Design scheme for gap-free piston reciprocating compressor

A design scheme, reciprocating technology, applied in mechanical equipment, liquid variable volume machinery, variable volume pump components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

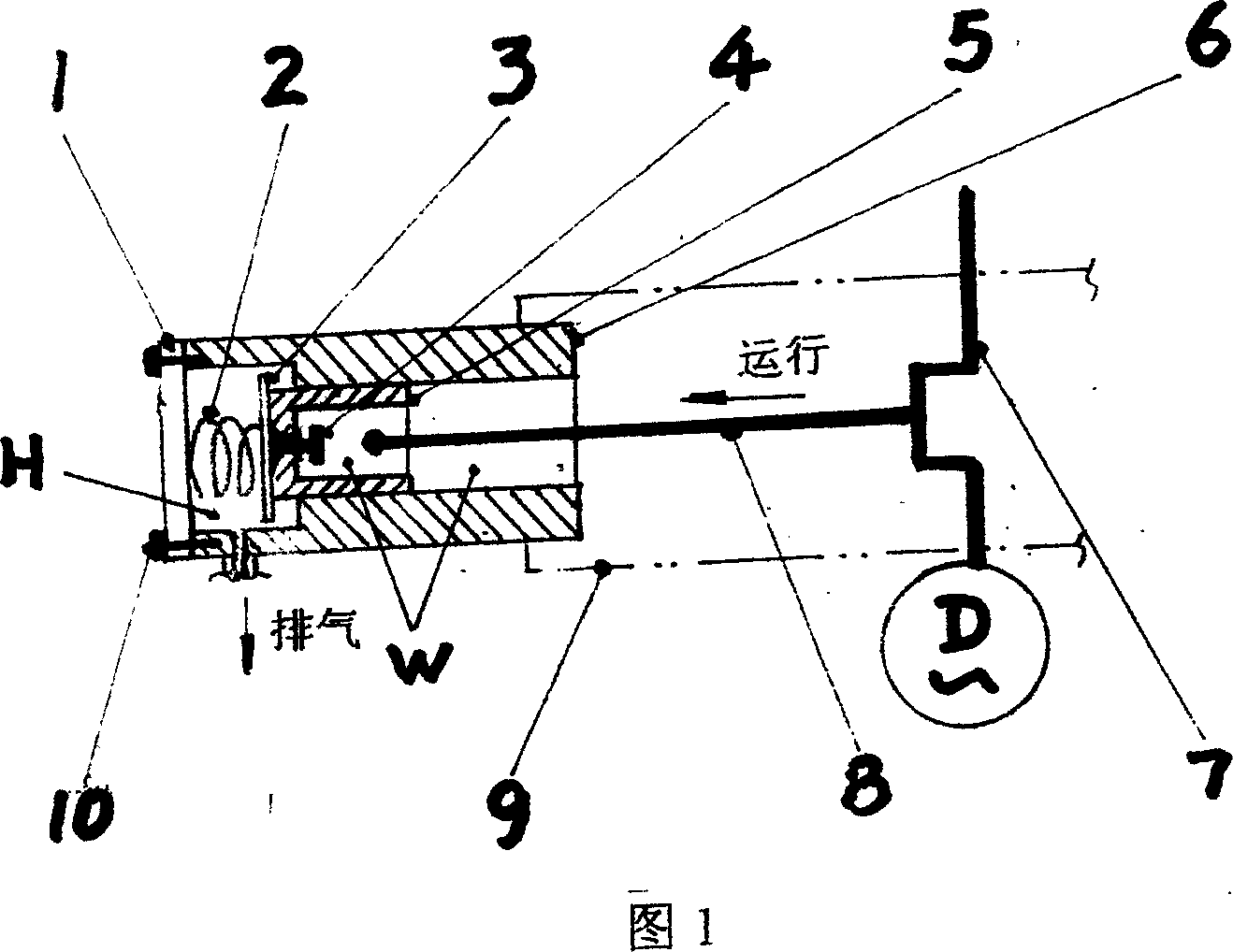

[0014] Figure 1 highlights the structural overview of the "no backlash" design of a crankshaft driven compressor.

