Stepping type conveying device and method for carrier roller of dip angle belt conveyor

A technology of belt conveyors and conveying devices, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of time-consuming and labor-consuming, and achieve the effects of reducing construction hidden dangers, high efficiency, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

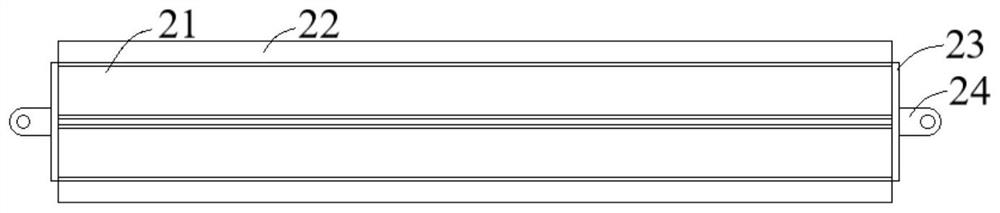

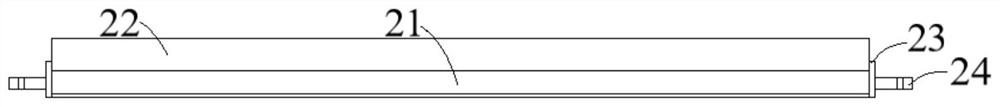

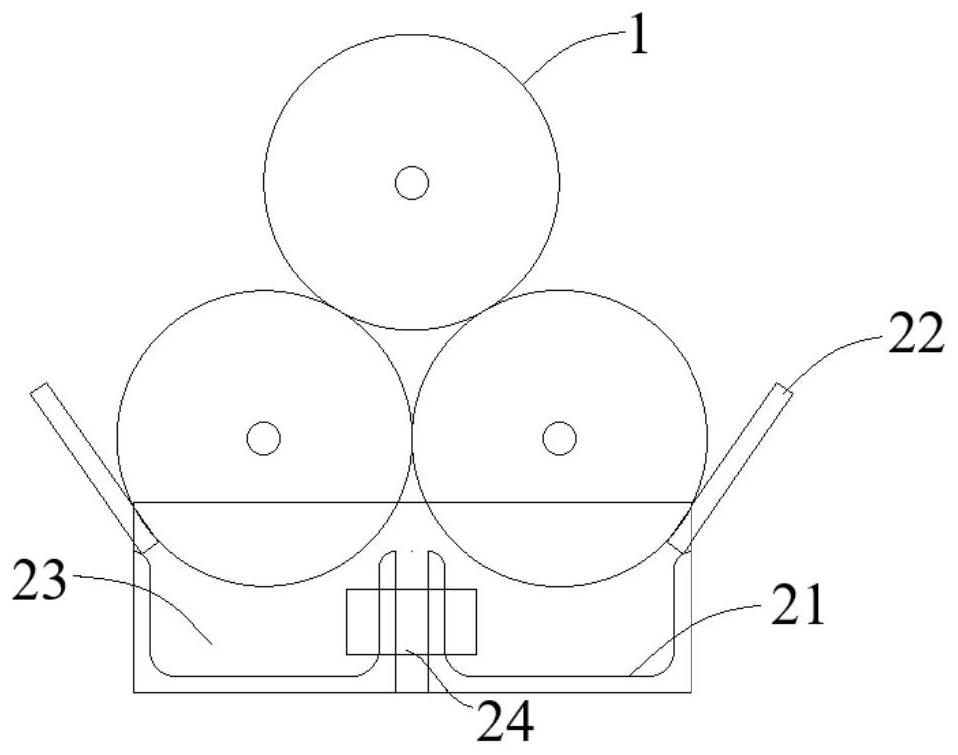

[0038] combine Figure 5 and Figure 6 , a step-by-step conveying device for idler rollers of an inclined belt conveyor in this embodiment, comprising an idler carrying device 2, a three-roller assembly 3, a conveyor bracket 4, a traction rope 5 and a hoist 6; There are multiple roller assemblies 3 arranged at intervals along the length direction of the conveyor bracket 4, and the idler carrying device 2 is placed on the three idler roller assembly 3, and the idler carrying device 2 is loaded with idler rollers 1, and the idler carrying device 2 is connected to the winch 6 through the traction rope 5, and the idler carrier device 2 is pulled by the winch 6 to move on the three idler roller assembly 3. In this embodiment, two hoisting machines 6 are arranged, respectively placed at both ends of the belt conveyor, on which a traction rope 5 is wound, and the idler carrying device 2 connected to it can move in the opposite direction under the traction of the two hoisting machine...

Embodiment 2

[0044] In this embodiment, a step-by-step conveying method for idler rollers of an inclined belt conveyor, the idler carrier device 2 is loaded with idler roller 1, and the installed three idler roller assembly 3 is used to transport the idler carrier device 2 to the idler roller to be installed 1 position, remove the idler roller 1 to assemble the three-idler roller assembly 3, and the assembled three-idler roller assembly 3 will be applied to the continuous conveyance of the idler carrier device 2. The specific steps are:

[0045] Step 1. Starting from the position of the head wheel of the belt conveyor, assemble several three-idle roller assemblies 3 along the length direction of the conveyor bracket 4, and several three-idle roller assemblies 3, so that the formed length can carry the idler carrying device 2;

[0046] Step 2. Place the idler carrier device 2 on the three idler assembly 3, and stack the idler 1 required for the next step of installation on it (it is worth n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com