Patents

Literature

72results about How to "Reduce external temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

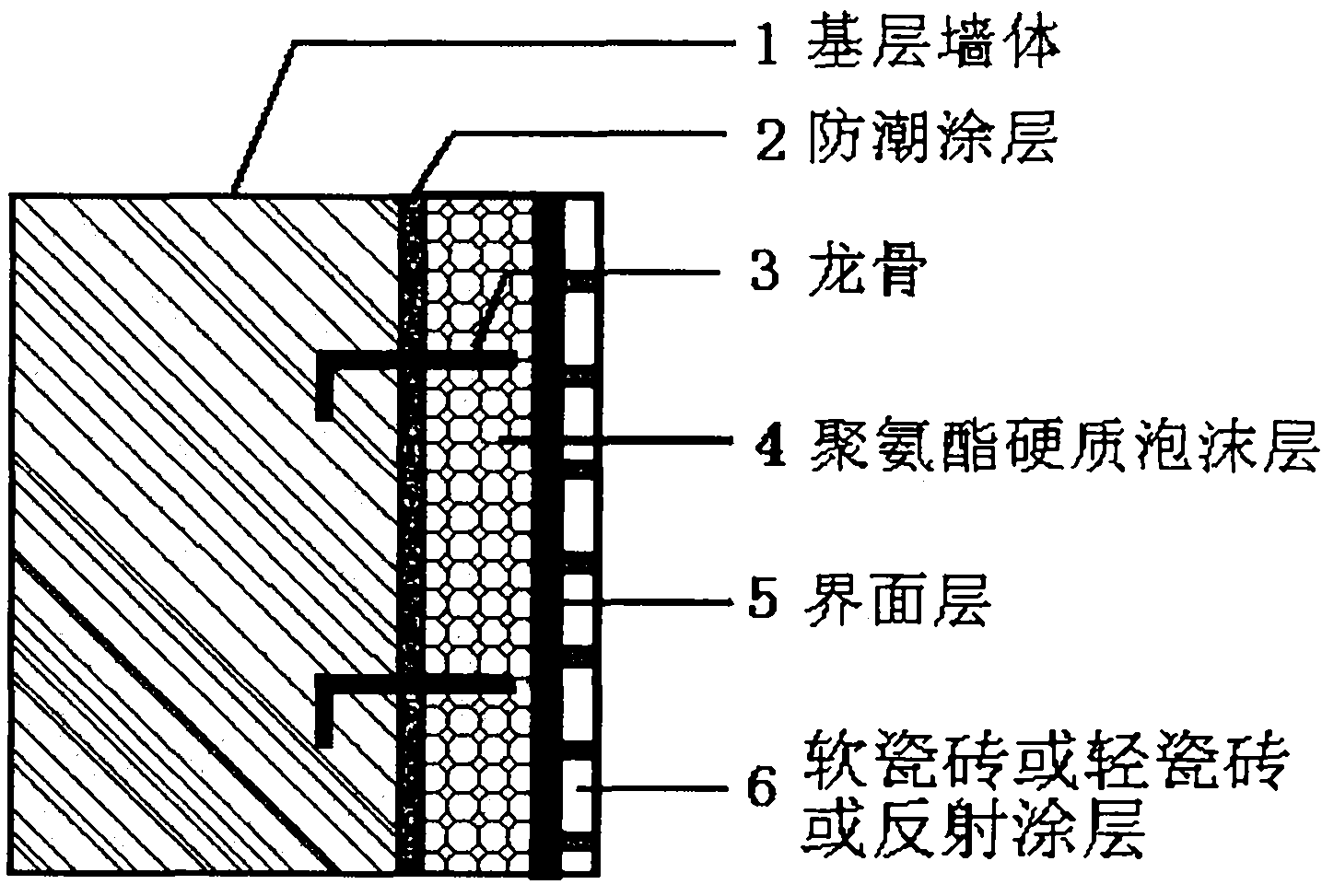

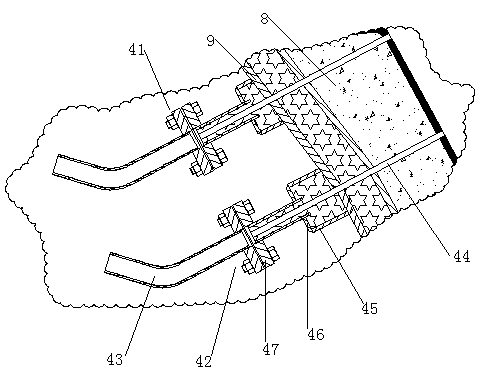

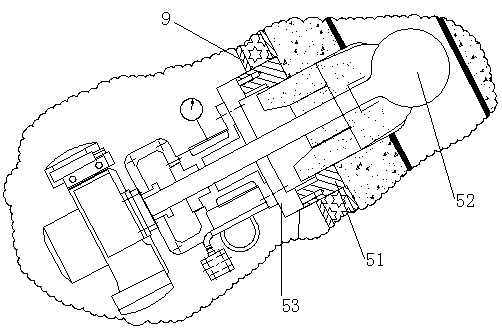

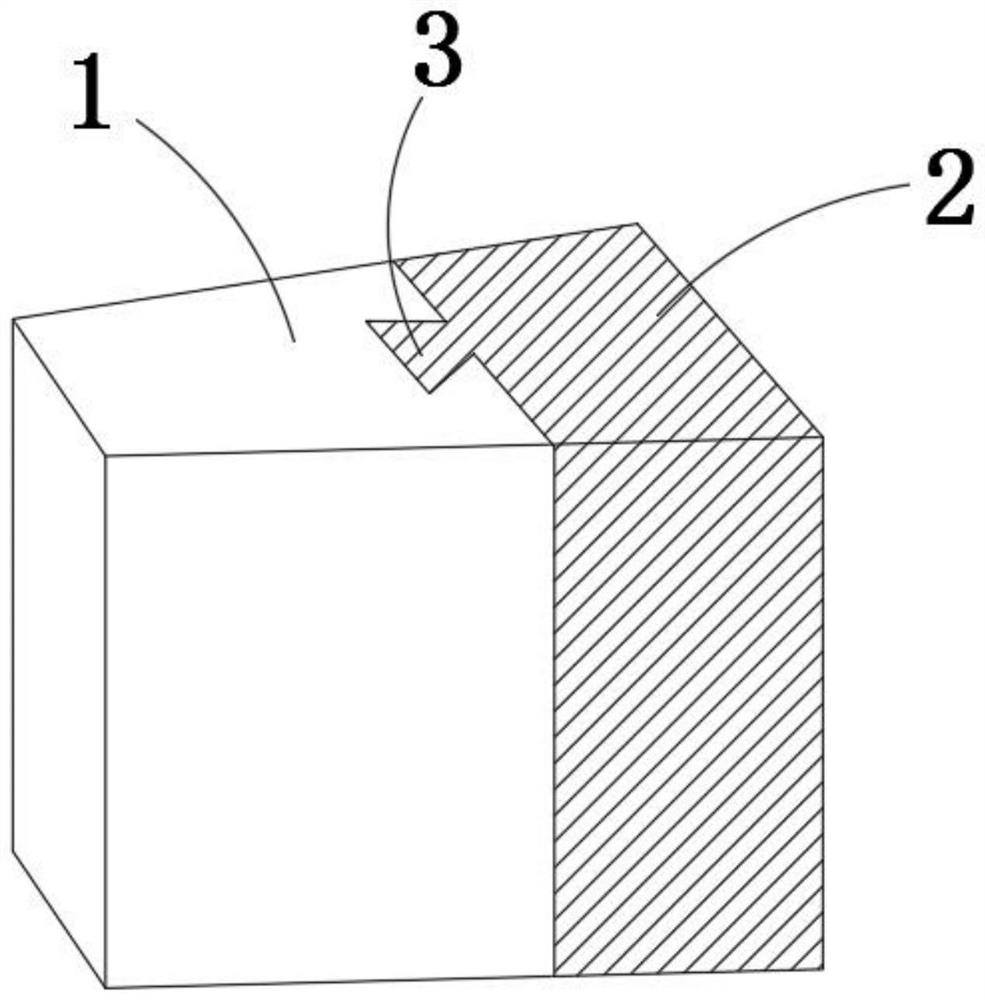

High flame retardant polyurethane rigid foam outer wall thermal insulation system

ActiveCN101956429AMeet the needs of beautificationImprove the problem of shrinkage and collapseHeat proofingBuilding material handlingWet bondingKeel

The invention discloses a high flame retardant polyurethane rigid foam outer wall thermal insulation system. From a basic unit wall provided with a keel and connecting pieces, a prime coat thickening layer, a polyurethane rigid foam layer, an interface layer, and soft tiles, light tiles or a reflective coating are arranged in turn. In the system, the prime coat thickening layer has high adhesion and good wet bonding strength for the basic unit wall and the polyurethane rigid foam; and the high flame retardant polyurethane rigid foam outer wall thermal insulation system is foamed by pure water, and is halogen-free, flame retardant, safe and environment-friendly. The vertical face of the wall is successfully foamed on site, and the polyurethane rigid foam can be directly sprayed and foamed on the basic unit wall which is treated by the prime coat thickening layer, can reach high adhesion to the basic unit wall after 24 to 48 hours, and has the coefficient of thermal conductivity of less than 0.03W / (m.K), the vertical burning reaching V-0 level, and the water absorption of less than 2.5 percent.

Owner:海聚高分子材料科技(广州)有限公司

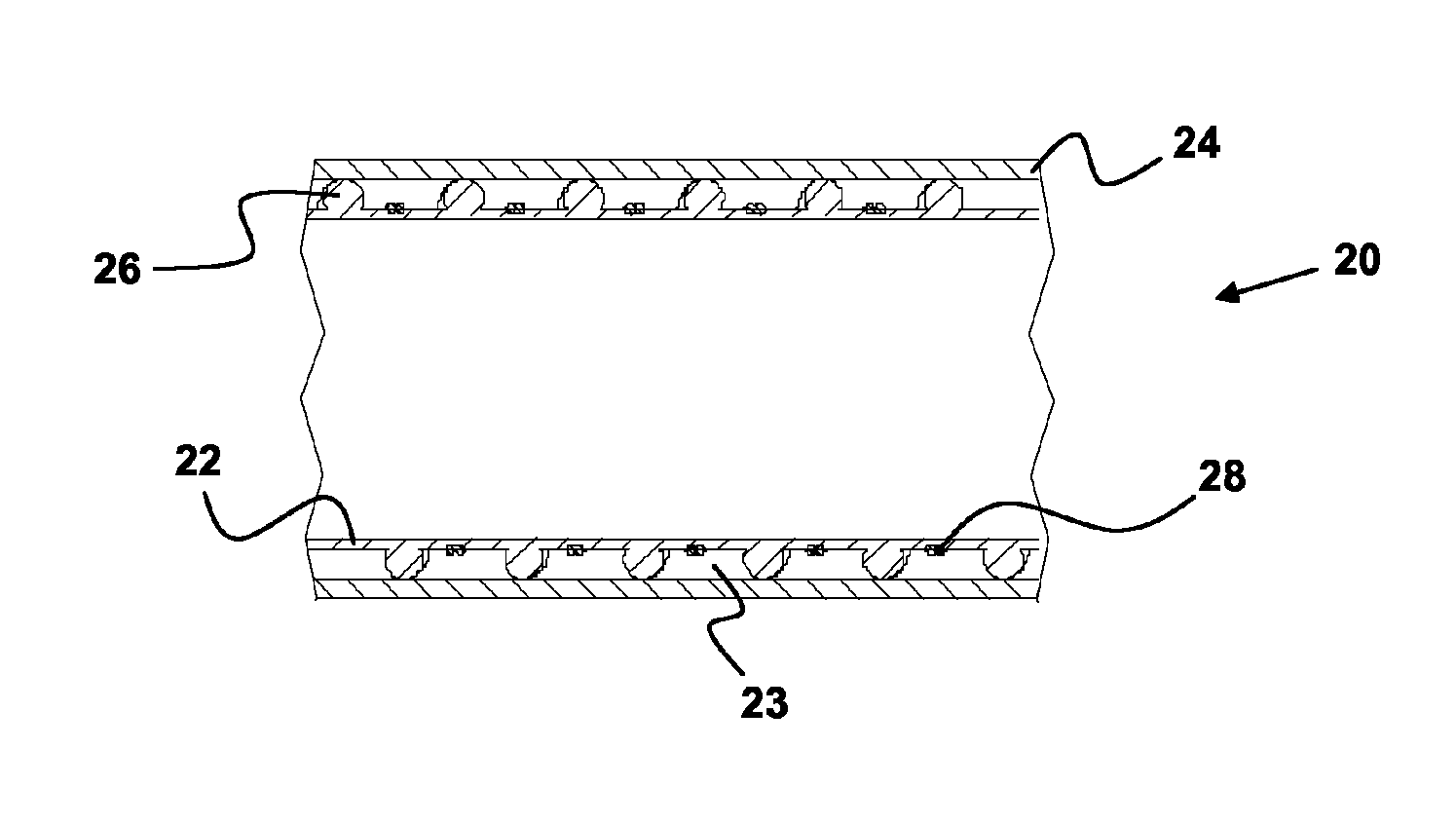

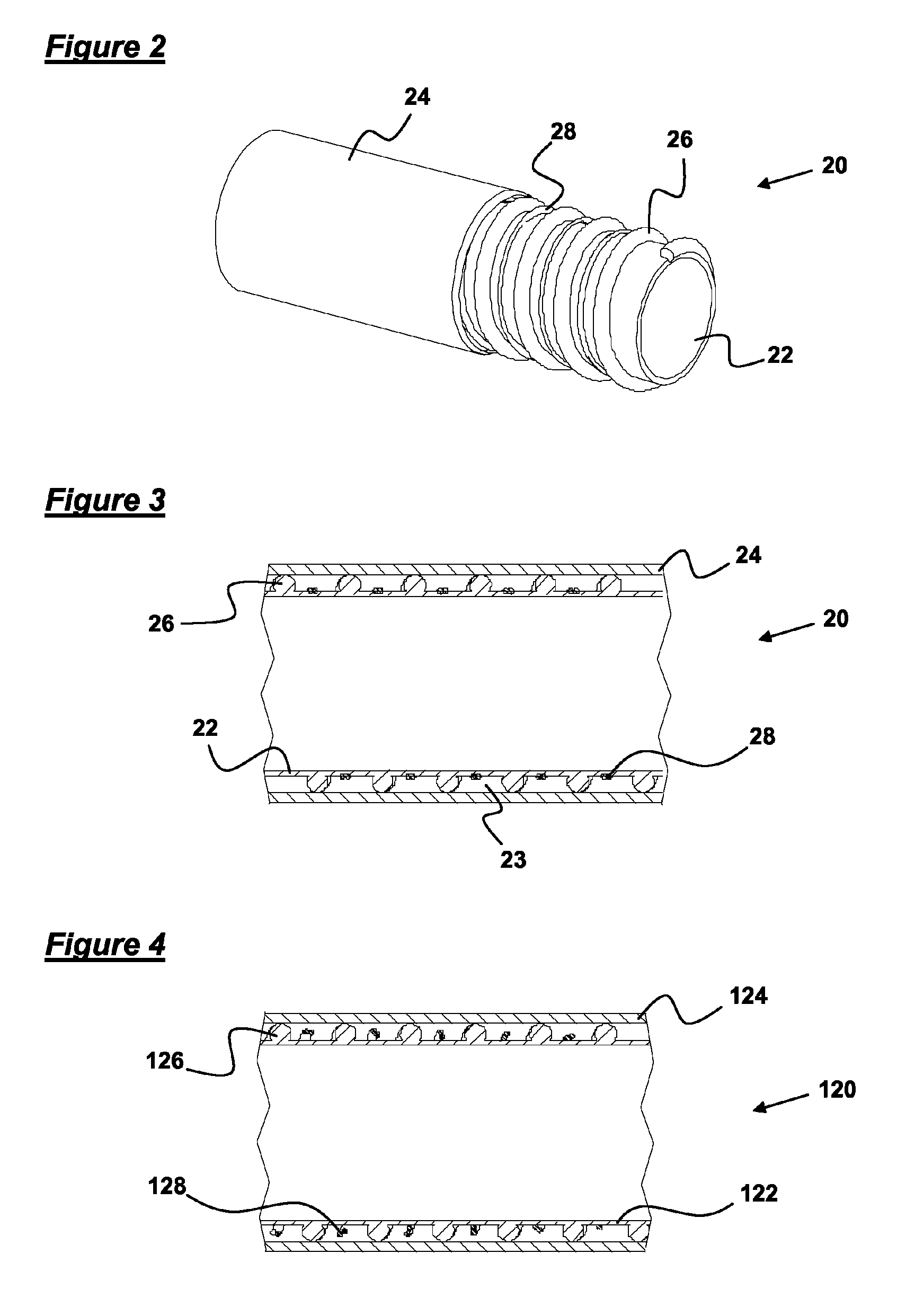

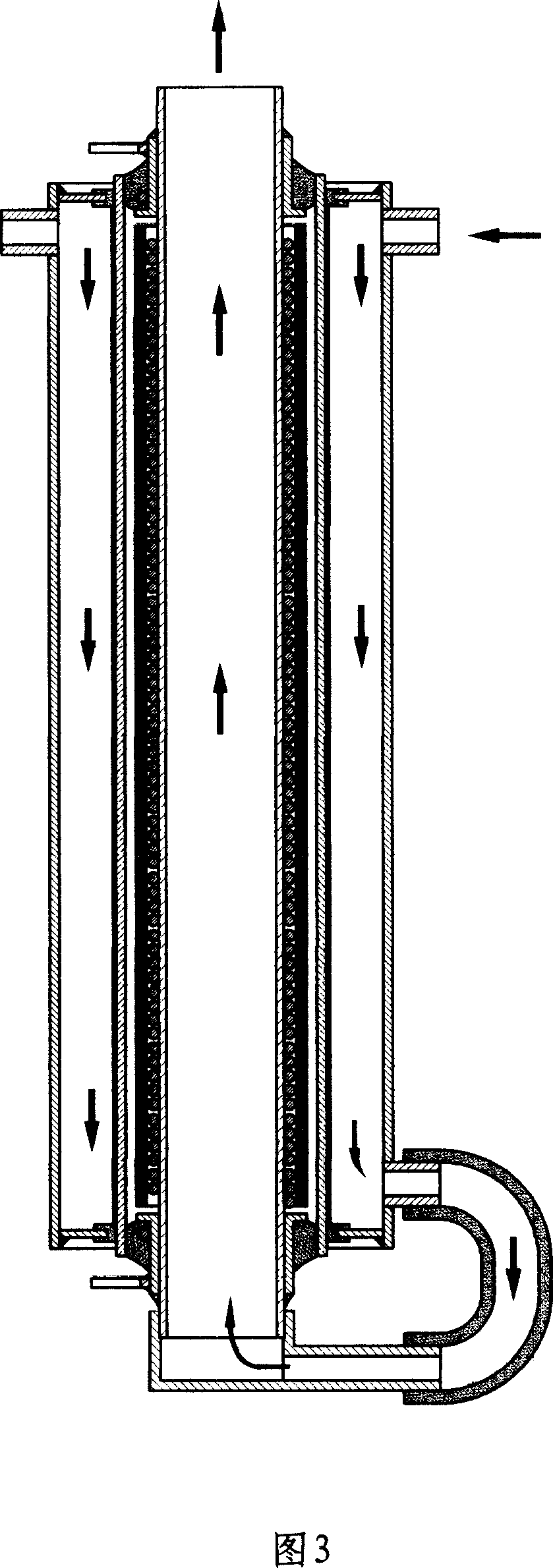

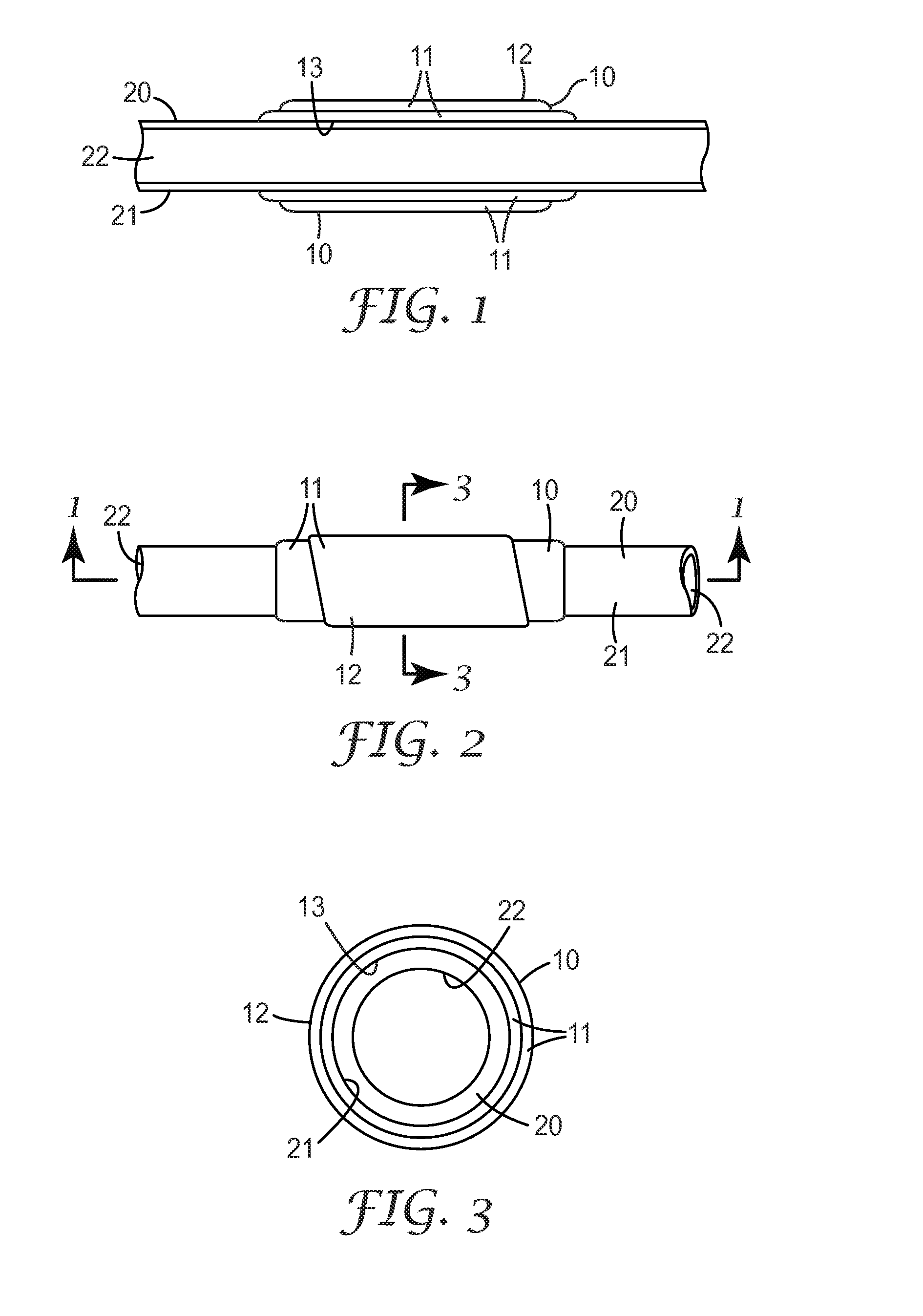

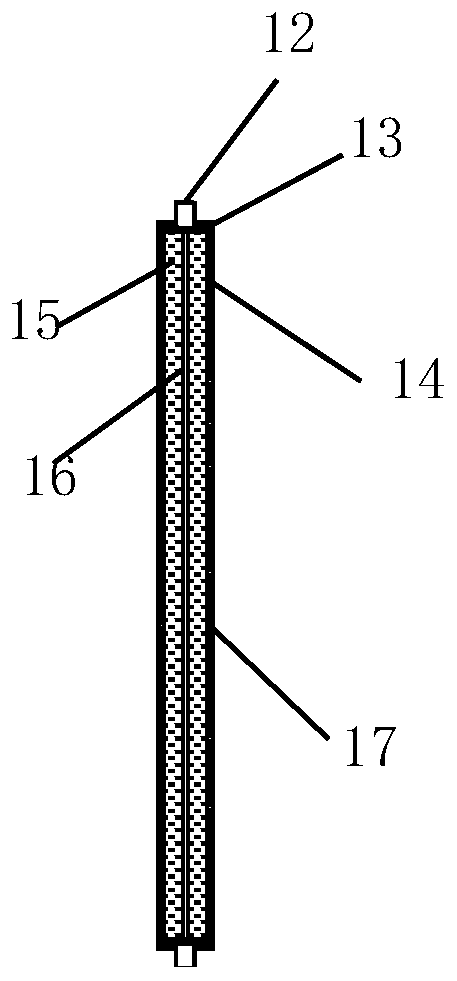

Ventilation tubes

ActiveUS8726901B2Easily connectableReduce riskRespiratorsOther heat production devicesVentilation tubeEngineering

A ventilation tube (20, 120, 220) is disclosed. The ventilation tube (20, 120, 220) comprises an inner wall (22, 122, 222) that defines a fluid passageway for 5 ventilation gases, an outer wall (24,124,224) that surrounds the inner wall (22, 122, 222) and has a greater thickness than the inner wall (22, 122, 222), a helical separator member (26, 126, 226) interposed between the inner and outer walls (22, 122, 222, 24, 124, 224) so as to define an insulation chamber between the inner and outer walls (22, 122, 222, 24, 124, 224), and a heating element (28, 128, 228) disposed within the insulation chamber.

