Mounting structure of wall leveling member and mounting method of mounting structure

A technology of installation structure and installation method, which is applied in the direction of building structure, covering/lining, construction, etc., can solve the problems of large error and slow wall leveling efficiency, so as to improve the fire protection level, reduce construction hidden dangers, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

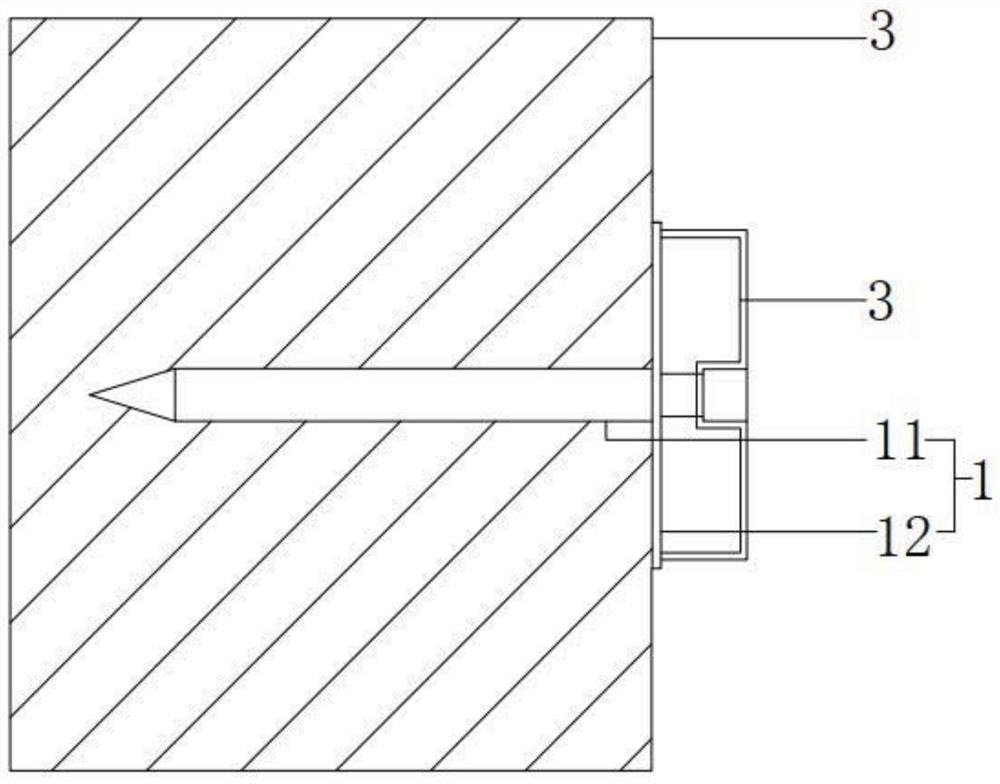

[0035] see Figure 1 to Figure 5 , the figure shows the installation structure of a wall leveling component provided by Embodiment 1 of the present invention, which mainly includes a leveling piece 1, an M-shaped keel 2, a wall base 3 and a decorative panel, and the leveling piece 1 includes The fixing rod 11 and the finding plate 12, the finding plate 12 is fixedly connected to the fixing rod 11, the M-shaped keel 2 is provided with a sinking groove 21, the fixing rod 11 runs through the sinking groove 21 and extends into the wall base 3, the M-shaped The keel 2 is fixedly connected on the metope base 3 by the fixing rod 11, and the side of the M-shaped keel 2 near the metope base 3 is against the scout plate 12, and the decorative panel is installed on the M-shaped keel 2.

