Patents

Literature

541results about How to "Improve exhaust efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction machine

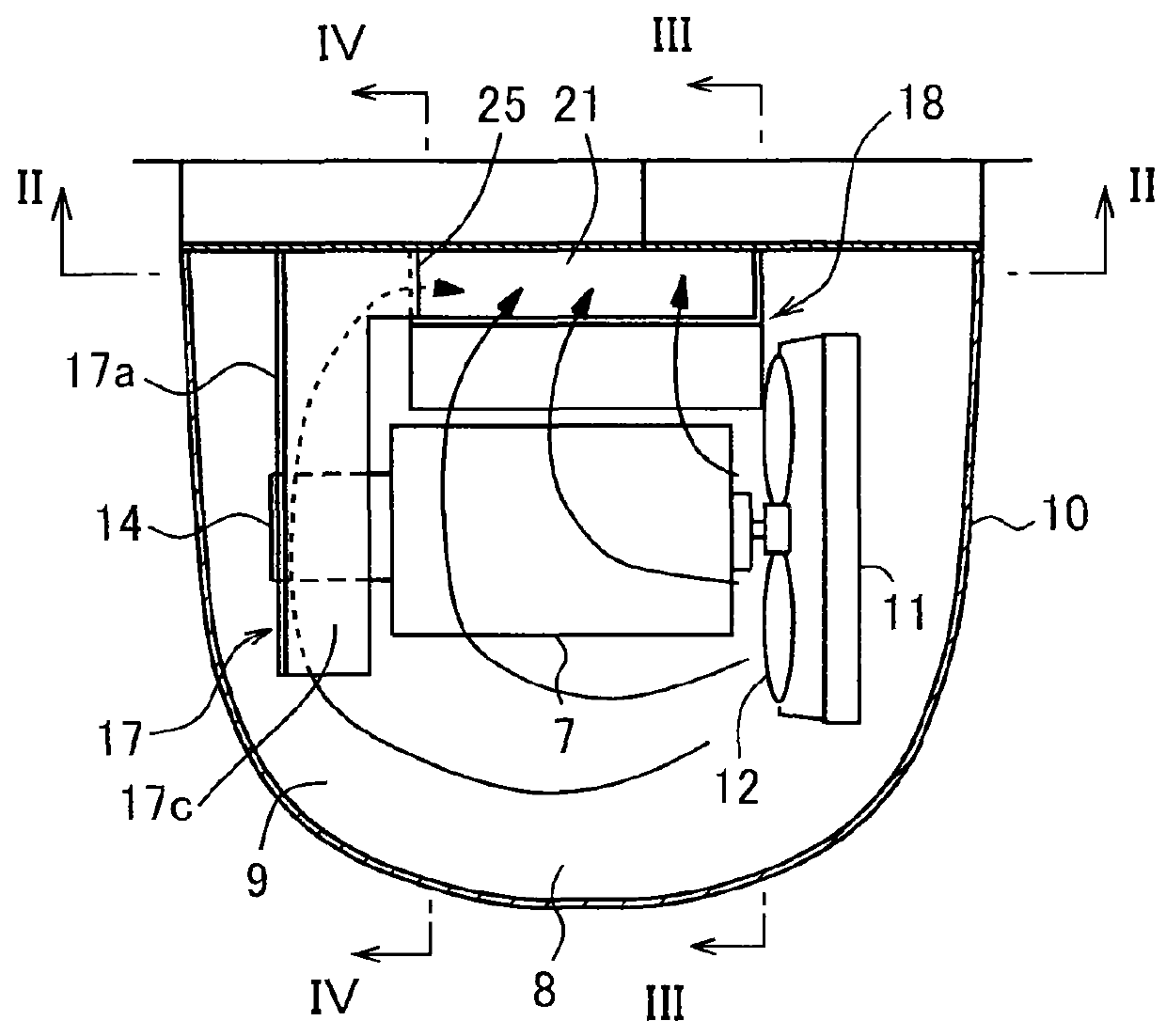

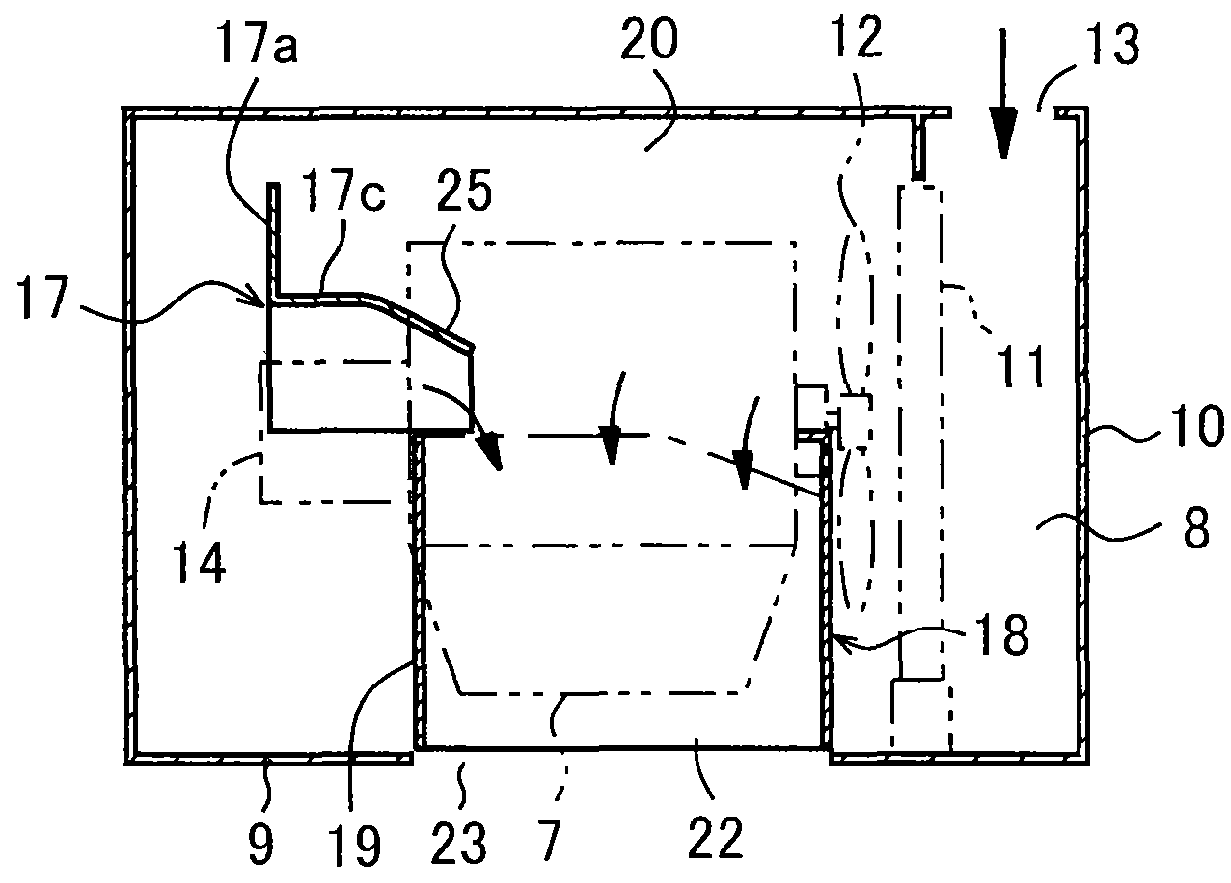

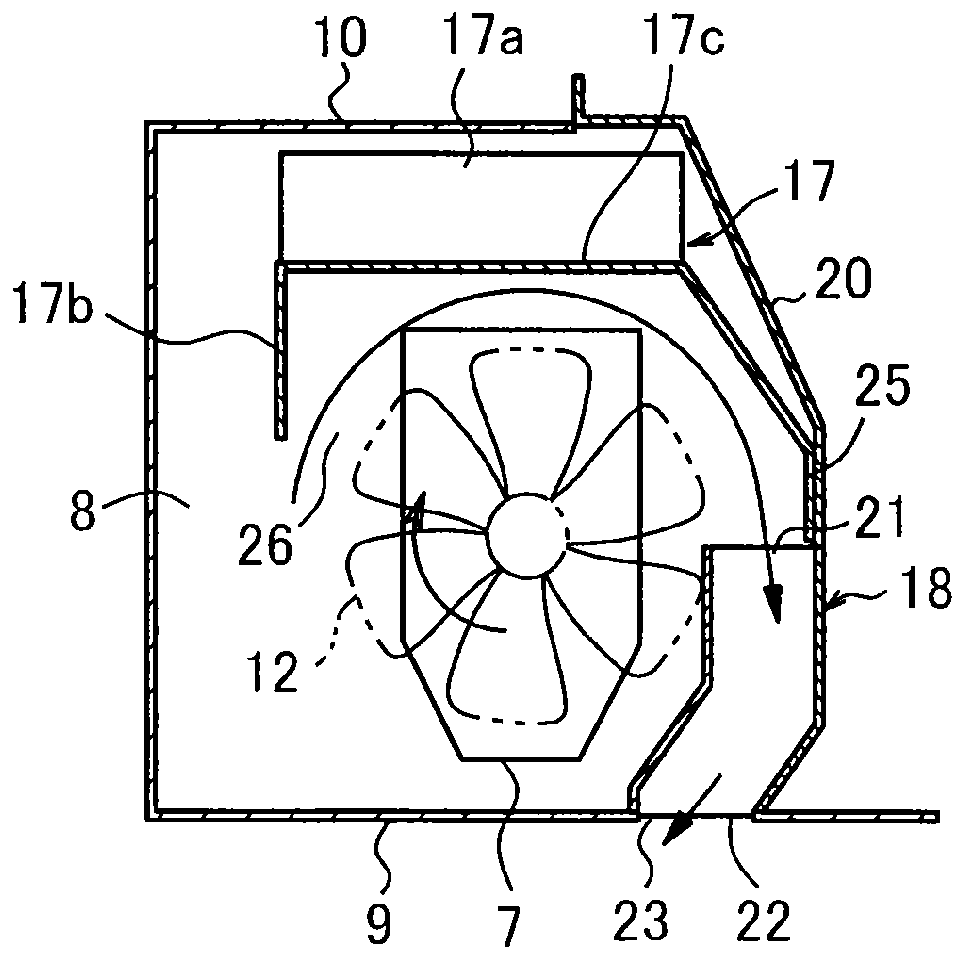

ActiveUS9376786B2Efficient collectionImprove exhaust efficiencyAir coolingSoil-shifting machines/dredgersEngineeringEngine room

In a construction machine having an engine room and capable of efficiently collecting air flowing in the engine room, a heat exchanger provided at a first side of the engine, and a fan provided at the first side and rotating to generate around the engine a flow of cooling air, further includes an exhaust duct extending in a fan axial direction parallel with a rotation axis of the fan along the engine. The exhaust duct guides the flow of the air to collect the air flowing downstream of the fan in the fan axial direction, in a region extending in the fan axial direction, and discharges the air to an outside of the engine room.

Owner:KOBELCO CONSTR MASCH CO LTD

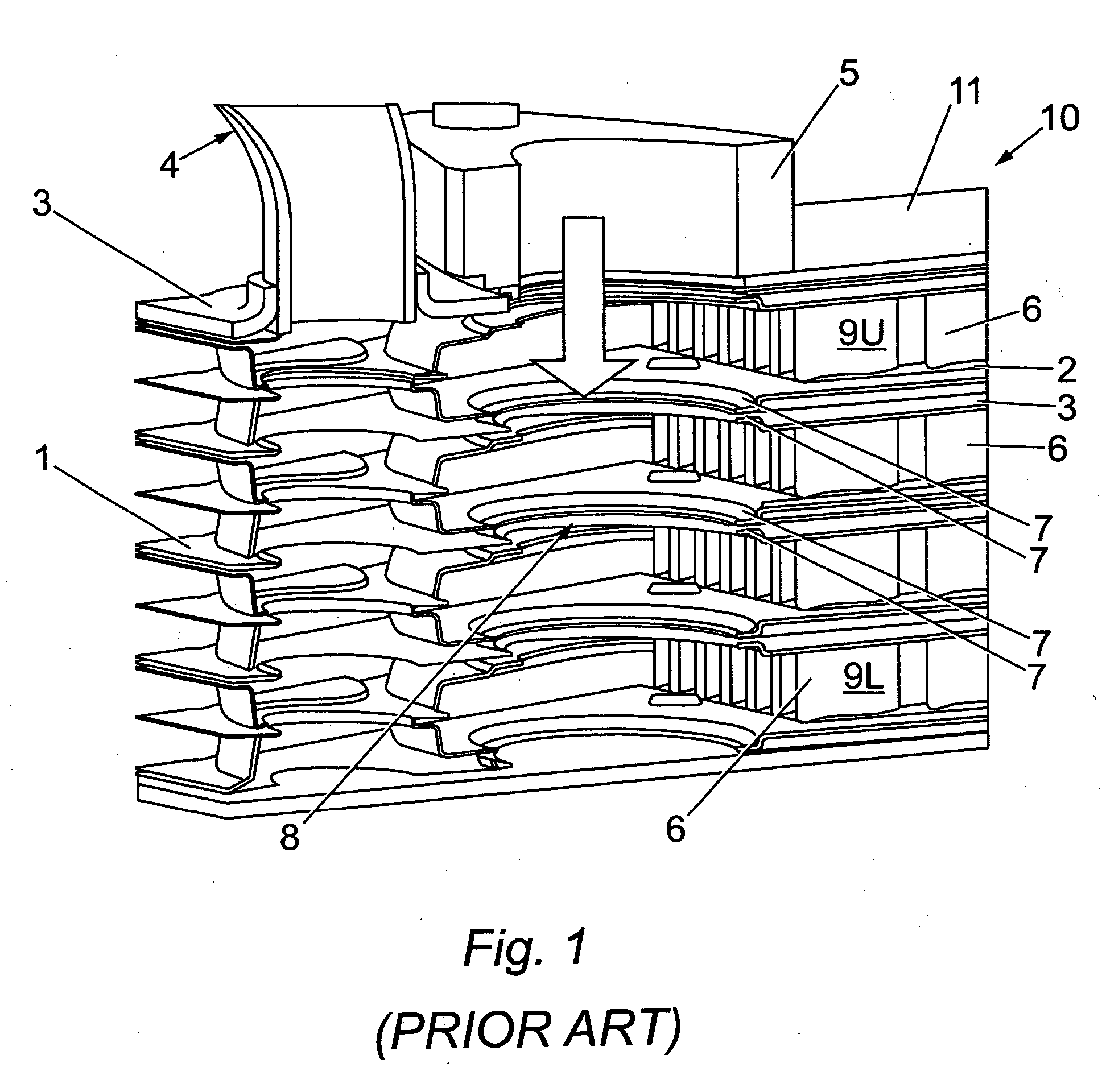

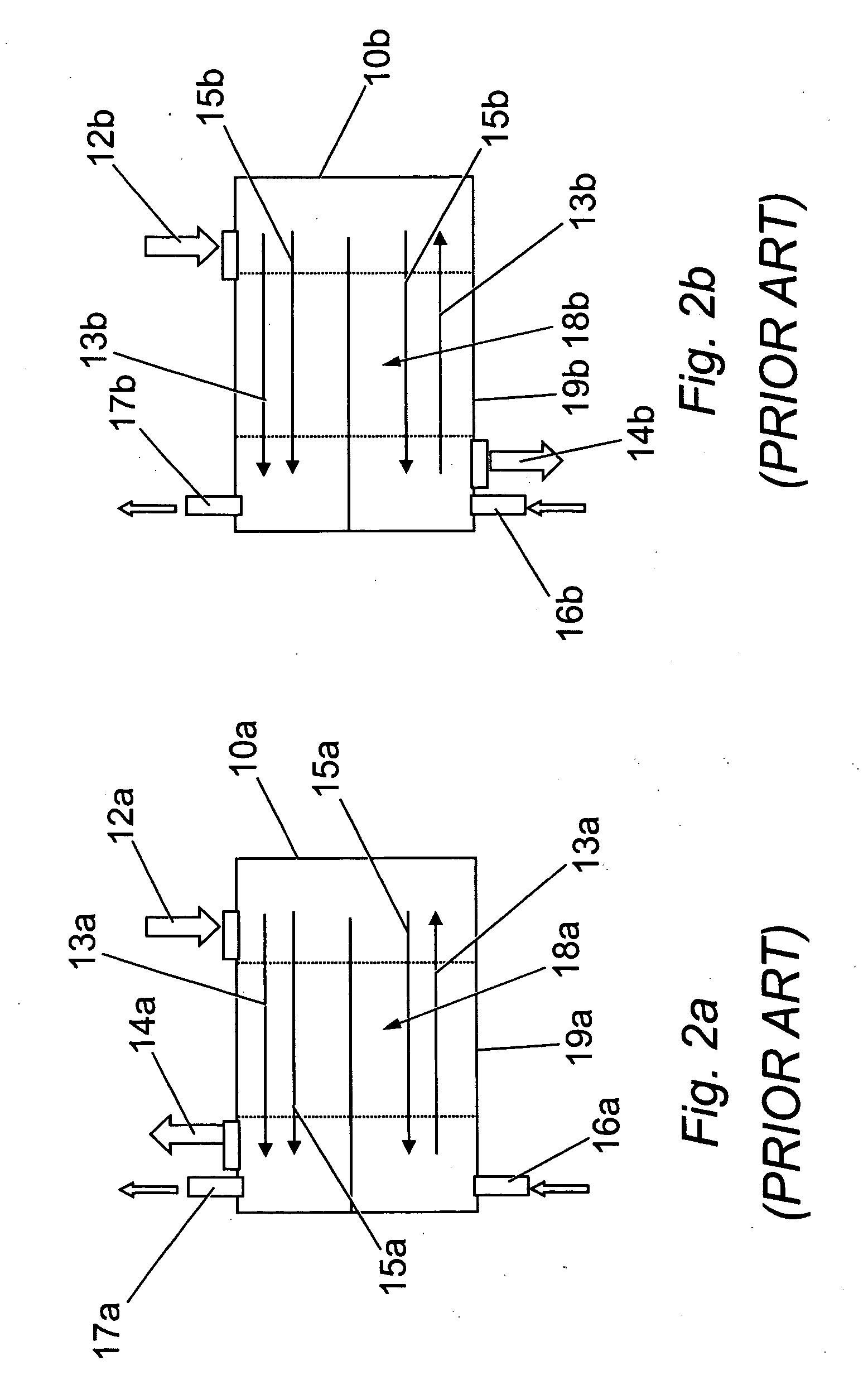

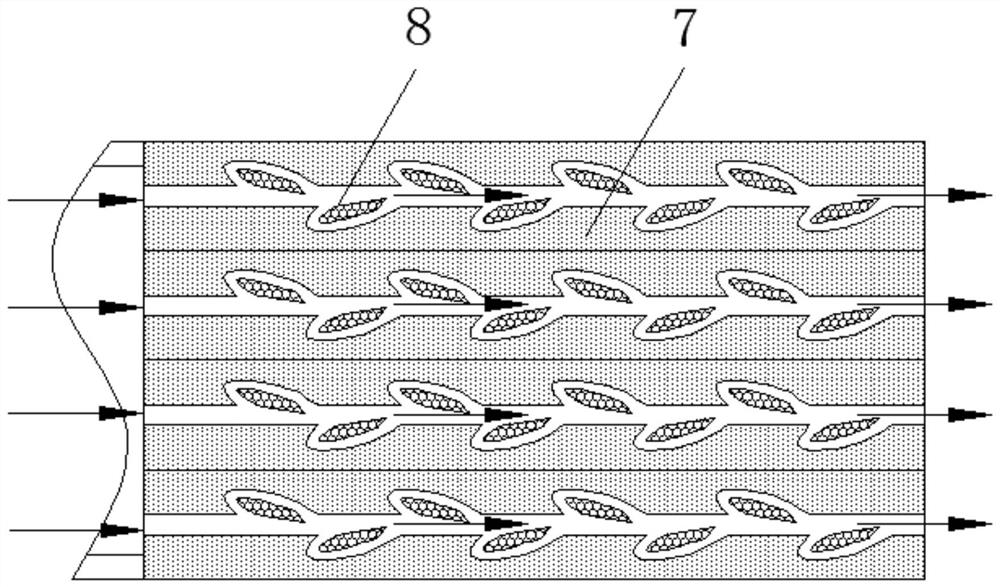

Exhaust gas cooler

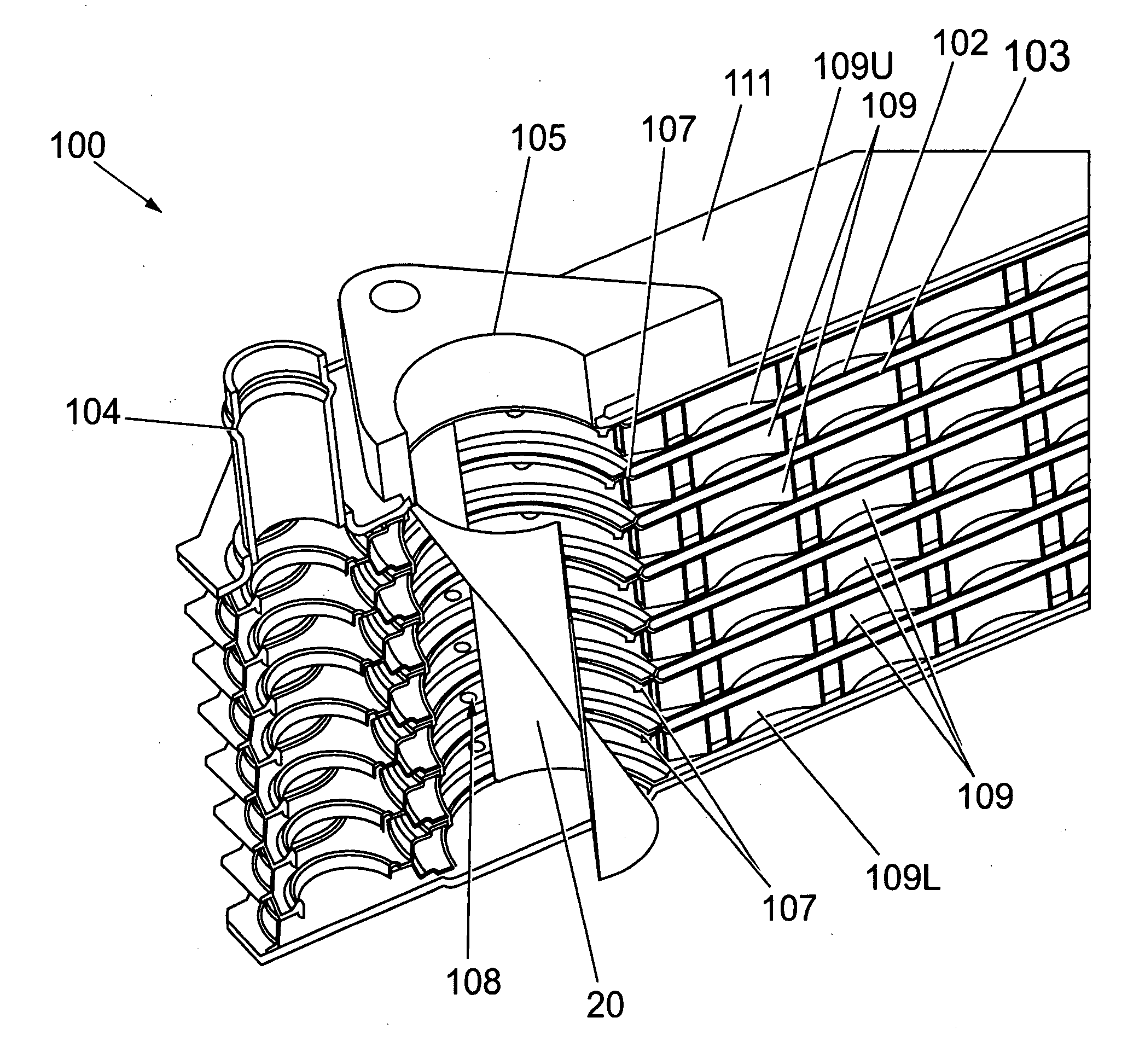

InactiveUS20060174611A1Improve exhaust efficiencyReduce flow rateNon-fuel substance addition to fuelInternal combustion piston enginesBalanced flowExhaust fumes

An exhaust gas cooler comprising an inlet chamber shaped to restrict exhaust gas flow to certain exhaust gas passages provided therein is disclosed. The inlet chamber may comprise a flow deflector which deflects a proportion of exhaust gas into, for example, the upper exhaust gas cooling passages thus restricting flow to lower exhaust gas cooling passages. In one embodiment the flow deflector is rotatably mounted and can also function as a bypass valve. Alternatively apertures provided within plates which can collectively define the inlet chamber may be of a differing size to restrict exhaust gas flow to certain exhaust gas cooling passages. A more balanced flow through the various exhaust gas cooling passages results increasing heat-exchange efficiency of the exhaust gas cooler.

Owner:HONEYWELL INT INC

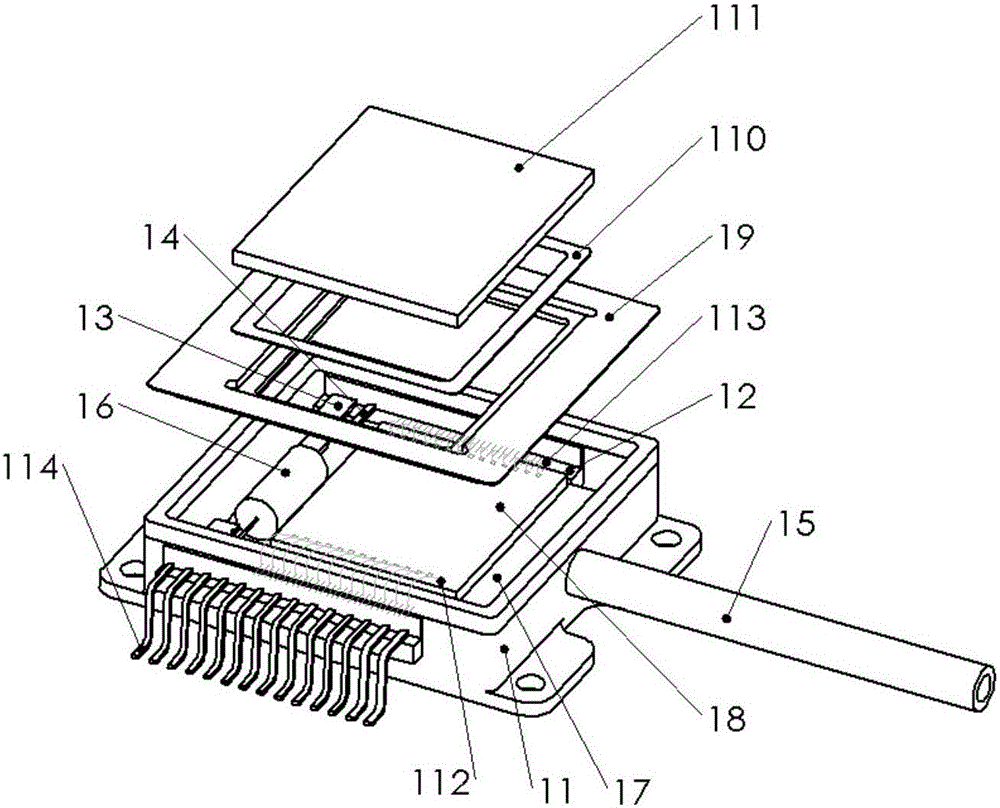

Vacuum formation method of lithium ion battery

ActiveCN101887994AImprove exhaust efficiencyShield negative influenceFinal product manufactureSecondary cells charging/dischargingEngineeringLithium-ion battery

The invention discloses a vacuum formation method of a lithium ion battery. In the method, an electrolyte injection process and a formation process of the battery are completed by adopting an integrated fixture with electrolyte-injecting and charging functions and a vacuum formation device with charging and vacuumizing functions. The vacuum formation device charges the battery arranged in the integrated fixture, and the battery is electrically connected with the vacuum formation device by the integrated fixture. The vacuum formation method of the invention provides an enclosed and controllable microenvironment, thereby reducing electrolyte waste, avoiding overflow loss of electrolyte and corrosion on a battery casing, the fixture or charging equipment, and effectively reducing environmental pollution.

Owner:东莞市鸿德电池有限公司 +1

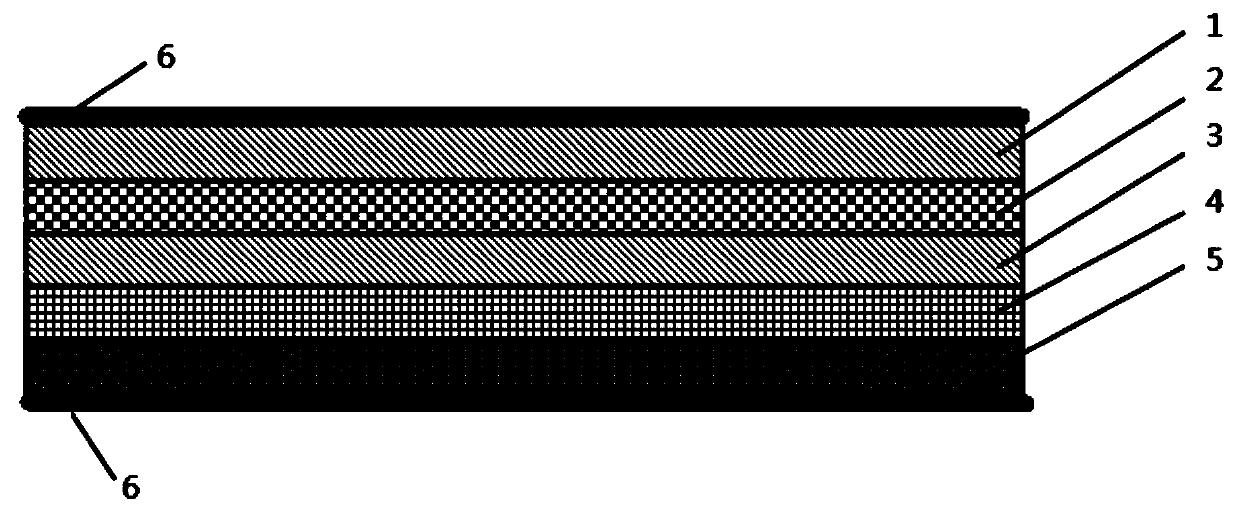

Multifunctional composite material armor plate and preparation method thereof

ActiveCN104215130ABoth infrared stealth featuresHigh strengthSynthetic resin layered productsLaminationCarbon fibersHeat resistance

The invention relates to a multifunctional composite material armor plate and a preparation method thereof. The armor plate comprises multiple structures of a rigid reinforcing layer, a middle bulletproof layer, a back bulge prevention layer and a buffer layer and the multiple structures are formed by die pressing, wherein the rigid reinforcing layer is formed from a fiber fabric, which is made of one or a plurality of aramid fibers and high-performance carbon fibers, and modified thermosetting resin by impregnation; the middle bulletproof layer is formed from a mixed fiber fabric, which is made of ultrahigh molecular weight polyethylene fibers and high-performance carbon fibers, and modified thermoplastic resin by impregnation; the back bulge prevention layer is formed by a fiber fabric, which is made of high-performance carbon fibers, and modified thermosetting resin by impregnation; the buffer layer is made of organic silicon or polyurethane foam. The invention provides the armor plate which is prepared by adopting multilayer laying and vacuum die-pressing integrated forming and has the characteristic of infrared stealth and has high intensity, high rigidity, low back bulge property, corrosion resistance and heat resistance.