Owner:INTERSURGICAL AG

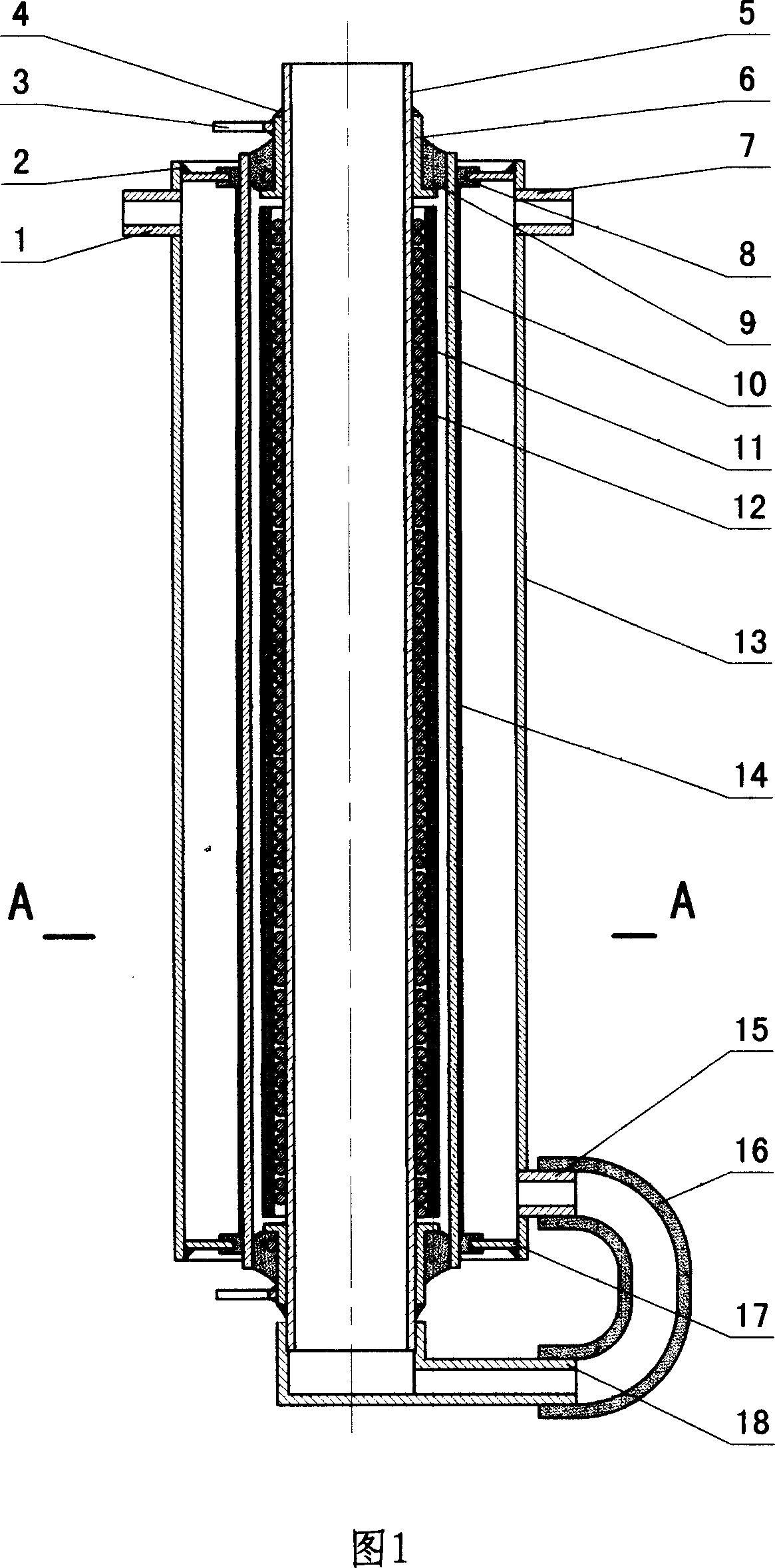

Energy-saving instantaneously heated type electric heater unit

The invention relates to an energy-saving instant heating electric-heat device, comprising a non-metal water pipe, an electric-heat wire twisted on the non-metal water pipe and a water leg could absorb heat. When the device is operated, the normal temperature water firstly flows inside the water leg, the water is gradually preheated by the heat leaked via the electric-heat wire, the water preheated go to the water pipe, the water is gradually reheated by the electrical-heat wire when the water is flowing, when the water flows to the outlet of the heat device, the water temperature reaches the needed temperature. The distinctive character is that the heat speed is high, energy-saving, and safe and deposition would not be easy to form. The device is mainly applied in the instant heating drinking machine, to heat the water flows inside. The invention can be used in the devices that need to instantaneously heat the flowing liquids.

Owner:黄樟焱

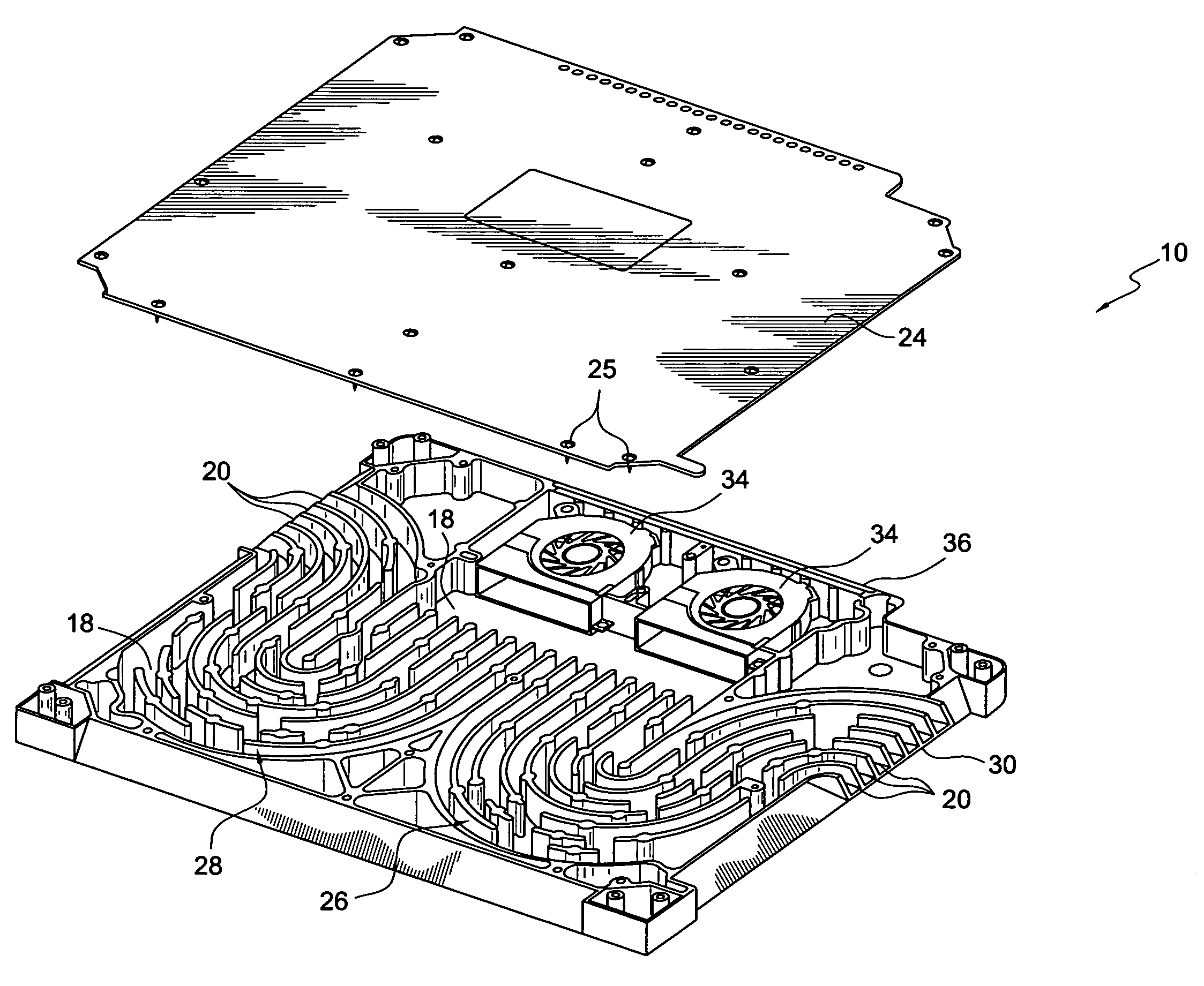

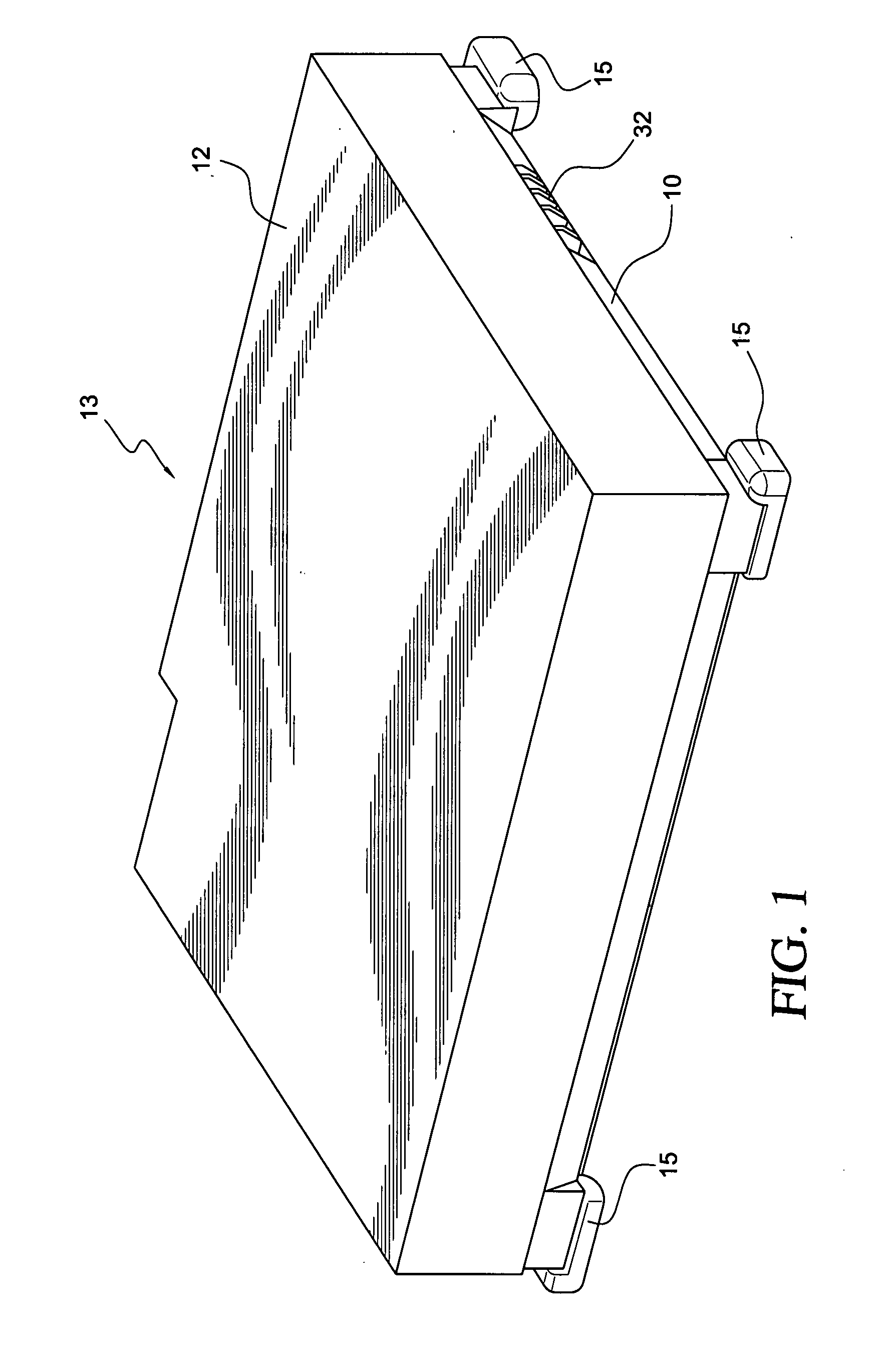

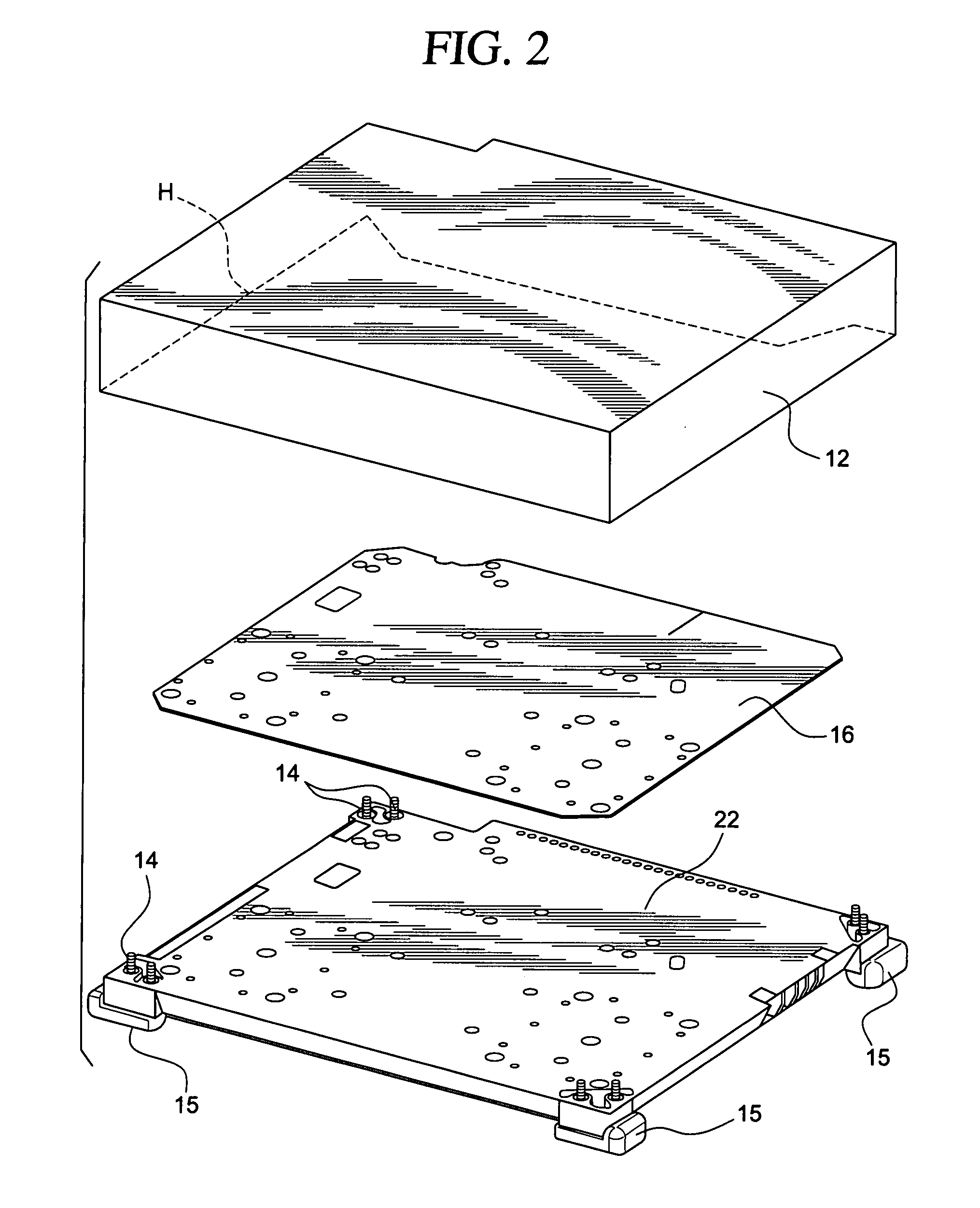

Compact surface-mount heat exchanger

InactiveUS20090073654A1Reduce external temperatureHeat dissipationIndirect heat exchangersCooling/ventilation/heating modificationsSurface mountingAtmospheric air

A temperature-stable portable device includes equipment enclosed in a portable case that seals the equipment from its surroundings, and a heat exchanger distinct from the case and attached to the exterior of the case by removable fasteners. The heat exchanger extends across at least most of a major surface of the case and is positioned to receive heat from the major surface by conduction. A sheet of material having good thermal conductivity is interposed between, and in contact with, the heat exchanger and the major surface of the case. The heat exchanger defines a chamber that is open to the atmosphere and has parallel flow passages and an arrangement for moving a heat exchange fluid through the chamber and out to the atmosphere in order to remove heat from the heat exchanger by convection.

