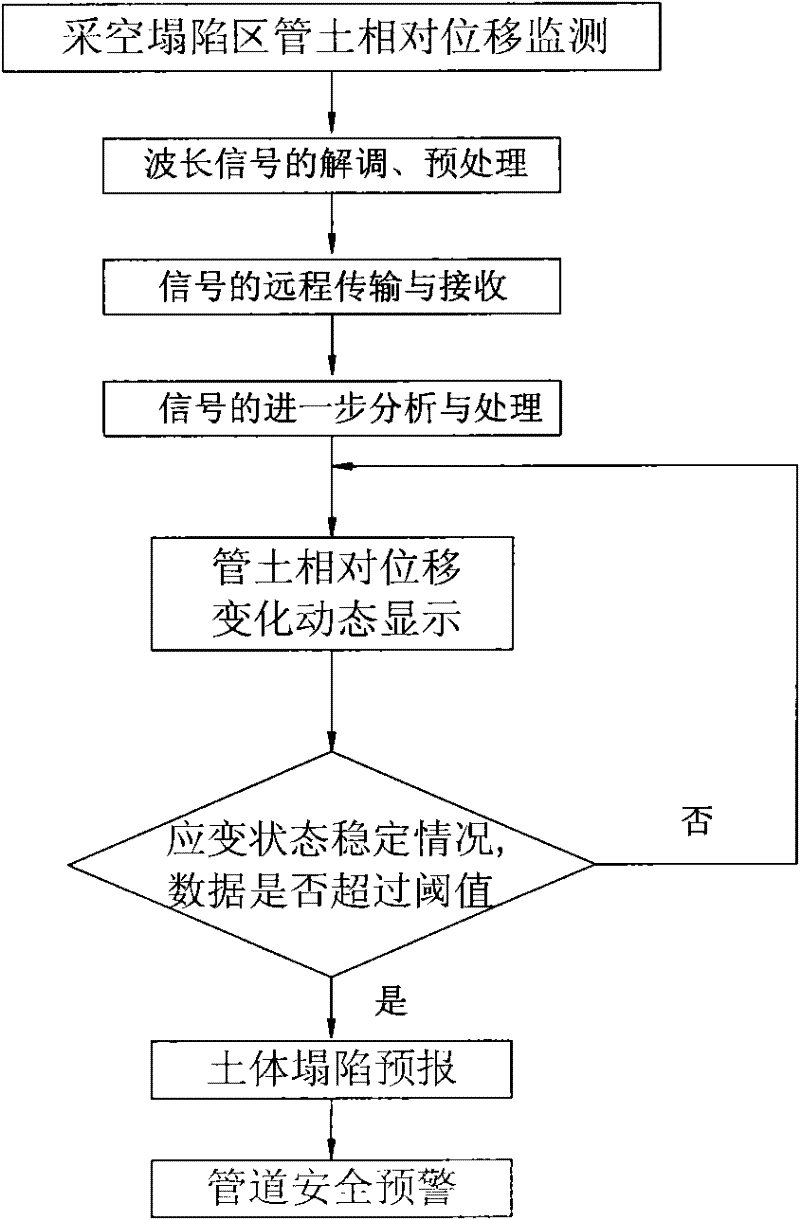

Mining subsidence area oil gas pipeline pipe soil relative displacement monitoring method, system thereof, and system construction method

ActiveCN102346012ARealize real-time automatic collectionRealize remote transmissionUsing optical meansSite monitoringRelative displacement

The invention provides a mining subsidence area oil gas pipeline pipe soil relative displacement monitoring method, a system thereof, and a system construction method. A wavelength signal acquired by s sensor is subjected to demodulation and pretreatment at an on-site monitoring station, and is sent to a remote monitoring center through remote transmission; the monitoring center receives data, carries out further analysis processing on the data through a specific algorithm, and calculates mining subsidence area pipe soil relative displacement change; through dynamic display of the mining subsidence area pipe soil relative displacement change, state stabilization conditions of pipe body and soil strain change are subjected to determination to determine whether the data exceeds a threshold or not; an alarming condition of pipe soil relative displacement is that a monitoring value exceeds a preset value and maintains constant; when a property value is less than the threshold, it is showsthat a pipeline is in a safe state; when a pipe soil relative displacement value reaches the threshold and maintains constant, an early warning of pipeline security is carried out.

Owner:PIPECHINA SOUTH CHINA CO

Vertical rod fixing piece and scaffold

PendingCN107558720AAvoid direct solderingReduced risk of damageScaffold accessoriesBuilding support scaffoldsStress concentrationCantilever

The invention provides a vertical rod fixing piece comprising a fixing sleeve, a fixing rod and a fastening assembly. An inner cavity of the fixing sleeve can be connected with the outer contour of anI-shaped steel cantilever beam in attached and sleeving modes. The fastening assembly is arranged on the fixing sleeve and used for firmly mounting the fixing sleeve on the exterior of the I-shaped steel cantilever beam. The fixing rod is welded to the fixing sleeve and used for inserting and fixing a vertical rod of a scaffold. According to the vertical rod fixing piece, by using the fixing sleeve with the welded fixing rod, the situation that the fixing rod is directly welded to the I-shaped steel cantilever beam is avoided, and the damage hidden danger of the I-shaped steel cantilever beamand the fixing rod in construction operation due to stress concentration is reduced; during mounting and demounting, an I-shaped steel cantilever beam without a welded fixing rod can penetrate through a shear wall independently, the aerial operation procedures are simplified, and the construction risks are reduced; and meanwhile, the collision deformation risk of scaffold parts in the process that the scaffold parts are stored and transported to other sites is also avoided. On the basis of the vertical rod fixing piece, the invention further provides the scaffold.