Owner:SHANDONG UNIV +1

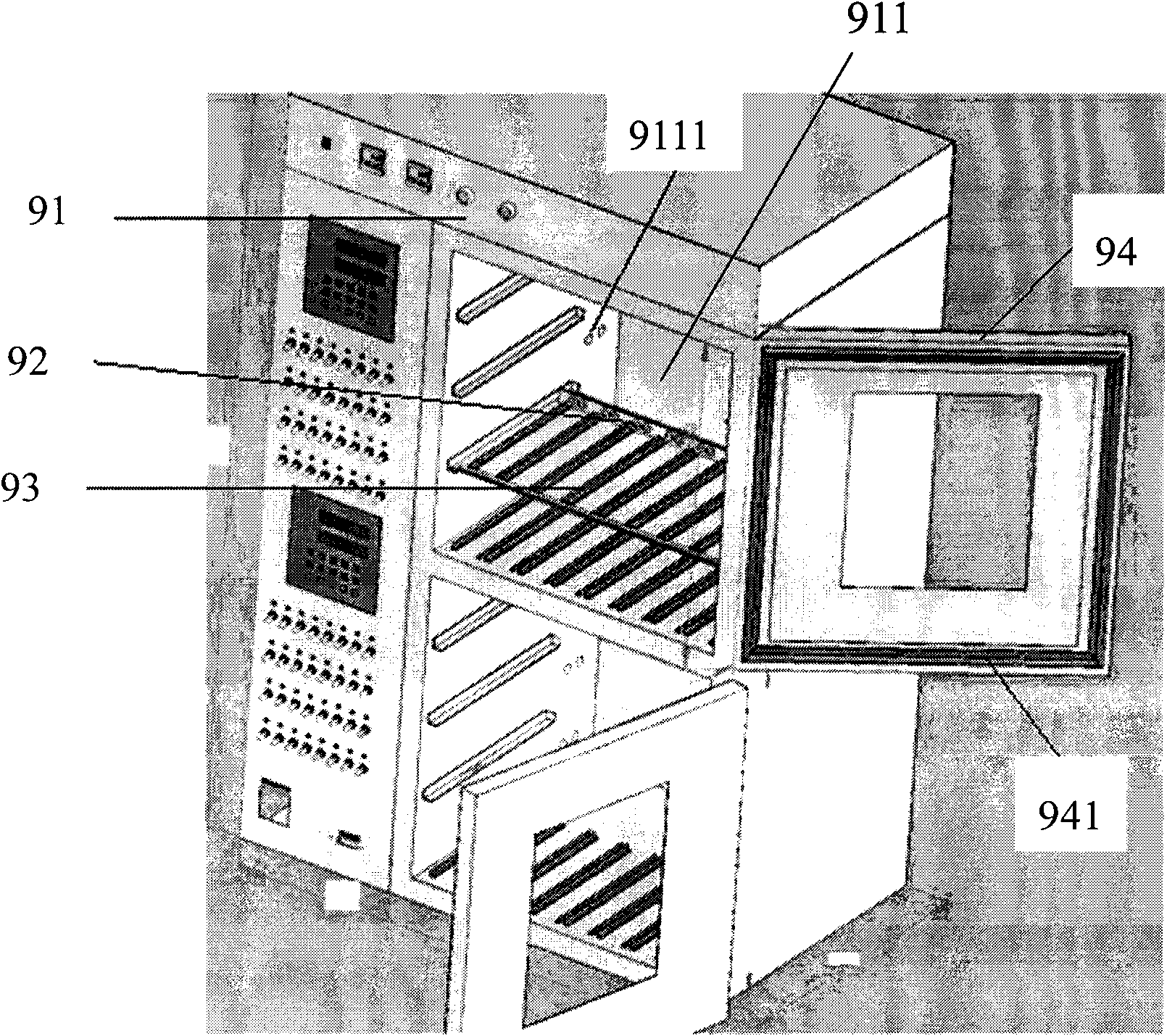

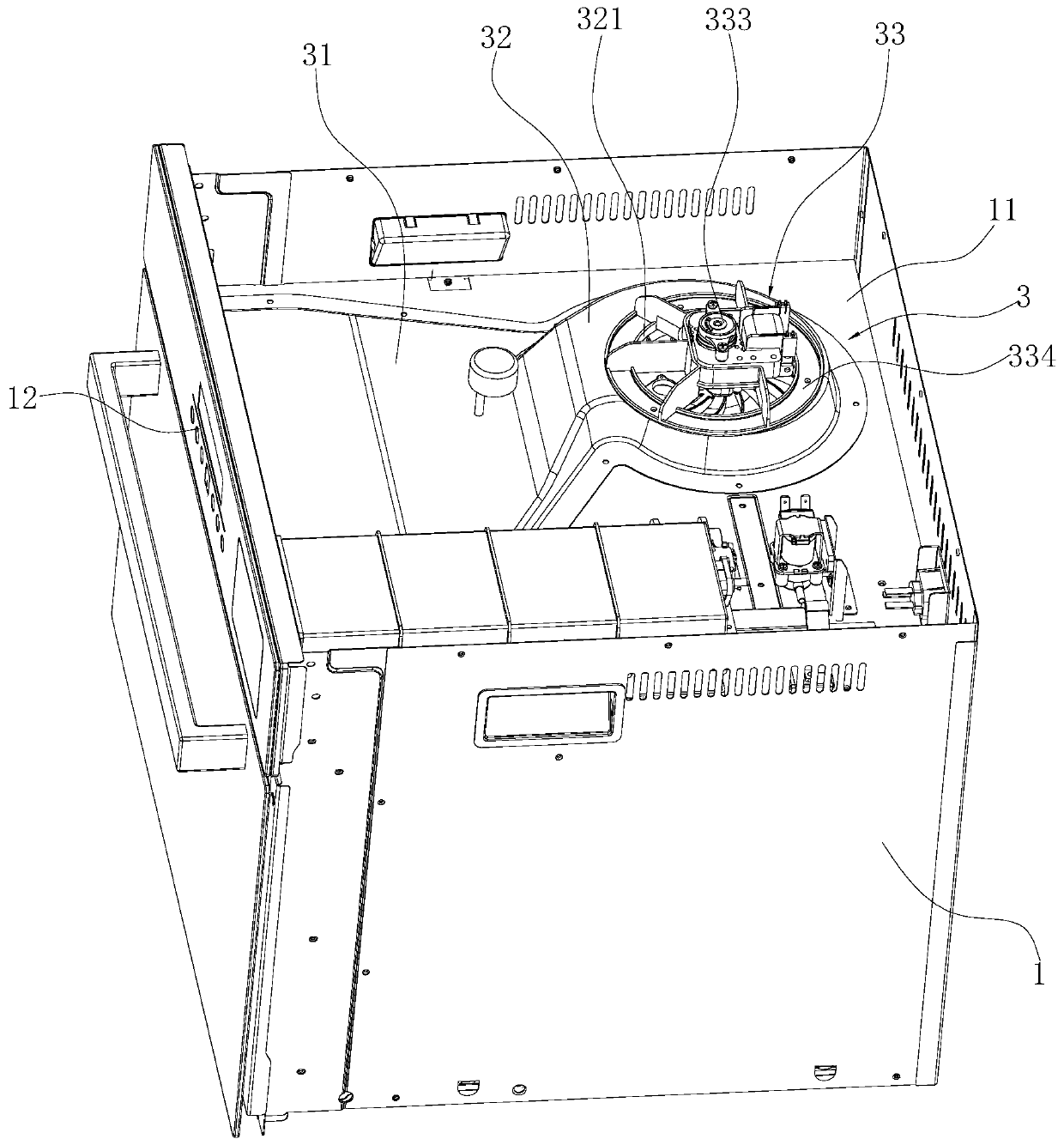

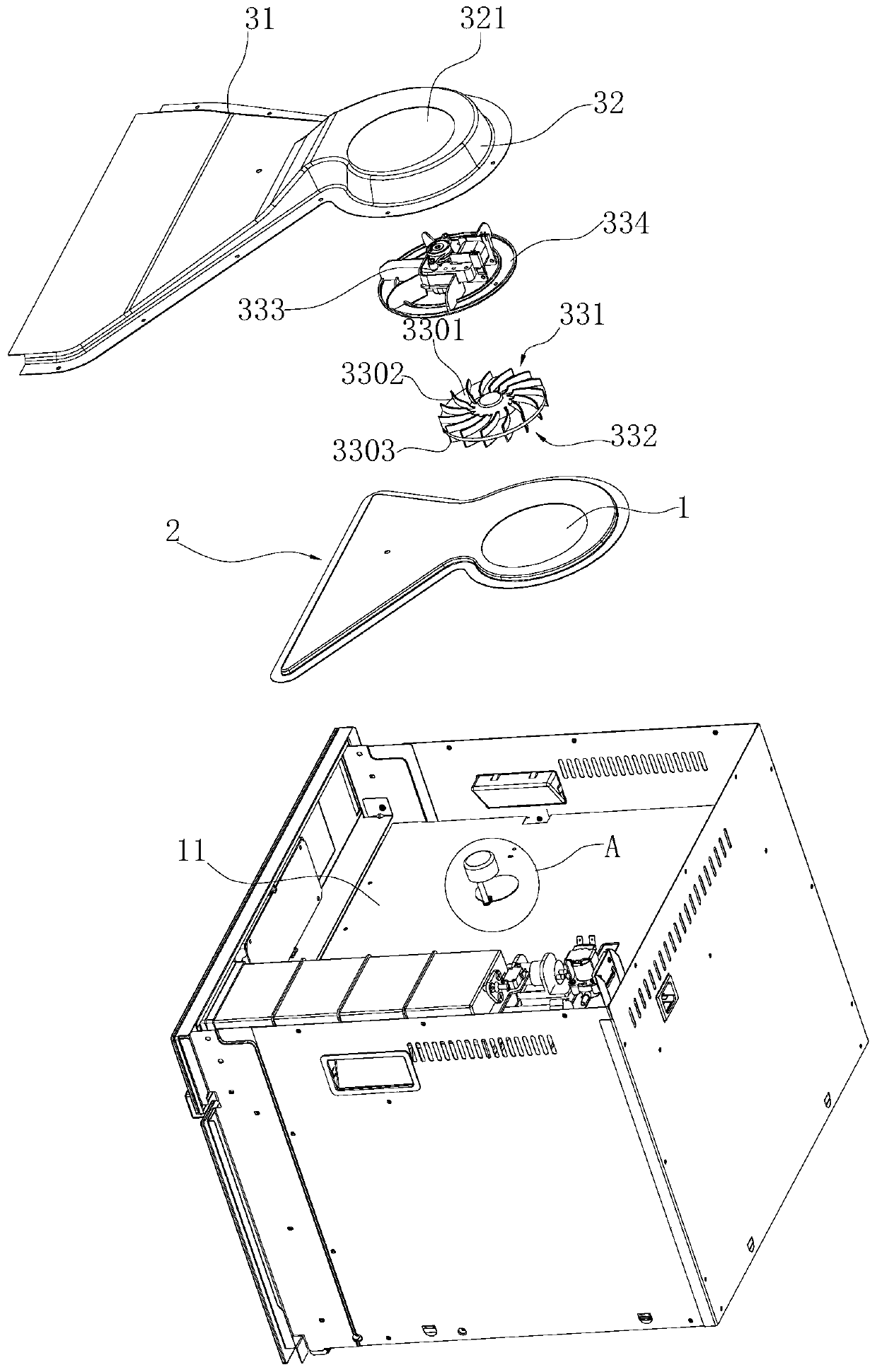

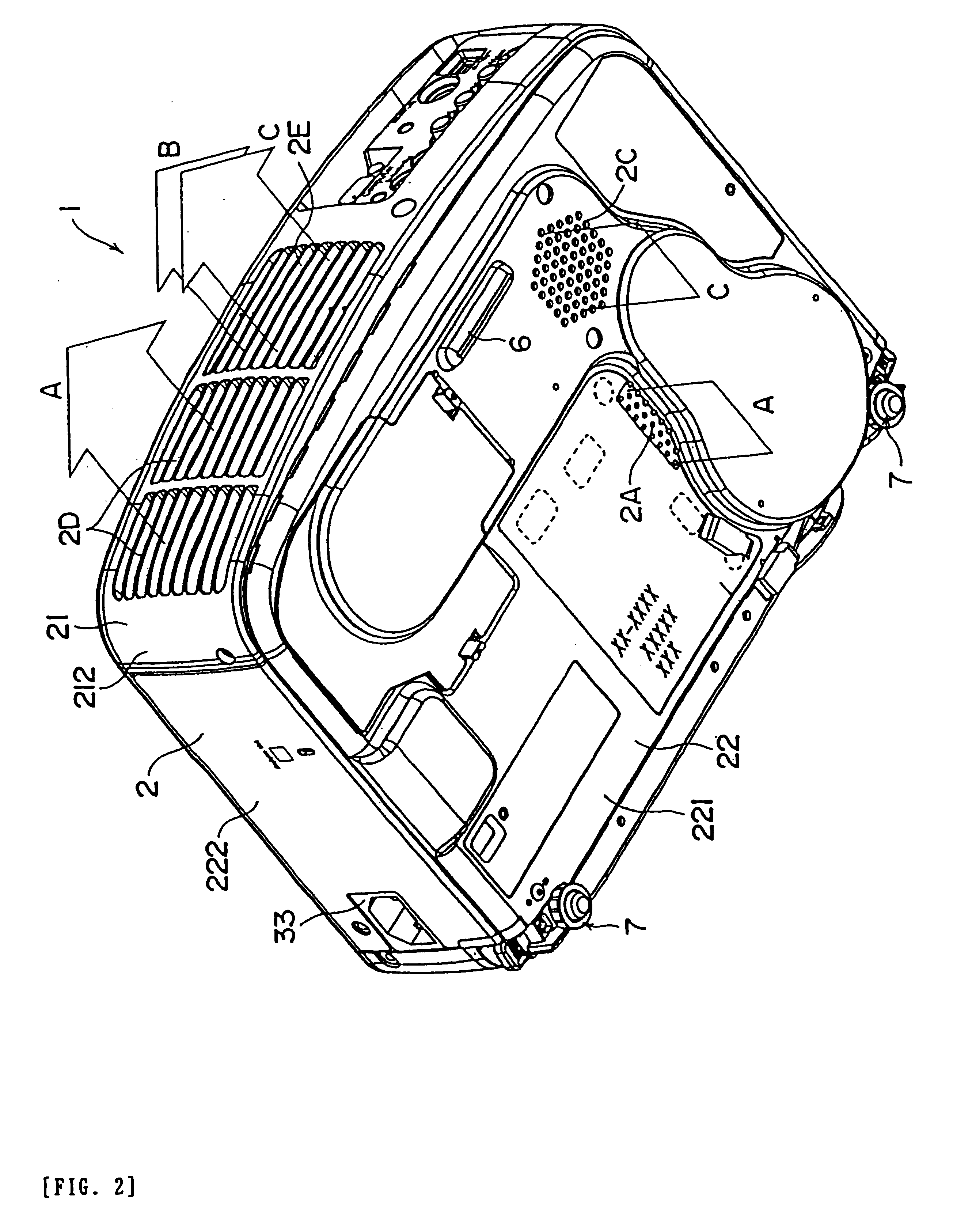

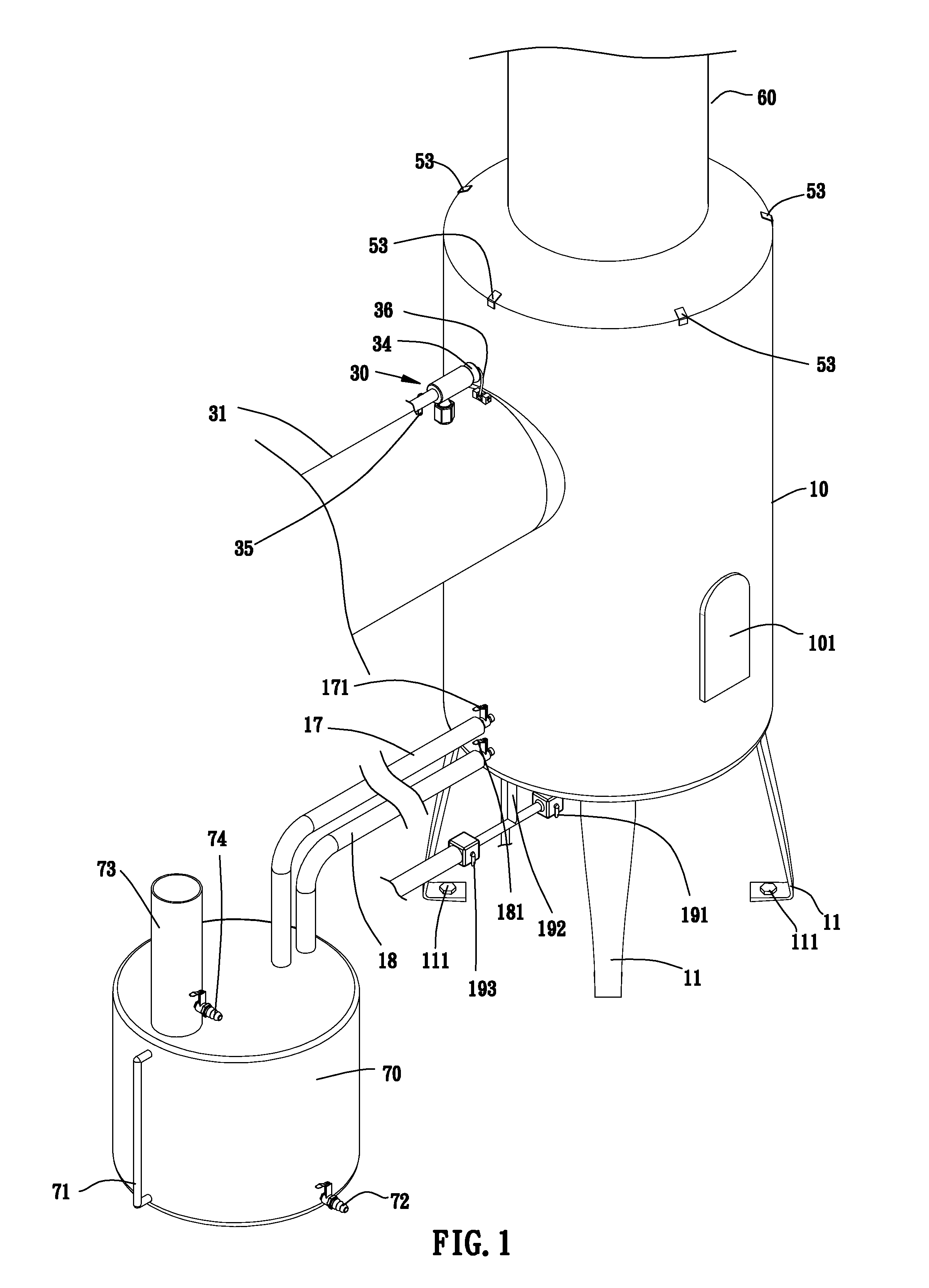

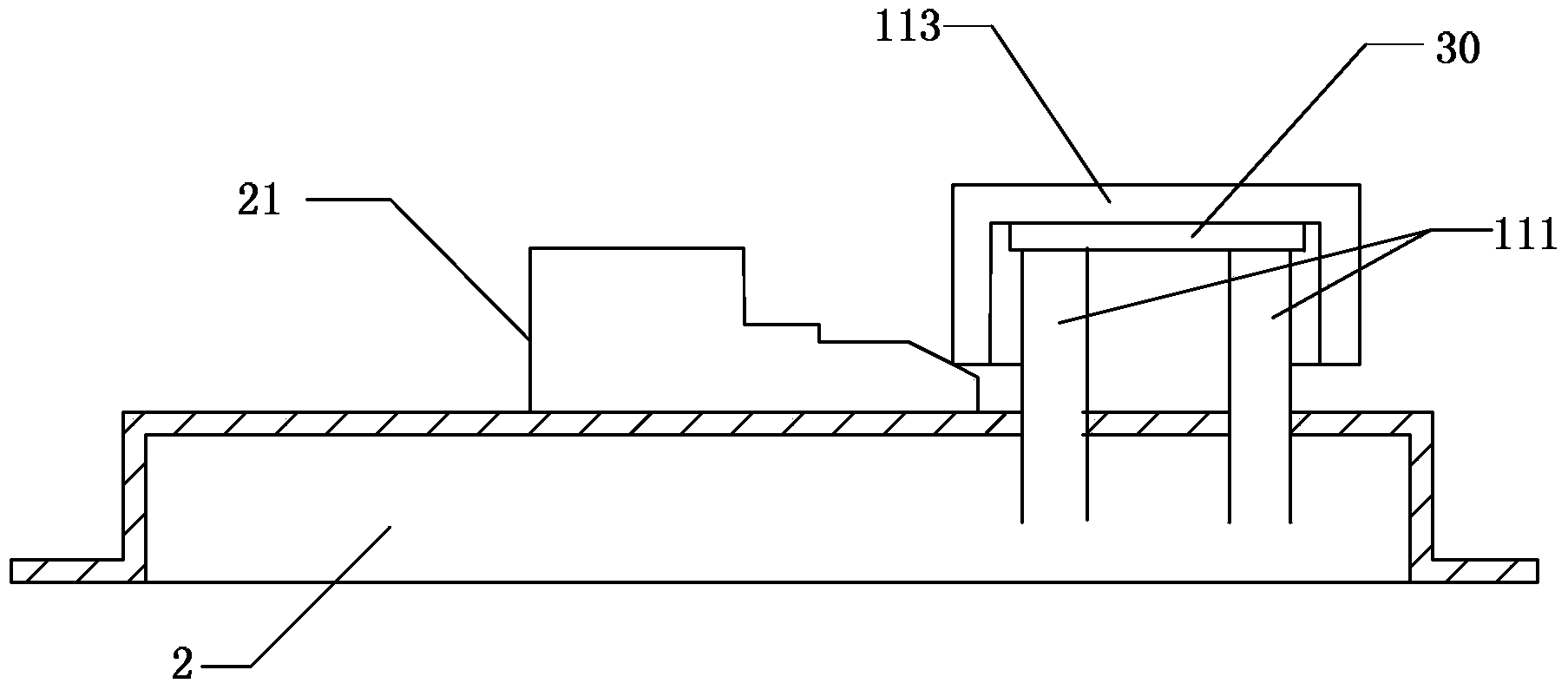

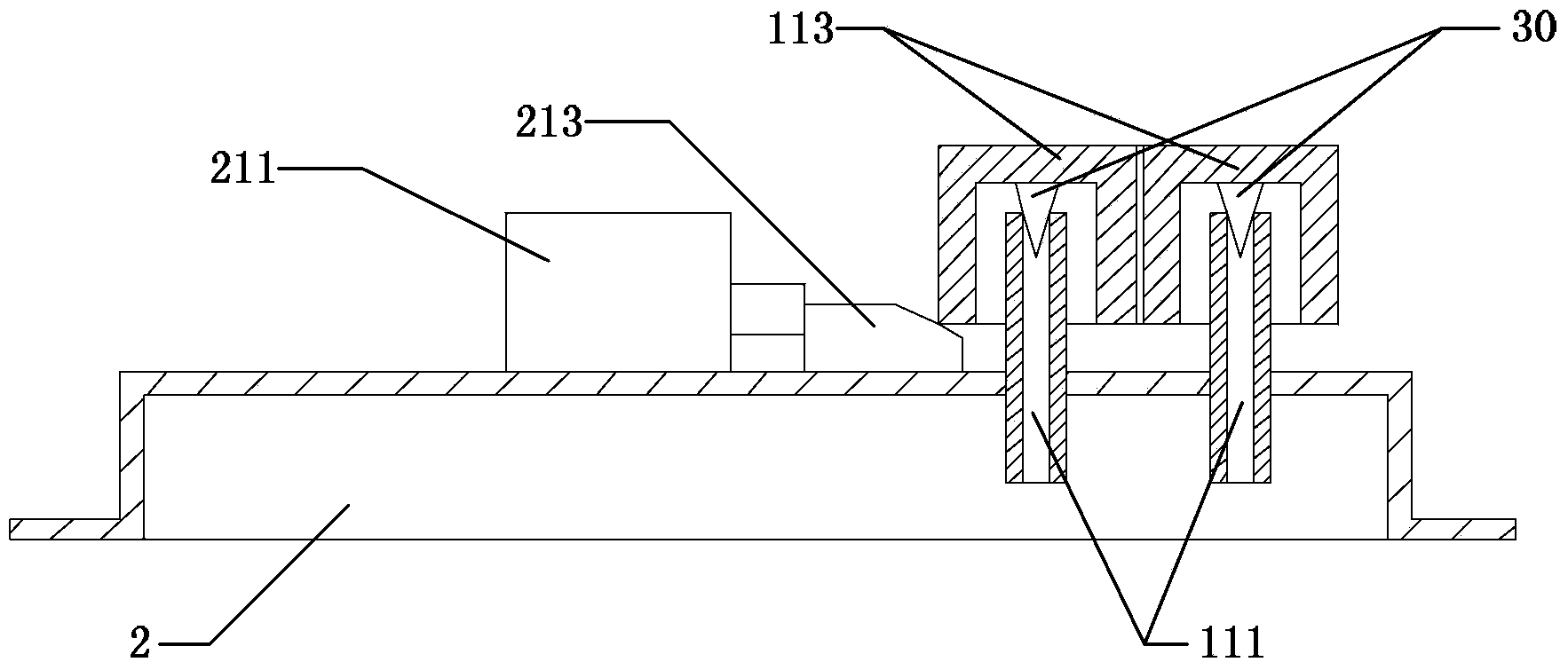

Exhaust structure, cooking device with exhaust structure, and exhaust method of cooking device

ActiveCN110477761AEasy dischargeImprove exhaust efficiencySteam cooking vesselsRoasters/grillsImpellerUsage experience

The invention relates to an exhaust structure. The exhaust structure comprises an inner container and an upper mounting plate positioned above the inner container; an exhaust hole is formed in the topwall of the inner container; the exhaust structure is characterized by further comprising an exhaust system with a fan and an exhaust cavity; an air inlet of the exhaust cavity is in fluid communication with the exhaust hole; the exhaust system comprises an exhaust channel communicating with the outside and a fan cavity used for installing the fan; the fan is provided with an upper impeller and alower impeller which are arranged in an up-down manner; the fan cavity is provided with an upper air inlet and a lower air inlet corresponding to the upper impeller and the lower impeller respectively; the lower air inlet of the fan cavity is in fluid communication with an air outlet of the exhaust cavity; and an air outlet of the fan cavity is in fluid communication with an air inlet of the exhaust channel. The invention further relates to a cooking device with the exhaust structure and an exhaust method of the cooking device. The exhaust efficiency of the cooking device can be improved; steam in the inner container can be prevented from being directly sprayed to a user after steaming; and the usage experience of the user is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

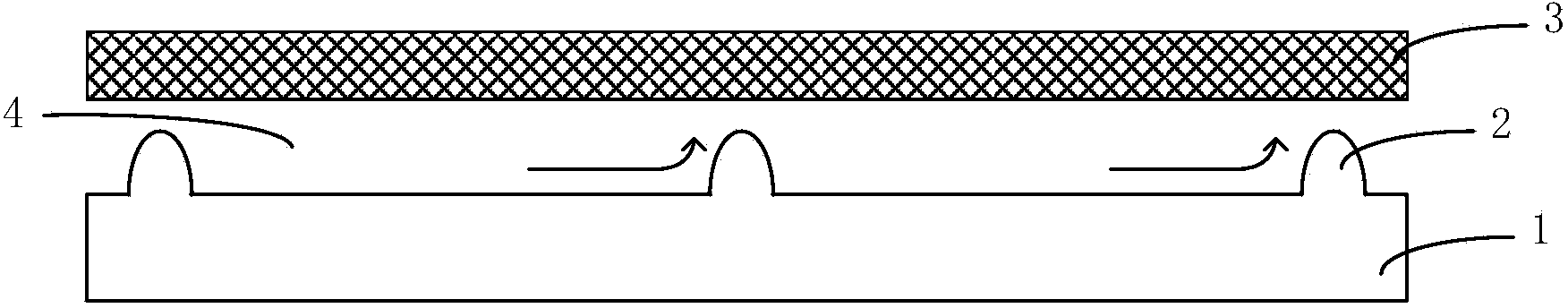

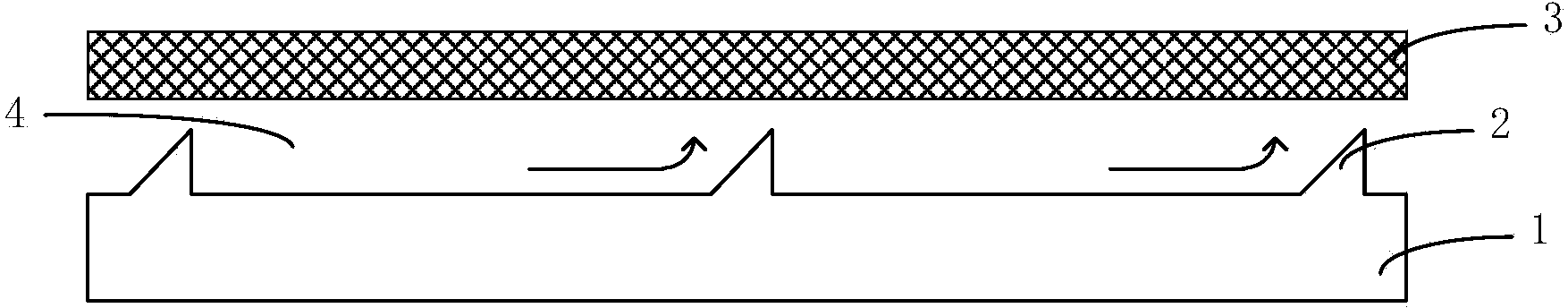

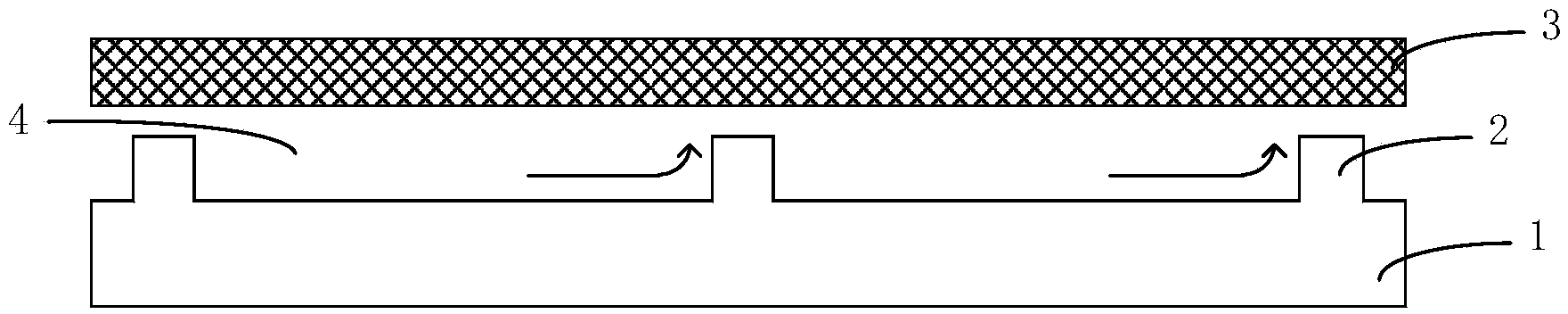

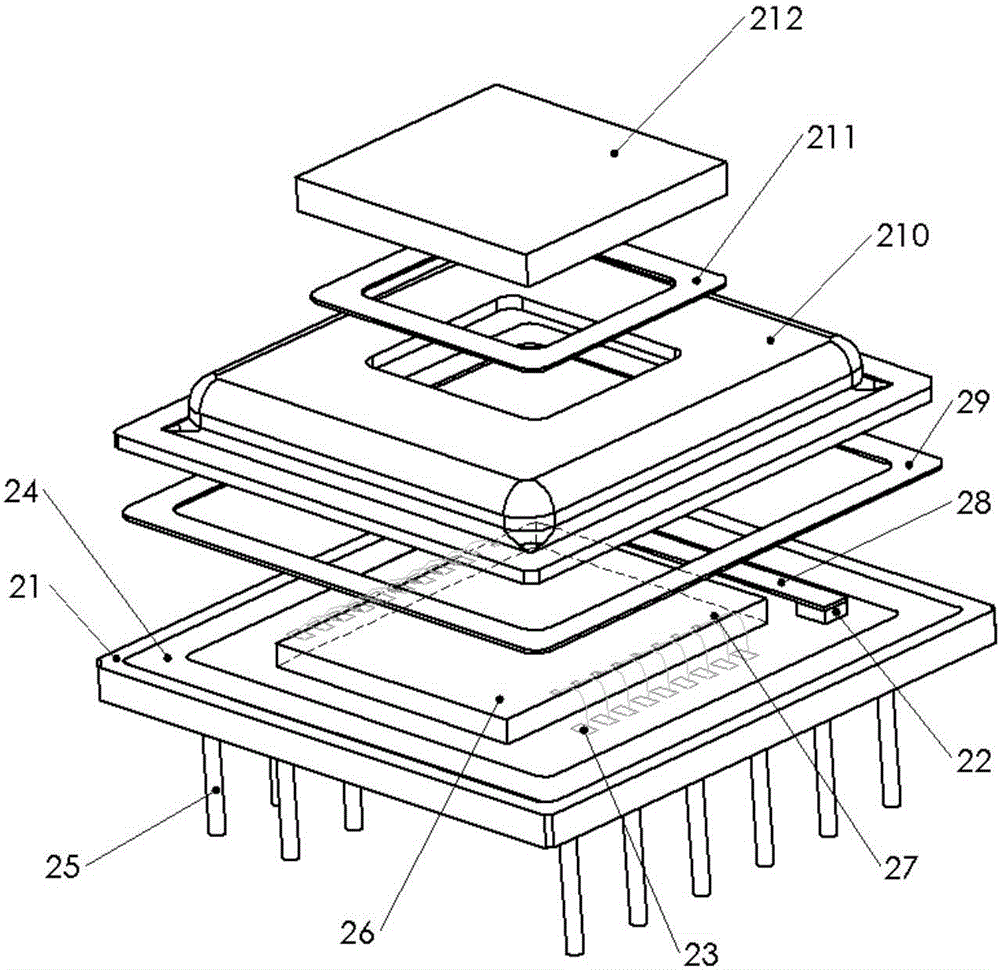

Microfluidic bubble removal device and preparation method thereof as well as microfluidic device

InactiveCN104225964AAvoid dependenceMeet exhaust requirementsLiquid degasificationLaboratory glasswaresEngineeringMicro gravity

The invention discloses a microfluidic bubble removal device and a preparation method thereof as well as a microfluidic device adopting the microfluidic bubble removal device. The microfluidic bubble removal device comprises a channel bottom layer and a porous drainage layer located above the channel bottom layer, wherein a microfluidic channel is formed between the channel bottom layer and the porous drainage layer, and at least one boss strip is arranged on the side, located on the microfluidic channel, of the channel bottom layer. According to the invention, dependence of the traditional microfluidic air removal method on gravity is eliminated, the air removal efficiency can be increased, and the air removal requirement of the microfluidic device in a micro-gravity environment can be met. The microfluidic bubble removal device is integrated with other microfluidic chips easily and can remove bubbles of liquids with different viscosities.