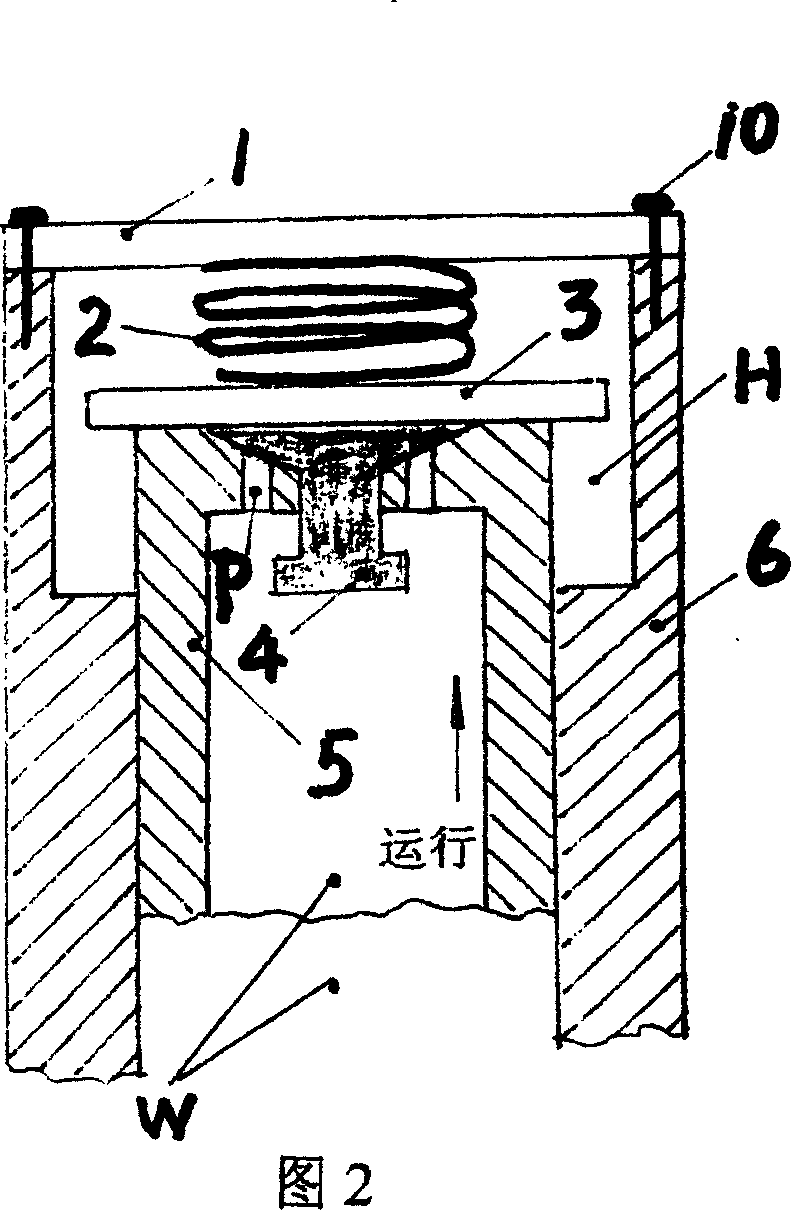

[0015] As shown in Fig. 2, the piston 5, which is doing the compression and exhaust work, squeezes all the compressed high-pressure gas into the high-pressure zone H, and then it continues to rush out of the cylinder 6 against the exhaust valve plate 3, and Enter high pressure zone H. At this time, the geometric space ("clearance") between the piston 5, the conical suction valve block 4 and the exhaust valve plate 3 is not difficult to reach extremely close to "zero", or even equal to "zero". . The stroke of the piston 5 rushing out of the cylinder 6 can usually be controlled at about 1 / 10 of its effective suction stroke length.

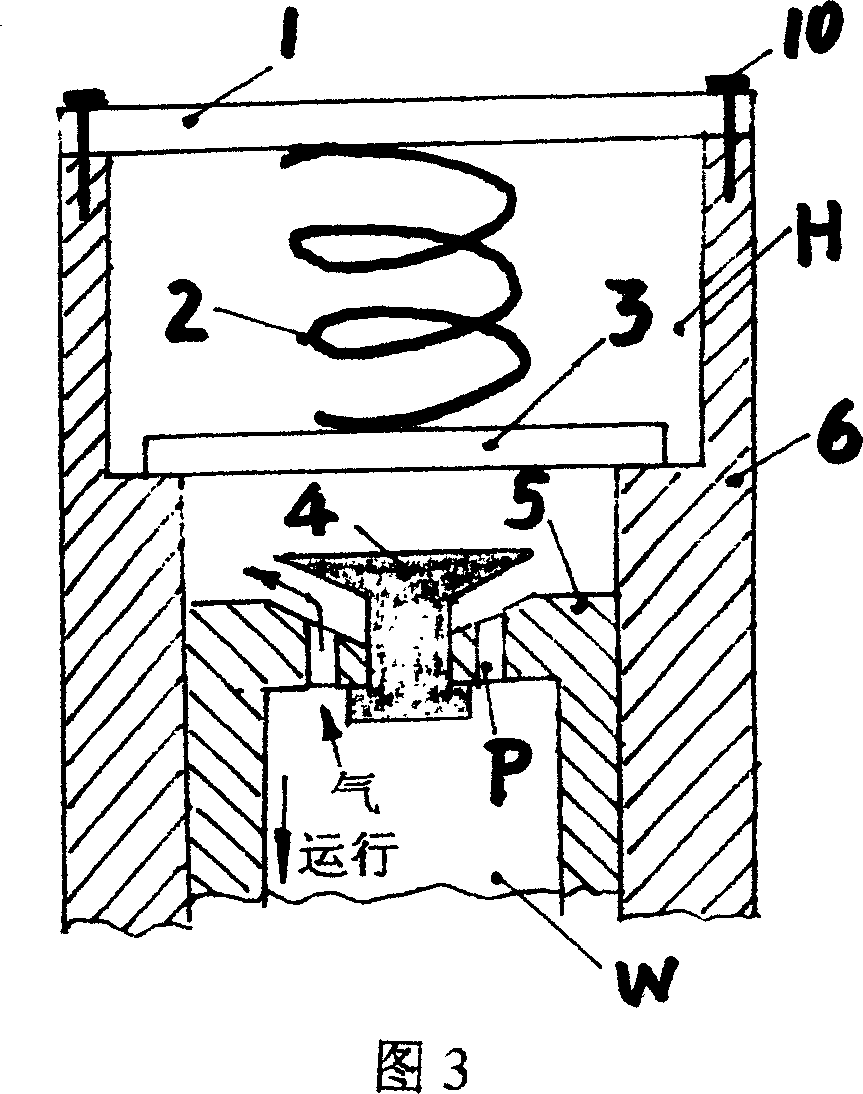

[0016] As shown in Figure 3, when the piston 5 retreated into the cylinder 6 completely, the exhaust valve plate 3 positioned by the spring 2 would naturally allow it to be driven by high air pressure to seal the top of the cylinder 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com