Owner:MILTOPE CORP

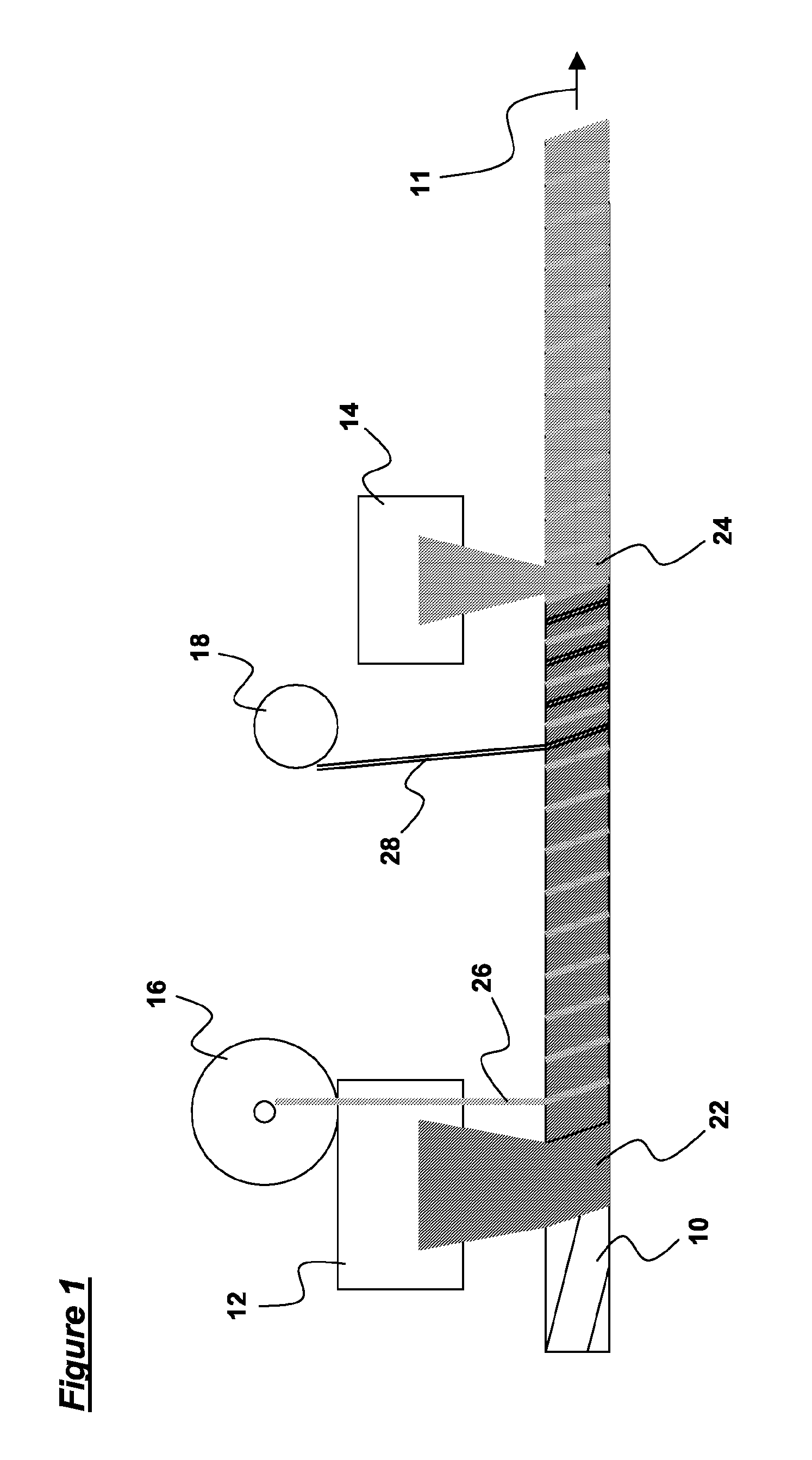

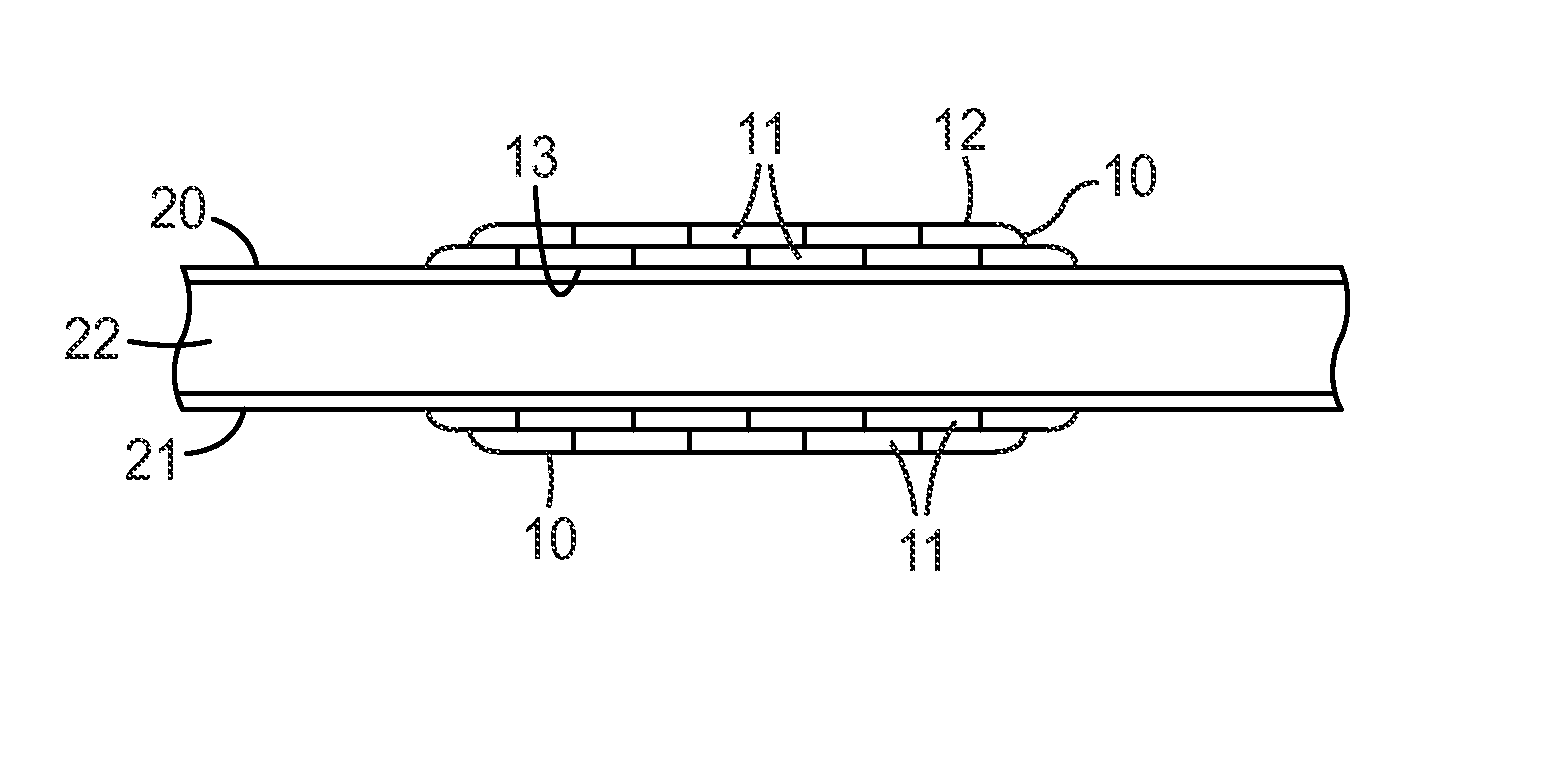

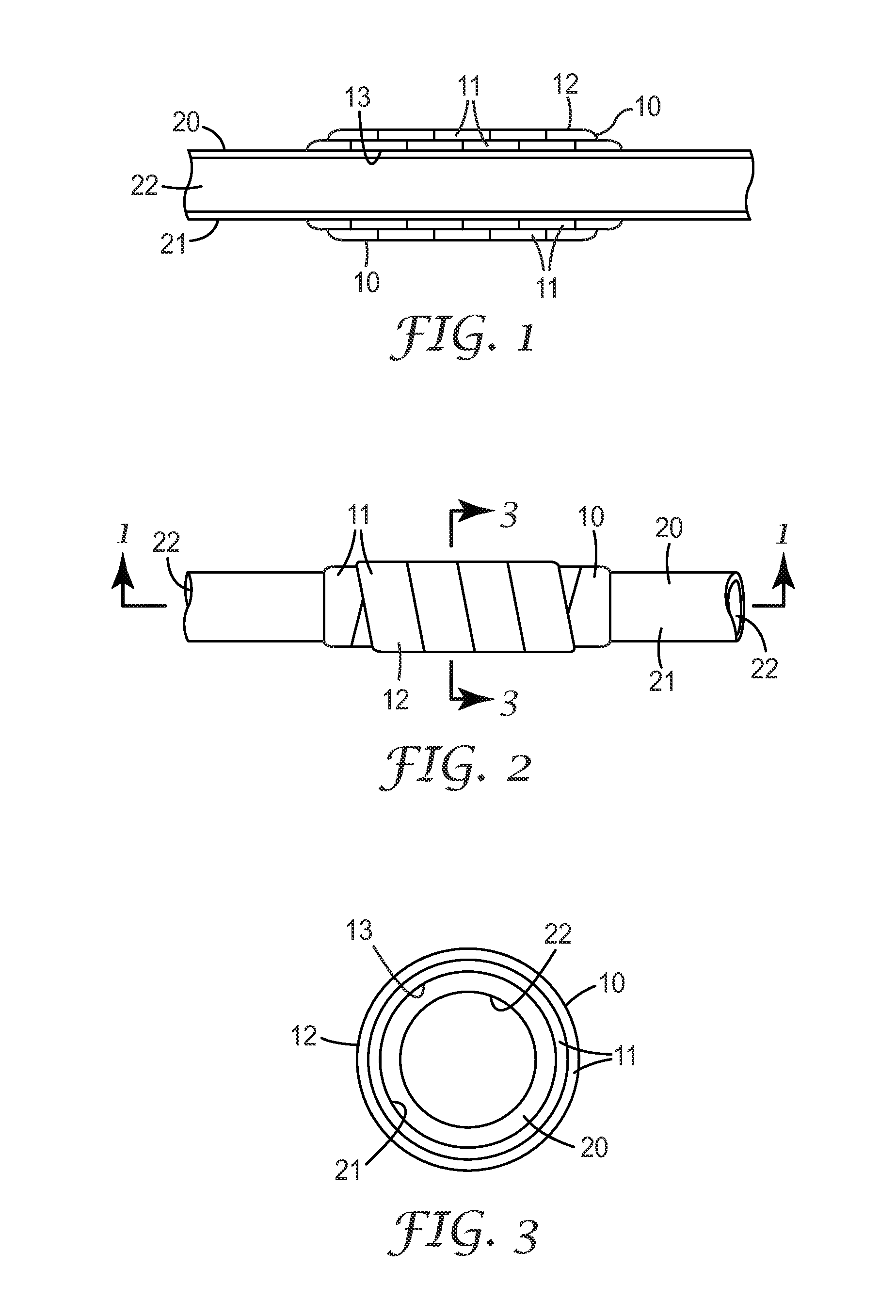

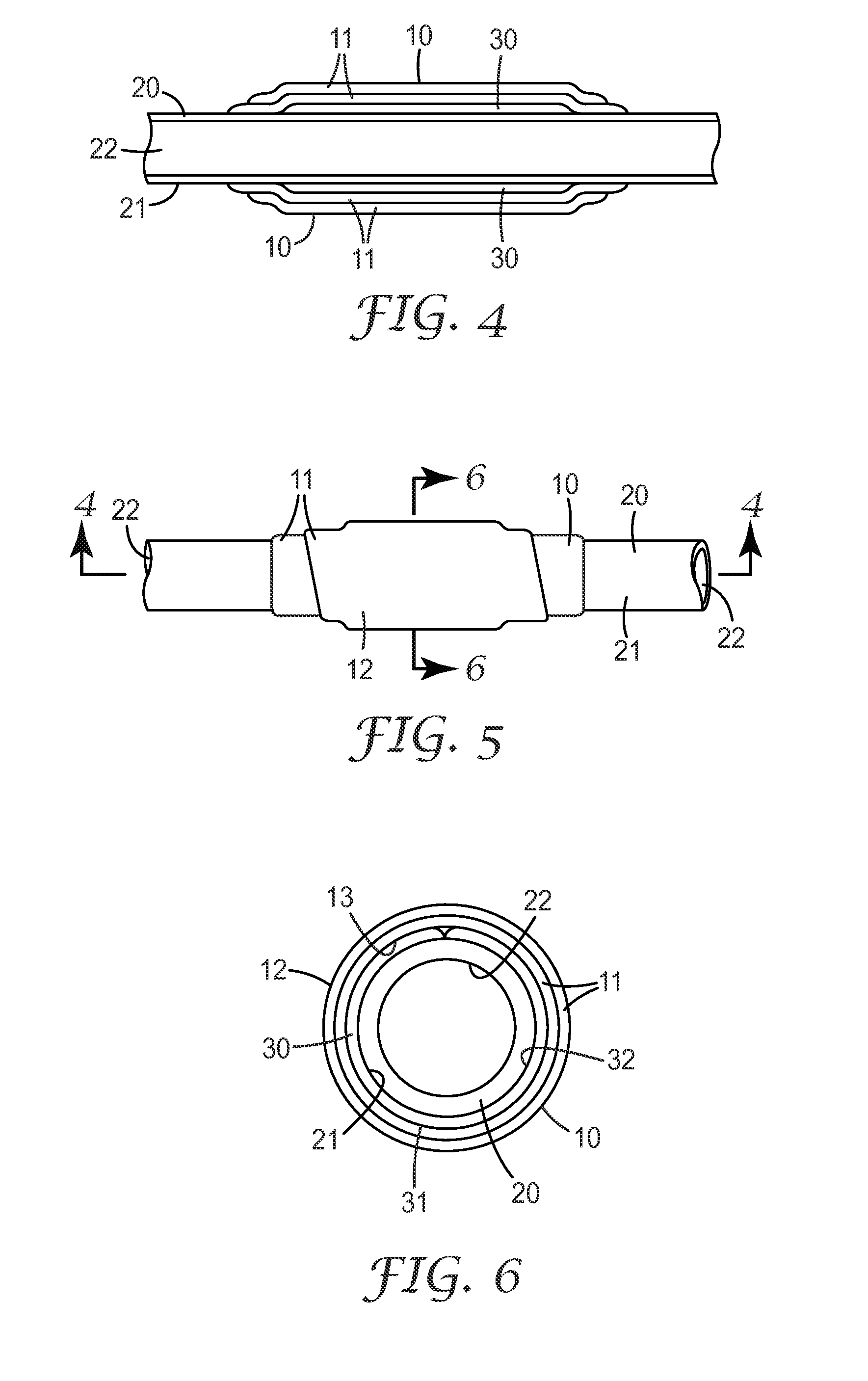

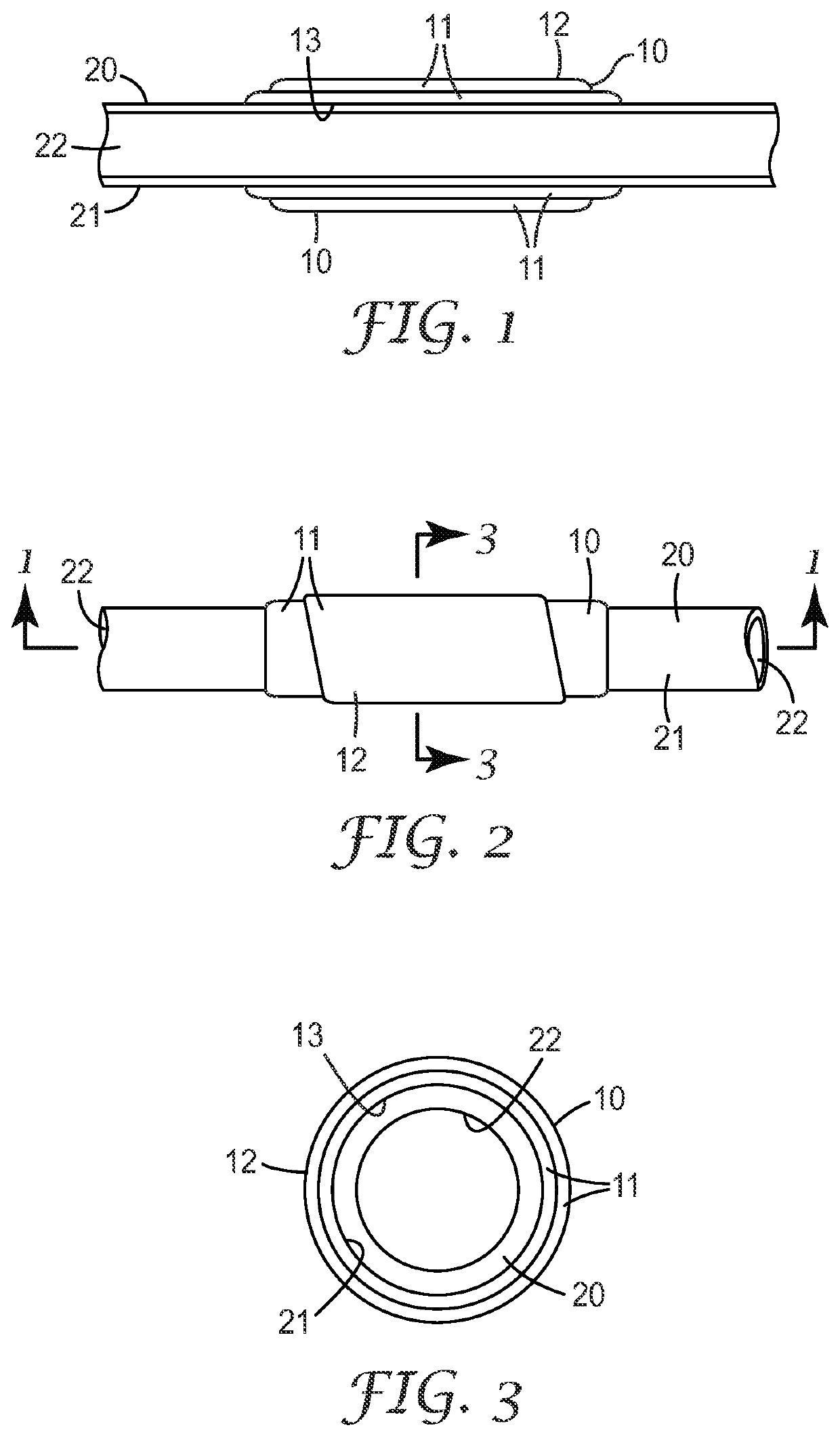

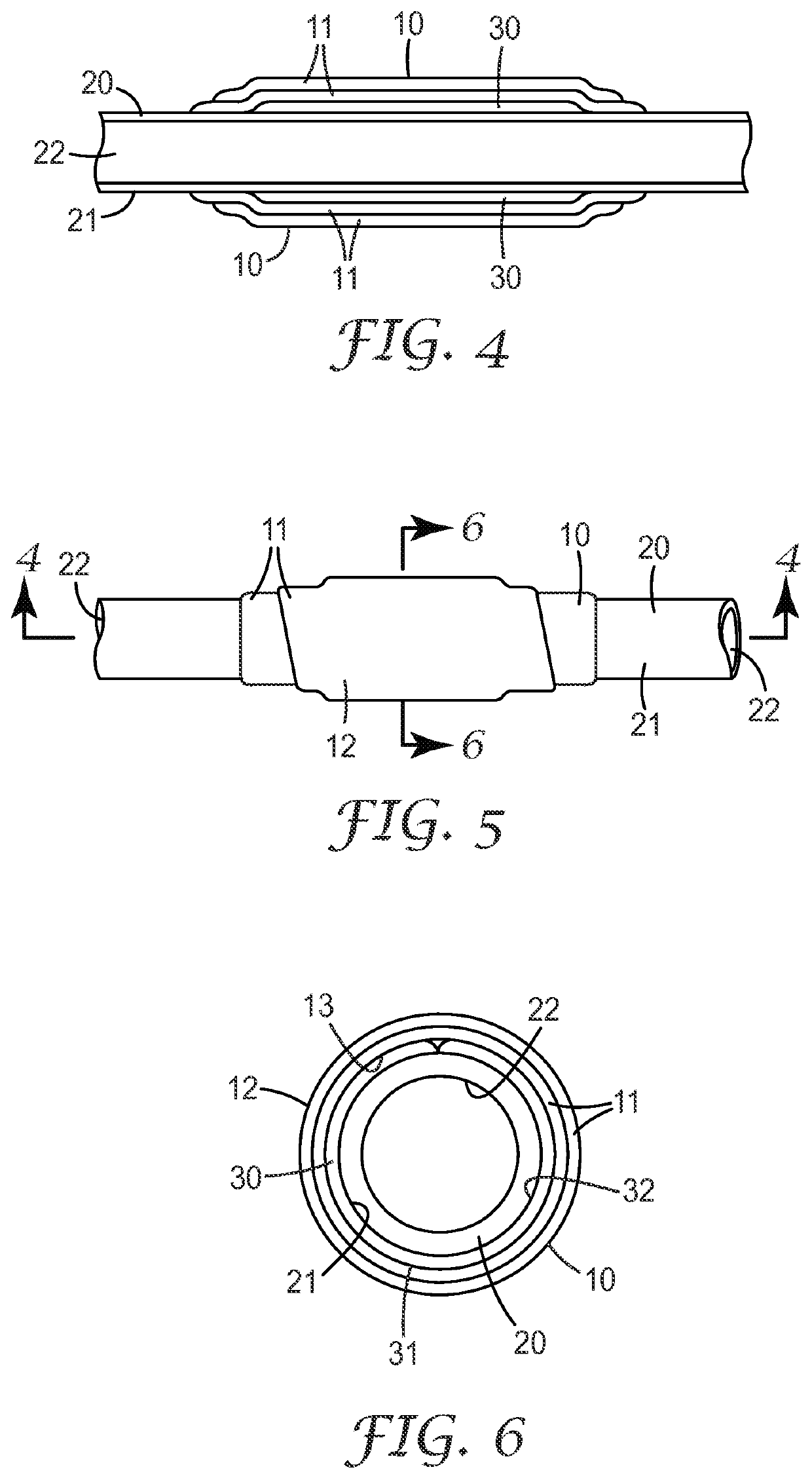

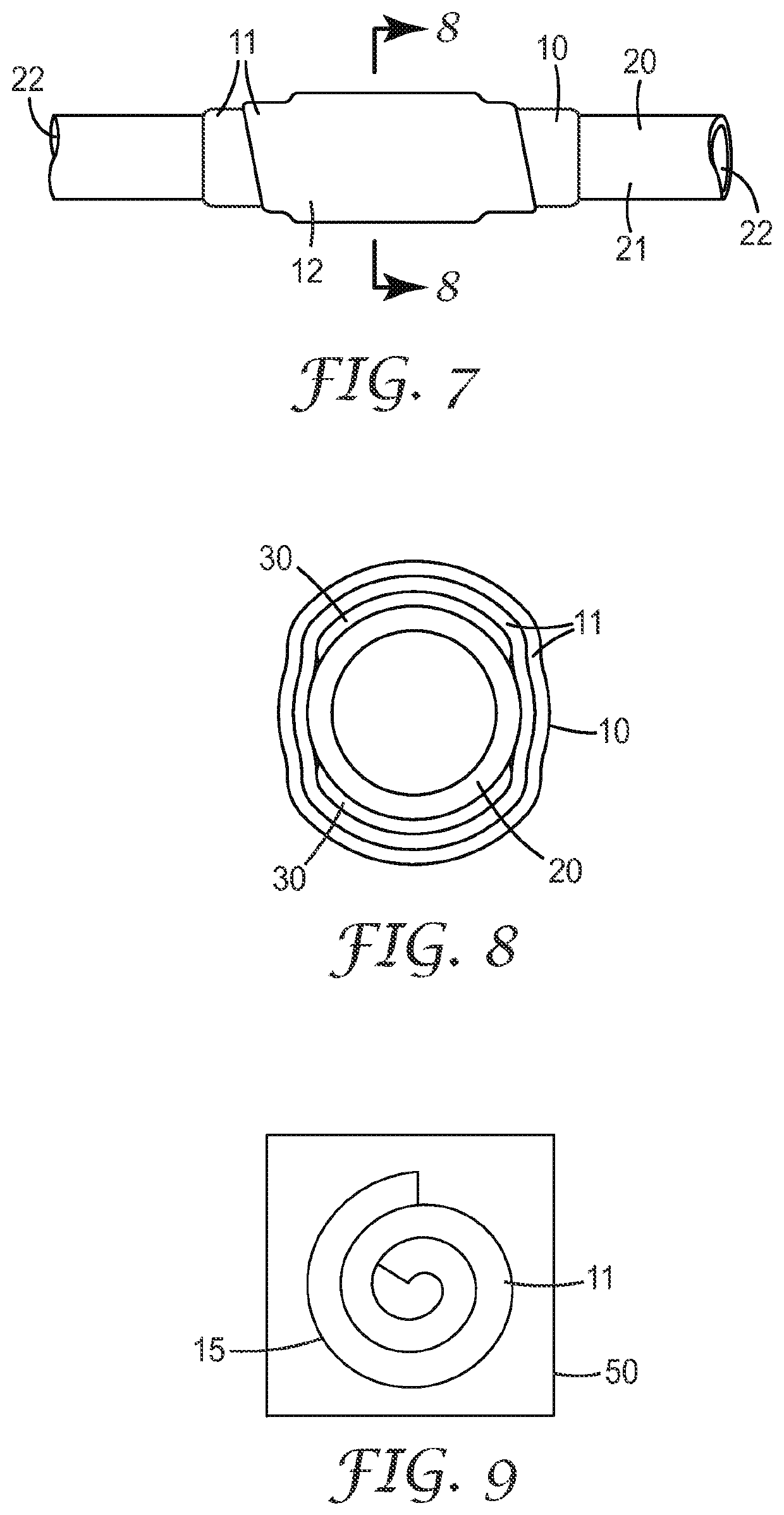

Thermally insulated components for exhaust systems

ActiveUS20150000259A1Low costImproved/lower emissionThermal insulationFibre treatmentFiberEngineering

A component of an exhaust system for an internal combustion engine. The component comprises an exhaust system structure (20) having an interior (22) through which exhaust gases flow and an exterior (21), and a thermal insulating wrap (10) for thermally insulating at least a portion of the exterior (21) of the exhaust system structure (20). The thermal insulating wrap (10) comprises an aqueous mixture comprising an inorganic binder and inorganic filler particles, and a fabric comprising inorganic fibers. The fabric is impregnated with the aqueous mixture so as to form a pliable binder wrap (11). The pliable binder wrap (11) is wound completely around at least a portion of the exhaust system structure (20). It can be desirable for the component to further comprise at least one thermal insulator comprising inorganic fibers, where the thermal insulator is disposed between the pliable binder wrap (11) and the exterior 21 of the exhaust system structure (20).

Owner:3M INNOVATIVE PROPERTIES CO

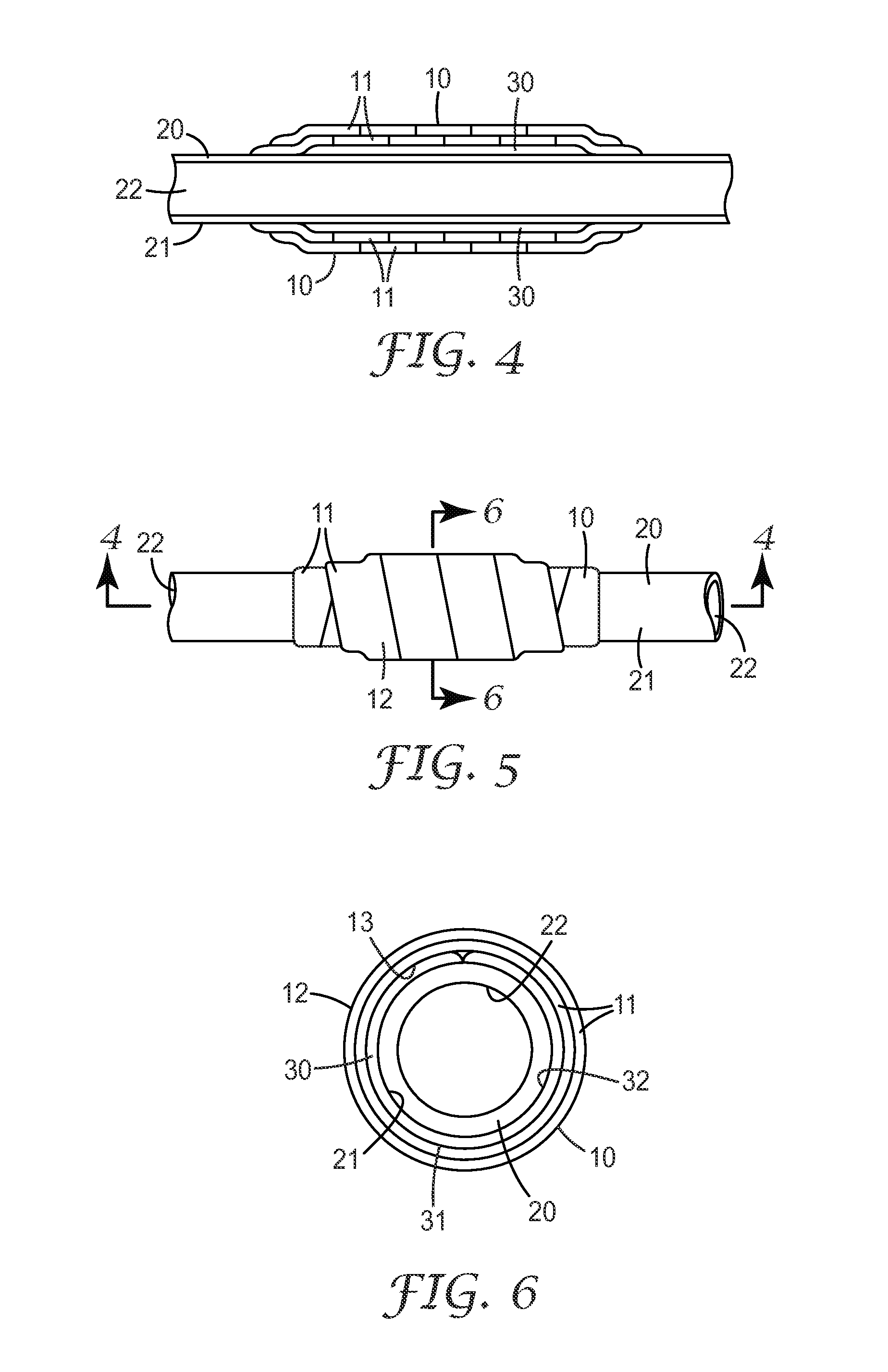

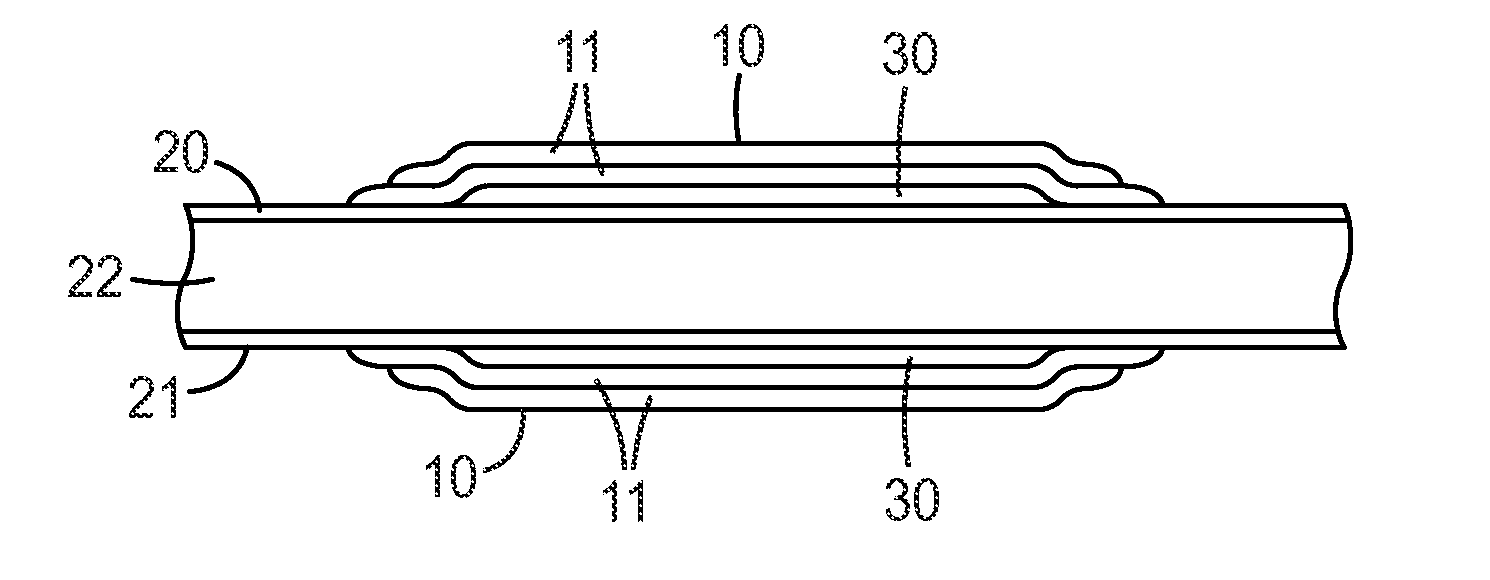

Thermally insulated components

ActiveUS20160084140A1Low costImproved and emissionExhaust apparatusFilament handlingFiberMaterials science

A thermally insulated component comprising a structure having a heated interior and an exterior, and a thermal insulating structure for thermally insulating at least a portion of the exterior of the component structure. The thermal insulating structure comprises an aqueous mixture comprising an inorganic binder and inorganic filler particles, and a fabric comprising inorganic fibers. The fabric is impregnated with the aqueous mixture so as to form a pliable binder structure. The pliable binder structure is disposed completely around at least a portion of the component structure. It can be desirable for the component to further comprise at least one thermal insulator comprising inorganic fibers, where the thermal insulator is disposed between the pliable binder structure and the exterior of the component structure.