Owner:CCCC FOURTH HIGHWAY ENG

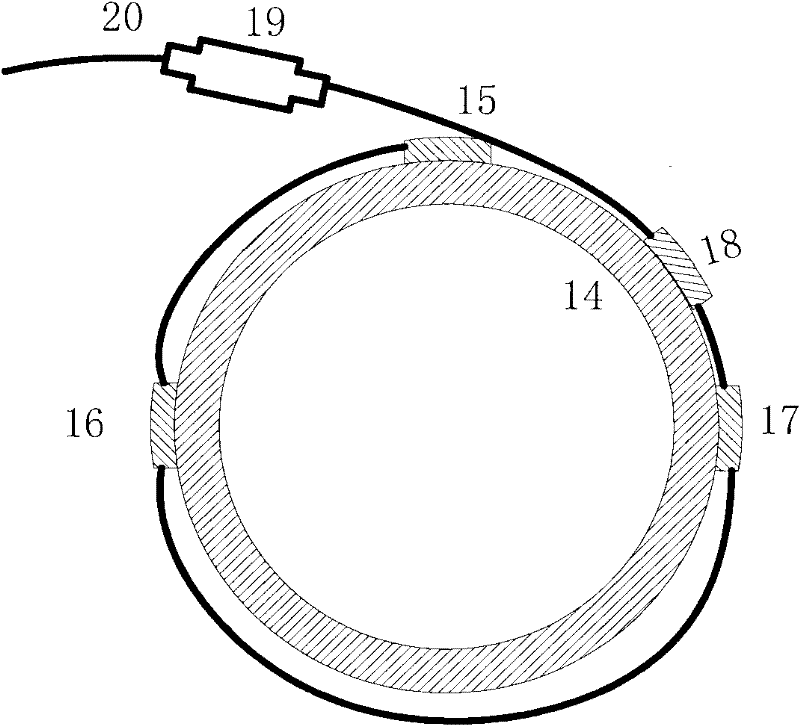

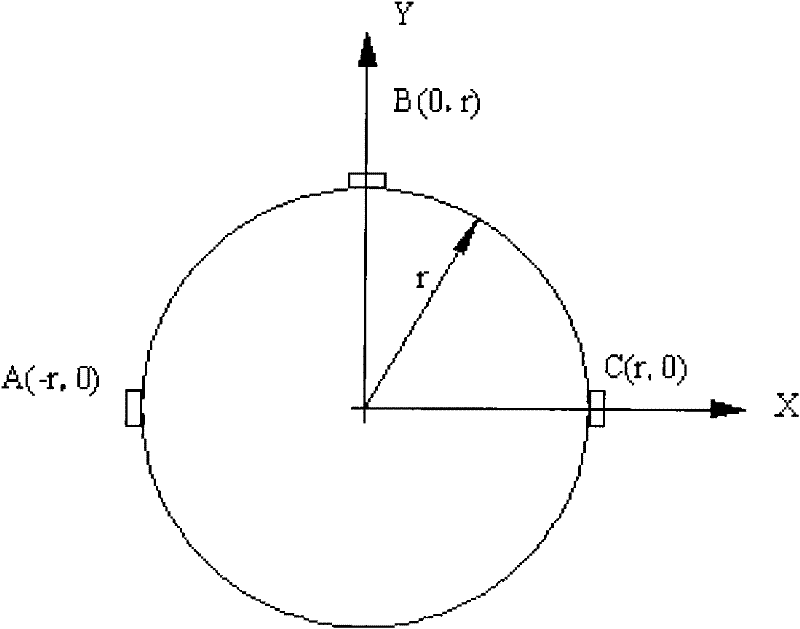

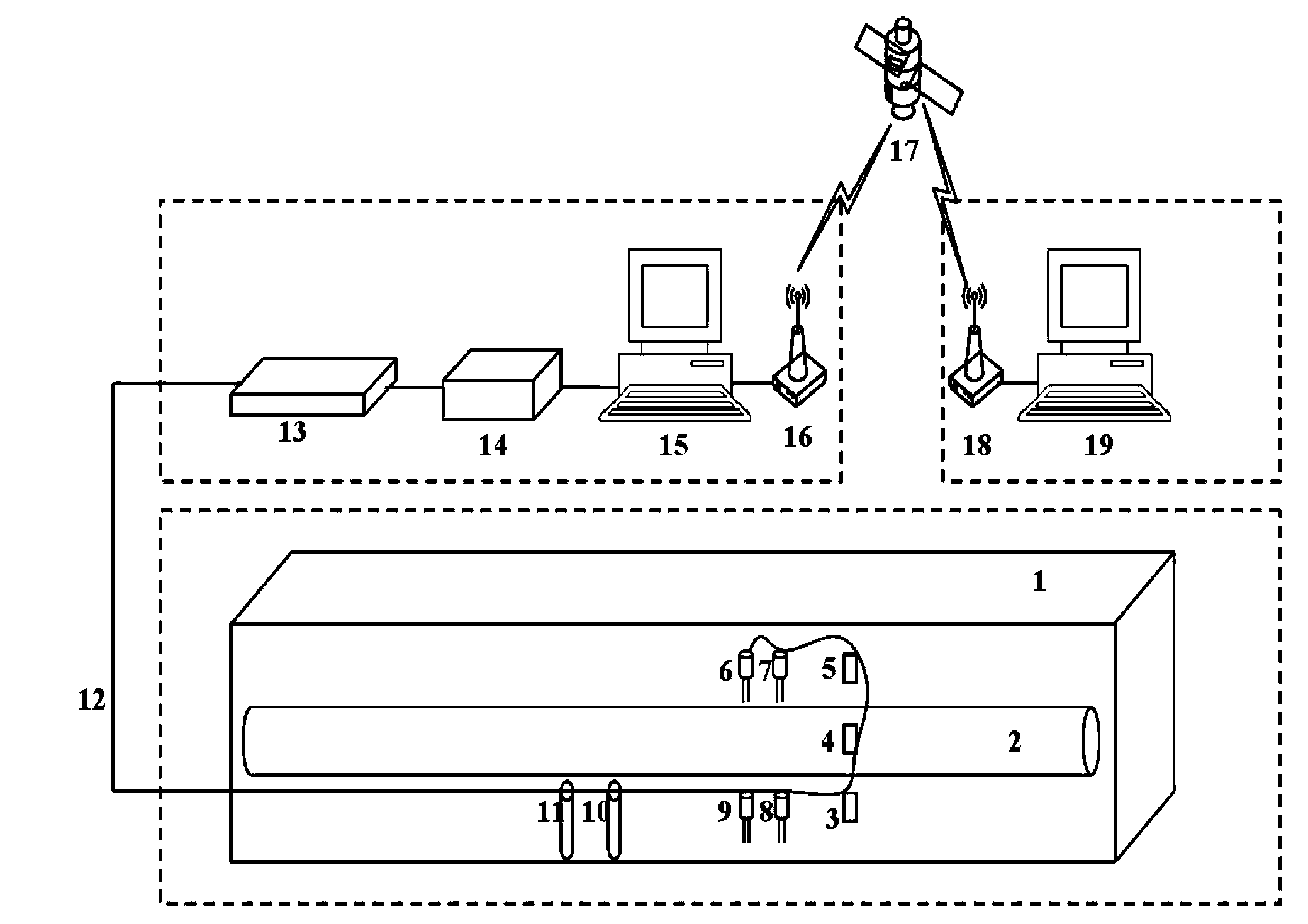

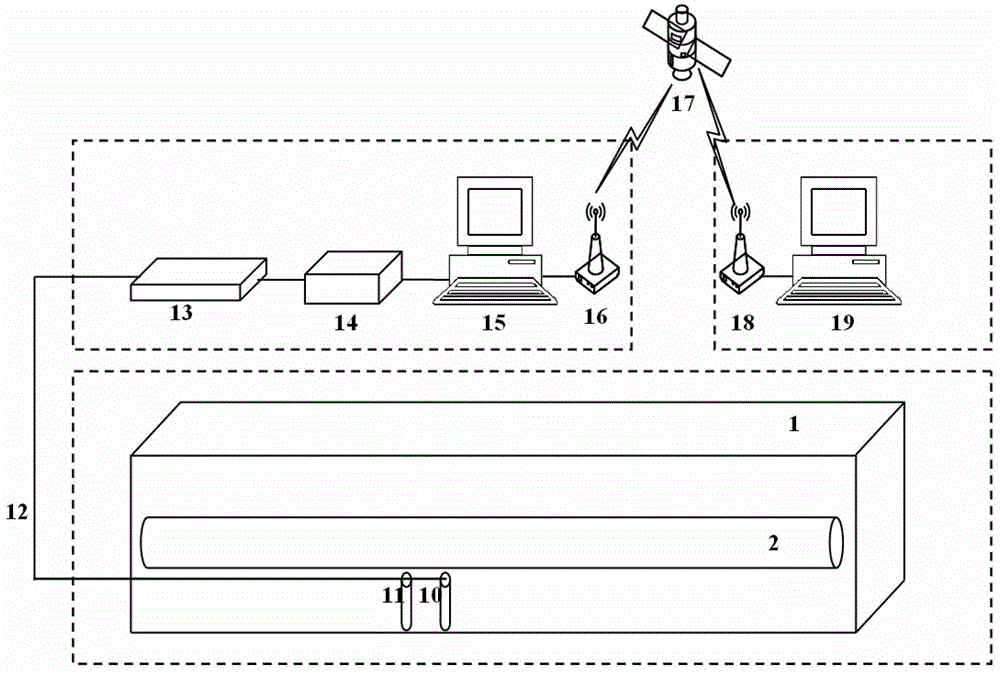

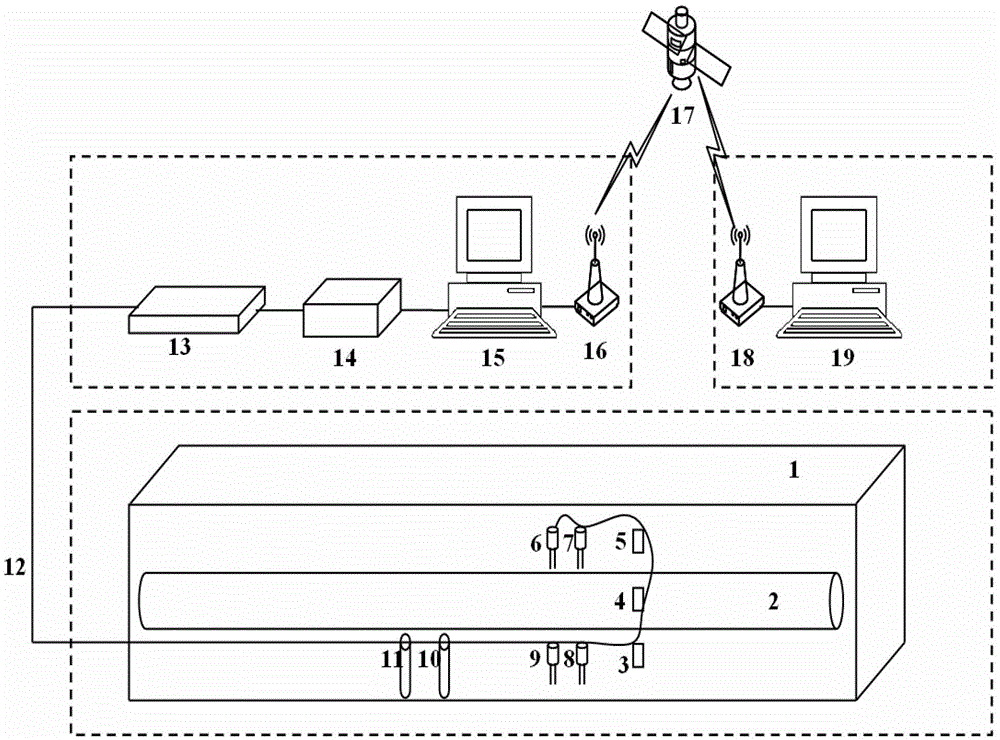

Freeze soil area oil and gas pipeline monitoring method and system and construction method of system

ActiveCN103383244AAvoid displacementLow running costForce measurementMaterial analysis by optical meansFiberPhotoswitch

The invention discloses a freeze soil area oil and gas pipeline monitoring method and system and a construction method of the system. The freeze soil area oil and gas pipeline monitoring method includes the steps of conducting monitoring on the temperatures and the moisture around pipelines and the displacement of a tube bodies through temperature sensor sets, moisture sensor sets and fiber bragg grating displacement sensor sets respectively, sending signals obtained through monitoring to a photoswitch (13) through optical cables (12), sending the signals to a lower computer (15) after the signals are demodulated by an interrogator (14), enabling the lower computer (15) to call self-programmed programs, control the photoswitch (13) and the interrogator (14), collect data and preprocess the data, transmitting the preprocessed data to a low-orbit satellite (17) through a satellite communication module (16), receiving the data through the low-orbit satellite (17) and forwarding the data to a satellite communication module (18), transmitting the received data to an upper computer (19) through the satellite communication module (18), analyzing and processing the data through the upper computer (19), and judging the safety condition of the pipelines to conduct damage forecasting. The freeze soil area oil and gas pipeline monitoring method and system and the construction method of the system are high in precision, high in stability and low in cost.

