Long-span cantilever steel structure construction method

A technology for steel structure construction and large-span cantilevering, which is applied in building construction, construction, and building materials processing. Efficiency and the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below with reference to accompanying drawing and embodiment:

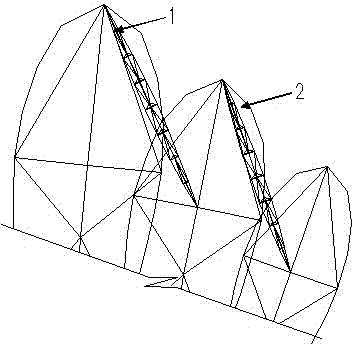

[0028] attached Figure 1-5 It can be seen that a construction method for a large-span cantilevered steel structure includes a buckling support rod 1 and a cantilevered structure 2, and the cantilevered structure 2 is connected to a supporting column 8 through a buckled support rod 1, including the following steps:

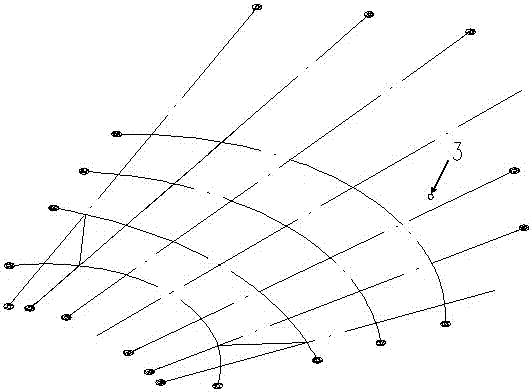

[0029] (1) Establish an absolute coordinate virtual network of buckling struts and cantilever structures on the computer; the coordinate origin 3 of the virtual network is consistent with the absolute coordinate origin of construction;

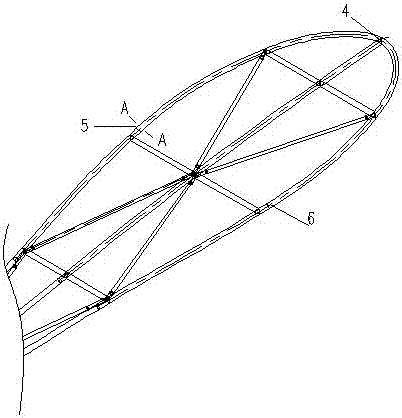

[0030] (2) Using computer simulation to install in place, select the absolute space coordinates X / Y / Z of the actual connection point 4, the actual connection point 5, and the actual connection point 6 on the cantilever structure; the connection point coordinates select position 7 as the installation point outside;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com