Owner:3M INNOVATIVE PROPERTIES CO

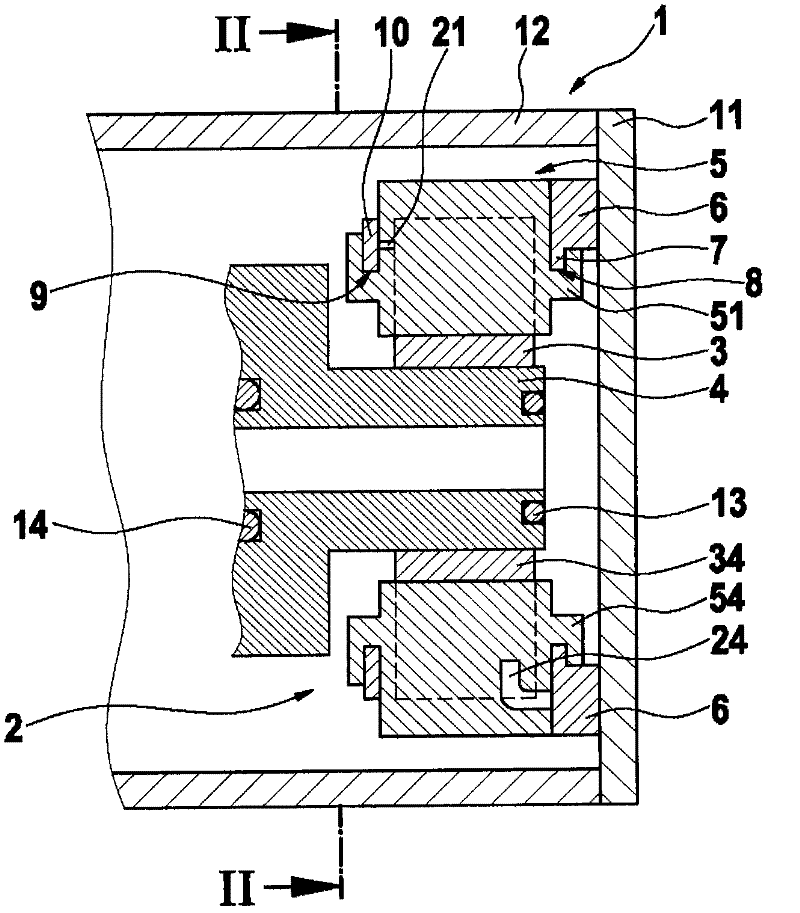

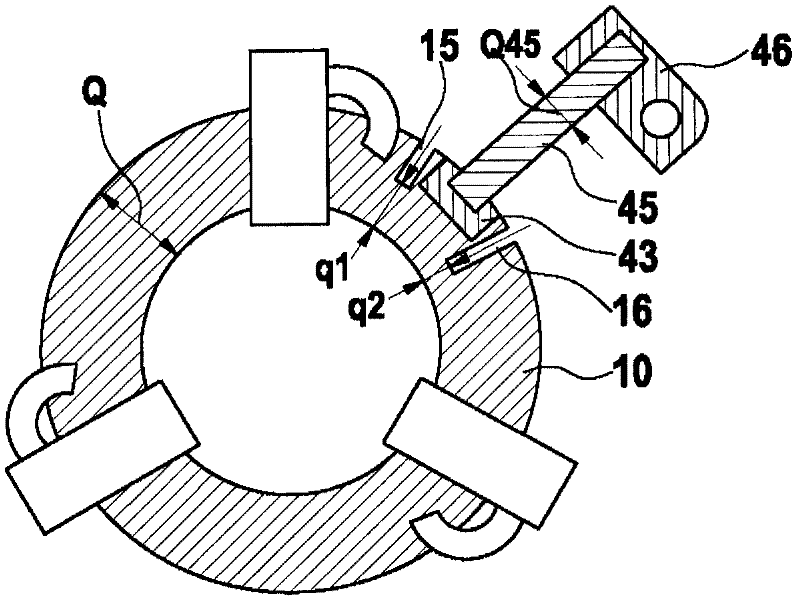

Brush apparatus for an electric machine and electric machine

ActiveCN102460909AIncrease temperatureReduce external temperatureVehicle connectorsPower operated startersBusbarElectric machine

The invention relates to an electric machine (1), especially a starter for an internal combustion engine, comprising a commutator (4) and a brush apparatus (2), brushes (3) being arranged on the commutator (4) in such a manner that at least one pair of brushes can rotate off-set from each other, every brush (3) being held in a brush holder (5), every brush holder (5) being fastened to an axial face on a brush plate (6), every brush (3) being alternately switchable in series either with a negative pole or a positive pole by a current conducting device (18, 19) to give a pair of brushes, and the brush plate (6) with connecting leads (24, 25, 26) leading to brushes (3) on the negative pole side and a busbar (10) with connecting leads (21, 22, 23) leading to brushes (3) on the positive pole side forming a respective current conducting device (18, 19). In order to protect the brush apparatus (2) from thermal overloads in an easy manner, at least one current conducting device (18, 19) is designed to have a unit for reducing heat dissipation.

Owner:SEG AUTOMOTIVE GERMANY GMBH

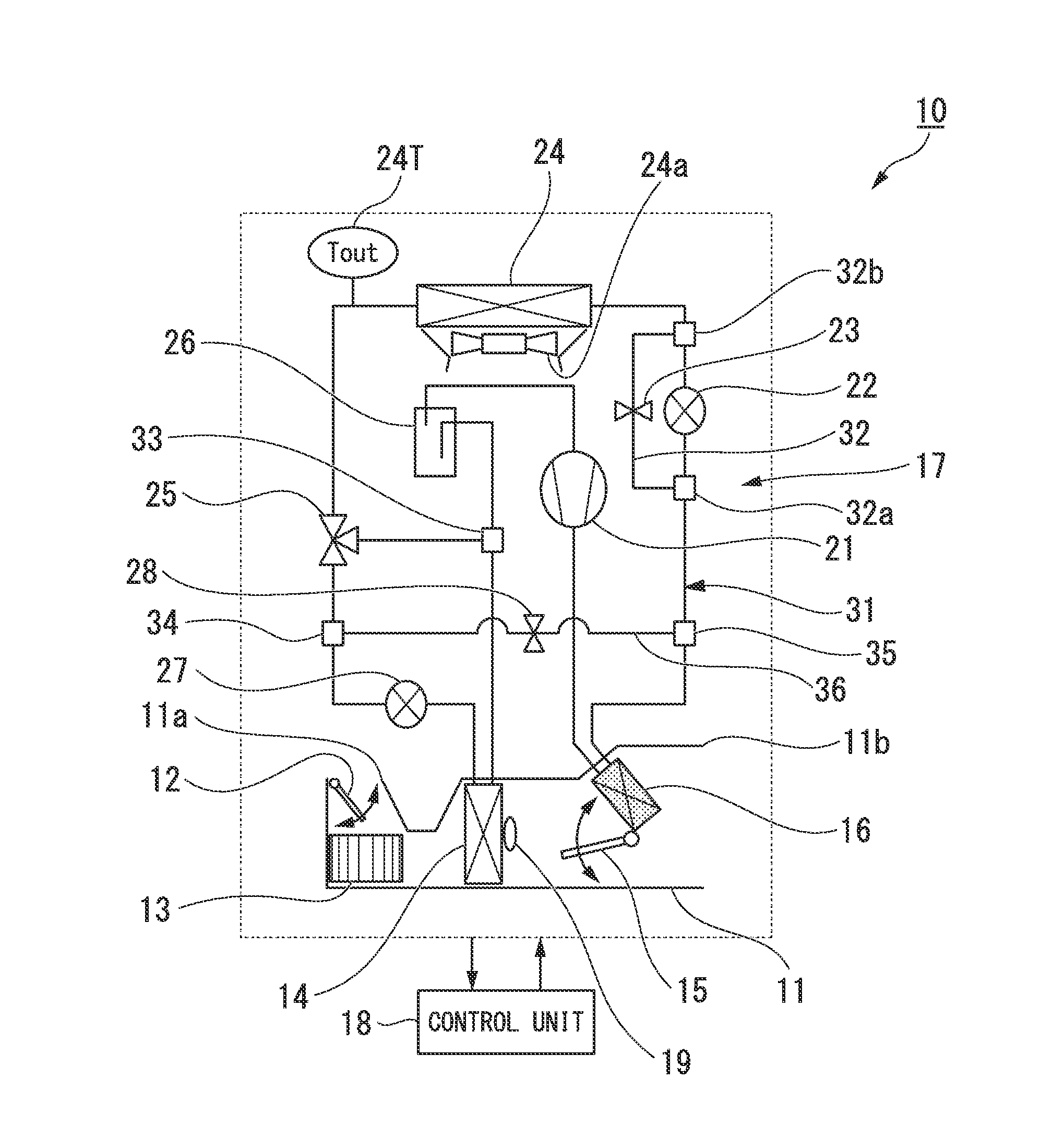

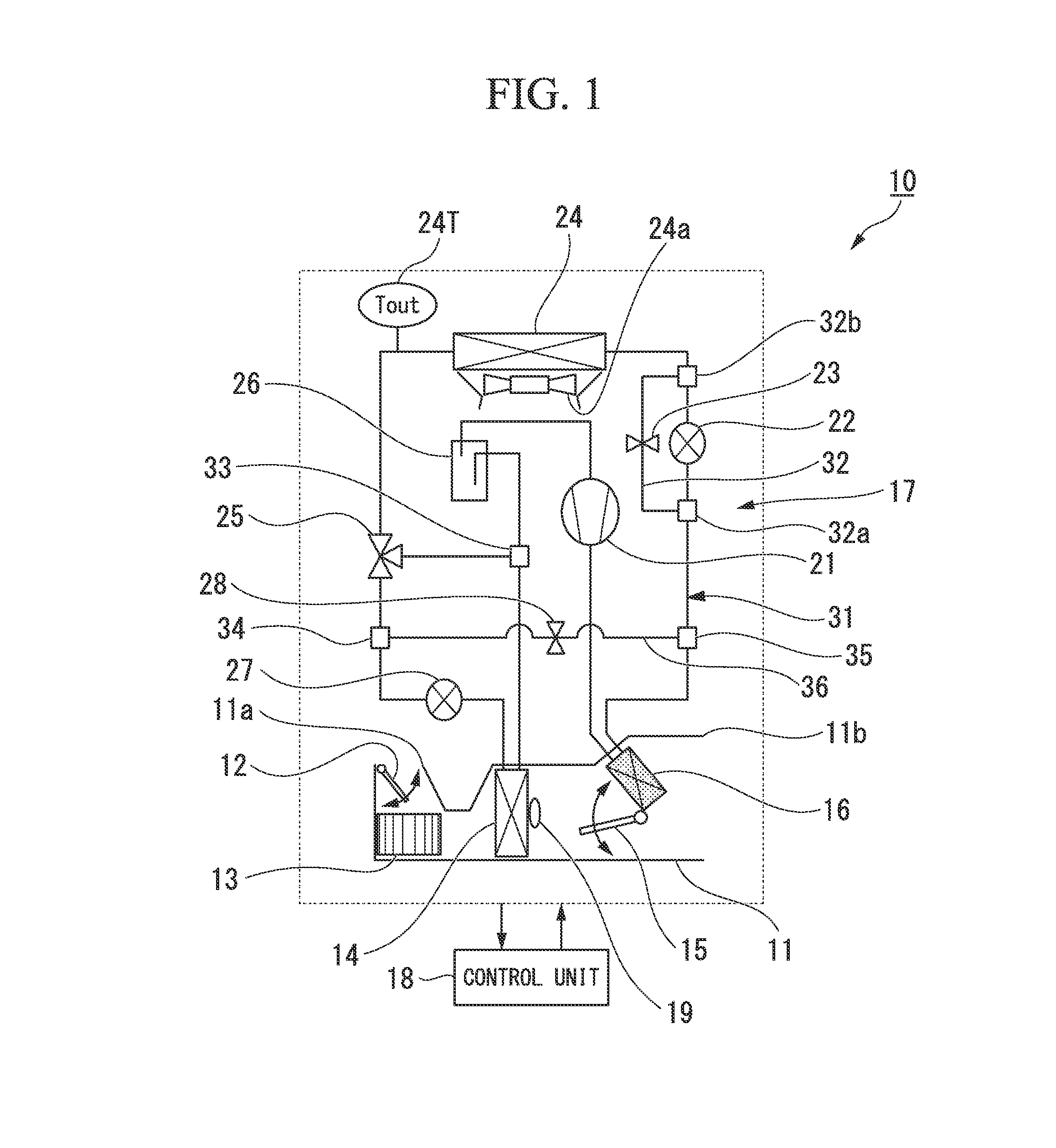

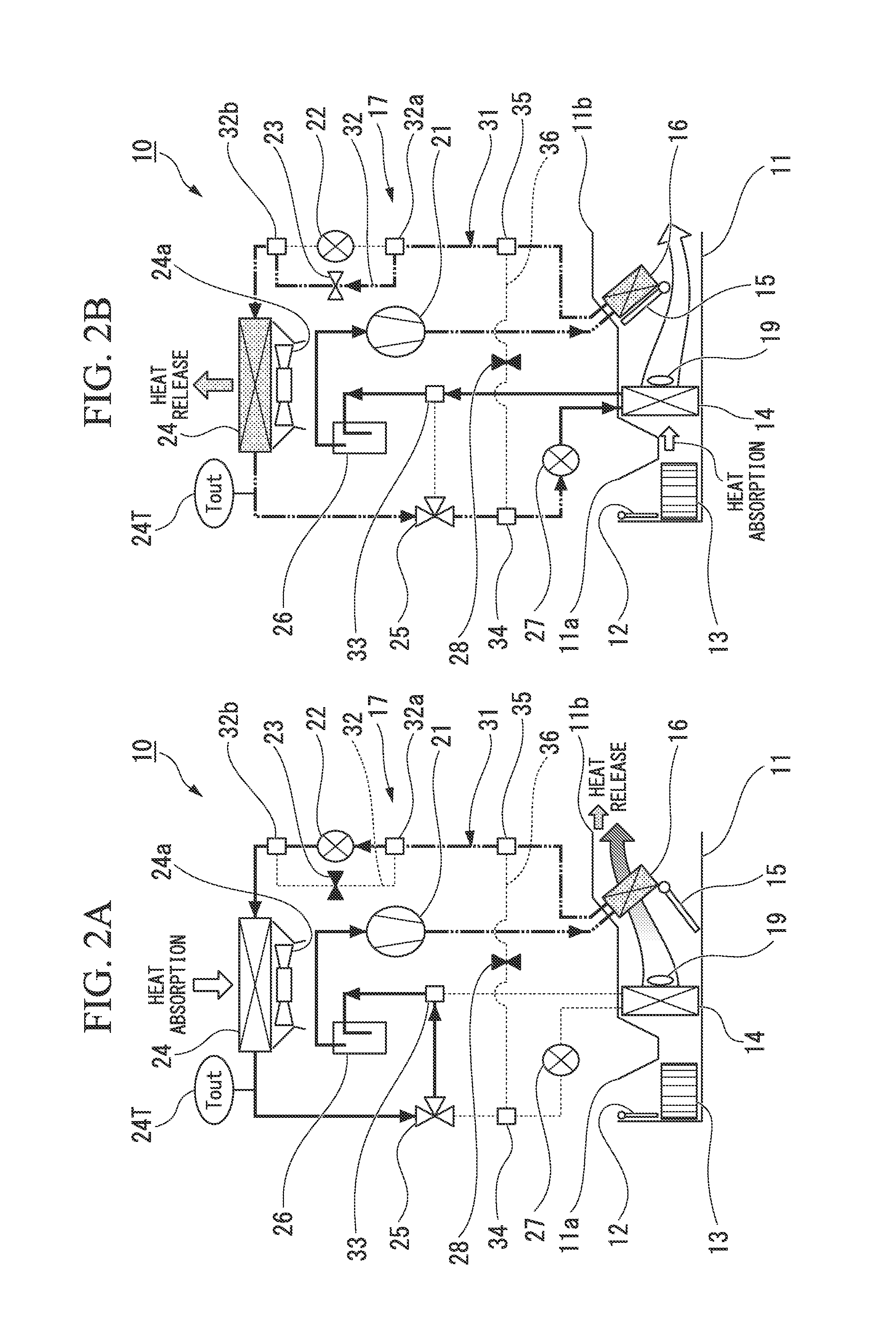

Air conditioner for vehicle

ActiveUS20140041404A1Increase temperature differenceReduce external temperatureLighting and heating apparatusVehicle heating/cooling devicesFrostTemperature difference

An air conditioner for a vehicle includes: a compressor that compresses a heat exchange medium; an internal heat exchanger that performs heat exchange between the heat exchange medium expelled from the compressor and air for air conditioning introduced inside a vehicle compartment; and an external heat exchanger that performs heat exchange between the heat exchange medium expelled from the internal heat exchanger and external air, wherein the air conditioner for a vehicle calculates a temperature difference between an external air temperature and a discharge port temperature of the external heat exchanger, calculates an average value of the temperature difference, and performs a defrosting operation which melts frost adhered to the external heat exchanger when an amount of change of the average value is equal to or greater than a first predetermined value.

Owner:HONDA MOTOR CO LTD

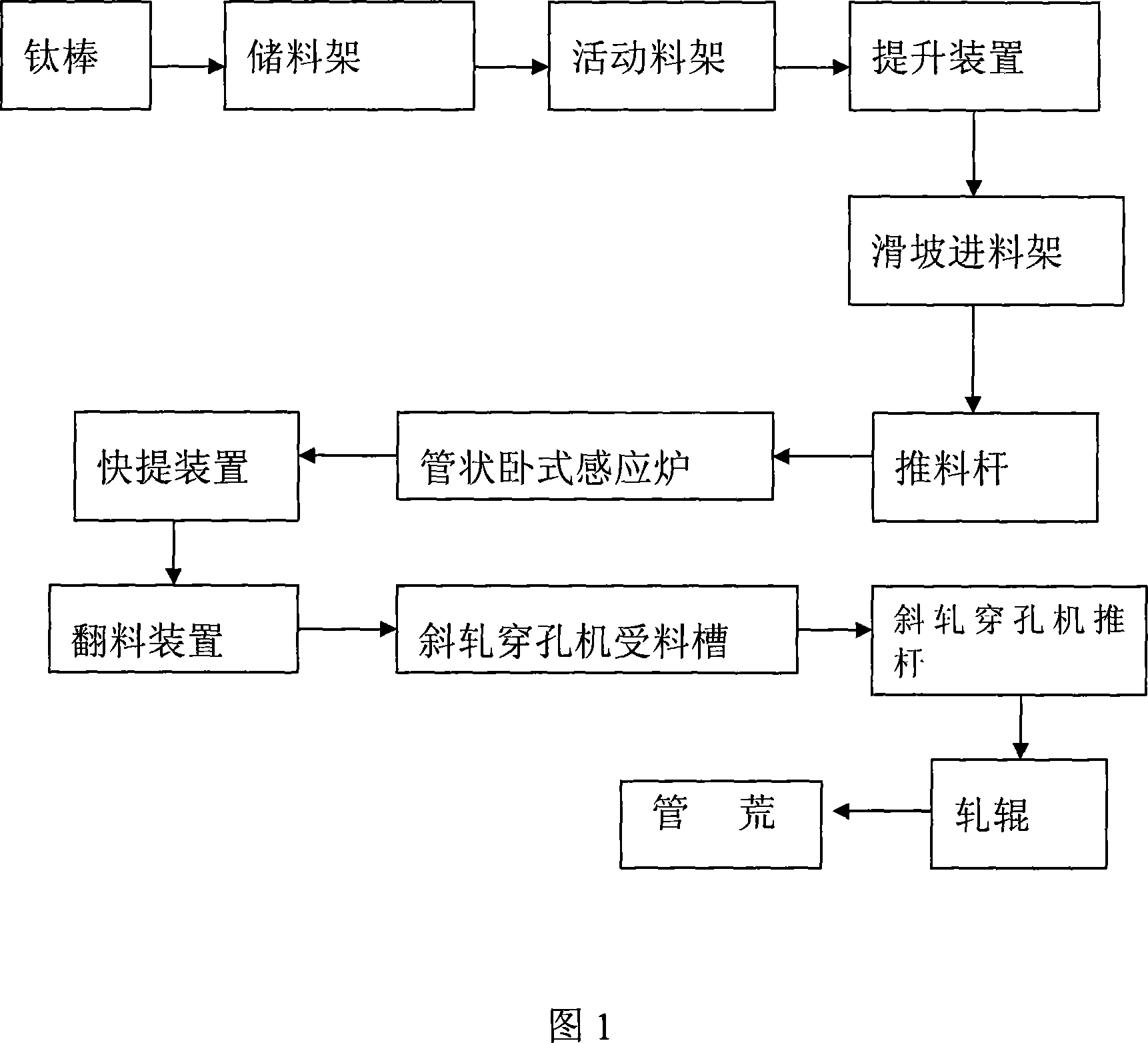

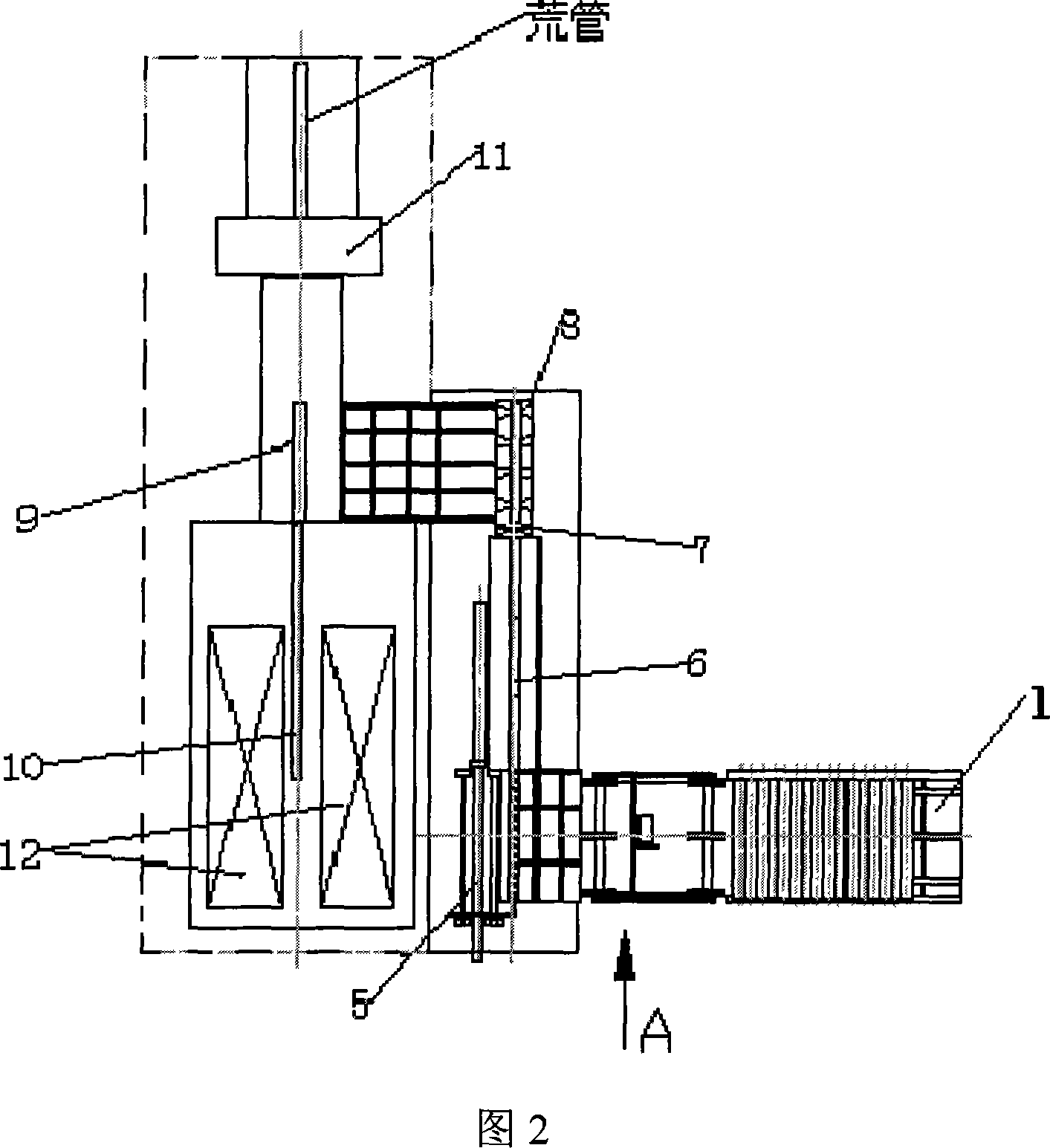

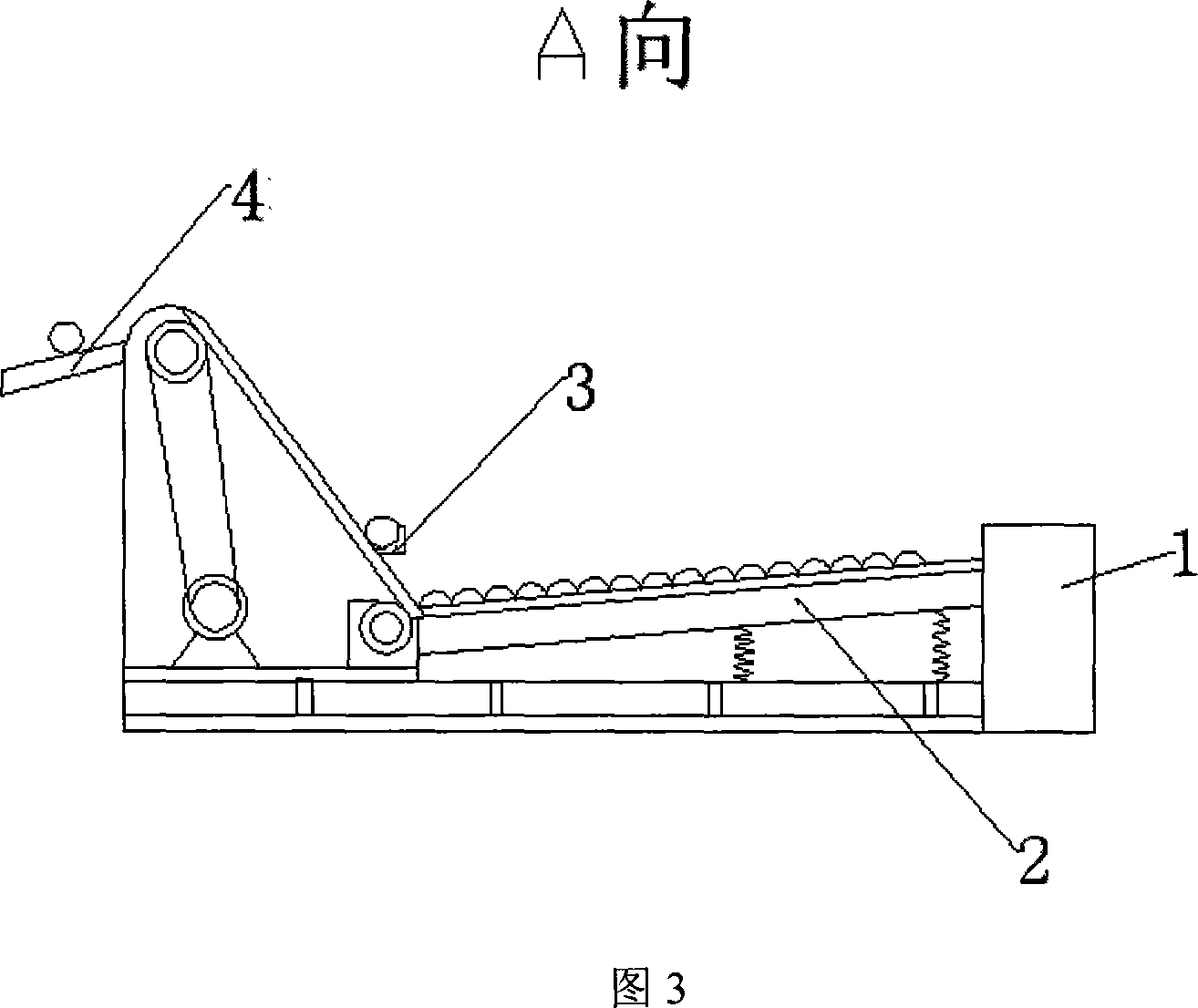

Process for heating titanium oblique perforating rod ingot

InactiveCN101029348AHeating fastReduce oxidationTemperature control deviceFurnace typesPunchingMonitoring system

Process for heating titanium-oblique rolling punch rod blank adopts horizontal step-by-step medium-frequency induction heating finance as tool. The heating furnace consists of automatic skip mechanism, core-watch temperature differential monitoring system and fast-extraction discharge mechanism. The process is carried out by hoisting titanium rod onto bedding rack by overhead traveling crane, arranging on movable bedding rack paralleled, lifting titanium-rod onto charge rack on slop by production beat, entering into horizontal step-by-step medium-frequency induction heating furnace successively, moving titanium-rod forwardly by step-by-step mode, raising temperature while homogeneous heating, discharging, entering into blow tank of oblique-rolling punch, nipping and punching to raw pipe. It's simple, safe and cheap and has no environmental pollution.