Owner:PIPECHINA SOUTH CHINA CO

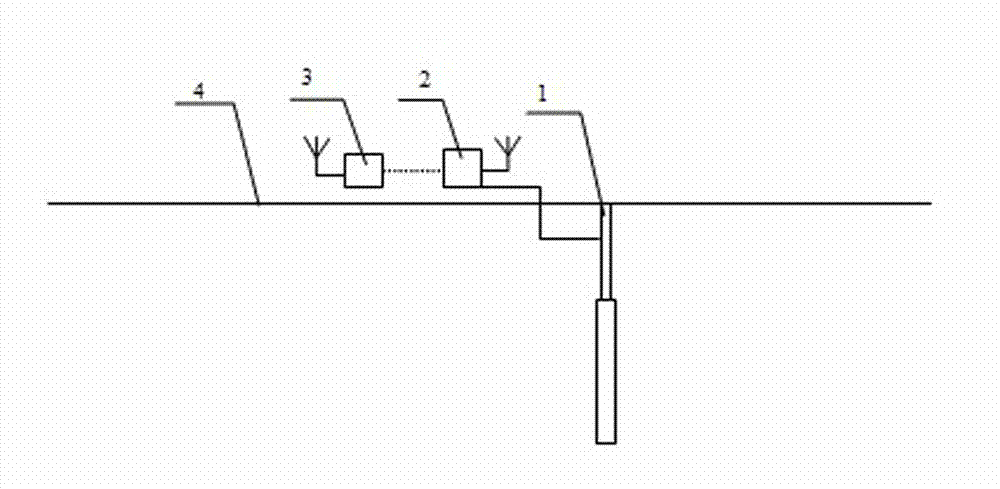

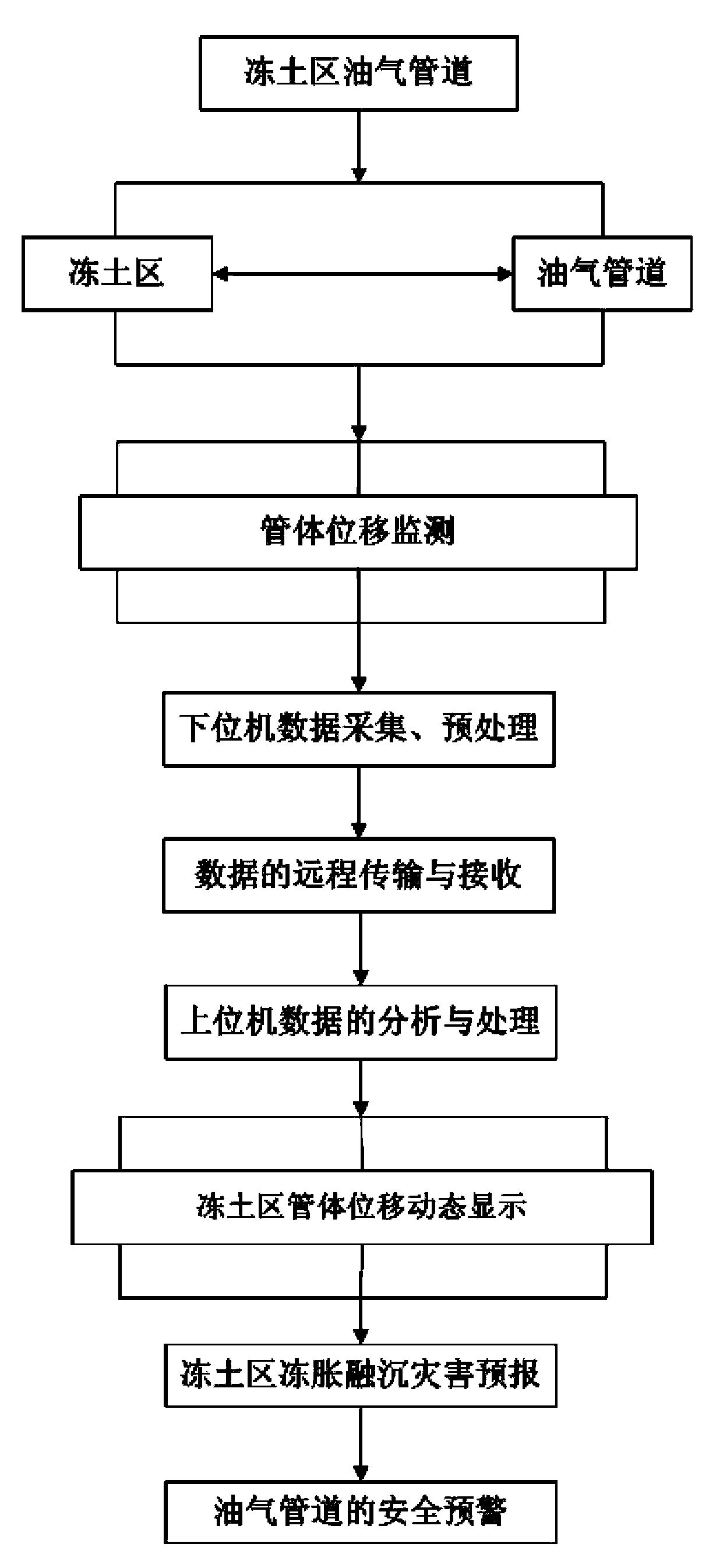

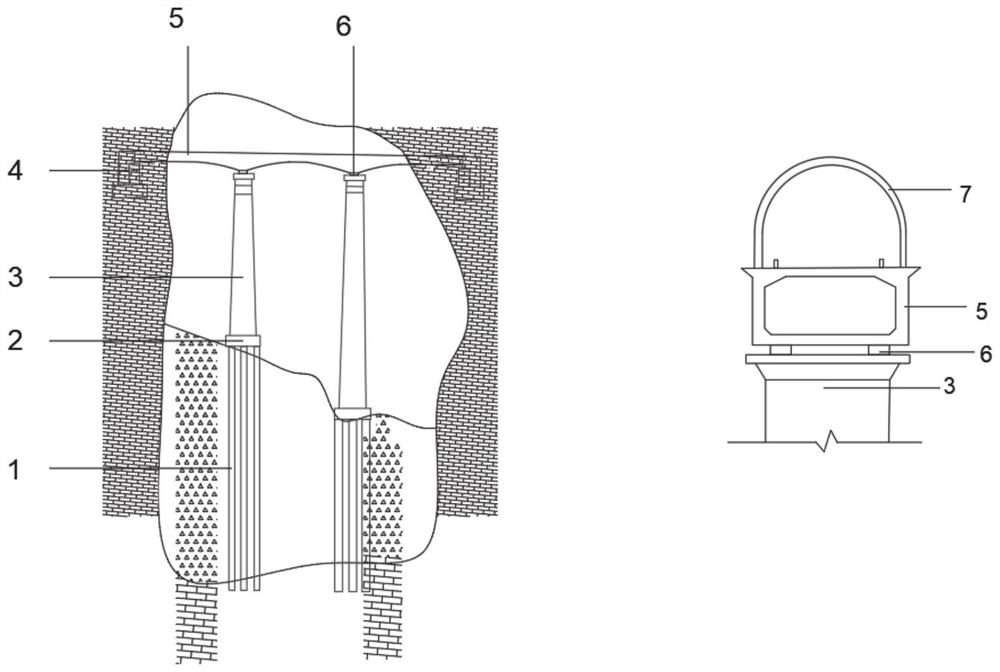

Freeze soil area oil and gas pipeline displacement monitoring method and system

The invention discloses a freeze soil area oil and gas pipeline displacement monitoring method and system. A plurality of fiber bragg grating displacement sensors a (10) and a plurality of fiber bragg grating displacement sensors b (11) are arranged on one sides of oil and gas pipelines (2) in a freeze soil area, all the sensors are connected in series in a welding mode and then introduced into a monitoring station through optical cables (12), the optical cables (12) are connected with a photoswitch (13), the photoswitch (13) is connected with a fiber bragg grating interrogator (14), the fiber bragg grating interrogator (14) is connected with a lower computer (15), data preprocessed by the lower computer (15) are transmitted to a low-orbit satellite (17) through a satellite communication module (16), data are forwarded by the low-orbit satellite (17) to a satellite communication module (18), and received data are transmitted by the satellite communication module (18) to an upper computer (19) and analyzed and processed by the upper computer (19). The freeze soil area oil and gas pipeline displacement monitoring method and system are high in precision, high in stability and low in cost.

Owner:PIPECHINA SOUTH CHINA CO

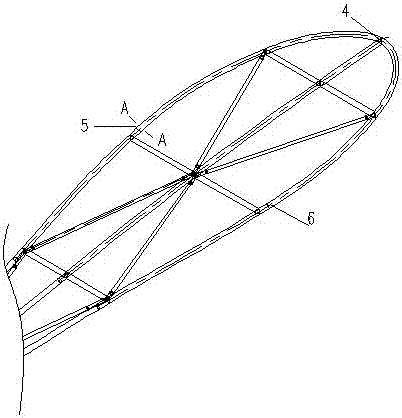

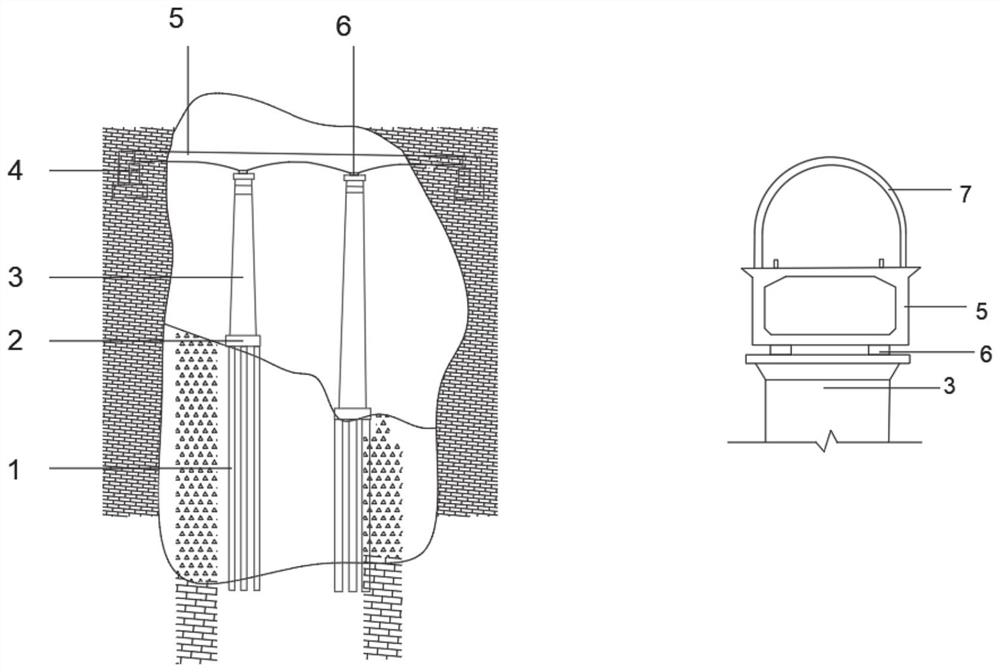

T-shaped rigid frame bridge suitable for tunnel to pass through huge karst cave and construction technology thereof

ActiveCN112575670ASimple structureEasy constructionProtective constructionBridge erection/assemblyBridge deckPipe

The invention relates to a T-shaped rigid frame bridge suitable for a tunnel to pass through a huge karst cave and a construction technology of the T-shaped rigid frame bridge, and belongs to the field of karst area tunnel engineering. An upper structure of a continuous beam bridge comprises supports (basin-type rubber supports), beam slabs (cast-in-place beam slabs), bridge deck structures (bridge deck pavement layers, waterproof layers, expansion joints and the like) and bridge deck accessory structures; the lower structure comprises piers (light piers), a bridge abutment (light bridge abutment), a foundation (steel pipe pile foundation) and a bearing platform (high pile bearing platform). According to the miniature steel pipe pile combined pier foundation, the steel pipe piles are simple in structure and convenient to construct, the construction amount and the construction time can be greatly reduced, and the pier foundation is more economical and safer. By means of the constructionmethod, problems that a traditional karst cave disposal method is improper, the cost is high, and hidden danger is caused to the tunnel structure and operation safety are solved, and reference experience is conveniently provided for later giant karst cave construction.