Owner:TSINGHUA UNIV +1

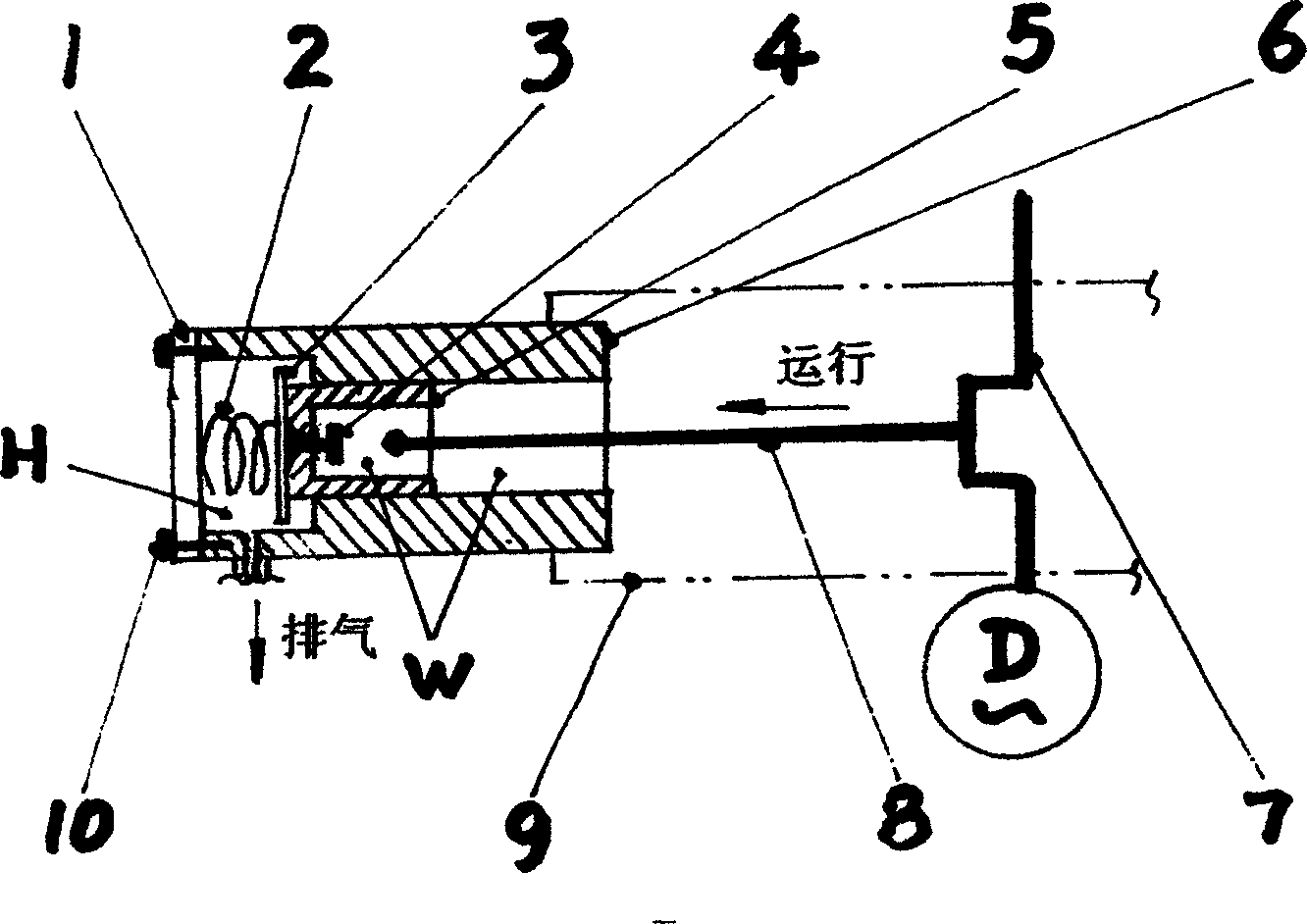

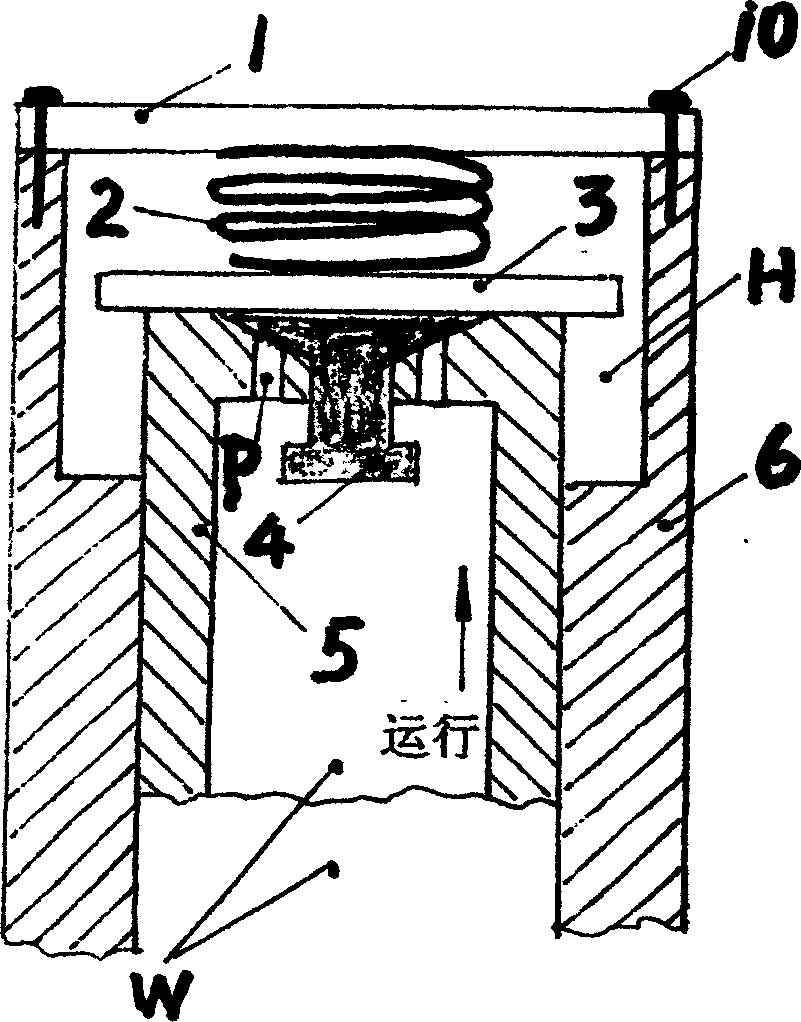

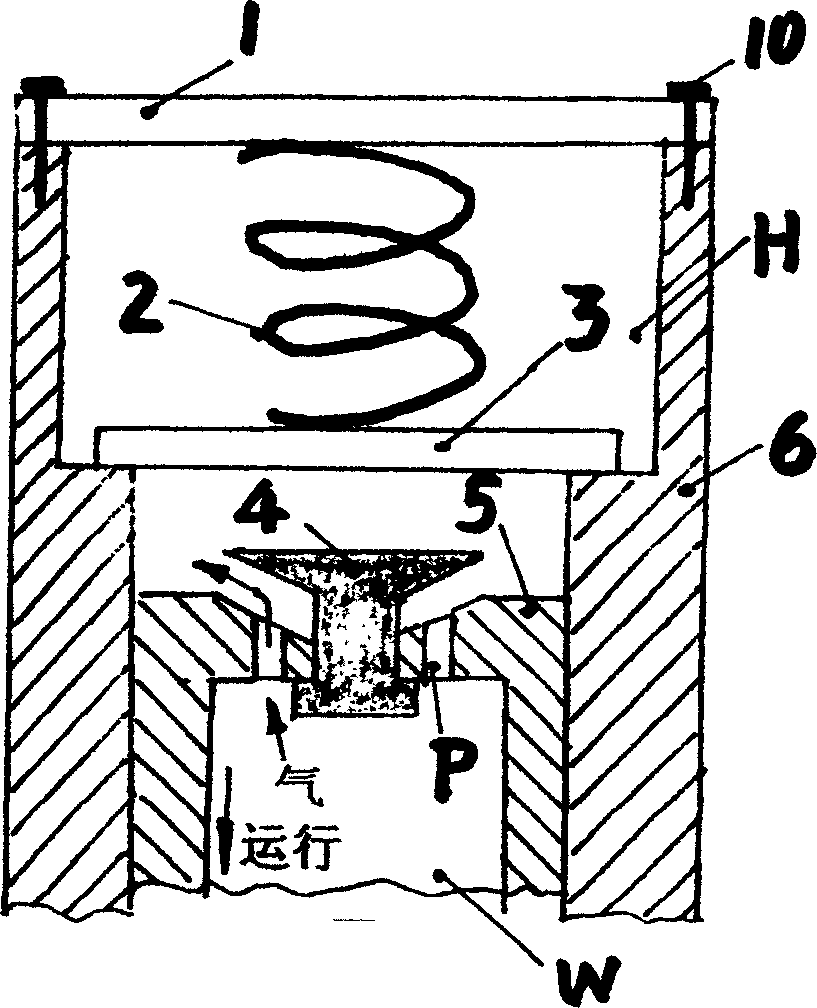

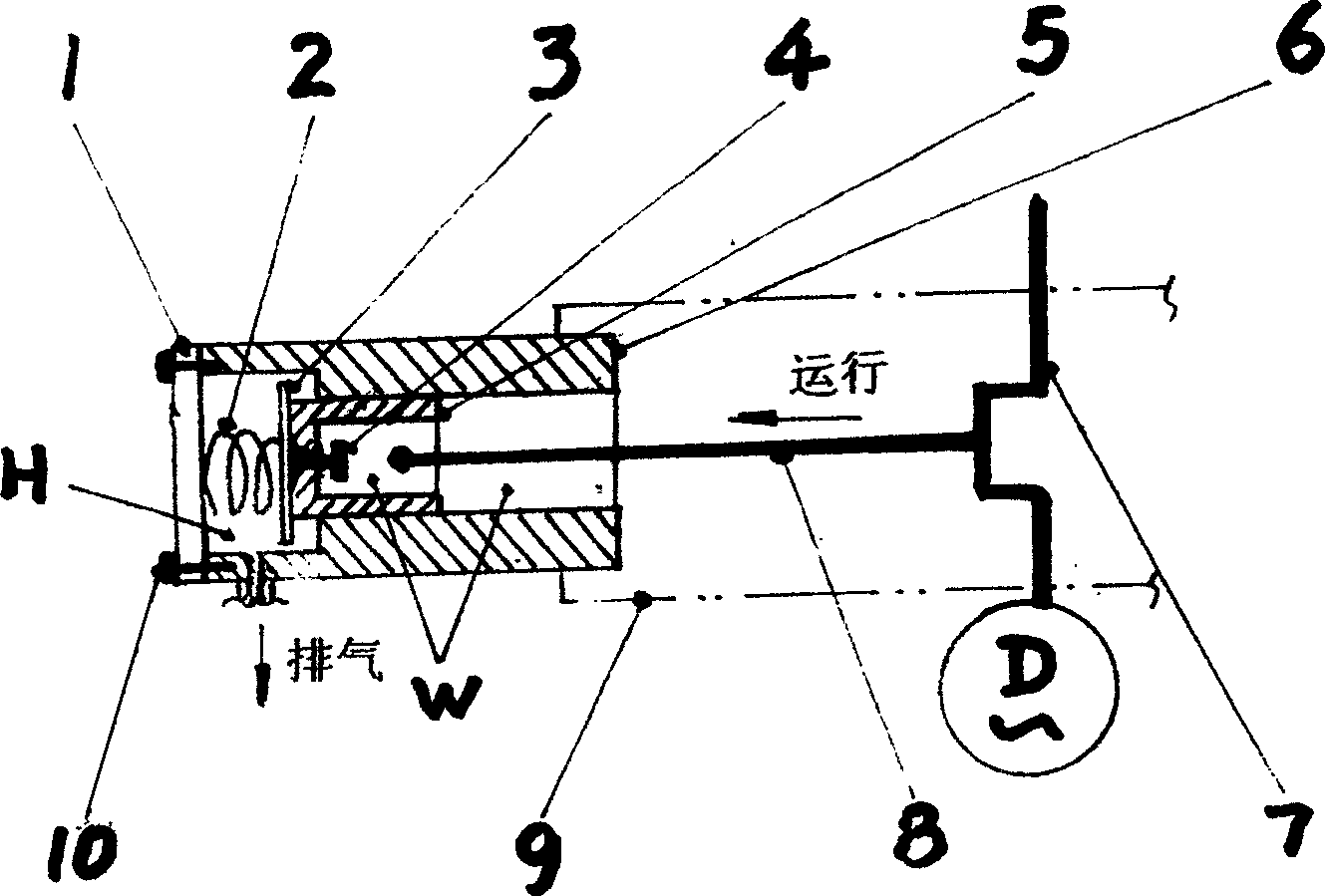

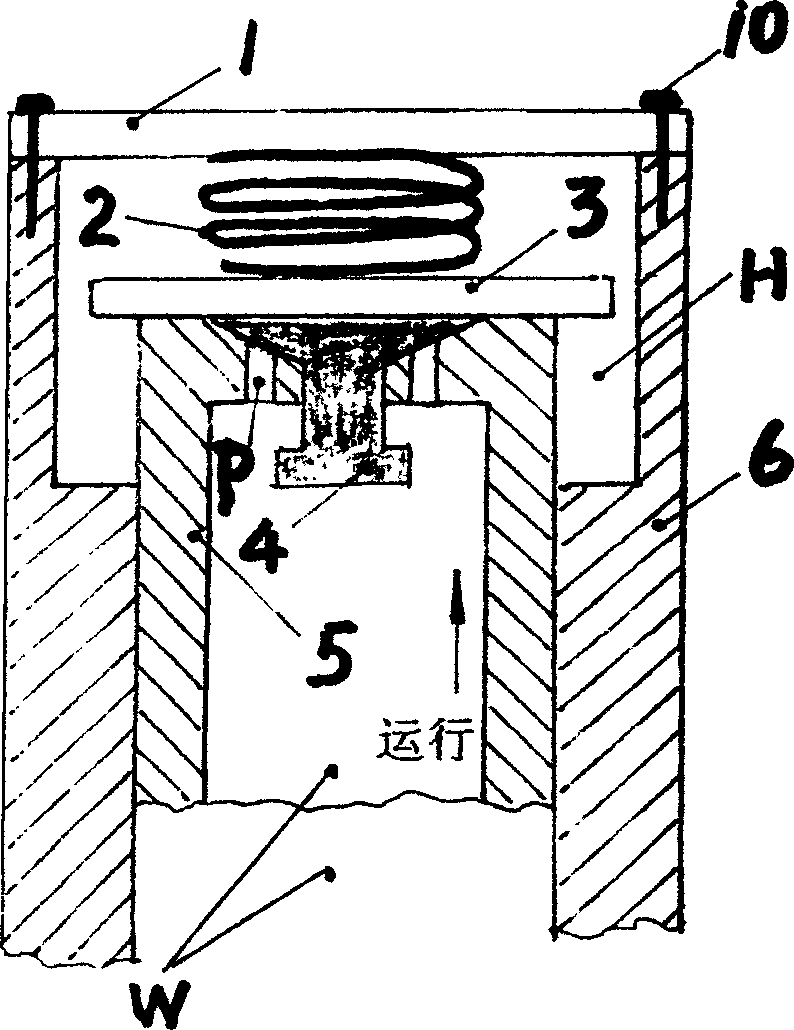

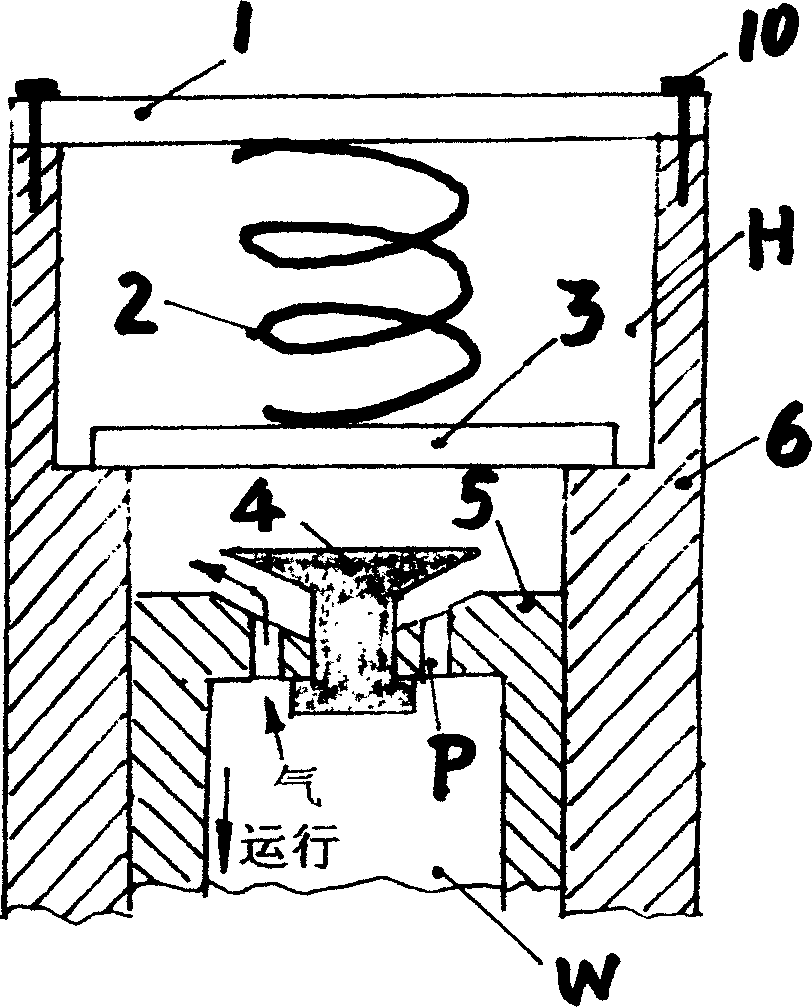

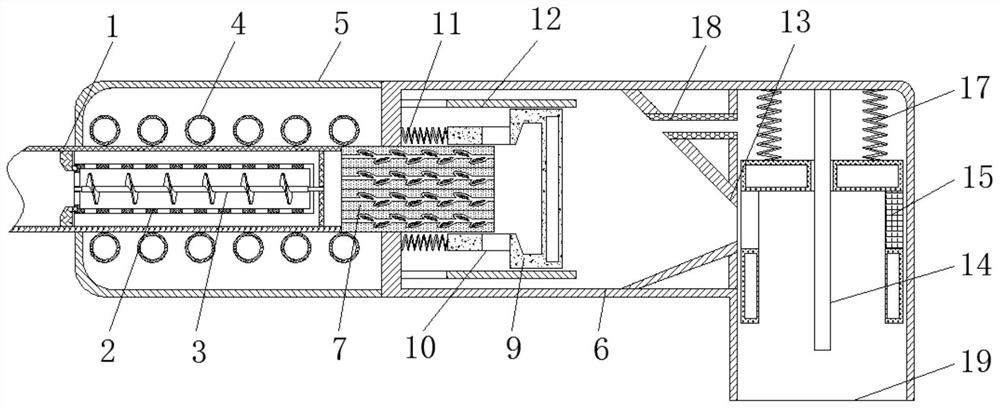

Gapless high-efficient design of piston reciprocating compressor

InactiveCN1680717AWork lessImprove exhaust efficiencyPositive displacement pump componentsPiston pumpsExhaust valveEngineering

A 'non cross gap' design for a kind of piston double acting compressor. Piston rushes out of cylinder when piston exhausting against exhaust valve plate, and runs into high pressure zone, then a nonspace state--' non cross gap' is formed among piston, exhaust valve plate and intake block, thus improves the compression ratio or exhaust efficiency greatly.

Owner:梁嘉麟

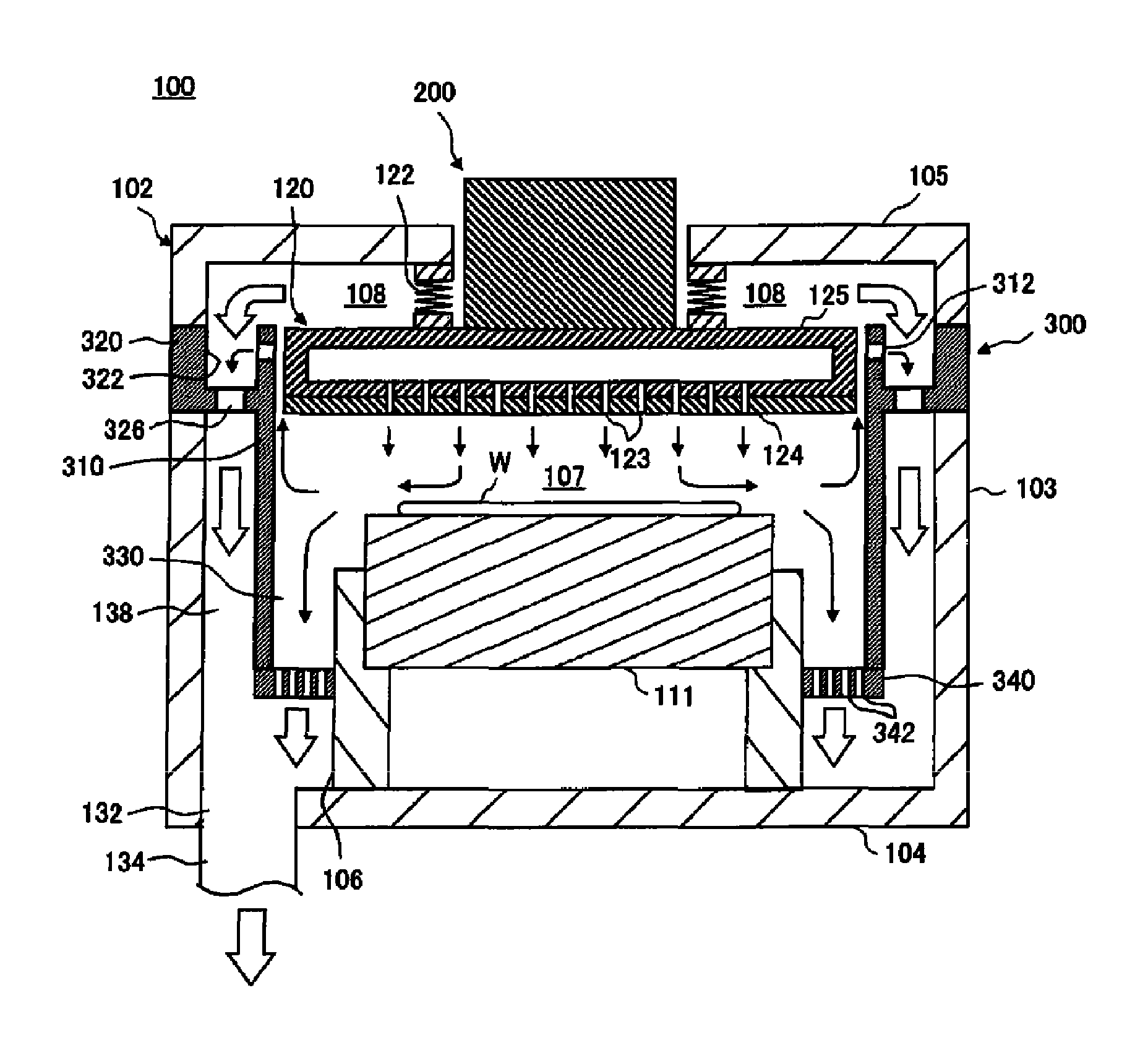

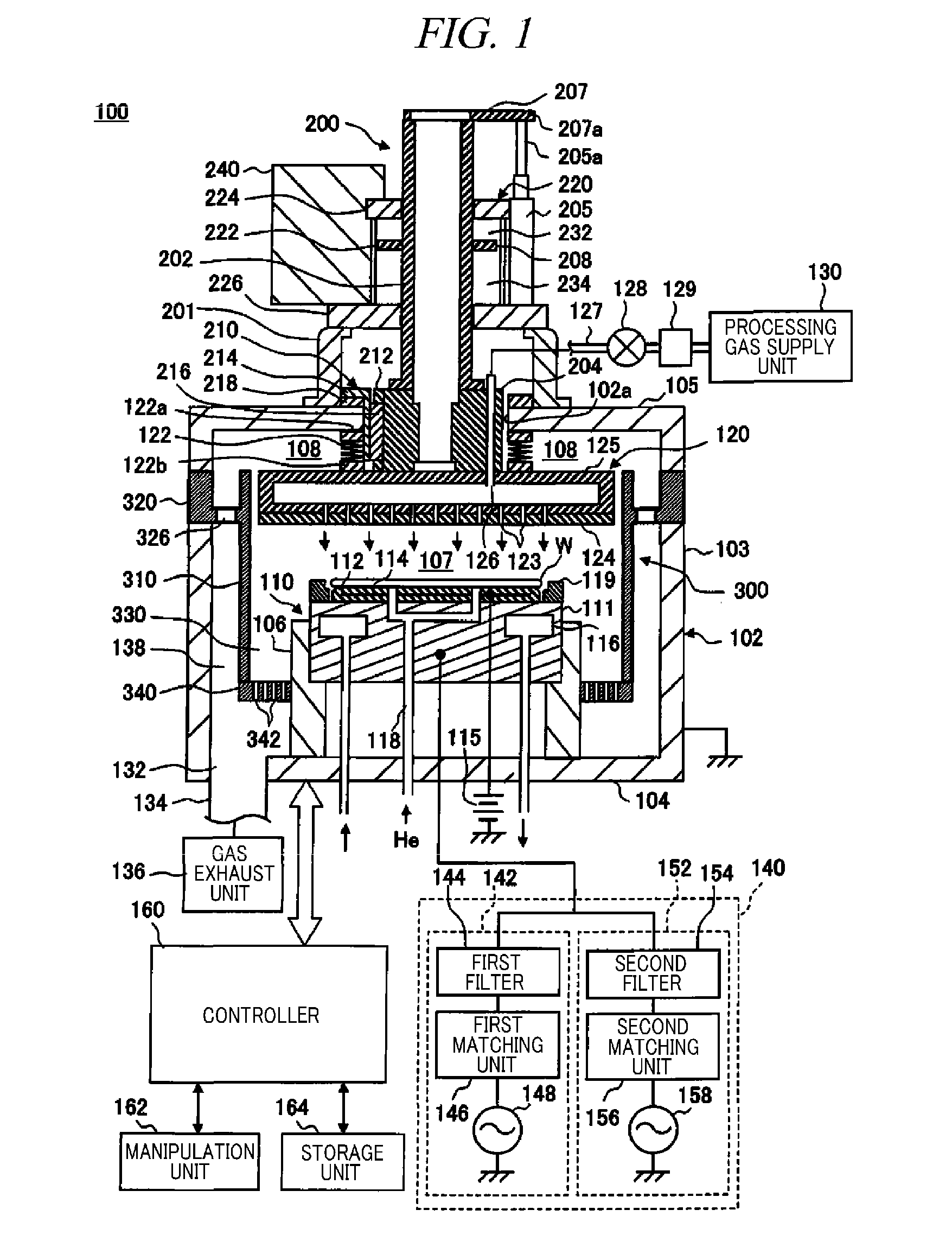

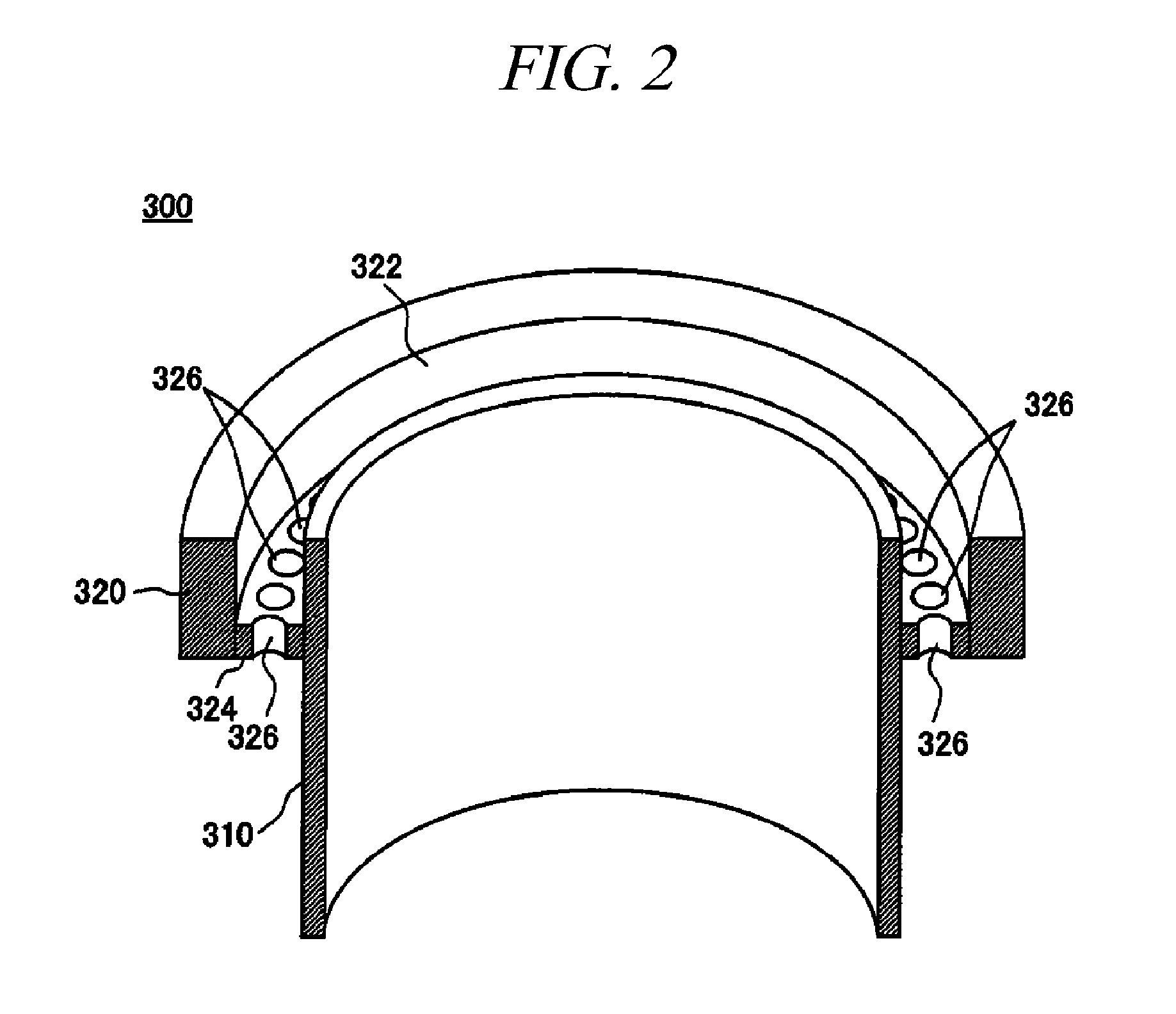

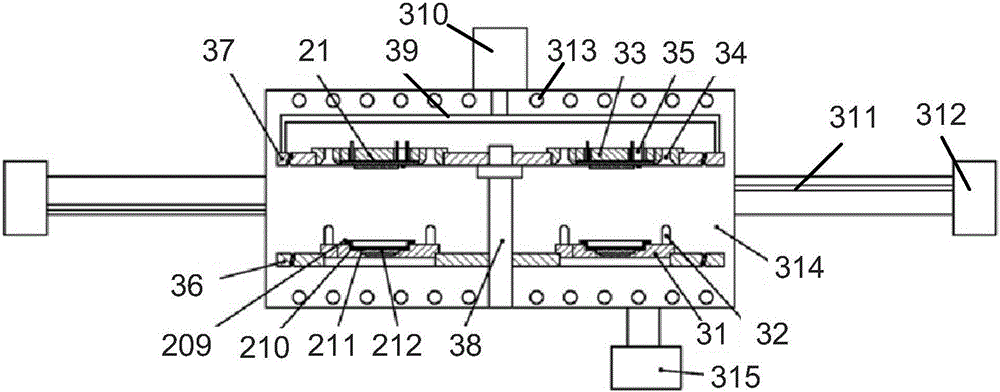

Plasma processing apparatus

ActiveUS8858754B2Increase exhaustImprove exhaust efficiencyElectric discharge tubesSolid-state devicesEngineeringProduct gas

There is provided a plasma processing apparatus capable of easily exhausting a processing gas introduced in a space above a vertically movable upper electrode. The plasma processing apparatus includes a vertically movable upper electrode 120 installed at a ceiling wall 105 of a processing chamber 102 so as to face a lower electrode 111 and having a multiple number of discharge holes 123 for introducing the processing gas; a shield sidewall 310 configured to surround the electrodes and a processing space between the electrodes; an inner gas exhaust path 330 formed at the inside of the shield sidewall and configured to exhaust the atmosphere in the processing space; and an outer gas exhaust path 138 installed at the outside of the shield sidewall and configured to exhaust the processing gas introduced into a space between the upper electrode and the ceiling wall.

Owner:TOKYO ELECTRON LTD

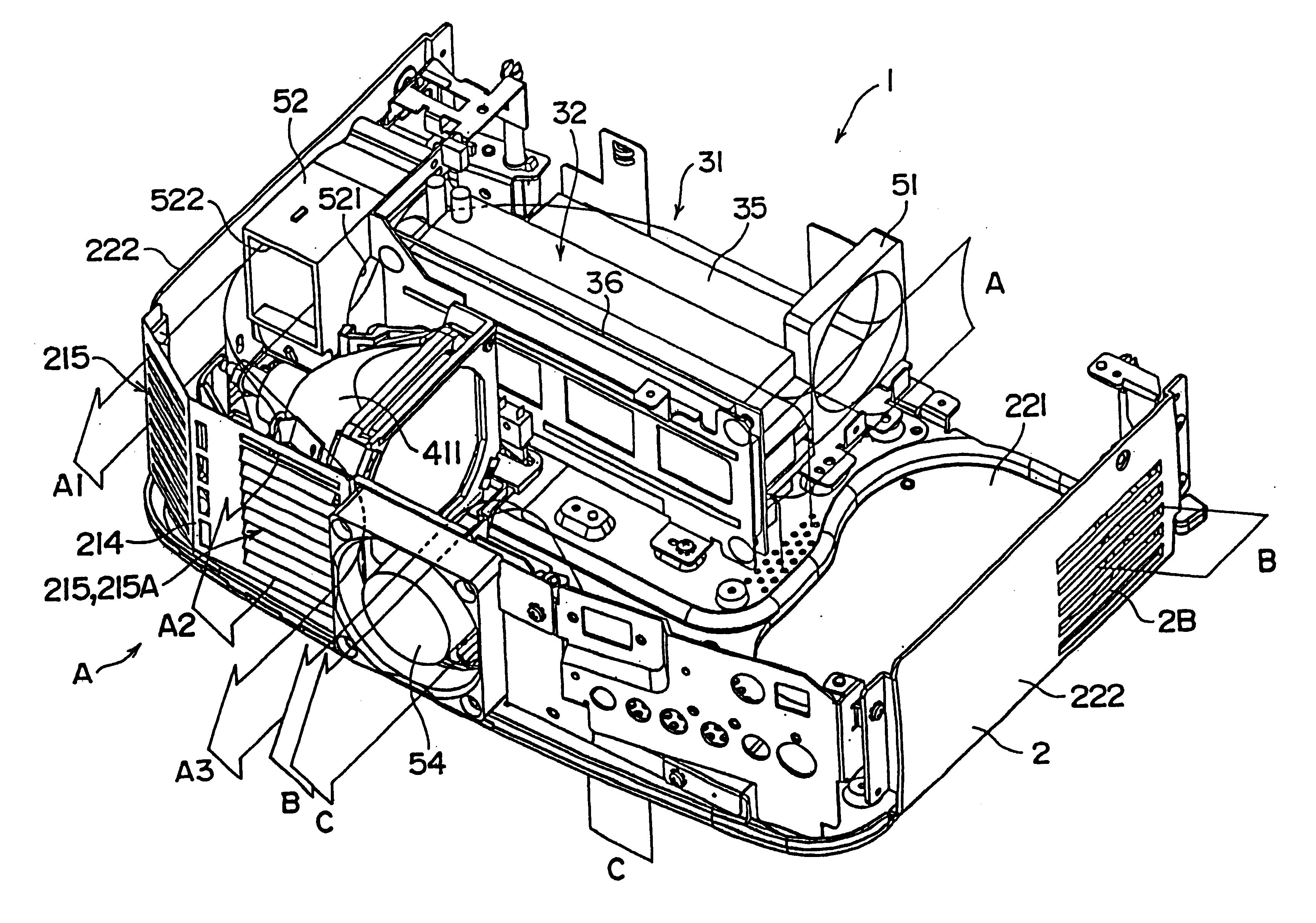

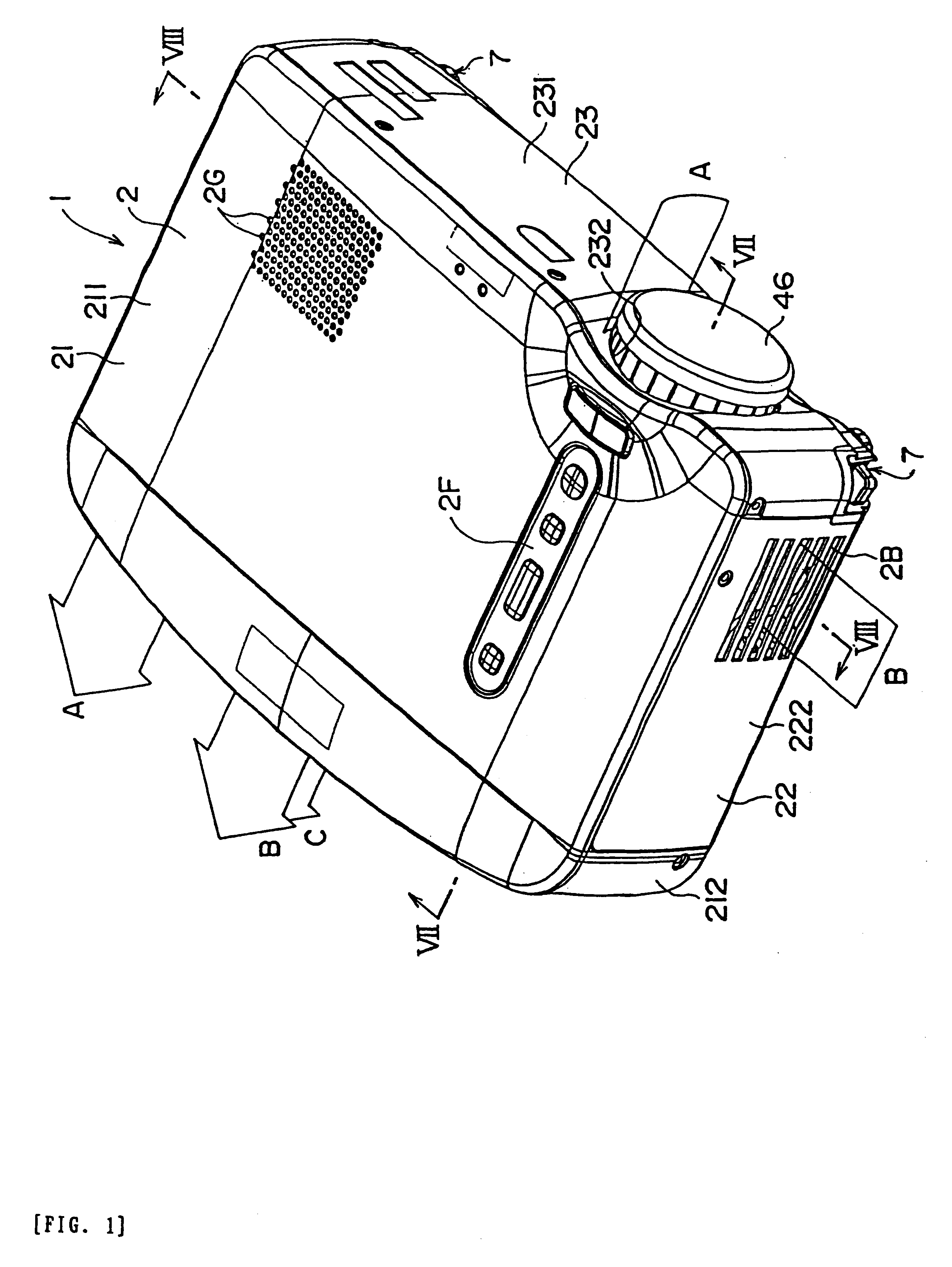

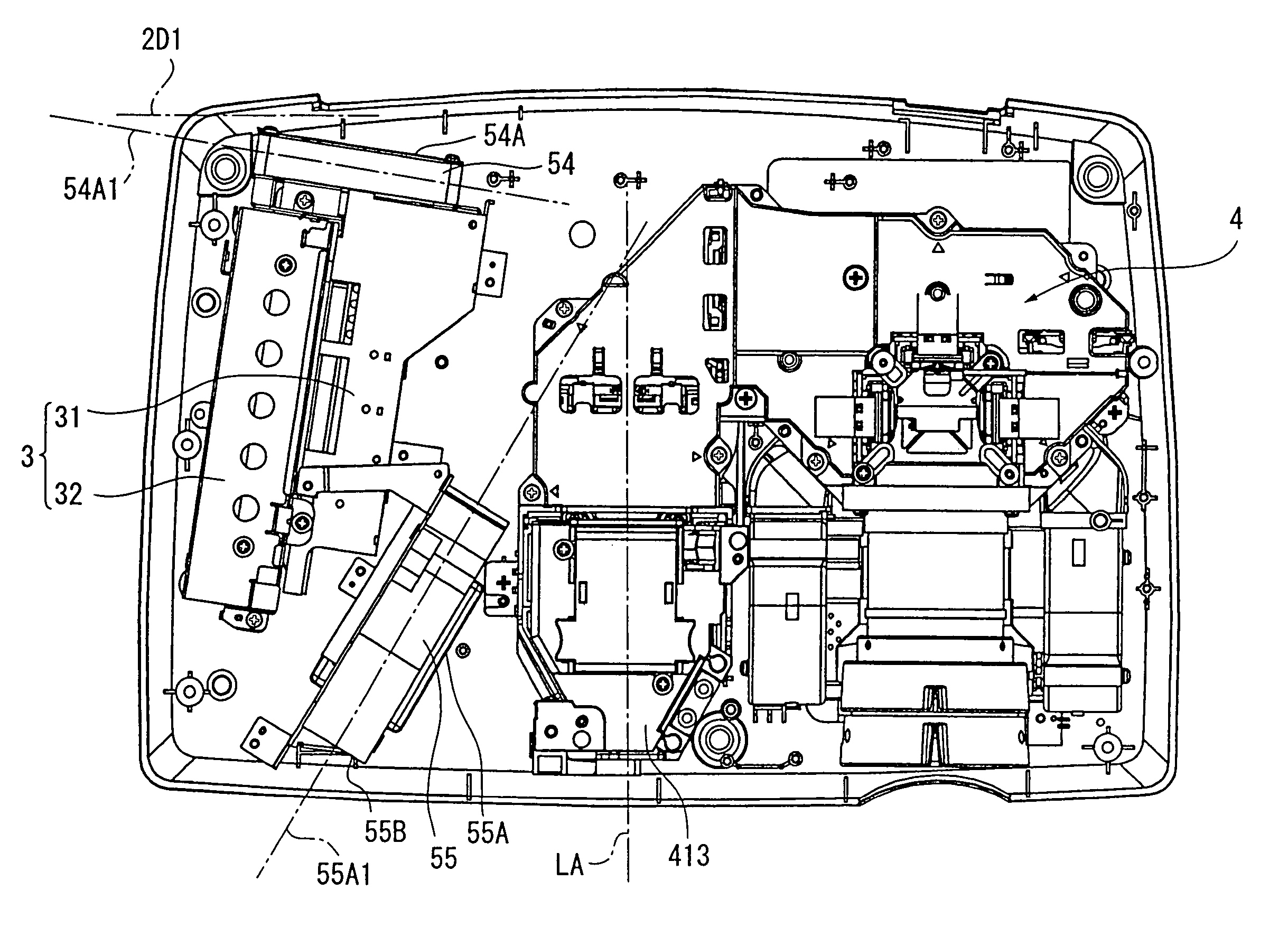

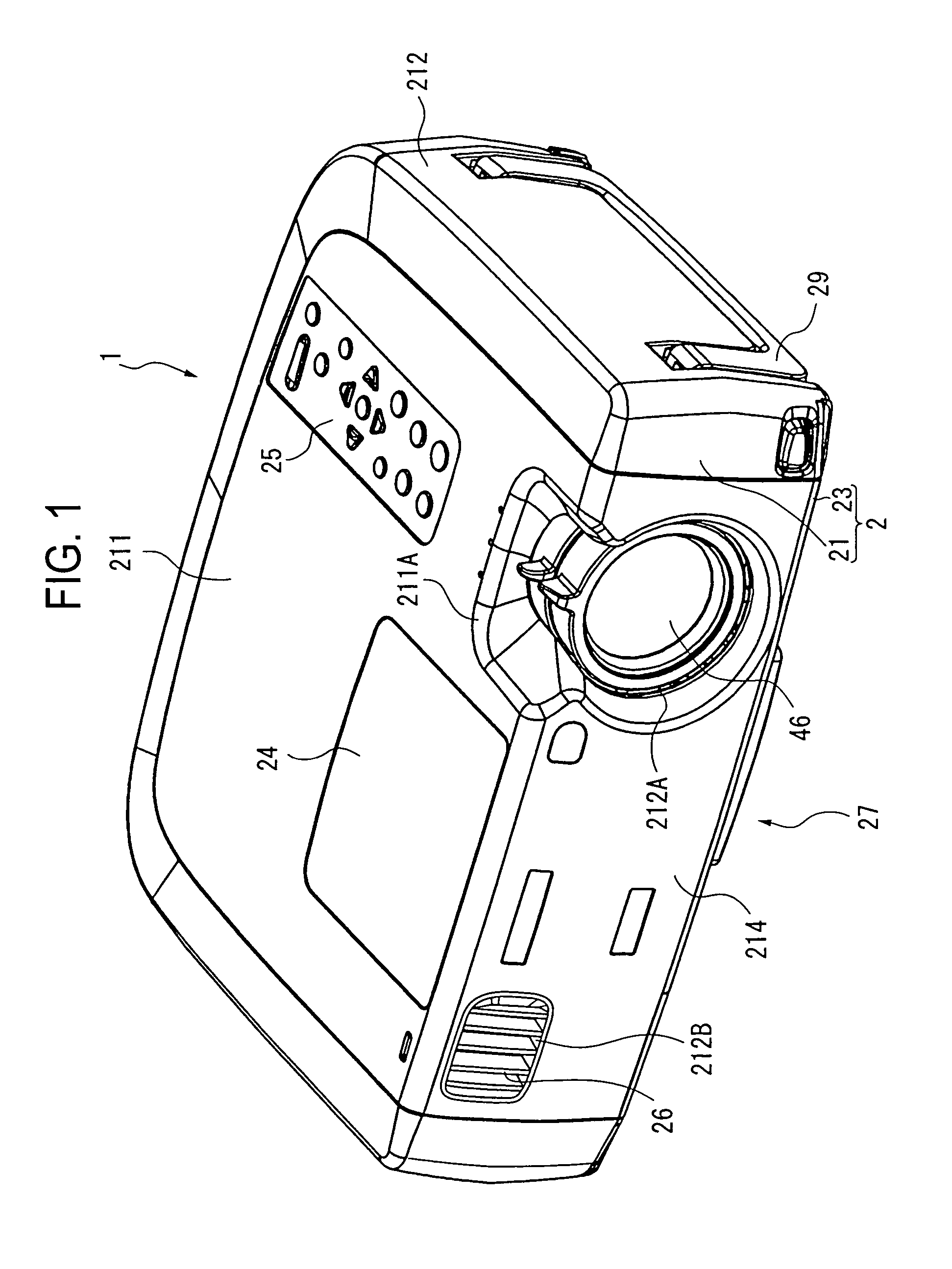

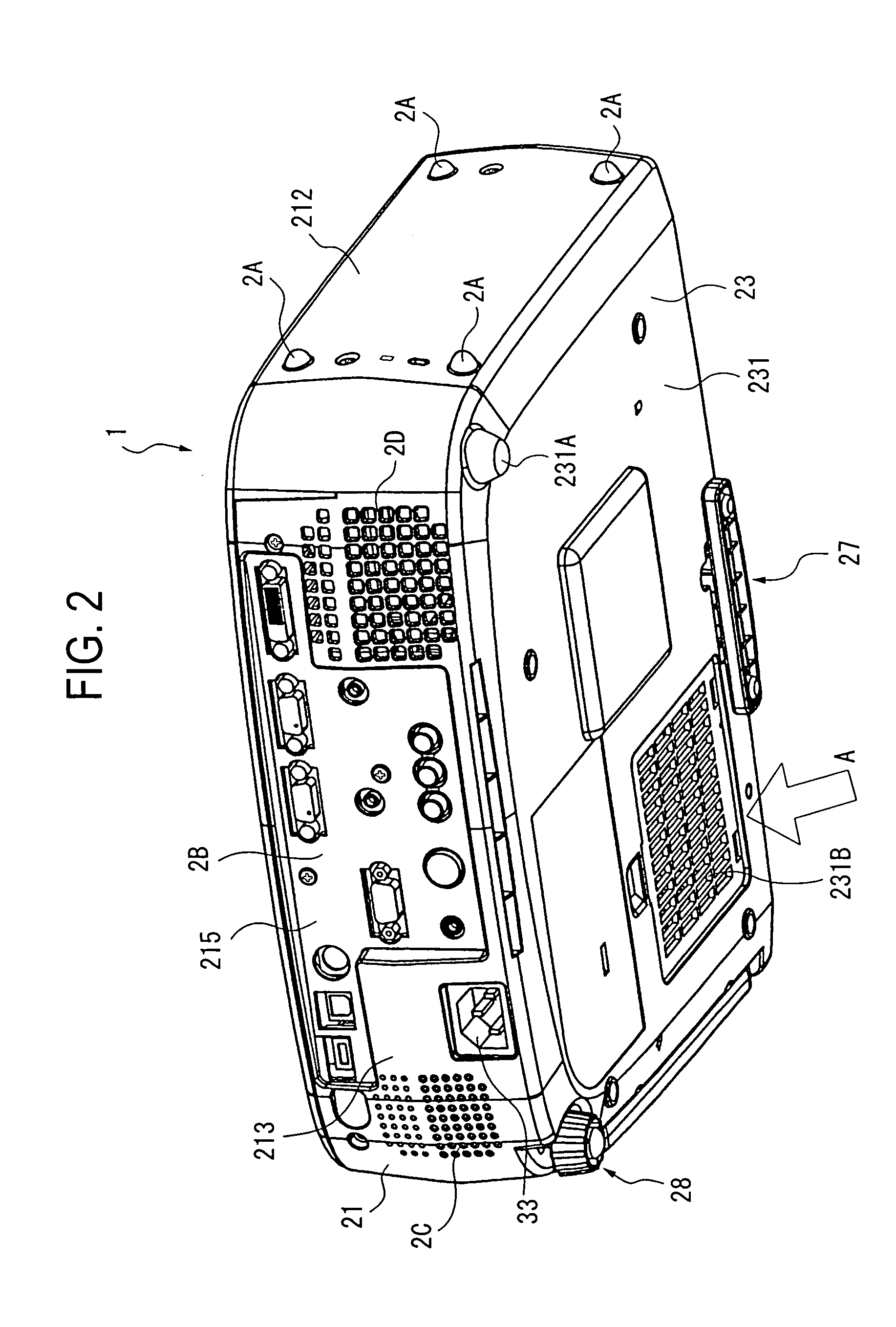

Projector

InactiveUS6558004B2Improve noiseIncrease in sizeTelevision system detailsProjectorsEngineeringAtmospheric pressure