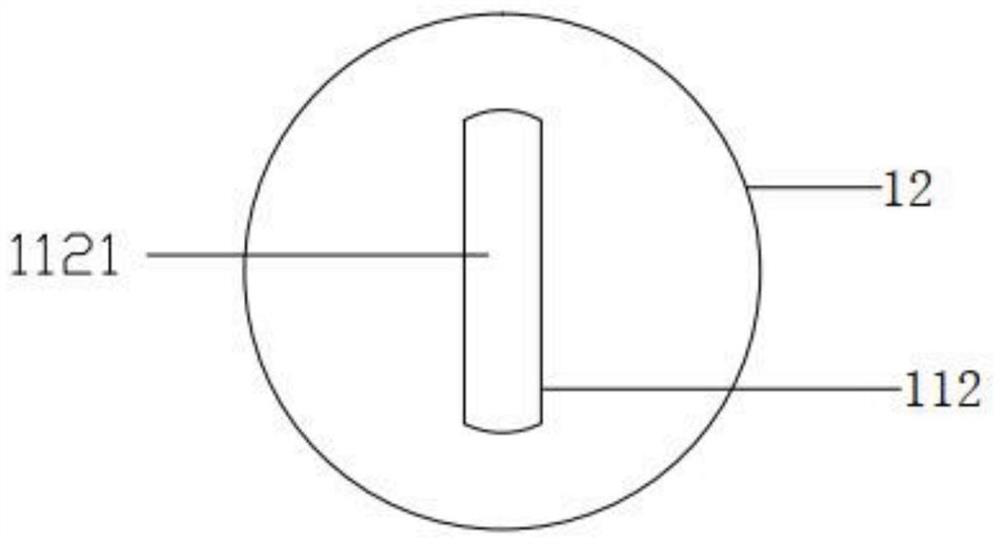

[0036] Specifically, see image 3 , the finder plate 12 is circular in a top view. Find flat also can be polygons such as rectangle, pentagon, can set according to actual situation.

[0037] On the ot...

Embodiment 2

[0049] see Figure 1 to Figure 5 , the figure shows the installation structure of a wall leveling component provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: sinking tank 21 is arranged along the length direction of the M-shaped keel 2. In this way, multiple leveling parts can be installed on the sinking tank, which ensures the flatness and connection strength of the M-shaped keel, and does not affect the flatness of the veneer at the same time.

Embodiment 3

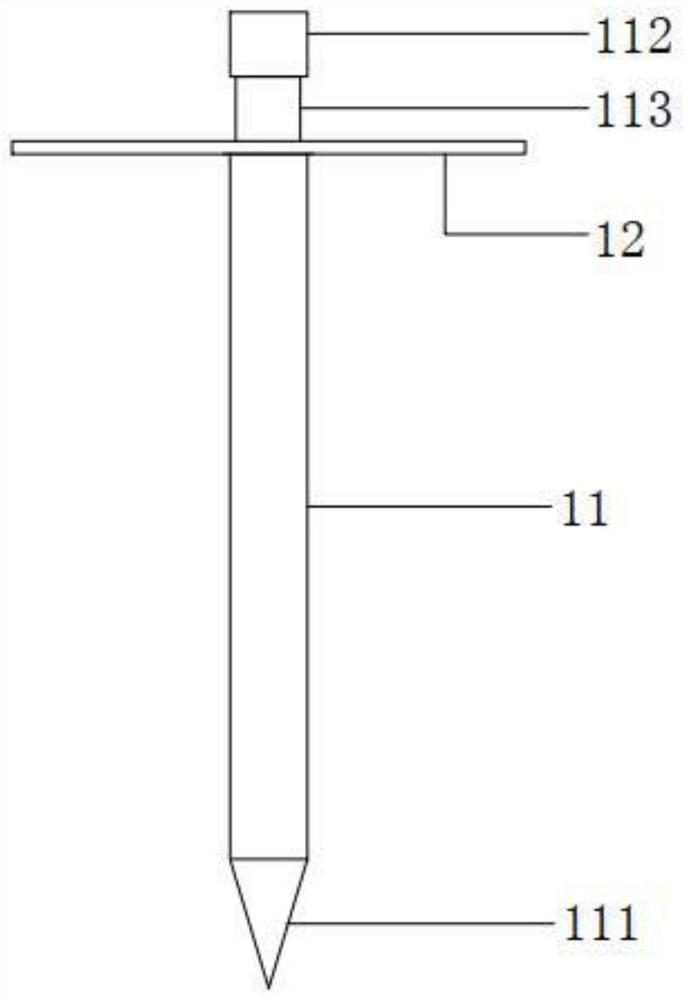

[0051] see Figure 1 to Figure 5 , the figure shows the installation structure of a wall leveling component provided by Embodiment 3 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the fixing rod 11 One end of the fixed rod 11 has a conical head 111, and the other end of the fixed rod 11 has an adjusting cover 112. The tapered head can facilitate the fixing rod to enter the wall and improve construction efficiency. The surface of the fixing rod 11 is provided with threads, which can improve the fixing strength. The adjusting cover can prevent the M-shaped keel from loosening and improve the firmness of the overall connection. The fixing rod 11 and Connecting rod 113 is arranged between adjusting cover 112, and the diameter of 113 of connecting rod is less than the diameter of fixed rod 11, finds flat like this and can prop up fixed rod, guarantees the flatness of finding flat, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com