Owner:中铁十四局集团建筑工程有限公司

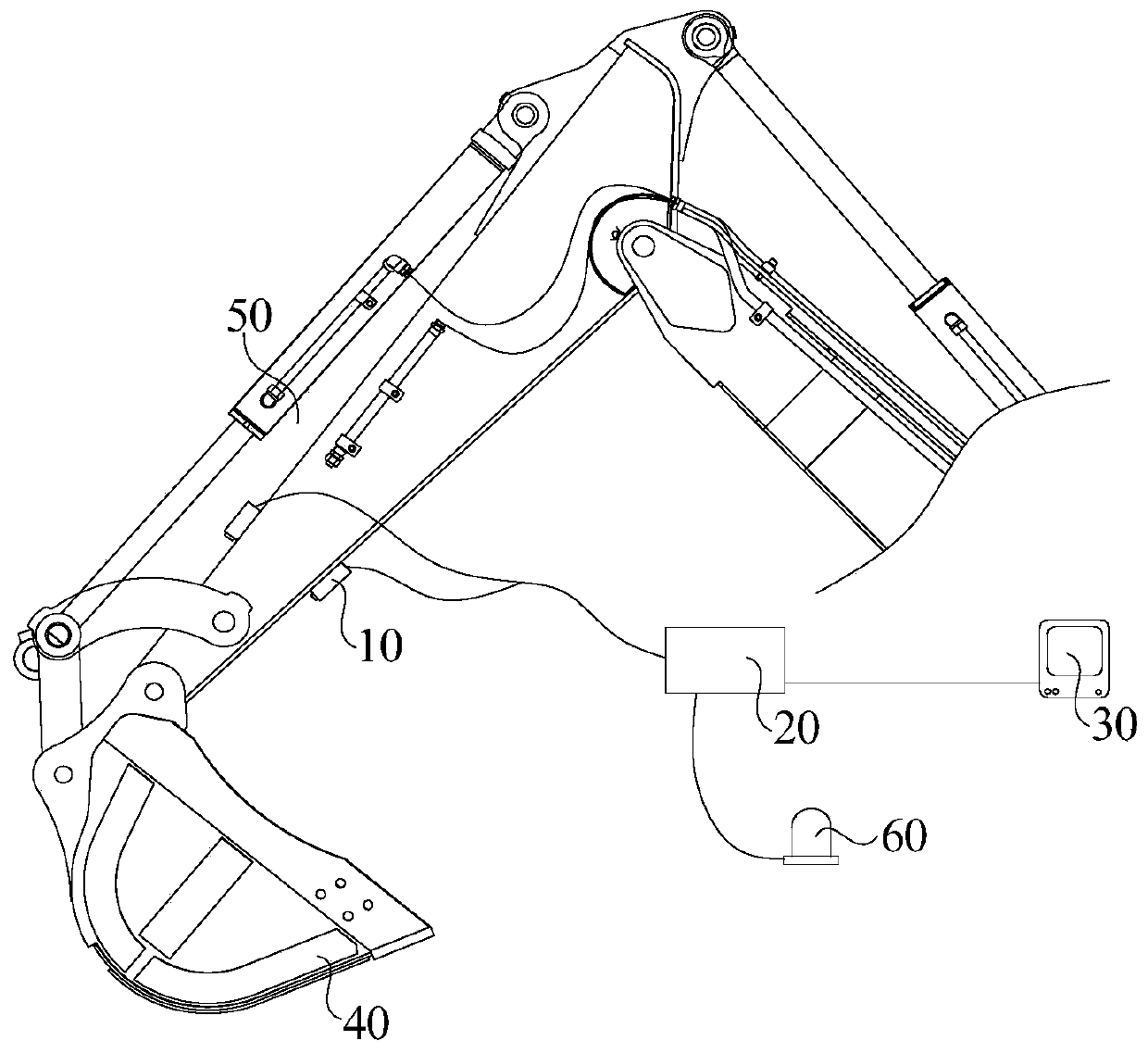

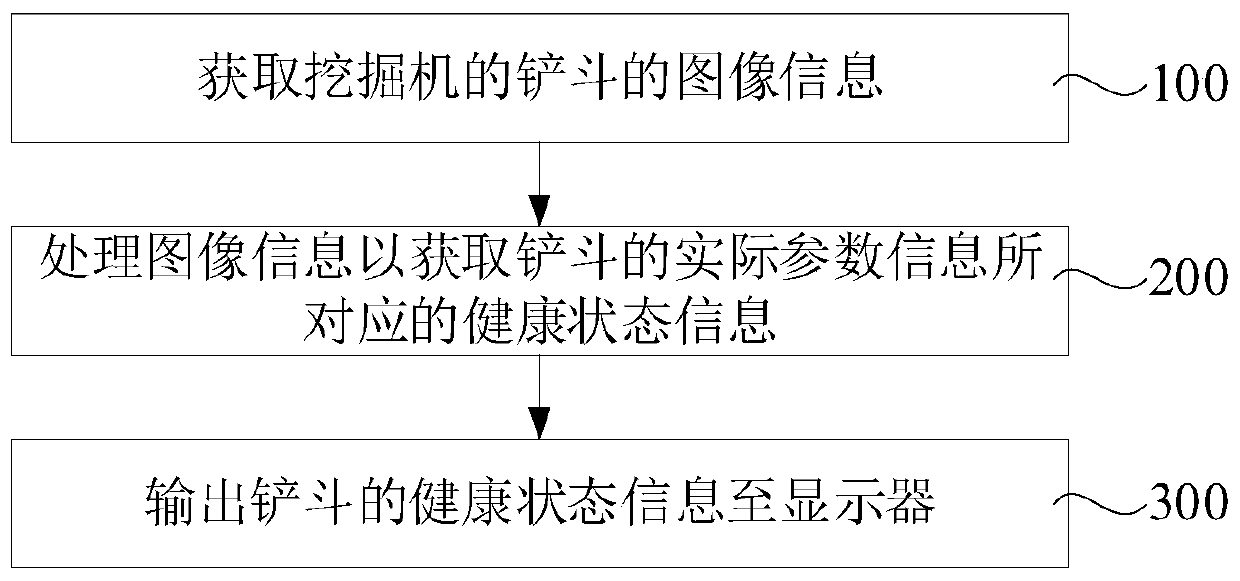

Bucket health status monitoring device and method and excavator

PendingCN111395423AFix subtle flawsReduce construction hazardsMechanical machines/dredgersOptically investigating flaws/contaminationDisplay deviceInformation processor

The invention discloses a bucket health status monitoring device and method and an excavator and relates to the technical field of excavators. The bucket health status monitoring device comprises image collectors, a processor and a displayer, wherein the image collectors are arranged on the excavator and used for obtaining image information of a bucket of the excavator; the processor is electrically connected with the image collectors and used for processing the received image information so as to obtain health status information corresponding to practical parameter information of the bucket;and the displayer is electrically connected with the processor and used for displaying the health status information of the bucket. By means of the bucket health status monitoring device provided by the invention, the defect that damage of the bucket of the excavator is not prone to being discovered can be overcome, and accordingly, potential construction hazards are reduced.

Owner:SANY HEAVY MACHINERY

Special waterproof and leak-stopping daub for deformation joint and expansion joint

ActiveCN108059774AImprove heat resistanceExcellent ozone resistanceOther chemical processesTetrafluoroethyleneThermoplastic elastomer

The invention relates to special waterproof and leak-stopping daub for a deformation joint and an expansion joint. The special waterproof and leak-stopping daub is prepared from butyl rubber, styrene-butadiene rubber, methyl vinyl silicone rubber, octamethylcyclotetrasiloxane, a polyamide thermoplastic elastomer and a tetrafluoroethylene-perfluorovinyl ether copolymer. The special waterproof and leak-stopping daub has high autologous cohesive force, has proprieties of being capable of resisting aging and resisting a humid basal surface, and the like, can be used for forming lasting and stablewater stopping layers in the expansion joint and the deformation joint, and is used for realizing a lasting leak-stopping effect, and problems of secondary leakage and the like cannot occur.