Owner:SEIKO EPSON CORP

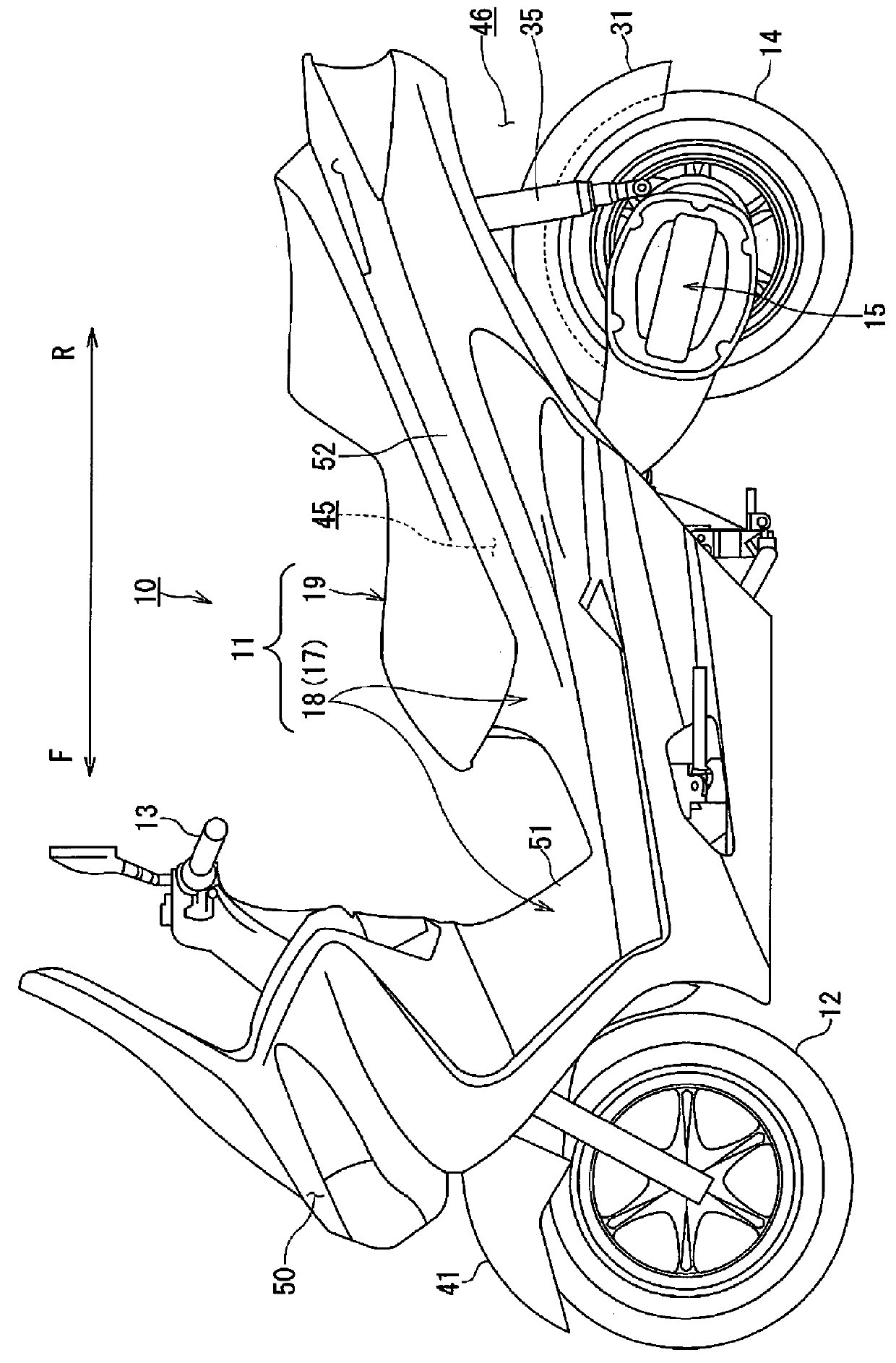

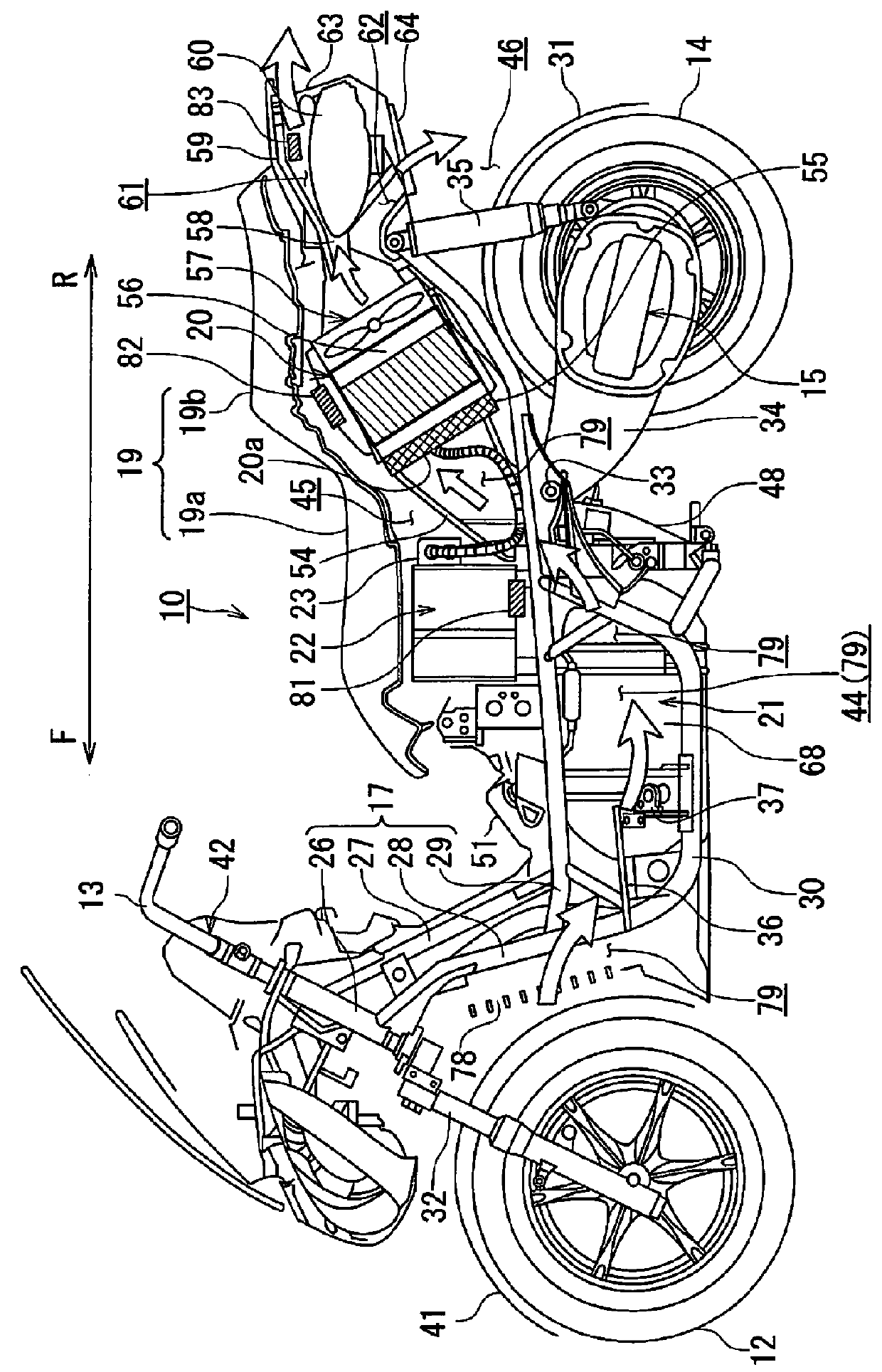

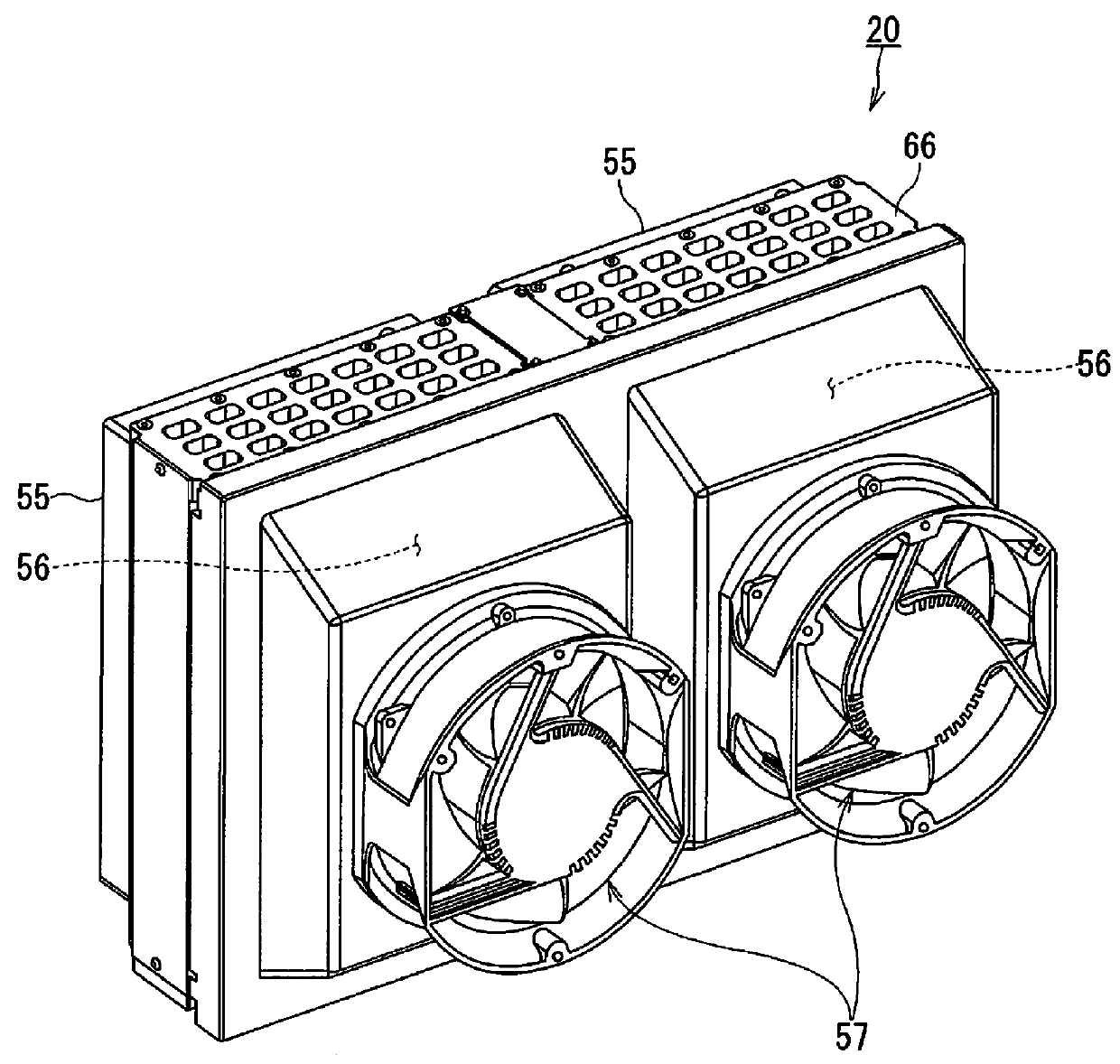

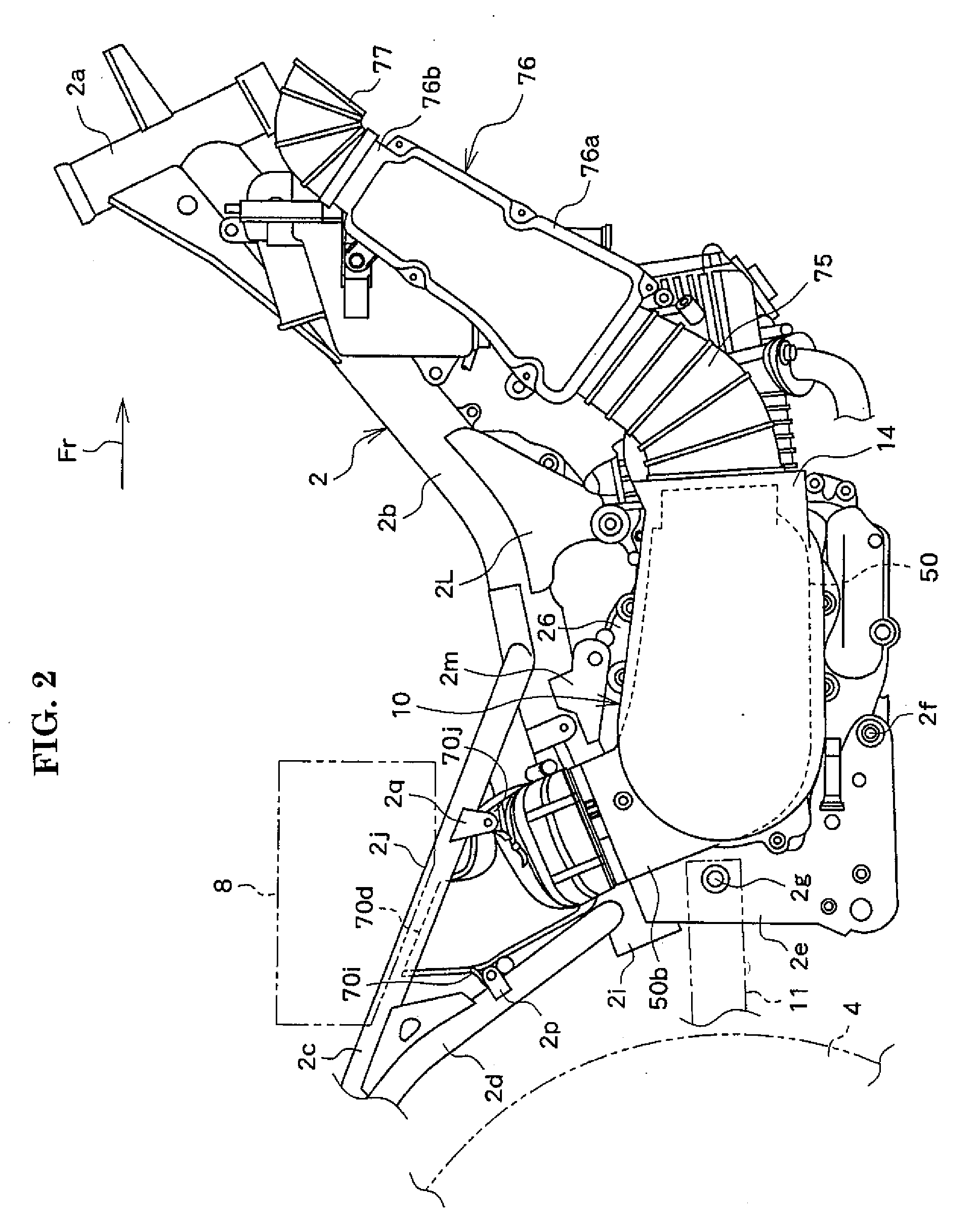

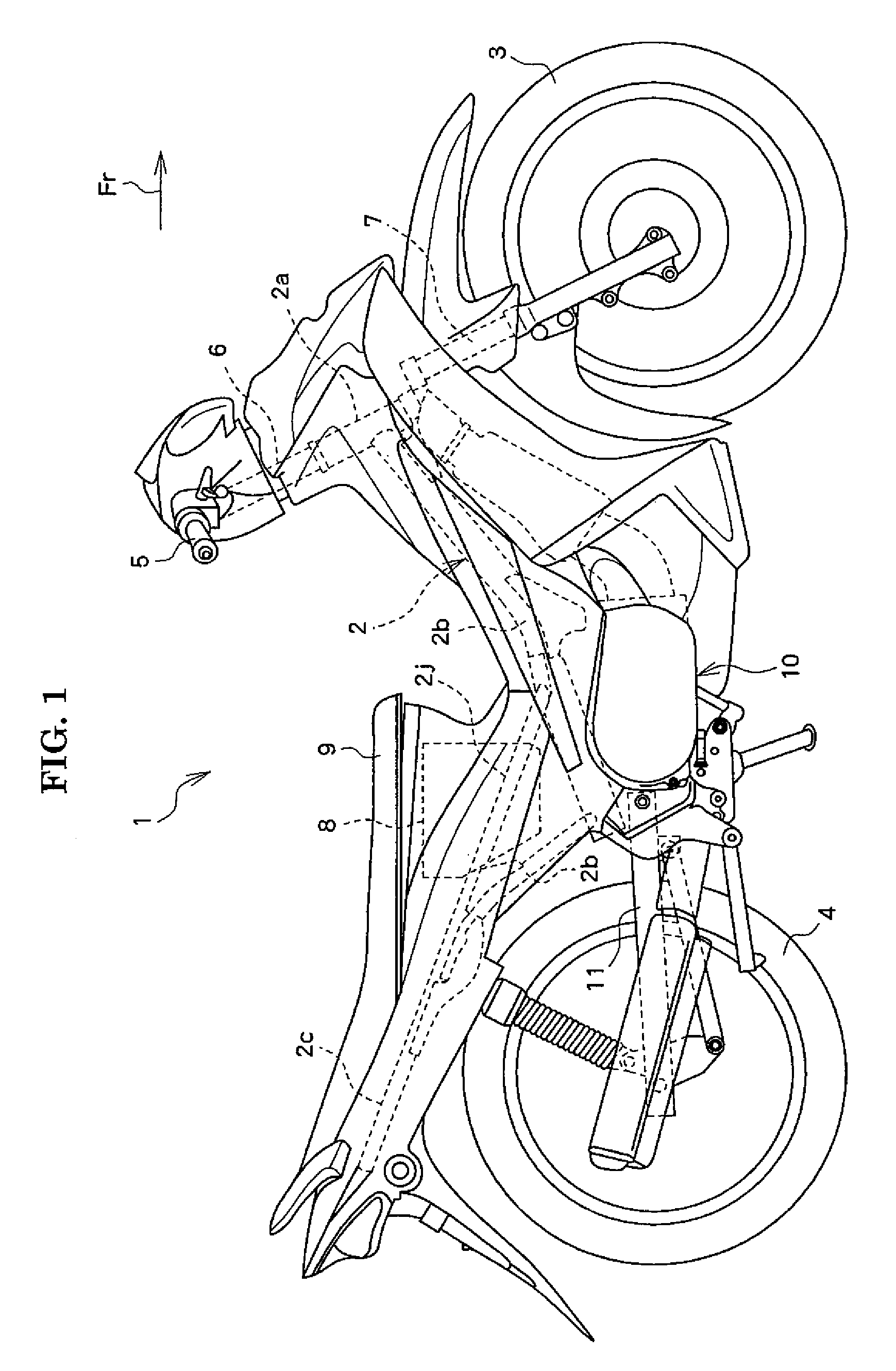

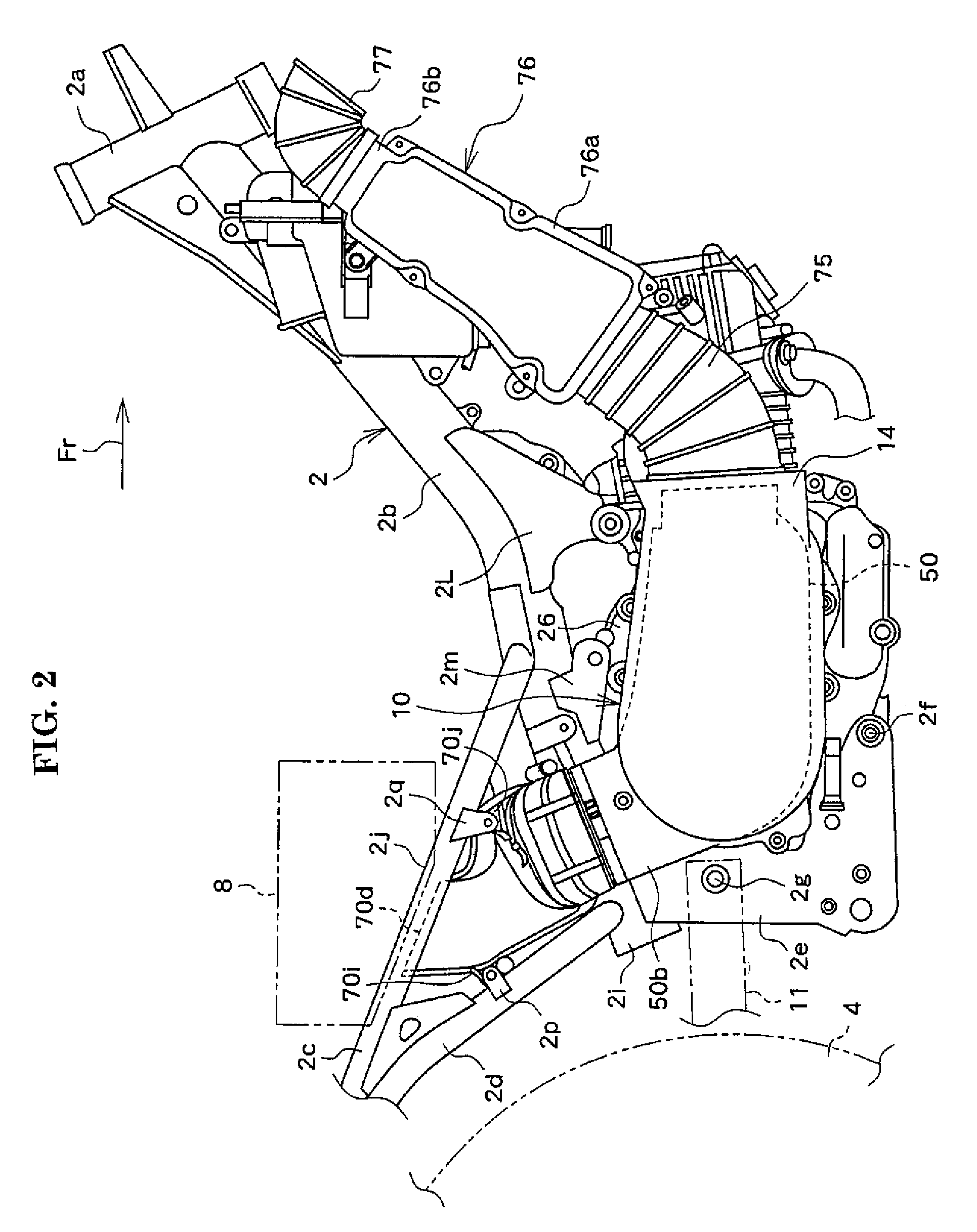

Fuel cell-powered motorcycle

ActiveUS20160056482A1Early detectionAvoid failureFuel cell heat exchangeReactant parameters controlDrive wheelHydrogen tank

An air-cooled fuel cell-powered motorcycle allowing early detection of a malfunction in a fuel cell stack. The fuel cell-powered motorcycle includes a vehicle body; an electric motor for driving a driving wheel, an air-cooled fuel cell for supplying electric power to the electric motor and a hydrogen tank for storing a fuel gas supplied to the fuel cell, respectively housed in the vehicle body; a fan for supplying air as a reactant and a coolant to the fuel cell; and an exhaust duct for discharging the air having cooled the fuel cell out of a rear end of the vehicle body, the exhaust duct having an inlet connected to a rear end portion of the fuel cell.

Owner:SUZUKI MOTOR CORP

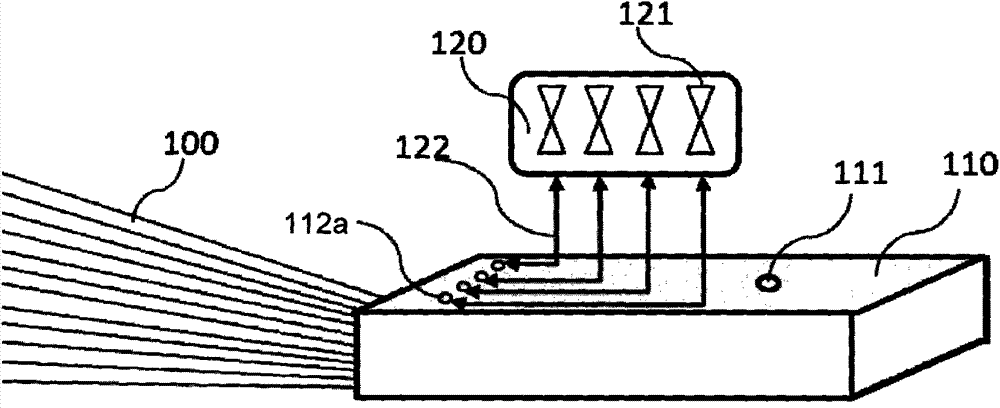

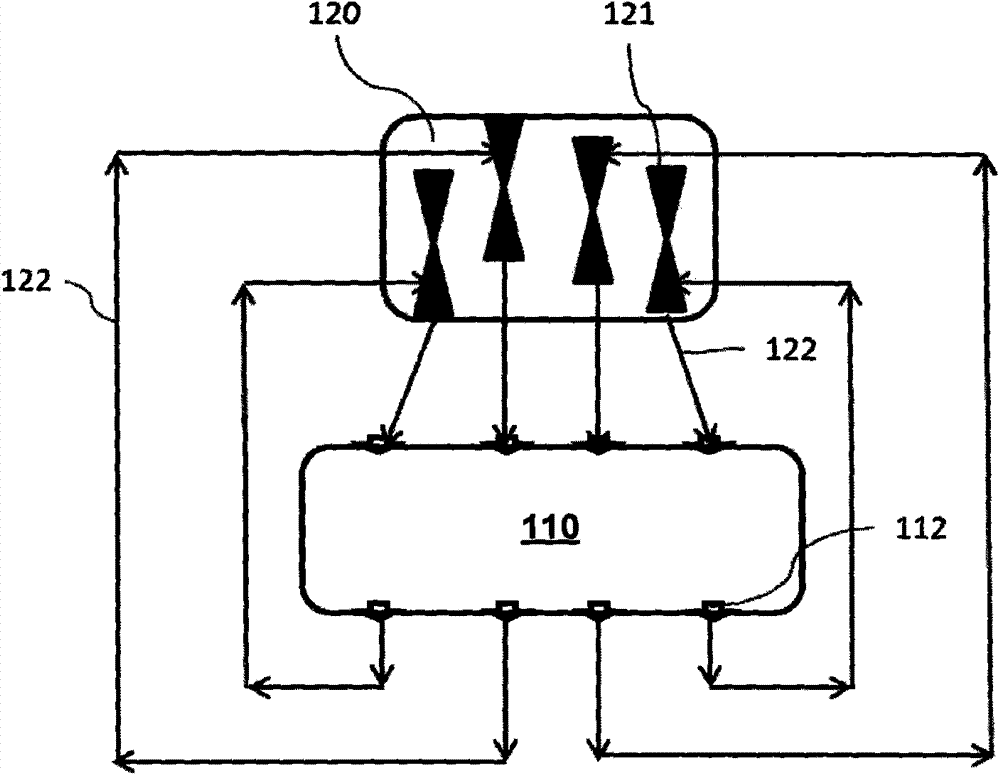

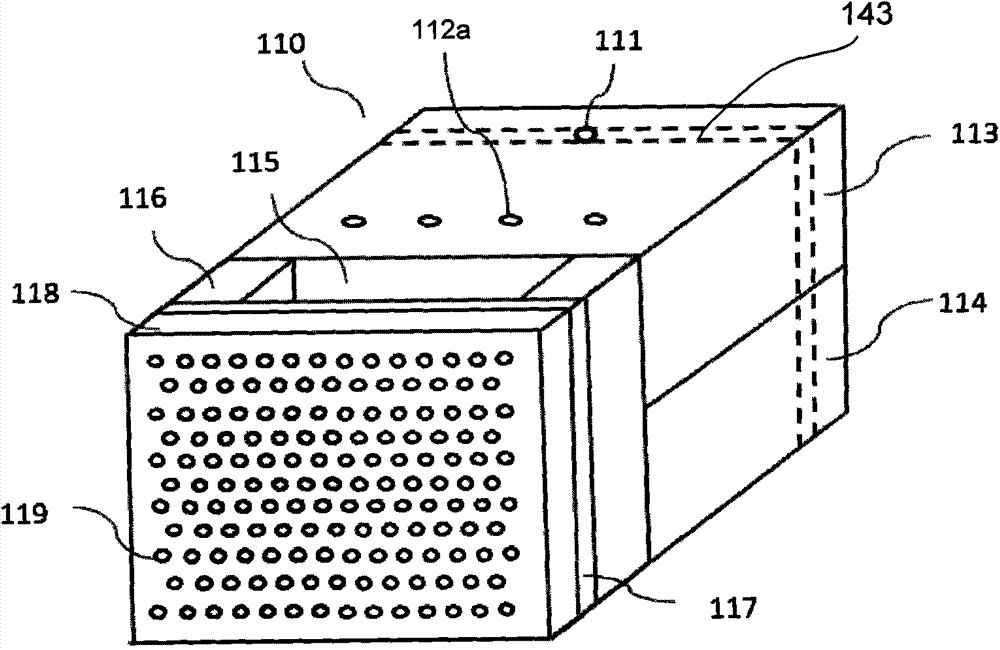

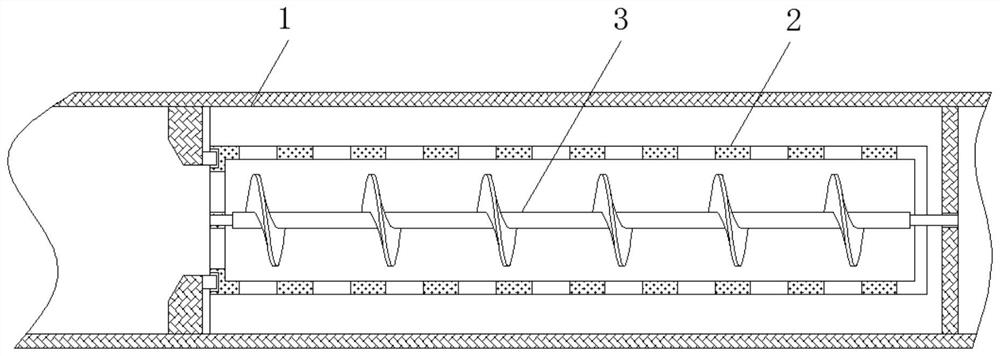

Multi-pipeline pump driving type fiber impregnation system

ActiveCN104742274AChange the unfavorable situationRaise the exhaustCoatingsPeristaltic pumpDiaphragm pump

The invention relates to a fiber impregnation system. The fiber impregnation system comprises a fiber impregnation box (110) and a driving pump (120) connected with the fiber impregnation box (110) by one or more refluxing hoses (122), wherein the refluxing hoses (122-1, 122-2 and 122-3) are used for recycling resin from the fiber impregnation box and refilling the fiber impregnation box with the resin under the driving action of the driving pump; and preferentially, the driving pump (120) is a peristaltic pump or a diaphragm pump. Besides, the invention also relates to equipment for performing pultrusion on fibers (100) to obtain a section material (200) by use of the fiber impregnation box. According to the fiber impregnation system, the fiber impregnation box and the peristaltic pump provided with at least one pump head are combined, and the quantity of pumps, pump heads and pipelines is increased as required by production and processing, thus, the fiber impregnation box is not required to be closely connected with a corresponding molding and solidifying device, and a yarn guiding plate can be arranged in the fiber impregnation box; and the fiber impregnation box and the corresponding molding and solidifying device can be separable and vacuumizing operation is carried out, and thus, the fiber exhaust efficiency is improved.