Owner:WESTERN TITANIUM TECH

Gradient composite technology ceramic tile and preparation method thereof in field of glass kilns

ActiveCN112225558AGood Thermal Gradient Reduction CapabilitiesLow thermal conductivityFiberZirconate

The invention discloses a gradient composite technology ceramic tile in the field of glass kilns, which is prepared by the following steps of on the basis of taking zirconium dioxide as a base material, compounding with other components to form a first-layer material with the mass percentage of 100%, gradually changing the content of the material by sections in a gradient manner and gradually increasing the content of other materials until a trace amount of zirconium dioxide exists, progressively increasing two or more than two other materials in a gradient manner and changing different components to form a plurality of layers of components in percentage by mass of 100 for implementing material distribution, so that gradual change from one side to the other side in a continuous gradient manner is realized. The ceramic tile comprises the following components: zirconium dioxide Zr02, silicon dioxide SiO2, yttrium oxide Y203, calcium zirconate eutectic CaZrO3, barium zirconate eutectic BaZrO3, magnesium-zirconium eutectic MgZrO3, corundum alpha-Al2O3, alumina powder alpha-Al2O3, alumina fiber whisker alpha-Al2O3, silicon carbide SiC, silicon nitride Si3N4 and magnesium oxide MgO. Thepreparation method is convenient to operate and comprises the following steps of 1, preparing raw material components, 2, carrying out process treatment on each layer of components, and d, sintering amolded product.

Owner:ZHENGZHOU FANGMING HIGH TEMPERATURE CERAMIC NEW MATERIAL CO LTD

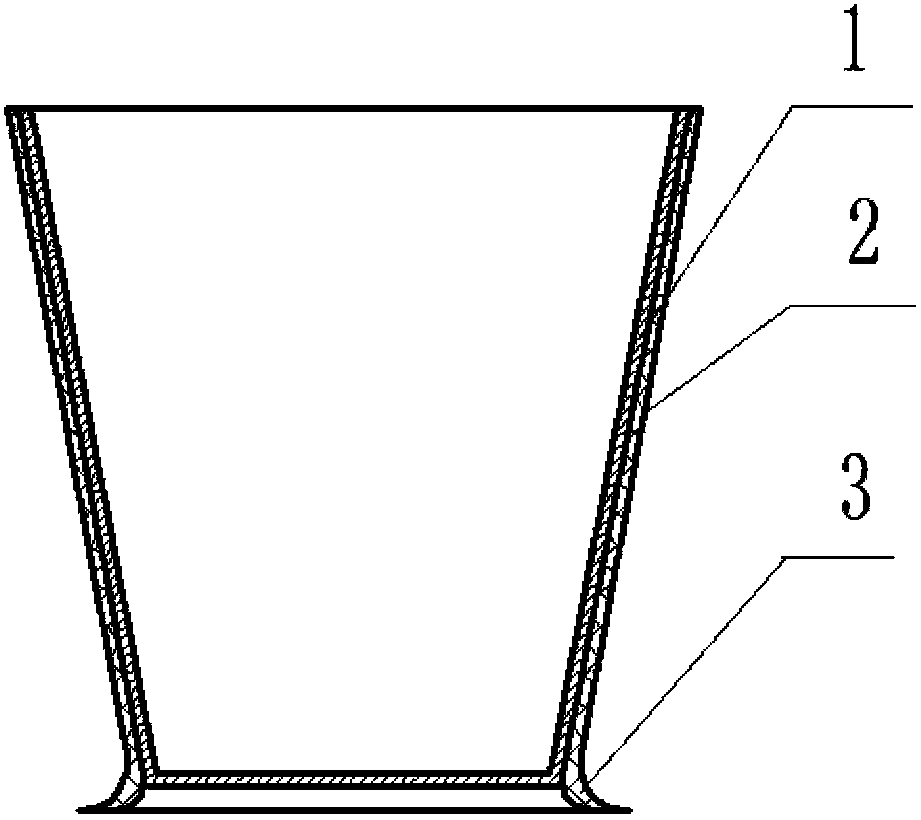

Novel heat insulation paper cup

InactiveCN103892650AHigh strengthWith strengthDrinking vesselsInsulation layerPulp and paper industry

The invention belongs to a novel heat insulation paper cup. The novel heat insulation paper cup comprises an internal cup body and an external heat insulation layer. The heat insulation layer is made of an aerogel heat insulation material, and outward bent corners are formed on the bottom of the external heat insulation layer. The internal cup body and the external heat insulation layer are combined in a hot-pressing mode. The novel heat insulation paper cup has the advantages that due to the heat insulation layer outside the cup body, the external temperature is greatly lowered, and users can hold the cup conveniently without being scalded; the heat insulation layer has certain strength, the phenomenon that after being poured into the paper cup, hot water spills due to heat deformation of the paper cup can be avoided; the outward bent corners are arranged on the bottom of the heat insulation layer, so that the stressing surface of the bottom is increased, and the whole cup body is stable.

Owner:TIANJIN DEBAO PRINTING

Fused quartziferous cast glazed tile for coke oven and preparation method thereof

ActiveCN102303971AReduce the surface temperature of the furnace doorFree from physical laborThermal conductivitySoft clay

The invention discloses a fused quartziferous cast glazed tile for a coke oven. The glazed tile comprises glazed water and a cast prefabricated member, wherein the glazed water comprises following components in percentage by weight: 30-50% of spodumene with a particle size of 10 to 0 micron, 5-20% of soft clay with the particle size of 10 to 0 micron, 10-20% of potash feldspar with the particle size of 10 to 0 micron, 5-15% of aluminum oxide with the particle size of 5 to 0 micron, 3-15% of quartz with the particle size of 10 to 0 micron, and 0.5-1% of organic plasticizer. The cast prefabricated member includes the following ingredients in percentage by weight: 30-50% of fused quartz, 25-35% of chamotte, 10-15% of alumina clinker, 10-15% of binding agent, 3-6% of silicon micropowder and 3-8% of aluminum oxide micropowder. Meanwhile, the invention further discloses a preparation method of the glazed tile. The glazed tile provided by the invention has excellent thermal shock stability and thermal impact resistance in coke oven production process; the glazed tile has low thermal conductivity and high strength, and can effectively reduce the external temperature of the furnace gate; and the production process does not have pollution.

Owner:宜兴市丁山耐火器材有限公司

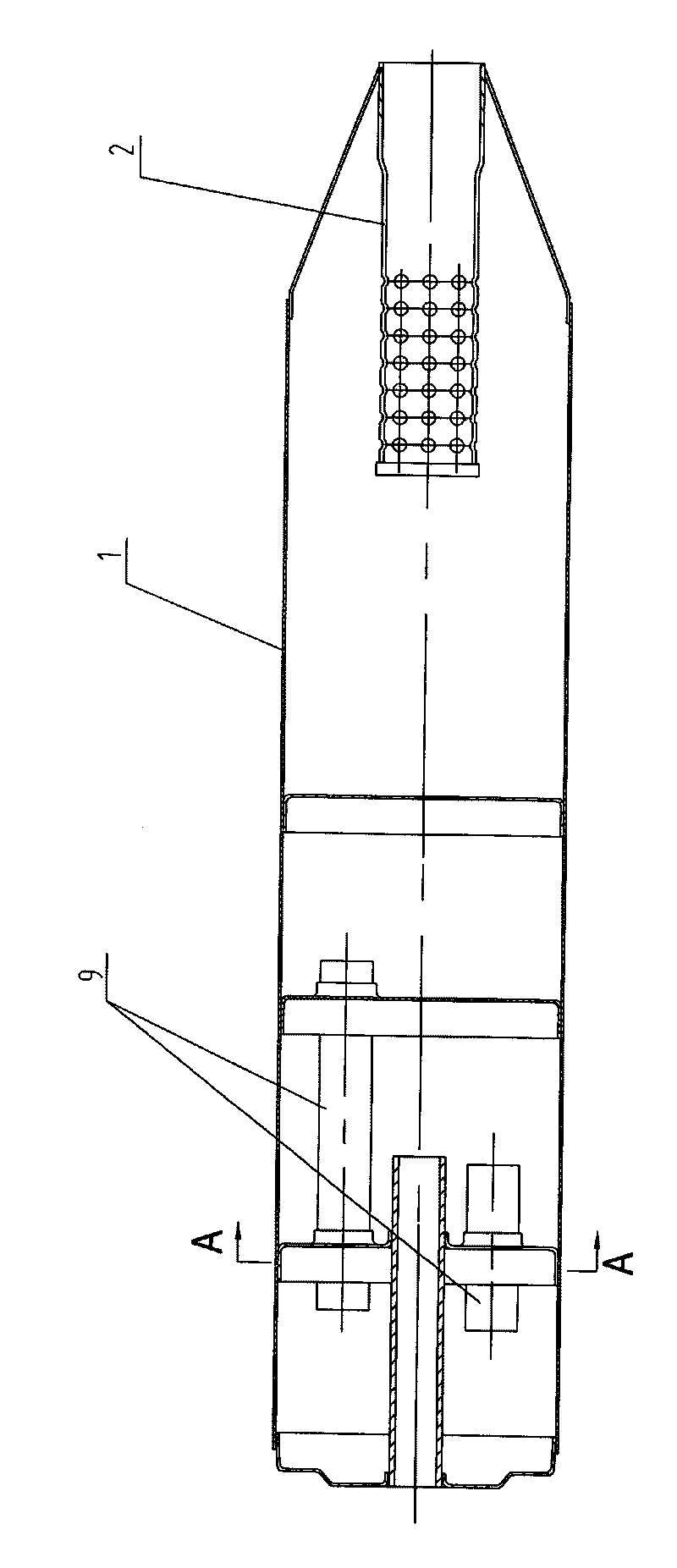

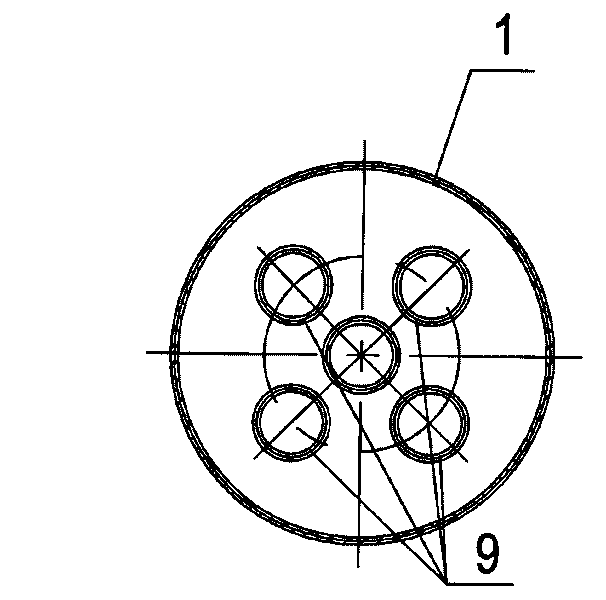

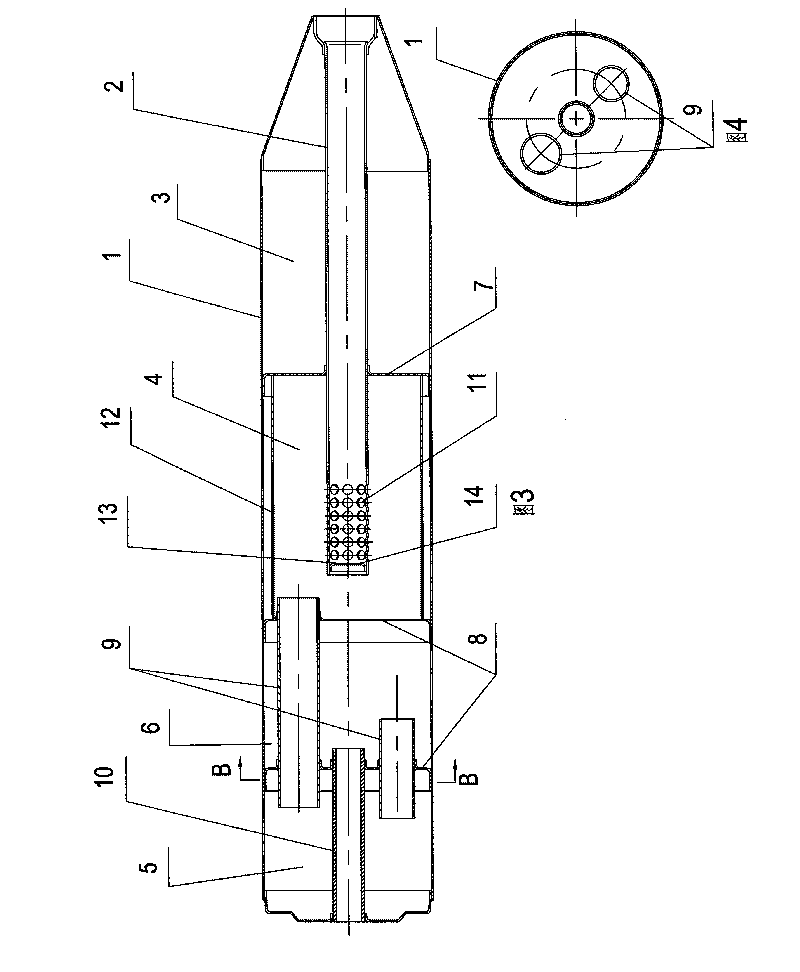

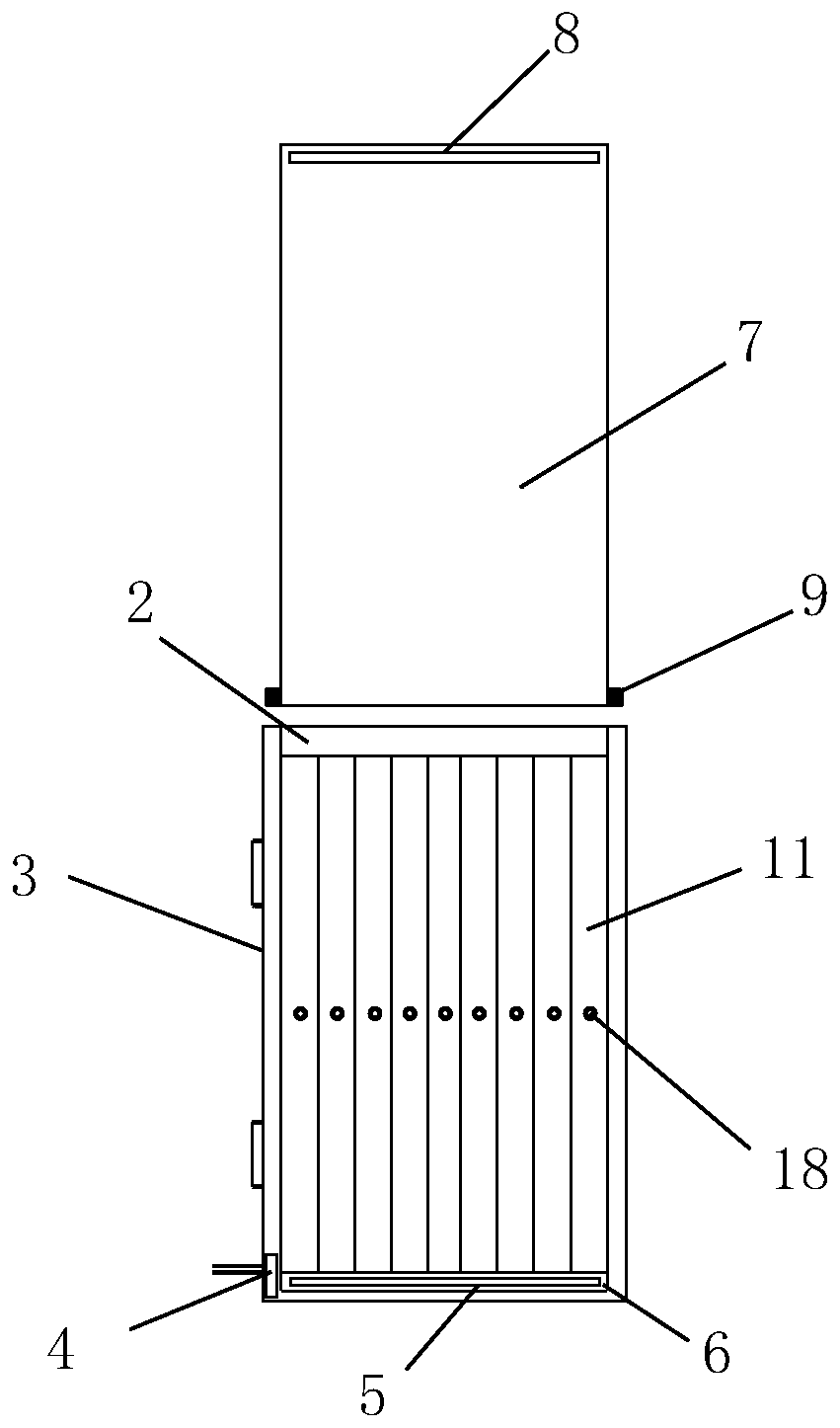

Motorcycle sound eliminator

InactiveCN101737121AReduce external temperatureImprove noiseExhaust apparatusSilencing apparatusLow speedEngineering

The invention provides a motorcycle sound eliminator which is provided with a sound eliminator cylinder body (1) and an inner connecting pipe (2), wherein an inner cavity of the sound eliminator cylinder body (1) is divided into a first sound eliminating cavity (3), a second sound eliminating cavity (4), a third sound eliminating cavity (5) and a fourth sound eliminating cavity (6); the pipe wall of the rear end of the inner connecting pipe (2) is provided with a radial exhaust small hole (11); a lining cylinder (12) is arranged in the second sound eliminating cavity (4) near the inside wall of the sound eliminator cylinder body (1); and the rear end of the inner connecting pipe (2) extends into the second sound eliminating cavity (4) after penetrating through a porous plate (7) between the first sound eliminating cavity (3) and the second sound eliminating cavity (4) and is provided with a cover (14) with an airflow through hole (13). The technical scheme of the invention reduces the appearance temperature of the sound eliminator cylinder body of the motorcycle, eliminates tail gas noise and improves the intermediate and low speed performance of an engine, and people feel strong for acceleration during riding.

Owner:CHONGQING LONCIN MOTOR

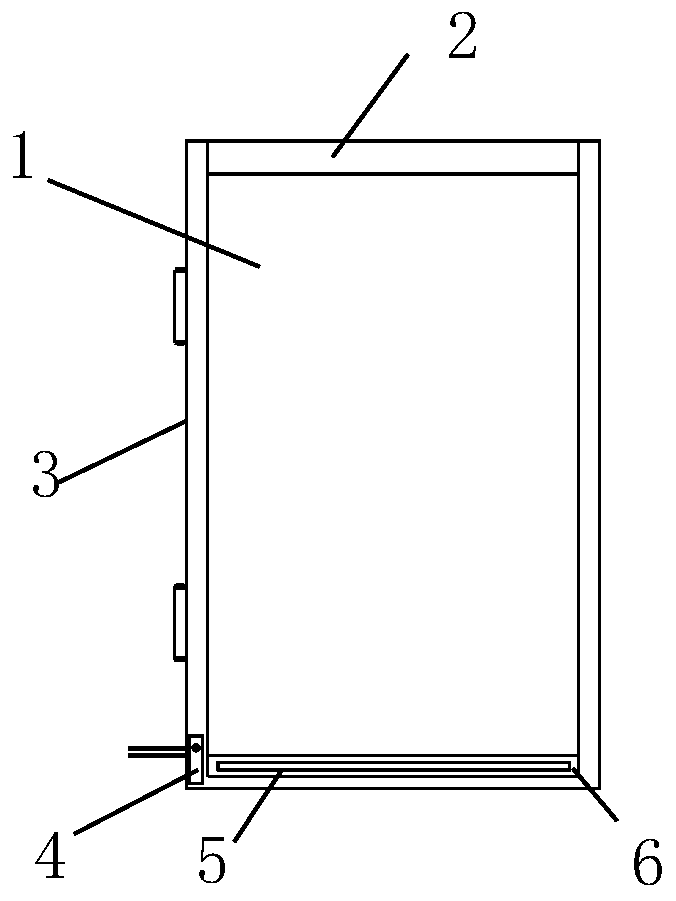

Fireproof door

ActiveCN110230459AWon't enterReduce external temperatureFireproof doorsSpecial door/window arrangementsEngineeringMechanical engineering

The invention discloses a fireproof door. The fireproof door comprises a door frame, wherein a hollow through cavity is formed in the middle of the door frame, and a more than one group of symmetricalfirst shaft hole are separately formed in the upper surface and the lower surface of the hollow cavity, and more than one flexible fireproof rod is arranged in the hollow cavity side by side; the fireproof rods are in sealing contact with each other, and the whole hollow cavity is sealed by the more than one fireproof rod; first rotating shafts are vertically disposed on the upper side and the lower side of the fireproof rods separately, and the first rotating shafts are rotatably mounted into the first rotating shaft holes formed in the upper surface and the lower surface of the hollow cavity; and an escape gap cavity is formed between the every two adjacent fireproof rods. The novel new fireproof door is adopted, the smoke can be effectively blocked from entering an escape space duringescape, and the heat on an escaper can be effectively reduced, the fireproof time of the fireproof door is further prolonged, and the function of safety protection is achieved.

