The main and auxiliary spans are environmentally friendly circular stockyards

A circular material yard and environment-friendly technology, which is applied in building types, large-capacity bulk material storage, loading/unloading, etc., can solve the problems of high main material shed, high material shed, large stacker investment, etc., to achieve The effect of increasing storage capacity, improving stability and reducing civil construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

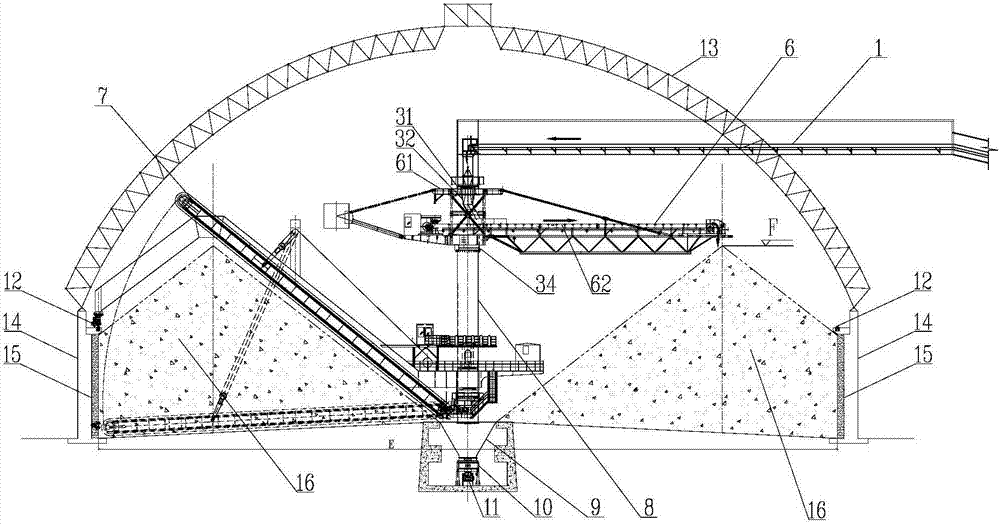

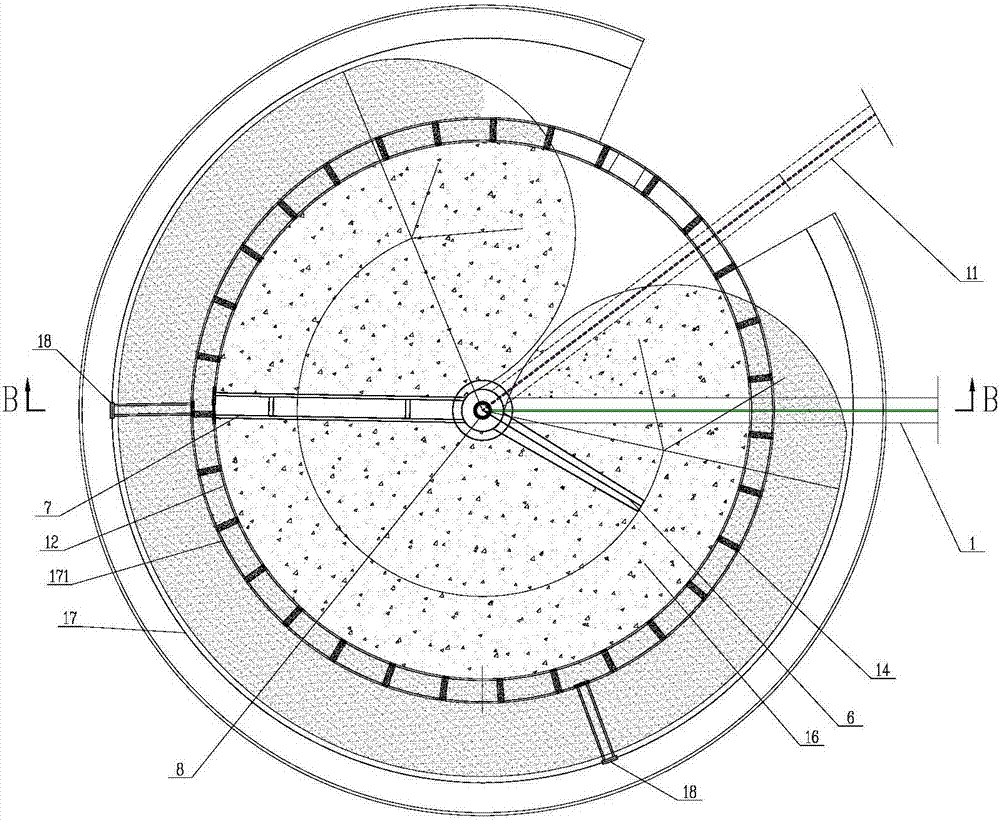

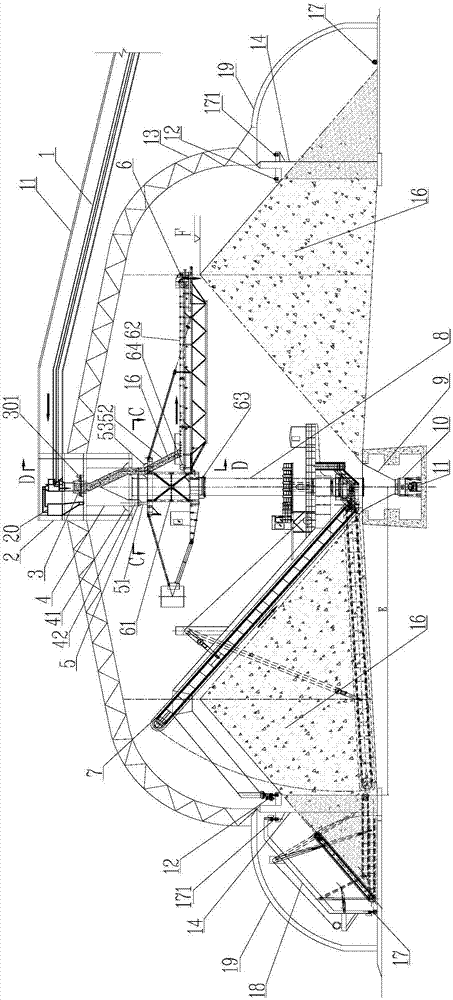

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

[0038] The upper end of the reclaimer refers to the end of the reclaimer away from the central column, and the lower end of the reclaimer refers to the end of the reclaimer close to the central column. The direction of the arrow in the drawings indicates the direction of feeding; the letter E indicates the span of the material shed, and F indicates the height of the material pile.

[0039] In this embodiment, the main and auxiliary spans are environmentally friendly circular stockyards, including a number of pillars 14 arranged in a ring shape. The upper part of the pillars 14 is supported by an arc-shaped main span shed 13, and a direction is arranged between the pillars and the ground. Outwardly protruding arc-shaped auxiliary span shed 19, the upper end of said arc-shaped auxiliary span shed 19 is sealed and connected with the lower end of said arc-shaped main span ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com