Owner:COVESTRO DEUTSCHLAND AG

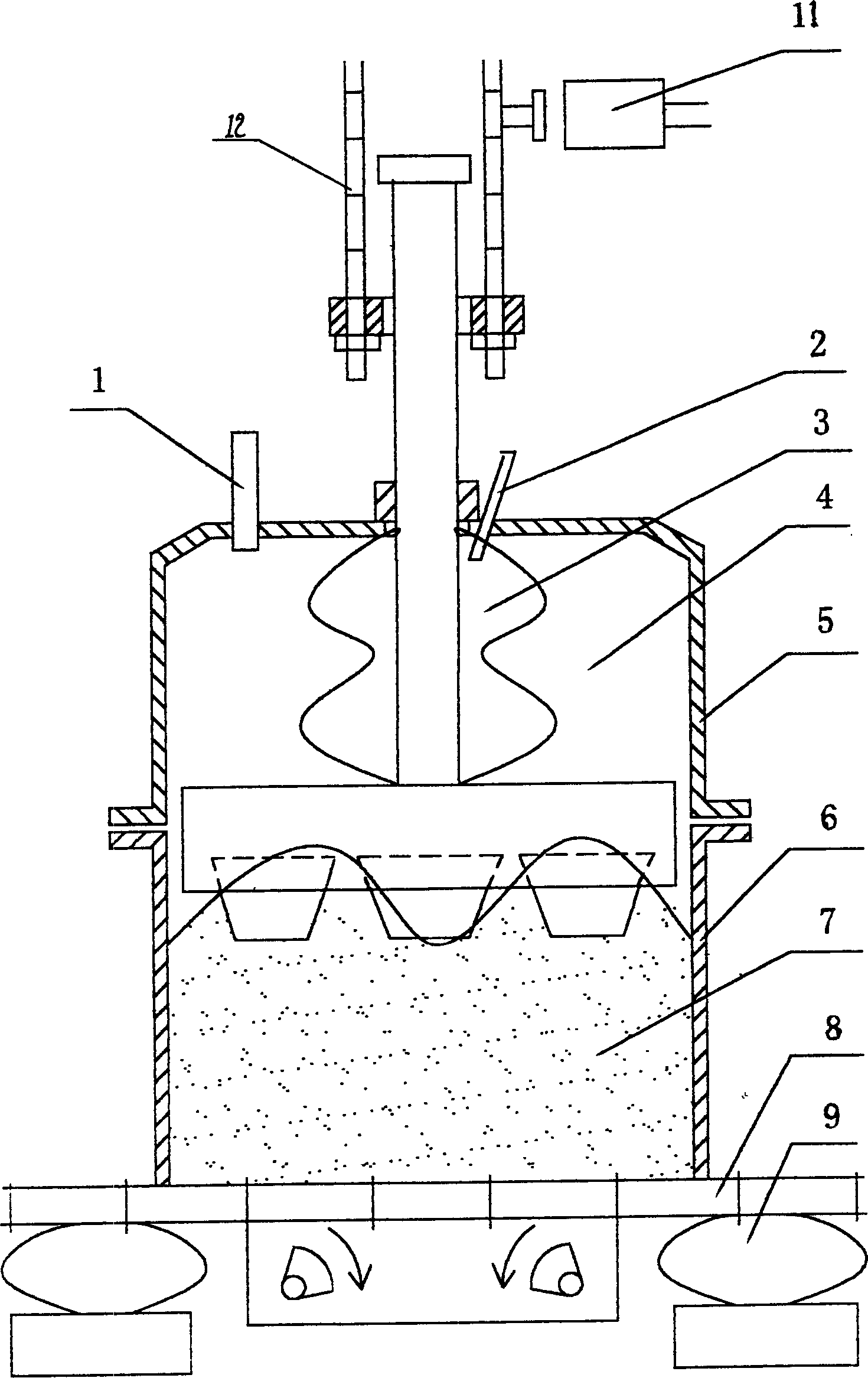

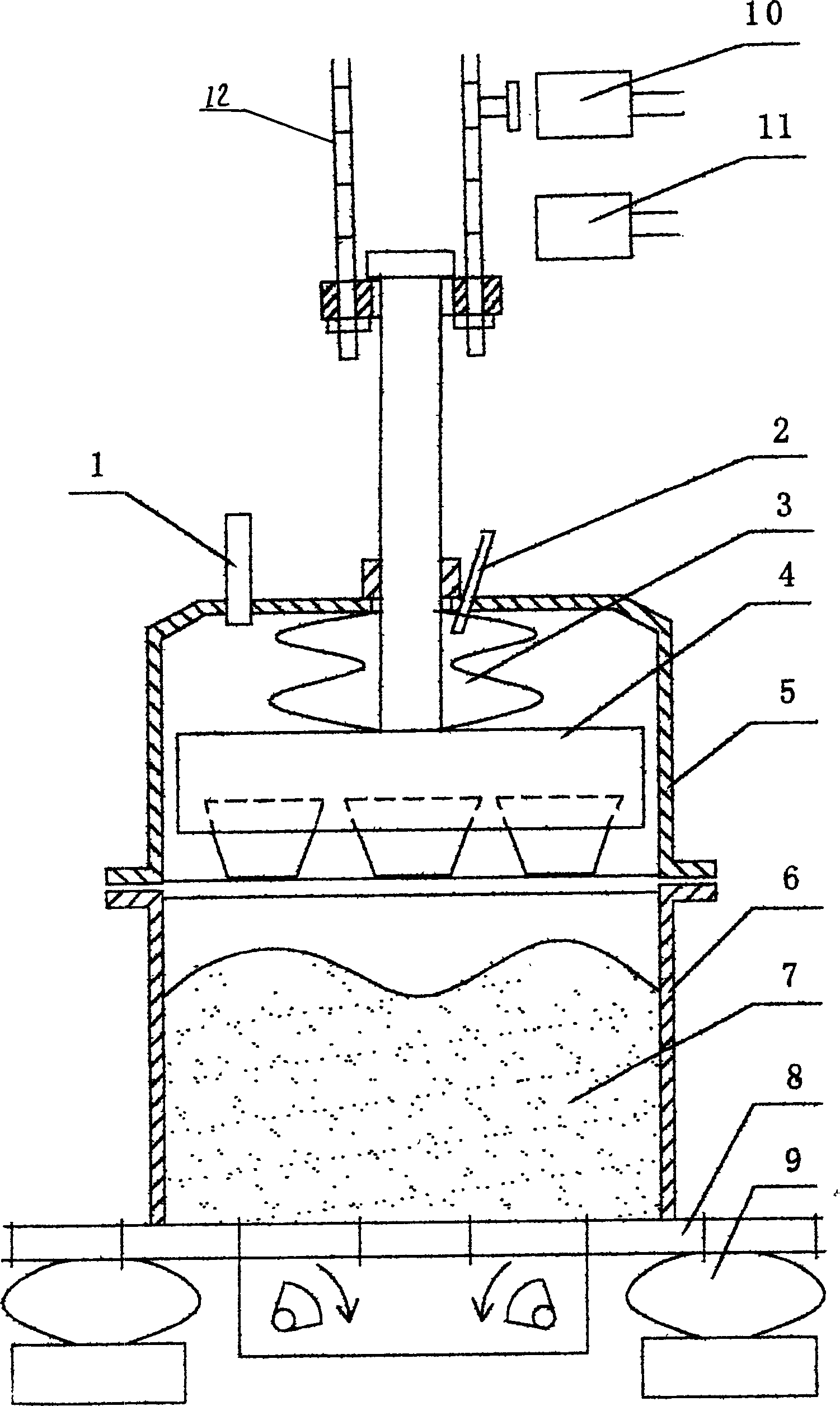

Anodic carbon block vibrating and shaping method for aluminium

InactiveCN1614096AHigh bulk densityHigh densityCeramic shaping apparatusVacuum pumpingDischarge efficiency

This invention relates to anode carbon blocks formed by vibration. Firstly, the heavy punch (4) and the heavy punch mantle (5) were lifted and the paste filler (7) was filled in the mould (6). Secondly, the two-bearing vibration table (8) was lifted to fall down the heavy punch and the heavy punch mantle to guarantee the he heavy punch mantle locked the mould closely. The heavy punch was stopped before it pressed the paste filler. When the vibration time was set, the heavy punch was fallen down rapidly to press the paste filler. When it was close to on / off (11), the heavy punch was forced. The system was vibrated until the set time to stop vibration was over. Then, it was demoulded and the carbon block discharged. The system began vibration before the heavy punch pressed the paste filler to provide the chance that the surface of the paste filler was flat automatically .During the vibration, the paste filler was from natural accumulation to vibration accumulation to discharge the gas in the filler and to improve the air discharge efficiency and shorten its time by the vacuum-pumping system.

Owner:马二红

Vacuum packaging structure, packaging method thereof, and vacuum packaging device

ActiveCN106847759AReduce volumeGuaranteed performanceSemiconductor/solid-state device detailsSolid-state devicesLight filterMaterials science

A vacuum packaging structure, a packaging method thereof, and a vacuum packaging device are provided. The vacuum packaging structure comprises: a base; a cover cap having an opening at the top, wherein the opening is covered with an infrared filter, and the cover cap, the infrared filter and the base form a vacuum chamber; an infrared detector chip positioned in the vacuum chamber and adhering to the surface of the base; and a getter layer located within the vacuum chamber and having both ends welded to the base surface. The vacuum packaging structure requires no exhaust pipe, simplifies components, and significantly reduces the volume of an infrared detector. Moreover, the infrared detector chip completely fits with the base, and a chip base material has good temperature uniformity and effectively guarantees detector performance.

Owner:ZHEJIANG DALI TECH +1

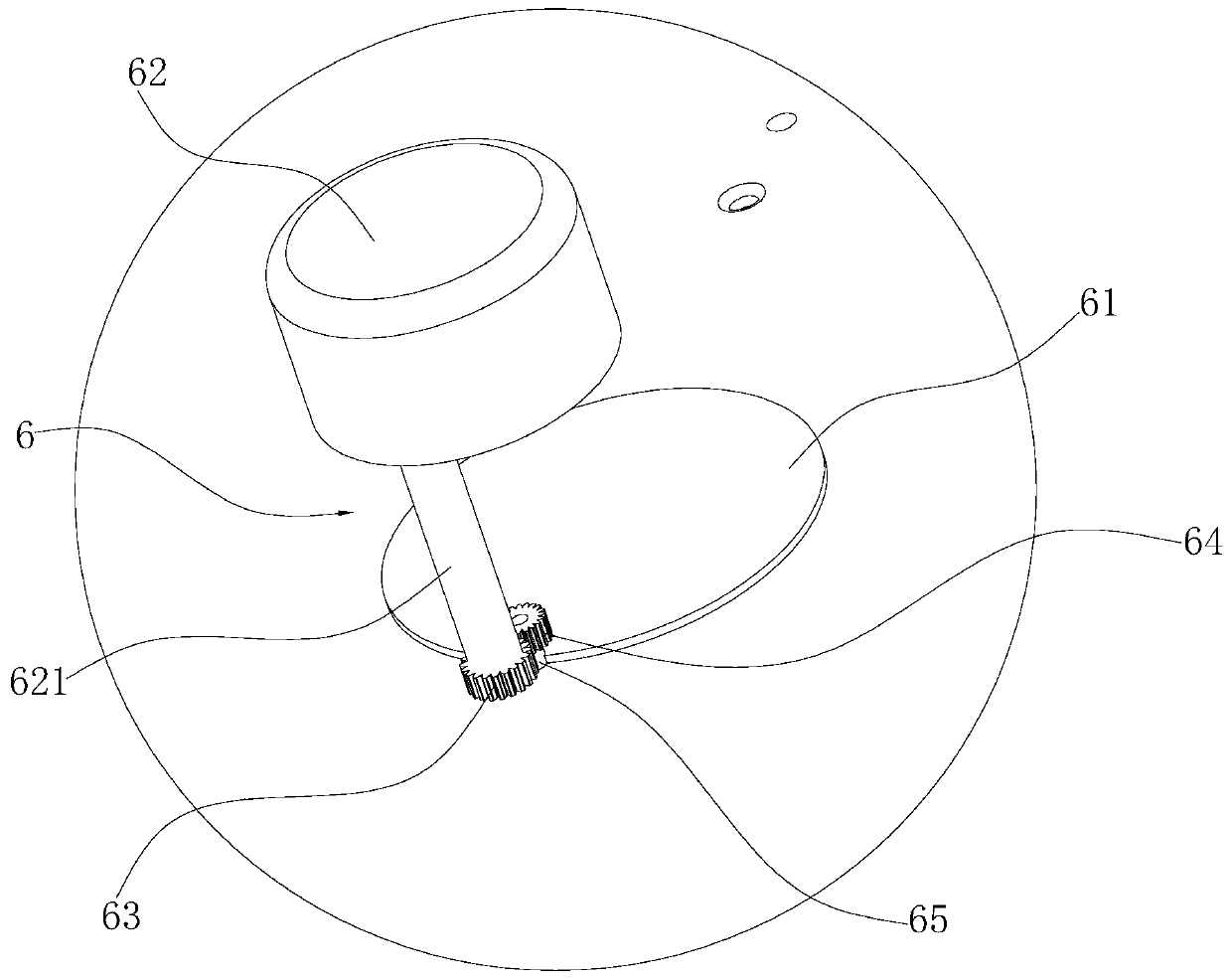

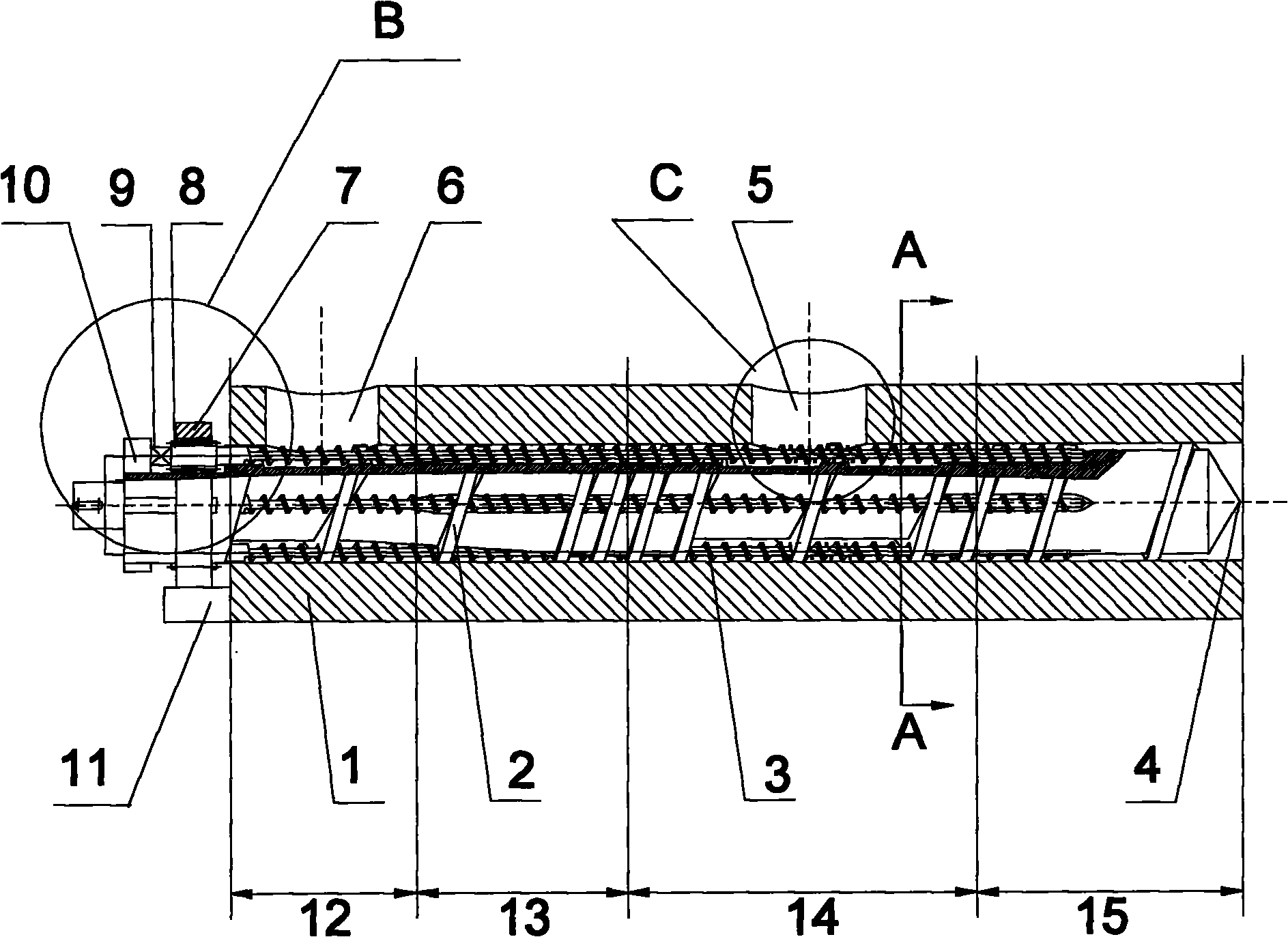

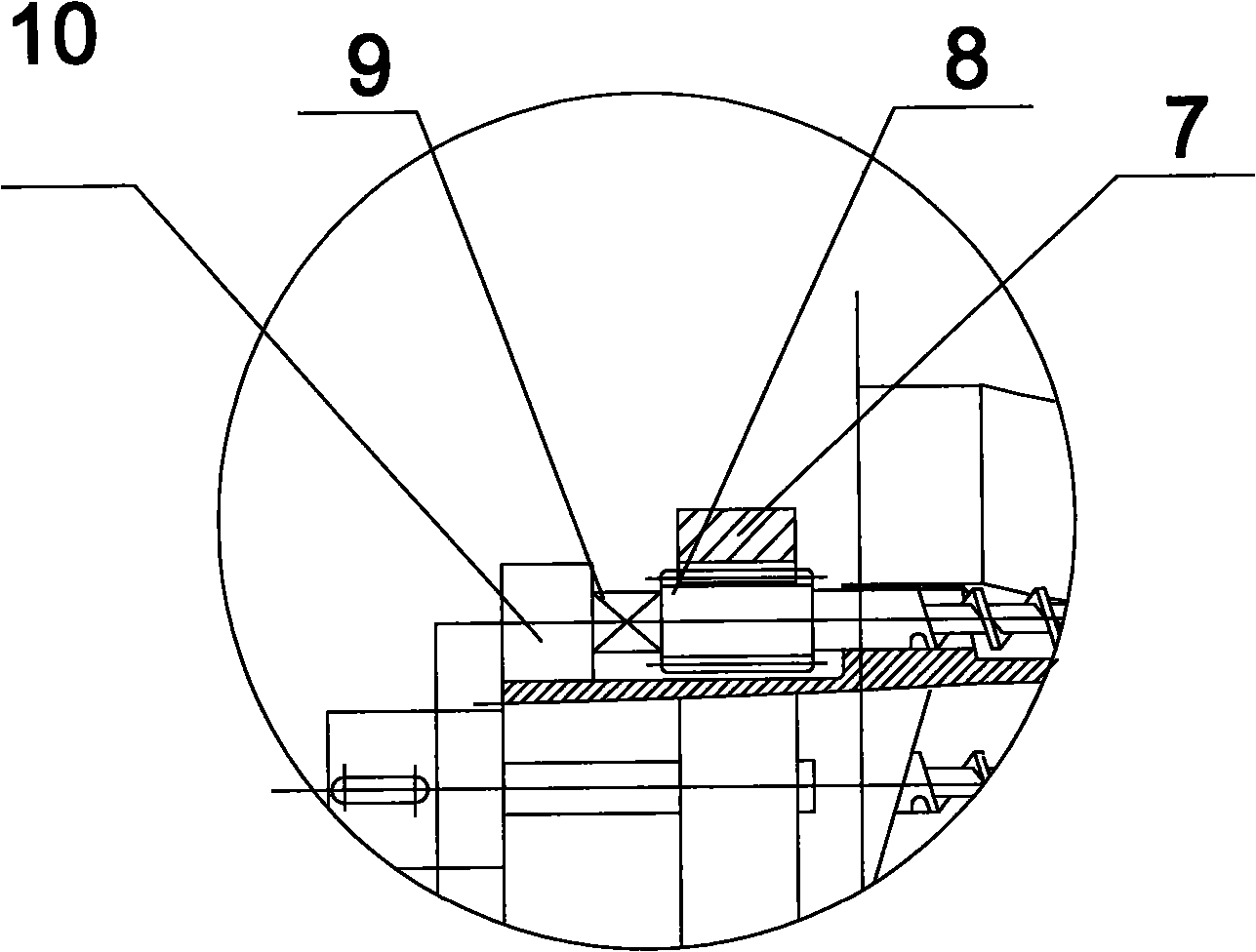

Embedded planetary-screw pulsation plasticizing exhaust extruder and method

The invention provides an embedded planetary-screw pulsation plasticizing exhaust extruder, which comprises a screw mechanism, a cylinder, a feed inlet, an air outlet, a discharge outlet and an actuating unit, wherein the screw mechanism comprises a main screw and a plurality of planetary screws, and the axis of the main screw is coincident with the axis of the cylinder; the screw arris of the main screw is provided with a plurality of holes which are matched with the planetary screws; the planetary screws are respectively inserted in the holes of the screw arris of the main screw, embedded into a screw slot and distributed around the main screw; the axes of the planetary screws are parallel to the axis of the main screw; the actuating unit comprises pulsation gears, planetary gears and a pulsation-gear transmission mechanism; the planetary gears are fixed at the ends of the planetary screws and are engaged with the pulsation gears; and the pulsation gears are connected with the pulsation-gear transmission mechanism. The invention also provides an embedded planetary-screw pulsation plasticizing exhaust method implemented by the device. The embedded planetary screw pulsation plasticizing exhaust extruder and the embedded planetary-screw pulsation plasticizing exhaust method have the advantages of adjustable retention time, low energy consumption, thorough exhaust, good uniformity of phase structure control, and the like.

Owner:GUANGDONG IND TECHN COLLEGE

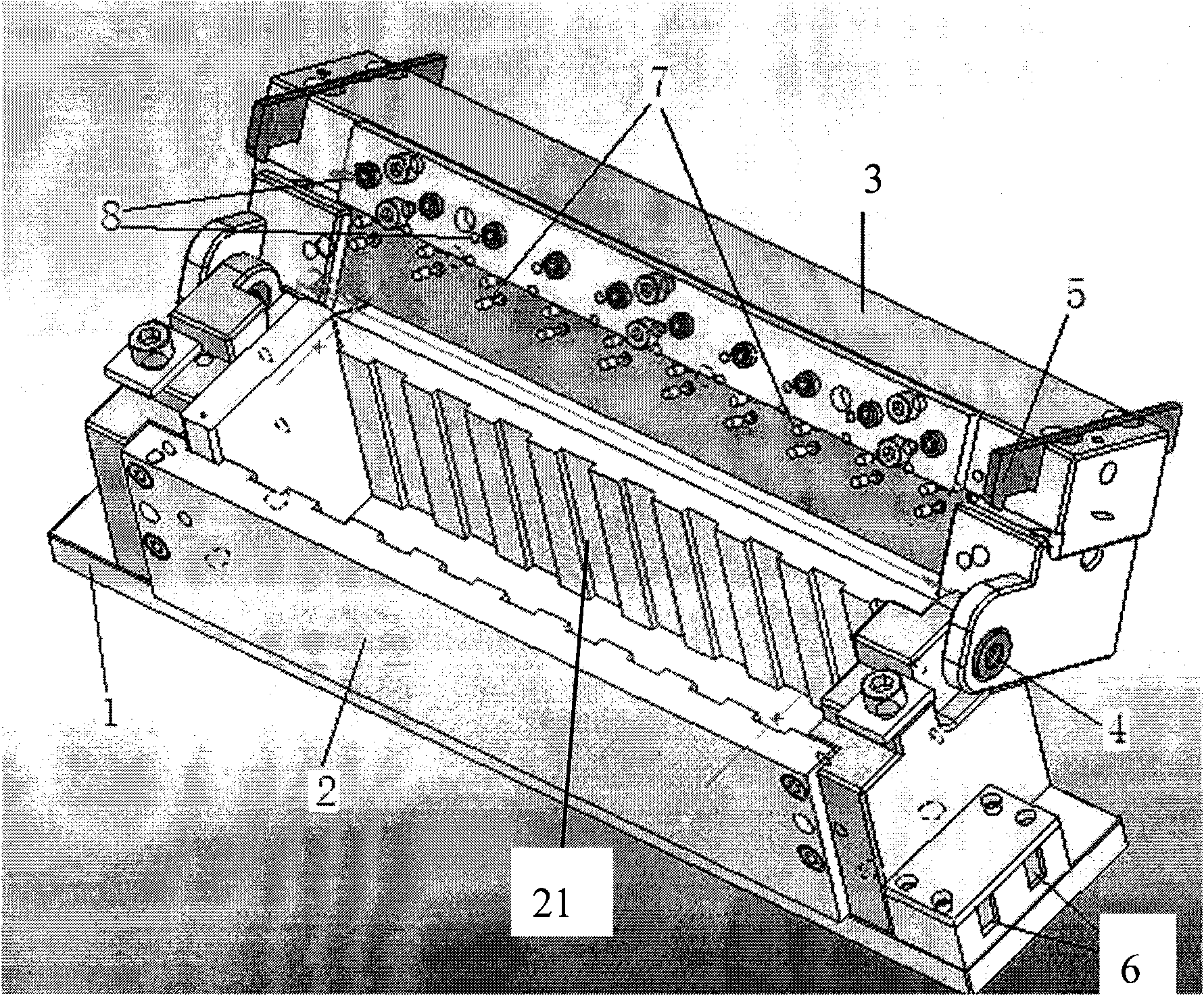

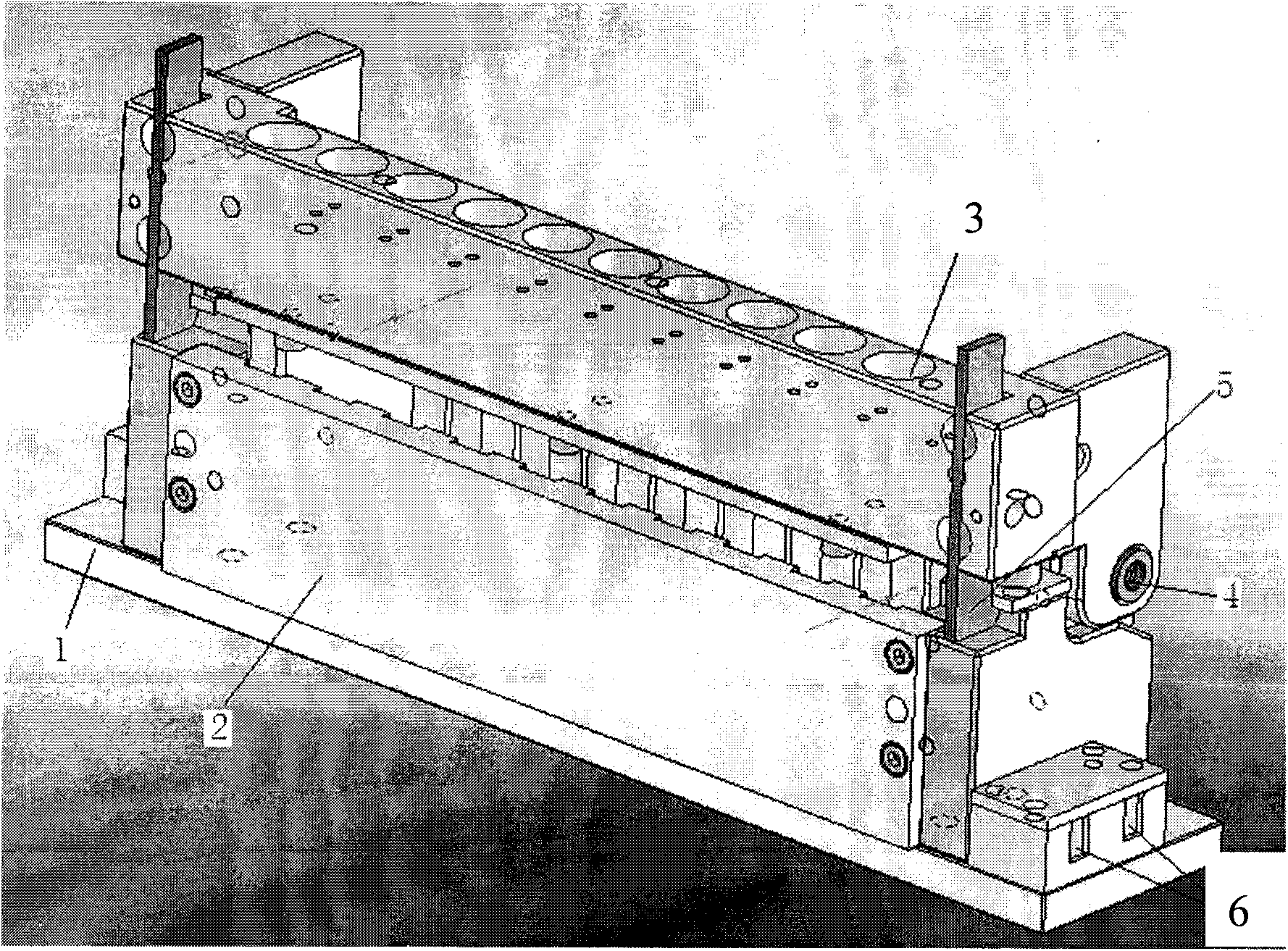

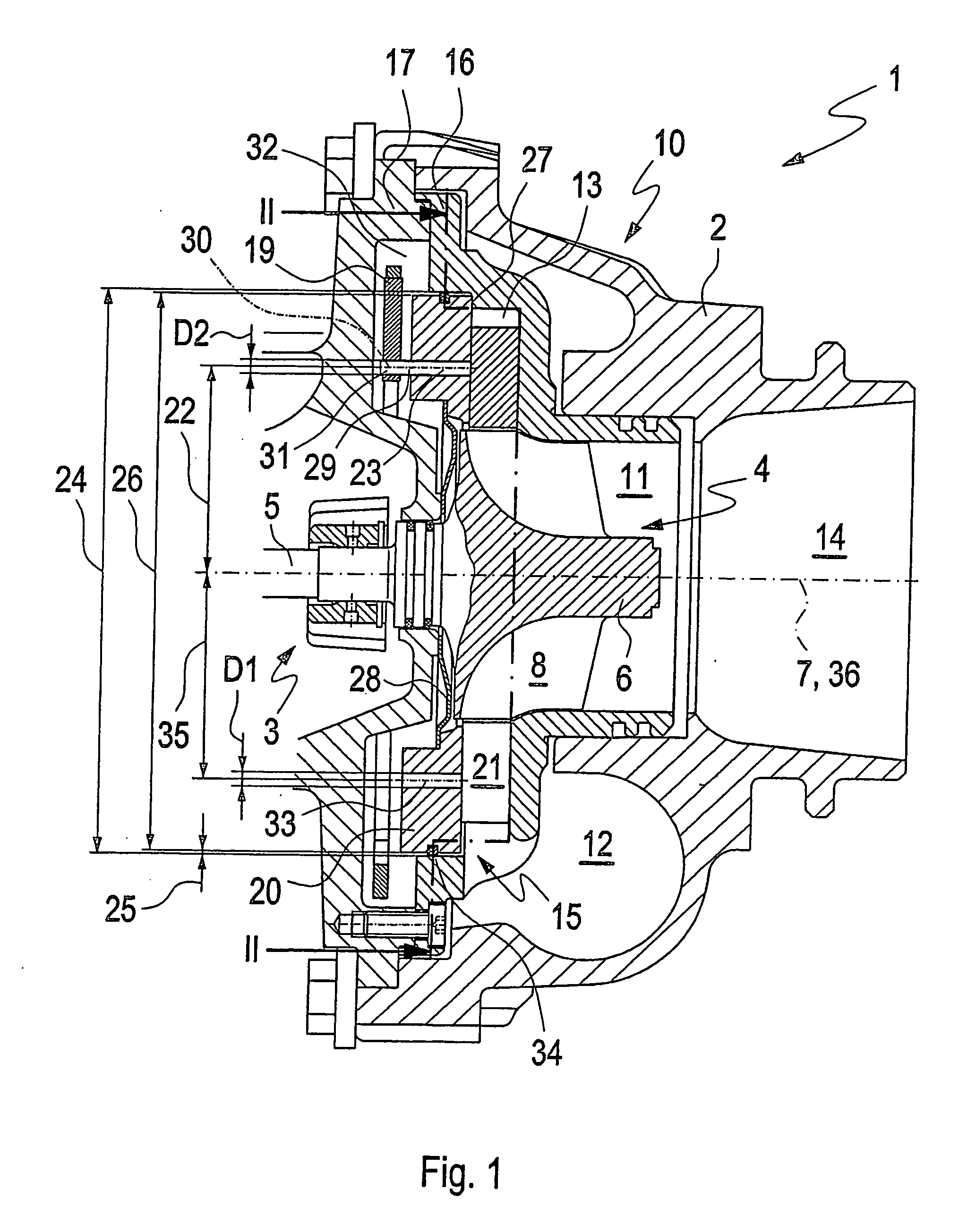

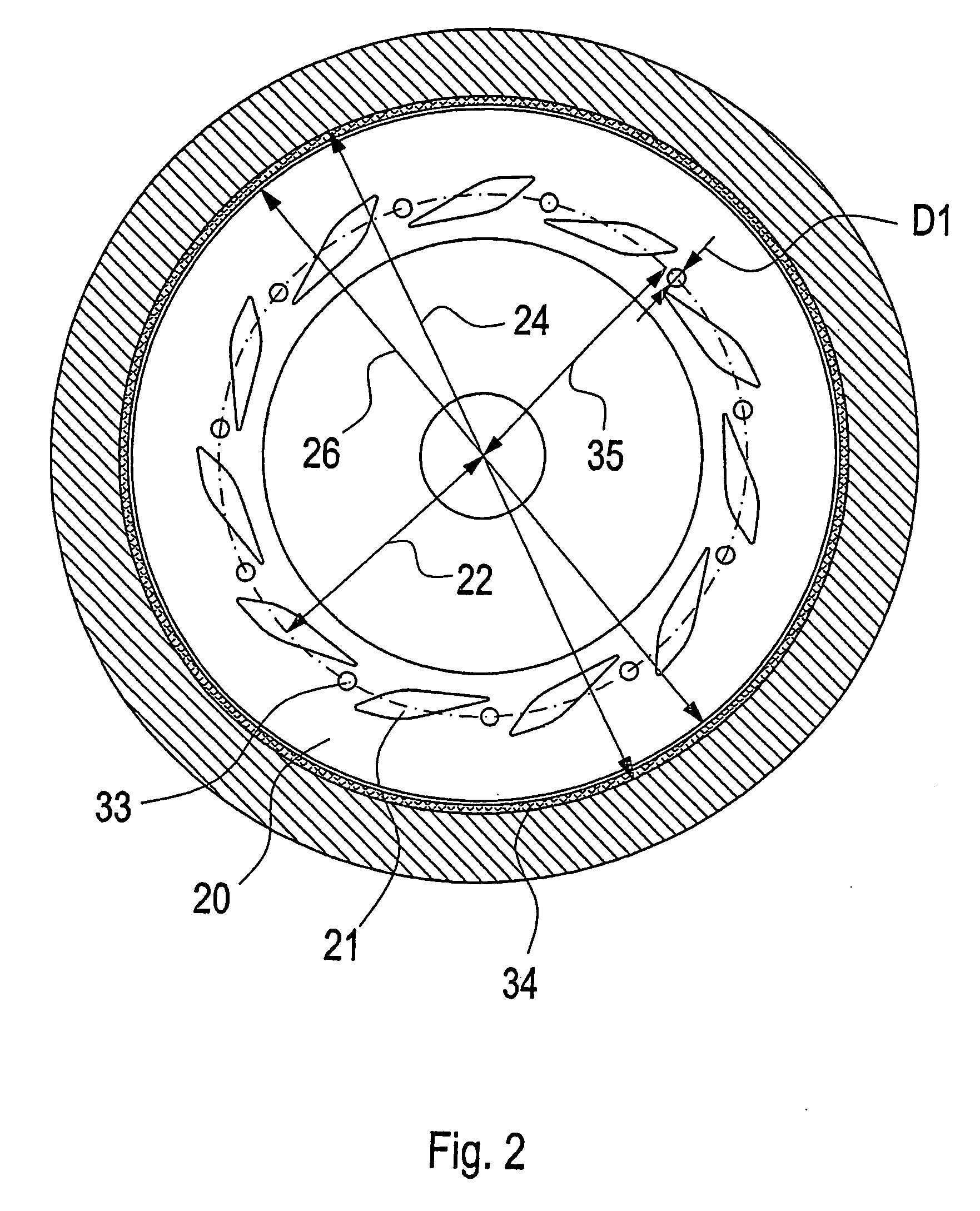

Turbocharger with adjustable turbine geometry and a vane carrier ring

InactiveUS20090094979A1Improve exhaust efficiencyExtended service lifeGas turbine plantsEngine controllersImpellerTurbine wheel

In an exhaust gas turbocharger for an internal combustion engine, which comprises a housing with an exhaust gas-conducting section with an inflow passage for directing exhaust gas to a turbine wheel arranged in the exhaust gas-conducting section including a carrier ring with an adjustable guide apparatus having guide vanes arranged on one side of the carrier ring for controlling the flow velocity of the exhaust gas flow to the turbine wheel, the carrier ring has at least one compensating opening extending therethrough so as to provide for pressure compensation between the inflow duct and a rear chamber which is arranged on a side of the carrier ring opposite the guide vanes.