Owner:南京康泰建筑灌浆科技有限公司

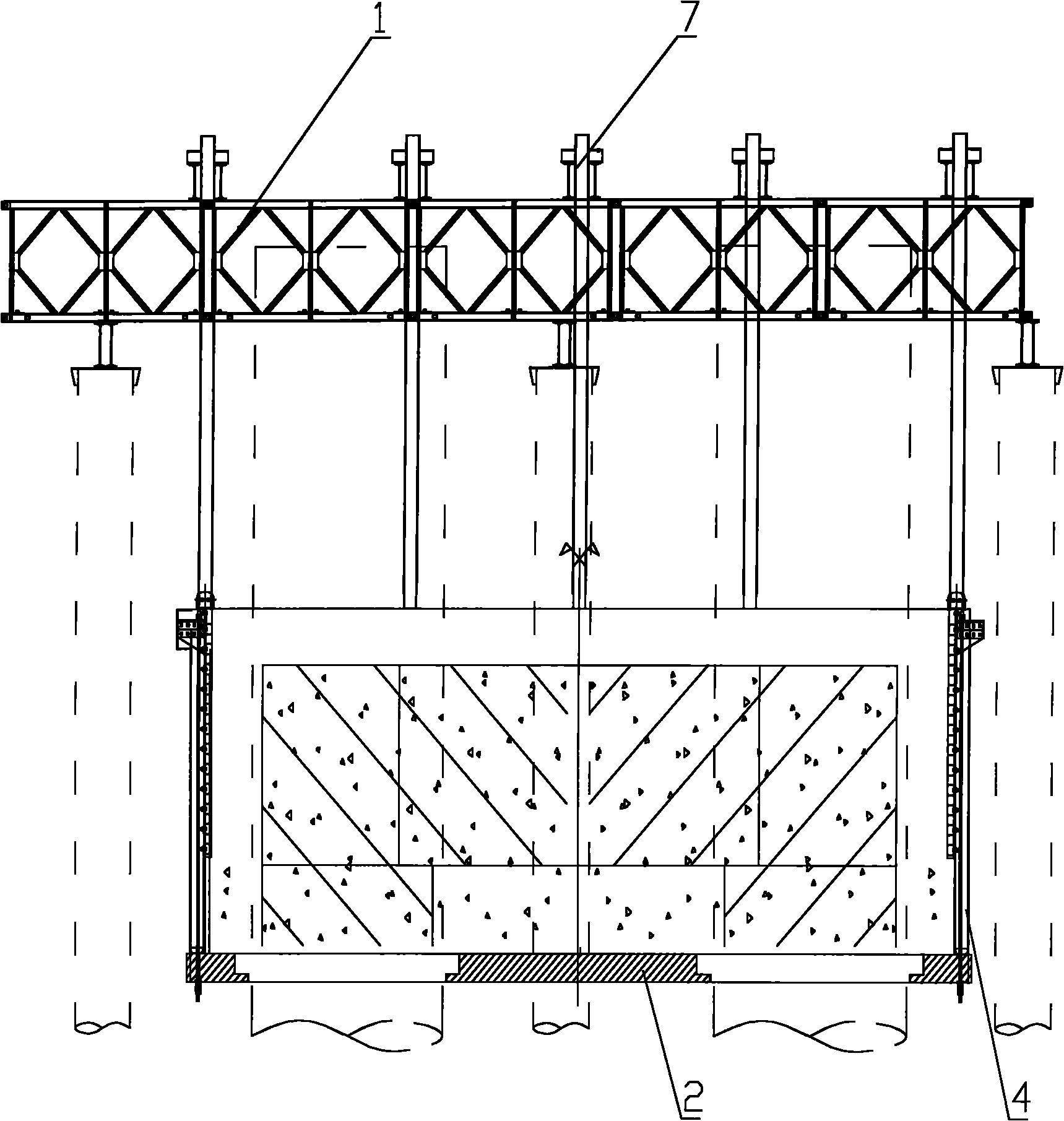

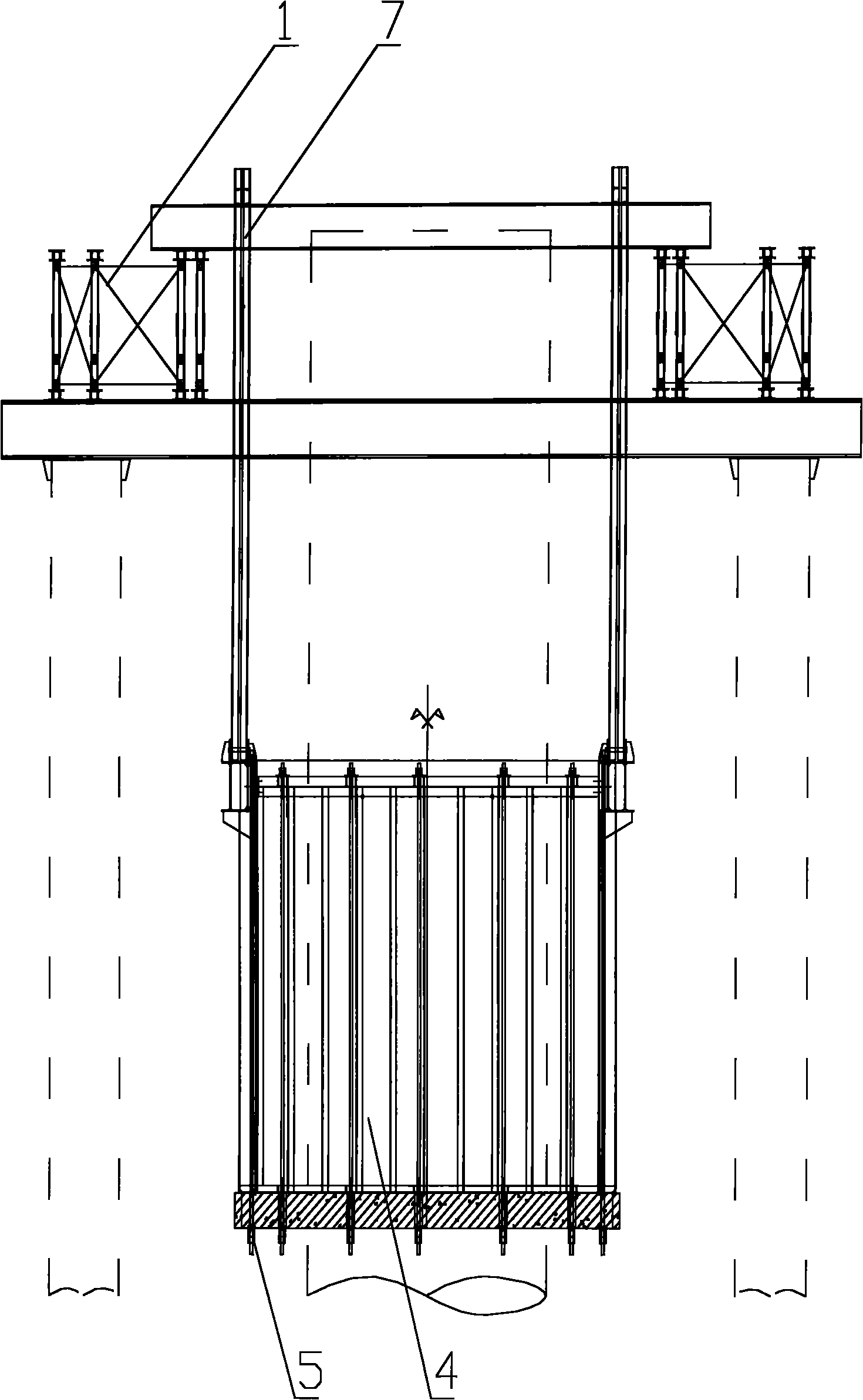

Steel-concrete structure hanging box and dismantling method thereof

InactiveCN102154989AReduce construction hazardsReduce construction costsBridge erection/assemblyReinforced concreteRebar

The invention discloses a steel-concrete structure hanging box which comprises a reinforced concrete base board and steel formworks fixed at the periphery of the base board, wherein the steel formworks are divided into steel side formworks and steel end formworks, cross beams are arranged at the tops of the steel formworks, a plurality of hole paths are distributed on the cross beams, the edges of the base board are provided with a plurality of draw bar holes, each draw bar hole respectively corresponds to each hole path, a vertical draw bar is arranged between each hole path and each draw bar hole in a penetrating way, both ends of the vertical draw bar are respectively anchored by draw bar nuts, the lower end of each vertical draw bar is connected with a steel wire rope, the other end of the steel wire rope is connected with the top ends of the steel formworks, and the steel side formworks and the steel end formworks are connected by bolts; when the steel-concrete structure hanging box is dismantled, the steel formworks can be dismantled only by dismantling the vertical draw bars and the bolts; for the steel-concrete structure hanging box and a dismantling method thereof, the dismantling of the steel formworks can be realized without the need of underwater operation of a diver, the construction danger is reduced, the dismantling workload is reduced, and the expense investment is reduced while the construction progress is accelerated.

Owner:中铁大桥局集团第六工程有限公司 +1

Freeze soil area oil and gas pipeline monitoring method

ActiveCN103383242AAvoid displacementLow running costForce measurementMaterial analysis by optical meansFiberPhotoswitch

The invention discloses a freeze soil area oil and gas pipeline monitoring method. The freeze soil area oil and gas pipeline monitoring method includes the steps of conducting monitoring on the temperatures and the moisture around pipelines and the displacement of a tube bodies through temperature sensor sets, moisture sensor sets and fiber bragg grating displacement sensor sets respectively, sending signals obtained through monitoring to a photoswitch (13) through optical cables (12), sending the signals to a lower computer (15) after the signals are demodulated by an interrogator (14), enabling the lower computer (15) to call self-programmed programs, control the photoswitch (13) and the interrogator (14), collect data and preprocess the data, transmitting the preprocessed data to a low-orbit satellite (17) through a satellite communication module (16), receiving the data through the low-orbit satellite (17) and forwarding the data to a satellite communication module (18), transmitting the received data to an upper computer (19) through the satellite communication module (18), analyzing and processing the data through the upper computer (19), and judging the safety condition of the pipelines to conduct damage forecasting. The freeze soil area oil and gas pipeline monitoring method is high in precision, high in stability and low in cost.

Owner:PIPECHINA SOUTH CHINA CO

Temperature sorting device of intermediate-frequency heating furnace and control method thereof

ActiveCN106955953AMeet the needs of useExtend your lifeSortingTemperature controlIntermediate frequency

The invention provides a temperature sorting device of an intermediate-frequency heating furnace and a control method of the temperature sorting device of the intermediate-frequency heating furnace. The temperature sorting device of the intermediate-frequency heating furnace can automatically isolate and store blanks, excessively high or excessively low in temperature, output from a discharging opening of the intermediate-frequency heating furnace in the heating process and enables blanks meeting a heating temperature requirement to enter a forging furnace to be forged; and meanwhile, because the raw materials entering the forging furnace are in a temperature controlled environment, the use demand of a die is met, and the service life of the die is prolonged. The bottoms of an over-temperature discharging channel and a low-temperature discharging channel are both provided with storage boxes or conveyer belts, the storage boxes or the conveyer belts are matched with the over-temperature discharging channel and the low-temperature discharging channel, so that the blanks output by the over-temperature discharging channel and the low-temperature discharging channel can be automatically conveyed to corresponding positions, and it is not needed that the relevant blanks not meeting the temperature requirement are manually taken out at the over-temperature discharging channel and the low-temperature discharging channel; and in this way, efficiency is improved, and construction hidden danger is lowered.

Owner:江苏苏美达德隆汽车部件股份有限公司

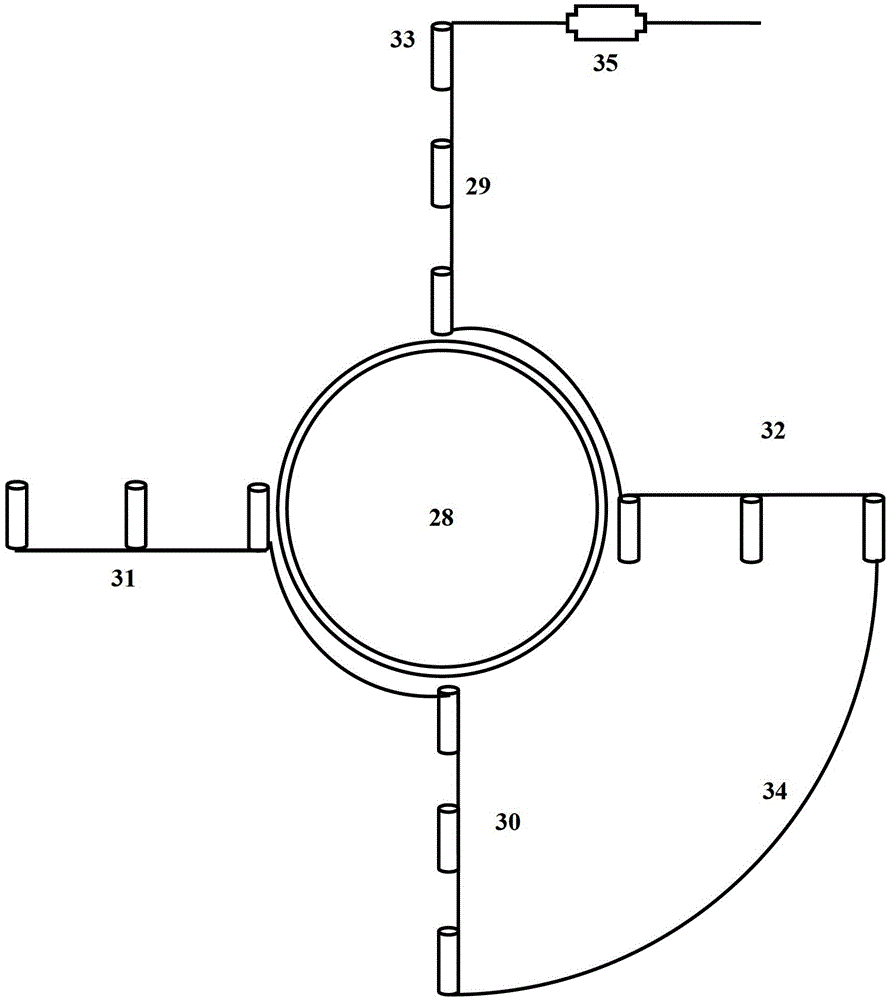

Freeze soil area oil and gas pipeline monitoring system

ActiveCN103383245ASimple networkingEasy to realize automatic real-time online monitoringMaterial analysis by optical meansThermometers using physical/chemical changesFiberGrating

The invention discloses a freeze soil area oil and gas pipeline monitoring system based on the fiber bragg grating sensing technology. Temperature sensor sets are arranged on the surfaces of oil and gas pipelines (2) in a freeze soil area and around the oil and gas pipelines (2) in the freeze soil area, moisture sensor sets are arranged around the oil and gas pipelines (2), fiber bragg grating displacement sensor sets are arranged on one side of the oil and gas pipelines (2), all sensors are connected in series in a welding mode and are led into a monitoring station through optical cables (12), the optical cables (12) are connected with a photoswitch (13), the photoswitch (13) is connected with a fiber bragg grating interrogator (14), the fiber bragg grating interrogator (14) is connected with a lower computer (15), data preprocessed by the lower computer (15) are transmitted to a low-orbit satellite (17) through a satellite communication module (16), data are forwarded by the low-orbit satellite (17) to a satellite communication module (18), and received data are transmitted by the satellite communication module (18) to an upper computer (19) and analyzed and processed by the upper computer (19). The freeze soil area oil and gas pipeline monitoring system is high in precision, high in stability and low in cost.