Owner:湖南消安建材有限公司

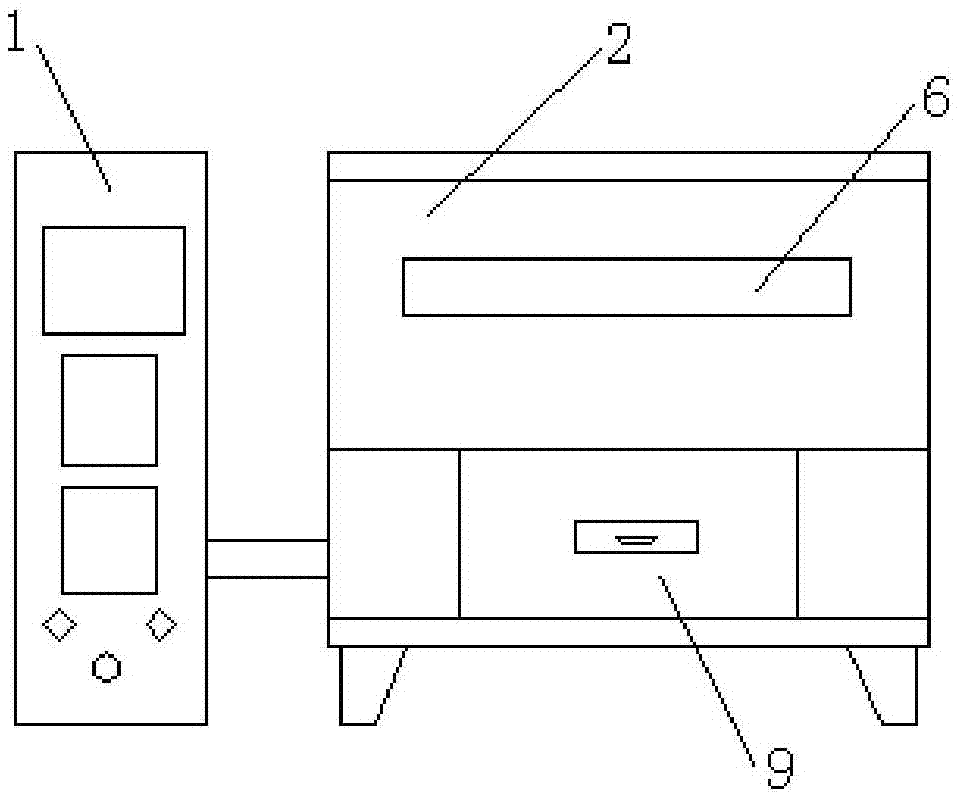

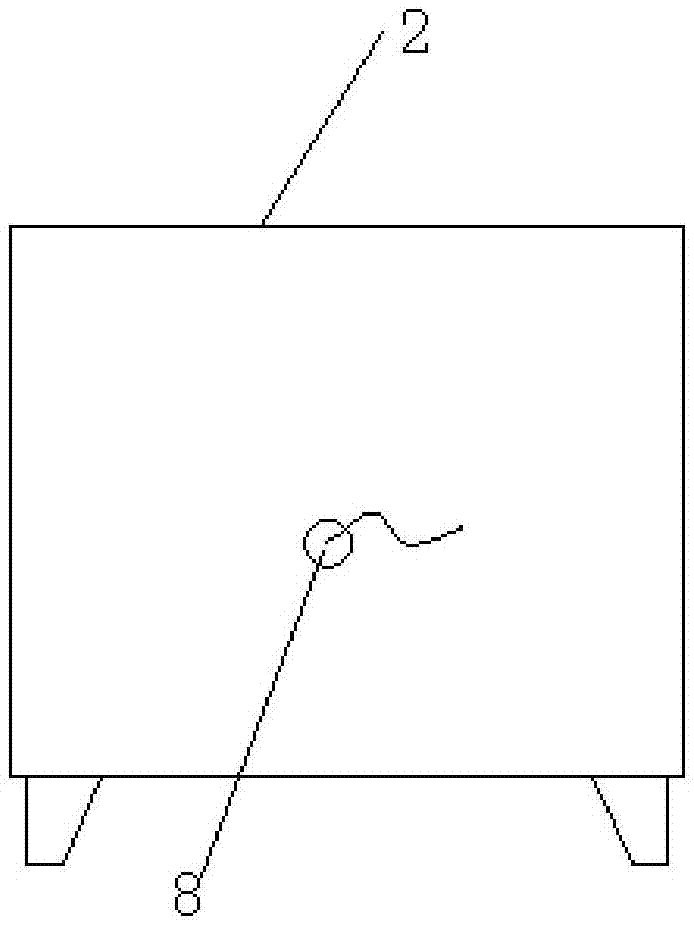

Energy-saving and environment-friendly high-temperature electric melting furnace

InactiveCN105444573AMeet the temperatureAvoid stickingControl devices for furnacesMonolithic liningsSemi openHearth

The invention discloses an energy-saving and environment-friendly high-temperature electric melting furnace. The energy-saving and environment-friendly high-temperature electric melting furnace comprises a control cabinet and a furnace body. The furnace body is composed of a hearth and a furnace lining. The hearth is composed of three insulating layers. A temperature measuring element is arranged on the back face of the furnace body. The hearth is of a semi-open type structure, and the hearth is filled with an aluminum oxide hollow ball plate. The high-frequency voltage transformation principle is adopted for saving electricity and energy, a plurality of silicon-molybdenum rods or silicon-carbide rods are used for heating, the temperature rise is fast, the effect is good, the high temperature of 1,600 DEG C can be generated, and the requirement for the temperature of pressure casting or crystal glass raw material smelting is highly met. A corundum plate, a silicon-carbide plate and a silicon oxide plate or a graphene plate are arranged in the hearth, crystal raw materials can be prevented from being attached into the hearth in the smelting process, and the cleanliness and transparency of crystal glass in the sintering process is guaranteed; meanwhile, the multiple insulating layers are arranged, dissipation of heat is effectively reduced, and resources are saved; and the external temperature of the furnace body is very low, and potential safety hazards of scalding are reduced. Noise is avoided during electric heating work, and the effects of safety, energy saving and environment friendliness are truly achieved.

Owner:聂晓彬 +1

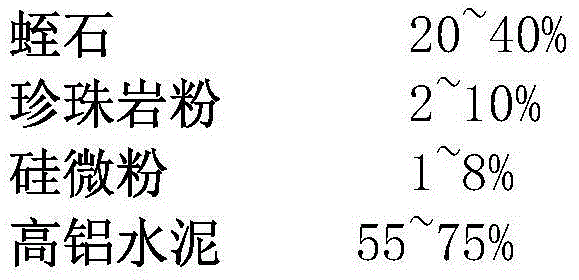

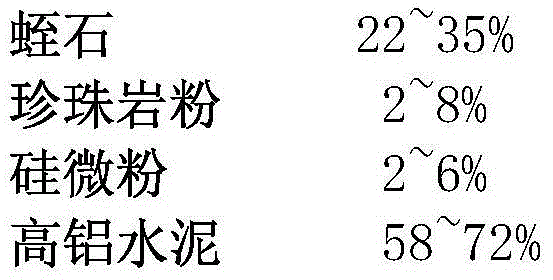

Lightweight, heat-insulation and fire-proof castable composition, and application and preparation method thereof

The invention discloses a lightweight, heat-insulation and fire-proof castable composition, and an application thereof in a nitrogen purification device and a preparation method thereof; the castable composition includes vermiculite, a perlite powder, a silica micro-powder and high-alumina cement. The castable composition has the characteristics of low thermal conductivity, low volume density, good thermal shock resistance, high use temperature and the like; at the same time, the castable composition also has good fluidity and easy and convenient construction; after being applied to the nitrogen purification device, the castable composition can effectively reduce heat loss of the nitrogen purification device, improves the thermal efficiency, reduces energy consumption, saves energy and reduces emissions. In addition, raw materials adopted by a lightweight, heat-insulation and fire-proof castable are non-toxic and non-corrosive, so the lightweight, heat-insulation and fire-proof castable has the characteristics of energy saving and environmental protection, and plays an important role in improving and protecting the environment. At the same time, all kinds of used raw materials can be purchased from markets, and the production costs of the lightweight heat-insulation and fire-proof castable are reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

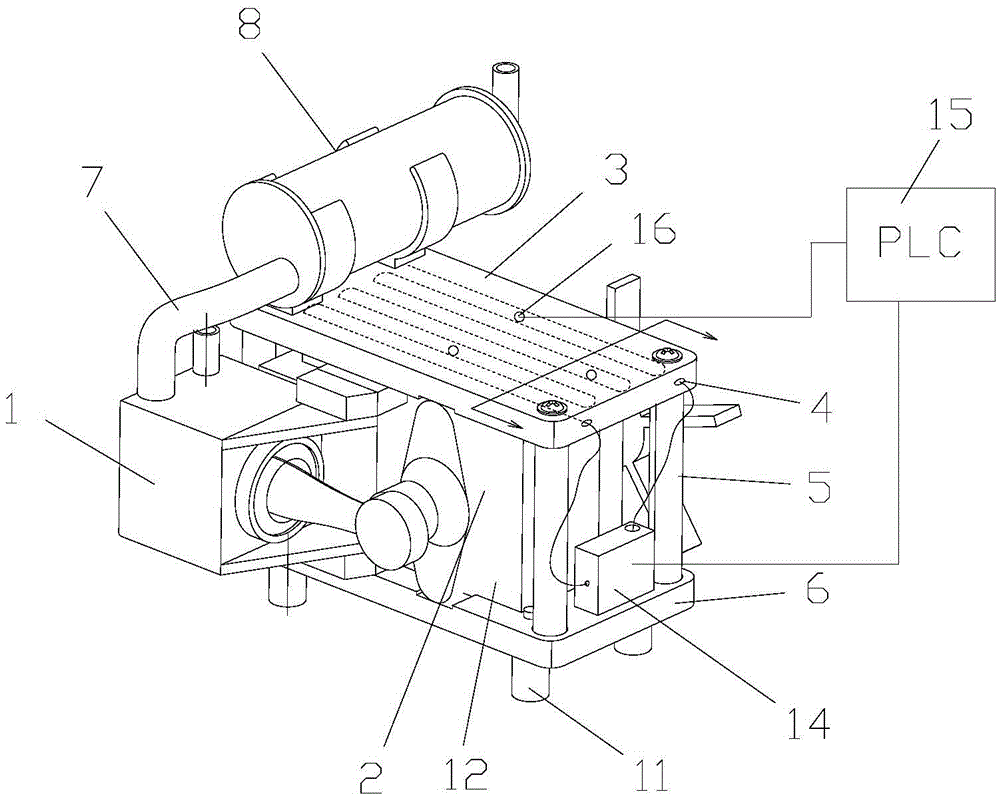

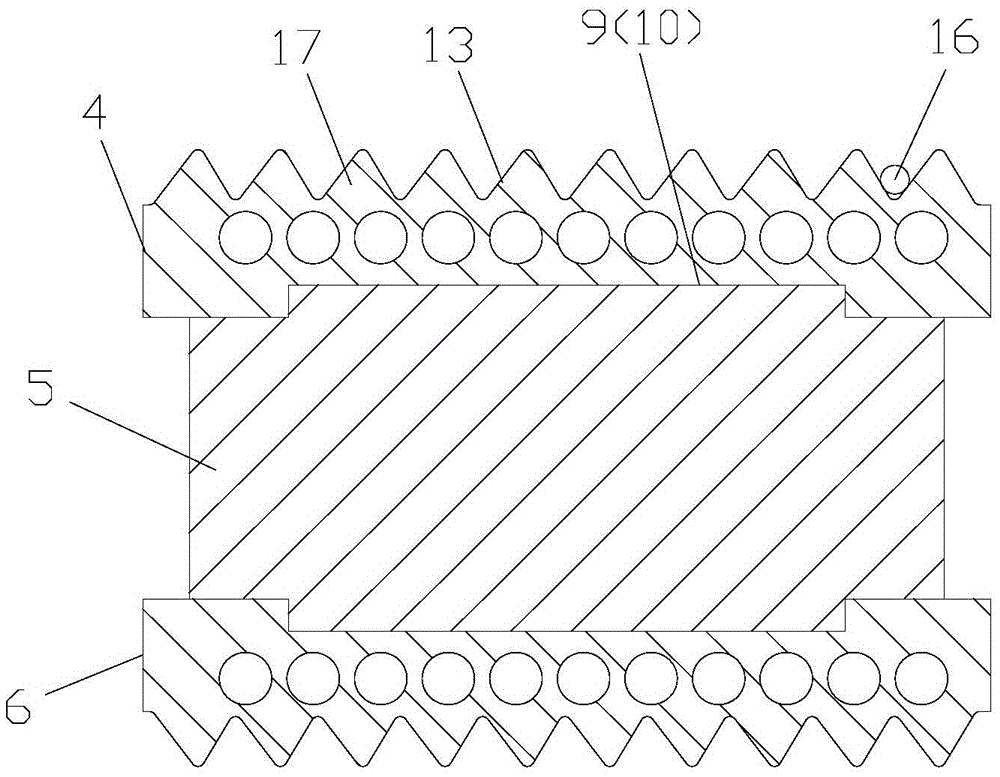

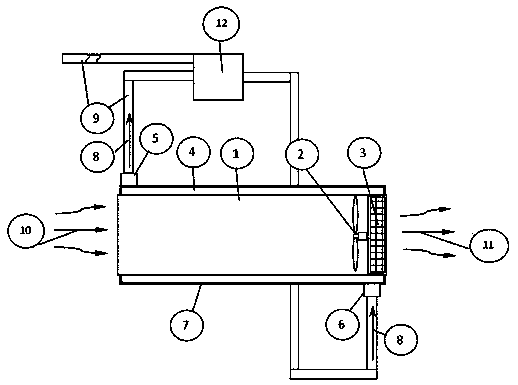

Intelligent cooling atomizer

InactiveCN105664309AReduce external temperaturePrevent skin damage accidentsMedical devicesMedical atomisersEngineeringDrive motor

The invention discloses an intelligent cooling atomizer, and belongs to the technical field of human body input media equipment. The intelligent cooling atomizer comprises a compressor and a compressing drive motor, and further comprises a radiating rack and an intelligent cooling system for forcing the radiating rack to cool, wherein the radiating rack comprises a motor top fixing plate, a motor bottom fixing plate and fixing plate supporting columns; the motor top fixing plate and the motor bottom fixing plate are made of a heat conduction material; the intelligent cooling system comprises bypass cooling channels which are arranged in the motor top fixing plate and the motor bottom fixing plate, a condenser communicated with the bypass cooling channels, a PLC connected with the condenser by a wire, and a plurality of temperature sensors. The intelligent cooling atomizer disclosed by the invention uses the radiating rack and the intelligent cooling system to force the atomizer to cool, in order to reach the set value and enable the surface to keep proper temperature to achieve the purpose of intelligently controlling temperature.

Owner:CHONGQING ZHIHEKANG MEDICAL INSTR

Warship invisible chimney design

InactiveCN107757856AStrong exhaust efficiencyImprove exhaust efficiencyAuxillariesPropulsion power plantsWater circulationMilitary ship

The invention relates to a warship chimney. The requirement of naval armaments for invisibility is higher and higher, and the possibility that a warship is investigated is greatly increased due to thelarge size, thick black smoke and the too high temperature of the exposed surface part of a chimney. By the adoption of the warship chimney, a smoke filter, a heat insulation layer, an exhaust fan, awater circulation cooling structure and the like are additionally arranged, black smoke of the warship chimney and the volume of the chimney are reduced, and the temperature of the outer portion is lowered. Through a series of transformation, the probability that the warship is found in the navigation process is reduced, and the invisibility effect of the warship chimney can be improved to a certain limit.

Owner:李宁

Fullerene modified fireproof thermal-insulation coating material and preparation method thereof

ActiveCN109722121AExtended service lifeStrong adhesionFireproof paintsAnti-corrosive paintsIonEmulsion

The invention discloses a fullerene modified fireproof thermal-insulation coating material and a preparation method thereof, and belongs to the technical field of coatings. The fireproof thermal-insulation coating material is a water-based environment-friendly coating and comprises the following raw materials in parts by weight: 15-42 parts of a resin emulsion, 14-51 parts of pigment and filler, 3-11 parts of an auxiliary agent, 0.3-5 parts of carbon fibers, 0.02-4 parts of fullerene, 3-12 parts of nano hollow porous thermal-insulation filler, 1-10 parts of a fire retardant and 16-50 parts ofdeionized water. The coating material prepared by the invention has functions of fire resistance, heat insulation and corrosion resistance, so that the situation that an equipment surface or a building surface needs to be repeatedly coated with different coatings is avoided, and the problem that rejection among different coatings and differences among construction processes are required to be considered is solved; moreover, the problems of poor corrosion resistance and the like of a conventional heat-insulation coating can be solved, so that the coating material provided by the invention can be widely applied to outer surface spraying of civil building outer walls, industrial equipment, storage tanks, pipelines and the like.

Owner:ZHUHAI HUADA WHOLEWIN CHEM LTD

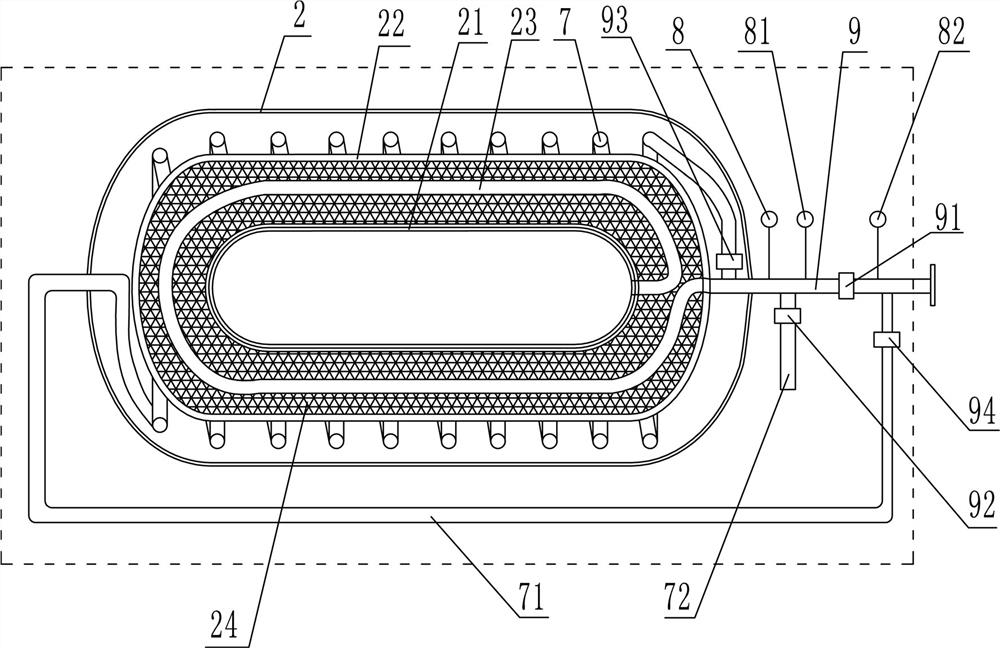

Small and light cryogenic high-pressure hydrogen storage device

PendingCN112393108ASimple structureReduce external temperatureContainer filling methodsPressure vesselsFiberCarbon fibers

The invention discloses a small and light cryogenic high-pressure hydrogen storage device. The small and light cryogenic high-pressure hydrogen storage device comprises an inner container and an outerbarrel, wherein the inner container is located in the outer barrel and wrapped by carbon fibers in a full winding mode; the outer side of a carbon fiber layer is further wrapped by a reflection heatinsulation layer; a hydrogen introducing pipe is arranged in an interlayer between the inner container and the outer barrel; one end of the hydrogen introducing pipe is communicated with the inner container from the head of the inner container; then the hydrogen introducing pipe is arranged around the inner container for a circle from the head of the inner container to the tail of the inner container and then towards the head of the inner container; then the other end of the hydrogen introducing pipe penetrates through the head of the outer barrel to be communicated with one end of a hydrogensupply pipe on the outer side of the head of the outer barrel; a first stop valve is arranged on the hydrogen supply pipe; a filling pipe is communicated to the hydrogen supply pipe between the firststop valve and the outer barrel; a second stop valve is arranged on the filling pipe; and the interlayer between the inner container and the outer barrel is further filled with aerogel and vacuumized.The device can improve the cruising ability of a small machine, and is light in weight, low in cost, safe, reliable and long in hydrogen storage maintaining time.

Owner:ZHANGJIAGANG RES INST OF HYDROGEN ENERGY CO LTD

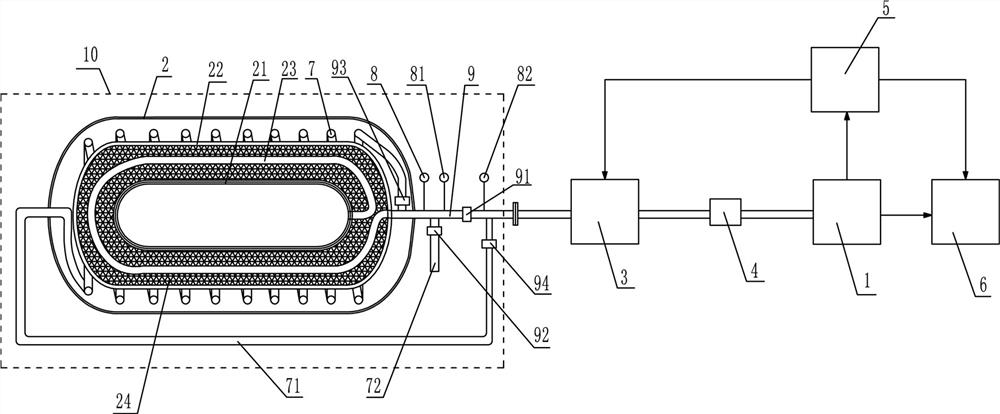

Small and light cryogenic high-pressure hydrogen storage power supply system

ActiveCN112448460ASimple structureImprove heat resistanceBatteries circuit arrangementsContainer filling methodsThermodynamicsBattery charge

The invention discloses a small and light cryogenic high-pressure hydrogen storage power supply system. The system comprises a hydrogen fuel cell, and also comprises a cryogenic high-pressure hydrogenstorage device for storing supercritical hydrogen, a heater, a pressure reducing valve and a storage battery, a hydrogen supply pipe of the cryogenic high-pressure hydrogen storage device is connected with an inlet of the heater through a pipeline, an outlet of the heater is connected with an inlet of the pressure reducing valve through a pipeline, an outlet of the pressure reducing valve is connected with a hydrogenation port of the hydrogen fuel cell through a pipeline, the hydrogen fuel cell is connected with the storage battery through a circuit, the hydrogen fuel cell can charge the storage battery, the storage battery is connected with the heater through a circuit, and the storage battery can supply power to the heater. The small and light cryogenic high-pressure hydrogen storage power supply system is long in cruising ability, light in weight, low in cost, safe, reliable and long in hydrogen storage maintaining time.