Owner:DAIMLER AG

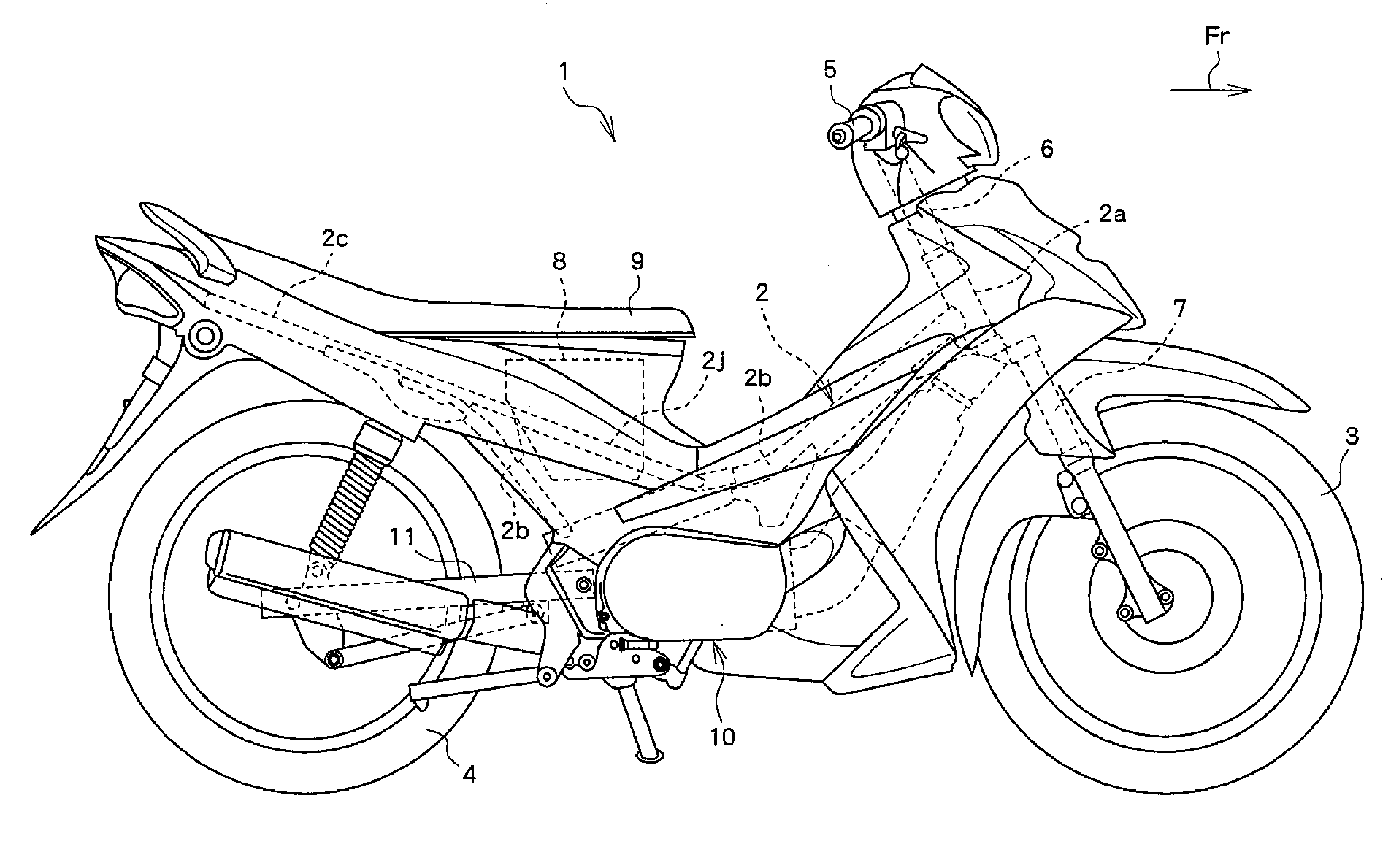

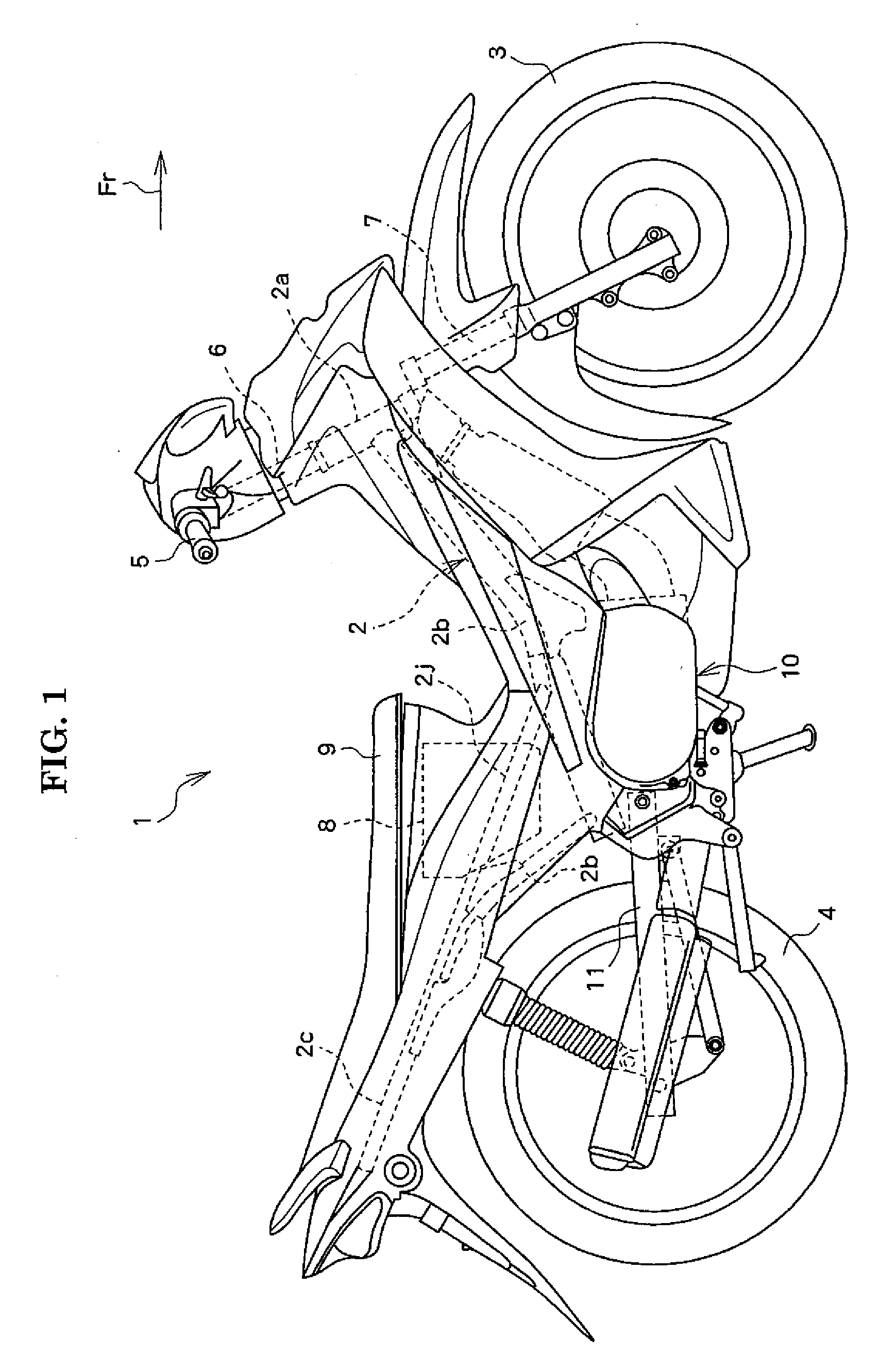

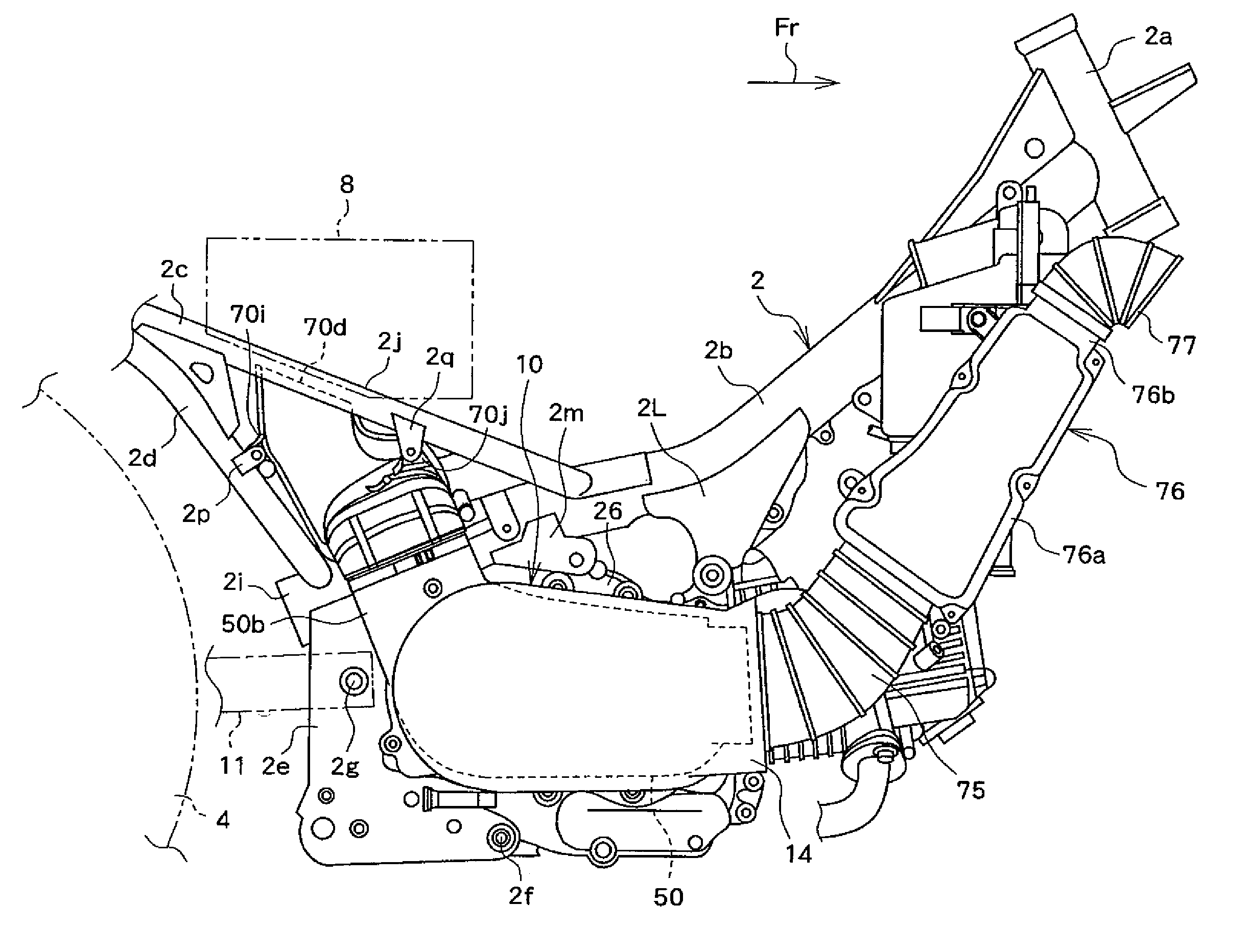

Straddle Type Vehicle

InactiveUS20090050391A1Improve exhaust efficiencyImprove efficiencyWheel based transmissionFrictional rollers based transmissionStraddleContinuously variable transmission

A straddle-type vehicle with enhanced heat exhaust efficiency in a transmission case housing a continuously variable transmission. The continuously variable transmission and an engine are arranged forward of a rear wheel 4. An air intake duct introduces outside air into the transmission case and an air exhaust duct exhausts air from the transmission case. The air exhaust duct is connected to and extends upward from a top portion of the transmission case. The air exhaust duct has an air exhaust port that is positioned above the transmission case.

Owner:YAMAHA MOTOR CO LTD

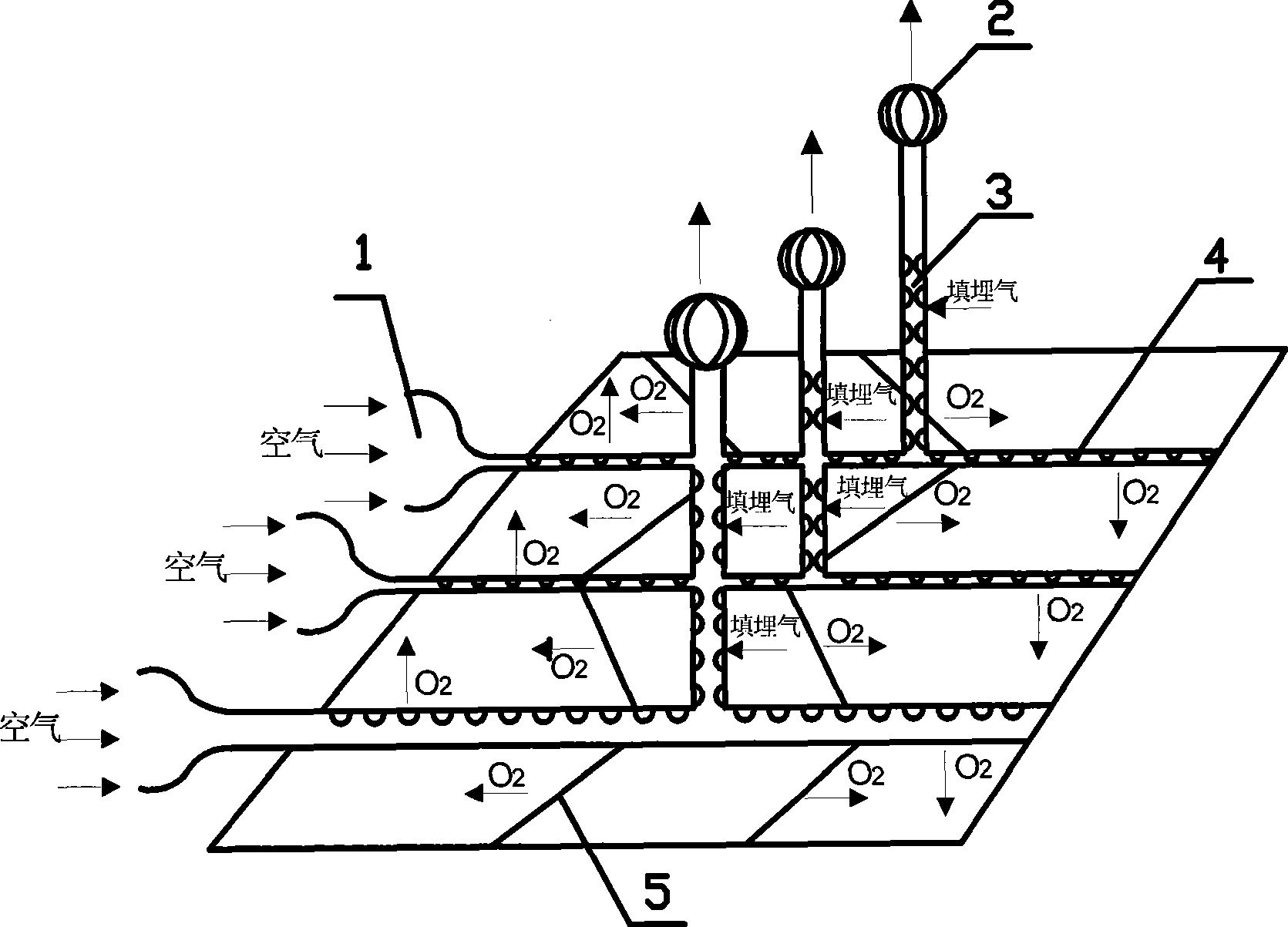

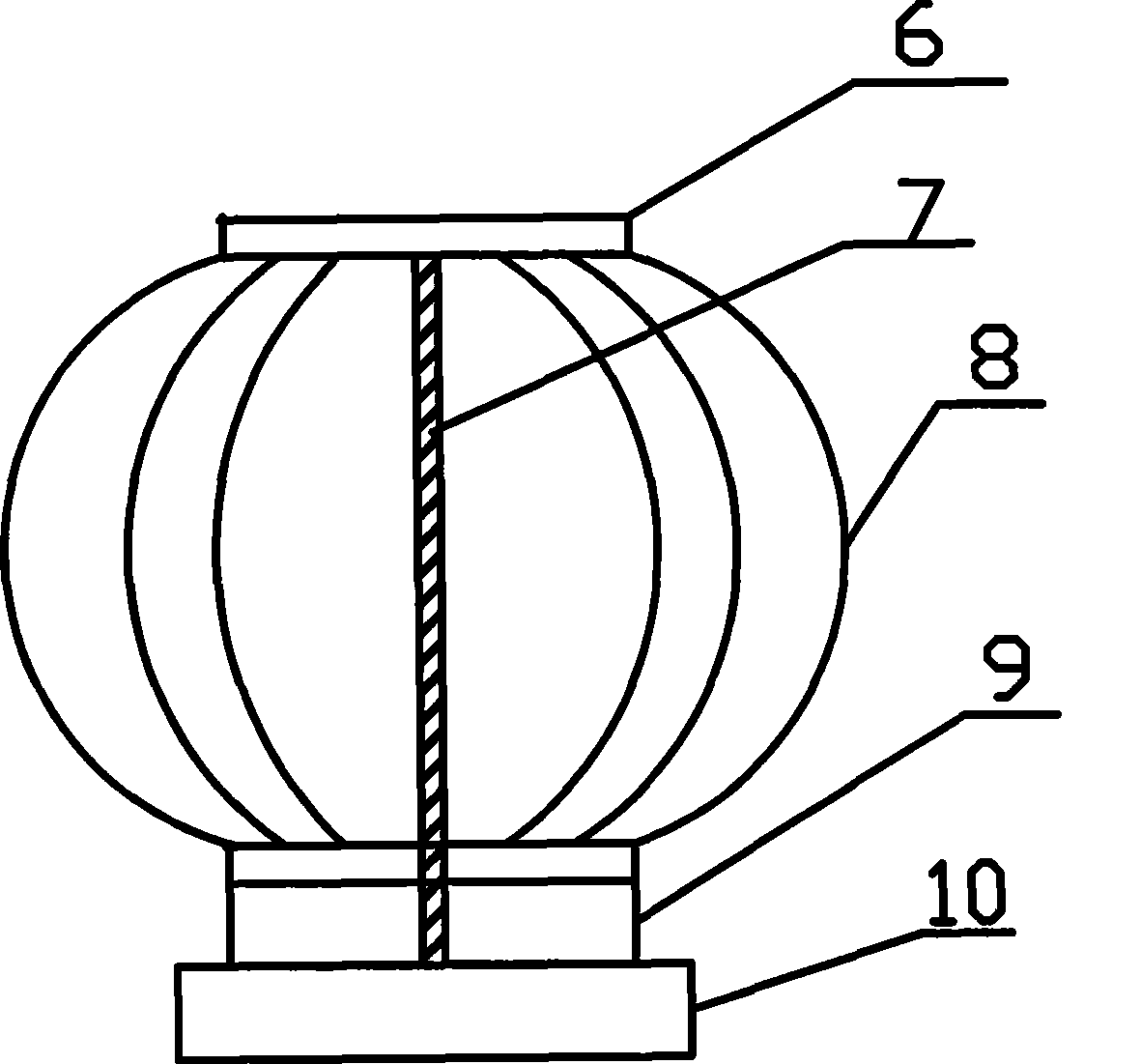

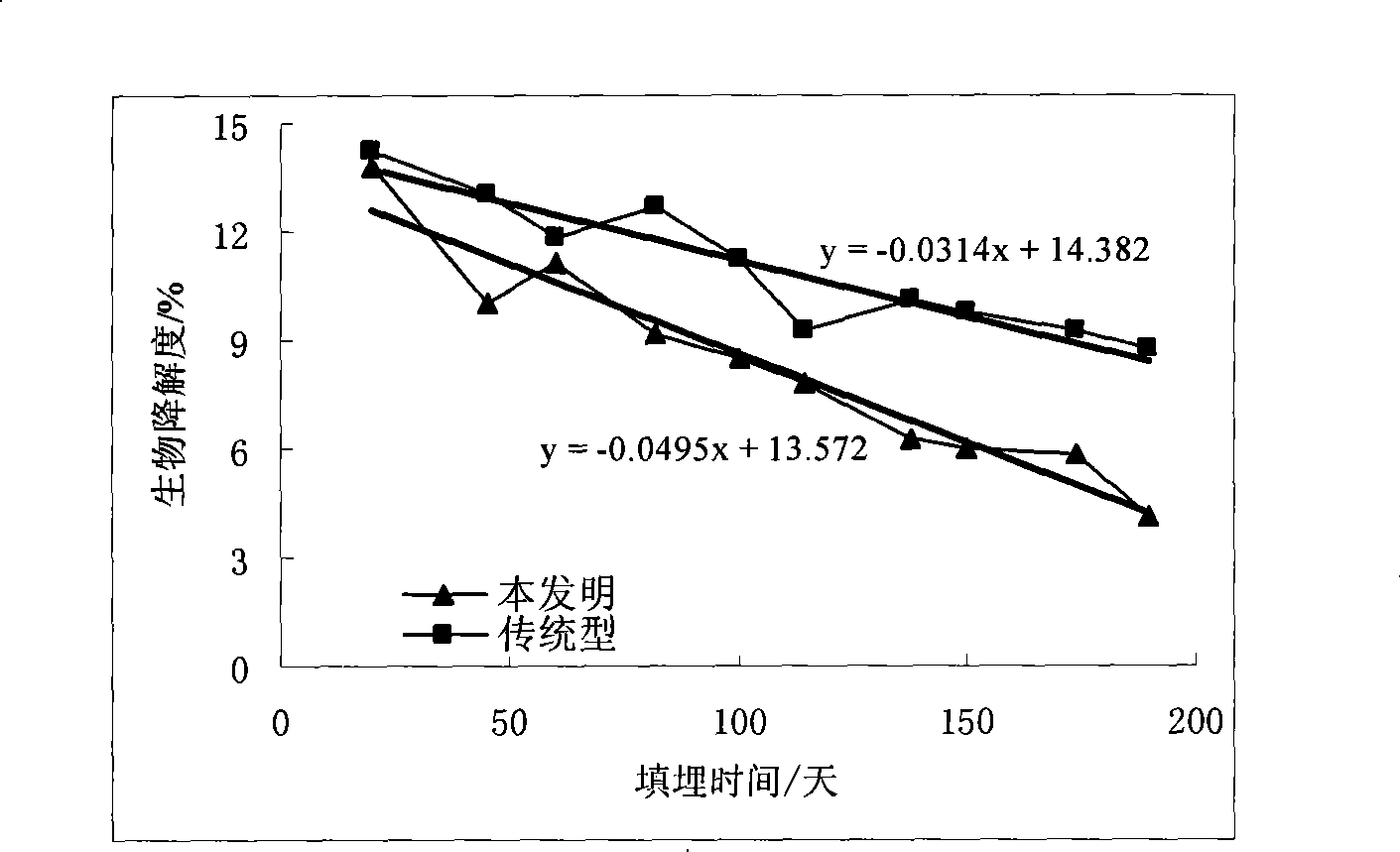

Filling method for reducing discharge of methane using wind force intensified ventilation

InactiveCN101439344AIncreased efficiency of entry into landfillReduce global warming potentialLandfill technologiesSolid waste disposalDecompositionEngineering

A landfill method for strengthening ventilation and reducing the drainage of methane by taking advantage of wind power relates to a quasi-aerobic garbage landfill process. The landfill method is characterized in that a wind housing (1) is mounted at the tail end of a percolating liquid collecting main pipe (4), wherein, the ratio of an inlet diameter and an outlet diameter equal of the wind housing (1) ranges from to 8:1 to 4:1; a wind cap (2) is mounted at the top end of a vertical air duct (3) and rotates under double drive of external natural wind and difference between internal temperature and external temperature of a landfill body, so as to generate negative pressure and centrifugal force, continuously draw out landfill air in the air duct (3), drive the wind cap (2) at the tail end of the percolating liquid collecting main pipe (4) to continuously suck outside air into a garbage body, thereby forming a sustaining and efficient ventilating system, promoting aerobic decomposition and stability of garbage, and greatly reducing methane discharge. The method consumes no power, thereby greatly reducing the discharge of the quasi-aerobic garbage landfill methane and achieving the energy conservation and the drainage reduction. The invention has the advantages of simple process, convenient disassembly and assembly, low cost, and can be widely applied to domestic garbage landfill yards.

Owner:TONGJI UNIV

Design plan of (no-gap) type crankshaft driving piston reciprocating compressor

InactiveCN1900518AWork lessImprove exhaust efficiencyMulti-stage pumpsPositive-displacement liquid enginesDesign planHigh-pressure area

The disclosed design scheme is based basic structure of traditional crankshaft drive model piston reciprocating type compressor with largest quantity of production and marketing in world. Characters are that when carrying out exhaust operation, carrying out vent valve, piston dashes out cylinder entering into high-pressure area. Thus, 'no clearance' state with no geometrical space is formed among piston, vent valve piece, and block of suction valve. Hermetically sealed construction of tapering shape cover is formed between block of suction valve and contact surface outside top part of piston. The invention creates condition for raising operational compression ratio or exhaust efficiency for the model of compressor.

Owner:梁嘉麟

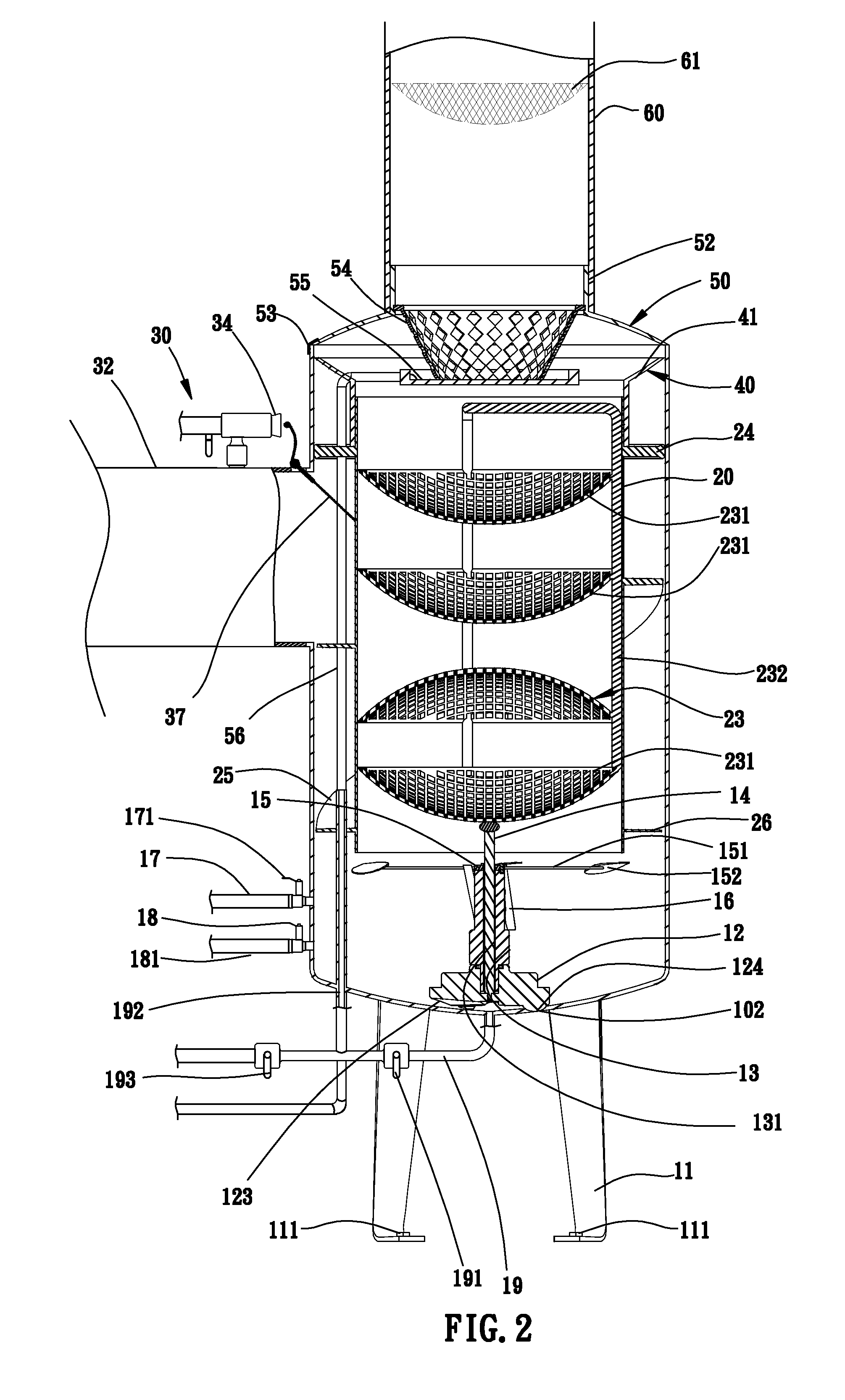

Environmentally-friendly Exhaust Device

InactiveUS20140157991A1Enhanced efficiencyEnhance environmentally friendly effectUsing liquid separation agentSeparation devicesPropellerEnvironmentally friendly

An environmentally-friendly exhaust device comprises an outer tank. An inner pipe is disposed inside the outer tank. An air propeller is disposed below the inner pipe inside the outer tank. An upper guiding plate and a lower guiding plate are disposed on a surface of the inner pipe for connecting with the outer tank. Thereby, air, oil mist and water are entered between the outer tank and the inner pipe; and are guided to the air propeller below through the upper and the lower guiding plates; and then are exhausted through the inner pipe upwardly. The purification of oil mist is processed integrally for enhancing the efficiency of exhaust and achieving the environmentally-friendly effects. Multiple layers of filter screens provided for carrying out multiple filtering are economically effective and can further enhance the environmentally-friendly effects.