Owner:PIPECHINA SOUTH CHINA CO

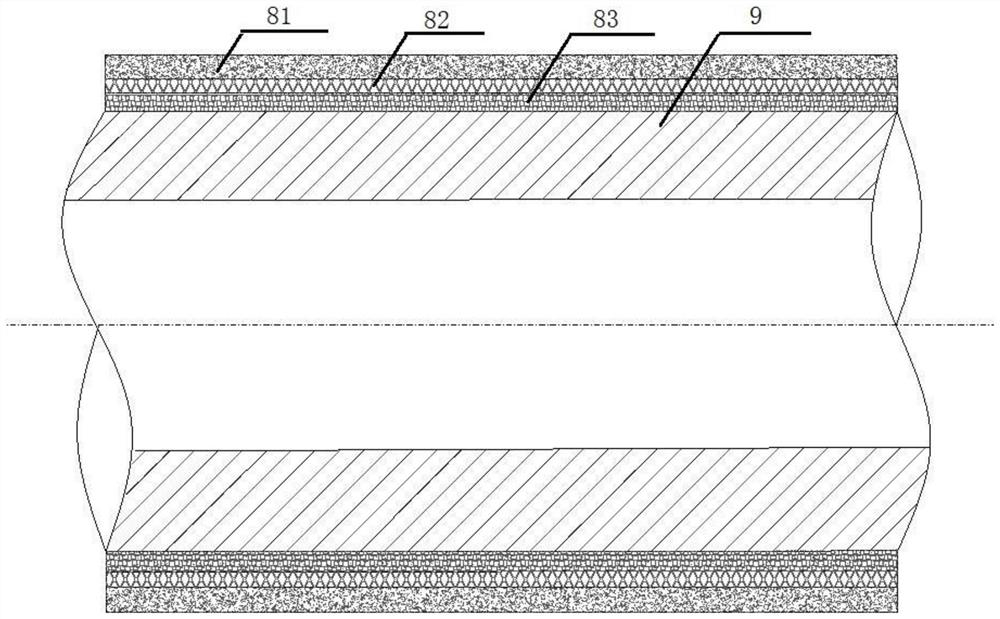

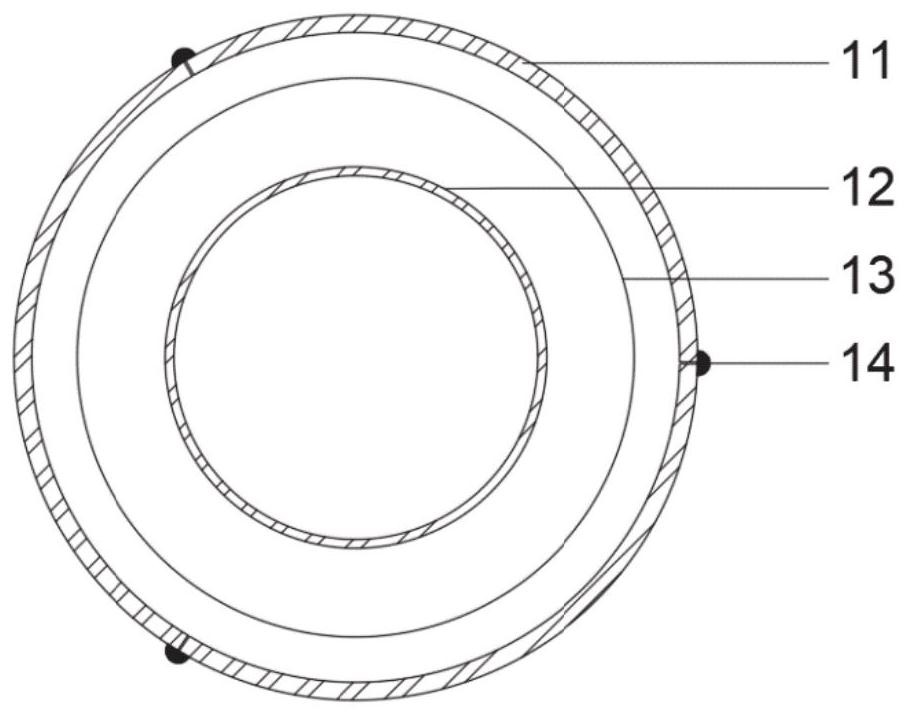

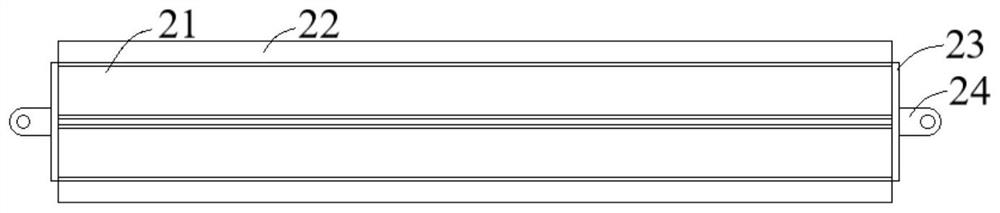

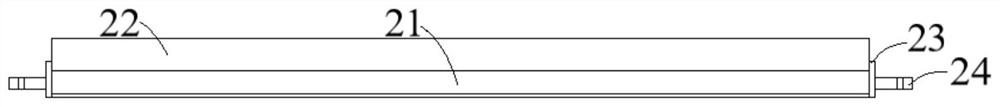

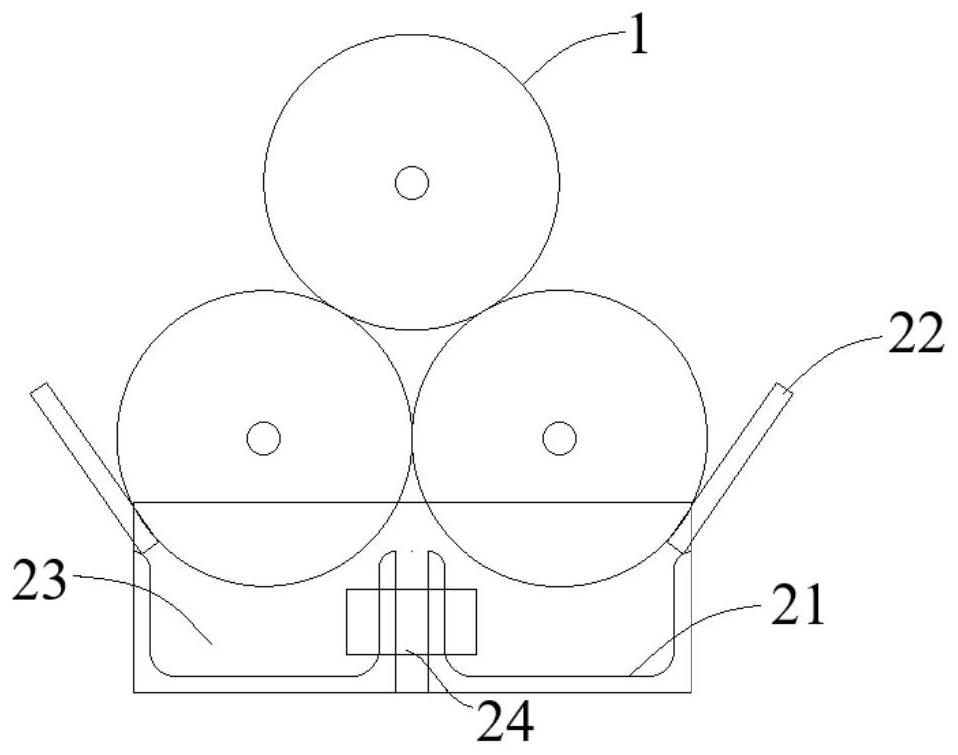

Large-caliber double-rubber-ring faucet-socket anti-corrosion steel pipe and installing method thereof

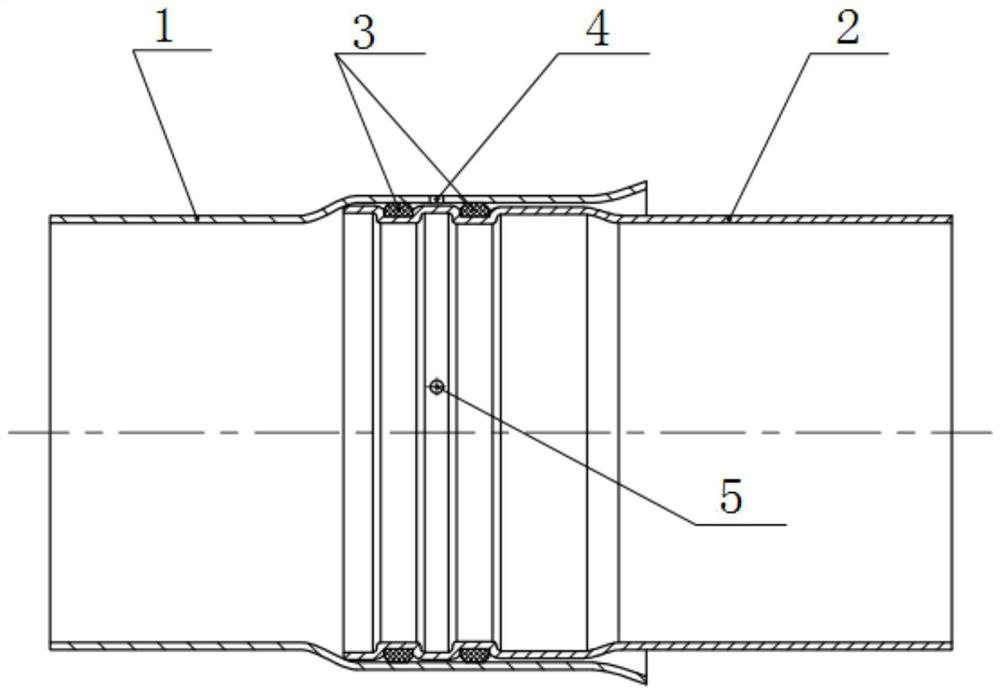

PendingCN111981215AAccelerated corrosionExtended service lifeSleeve/socket jointsPipe laying and repairPipeMechanical engineering

The invention is suitable for the technical field of pipeline faucets and sockets, and provides a large-caliber double-rubber-ring faucet-socket anti-corrosion steel pipe. The large-caliber double-rubber-ring socket anti-corrosion steel pipe comprises a first pipeline and a second pipeline; the end of the first pipeline is provided with a faucet which comprises an arc section, a straight edge section and an inclined section arranged from outside to inside in sequence; the end of the second pipeline is provided with a socket which comprises a parallel section provided with a plurality of grooves, and a guide section connected with the parallel section, deformation pieces are arranged in the grooves of the parallel section, the sum of the thickness of the deformation pieces and the parallelsection is larger than the diameter length of the straight edge section, the diameter length of the arc section is larger than the sum of thickness of the deformation pieces and the parallel section,and the parallel section is provided with exhaust holes. The first pipeline and the second pipeline are provided with at least three layers of anti-corrosion structures. Therefore, according to the large-caliber double-rubber-ring socket anti-corrosion steel pipe, the pipeline connection time can be effectively shortened, the pipeline connection leakproofness can be effectively ensured, and the working quality and efficiency are improved.

Owner:WEIFANG EAST PIPE IND TECHNICAL CO LTD

A method and system for monitoring displacement of oil and gas pipelines in permafrost regions

The invention discloses a freeze soil area oil and gas pipeline displacement monitoring method and system. A plurality of fiber bragg grating displacement sensors a (10) and a plurality of fiber bragg grating displacement sensors b (11) are arranged on one sides of oil and gas pipelines (2) in a freeze soil area, all the sensors are connected in series in a welding mode and then introduced into a monitoring station through optical cables (12), the optical cables (12) are connected with a photoswitch (13), the photoswitch (13) is connected with a fiber bragg grating interrogator (14), the fiber bragg grating interrogator (14) is connected with a lower computer (15), data preprocessed by the lower computer (15) are transmitted to a low-orbit satellite (17) through a satellite communication module (16), data are forwarded by the low-orbit satellite (17) to a satellite communication module (18), and received data are transmitted by the satellite communication module (18) to an upper computer (19) and analyzed and processed by the upper computer (19). The freeze soil area oil and gas pipeline displacement monitoring method and system are high in precision, high in stability and low in cost.

