Warship invisible chimney design

A technology for chimneys and warships, which is applied to ships, auxiliary equipment, and ship propulsion. It can solve the problems of being easily corroded by seawater and inconvenient maintenance, and achieve the effects of increasing the space used, reducing the temperature of the outer surface, and reducing the volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

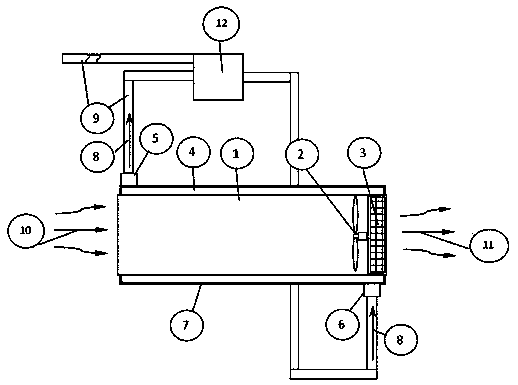

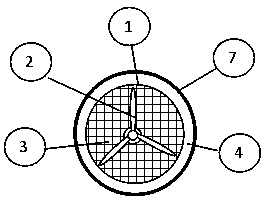

[0026] A warship "invisible" chimney design, which consists of the following parts: 1 chimney exhaust channel, 2 exhaust fan with motor, 3 filter screen, 4 annular cooling pipe, 5 cooling liquid outlet of cooling pipe, 6 cooling liquid of cooling pipe Inlet, 7 outer wall heat insulation layer, 8 coolant flow direction, 9 other pipes of heat dissipation part, 10 exhaust gas flow direction in the chimney, 11 exhaust gas discharge direction, 12 hot coolant heat exchange device inside the warship.

[0027] The hot exhaust gas produced by the warship boiler is discharged from the warship through 1 chimney exhaust channel. The hot exhaust gas is discharged from the interior of the warship to the exterior of the warship.

[0028] The wall of the chimney is designed as a ring structure, and 4 ring cooling pipes are formed inside the ring, and the cooling liquid, such as cold water, enters the 4 ring cooling pipes through the cooling liquid inlet of the 6 cooling pipes, and the cold wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com