Owner:YANG CHUN REI +1

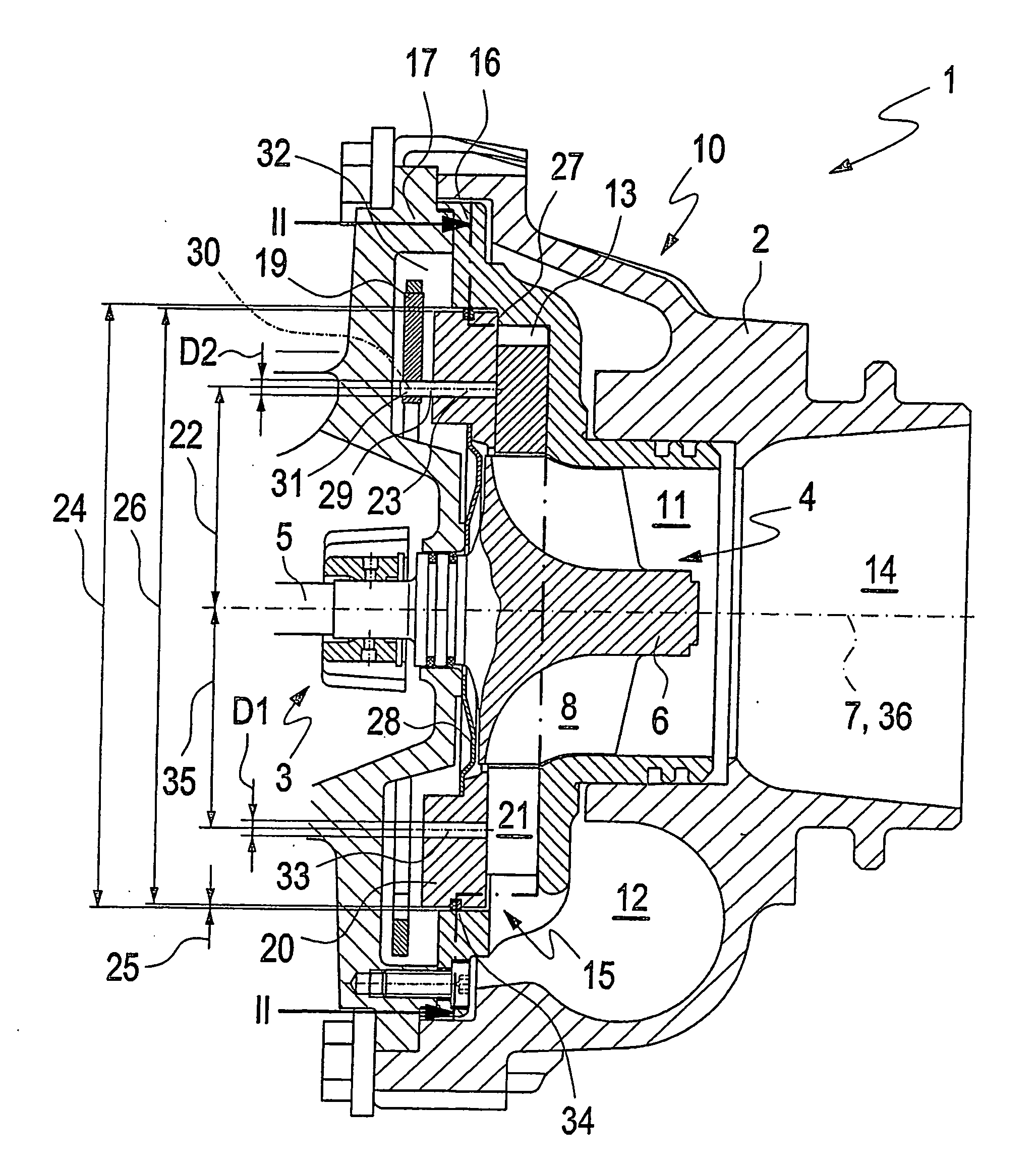

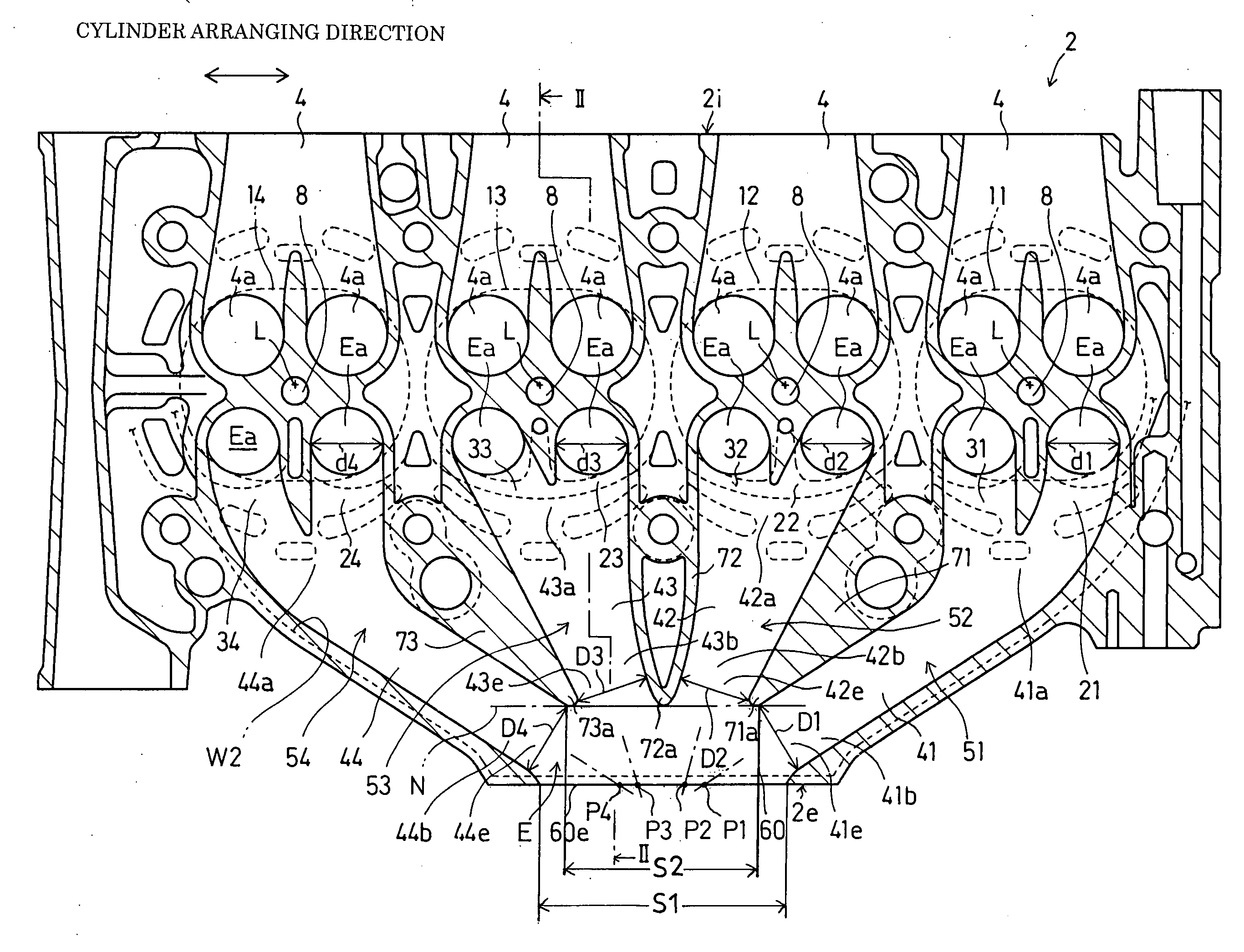

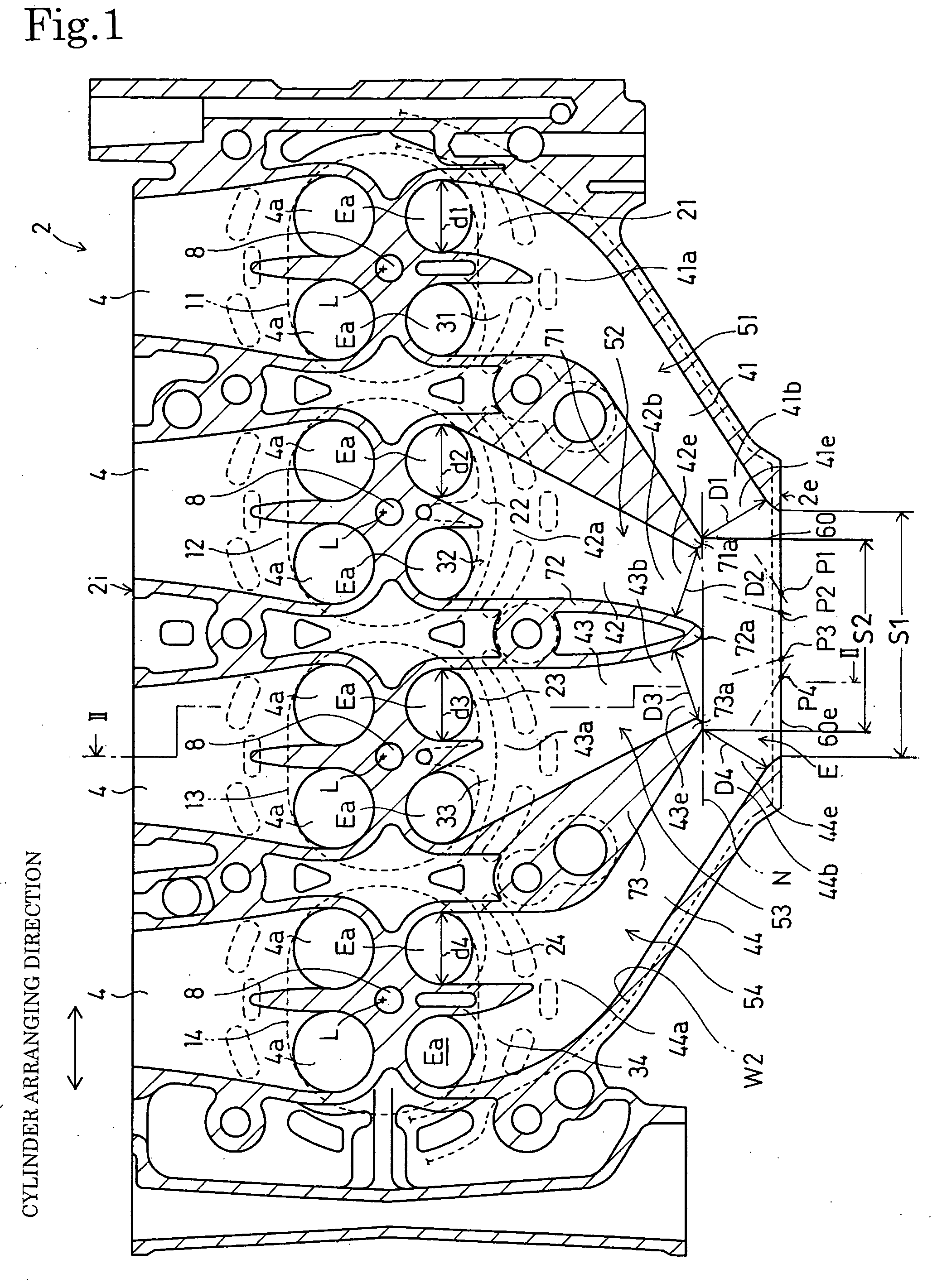

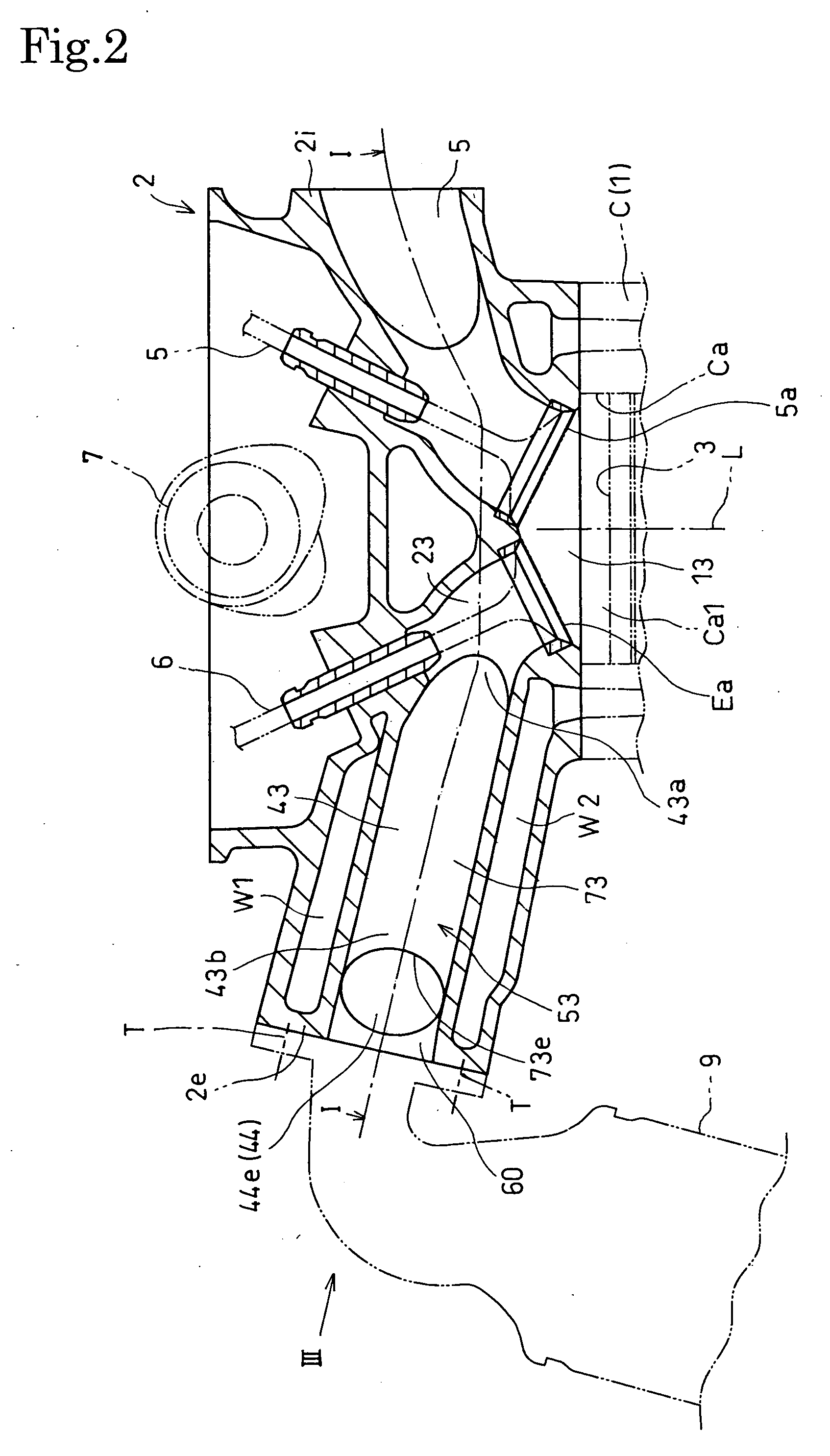

Multiple-cylinder internal combustion engine having cylinder head provided with centralized exhaust passageway

InactiveUS20100251704A1Improve exhaust efficiencyIncrease output of engineCylinder headsSilencing apparatusExhaust valveCombustion chamber

A cylinder head 2 for a multiple-cylinder internal combustion engine is provided with a centralized exhaust passageway E. The centralized exhaust passageway E includes individual exhaust passageways 51 to 54 connected to combustion chambers defined by recesses 11 to 14, and a central passageway 60 collecting the exhaust gas flowing through the individual exhaust passageways 51 to 54. Each of the exhaust passageways 51 to 54 has two branch passageways 21,31; 22,32; 23,33; 24,34 extending from the exhaust ports Ea opened and closed by exhaust valves 6, and a merging passageway 41; 42; 43; 44 having one end connected to the two branch passageways. The respective passage diameters D1 to D4 of the merging passageways 41 to 44 are substantially equal to the passage diameters d1 to d4 of the branch passageways. The merging passageways 41 to 44 and the central collecting passageway 60 are surrounded with water jackets W1 and W2 from above and below. Thus exhaust gas cooling efficiency can be improved without enlarging the cylinder head provided with the centralized exhaust passage.

Owner:HONDA MOTOR CO LTD

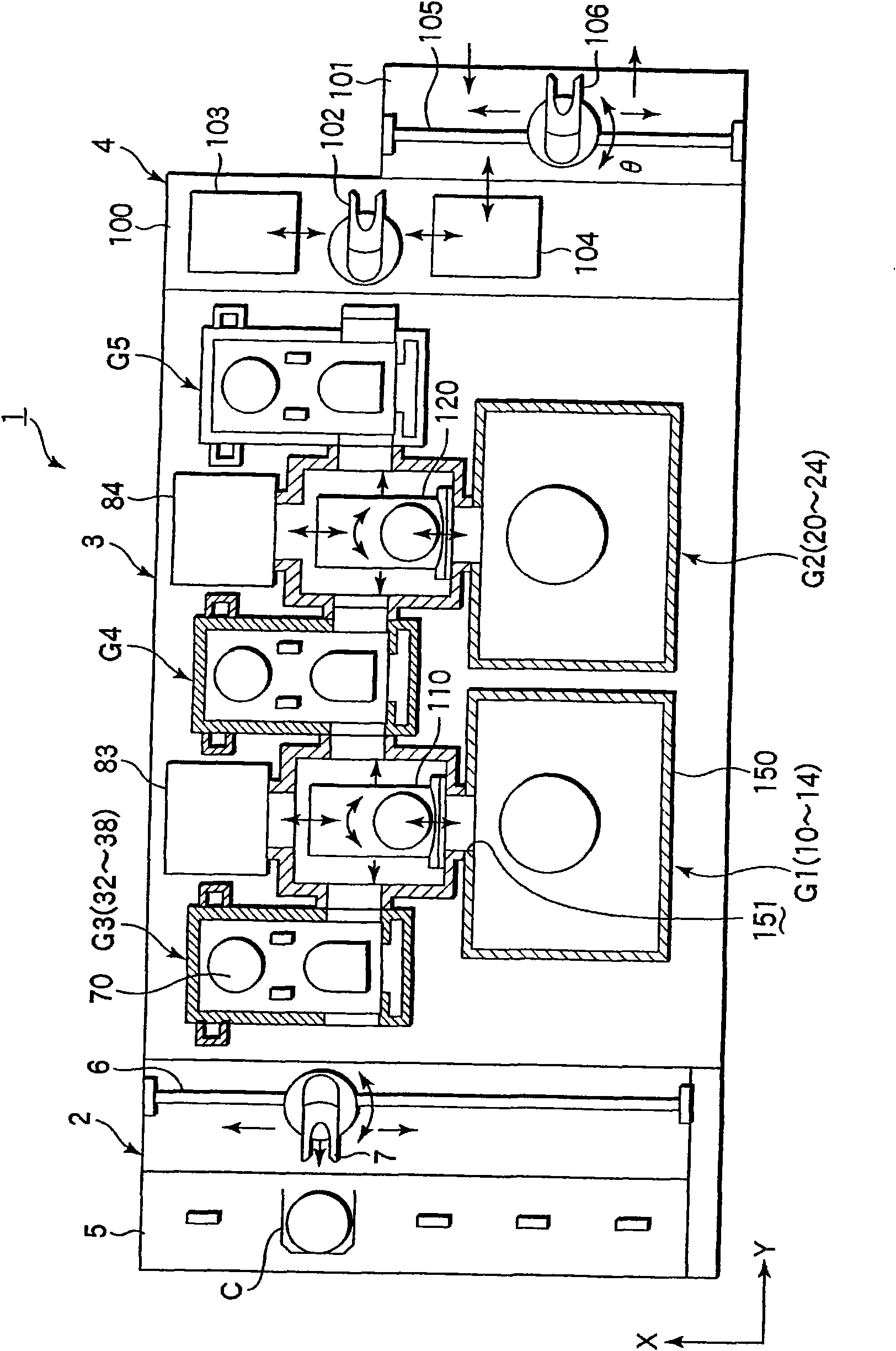

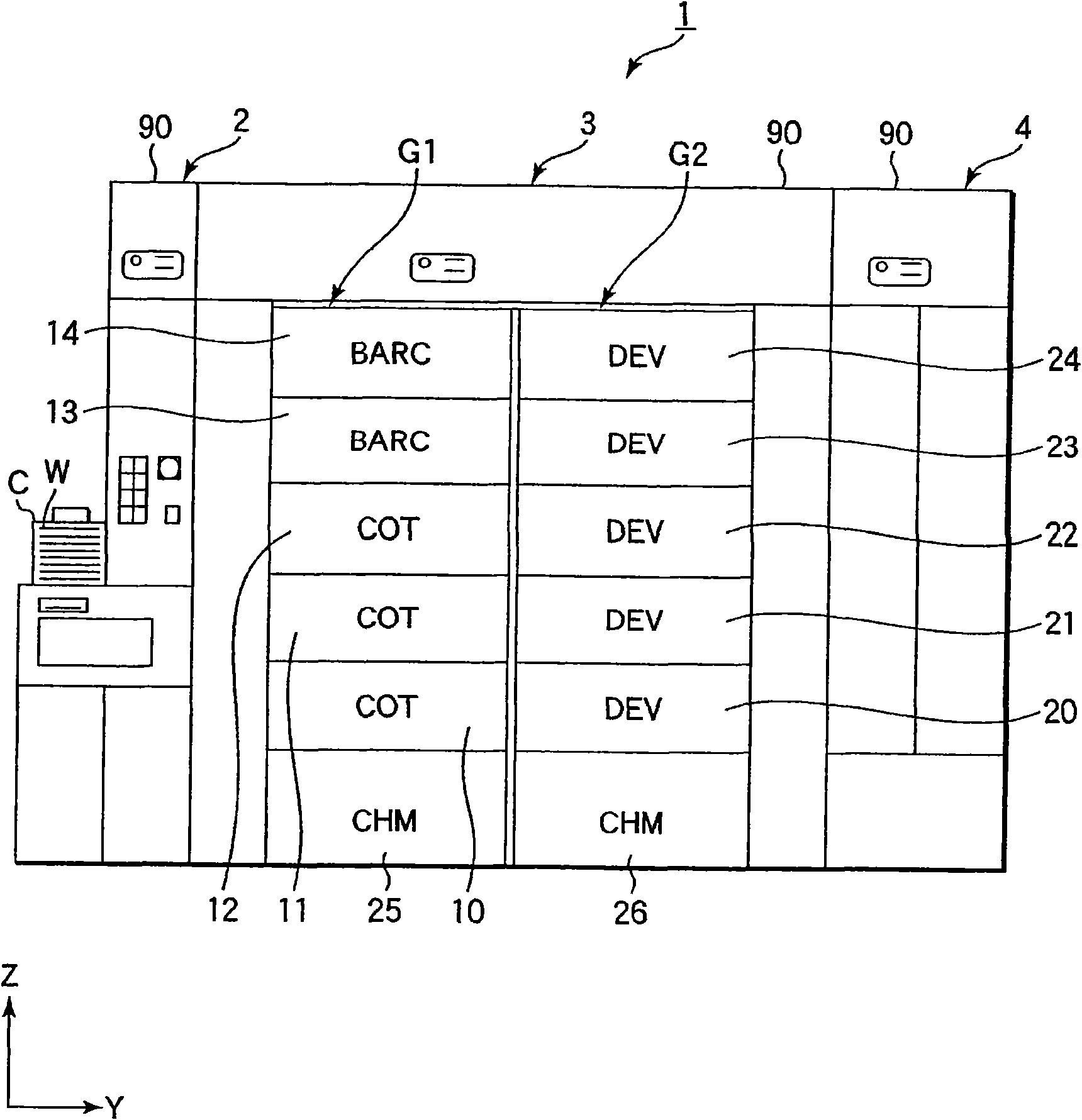

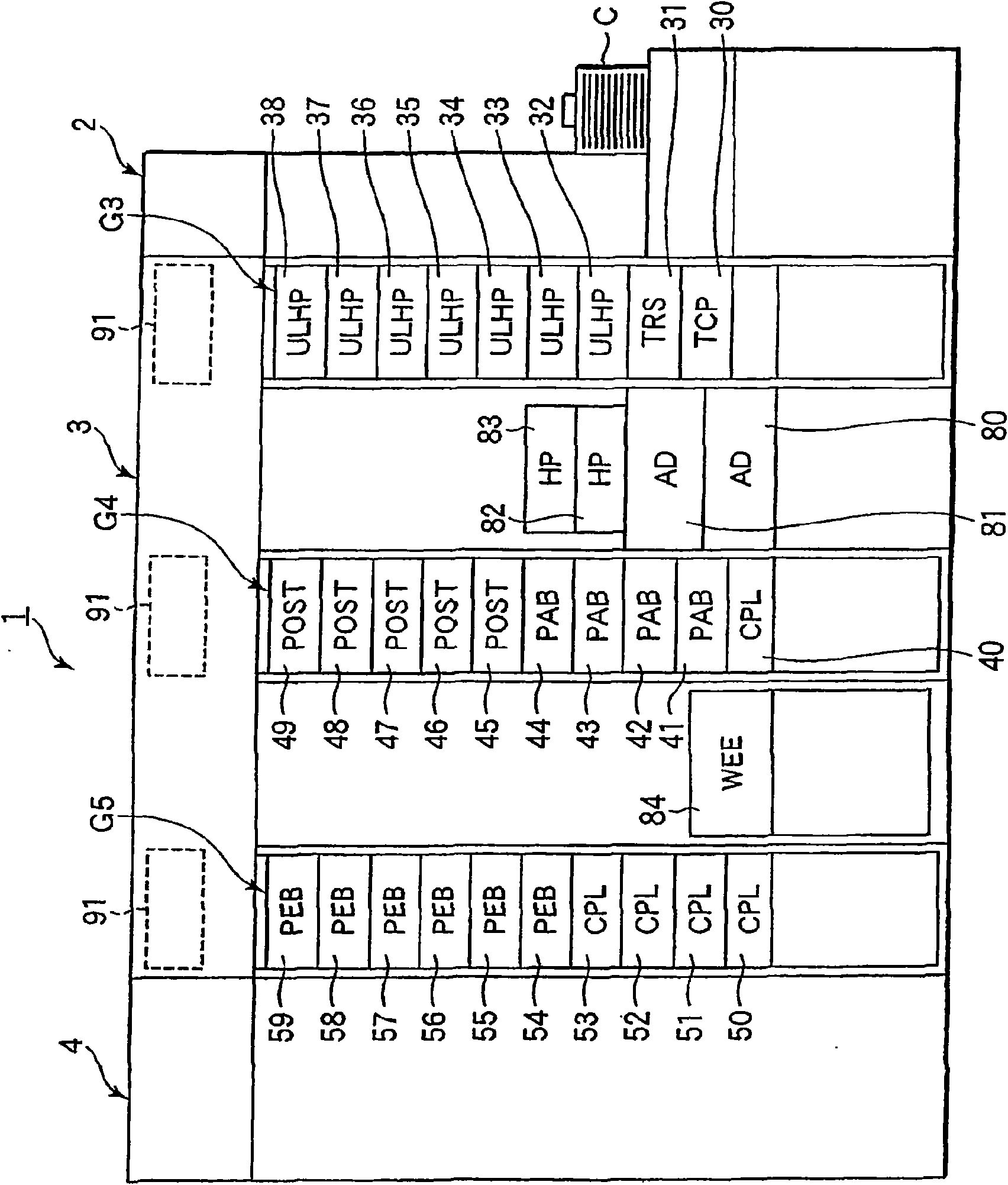

Substrate processing apparatus

ActiveCN101615566AImprove exhaust efficiencyEfficient recyclingPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistAirflow

The invention provides a substrate processing apparatus to form a resist film by supplying a resist liquid to a surface of a wafer (W) rotated by a rotating chuck (16) from a spraying nozzle (17) and expanding the surface, comprising an outer cover (62) surrounding an outer side wall (62a) at outside of the wafer kept by the rotating chuck, an inner cover located below an outer periphery of the wafer, and a middle cover (64) fixed on an inner periphery of the outer side wall of the cover, meanwhile located at a gap (65) between the inner periphery of the outer side wall of the cover and the outer periphery of the wafer and communicating with a plurality of vents (66) at an upper part of the outer cover and the outer side of the inner cover. When supplying the resist, the vents are closed by a closing part, and airflow is blocked. When forming the resist film, the vents are opened and airflow can flow through the vents.

Owner:TOKYO ELECTRON LTD

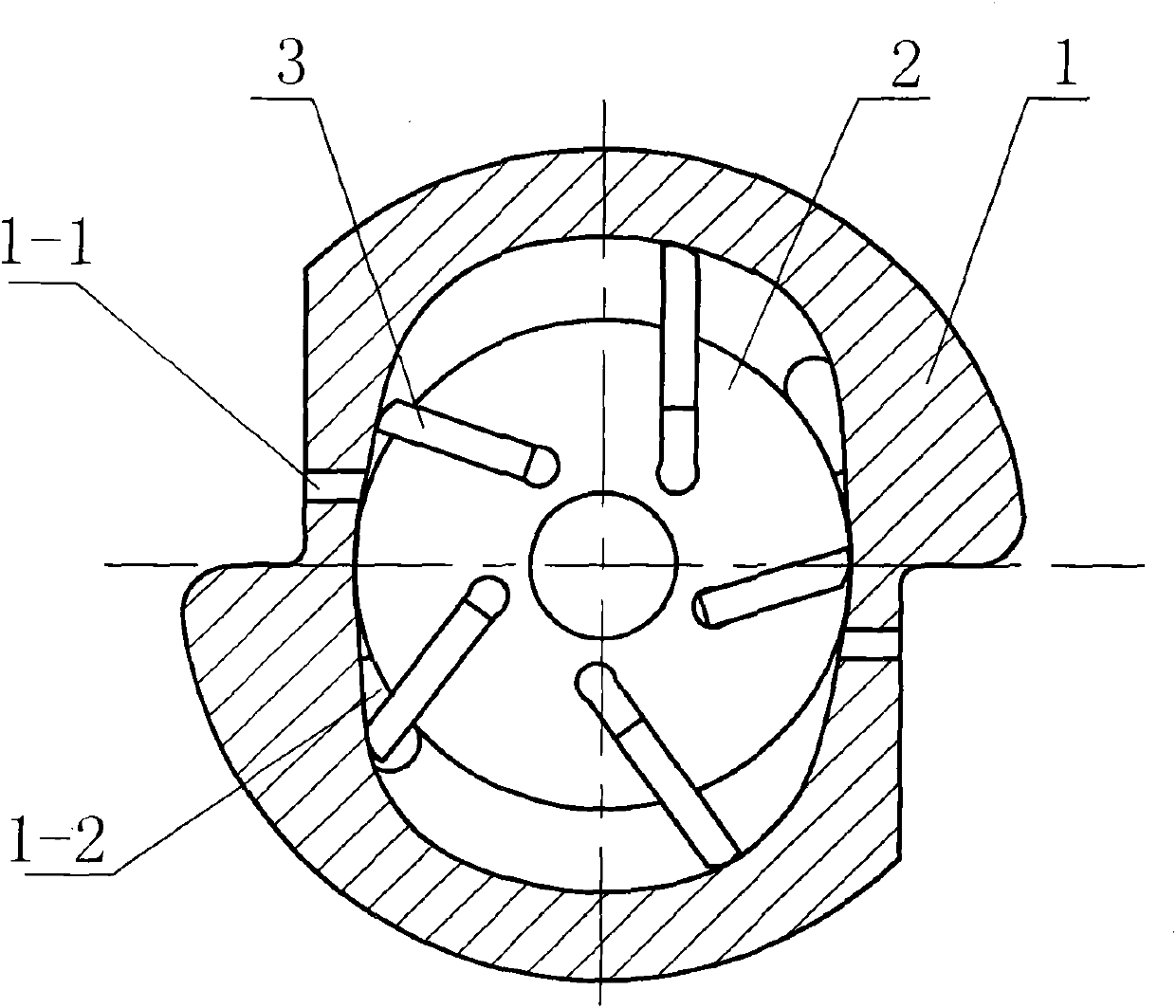

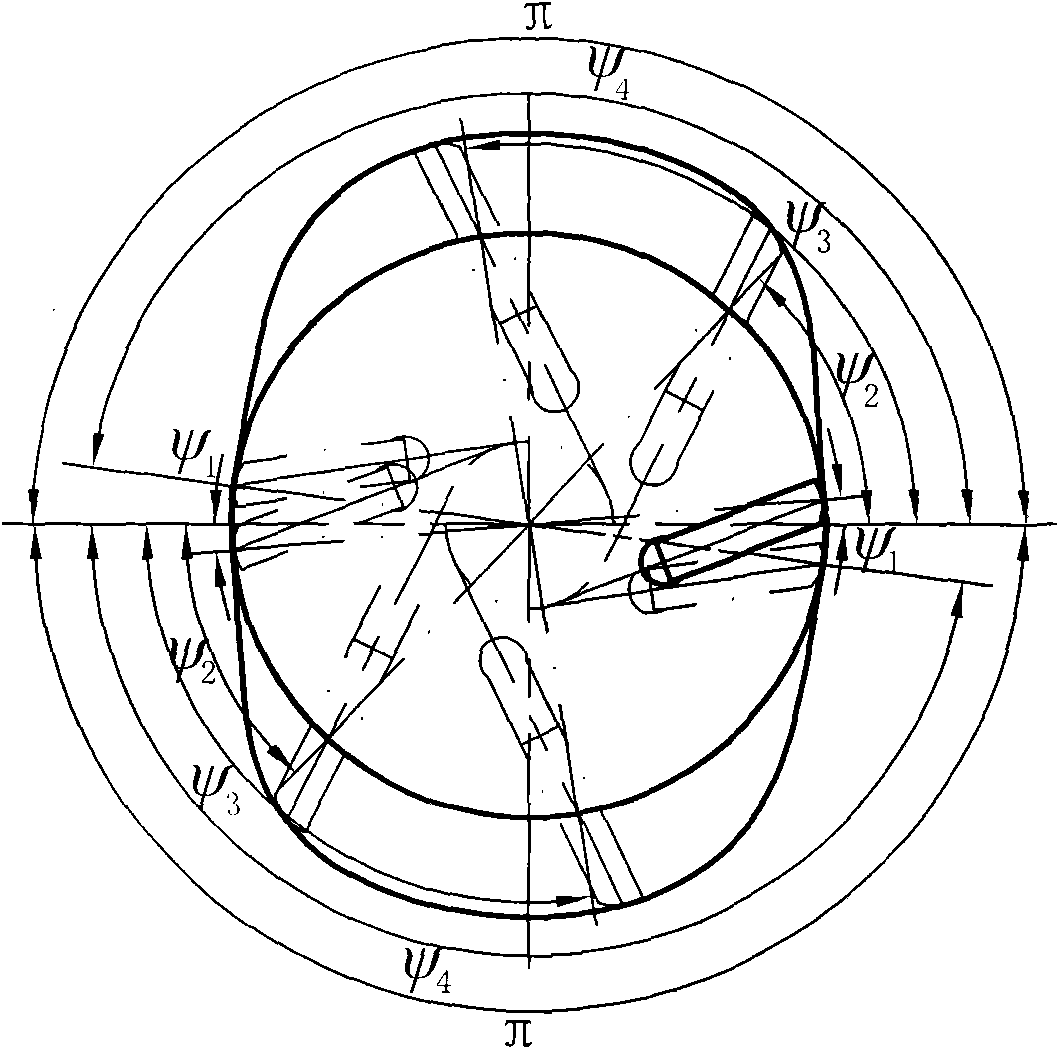

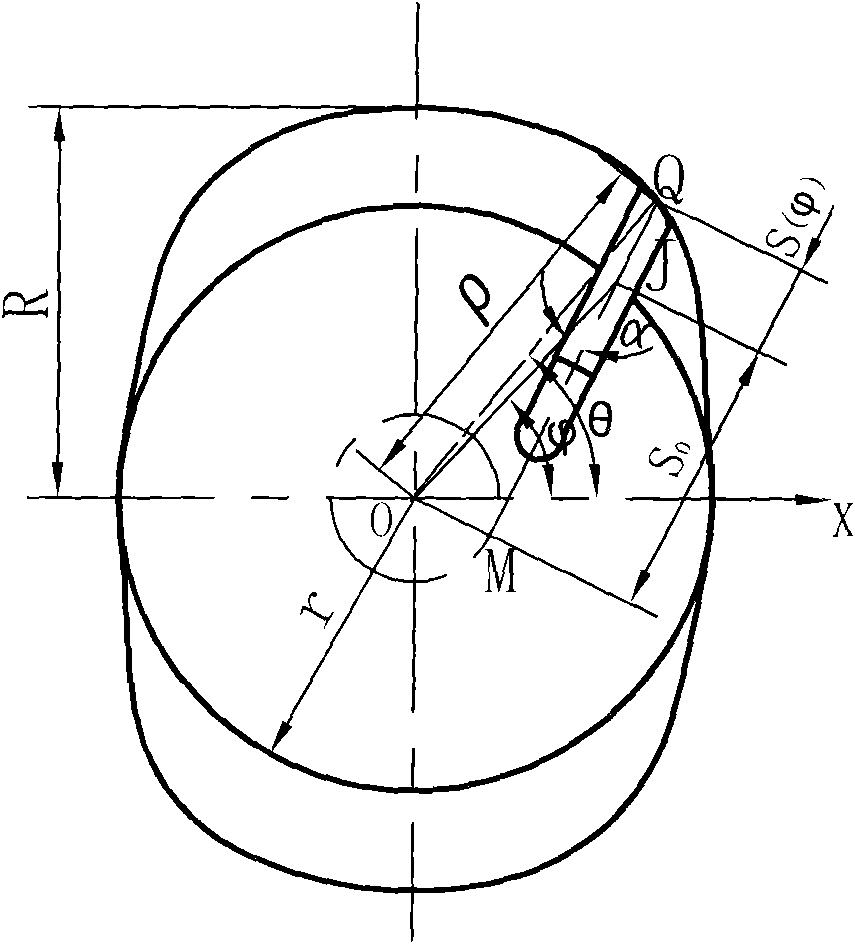

Rotary vane compressor

InactiveCN101975164ASmall inertia forceImprove sealingRotary piston pumpsRotary piston liquid enginesTruckMoving speed

The invention discloses a rotary vane compressor and relates to a rotary vane compressor for a vehicle air conditioner, in particular to a rotary vane compressor for an air conditioner on a sedan car, an SUV, a mini bus and a light / heavy truck. The compressor comprises a cylinder body, a rotor, vanes, a front end cover and a back end cover, wherein symmetrical working cavities are formed by the center line of the cylinder body and the contour in the cylinder body; and on any cross section of each working cavity, a first circular arc section contour, a first vane extension section contour, a second circular arc section contour, a first vane constriction section contour, a third circular arc section contour, a fourth circular arc section contour, a second vane extension section contour, a fifth circular arc section contour, a second vane constriction section contour and a sixth circular arc section contour are sequentially distributed along the contour of a rotor angle of 0-360 degrees in the counterclockwise direction, and the tail end of each section contour form smooth connection with the head end of the adjacent contour. The compressor increases the displacement, improves the compression efficiency and the volume efficiency, ensures that the moving speed and acceleration of the vanes are not subject to sudden change, realizes that the vanes do not impact the cylinder body and simultaneously improves the sealability between the cylinder body and the rotor.

Owner:CHONGQING UNIV

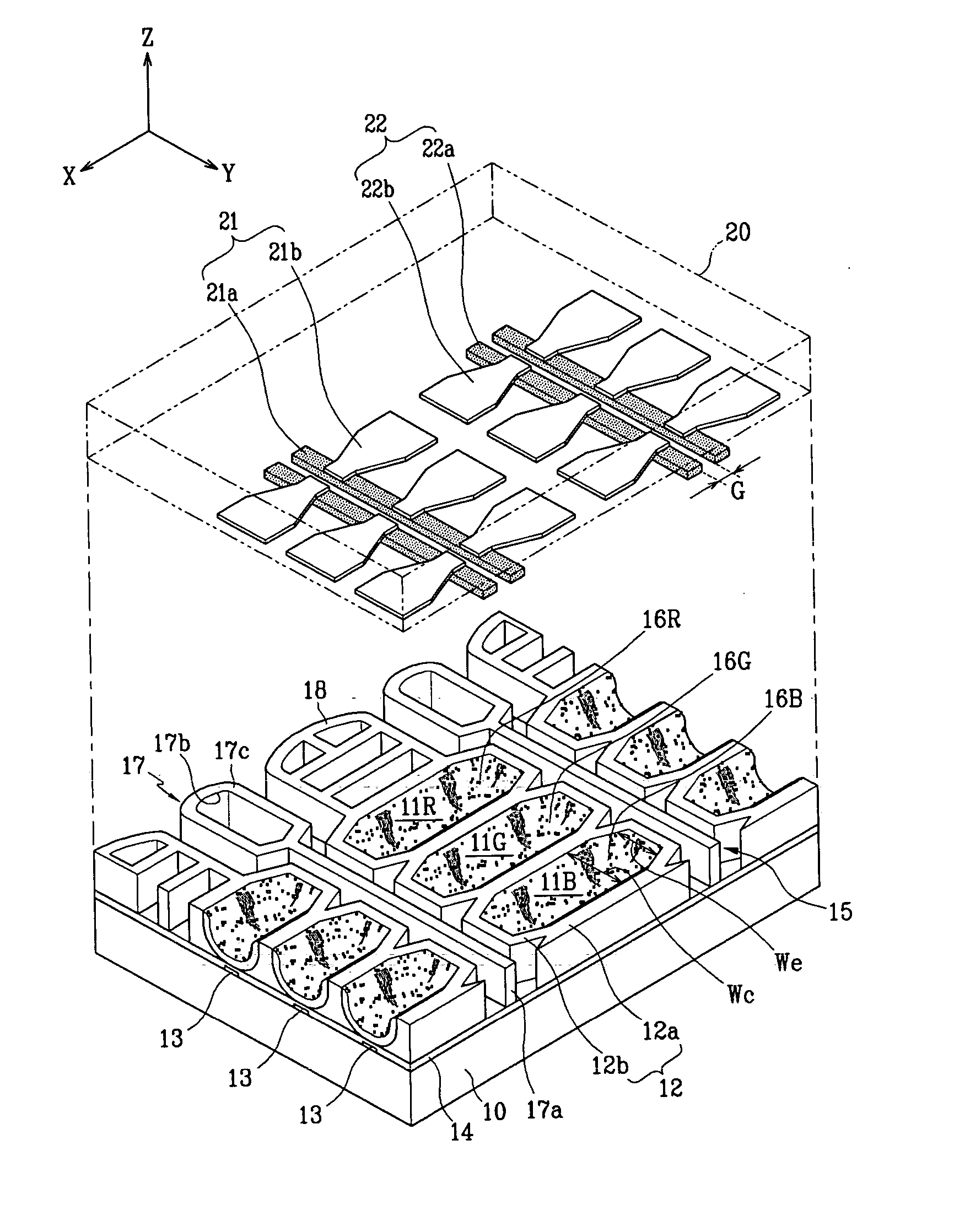

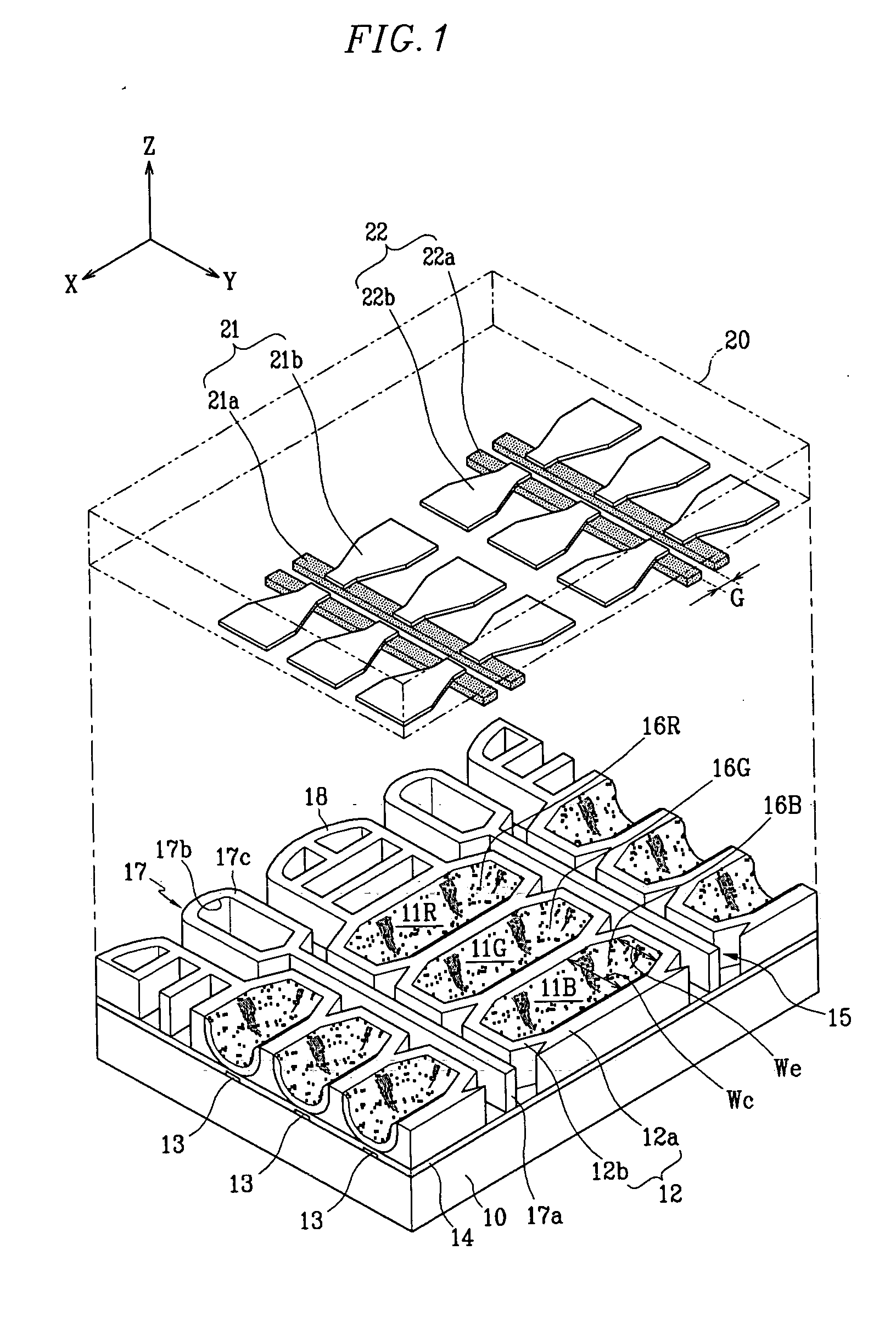

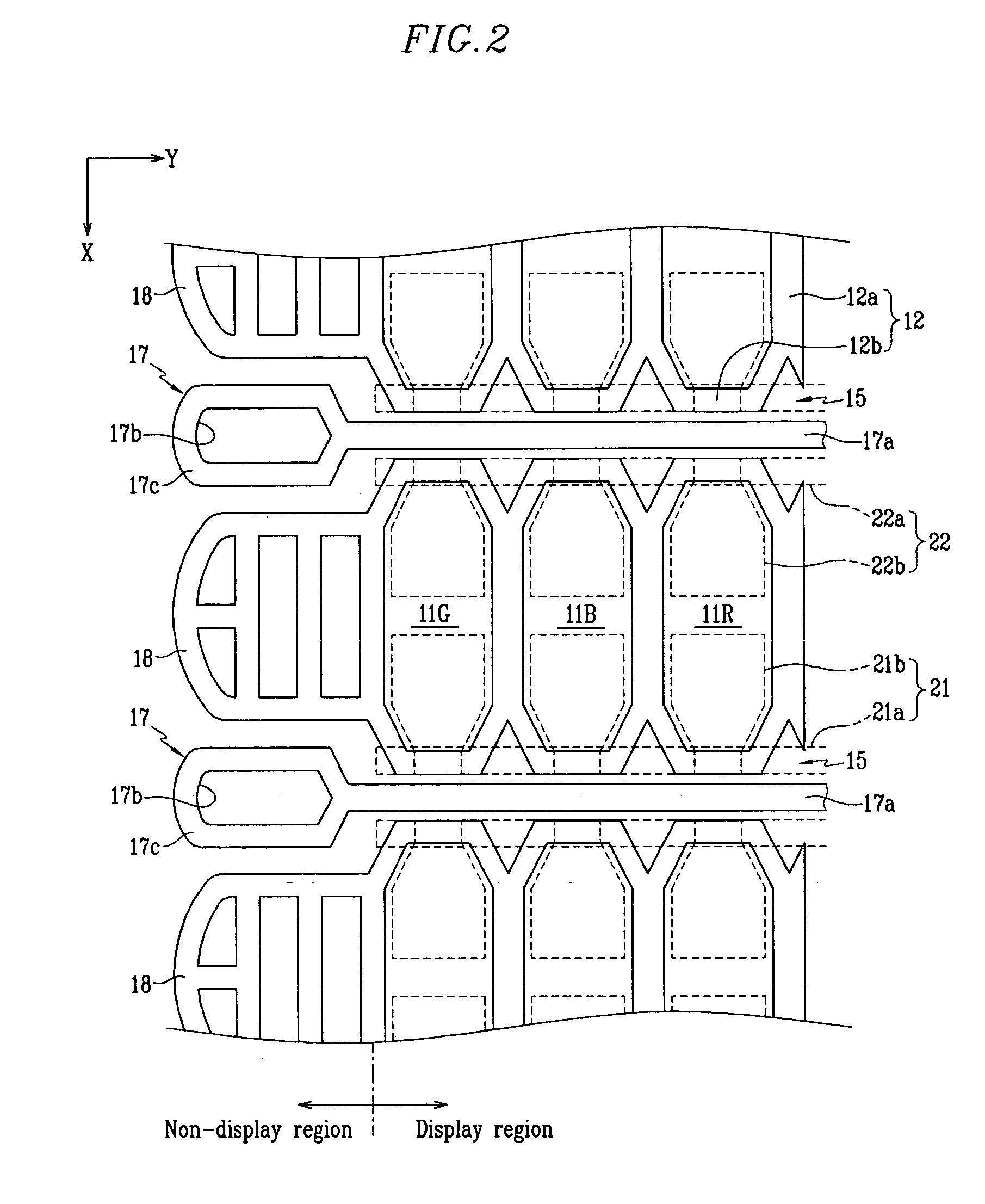

Plasma display panel

InactiveUS20050242728A1Improve discharge efficiencyPrevent bright image stickingAddress electrodesSustain/scan electrodesPhosphorPlasma display

A plasma display panel includes a first substrate, and a second substrate opposing the first substrate. A plurality of address electrodes are formed on the first substrate along a first direction, and a plurality of barrier ribs are mounted between the first and second substrates and defining a plurality of discharge cells that are formed into a plurality of rows along a second direction which is substantially perpendicular to the first direction. Non-discharge regions are formed between the respective rows of the discharge cells, and a plurality of transverse barrier ribs are formed along the second direction respectively within the non-discharge regions. Each of a plurality of phosphor layers is formed in a respective one of the discharge cells. Display electrodes are formed on the second substrate. At least one end of each of the transverse barrier ribs includes an annular branched segment.