Owner:PIPECHINA SOUTH CHINA CO

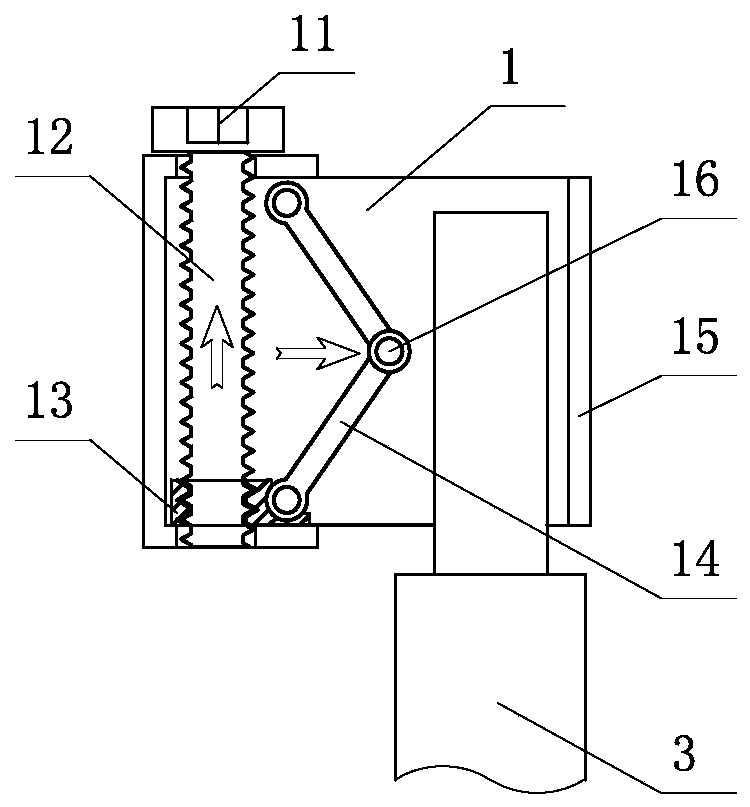

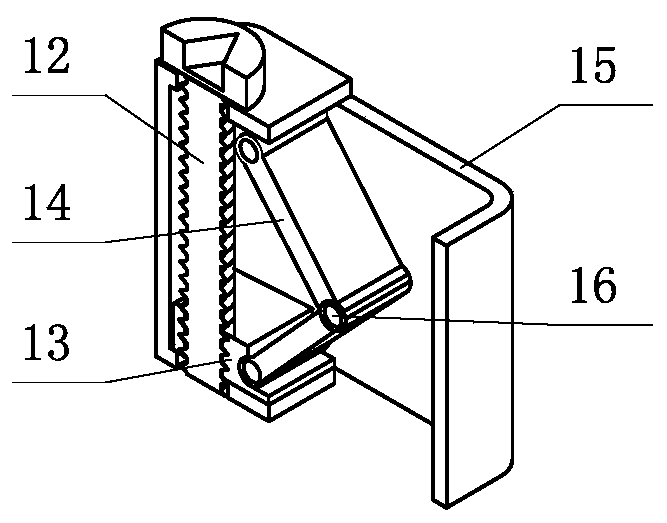

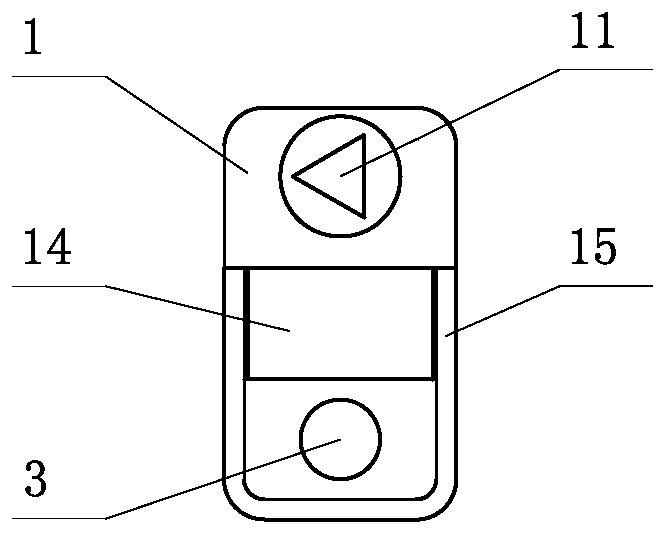

Triangular expansion type electrical wire holder

InactiveCN110661109AReduce the difficulty of operationSuitable for installationClamped/spring connectionsScrew threadElectric wire

The utility model relates to a triangular expansion type electric wire holder. The force application part of the wire holder is changed from the vertical direction of a wire into a direction the sameas a direction in which the wire penetrates into the wire holder. The wire holder is mainly composed of a wire holder shell, a screw rod, a driving nut, connecting rods and a linkage shaft. When the screw rod is rotated in a forward direction, the driving nut matched with the bottom of the screw rod rises according to a meshing force between screw threads; the hinged linkage shaft portion of the two connecting rods extrude towards a wiring area, so that the wire is clamped between the shell and the linkage shaft; and the functions of the installation, connection and conduction of the wire arecompleted. The above can be operations can be performed inversely, so that the clamped wire can be relieved. In the whole operation of connecting the wire into the wire holder, the clamping or unclamping action of the mechanism in the wire holder on the wire is completed in the wire holder, so that the appearance size of the wire holder is not changed.

Owner:LIANG PING

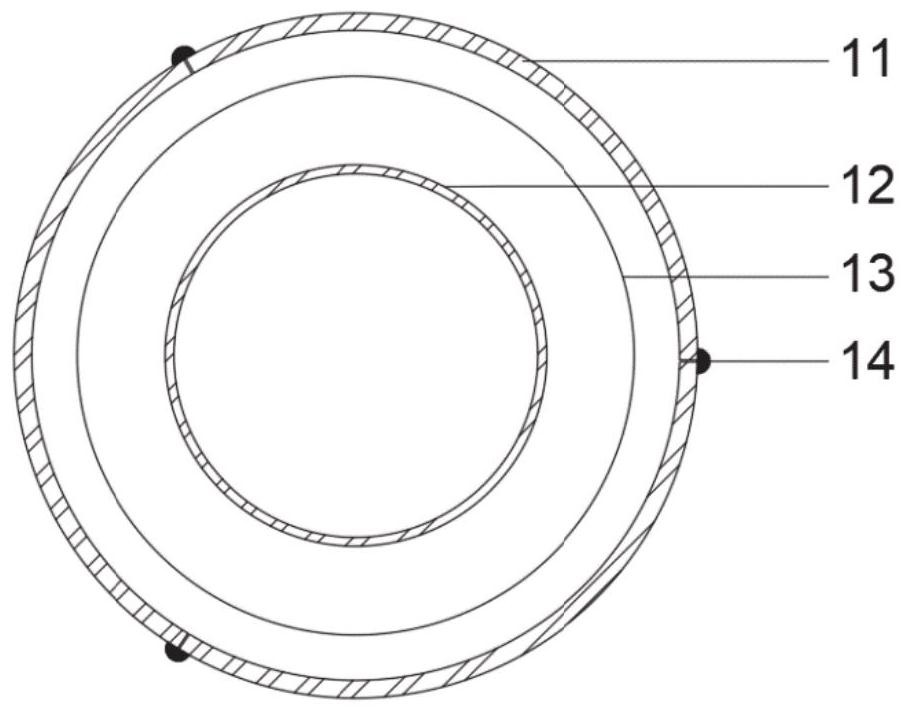

Sensor device, wheel, and wheel failure monitoring method

PendingCN112622978AReduce the difficulty of combinationReduce construction costsWheel-rims surveying/measuringSignalling indicators on vehicleControl engineeringMonitoring methods

The invention provides a sensor device, a wheel and a wheel fault monitoring method, relates to the technical field of train monitoring equipment, and aims to solve the technical problem that an existing train wheel monitoring device needs an external power supply and a lead to a certain extent. The sensor device provided by the invention is used for a wheel and comprises a first mounting component, a second mounting component, a magnet, a coil and a sensing mechanism, the first mounting component is connected with a rotating shaft of a wheel. The magnet is installed on the side, deviating from the rotating shaft, of the first mounting component. The second mounting component is connected with a shaft end cover of the wheel, and the rotating shaft rotates relative to the shaft end cover, so that the first mounting component rotates relative to the second mounting component; the coil is mounted on the second mounting component and is arranged opposite to the motion trail of the magnet; the sensing mechanism is arranged on the side, away from the coil, of the second mounting component and connected with the coil wire so as to provide power for the sensing mechanism.

Owner:北京竞业达数码科技股份有限公司

Long-span cantilever steel structure construction method

InactiveCN107060336AEnsure personal safetyReduce construction proceduresBuilding material handlingTotal stationEngineering

The invention relates to a long-span cantilever steel structure construction method. A buckling supporting rod and a cantilever structure are included. The cantilever structure is connected to a supporting column through the buckling supporting rod. The construction method includes the following steps that an absolute coordinates virtual network of the buckling supporting rod and the cantilever structure is established on the computer, marking is conducted in a practical connecting point position of the cantilever structure; practical connecting point coordinates are measured on the scene through a total station, the practical connecting point coordinate are controlled, the cantilever structure and the buckling supporting rod are installed synchronously, and an installing position is controlled through the total station. According to the long-span cantilever steel structure construction method, the buckling supporting rod and the cantilever structure are installed synchronously, temporary fixing devices such as all kinds of jacks do not need to be installed and temporarily arranged, the cantilever structure does no need to conduct unloading, construction processes are reduced, construction efficiency is improved, construction cost is reduced, construction hidden danger is reduced, personal safety of construction personnel is ensured, and construction quality is improved.

Owner:CHINA 22MCC GROUP CORP

Continuous beam bridge suitable for tunnel to pass through huge karst cave and construction technical method thereof

ActiveCN112627002ASimple structureEasy constructionBridge erection/assemblyBulkheads/pilesBridge deckPipe

The invention relates to a continuous beam bridge suitable for a tunnel to pass through a huge karst cave and a construction technical method thereof, and belongs to the field of karst area tunnel engineering. The upper structure of the continuous beam bridge comprises a support (basin-type rubber support), a beam plate (cast-in-place beam plate), a bridge deck structure (a bridge deck pavement layer, a waterproof layer, an expansion joint and the like) and bridge deck accessory structures (crash barriers, isolation piers, sound insulation screens and the like). The lower structure comprises piers (light piers), a bridge abutment (light bridge abutment), a foundation (steel pipe pile foundation) and a bearing platform (high pile bearing platform). The miniature steel pipe pile combined pier foundation is used, the steel pipe piles are simple in structure and convenient to construct, the construction amount and the construction time can be greatly reduced, and the continuous beam bridge is more economical and safer. By means of the construction method, the problems that a traditional karst cave disposal method is improper, the cost is high, and hidden danger is caused to the tunnel structure and operation safety are solved, and reference experience is conveniently provided for later giant karst cave construction.