Owner:ZHANGJIAGANG RES INST OF HYDROGEN ENERGY CO LTD

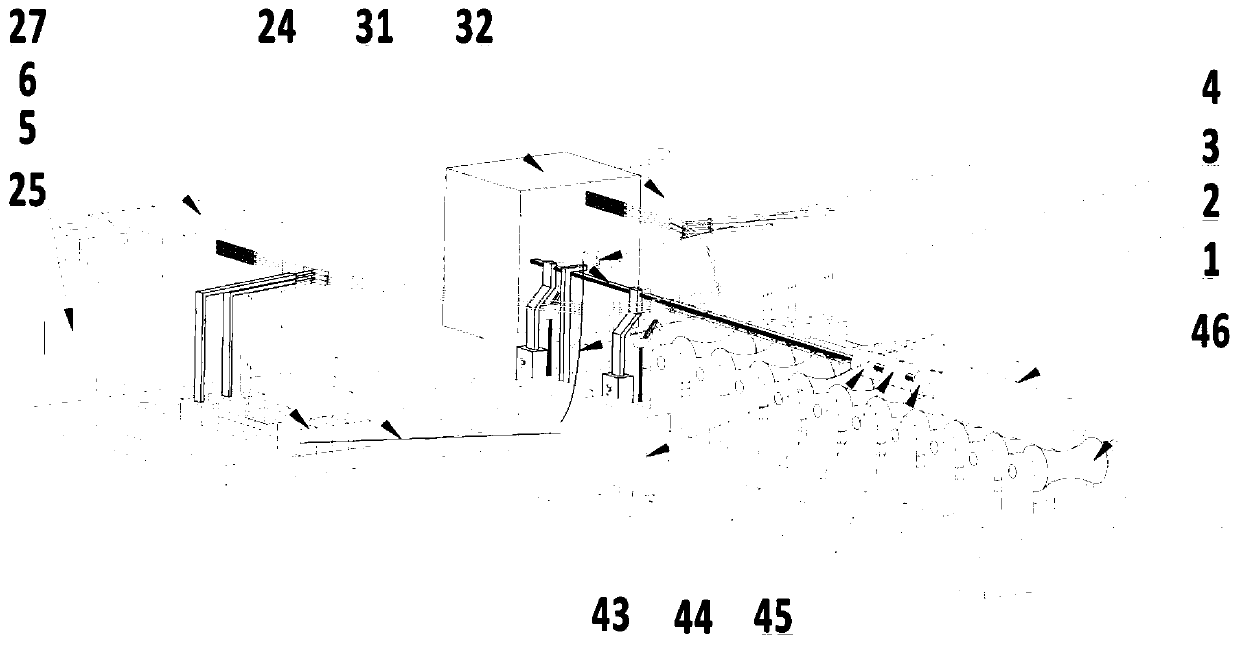

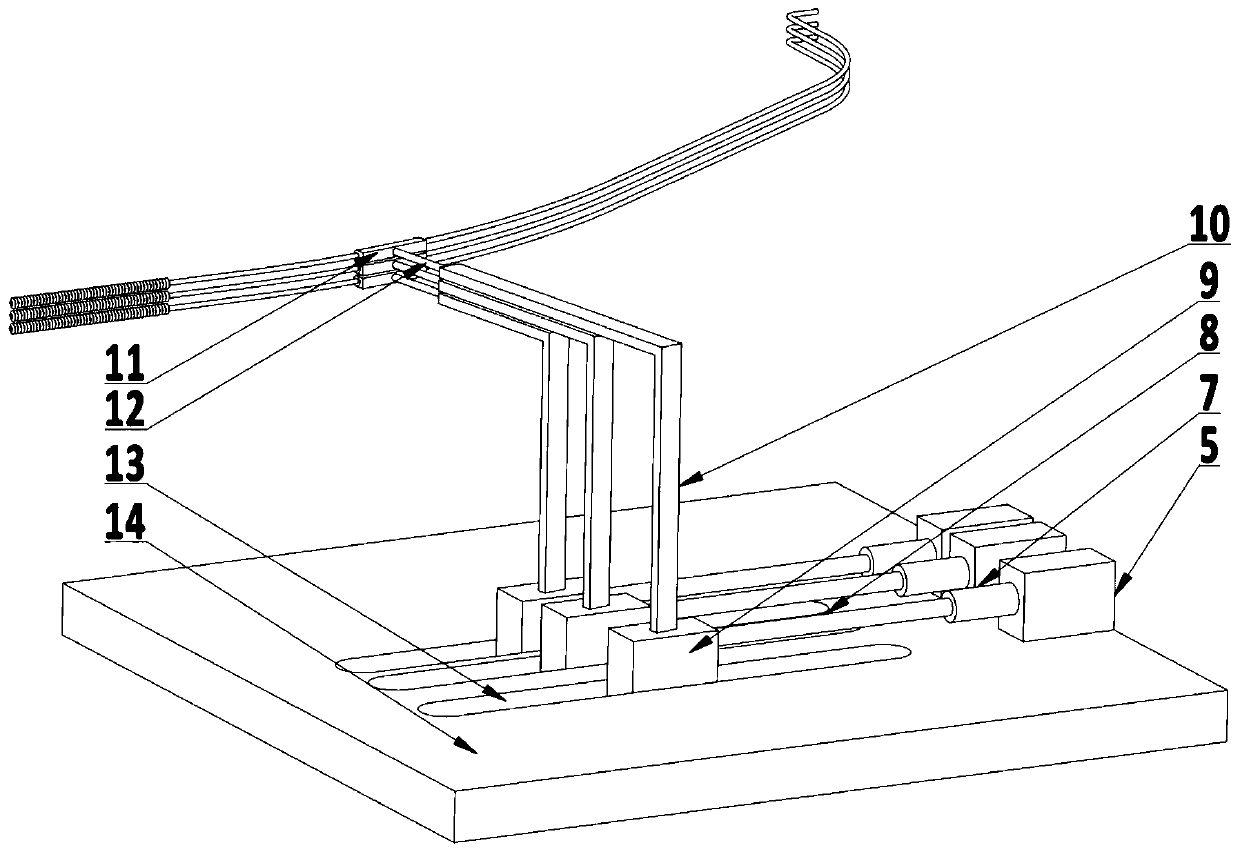

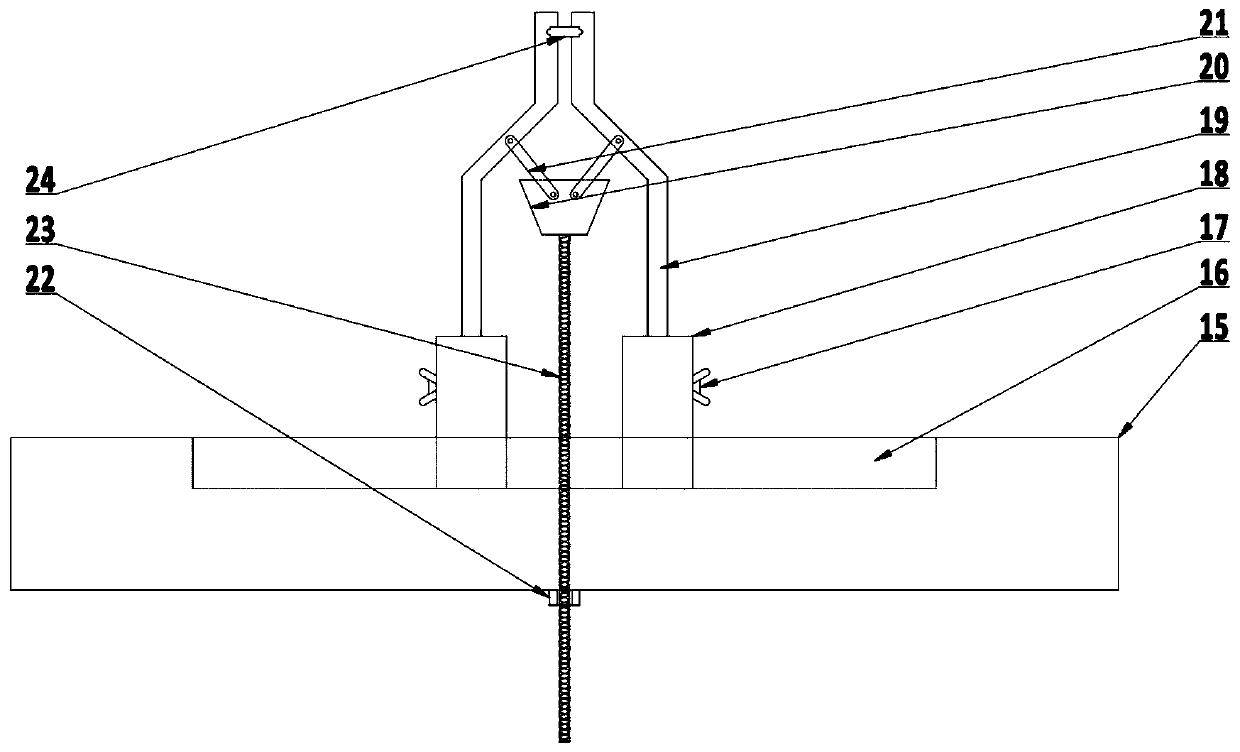

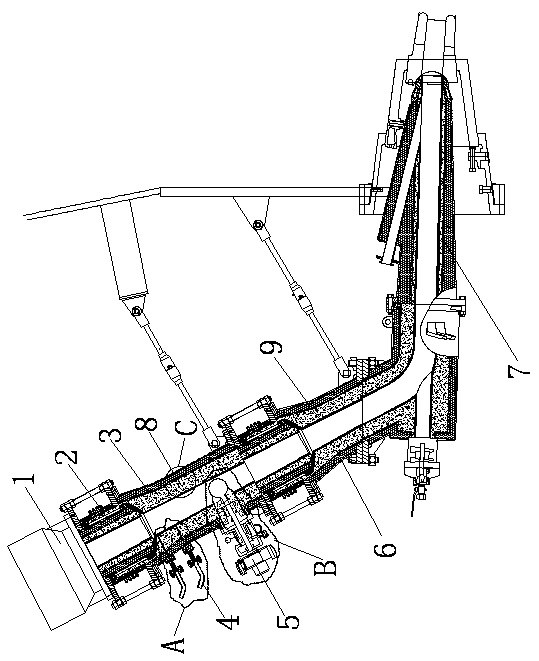

Rock drill steel tube blank heating system and heating method

ActiveCN111389938AQuality improvementExtend your lifeTemperature control deviceMeasuring devicesEngineeringMechanics

The invention discloses a rock drill steel tube blank heating system. The rock drill steel tube blank heating system comprises a feedback device, a propelling device, a locating device, a heating device, a heating device, a temperature measuring device and a conveying device. The distances d1 and d2 between three flame heaters are controlled through the feedback device. The heating temperature offlame injectors is controlled through an oxygen distribution box and a fuel gas distribution box. On the other hand, the invention further comprises a rock drill steel tube blank heating method. Through a gradient flame heating roll-forming method, the compactness of a rolled part is controlled, the rock drill steel internal defects caused by the same deformation of uniformly heated tube blanks inthe prior art are avoided, the quality of rock drill steel is improved, and the service life of the rock drill steel can be prolonged. The radial temperature of the rock drill steel tube blank is accurately controlled through the feedback device. Through flame heating, the cost is low, just one set of the flame injector of which the size is matched with different sizes of rock drill steel tubes needs to be designed, and other devices are all universal assemblies without replacement.

Owner:北渤智能科技秦皇岛有限公司

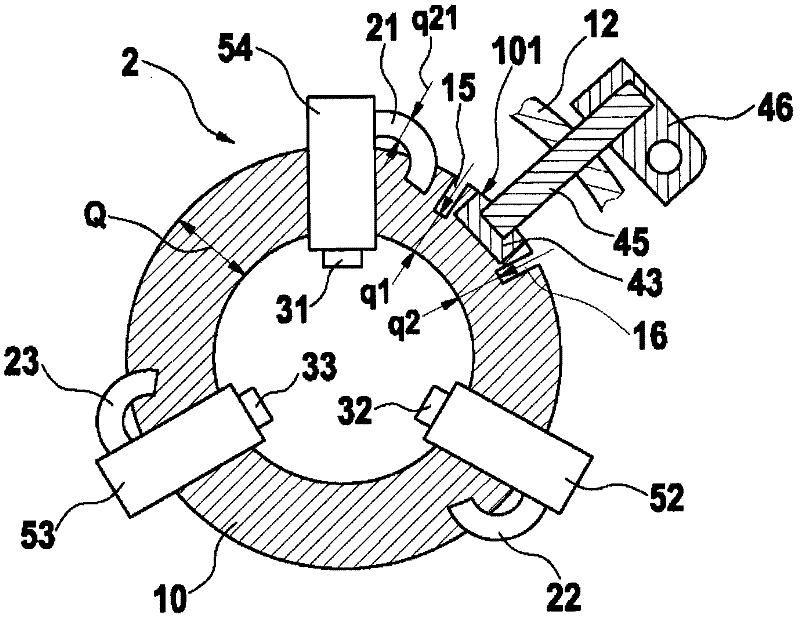

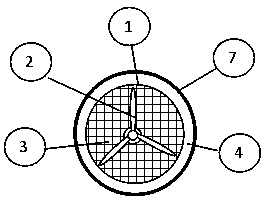

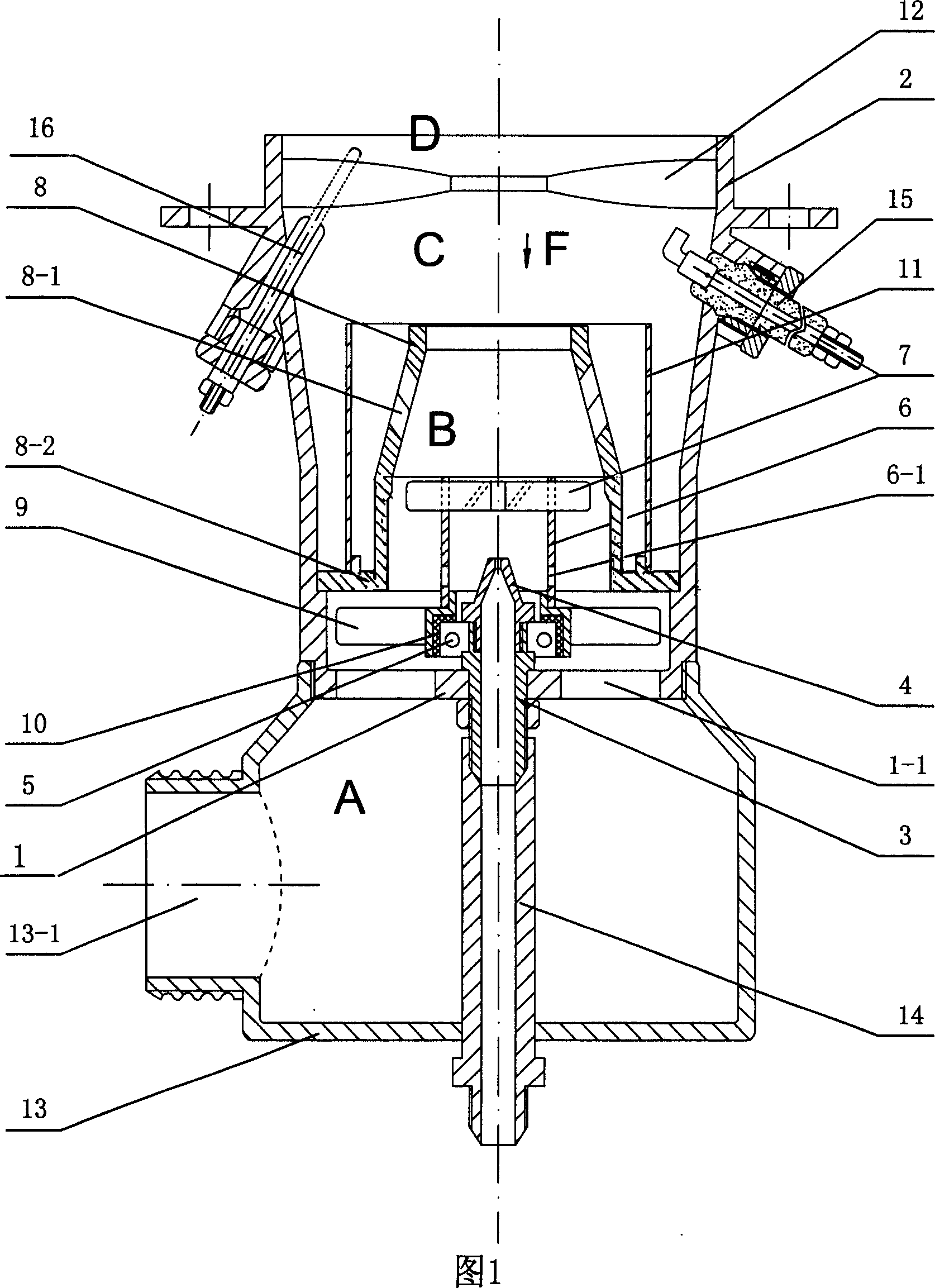

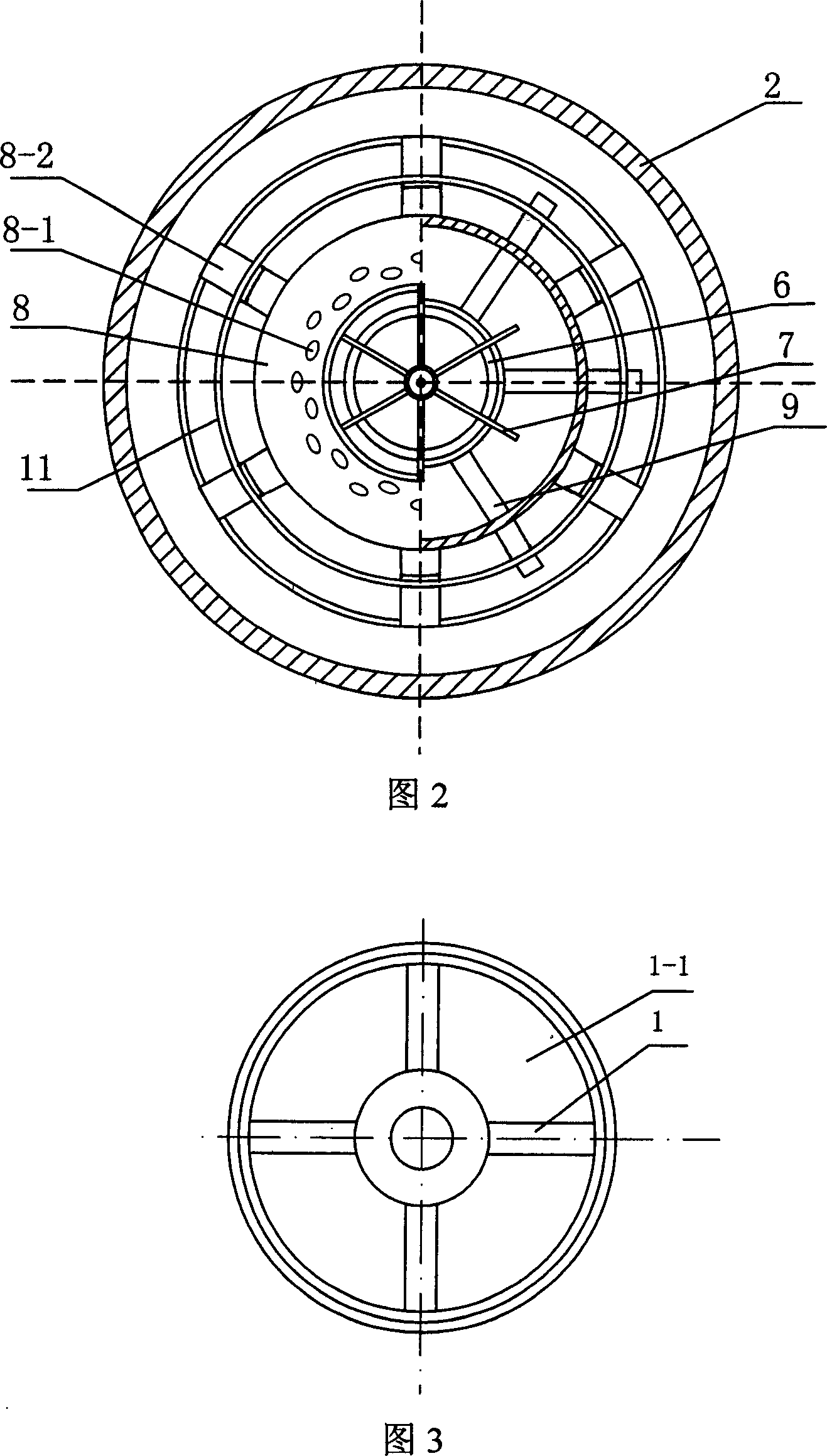

Spinning multistage mixed flow burner

InactiveCN101004266AReduce external temperatureSimple structureGaseous fuel burnerCombustorMixed flow

The present invention relates to an automatic rotary multi-stage mixed flow combustor. It includes the following several portions: a shell body with bottom plate, on the bottom plate a centre pipe shaft is set, on the bottom plate around the centre pipe shaft several air-feeding holes are set, the top portion of said pipe shaft is equipped with a nozzle, and the shaft body of said pipe shaft is equipped with a bearing; and said bearing is connected with a rotary vane conduct pipe. Besides, said invention also provides the working principle of said mixed flow combustor and its concrete operation method.

Owner:王战勇

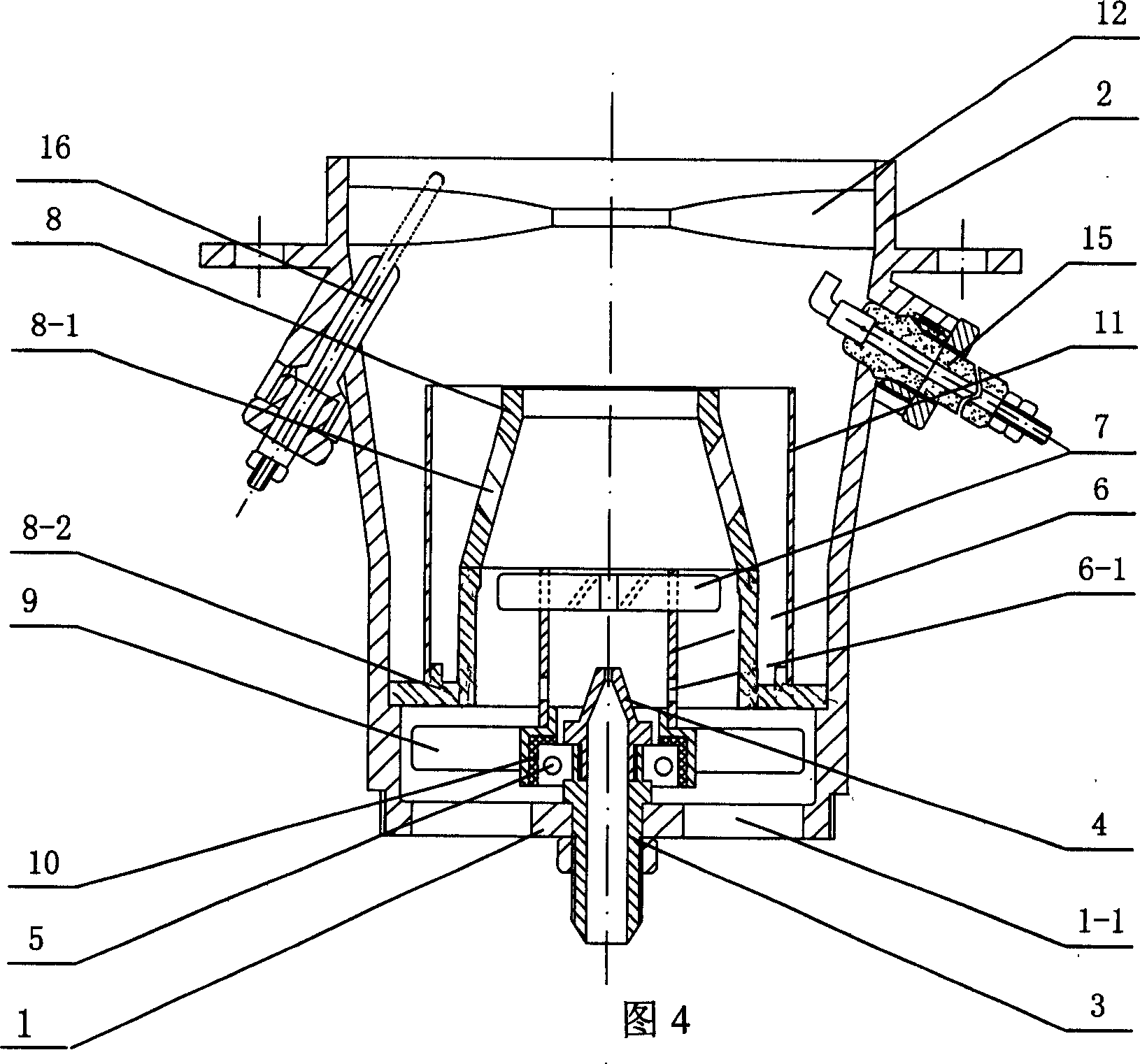

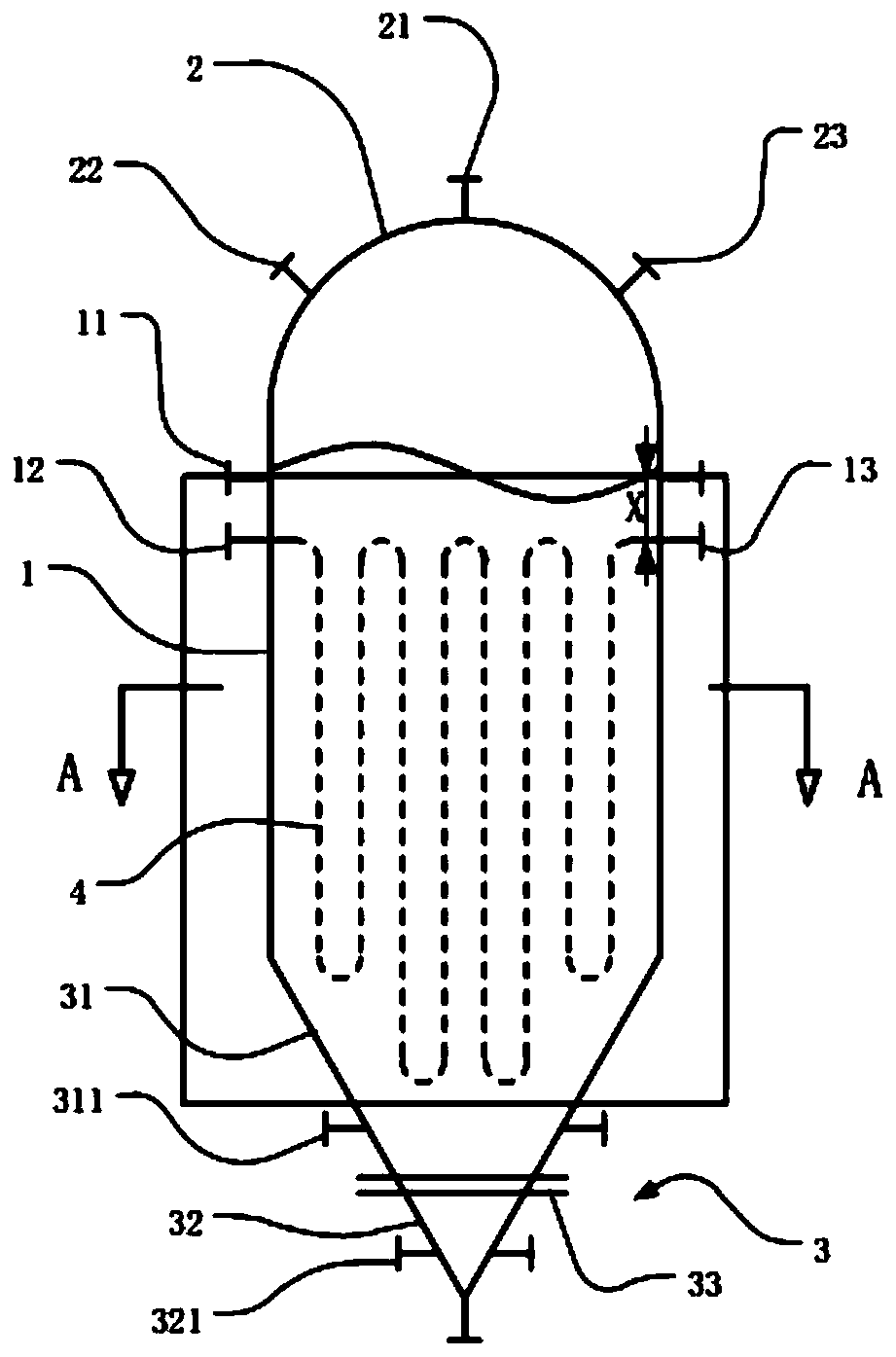

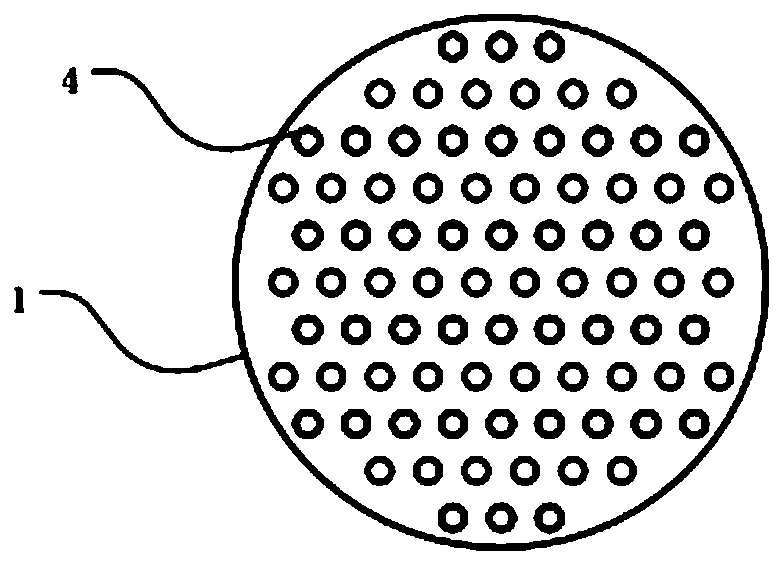

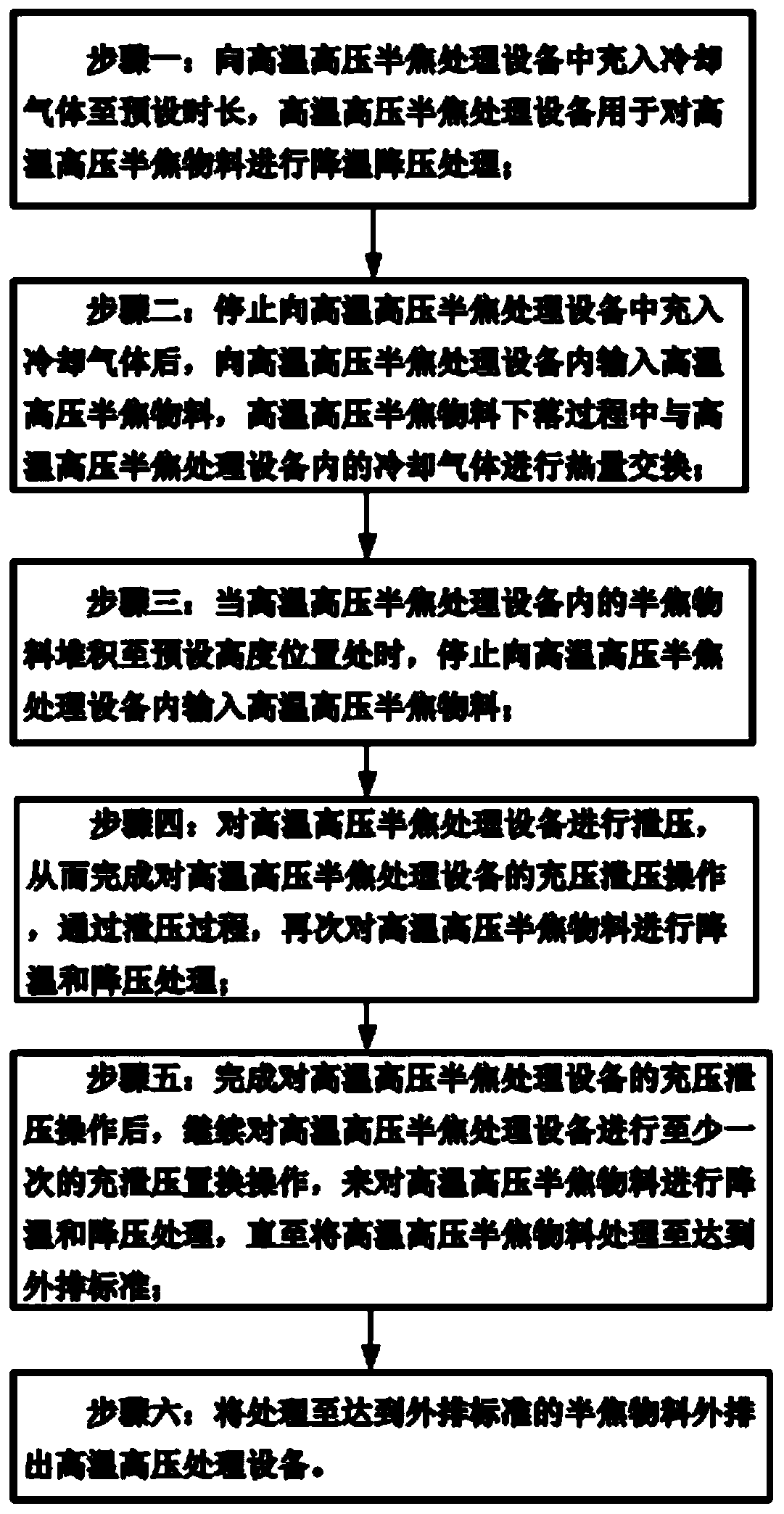

High-temperature and high-pressure semi-coke cooling and depressurizing method

InactiveCN110699095AImprove processing efficiencyEffective cooling and pressure reduction treatmentCoke quenchingThermodynamicsProcess engineering

The invention relates to a high-temperature and high-pressure semi-coke cooling and depressurizing method which comprises the following steps: I, filling a cooling gas into high-temperature and high-pressure semi-coke treatment equipment for a preset duration; II, after the cooling gas is stopped, inputting a high-temperature and high-pressure semi-coke material into the high-temperature and high-pressure semi-coke treatment equipment, and performing heat exchange on the semi-coke material with the cooling gas in the high-temperature and high-pressure semi-coke treatment equipment in the falling process; III, when the semi-coke material in the high-temperature and high-pressure semi-coke treatment equipment is accumulated to a preset height, stopping inputting the semi-coke material into the high-temperature and high-pressure semi-coke treatment equipment; and IV, releasing the pressure of the high-temperature and high-pressure semi-coke treatment equipment, so as to complete the operation of charging and releasing the pressure of the high-temperature and high-pressure semi-coke treatment equipment, and through the pressure release process, performing cooling and depressurizing treatment on the high-temperature and high-pressure semi-coke material for a second time. By adopting the cooling and depressurizing method, the high-temperature and high-pressure semi-coke material is subjected to effective and efficient cooling and depressurizing treatment, and the investment cost of treatment can be also greatly lowered.