Owner:SAMSUNG SDI CO LTD

Straddle type vehicle including air exhaust duct for continuously variable transmission

InactiveUS7882911B2Improve exhaust efficiencyImprove efficiencyWheel based transmissionFrictional rollers based transmissionContinuously variable transmissionAerospace engineering

A straddle-type vehicle with enhanced heat exhaust efficiency in a transmission case housing a continuously variable transmission. The continuously variable transmission and an engine are arranged forward of a rear wheel 4. An air intake duct introduces outside air into the transmission case and an air exhaust duct exhausts air from the transmission case. The air exhaust duct is connected to and extends upward from a top portion of the transmission case. The air exhaust duct has an air exhaust port that is positioned above the transmission case.

Owner:YAMAHA MOTOR CO LTD

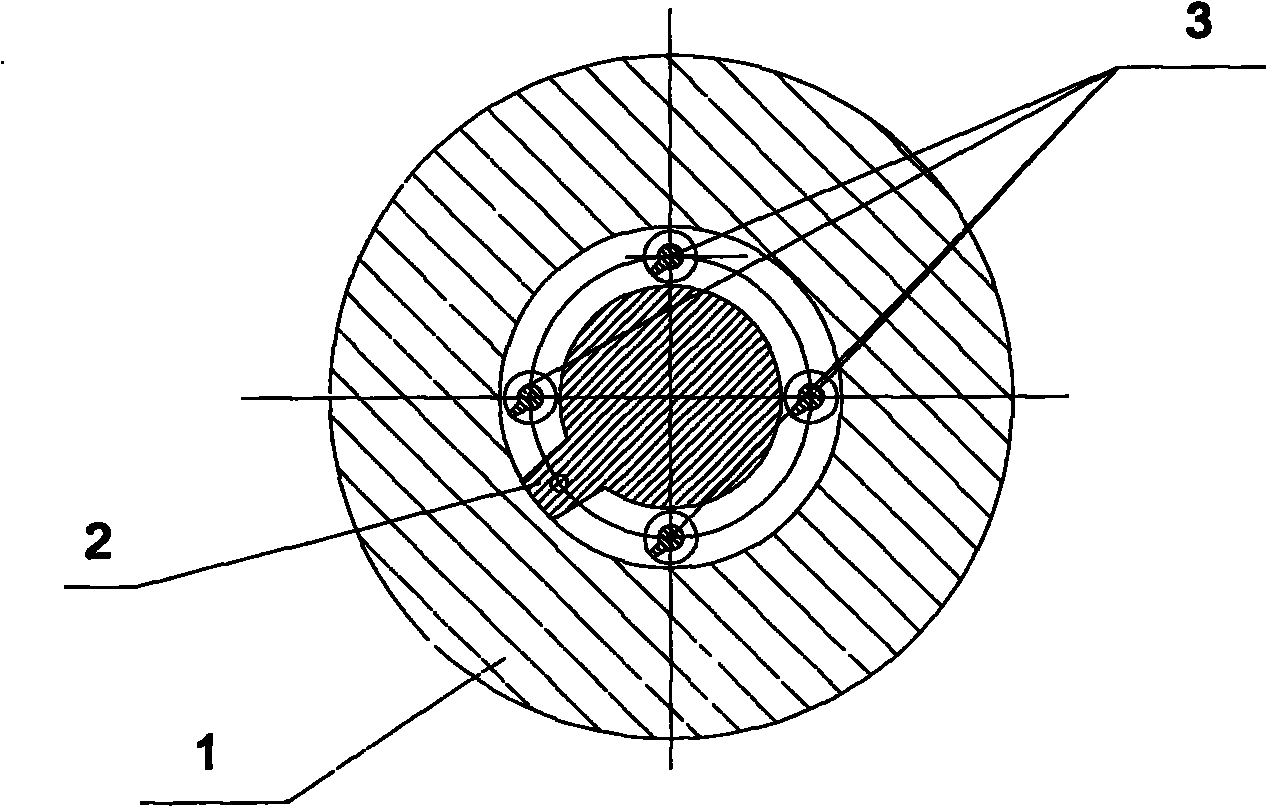

Seven planet screw combination device and method for plastifing, exhausting and extruding

The invention relates to a seven planet screw combination device and method for plastifing, exhausting and extruding, comprising a screw mechanism, a cylinder, a material inlet, an air exhaust, a material outlet and a power mechanism. The screw mechanism comprises a center screw and six planet screws; the axis of the center screw is coincident with the axis of the cylinder; the axes of the six planet screws are all parallel to the axis of the center screw and surrounds the center screw; the center screw is meshed with each planet screw; each planet screw is meshed with two adjacent planet screws; the lines connecting the center of each planet screw form a regular hexagon; the center distance of any two adjacent planet screws is equal to the length of a side of the regular hexagon; the center screw is arranged in the center of the regular hexagon; and the power mechanism is respectively connected with the screw mechanism and the cylinder. The invention also provides a method for plastifing, exhausting and extruding. The invention has the advantages of adjustable retention time, low power consumption, thorough air exhaust and self-cleaning function, etc.

Owner:GUANGDONG IND TECHN COLLEGE

Water intake preventing automobile exhaust pipe utilizing tesla valve

ActiveCN111963290AImprove athletic abilityHigh speedExhaust apparatusSilencing apparatusWater flowEngineering

The invention relates to the technical field of automobile exhaust and discloses a water intake preventing automobile exhaust pipe utilizing a tesla valve. The water intake preventing automobile exhaust pipe comprises an exhaust pipe; a shunt pipe is rotatably connected into the exhaust pipe; a turbine rod is fixedly connected into the shunt pipe; a radiating pipe is connected with the external part of the exhaust pipe in a sleeving manner; a rear radiating shell is movably connected with the external part of the radiating pipe; an exhaust cover is fixedly connected with the external part of the exhaust pipe; an anti-reflux pipe is fixedly connected into the exhaust cover; and the tesla valve is arranged in the anti-reflux pipe. Through cooperative application of the anti-reflux pipe, thetesla valve, a movable block, a ventilating opening, a reset spring and a sealing plate, external water is effectively prevented from entering the exhaust pipe to realize a waterproof effect, and automobile safety is ensured; and under the action of the tesla valve, gas backward flow is effectively avoided, so that the possibility that an engine leaks oil due to gas backward flow is avoided, the automobile safety is further ensured and the using effect of the water intake preventing automobile exhaust pipe is effectively improved.

Owner:克康湘潭排气控制系统有限公司

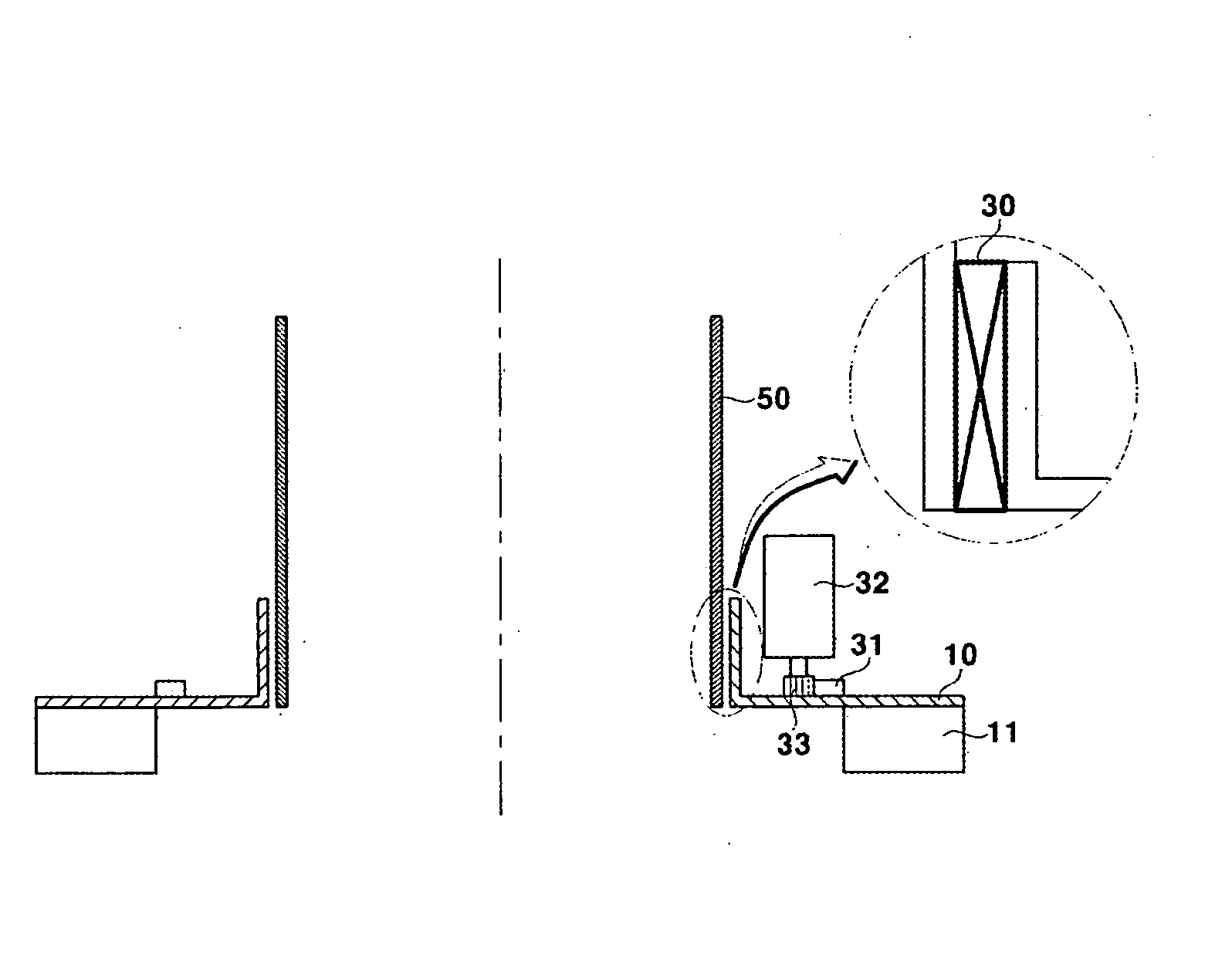

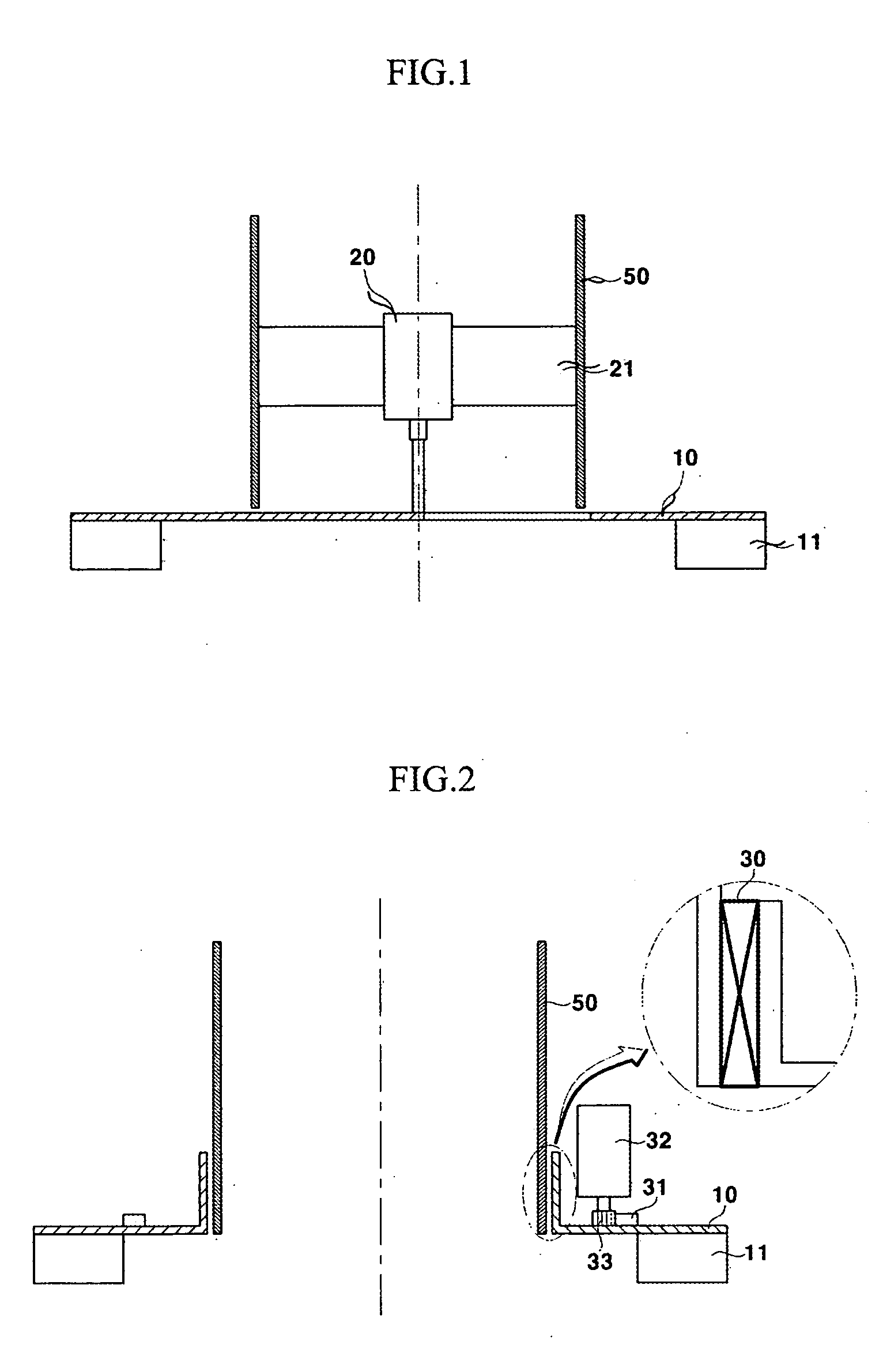

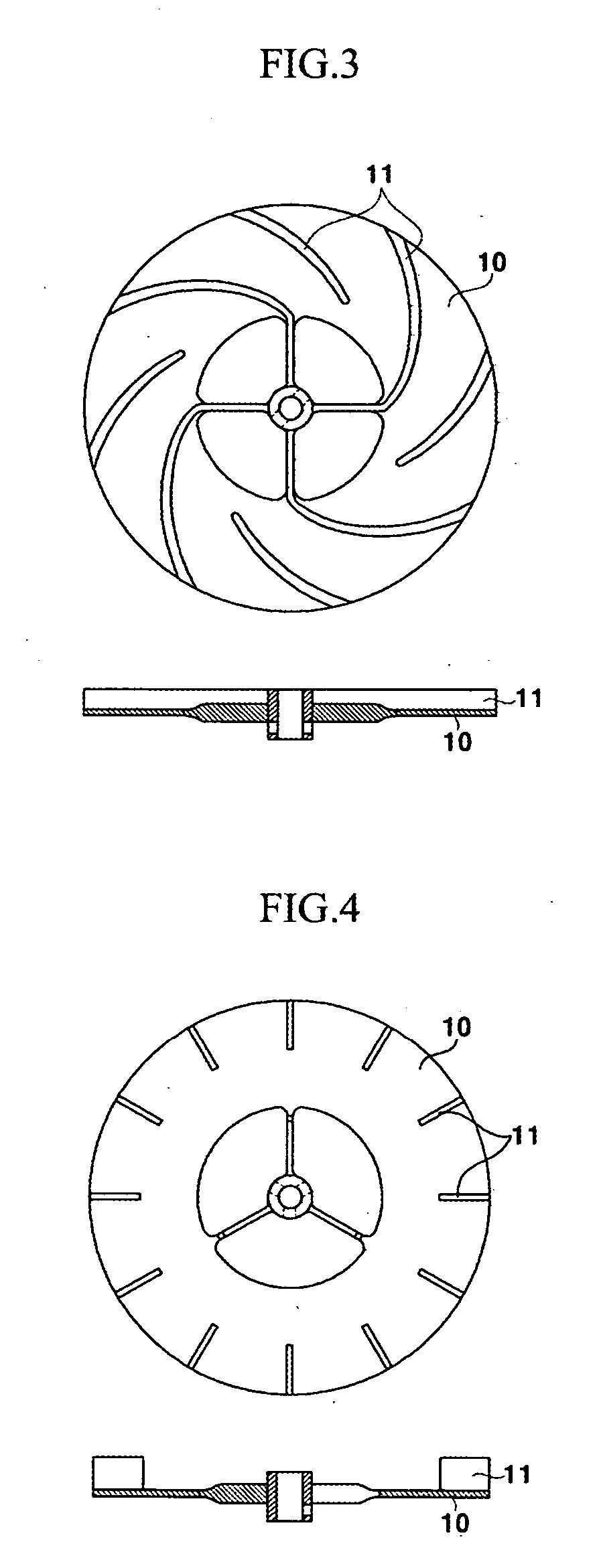

Projector exhaust fan

InactiveUS7018048B2Improve exhaust efficiencyEfficiently sucking the air inside the projectorTelevision system detailsProjectorsSiroccoEngineering

Owner:SEIKO EPSON CORP

Local exhaust ventilator with rotating swirler

InactiveUS20050164628A1Reduce noiseSimple structurePump componentsLighting and heating apparatusExhaust gasAerospace engineering

The present invention relates to a local exhaust ventilator which has a rotating swirler to make a swirl flow for increasing exhaust efficiency by expanding an exhaust region. Disclosed is a local exhaust ventilator with a simplified structure, wherein noise due to interference of turbulence is reduced and exhaust gas is removed at a wide area. The local exhaust ventilator includes a disk-shaped swirler rotatably mounted at an exhaust tube, a wing installed at the swirler perpendicular thereto to form a swirl flow, and a driving unit installed at the exhaust tube to rotate the swirler.

Owner:POSTECH ACAD IND FOUND

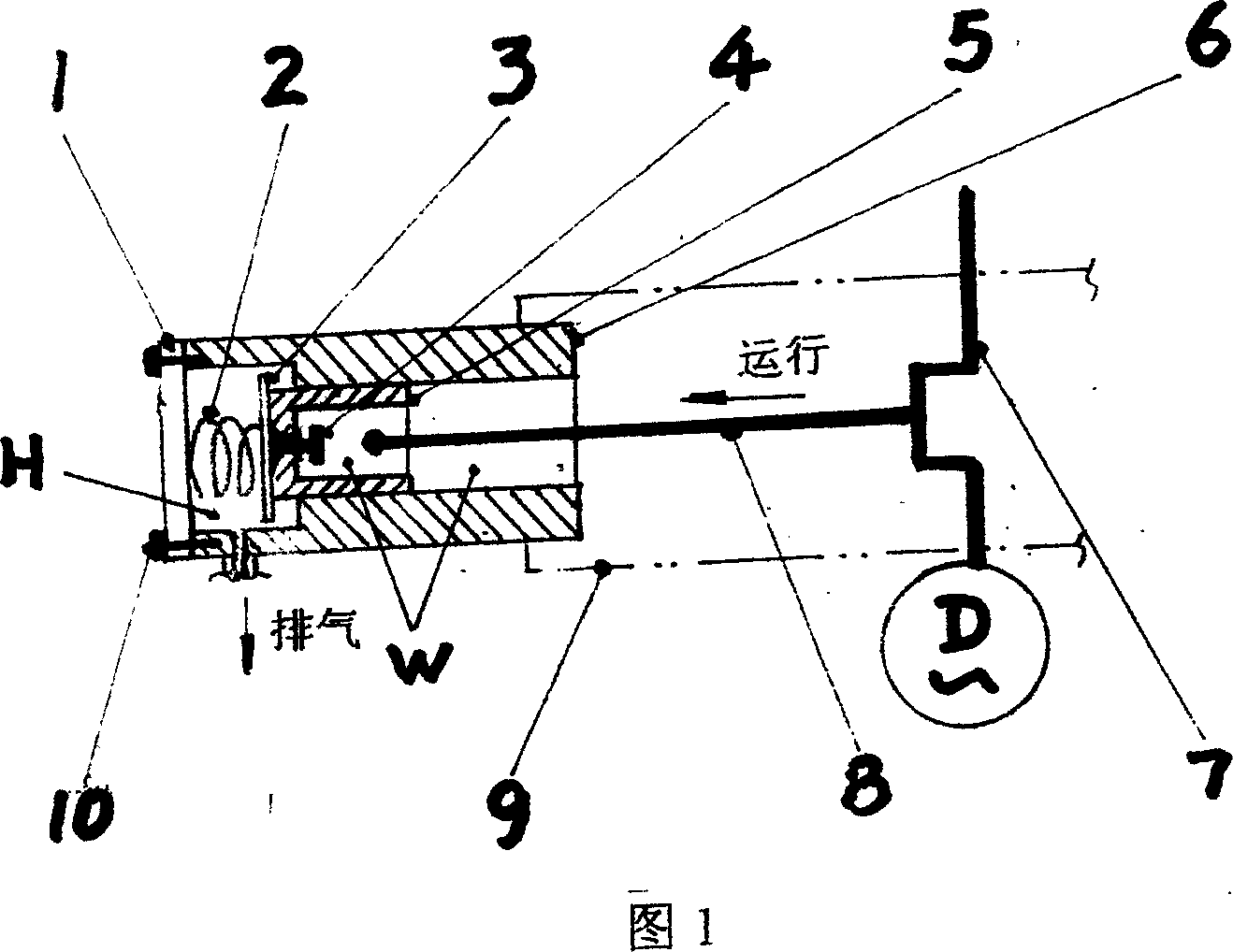

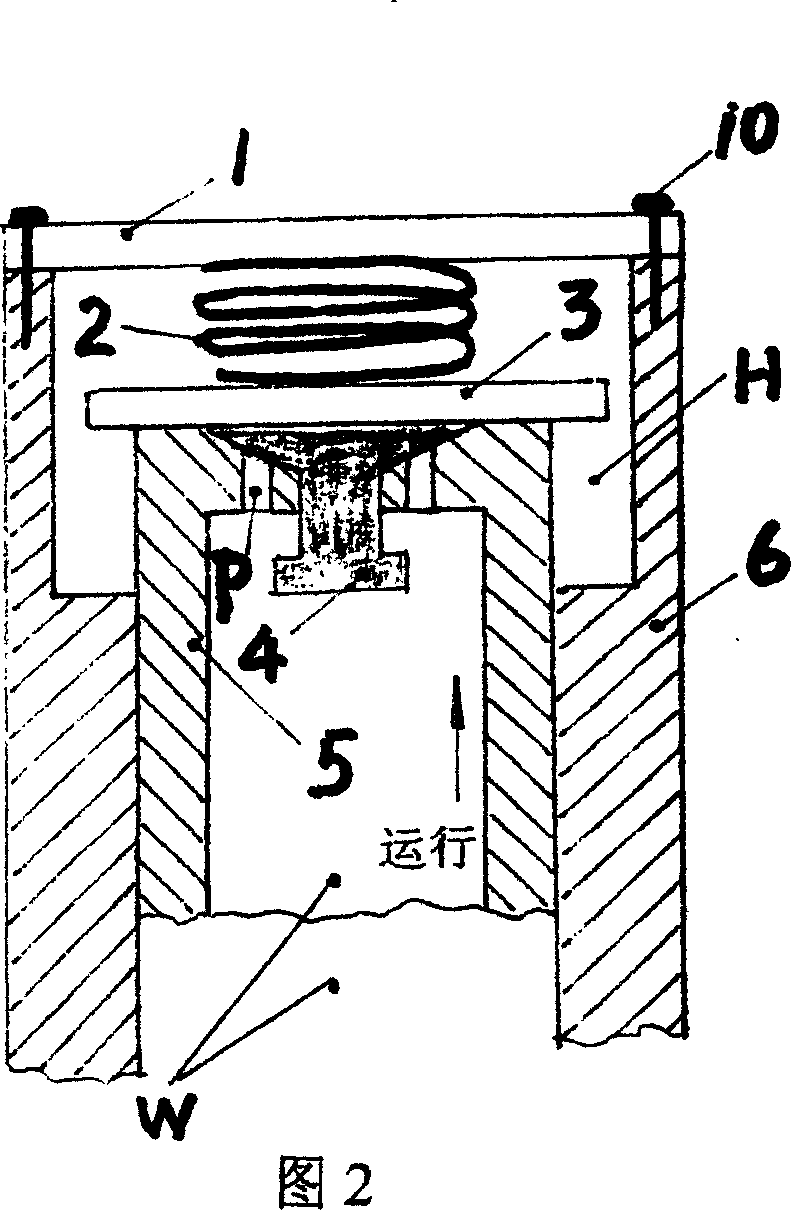

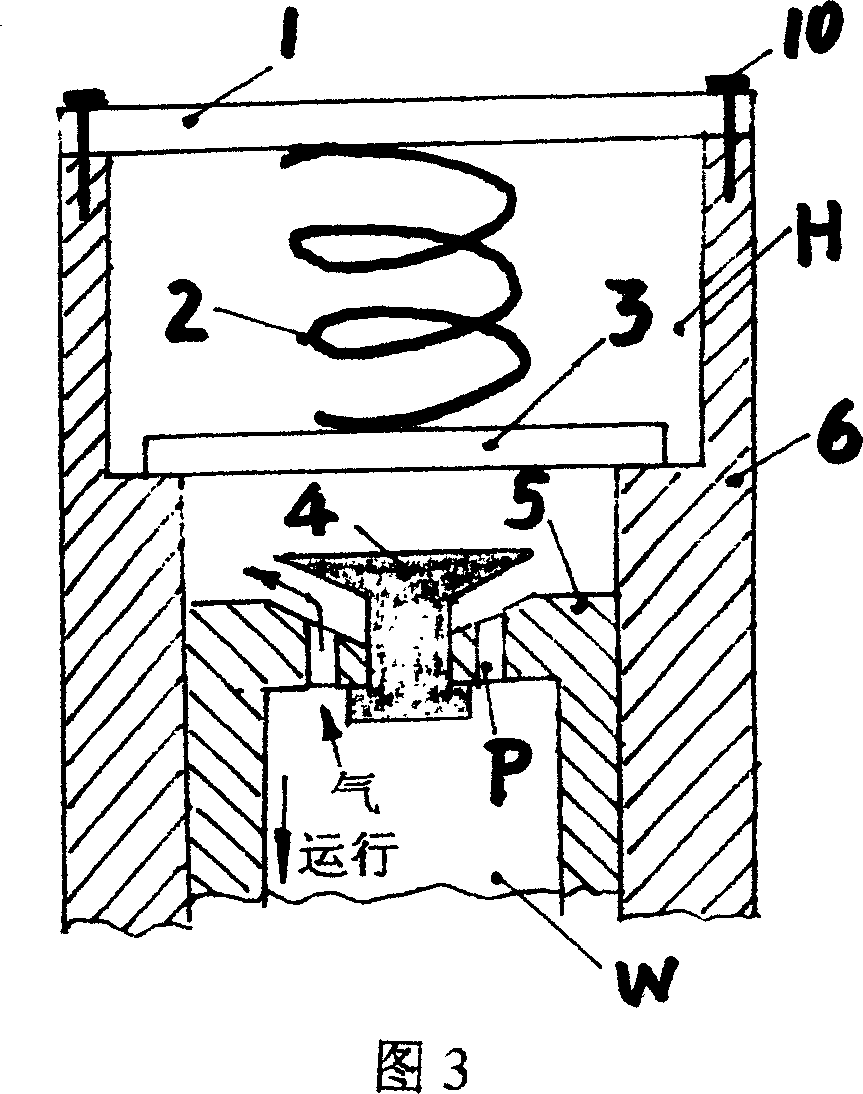

Design scheme for gap-free piston reciprocating compressor

InactiveCN1928363AWork lessImprove exhaust efficiencyPositive displacement pump componentsPump controlDischarge efficiencyEngineering

The invention relates to a designing scheme of a no-gap piston reciprocation compressing engine, which is based on the basic structure of conventional piston reciprocation compressing engine with the most production and sale, characterized in that gasvalve chip (3) driven by piston (5) in discharging process dashes out of cylinder (6) and enter into high pressure region (H), here the no-gap state among piston (5), gasvalve chip (3) and sorption valve block (4) while conical-capping sealing structure is formed by the contacting face between sorption valve block (4) and the outside of piston (5) top. Based on the said characters, there is the condition to widely improve working compressing ratio or discharging efficiency of the compressing engine so that conventional piston reciprocation compressing engine is presented with a brand-new appearance.

Owner:梁嘉麟

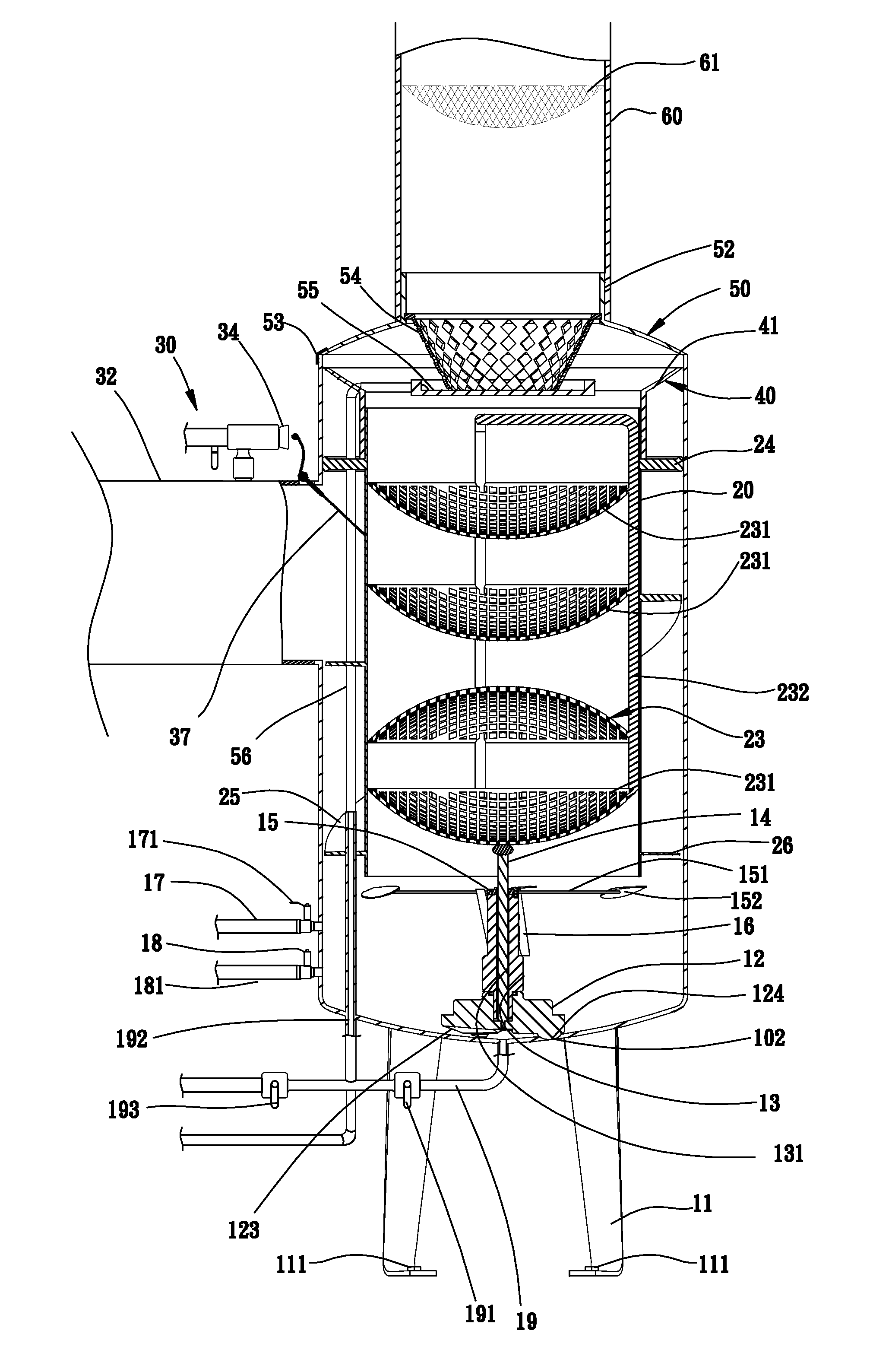

Household electric heating cooker

ActiveCN104000481ASolve the problem of low exhaust efficiencyImprove exhaust efficiencyPressure-cookersBiochemical engineeringAtmosphere

The invention discloses a household electric heating cooker. The household electric heating cooker comprises a utensil main body and a cover body; the cover body covers the main body to form into a cooking chamber; the cover body is provided with at least two exhaust channels which are communicated with atmosphere; the cover body is also provided with exhaust pressure limit devices; the exhaust pressure limit devices are corresponding to the exhaust channels in structure and number; the exhaust pressure limit devices are triggered manually or electrically to sequentially or simultaneously enable at least two exhaust channels to be opened. The household electric heating cooker can improve the exhaust efficiency.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com