Owner:中铁十四局集团建筑工程有限公司

Stepping type conveying device and method for carrier roller of dip angle belt conveyor

ActiveCN111674827ALess likely to damage idler rollersIt is not easy to lose the idler rollerConveyorsRollersTransport corridorControl engineering

The invention provides a stepping type conveying device and method for a carrier roller of a dip angle belt conveyor, and belongs to the technical field of belt conveyors of an iron-making system. Thestepping type conveying device comprises a carrier roller carrying device, three-carrier-roller assemblies, a conveyor support, traction ropes and winches. The multiple three-carrier-roller assemblies are arranged in the length direction of the conveyor support at intervals, the carrier roller carrying device is placed on the three-carrier-roller assemblies and connected with the winches throughthe traction ropes, the carrier roller carrying device is pulled by the winches to move on the three-carrier-roller assemblies, and the carrier roller carrying device is arranged to be of a double-groove type and can carry 3N carrier rollers which are matched with the number of carrier rollers of the three-carrier-roller assemblies. When the stepping type conveying device is adopted to convey thecarrier rollers, the support of the belt conveyor is utilized to transport carrier rollers needing to be installed in the next step on the installed three-carrier-roller assemblies, new three-carrier-roller assemblies are formed and continue to be applied to the conveying of the next step, no additional design of transport corridors is required, and the situation that other space is occupied, causing the obstruction to the installation of the carrier rollers by builders cannot happen.

Owner:CHINA MCC17 GRP

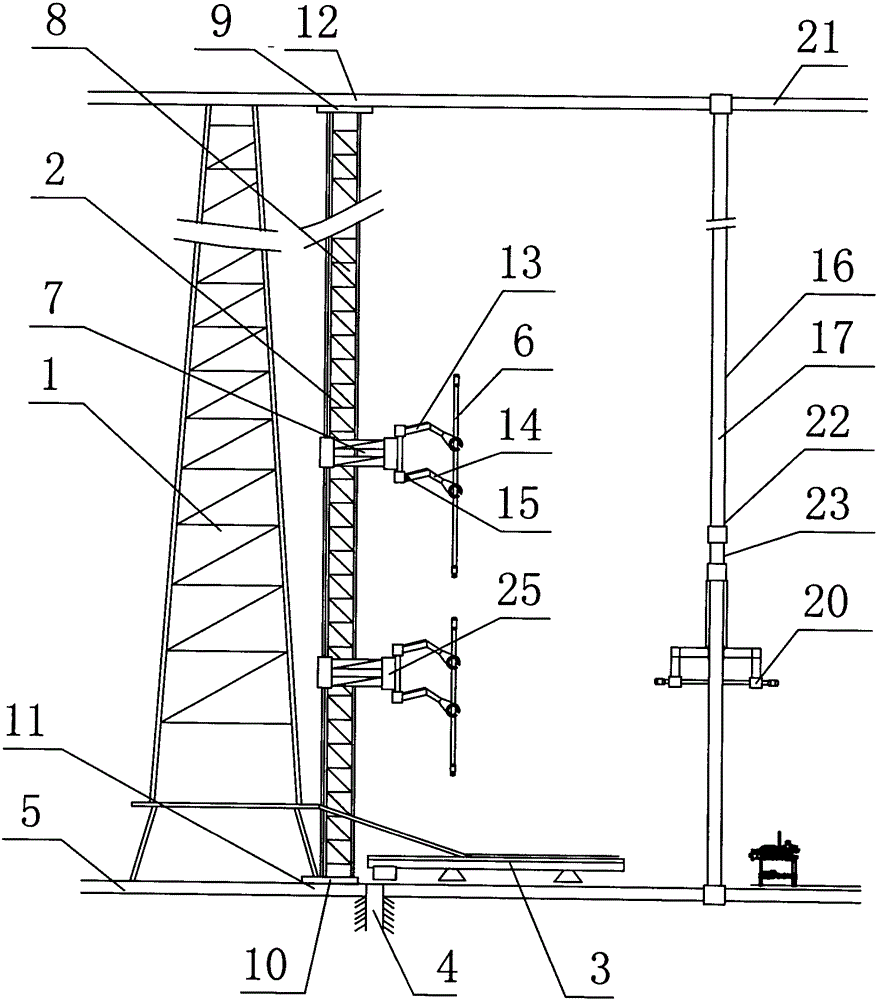

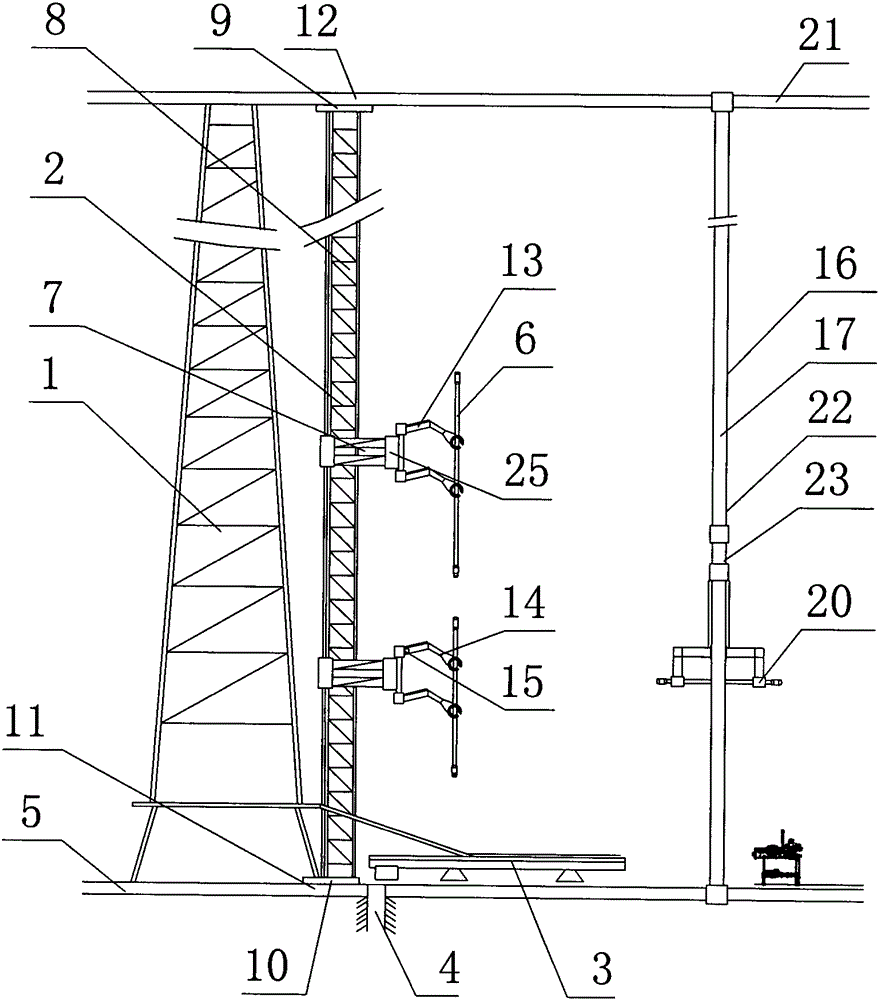

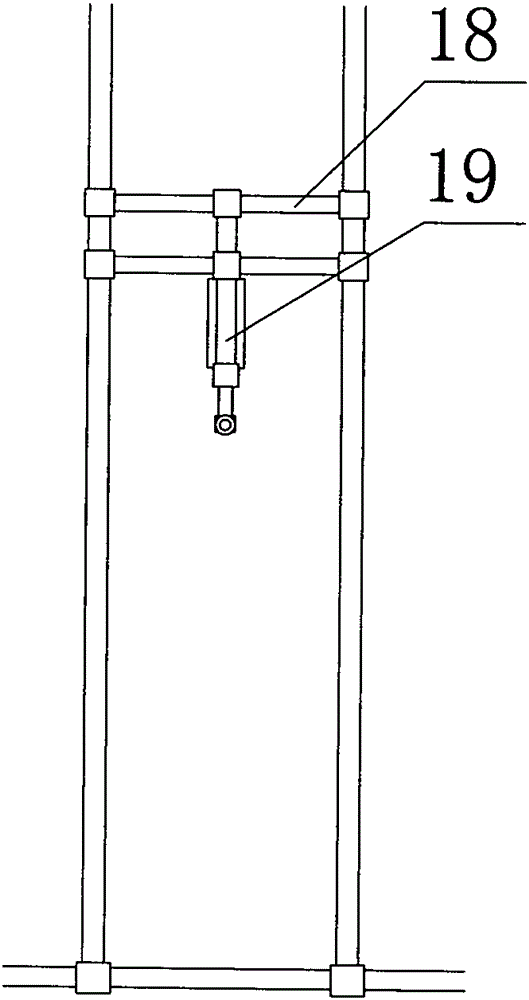

Offshore drilling platform automatic piping system

ActiveCN103244062BReach the standard of unmanned operationGuarantee personal safetyDrilling rodsDrilling casingsProgrammable logic controllerWell drilling

The invention discloses an automatic pipe arranging system for a marine drilling platform. The automatic pipe arranging system for the marine drilling platform comprises a derrick, at least one set of pipe grabber for grabbing and arranging drill pipes, a hydraulic catwalk, a mouse hole and a PLC (Programmable Logic Controller) control unit for controlling the whole system, wherein the derrick is fixed on the drilling platform, and the mouse hole is fixed below the drilling platform. The automatic pipe arranging system for the marine drilling platform is characterized in that a guide rail stand column is provided with an upper mechanical arm and a lower mechanical arm, the front ends the upper mechanical arm and the lower mechanical arm are both provided with a rotation type connecting base, the rotation type connecting base of the upper mechanical arm is at least provided with a pipe grabbing hand and a make-up and break-out device, and the rotation type connecting base of the lower mechanical arm is at least provided with a pipe grabbing hand. The automatic pipe arranging system for the marine drilling platform has the advantages of achieving the abutting joint of the drill pipes in the air and being capable of automatically adjusting the position of the upper drill pipe and the lower drill pipe during an abutting joint process, shortening abutting joint time, improving working efficiency and reducing construction cost.

Owner:JINYOU MACHINERY NANTONG

A monitoring system for oil and gas pipelines in permafrost regions

ActiveCN103383245BSimple networkingEasy to realize automatic real-time online monitoringMaterial analysis by optical meansThermometers using physical/chemical changesFiberGrating

The invention is an oil and gas pipeline monitoring system in permafrost regions based on optical fiber grating sensing technology. Install a temperature sensor group on the surface of the oil and gas pipeline a(2) and its surroundings in the permafrost region (1), install a water content sensor group around the oil and gas pipeline a(2), and install a fiber grating displacement sensor on the side of the oil and gas pipeline a(2) The sensor group, all the sensors are connected in series, lead to the monitoring station by the optical cable (12), the optical cable (12) is connected with the optical switch (13), the optical switch (13) is connected with the fiber grating demodulator (14), and the fiber grating demodulator (14) is connected. The instrument adjustment (14) is connected with the lower computer (15), and the data preprocessed by the lower computer (15) is transmitted to the low-orbit satellite (17) through the satellite communication module a (16), and the low-orbit satellite (17) forwards the data to The satellite communication module b (18), the satellite communication module b (18) transmits the received data to the upper computer (19) for analysis and processing. The invention has high precision, high stability and low cost.

Owner:PIPECHINA SOUTH CHINA CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com