Owner:ENN SCI & TECH DEV

Thermally insulated components

ActiveUS10563560B2Improved and emissionLow costLiquid surface applicatorsExhaust apparatusFiberPhysical chemistry

A thermally insulated component comprising a structure having a heated interior and an exterior, and a thermal insulating structure for thermally insulating at least a portion of the exterior of the component structure. The thermal insulating structure comprises an aqueous mixture comprising an inorganic binder and inorganic filler particles, and a fabric comprising inorganic fibers. The fabric is impregnated with the aqueous mixture so as to form a pliable binder structure. The pliable binder structure is disposed completely around at least a portion of the component structure. It can be desirable for the component to further comprise at least one thermal insulator comprising inorganic fibers, where the thermal insulator is disposed between the pliable binder structure and the exterior of the component structure.

Owner:3M INNOVATIVE PROPERTIES CO

Energy-saving environment-friendly air supply branch pipe

InactiveCN105506208AConserve non-renewable energyReduce heat lossBlast furnace detailsHeating stovesAir volumeThermal insulation

The invention relates to a blast furnace air supply pipeline, in particular to an energy-saving environment-friendly air supply branch pipe. The energy-saving environment-friendly air supply branch pipe comprises a gooseneck, a compensator, a middle segment, a lower segment, and a straight blow pipe, wherein a piezometric pipe used for measuring temperature, pressure and volume of hot wind in the air supply branch pipe and a flow control valve used for adjusting the pressure of the wind in the air supply branch pipe are mounted in the middle segment; a multiple heat-insulating thermal insulation structure is arranged on the inner side of the metal steel shell of the air supply branch pipe. Due to flow rate and wind pressure adjustment, hot wind parameters of all air supply branch pipes can be consistent, so that smelting efficiency and molten iron quality of a blast furnace can be improved greatly, and energy consumption can be reduced; due to the multiple heat-insulating thermal insulation structure, temperature on the outer surface of each air supply branch pipe can be lowered effectively, temperature of hot wind sent into the blast furnace is raised, the operation environment is improved, and non-renewable energy is saved.

Owner:TANGSHAN JINSHAN TENGYU SCI & TECH

Low-thermal-conductivity brick for rotary cement kiln and production and manufacturing method of low-thermal-conductivity brick

PendingCN111964434ASolve pollutionReduce external temperatureFurnace componentsRotary drum furnacesTunnel kilnFire brick

The invention belongs to refractory materials and production methods thereof, and particularly relates to a low-thermal-conductivity brick for a rotary cement kiln and a production and manufacturing method of the low-thermal-conductivity brick. The production method of the low-thermal-conductivity brick comprises the following steps that magnesia particles, magnesium aluminate spinel particles, spinel fine powder and magnesia fine powder are mixed, then a binding agent is added to prepare pug, the pug is pressed into a green body, the green body is dried and fired in a high-temperature tunnelkiln to obtain a main body refractory brick, the main body brick is placed on an operating platform, and is clamped by a grinding tool, a steel mesh meshes with the main body brick, the binding agentis added into a heat insulator raw material for mixing, then a castable is poured into the grinding tool according to a specified amount, vibrating and molding is conducted, demolding is conducted after 24 hours, then drying is conducted to 350 DEG C, and then packaging is conducted after cooling. The low-thermal-conductivity brick for the rotary cement kiln and the production and manufacturing method of the low-thermal-conductivity brick have the advantages that the problem of Cr < 6 + > public nuisance pollution of the magnesite-chrome brick of the rotary cement kiln is solved, meanwhile, the temperature of a cylinder of the rotary cement kiln is reduced, the service life of the brick for a transition zone of the rotary cement kiln, which is utilized in multiple aspects, is prolonged, and meanwhile, the energy and equipment consumption is reduced.

Owner:武连明

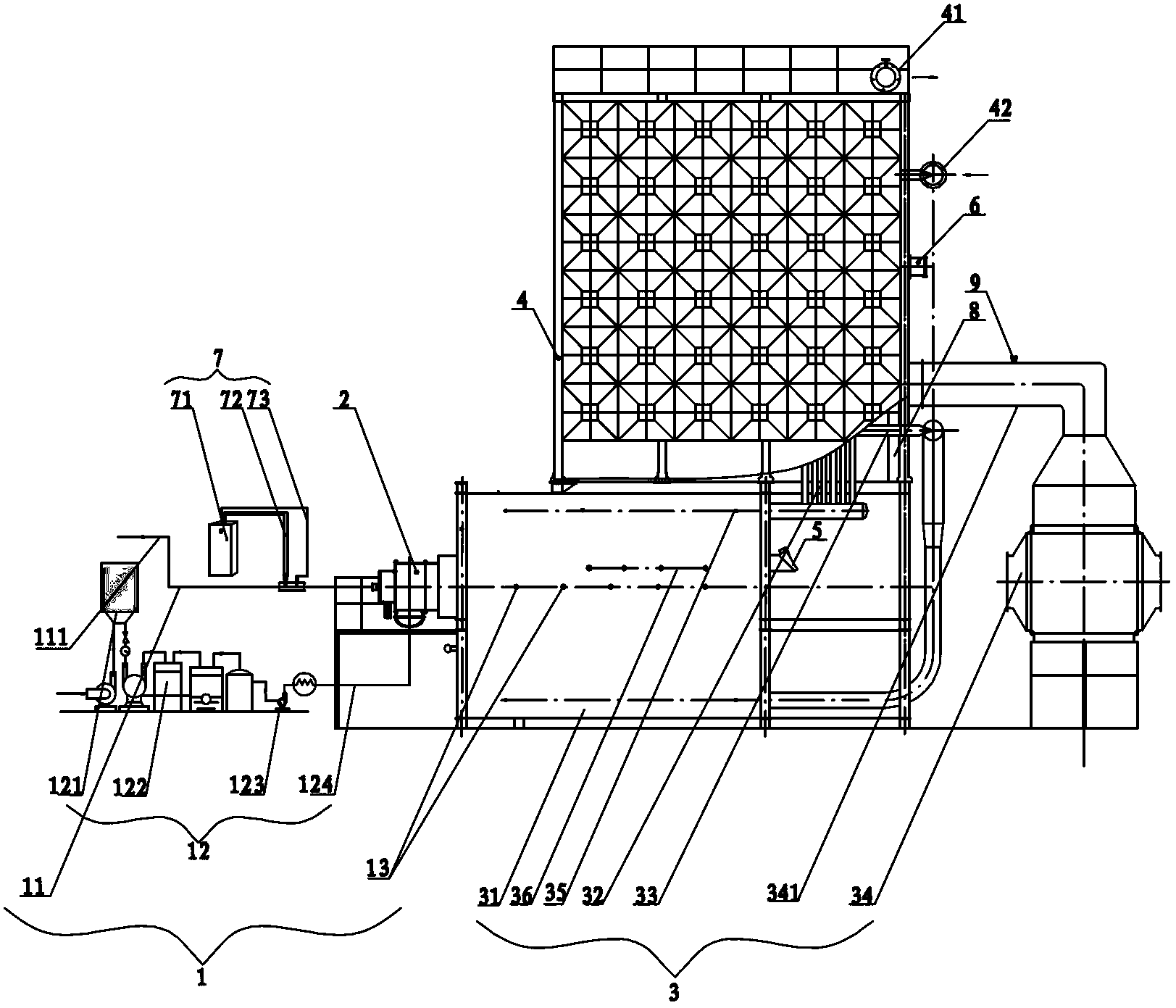

Efficient oxygen-enriched-combustion multiple-unit-powder heat transfer oil boiler system

InactiveCN103225881AFast ignitionIncrease temperatureFuel supply regulationStorage heatersCombustion chamberCombustor

The invention relates to an efficient oxygen-enriched-combustion multiple-unit-powder heat transfer oil boiler system, and belongs to the technical field of heat transfer oil equipment. The efficient oxygen-enriched-combustion multiple-unit-powder heat transfer oil boiler system comprises an air inlet system, a burner and a boiler body, wherein the boiler body comprises a combustion chamber as well as a radiation heat-exchange surface and a convection heat-exchange surface, which adopt exhaust pipe structures, and are arranged in series on the outer wall of the combustion chamber; the burner is communicated with the combustion chamber; the air inlet system comprises a primary air inlet device, a secondary air inlet device and a tertiary air inlet device; the primary air inlet device and the secondary air inlet device are both connected to the burner; the primary air inlet device is put in from the middle part of the burner; the secondary air inlet device is put in from bottom of the burner; and the tertiary air inlet device is arranged in the middle of the side wall of the combustion chamber and used for directly supplying wind for the combustion chamber. The efficient oxygen-enriched-combustion multiple-unit-powder heat transfer oil boiler provided by the invention has the advantages of high automatic degree, high heat efficiency and the like.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Shielded wire grounding device for electrical equipment

ActiveCN113628797BImprove stabilityReduce external temperatureInsulated cablesInsulated conductorsEngineeringControl theory

The invention discloses a grounding device for shielded wires of electrical equipment. The grounding device for shielded wires of electrical equipment comprises: a stable seat; a frame located outside the stable seat; a communication port located outside the frame; at least four sets of connection limit components, The connection limiting component is arranged inside the communication port, and is used for limiting and fixing the outer end of the cable; the fixing component, the fixing component is connected with the frame, and is used for limiting and fixing the inside of the cable; wherein, the fixing component It includes: an adjustment assembly, the adjustment assembly is arranged outside the frame, and is used for pressurizing and fixing adjustment of the internal cables; at least two sets of support assemblies, the support assemblies are connected with the frame, and are used for insulating support of the cables. The connection limit component cooperates with the fixed component to provide external protection for the cable and further improve the stability of the cable when it is grounded. At the same time, a heat exchange component is installed outside to further ensure the external air circulation of the cable and reduce the external temperature of the cable. temperature.

Owner:江苏龙源电材有限公司

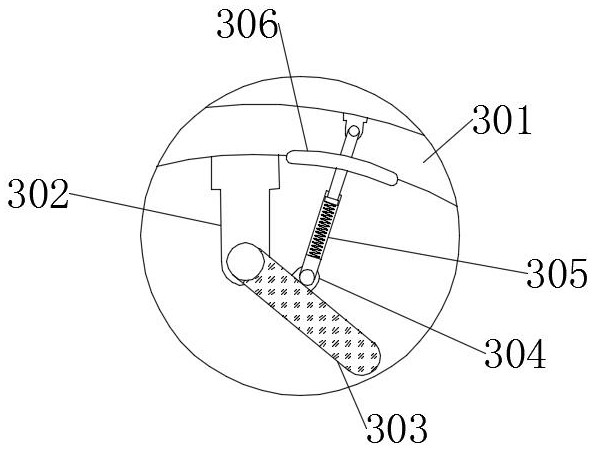

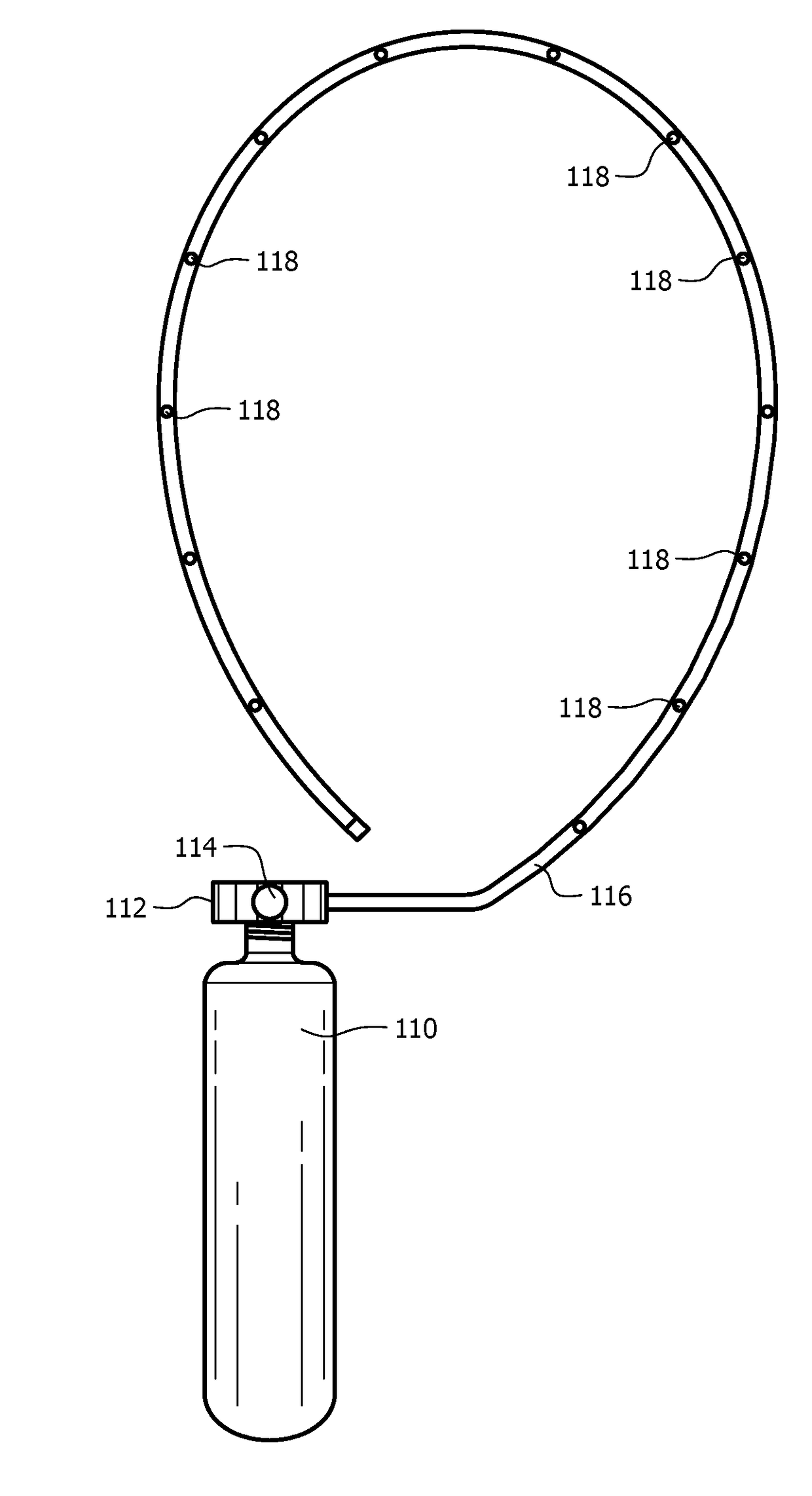

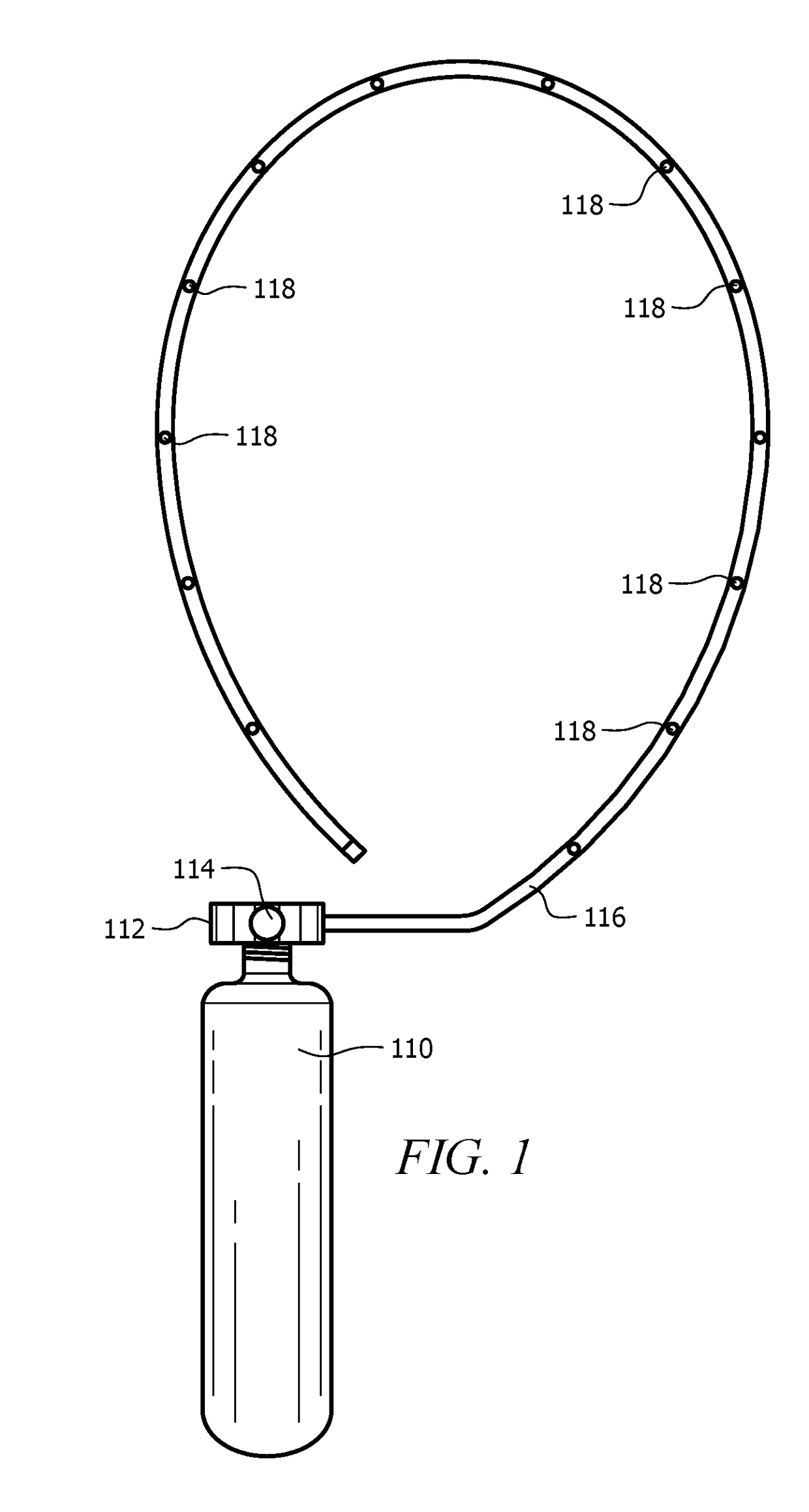

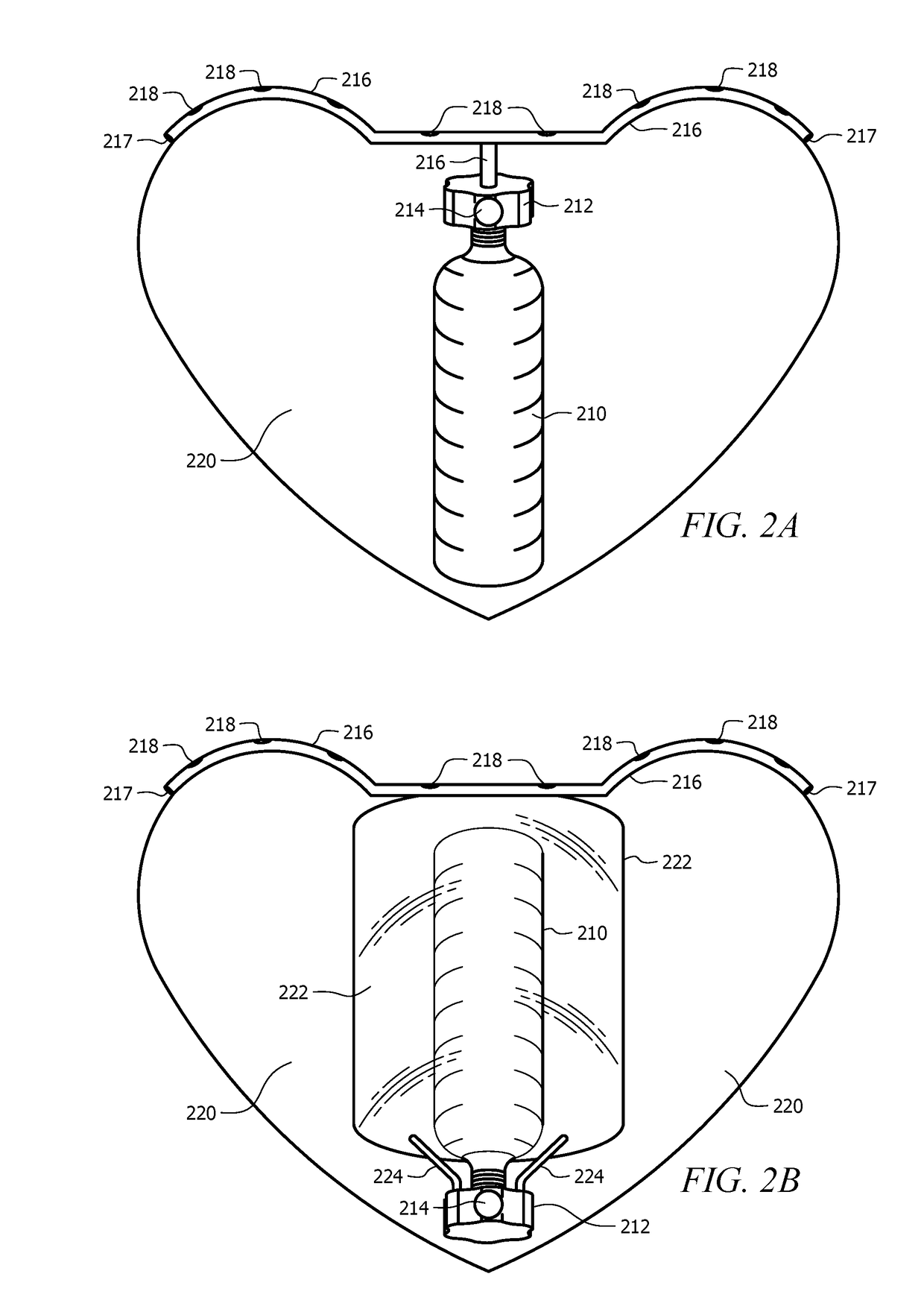

Body Cooling Device

InactiveUS20170246028A1Quick upgradeRapid coolingTherapeutic coolingTherapeutic heatingBiomedical engineeringBody cooling

A portable body cooling device, worn on the upper torso of a person, that uses a compressed or liquefied gas cartridge to vent cool gas onto the skin of the wearer as well as to act as a heat sink during the gas release. The cartridge is in contact with a conductive material that transfers heat from the skin of the wearer to the cartridge. The cooling device provides immediate and temporary relief from heat flashes.

Owner:CAHOON COLIN PAUL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com